Pump suction type quantitative evacuation priming device

A liquid injection device and vacuum pumping technology, which is applied to structural parts, electrical components, battery pack parts, etc., can solve problems such as multiple fillings, uneven acid control, and slow acid down speed, so as to simplify the production process , high injection precision, and the effect of reducing waste

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

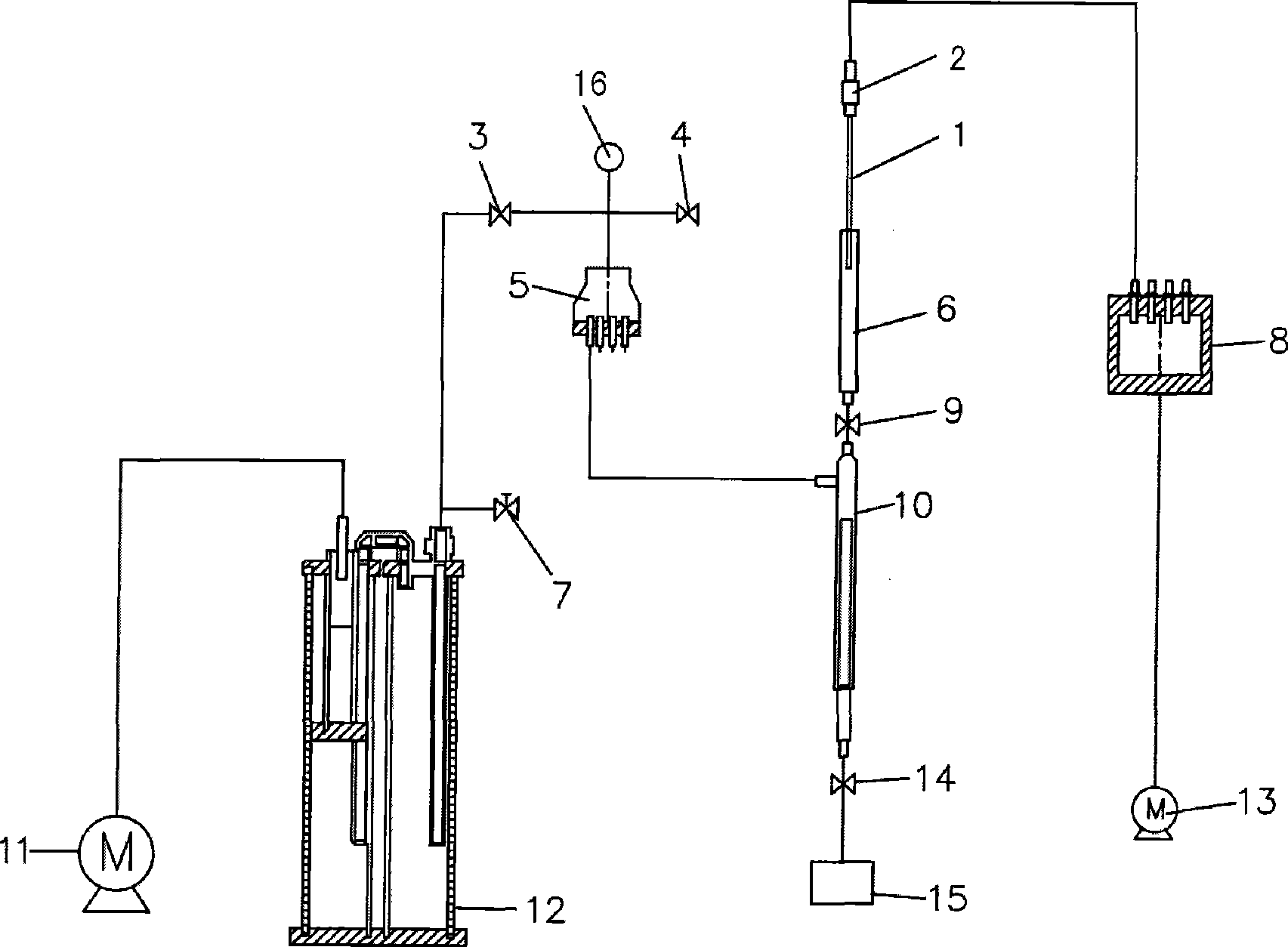

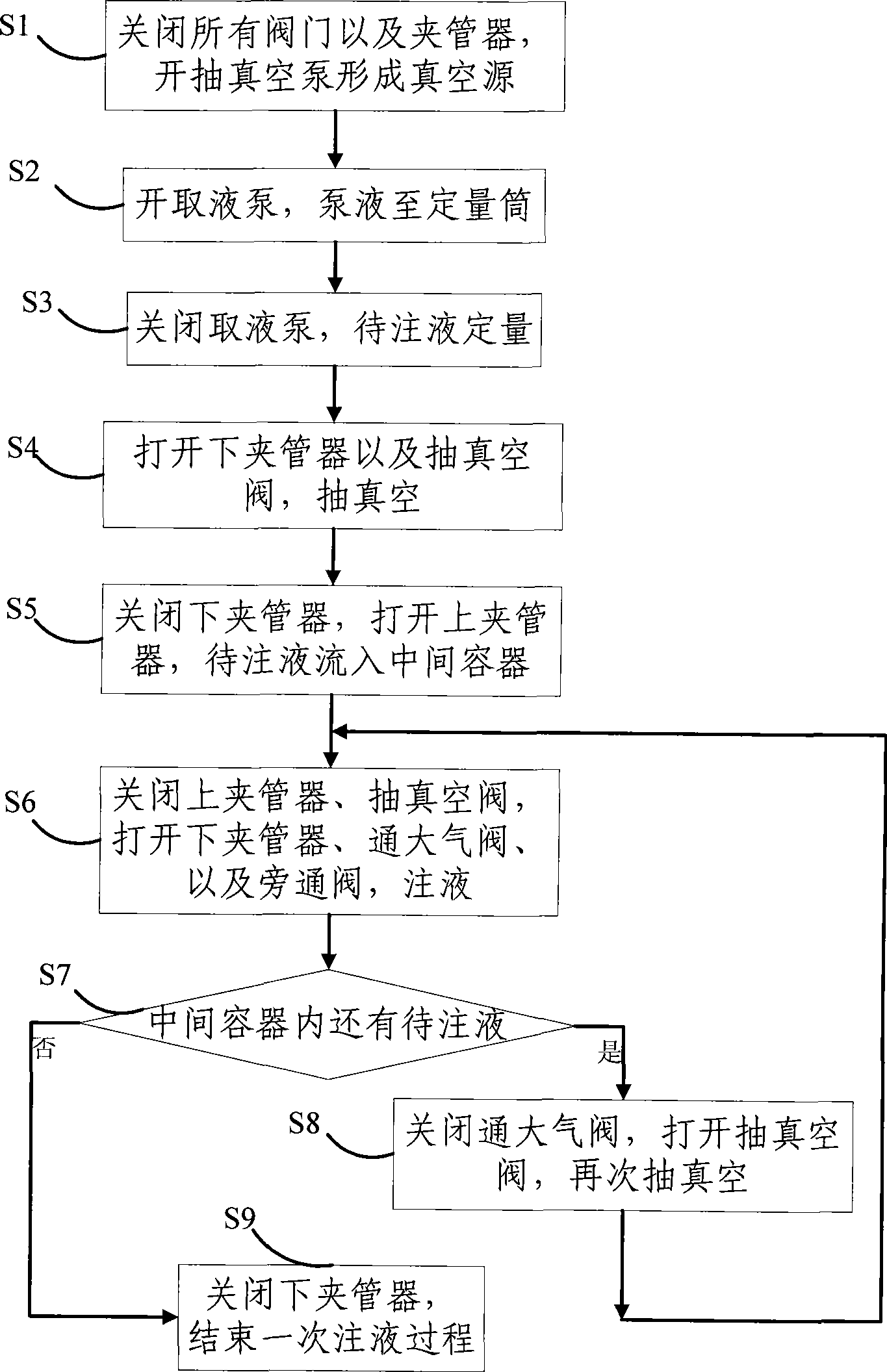

[0019] Such as figure 1 As can be seen, the pump-type quantitative vacuum liquid injection device proposed in this embodiment is especially suitable for filling electrolytes that require high control precision and are difficult to fill, such as sealed storage batteries and lithium batteries.

[0020] The device includes a pump-suction quantitative unit and a vacuum liquid injection unit connected thereto. The pump suction quantitative unit includes: a quantitative cylinder 6, which is connected with the vacuum liquid injection unit, and is used for quantitatively pumping liquid to be injected; pump liquid return suction pipe 1. Insert the dosing cylinder 6 from the liquid inlet of the dosing cylinder 6, the insertion depth is adjusted by the liquid volume adjustment rod 2 connected to the upper end of the pump liquid return suction pipe 1; the pump liquid buffer 8, the liquid outlet is connected with the pump liquid return suction pipe 1; The liquid pump 13 is connected with t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com