Liquid injection cup device

A liquid injection cup and liquid technology, which is applied to electrical components, circuits, battery pack components, etc., can solve the problems of harsh material requirements, wear and tear of rubber sealing rings, difficulties, etc. high cost effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

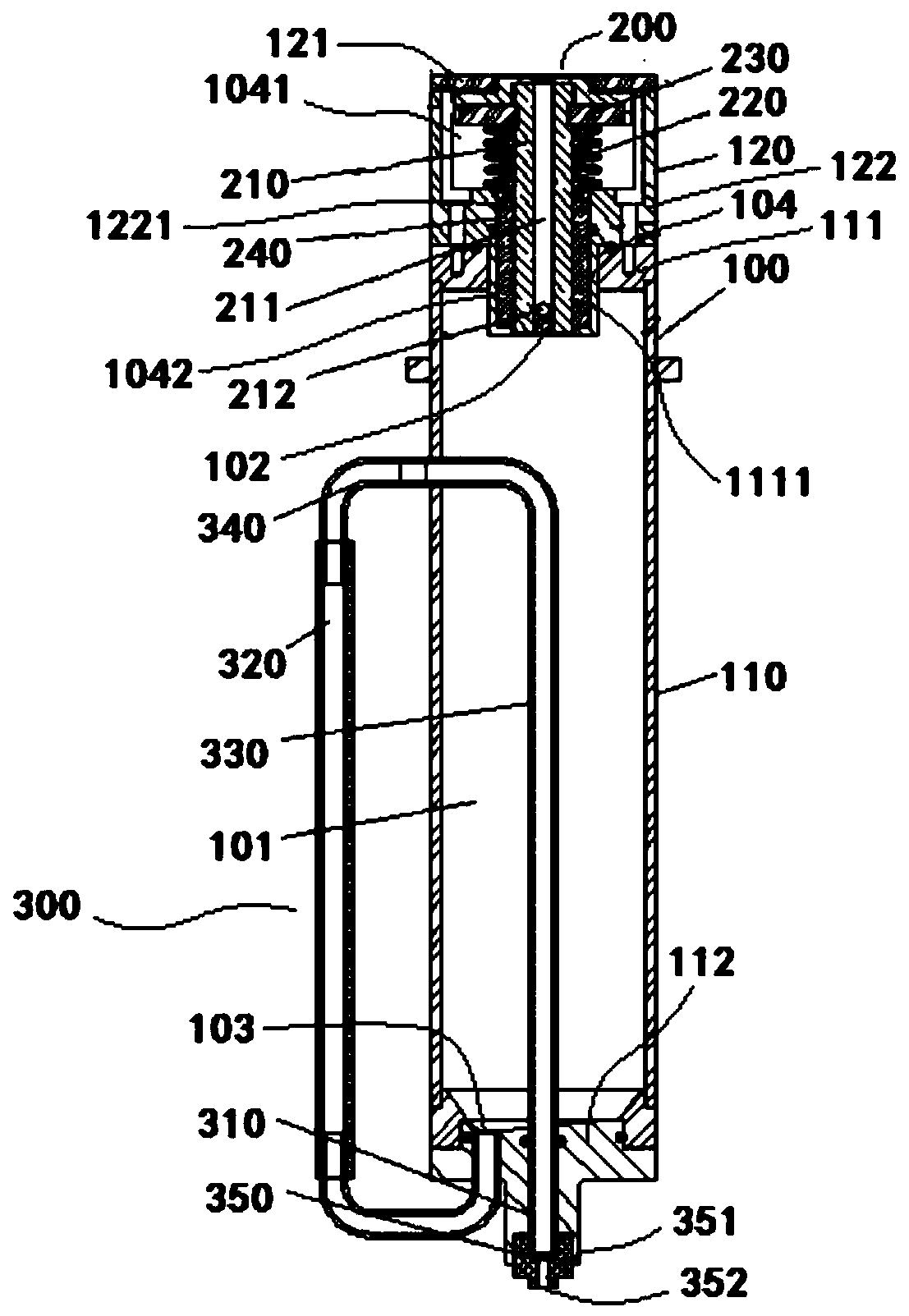

[0031] This embodiment provides a liquid injection cup device, which is mainly used in lithium battery liquid injection machines, and can be used in combination with the vacuum pumping mechanism, positive pressure adding mechanism or liquid injection mechanism on the lithium battery liquid injection machine to respectively Realize the functions of vacuumizing the battery, adding positive pressure and injecting liquid.

[0032] Please refer to figure 1 , the liquid injection cup device includes a vacuum cup 100 , a liquid guiding structure 200 and a liquid outlet structure 300 .

[0033] Wherein, the vacuum cup 100 has a cavity 101 for containing liquid, and an inlet 102 and an outlet 103 communicating with the cavity 101 . When filling the battery, the liquid is the electrolyte.

[0034] The liquid guiding structure 200 is sealed and arranged at the inlet 102, and the liquid guiding structure 200 is movable. On its moving path, there are at least a communication position thr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com