Patents

Literature

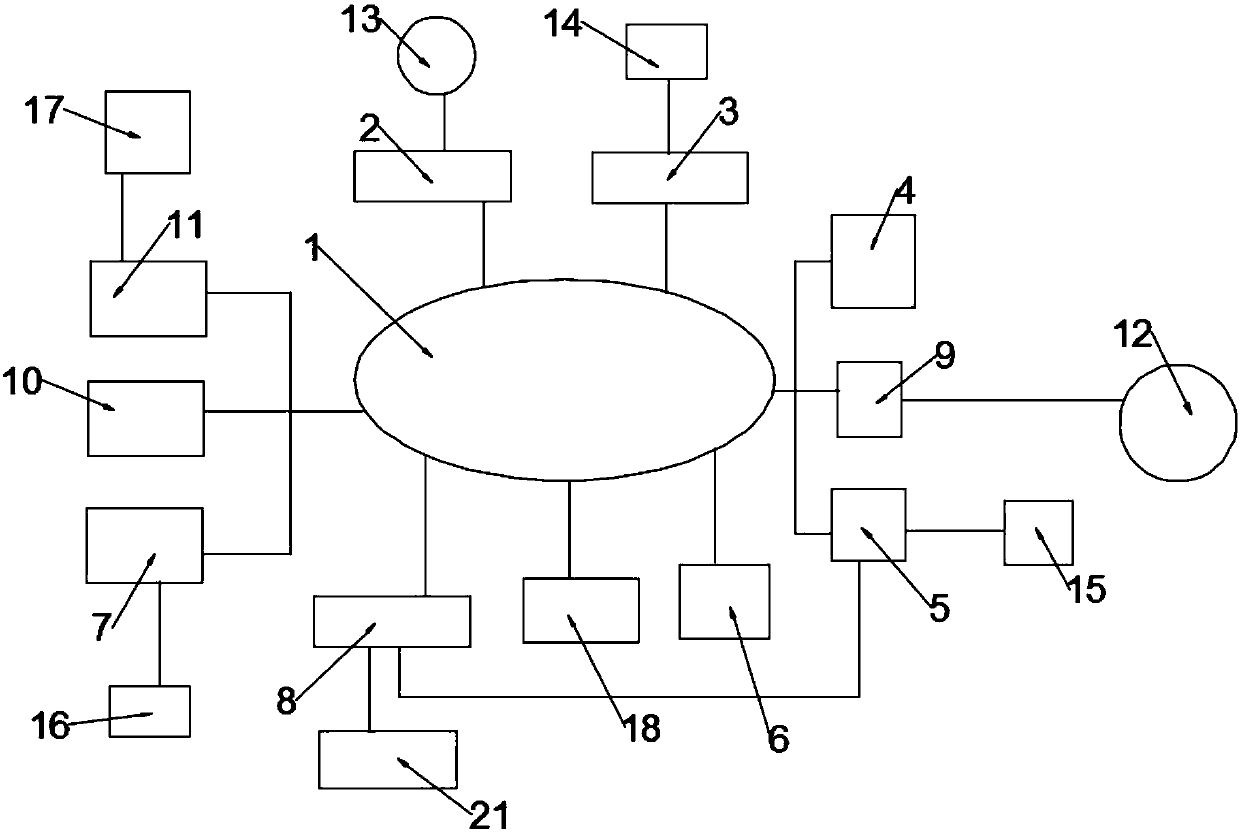

52 results about "Self weighing" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Electronic traveling suitcase

The electronic traveling suitcase includes a self-weighing feature that displays its weight (including contents) in pounds or kilograms, as selected by the user, on an LCD screen. Security features include a lock, which can be digitally programmed. Moreover, a programmable electronic traveler's identity and password are provided for additional security. An electric motor powers wheels disposed on the suitcase. The motor is powered by a rechargeable battery. An infrared remote control allows the user to control the suitcase from a distance. A light ribbon is disposed on the exterior periphery of the suitcase and flashes in a unique pattern to allow the user to find the bags among a plurality of bags. A built-in alarm system is provided and triggers when unauthorized personnel handle the suitcase. The device remotely notifies the user when it is being stolen or tampered with. The unit will shock the unauthorized person or thief.

Owner:AL QAFFAS QASEM A

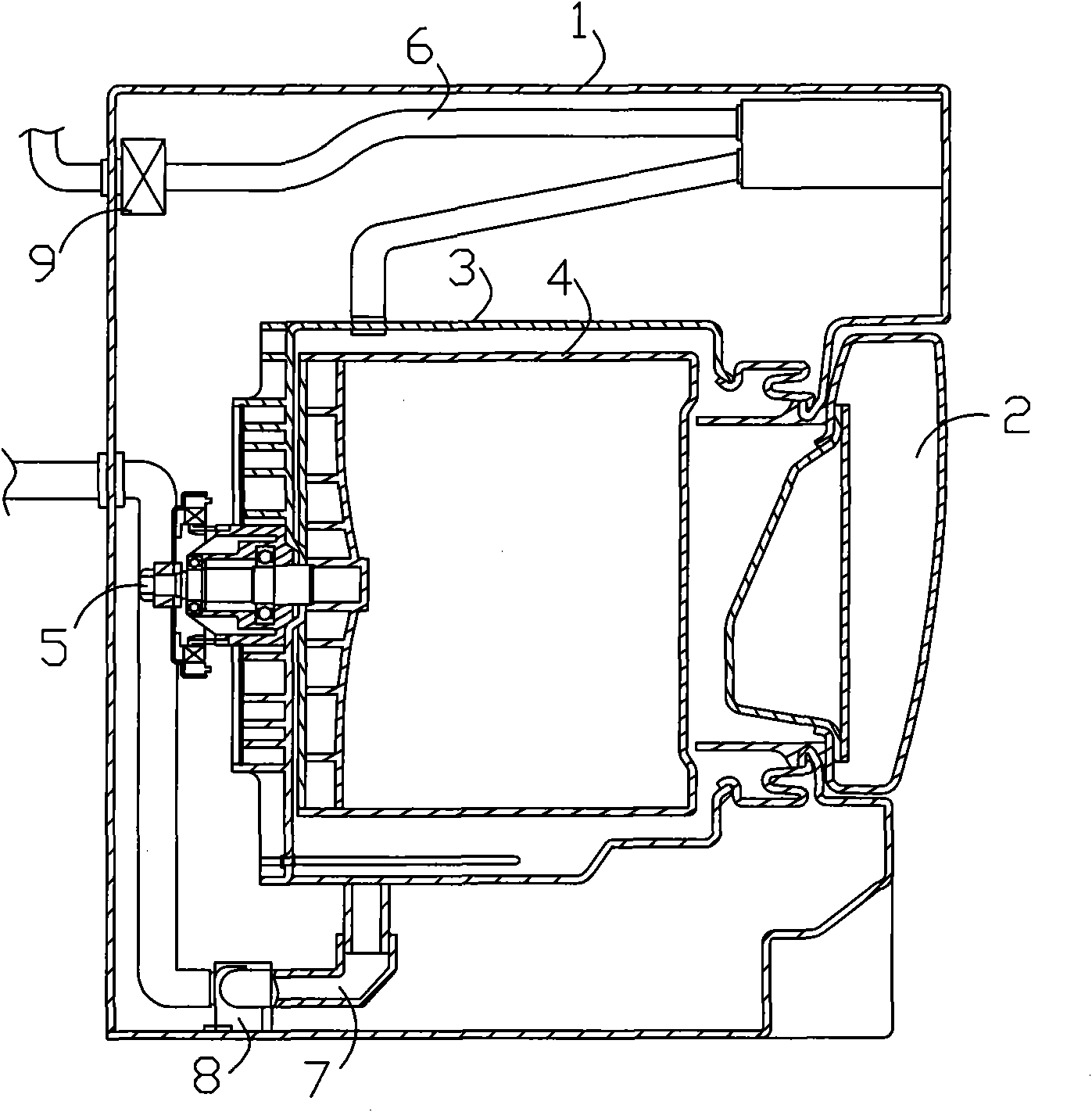

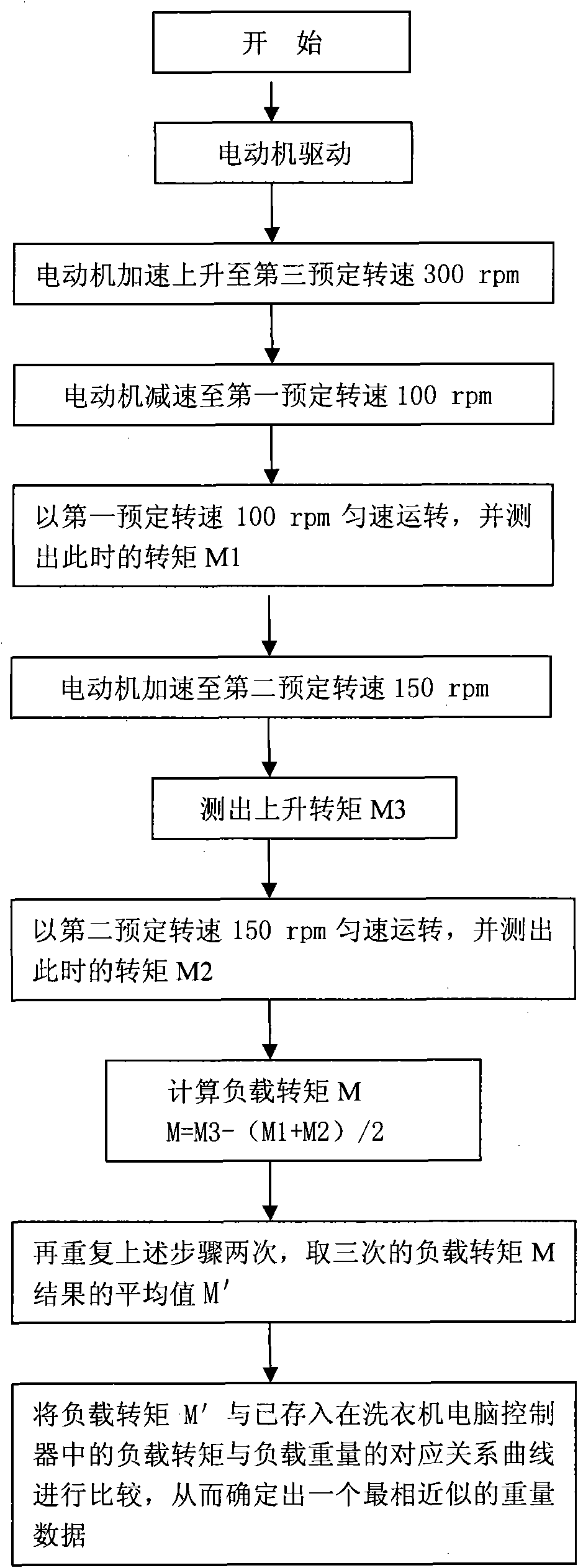

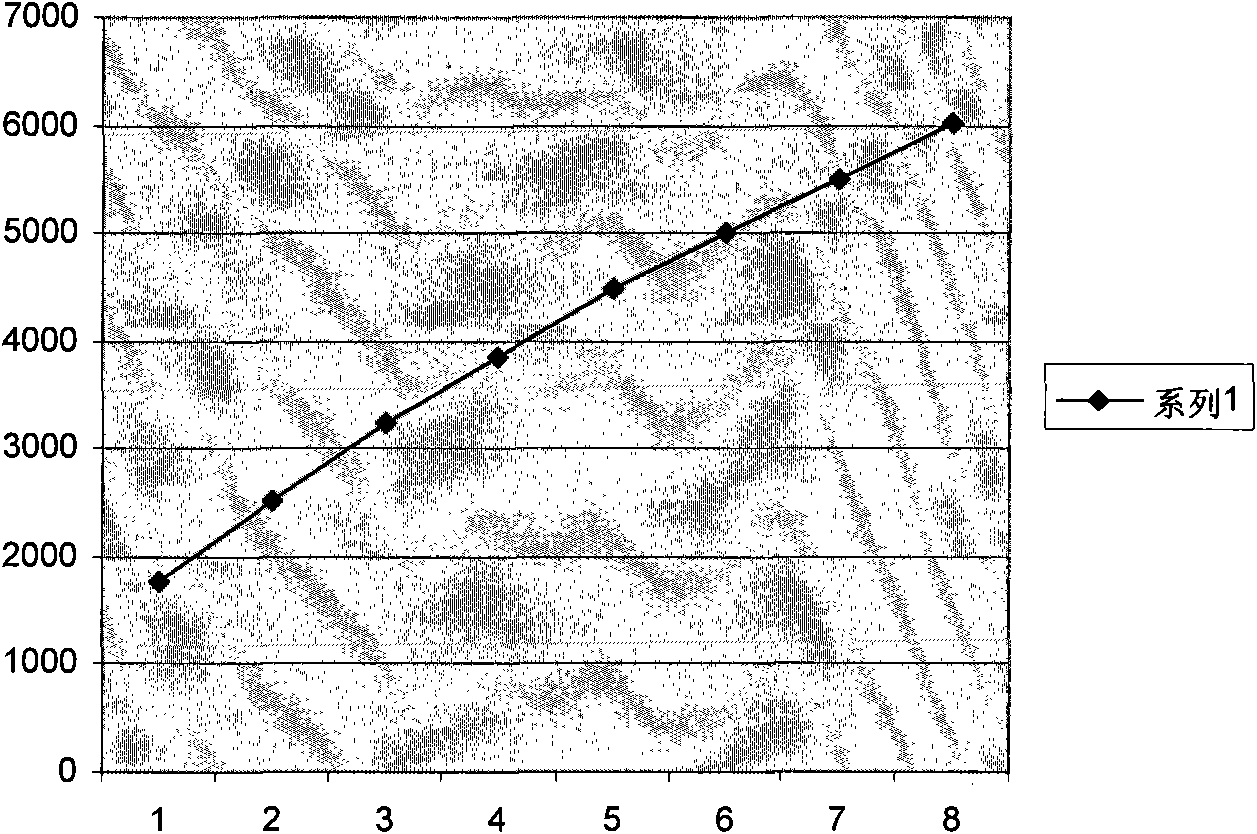

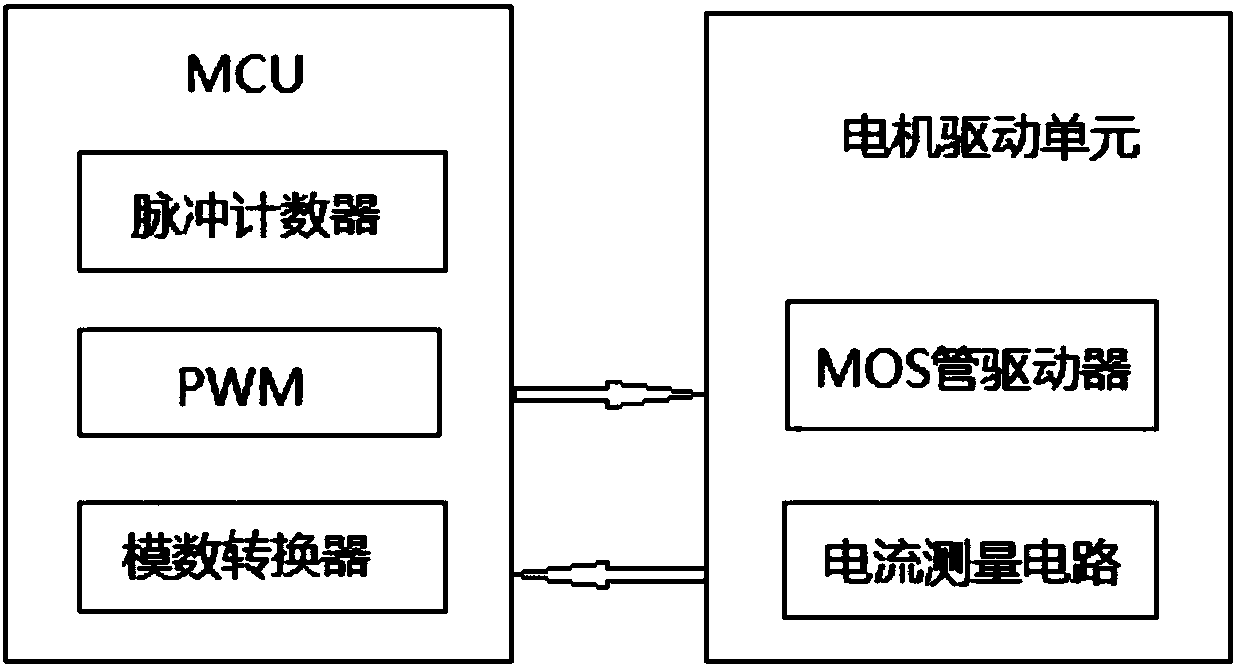

Self-weighing method for drum-type washing machine

ActiveCN101526388AAccurate measurementAutomatic weighing is accurateOther washing machinesControl devices for washing apparatusLoad torqueControl theory

The invention relates to a self-weighing method for a drum-type washing machine. Firstly, controlling a motor to reach a first preset speed and to rotate at the first preset speed constantly, and measuring the torque of the motor rotating constantly at the first preset speed; secondly, controlling the motor to accelerate from the first preset speed to a second preset speed, and measuring the accelerating torque of the motor accelerating from the first preset speed to the second preset speed; thirdly, controlling the motor to rotate constantly at the second preset speed, and measuring the torque of the motor rotating constantly at the second preset speed; and finally, working out a corresponding load torque by subtracting an average value of the torque of the motor rotating constantly at the first preset speed and the torque of the motor rotating constantly at the second preset speed from the accelerating torque of the motor accelerating from the first preset speed to the second preset speed according to the test results, and after a correction step, comparing the obtained load torque with a curve, pre-stored in a computer controller of the washing machine, of the corresponding relation of a load torque and a load weight to obtain a most similar weight data. The method has the advantages of high test accuracy and short test time.

Owner:QINGDAO HAIER WASHING MASCH CO LTD

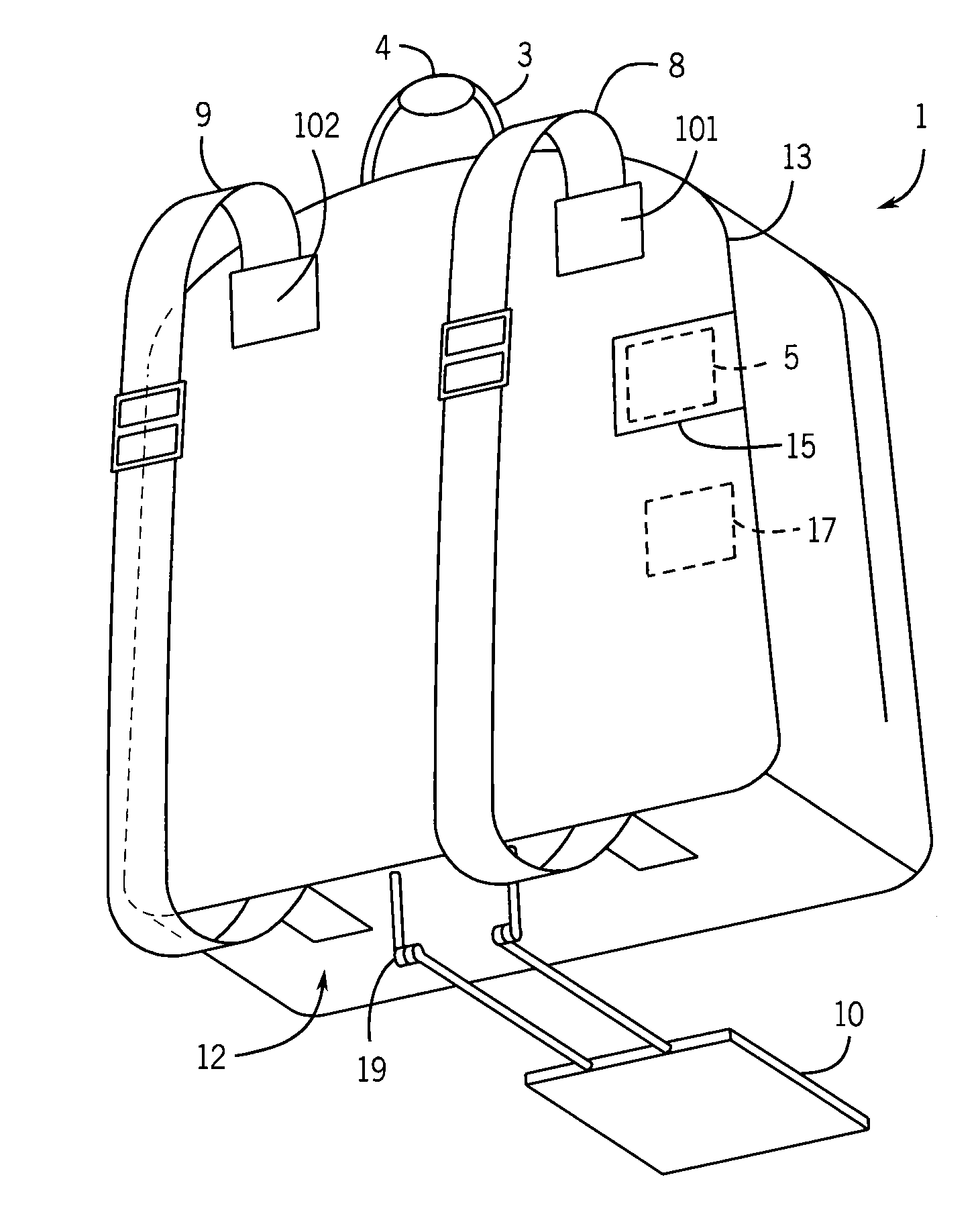

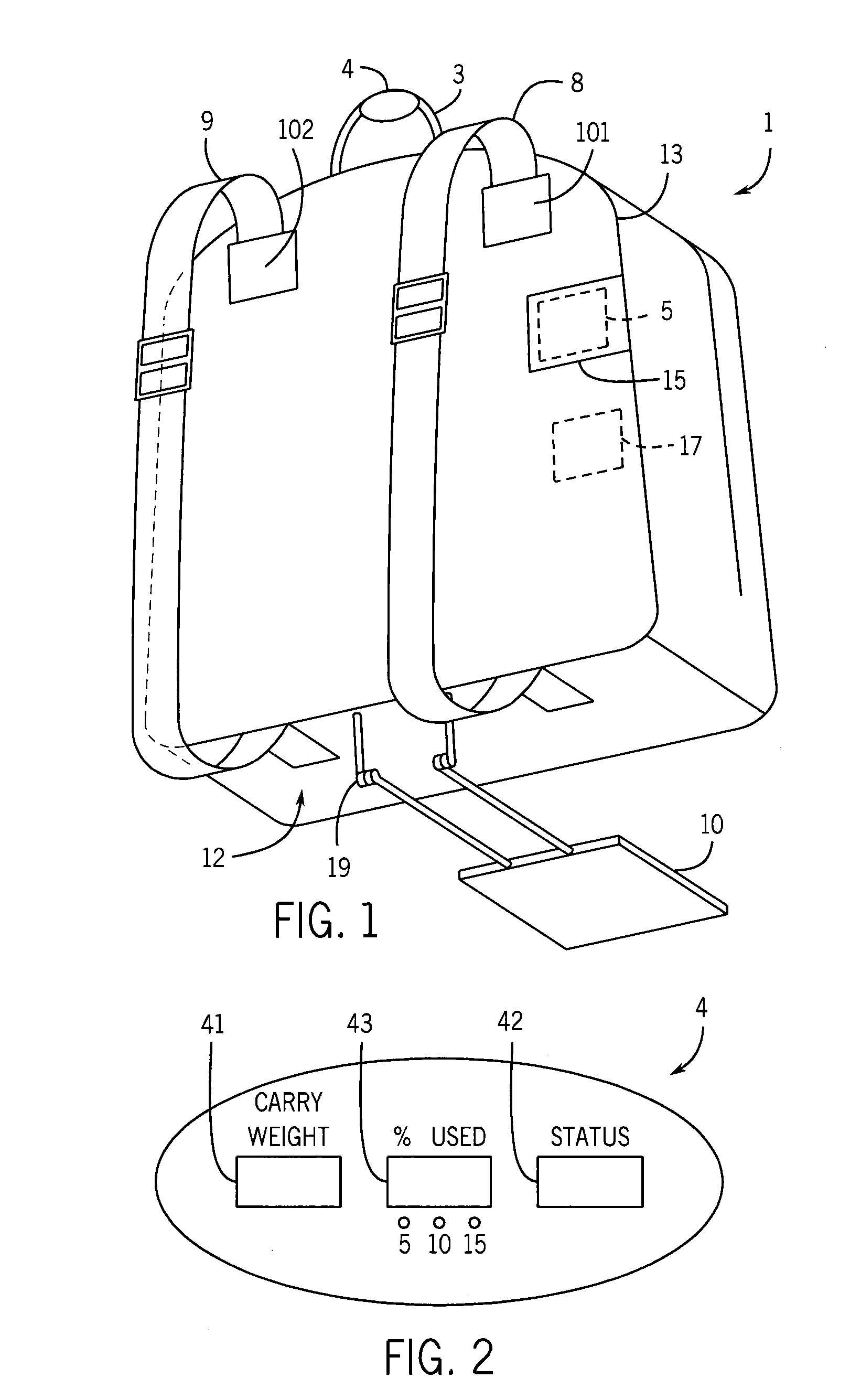

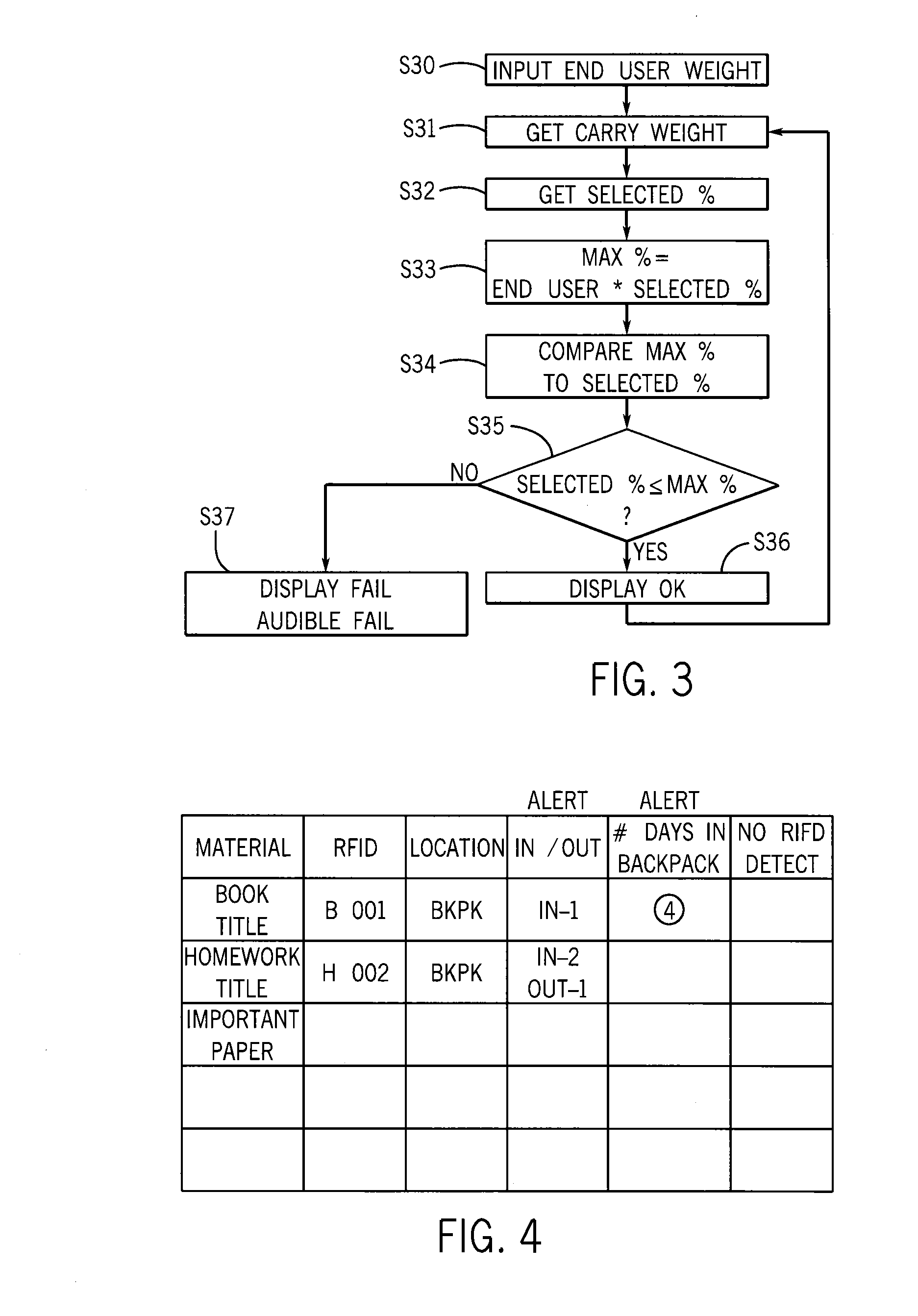

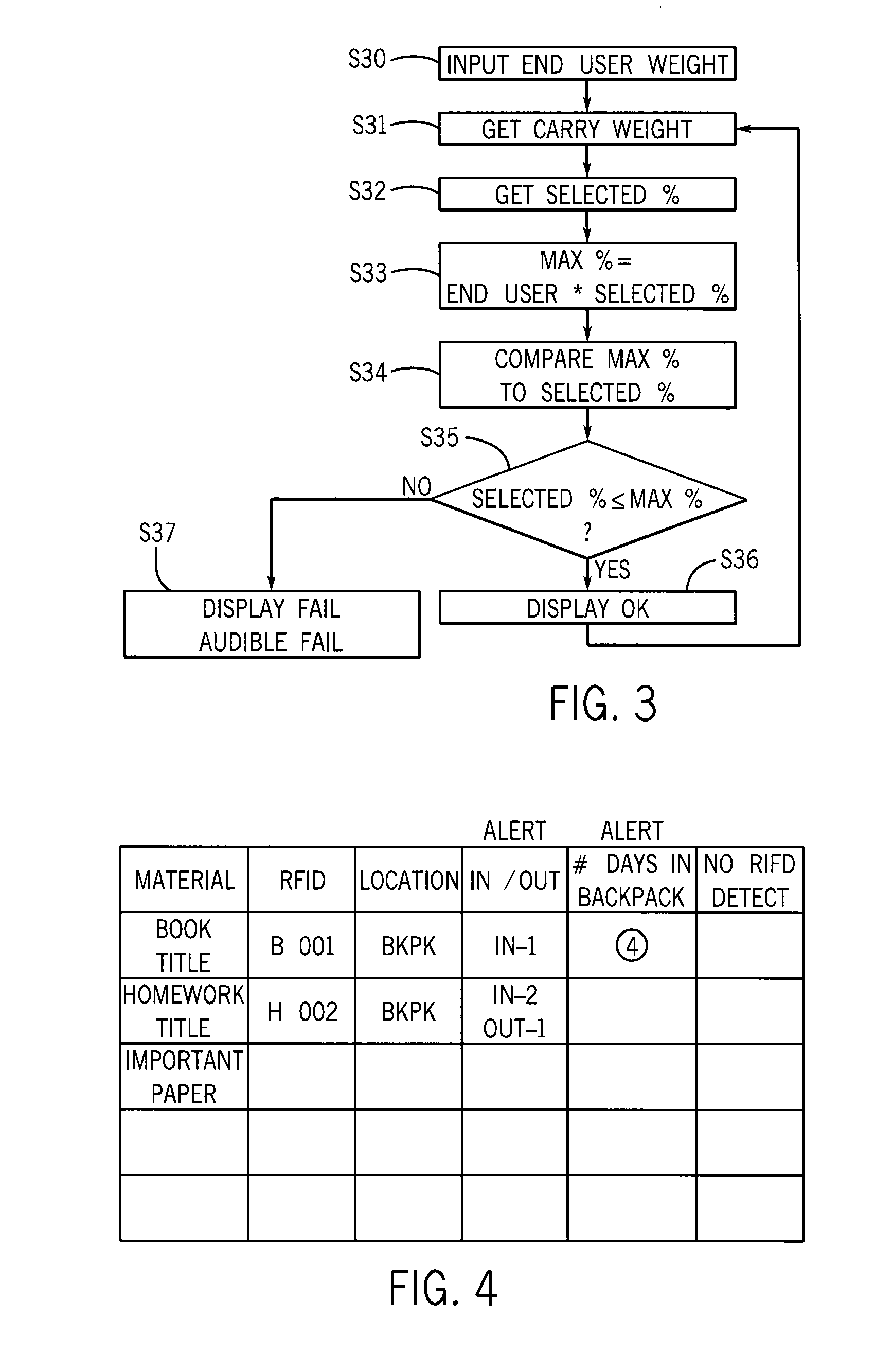

Self-weighing backpack with weight notification features

InactiveUS20140326771A1Less strainIncrease kinetic energyTravelling sacksPursesEngineeringStrain gauge

A self-weighing backpack includes a container body that is connected to right and left carry straps that include strain gauges. Processing circuitry is included that compares dynamic force measurements to a predetermined threshold force and generates an alert when the predetermined threshold force is exceeded.

Owner:ALMALKI BADER ABDULLAH

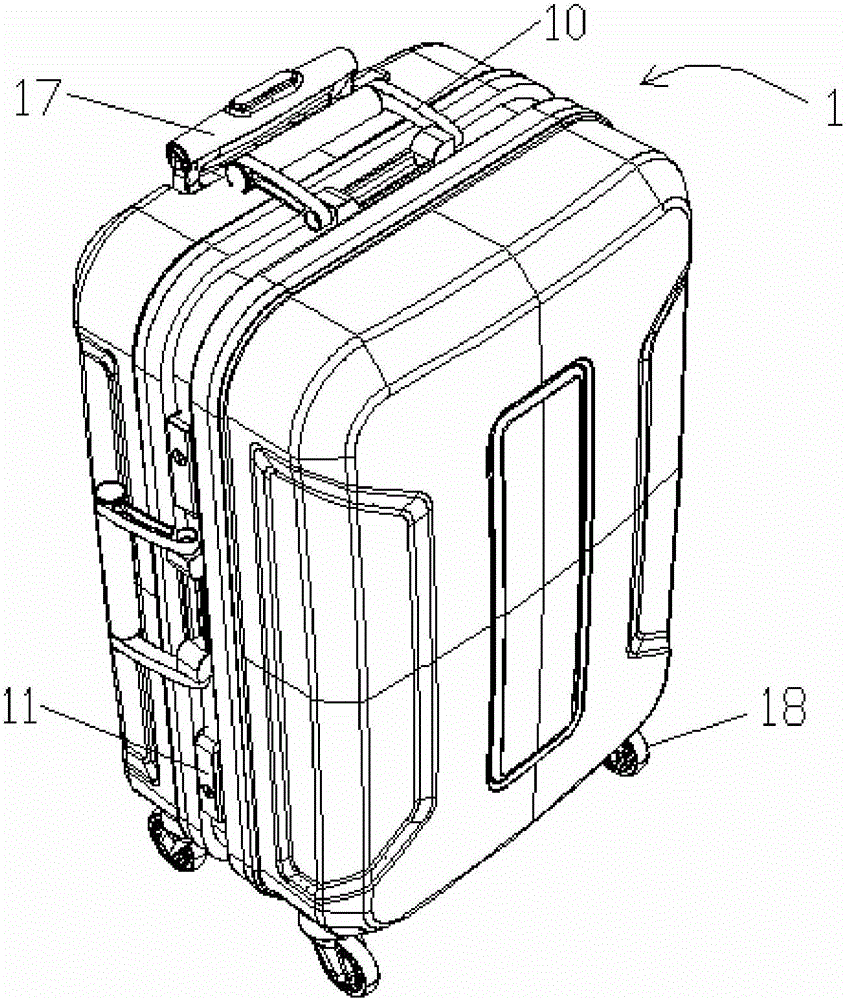

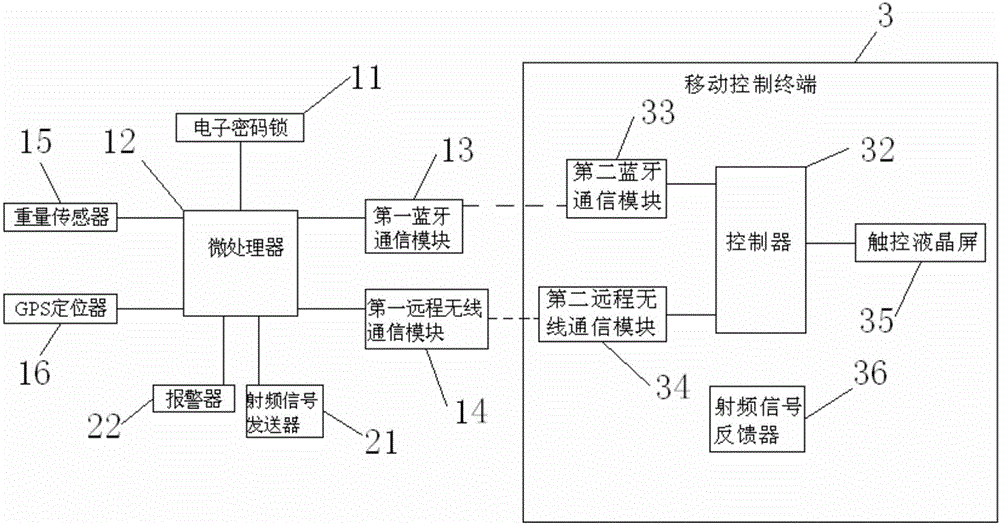

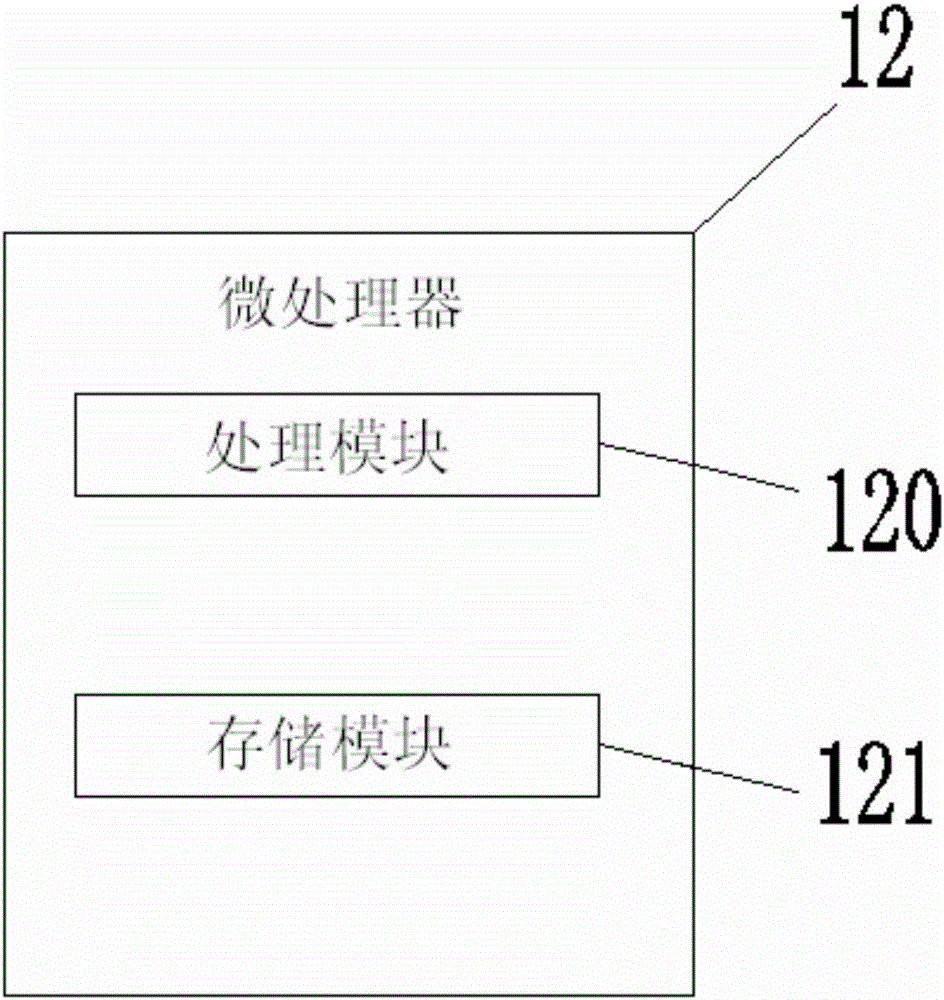

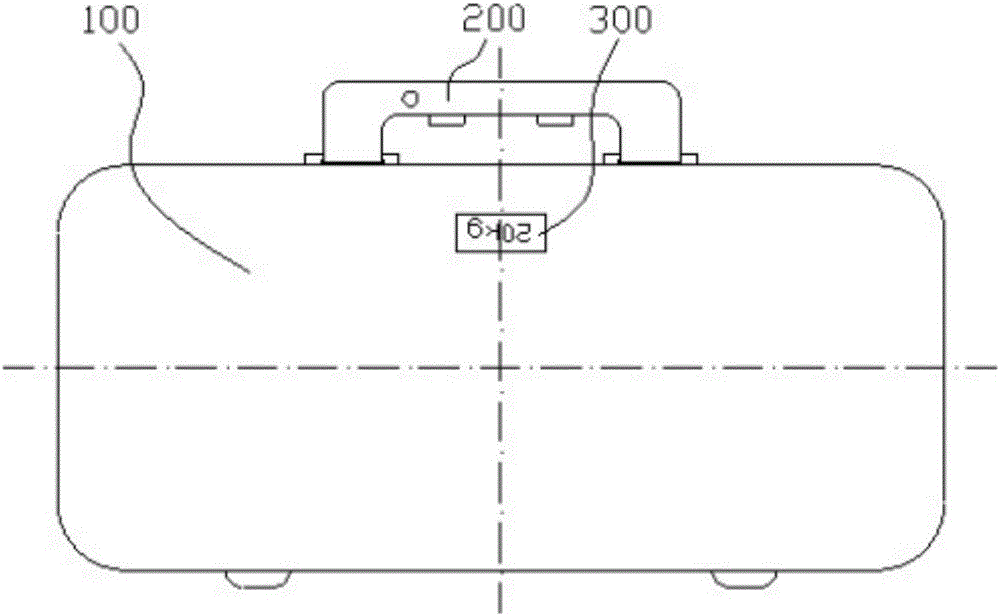

Smart trunk

The invention discloses a smart trunk. The smart trunk comprises a trunk main body and a mobile control terminal, wherein an electronic password lock, a microprocessor, a first Bluetooth communication module, a first remote wireless communication module, a weight sensor and a handle are arranged on the trunk main body; the first Bluetooth communication module, the first remote wireless communication module and the weight sensor are connected with the microprocessor; the handle is connected with the weight sensor; the mobile control terminal comprises a controller, a second Bluetooth communication module, a second remote wireless communication module and a touch liquid crystal screen; the second Bluetooth communication module, the second remote wireless communication module and the touch liquid crystal screen are connected with the controller; the two Bluetooth communication modules are in one-to-one wireless connection; the two remote wireless communication modules are in one-to-one wireless connection; when the microprocessor and the controller transmit data through a Bluetooth communication manner when the first Bluetooth communication module is connected with the second Bluetooth communication module. The smart trunk has the functions of self-weighing of the trunk main body and unlocking and setting passwords through remote control manners, and facilitates application of a user.

Owner:HAINING DIDI SUITCASE INTELLIGENCE TECH CO LTD

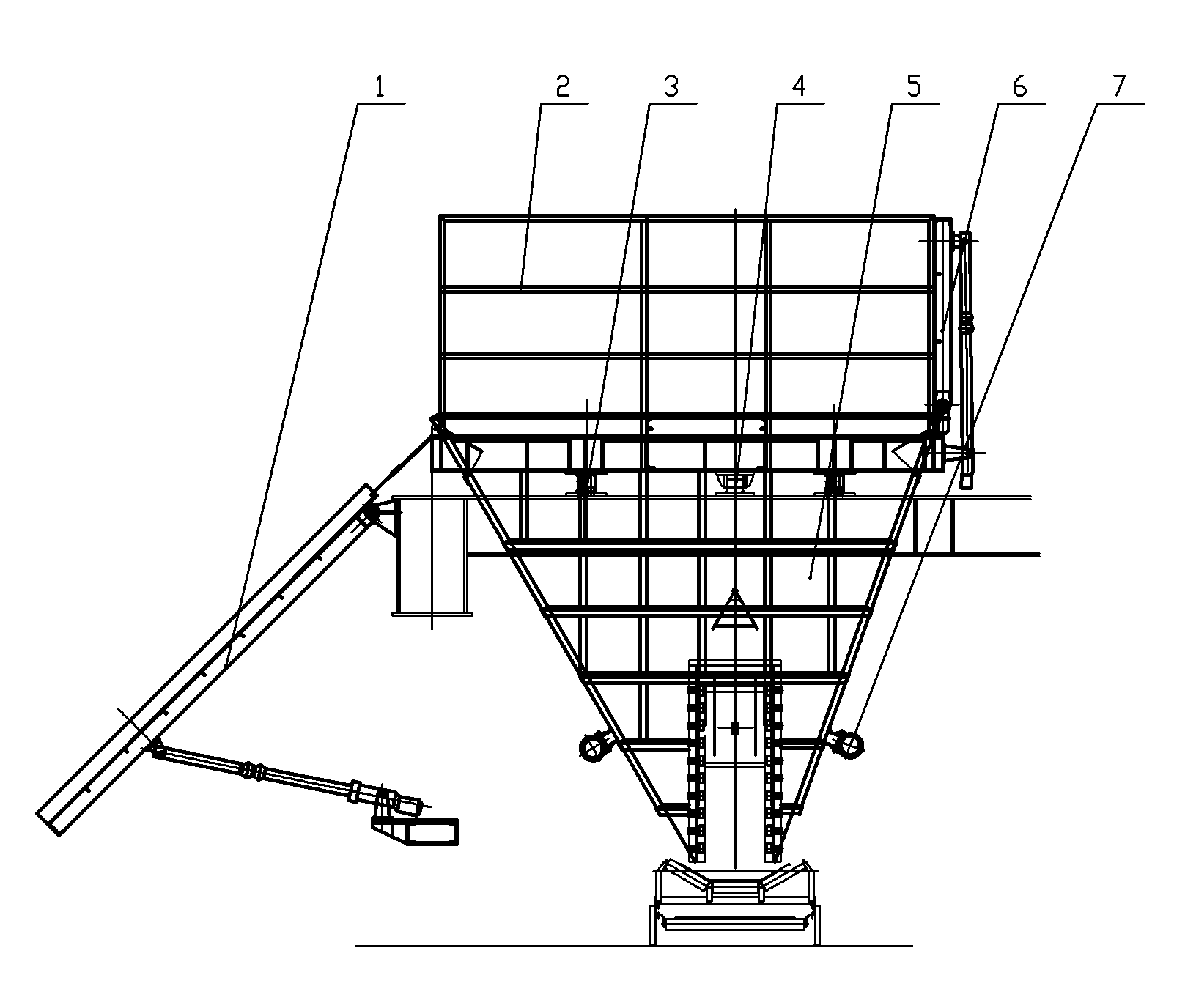

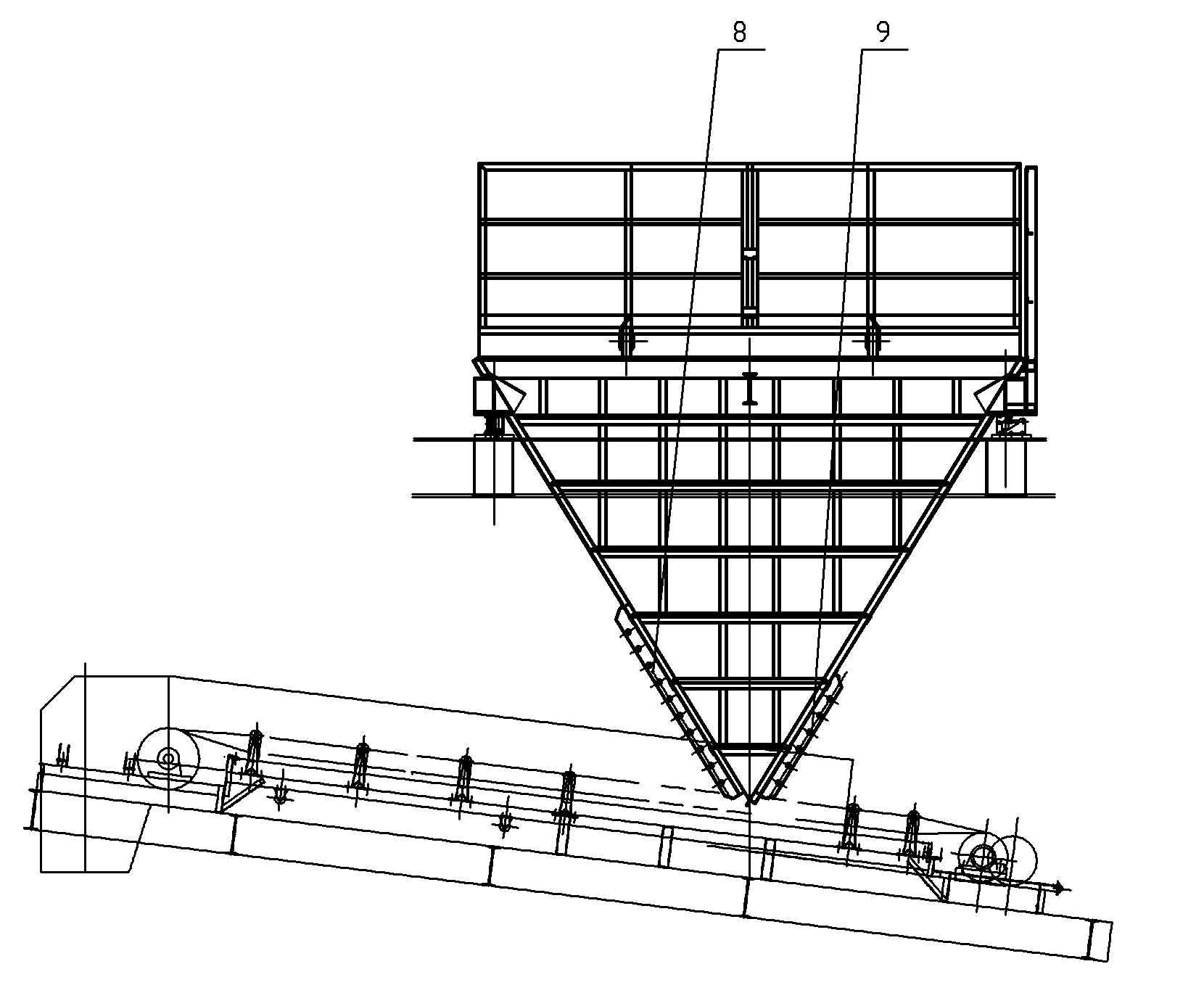

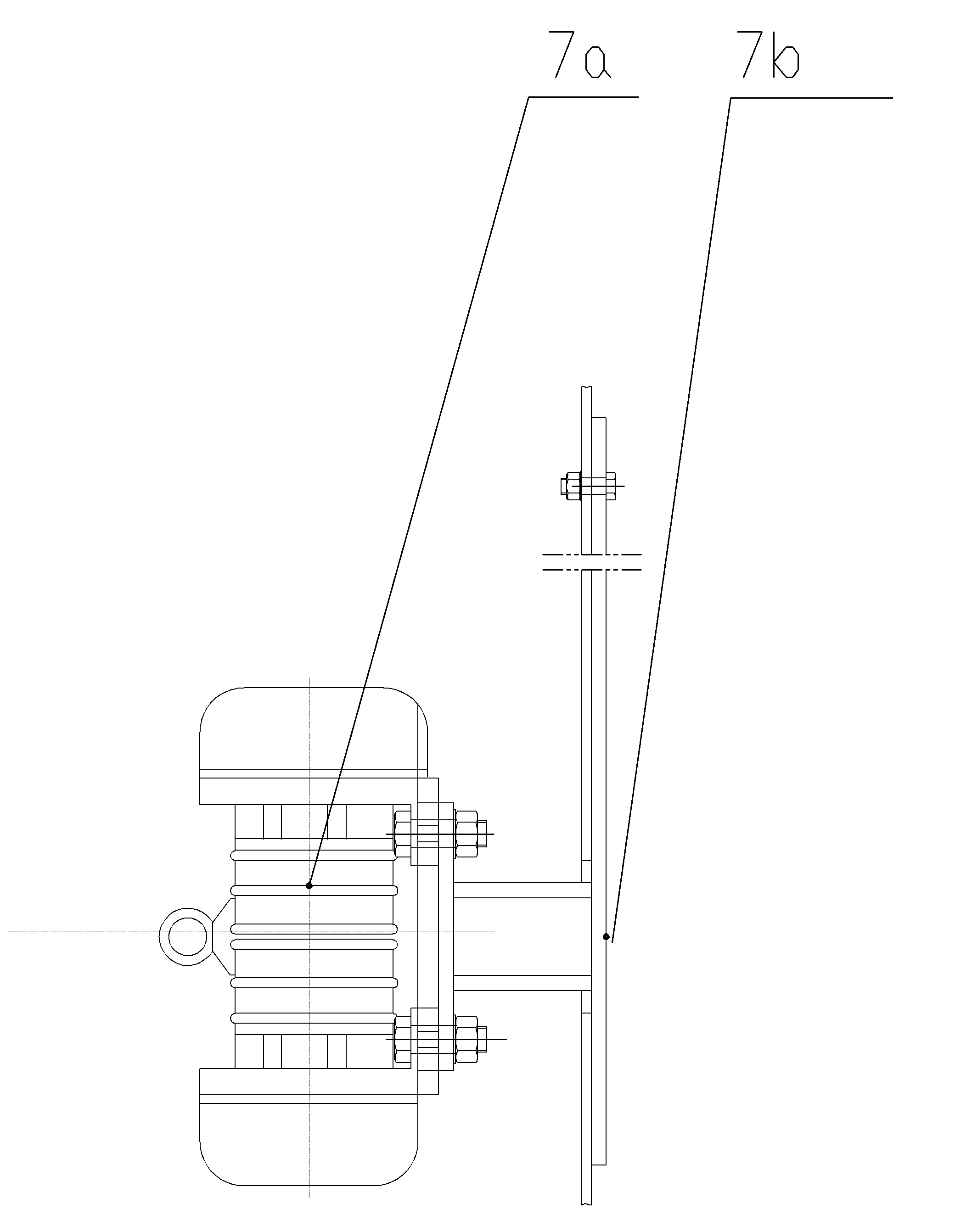

Self-weighing hopper of loading and unloading device

InactiveCN101934902AAvoid blockingEffective vibration dispersionLarge containersLoading/unloadingSelf weighingWindshield

The invention relates to a self-weighing hopper of a loading and unloading device. The self-weight hopper is mainly characterized in that a material collecting plate is arranged at an upper hole of a hopper body of the hopper, side windshield plates are respectively fixed on both sides of an edge of the upper hole of the hopper body of the hopper, and the edge is perpendicular to a shoreline; a weighing load unit and an anti-deflexion device are both arranged under a supporting beam of the hopper body of the hopper; a rear windshield plate is arranged at the upper hole of the hopper body of the hopper; bin-wall vibrators are respectively arranged on both sides of a hopper wall without a hopper door at the middle lower part of the hopper body; a main hopper door and a secondary hopper door are respectively arranged on both sides of a discharging hole of the hopper; a vibrating motor of each bin-wall vibrator is connected with a built-in vibration plate by a motor installing bracket, the built-in vibration plate is fixed on the inner side of the hopper wall of the hopper by bolts, and a safe lifting lug and a safe chain are hung on the vibrating motor. In the invention, the weighing load unit has high precision; the structure modes of the main hopper door and the secondary hopper door avoid the phenomena of material blockage, and the like due to poor fluidity of materials; and compared with the traditional vibrating motor, the built-in vibration plate is directly arranged on the hopper wall in order to more effectively vibrate and disperse blocked materials.

Owner:无锡工力工程机械厂

Self-weighing method for intelligent mobile luggage

Owner:LINGDONG TECH BEIJING CO LTD

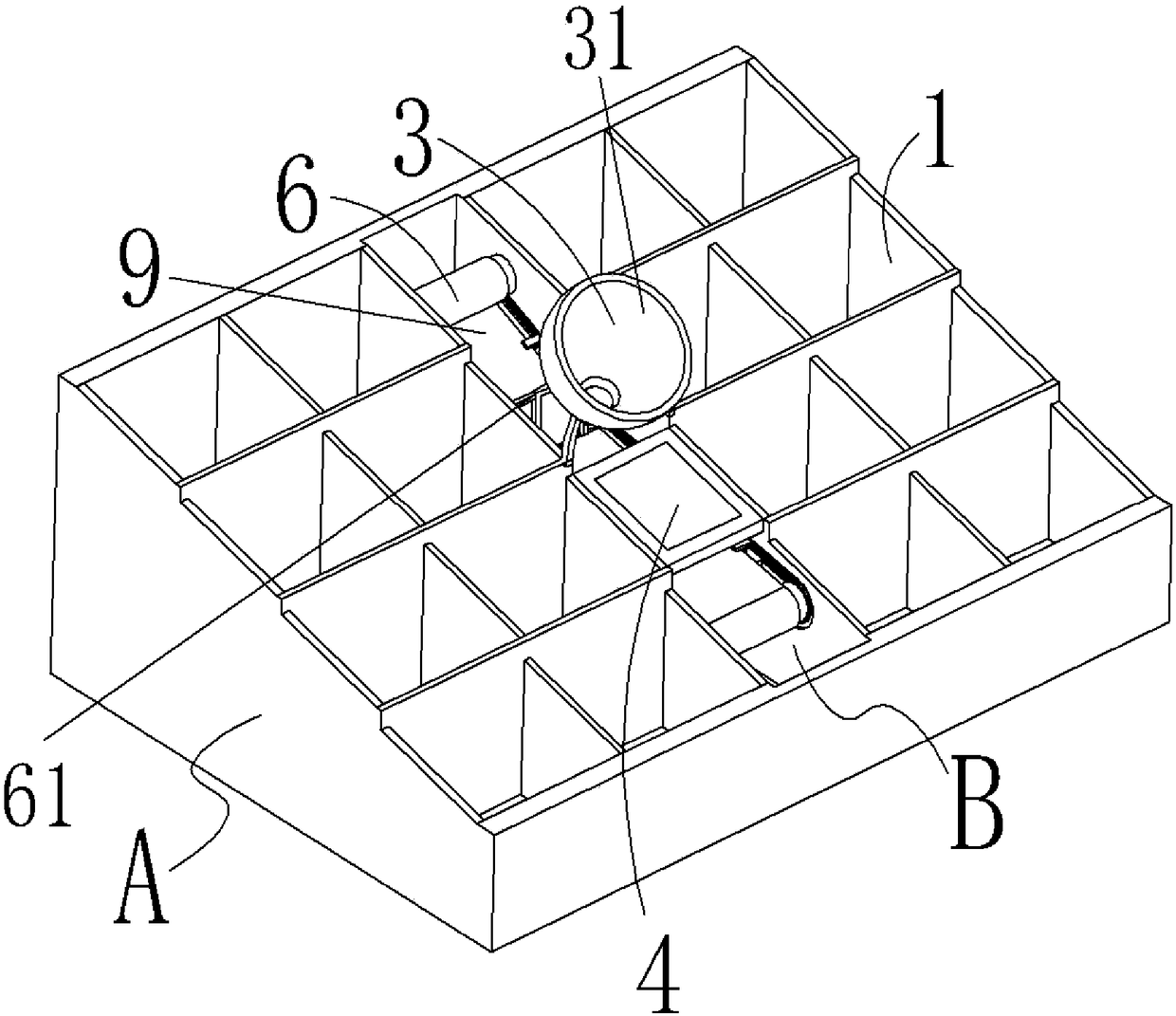

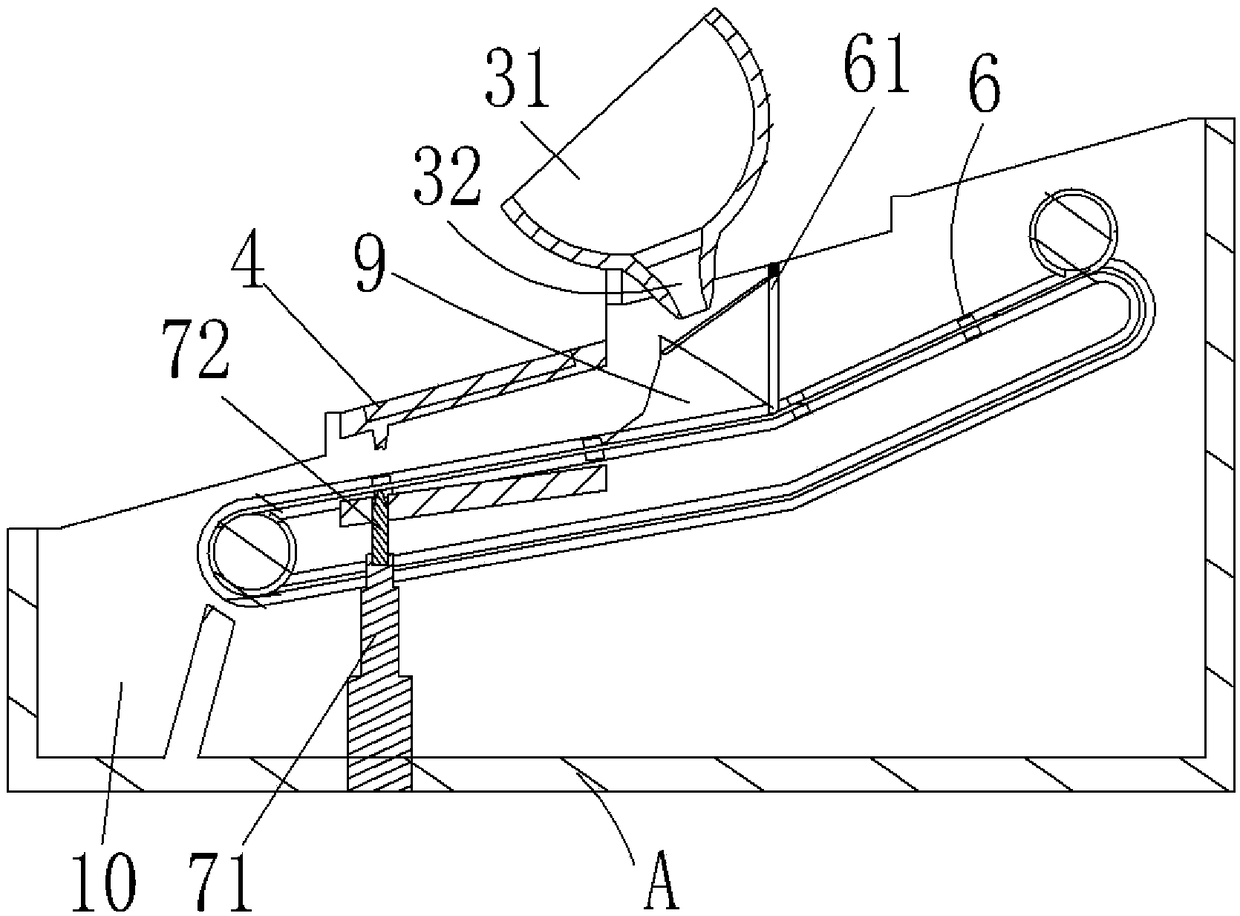

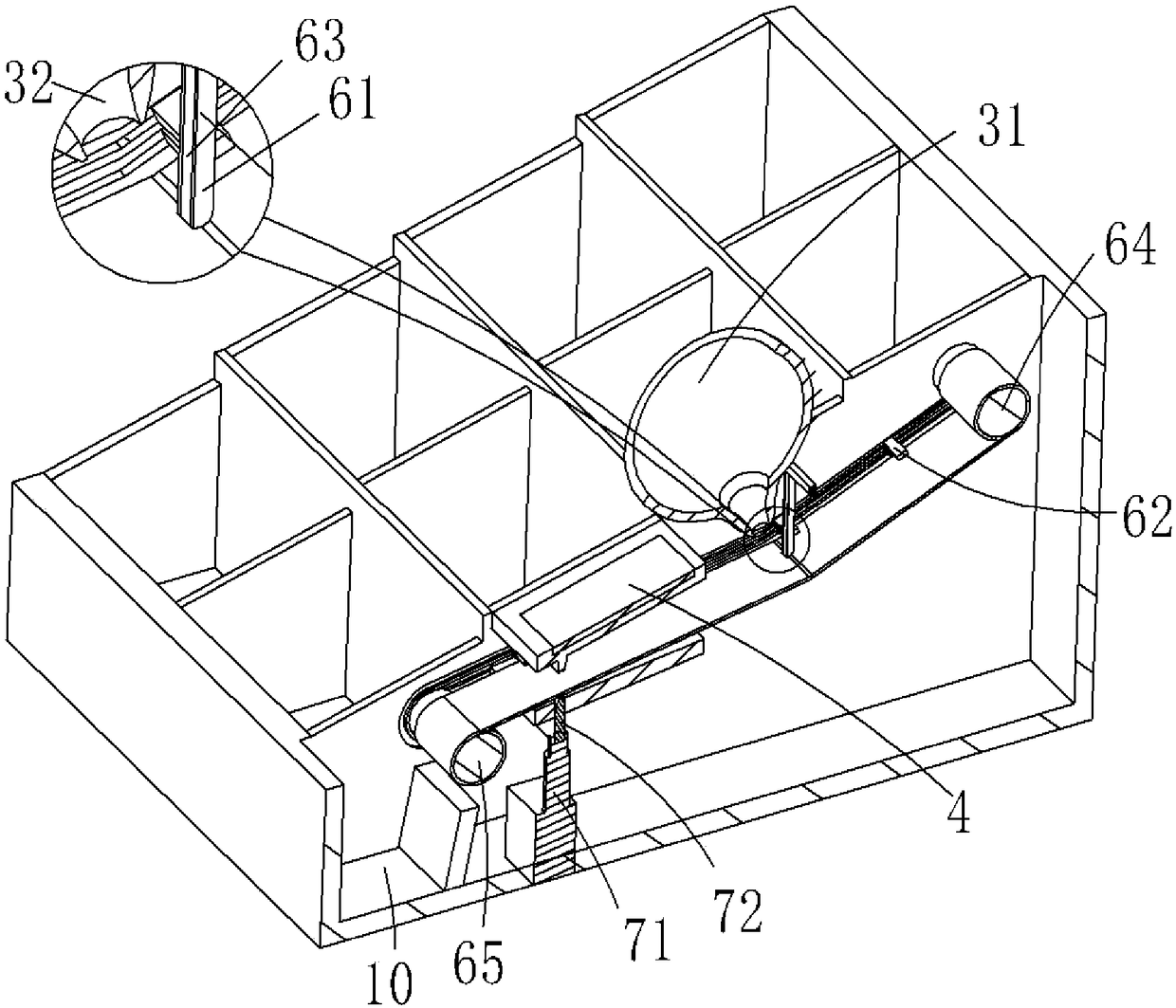

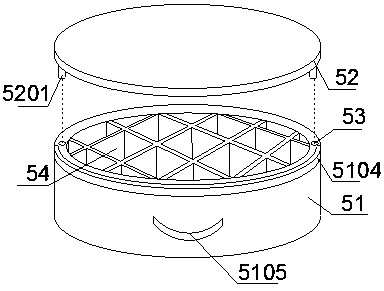

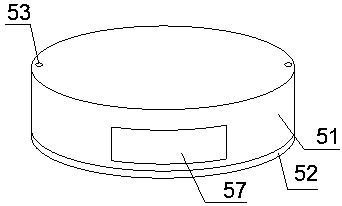

Self-weighing settlement display rack for bulk candies in supermarket

PendingCN108182771AConvenient shoppingReduce usageCash registersApparatus for meter-controlled dispensingHydraulic pumpEngineering

The supermarket uses a self-weighing settlement display rack for bulk candies in a supermarket. The display rack is provided with a plurality of grids for placing candies and is characterized in thatthe bottoms of the grids are provided with numbered weight sensors corresponding to the types and prices of the candies placed in the grids. The middle of the display rack is provided a settlement platform which includes a collection mechanism and a development board equipped with a touch panel. The weight sensors are connected with the development board which is connected with a delivery mechanism, a sealing mechanism and a price label printing mechanism. The collection mechanism is a candy collecting cover body. The delivery mechanism conveys a bag body to a lower port of the cover body andone side of the bag body is opened by a fork to connect the lower port. The sealing mechanism is formed by the push of a heating and sealing block with a hydraulic pump. According to the display rack,weighing and pricing are integrated into one body, the shopping of a shopper is facilitated, the whole shopping time is saved, the use amount of bags for loading the candies is reduced, weighing staff arrangement is canceled by the supermarket, and the cost is saved.

Owner:梁钗

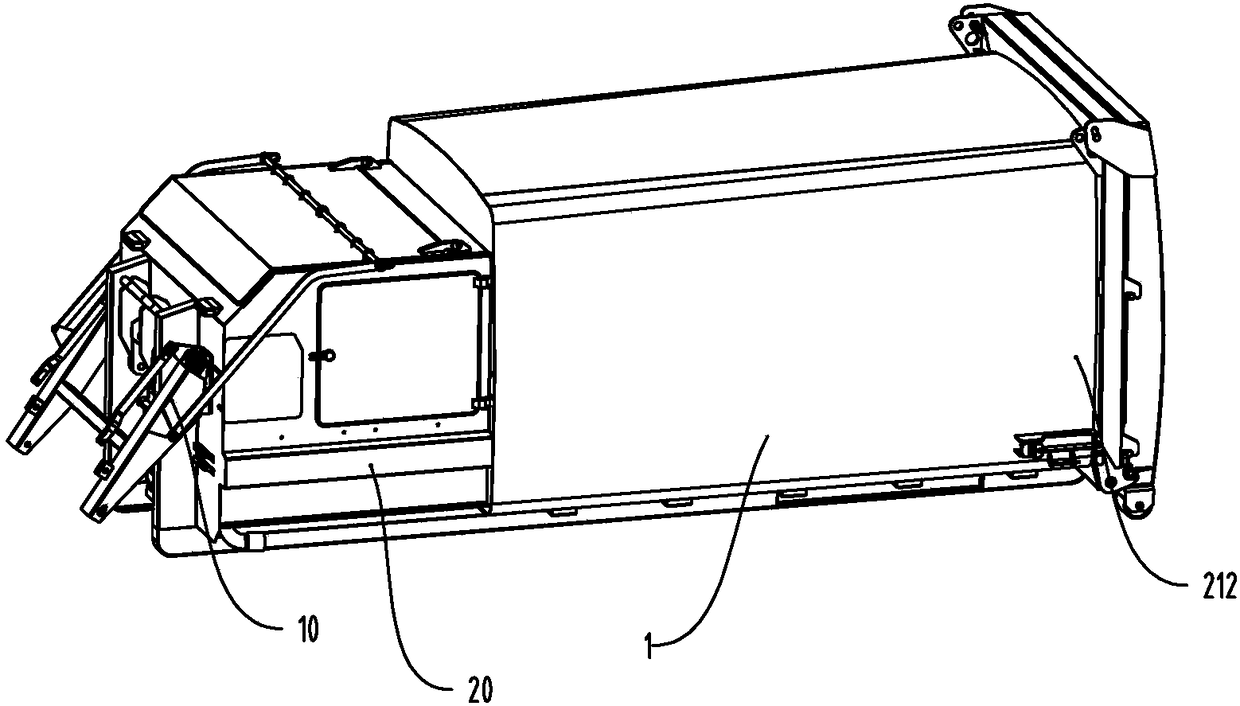

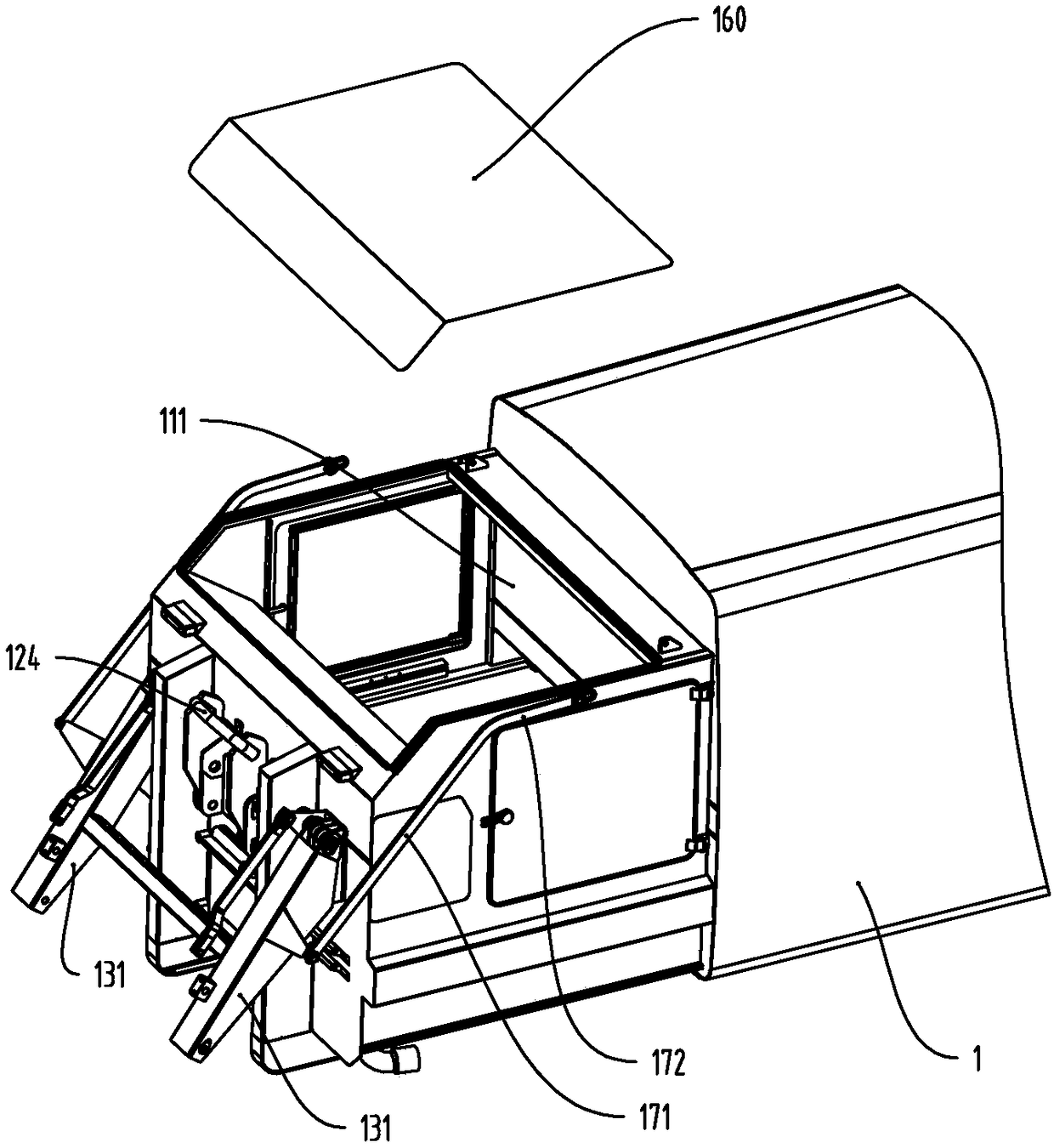

Self-weighing garbage compression box

PendingCN108516269ARealize automatic pushIncrease profitRefuse receptaclesRefuse transferringEngineeringWater collection

The invention provides a self-weighing garbage compression box which comprises a compression box body. One end of the compression box body is connected with an overturning mechanism for dumping garbage, and the other end of the compression box body is provided with a garbage outlet. A drainage device is arranged on the side, close to the overturning mechanism, of the bottom of an inner cavity of the compression box body, and the overturning mechanism comprises a garbage overturning bucket, a lifting arm and a locking piece which comprises a lock hook, a balance weight and a connecting rod forconnecting the lock hook with the balance weight. Before the lifting arm is lifted, the lock hook and a rotary shaft hole form a supporting hole with an opening; and after the lifting arm is lifted, the lock hook and the rotary shaft hole form a closed hole gradually. The drainage device comprises a garbage push plate which divides the inner cavity of the compression box body into a compression bin and a water collection bin. A plurality of pollution discharge holes communicating with the water collection bin are formed in the garbage push plate. A weighing sensor is arranged at the bottom ofthe garbage box body and used for detecting the weight of the garbage in the garbage box body.

Owner:SHENZHEN ZHISHI ENVIRONMENTAL PROTECTION TECH CO LTD

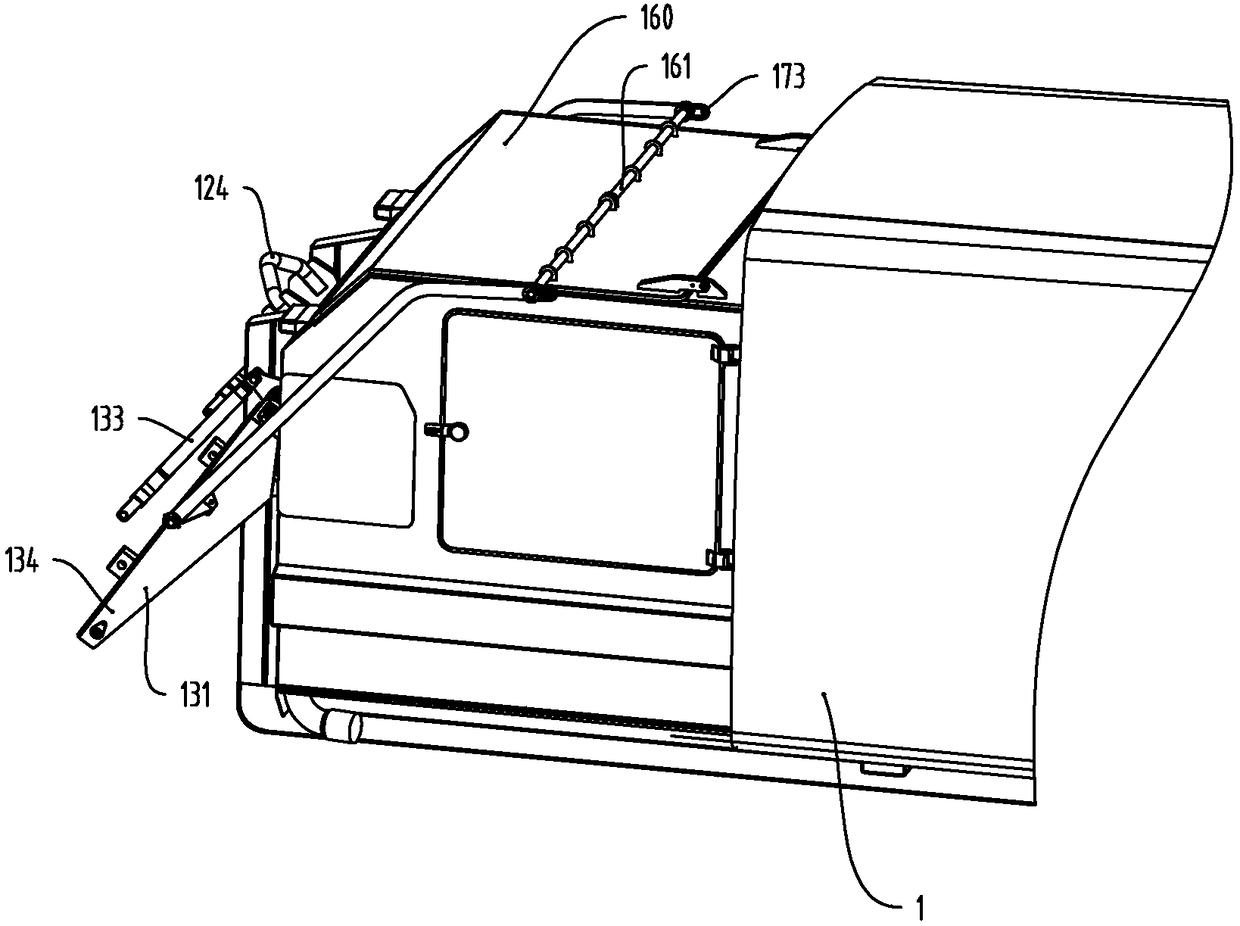

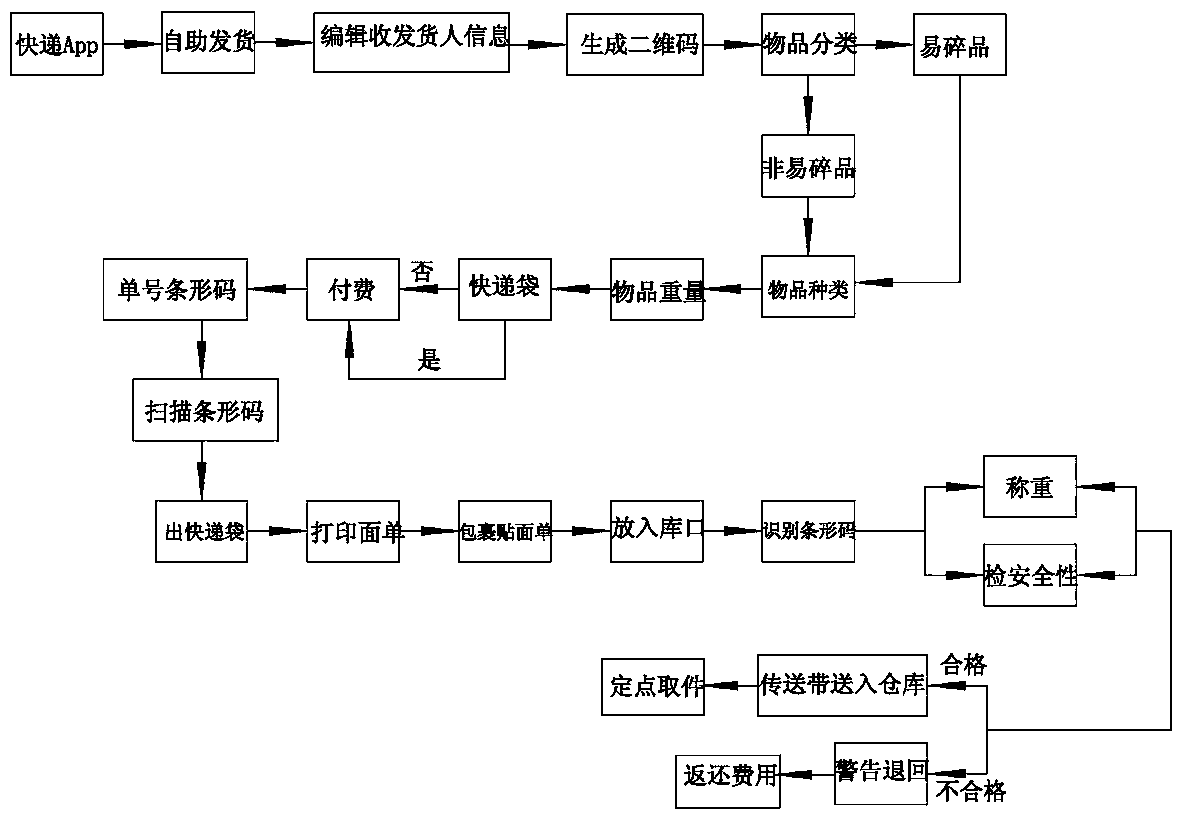

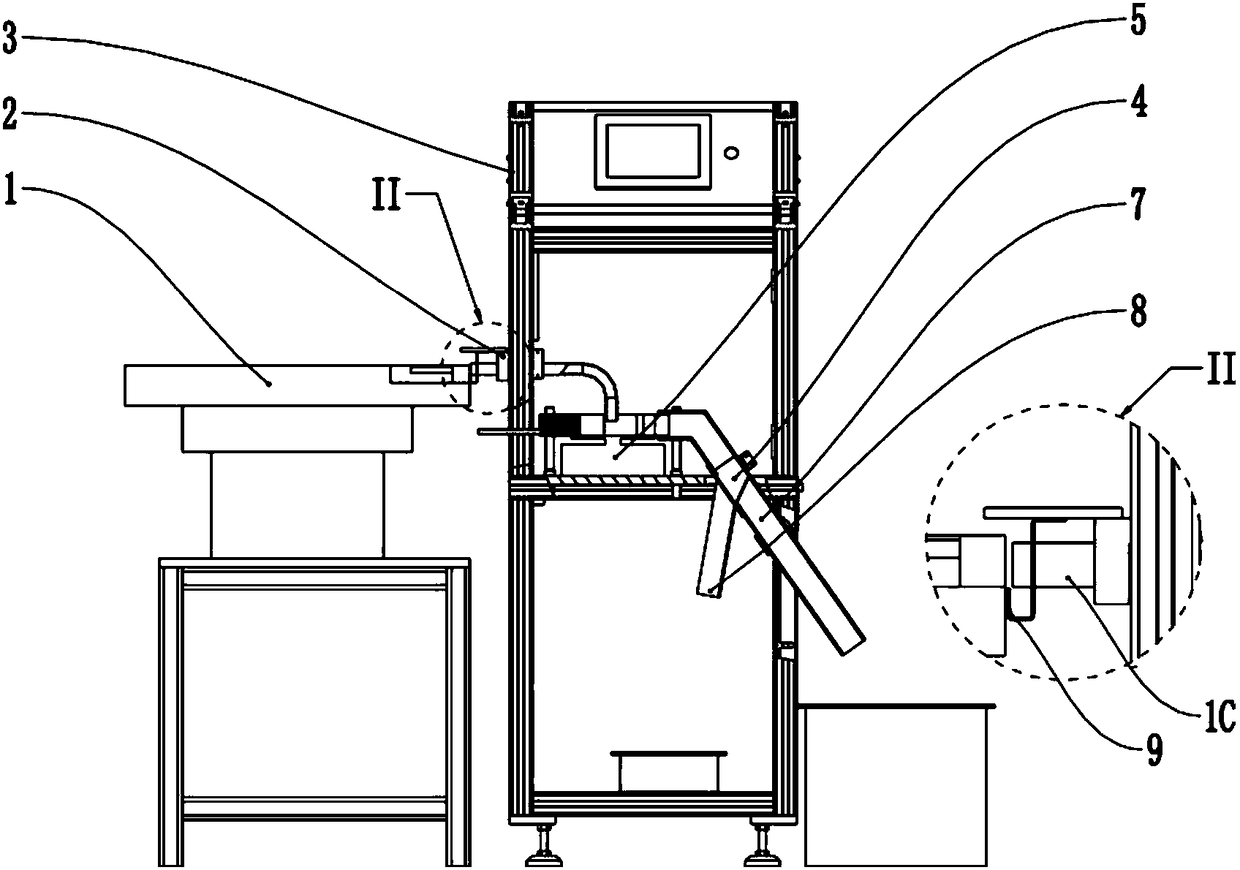

Self-service mailing system and self-service mailing method

InactiveCN108665208AEnsure safetyEasy to manage statisticsFranking apparatusApparatus for meter-controlled dispensingSafety testingSelf-service

The invention discloses a self-service mailing system and a self-service mailing method. The self-service mailing system comprises a user terminal, an express self-service machine and a warehouse; Theexpress self-service machine is provided with a courier bag and a printer, and the express self-service machine is provided with a bag outlet; The warehouse entrance is provided with an identification system and a warehouse entry inspection system. According to the self-service mailing method of the present invention, the system automatically generates the personal information of the consignee and the consignor to a two-dimensional code , only retains the address information, which protects the user's privacy; during the delivery process, scanning the two-dimensional code of a receipt with the app unique to the courier company, after the mobile phone number / name is displayed, the transfer can be completed directly, and the sorter can be automatically sorted. The way to fill in the mailinginformation is optimized, through self-weighing, online payment, self-printing express receipt, placing the finished courier in the warehouse entrance for weight and safety testing, the express can be completed without the help of the courier, the operation process is clear, flexible, convenient and fast.

Owner:陈雨

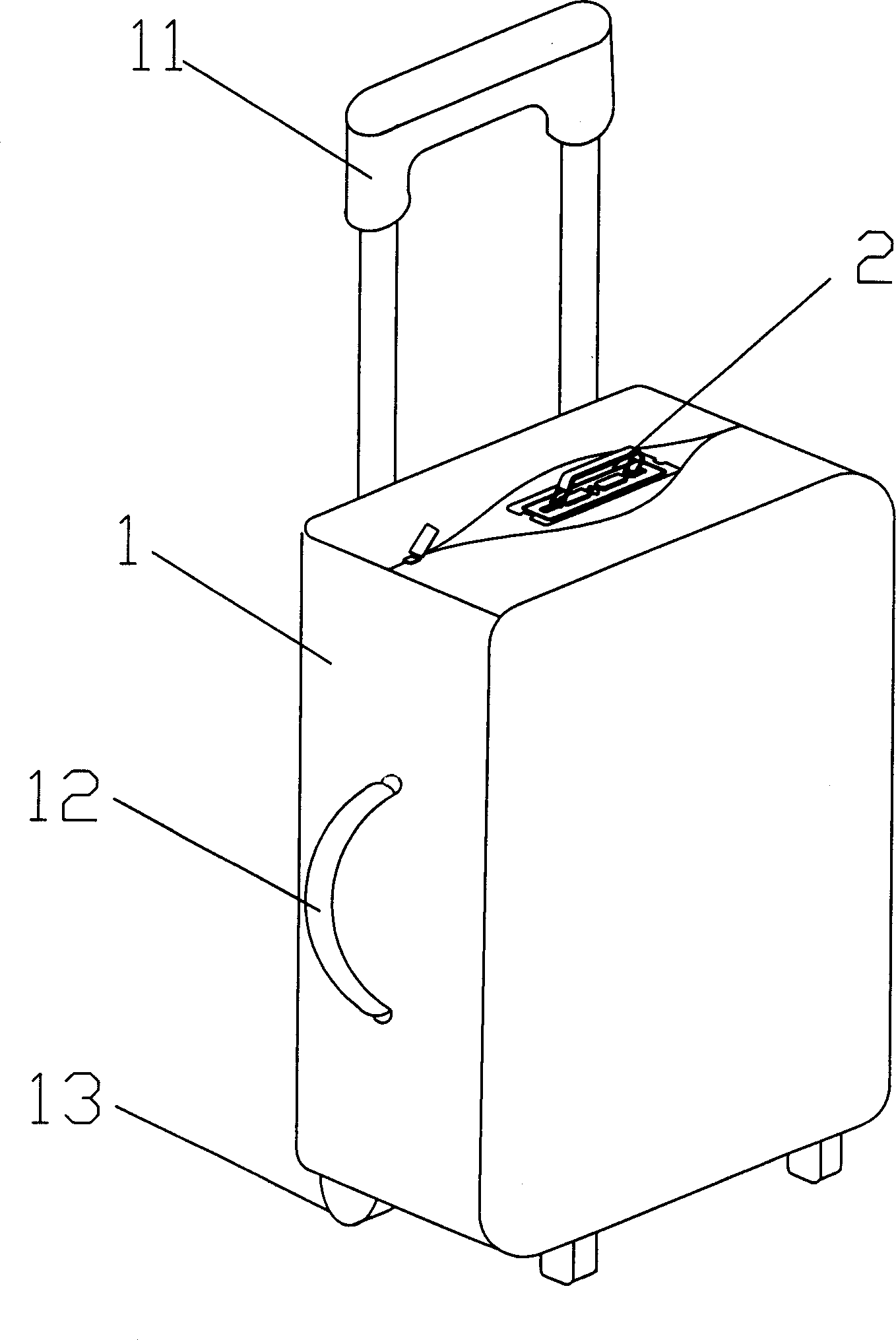

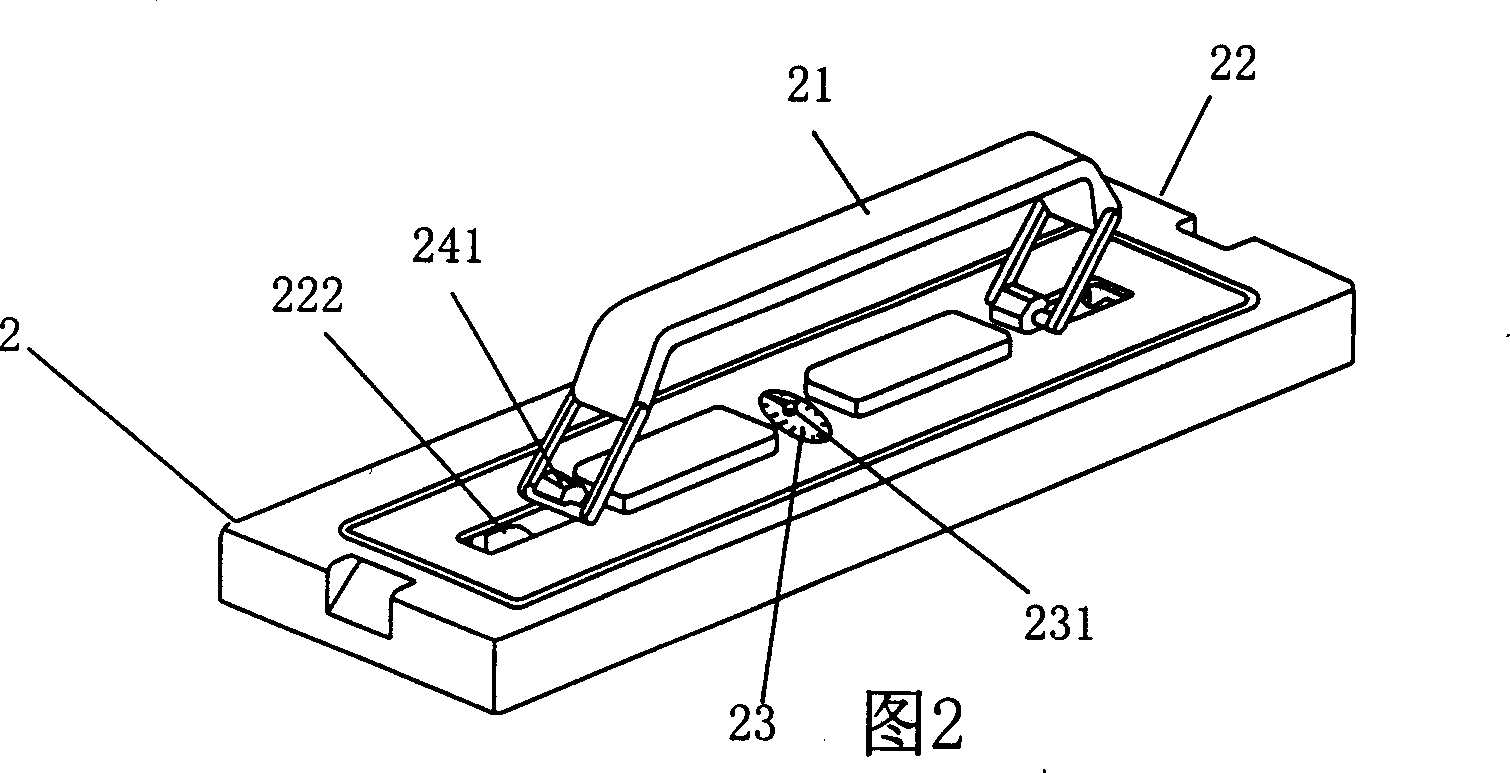

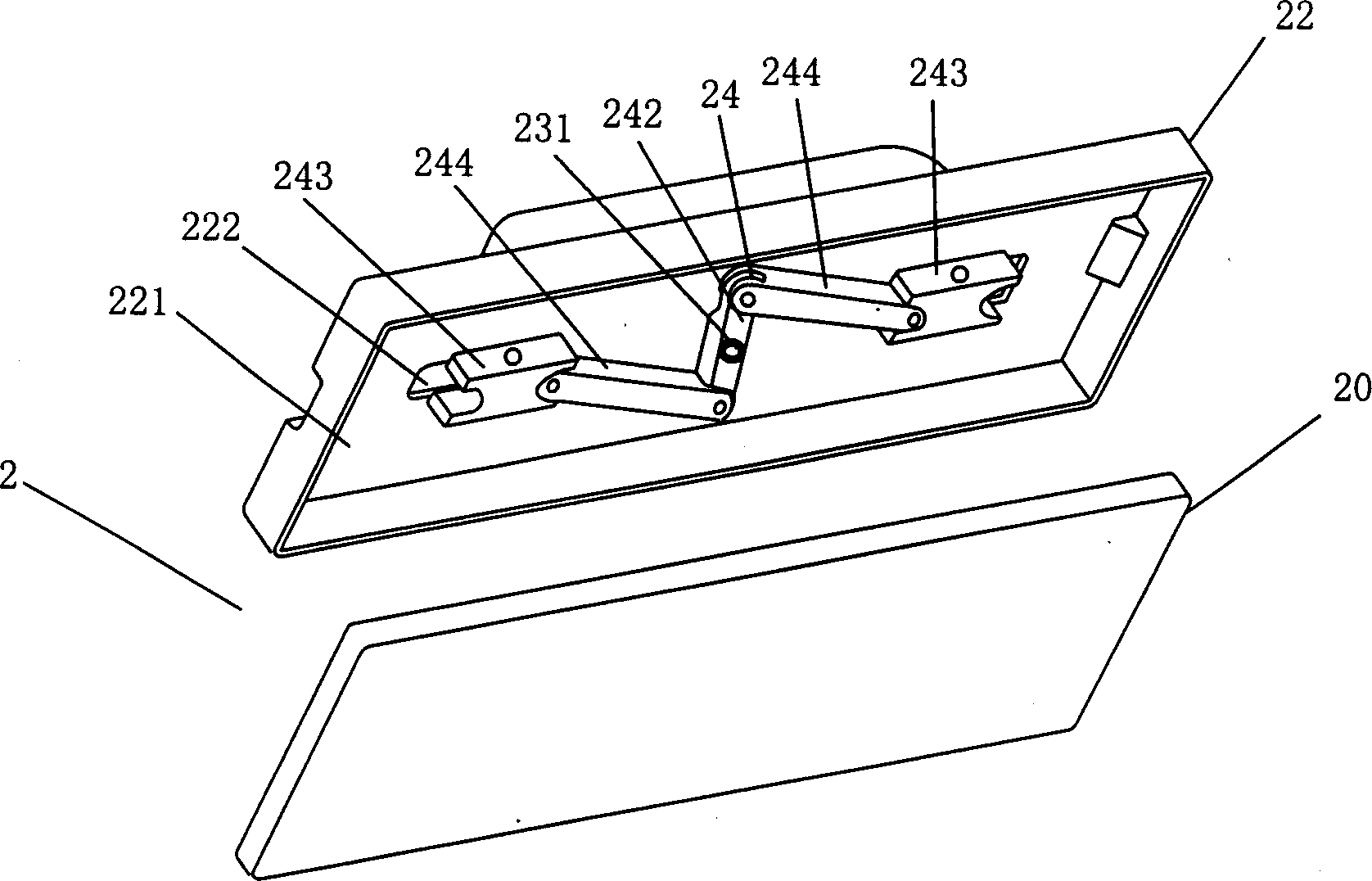

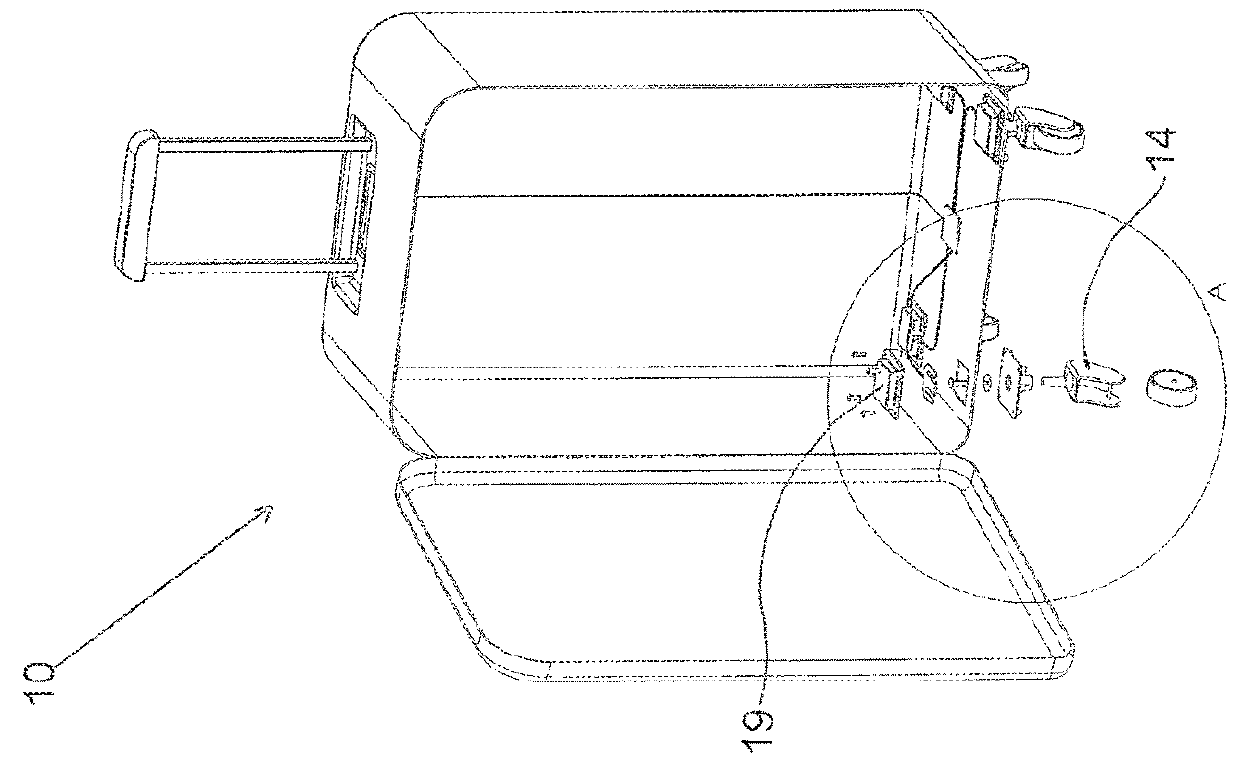

Suitcase weighing method and self-weighing type suitcase thereof

InactiveCN1488921AMaster the total weightTo achieve the purpose of weighingSpecial purpose weighing apparatusEngineeringSelf weighing

The present invention discloses a weighing method of suitcase and its self-weighed suitcase, which is characterized by that a weighing device with handle is mounted on proper position of the suitcase body, and the fixed self-body of the weighing device is fixedly connected with box body of the suitcase, and the indication plate capable of displaying weight index and the handle are mounted on the external side of the box body, when the handle is lifted, it can drive the weighing device and make it work, and the whole weight of the suitcase can be displayed on the indication plate. Said self-weighed suitcase includes suitcase box body, pulling-bar group mounted on one side of the box body, rollers and weighing device.

Owner:JINXIONG ENTERPRISE CO LTD XIAMEN

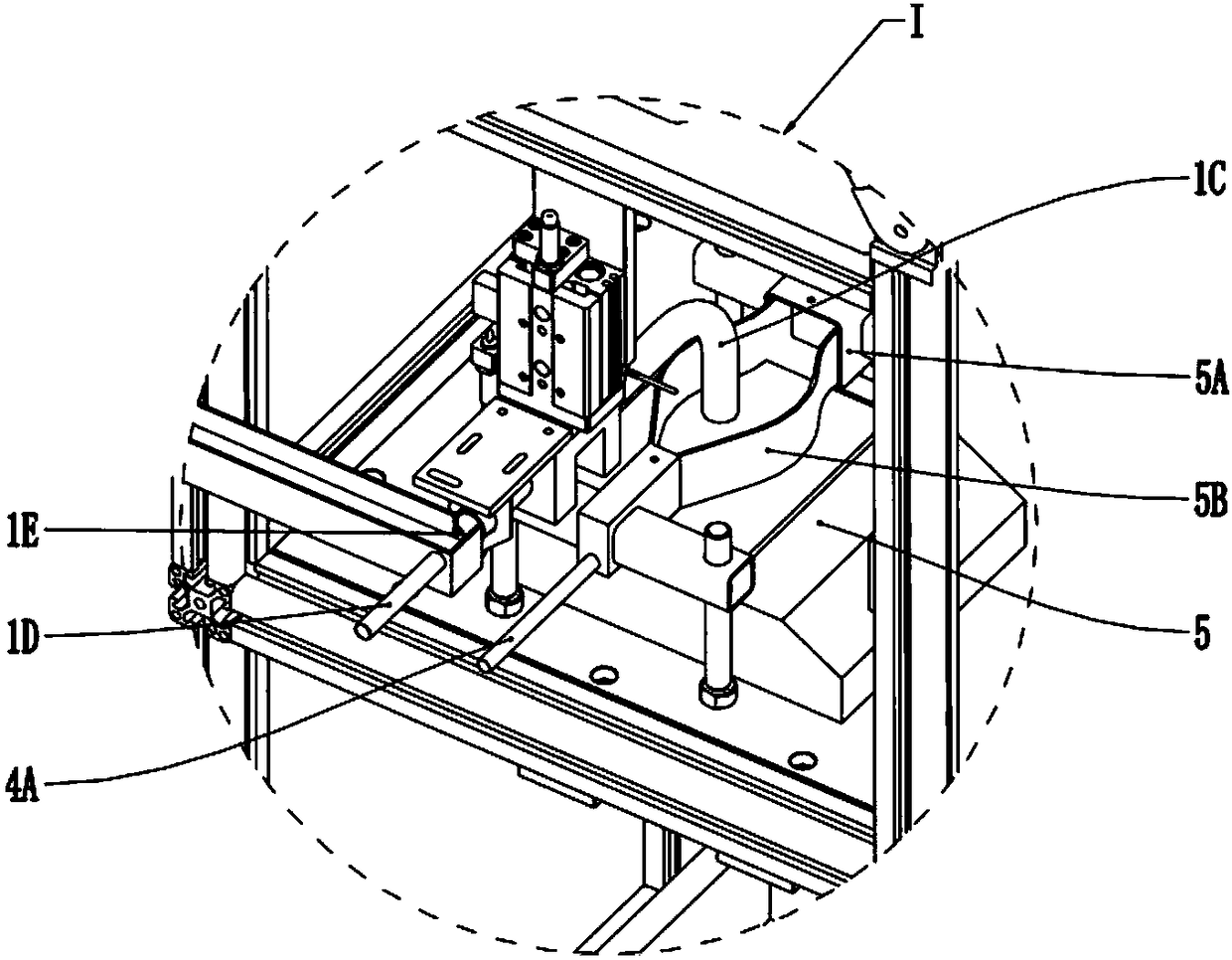

Material bag self-weighing, self-detecting and self-classifying stacking device for stacker crane

ActiveCN103863832AEase of implementation of technical transformationSimple structureControl devices for conveyorsStacking articlesEngineeringCantilever

The invention discloses a material bag self-weighing, self-detecting and self-classifying stacking device for a stacker crane. A cantilever and a weighing sensor of the stacker crane are connected, and the weighing sensor is connected with a stacker crane grip assembly. The stacking device is mainly characterized in that an intelligent controller conducts self-weighing, self-detecting and self-classifying stacking operation on a material bag through 360-degree rotary fixed point control over a main body of the stacker crane according to preset control software. The stacking device has the advantages of being simple in structure, high in operation working efficiency and the like, and the stacker crane can conduct self-weighing, self-detecting and self-classifying stacking operation on the material bag.

Owner:CHANGZHOU REITRON AUTOMATIC EQUIP

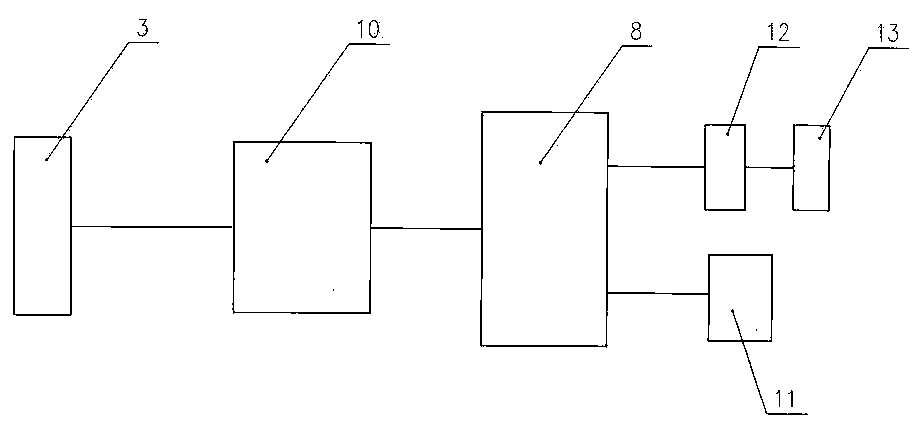

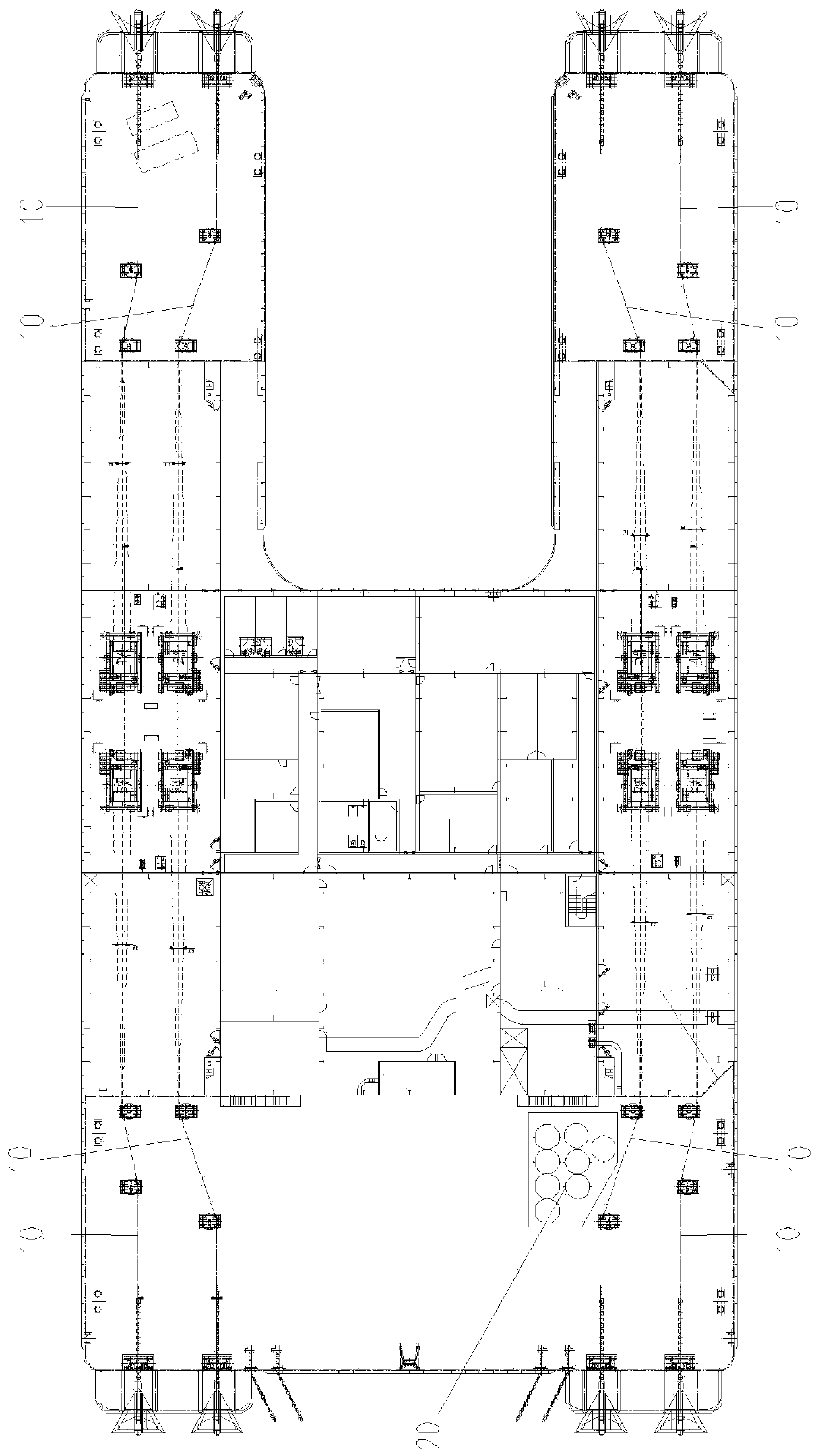

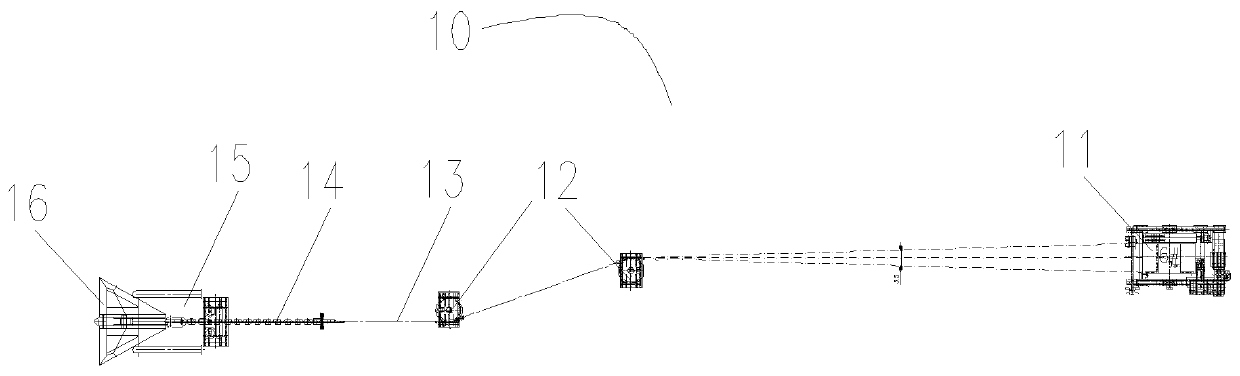

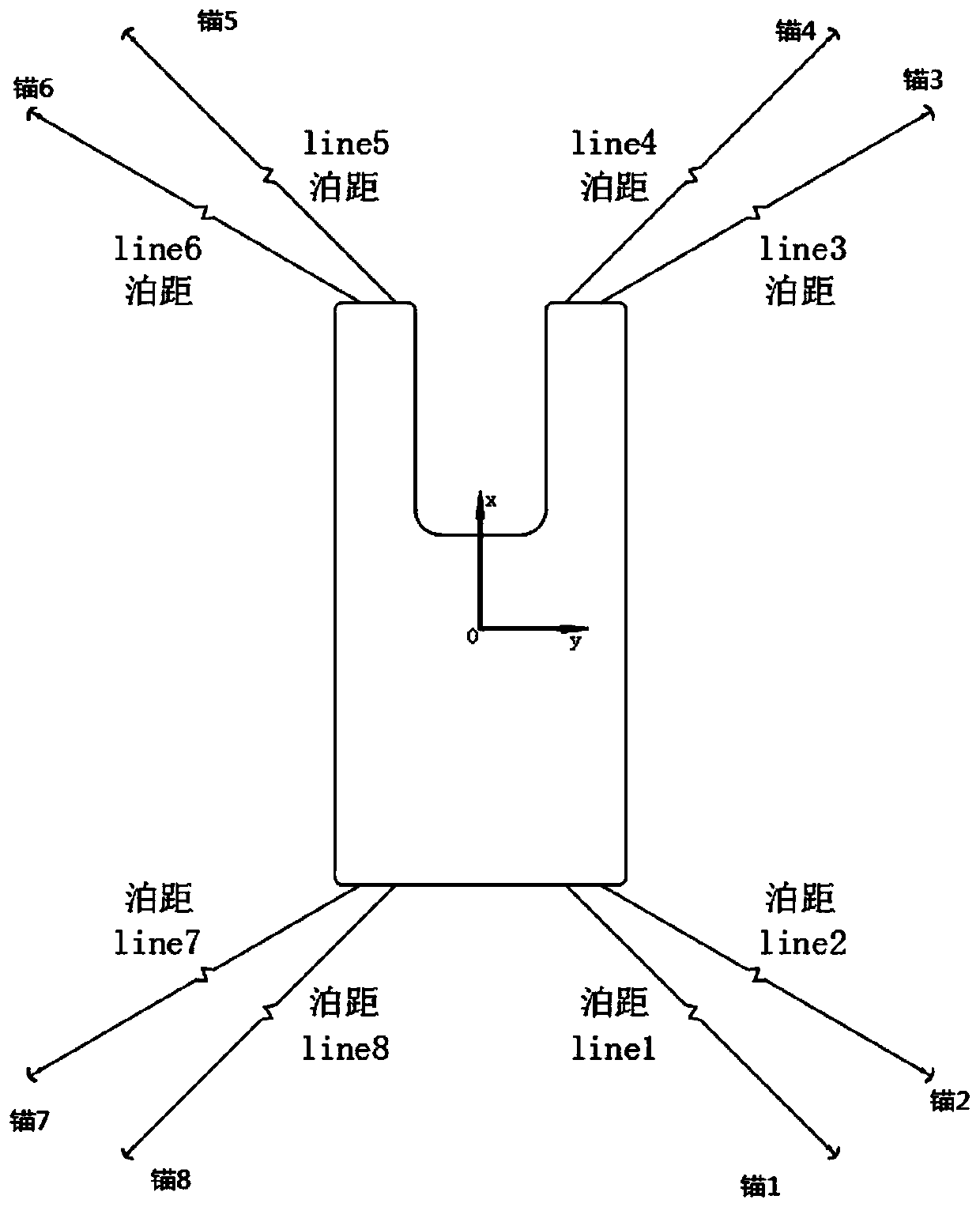

Multi-point mooring and position-fixing system for floating installation and ship-moving operation and ship-moving method

ActiveCN110217346AImprove economyLift variable weightWind motor assemblyWind energy generationElectricityMarine engineering

The invention provides a multi-point mooring and position-fixing system for floating installation and ship-moving operation and a ship-moving method. The invention establishes the multi-point mooringand position-fixing system by integrating various factors. A mooring line weighing anchor and dropping anchor boat sequentially unties each position-fixing mooring line from a current position to weigh anchor and drops anchor after sailing to a designated position. An offshore wind turbine installation vessel is dragged through the sequential adjustment of the mooring distance of each of the mooring lines so as to ensure the smooth running of installation operation of the offshore wind turbine installation vessel. Through the cooperation of self weighing anchor and dropping anchor operation with the retraction and extension of mooring ropes, the need for transfer and ship-moving operation during the installation operation of pile foundations of an offshore wind farm can be satisfied.

Owner:SHANGHAI MERCHANT SHIP DESIGN & RES INST

Polypropylene fiber continuous glass fiber blended thermal composite reinforcing material and preparation method thereof

Owner:CHANGZHOU UNIV

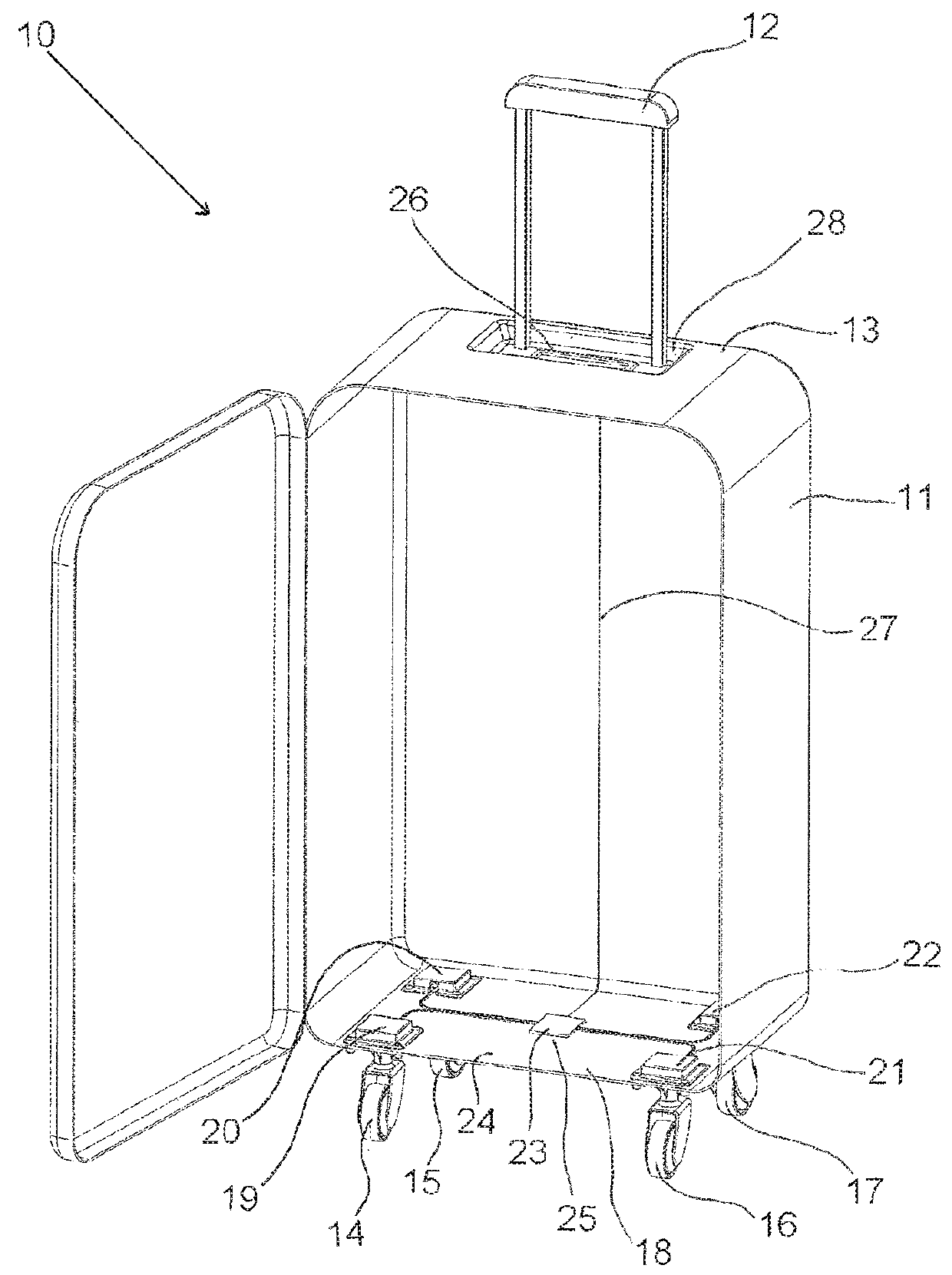

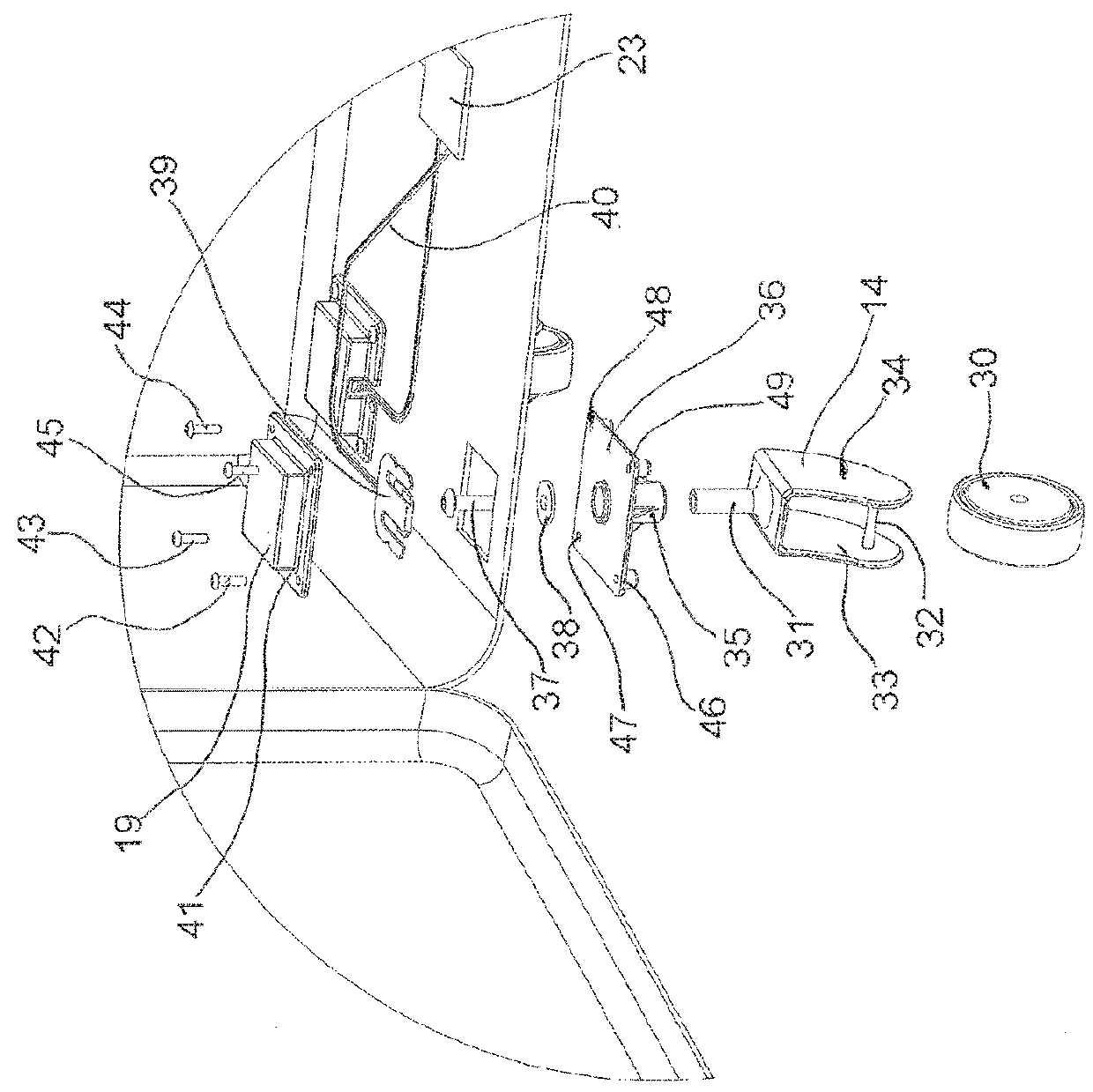

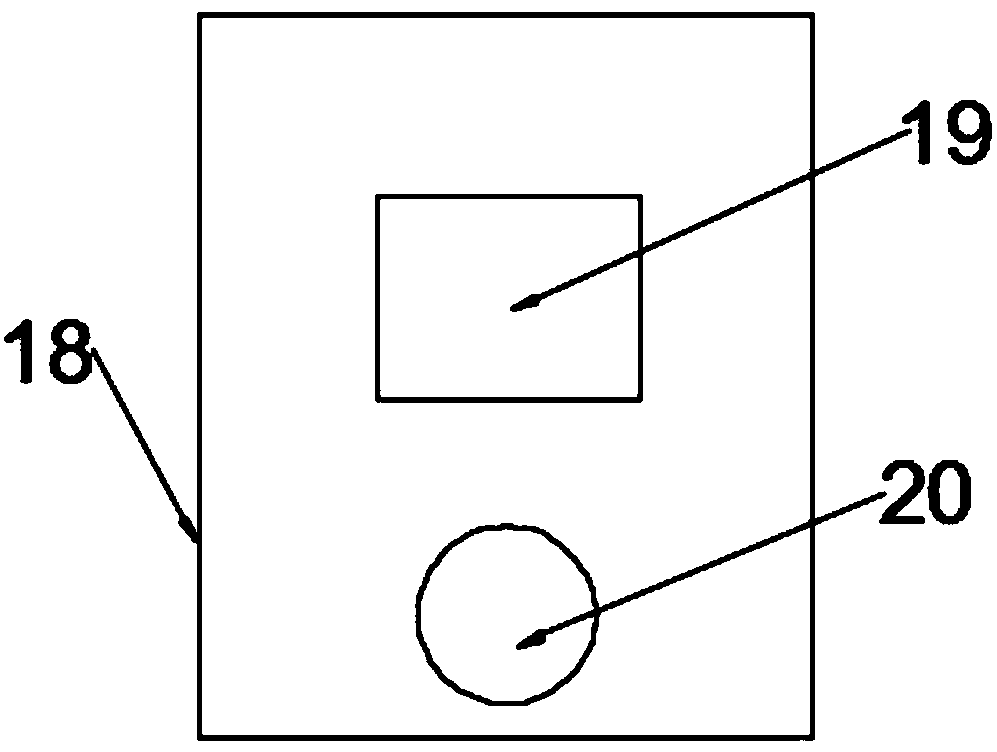

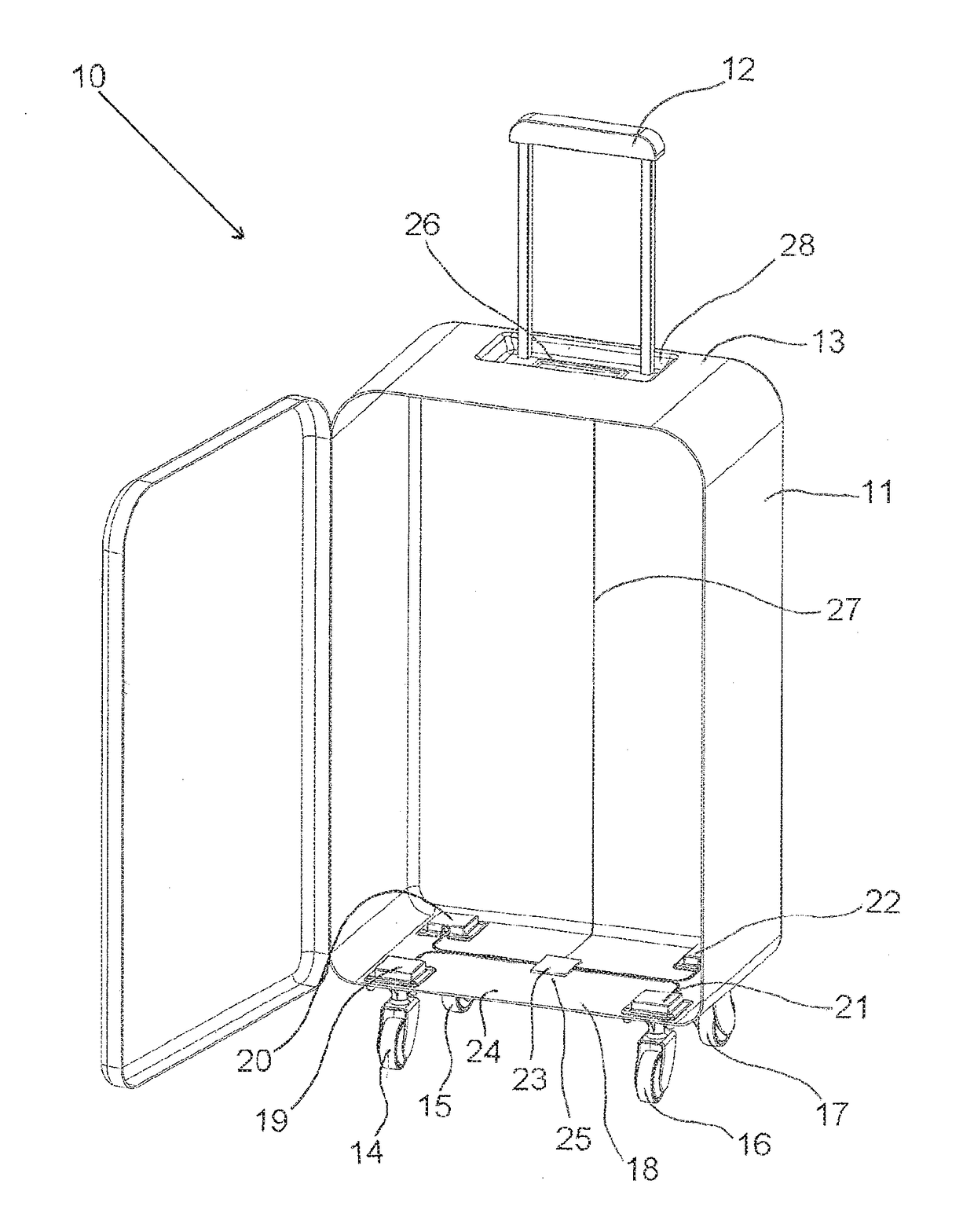

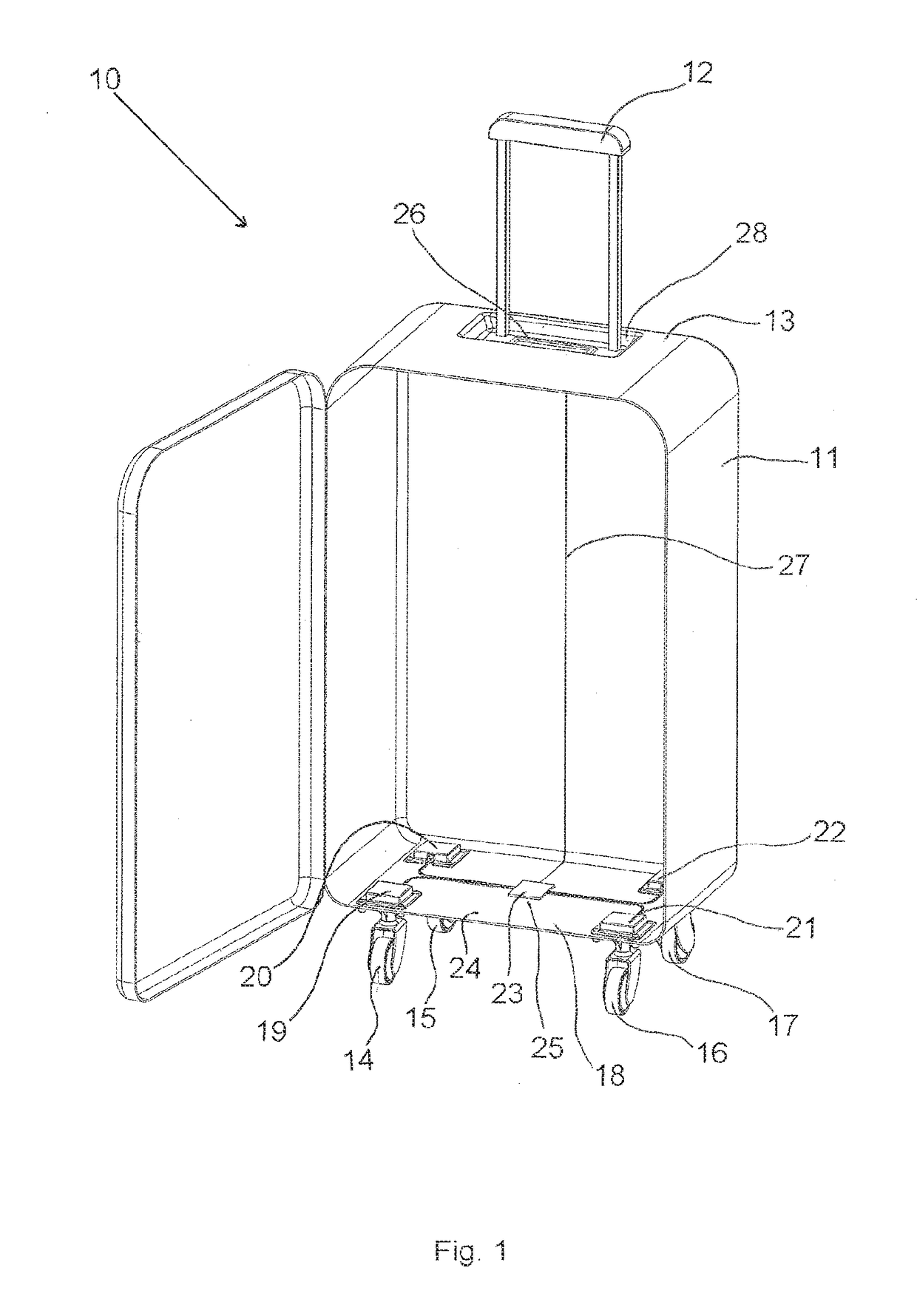

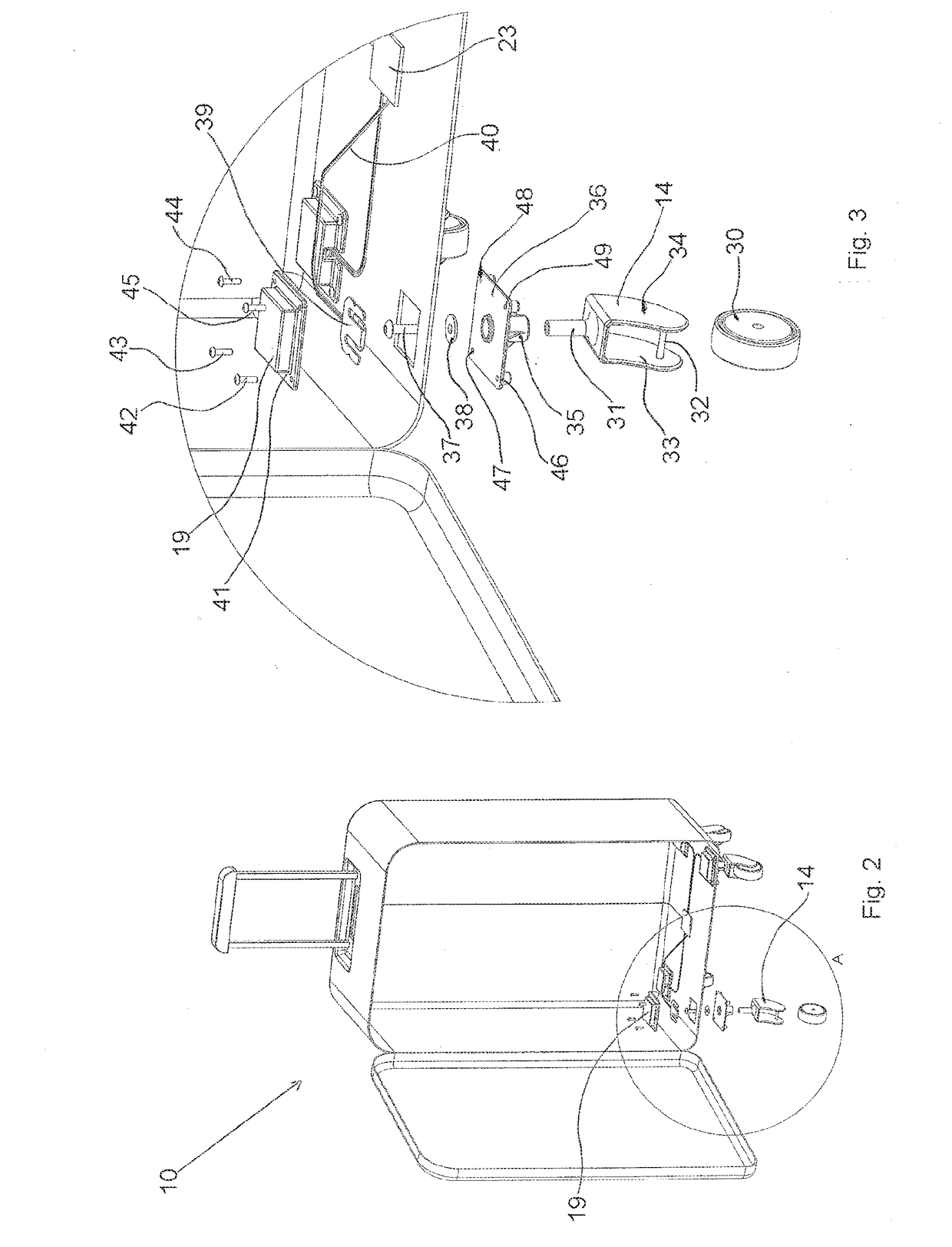

Luggage with weight sensors

ActiveUS10039362B2Convenient ArrangementPrecise positioningPursesLuggageLiquid-crystal displayEngineering

A self-weighing luggage device comprises a housing with a towing handle at one end and four wheel units mounted at the other end. Four weight determining sensors are incorporated into the wheel units, respectively. Each weight determining sensor is wired to a central circuit board, which is mounted on the inner surface of other end at position. The central circuit board is connected to a Liquid Crystal Display (LCD) mounted in a recess in the handle end of the housing, which recess is adapted to receive the handle in a stowed position, such that the LCD is protected by the handle. In use, the self-weighing luggage device is stood on the ground on the four wheel units and the weight readings from each weight determining sensor are combined to give the total weight of the self-weighing luggage device, which total weight is displayed on the LCD.

Owner:SELFWEIGHING SUITCASE CO LTD

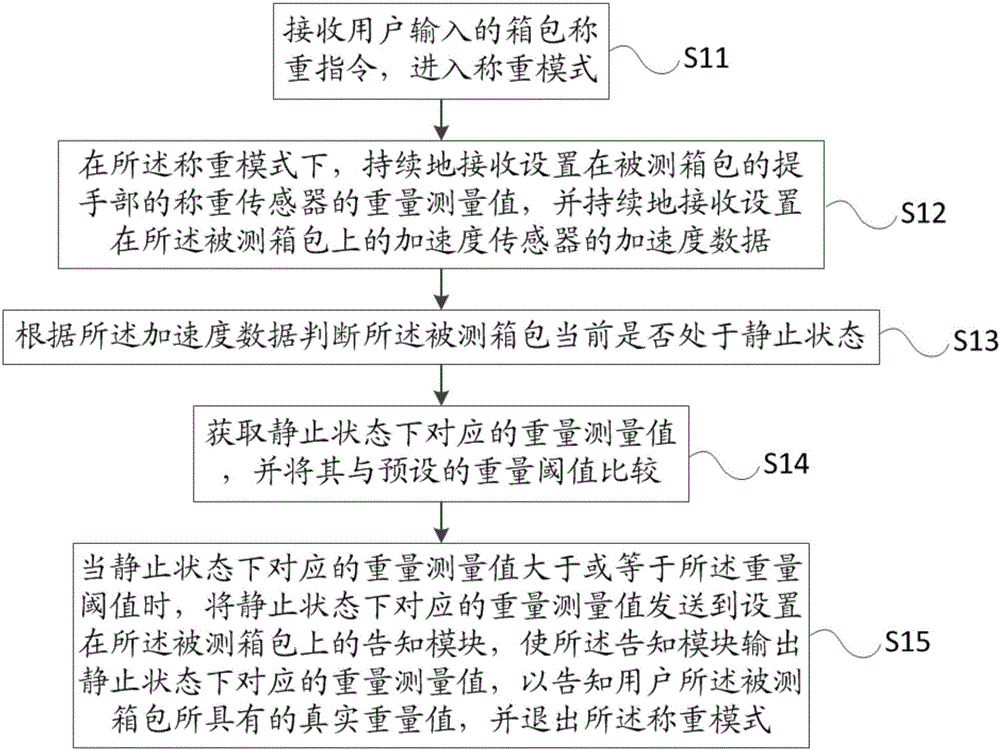

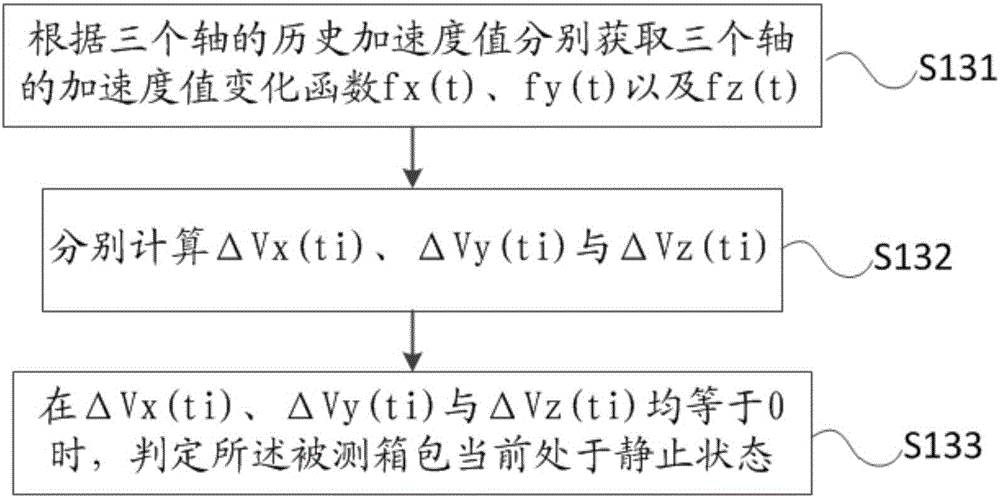

Self-weighing method and device of case and case with self-weighing function

The invention provides a self-weighing method and device of a case and the case with a self-weighing function. The method comprises that a case weighing instruction input by a user is received; the weight measuring value and acceleration data of the measured case are received continuously; whether the measured case is in a static state at present is determined according to the acceleration data; the weight measuring value corresponding to the static state is obtained, and compared with a preset weight threshold; and when the weight measuring value corresponding to the static state is greater than or equivalent to the weight threshold, the weight measuring value corresponding to the static state is sent to a notification model arranged on the measured case, so that the notification module outputs the weight measuring value corresponding to the static state. According to the self-weighing method of the case, whether the case is in the static state is determined automatically, only the weight measuring value, greater than or equivalent to the weight threshold, corresponding to the static state is output, the user needs not to make determination by himself / herself, and the accuracy of a measuring result obtained by the user finally is ensured.

Owner:GUANGZHOU SHIYUAN ELECTRONICS CO LTD

Preparation method of polypropylene fiber-glass fiber thermoplastic composite material

InactiveCN105908362AHigh strengthImprove impact resistanceNon-woven fabricsMonocomponent polyolefin artificial filamentGlass fiberPolymer science

The invention discloses a preparation method of a polypropylene fiber-glass fiber thermoplastic composite material. The preparation method comprises the following preparation steps of 1 preparing of polypropylene fibers; 2 preparing of glass fibers; 3 mixing of the polypropylene fibers and the glass fibers, wherein the polypropylene fibers and the glass fibers are mixed through a fiber self-weighing mixing system, the humidity of a mixing environment is controlled to be 33% to 43%, and the temperature of the mixing environment is controlled to be 20 DEG C to 30 DEG C; 4 fiber needling felt forming, wherein the precisely-mixed polypropylene fibers and glass fibers are carded with a carding machine and lapped through a clamping type lapping machine to obtain a fiber net, then fiber needling felt forming is conducted through pre-needling equipment and main needling equipment, and lastly cutting and rolling are conducted to obtain the polypropylene fiber-glass fiber thermoplastic composite material. According to the preparation method, the process steps are simple, the production process is continuous, the production efficiency is high, the equipment is simple, and the technology is convenient to master; the polypropylene fiber-glass fiber thermoplastic composite material has the advantages that on one hand, the good heat-conducting property is achieved, on the other hand, the mechanical property of a heat-conducting material is enhanced, and processing is convenient.

Owner:ZHEJIANG HENGZE ENVIRONMENT TECH CO LTD

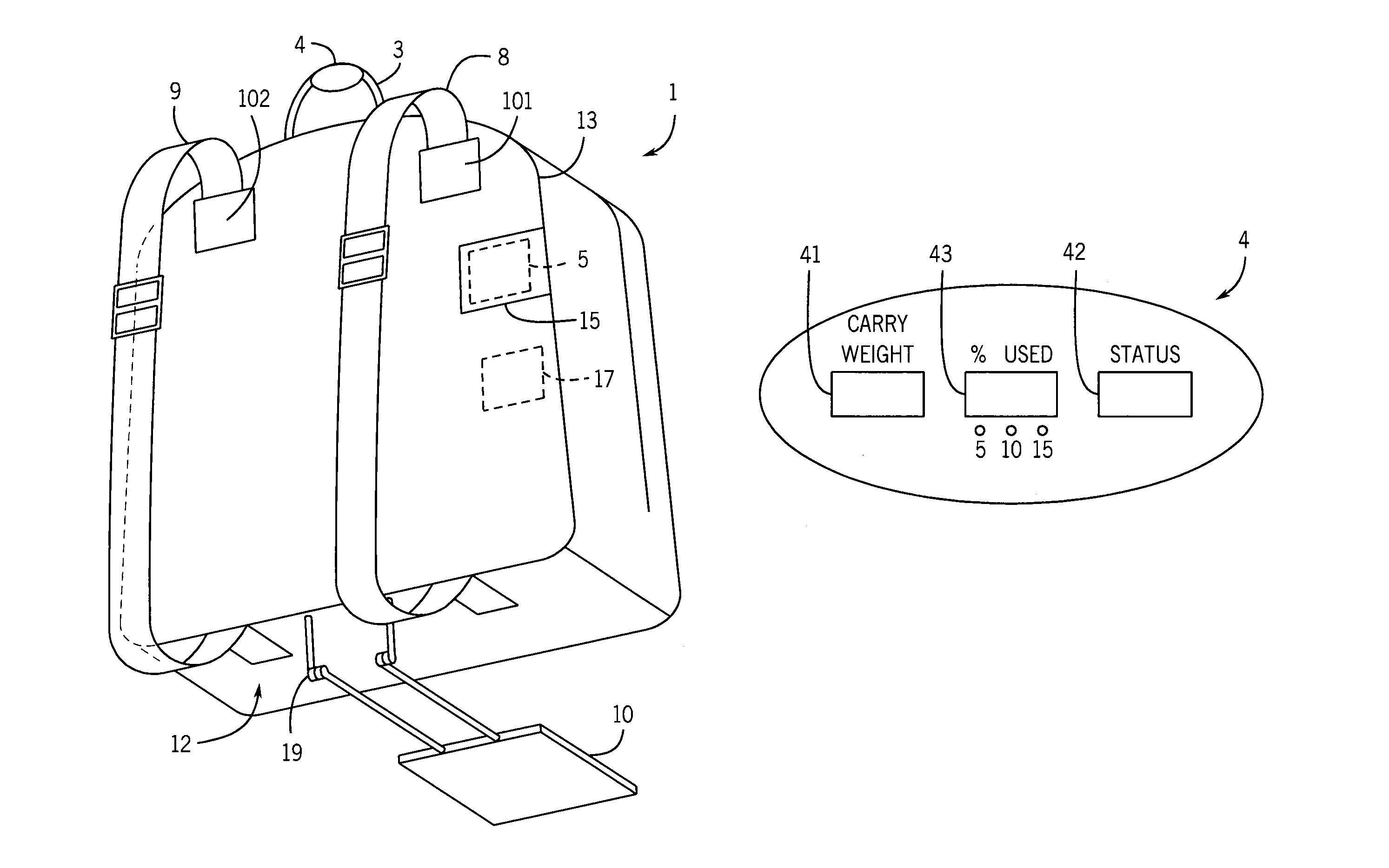

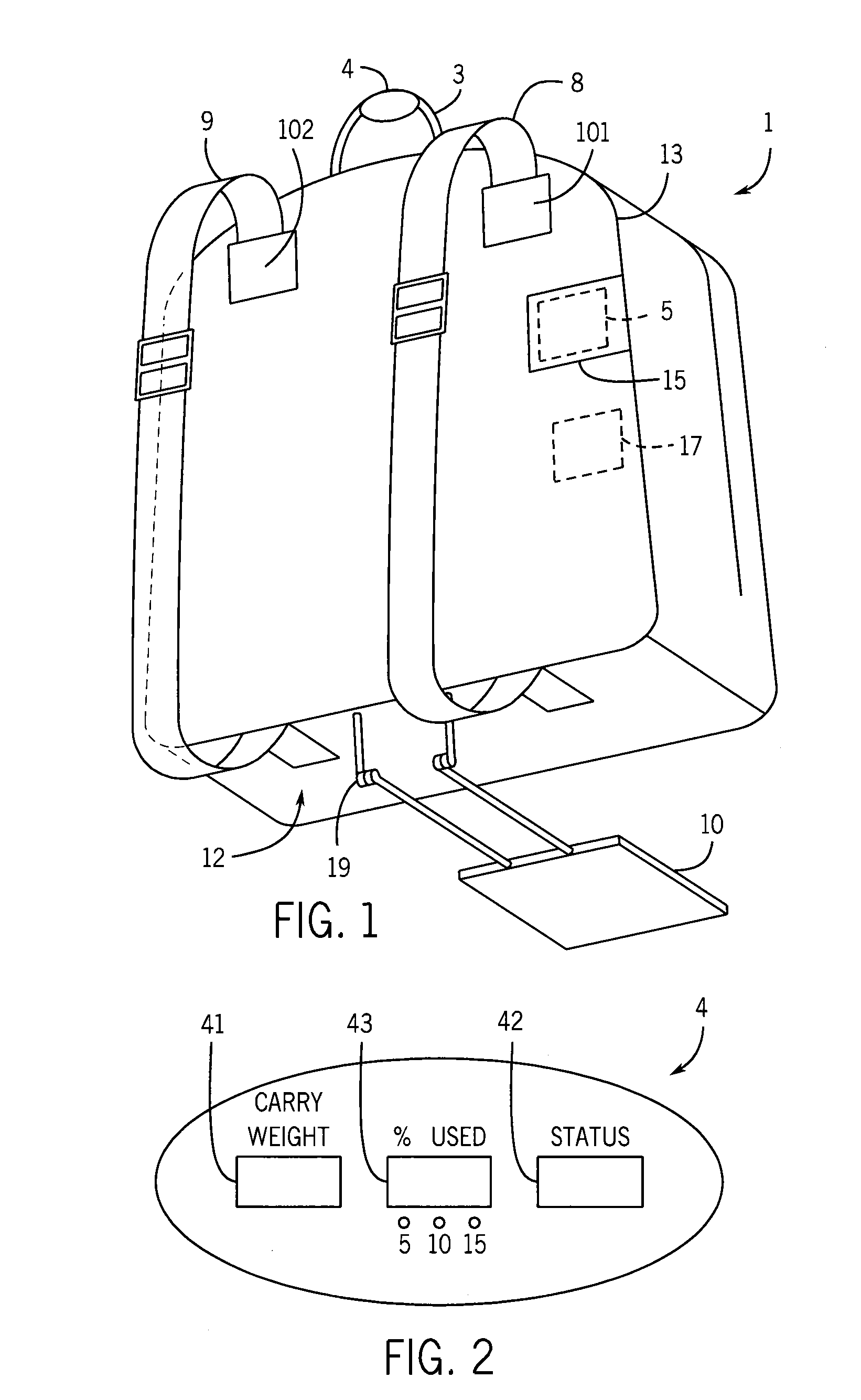

Self-weighing backpack with weight notification features

InactiveUS8910843B2Over burdening his exoskeleton structureLess strainTravelling sacksPursesEngineeringStrain gauge

A self-weighing backpack includes a container body that is connected to right and left carry straps that include strain gauges. Processing circuitry is included that compares dynamic force measurements to a predetermined threshold force and generates an alert when the predetermined threshold force is exceeded.

Owner:ALMALKI BADER ABDULLAH

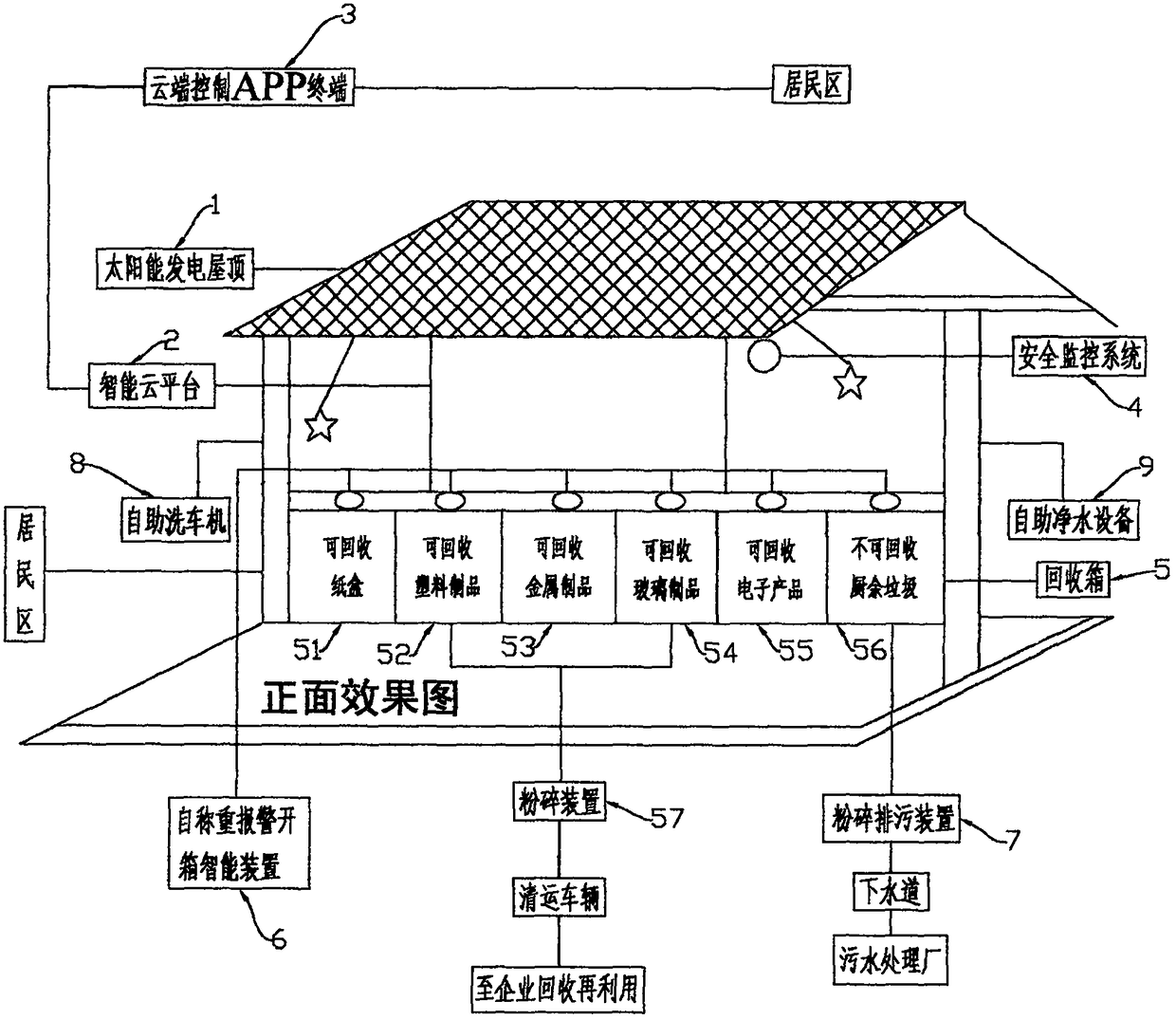

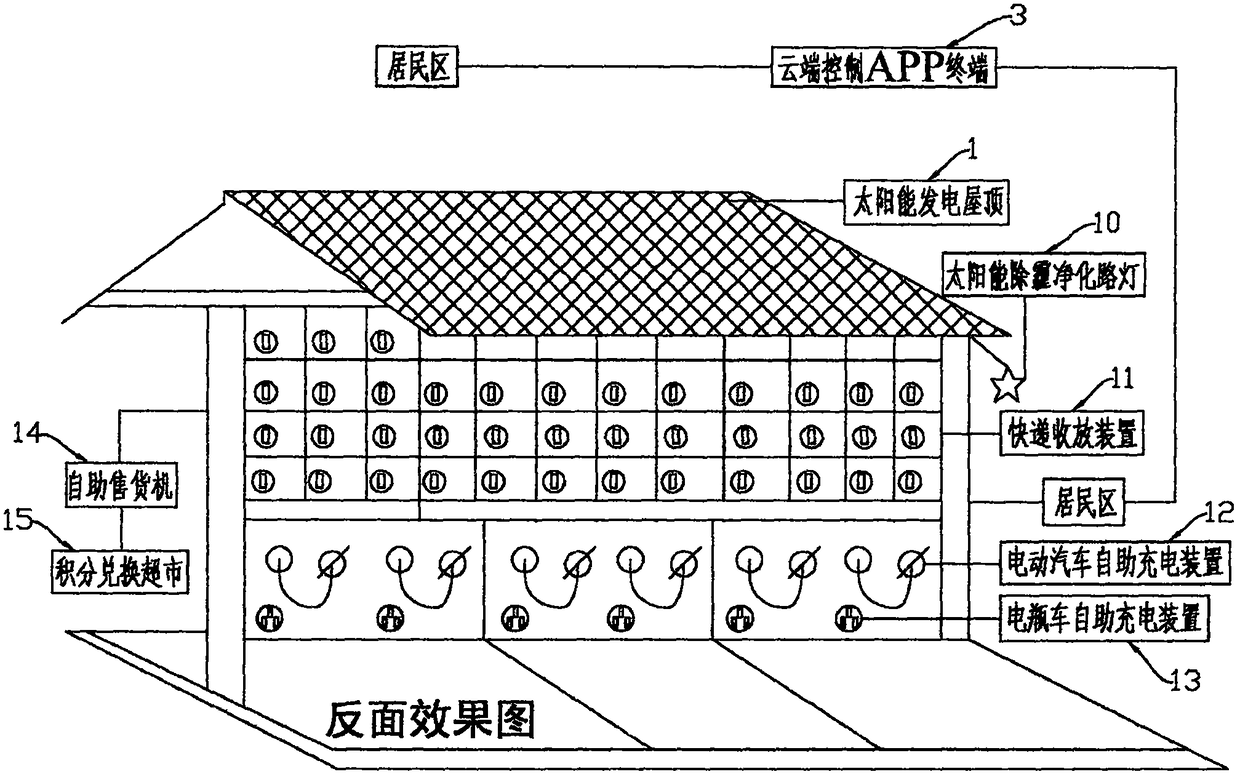

Intelligent and environment-friendly garbage self-service sorting treatment system

InactiveCN108820640AGood Classification HabitsPromote environmental protectionWaste collection and transferRefuse receptaclesNetwork connectionSignaling network

An intelligent and environment-friendly garbage self-service sorting treatment system comprises a solar power generating roof. An intelligent cloud platform is arranged below the solar power generating roof and connected to a cloud control APP terminal through a network. The intelligent and environment-friendly garbage self-service sorting treatment system further comprises a safety monitoring system which is connected with the intelligent cloud platform through a signal network. The intelligent and environment-friendly garbage self-service sorting treatment system further comprises a recycling box, and self-weighing alarming box-opening intelligent devices are arranged on the upper portion of the recovering box and is in network connection with the intelligent cloud platform through signal and information transmission. The intelligent and environment-friendly garbage self-service sorting treatment system further comprises a solar haze removal purification street lamp and an express receiving and storing device. The express receiving and storing device is placed on the other panel opposite to the intelligent cloud platform, and an electric car self-service charging device and a battery car self-service charging device are arranged below the express receiving and storing device. The express receiving and storing device, the electric car self-service charging device and the battery car self-service charging device are in network connection with the intelligent cloud platform, and the solar haze removal purification street lamp is electrically connected with the solar power generating roof.

Owner:阜阳市鑫卡邦智能科技有限公司

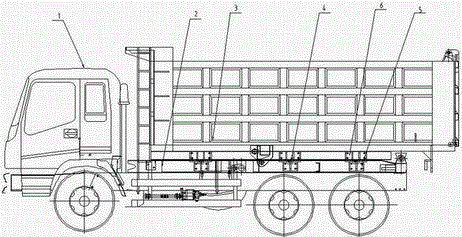

Self-weighing truck

InactiveCN106427757APrevent over-shipmentEliminate the trouble of looking for weighbridges everywhereVehicle frameLogistics management

The invention provides a self-weighing truck. The self-weighing truck comprises a truck head, a truck frame and a truck compartment, wherein the truck frame is fixedly connected to the rear part of the truck head; and the truck compartment is erected on the truck frame. The self-weighing truck is characterized in that weighing sensors are arranged at connection positions of the truck frame and the truck compartment, and are separately and symmetrically arranged at a front position, a middle position and a rear position of the truck frame of the truck; and the sensors send a signal to a display instrument of a truck control system through a circuit wire. According to the self-weighing truck disclosed by the invention, through the own weighing of the truck compartment, a driver and a supervision department conveniently and accurately judge the weight of goods loaded in and unloaded from the truck, so that the purposes that the truck is free from less freight and excess freight are achieved, accurate basis is provided for determining the weight of loaded freight in the truck, the weight of the freight unloaded from the truck, and the weight of the freight left in the truck, and the trouble that when the bulk goods is traded, a wagon balance needs to be searched everywhere for weighting is avoided; and besides, the weighting system display instrument can monitor and transmit the weight of the goods in the truck in a real-time manner through an APP downloaded by a cellphone and the Internet, so that the management of the truck by large logistics companies and truck teams is facilitated, and the driver is prevented from allocating more goods and earning more money halfway.

Owner:SHIYAN GAOKE ELECTRONICS WEIGHING APP MFG CO LTD

Suitcase

InactiveCN107744231AEasy to loseIntelligent alarmBatteries circuit arrangementsPursesMicrocontrollerMicrocomputer

The invention discloses a suitcase. The suitcase comprises a casing, a casing cover, a telescoping pull bar and rollers, the rollers are positioned at a lower part of the casing, the casing cover is connected with the casing through a zip fastener, a single-chip microcomputer, a display module, a positioning module, a weighing module, a charging module, an alarming module, an unlocking module, a power supply module, a communication module, a voice module and an image acquisition module are arranged in the casing, and a solar cell panel, a USB interface, a charging port, a display panel and a camera are arranged outside the casing. The product employs the solar cell panel to absorb solar energy, and then transforms the solar energy to provide more auxiliary functions to the suitcase, the power supply module can be charged through the charging port by people, and the product is suitable for a plurality of conditions; the product solves the problem of easy loss of the suitcase while travelling, is capable of charging electronic equipment for people, and has intelligent functions of self weighing, loss resisting, and alarming, so that the suitcase has the advantages of safety, intelligent performance and convenience, and the suitcase provides more convenient life for people.

Owner:王力行

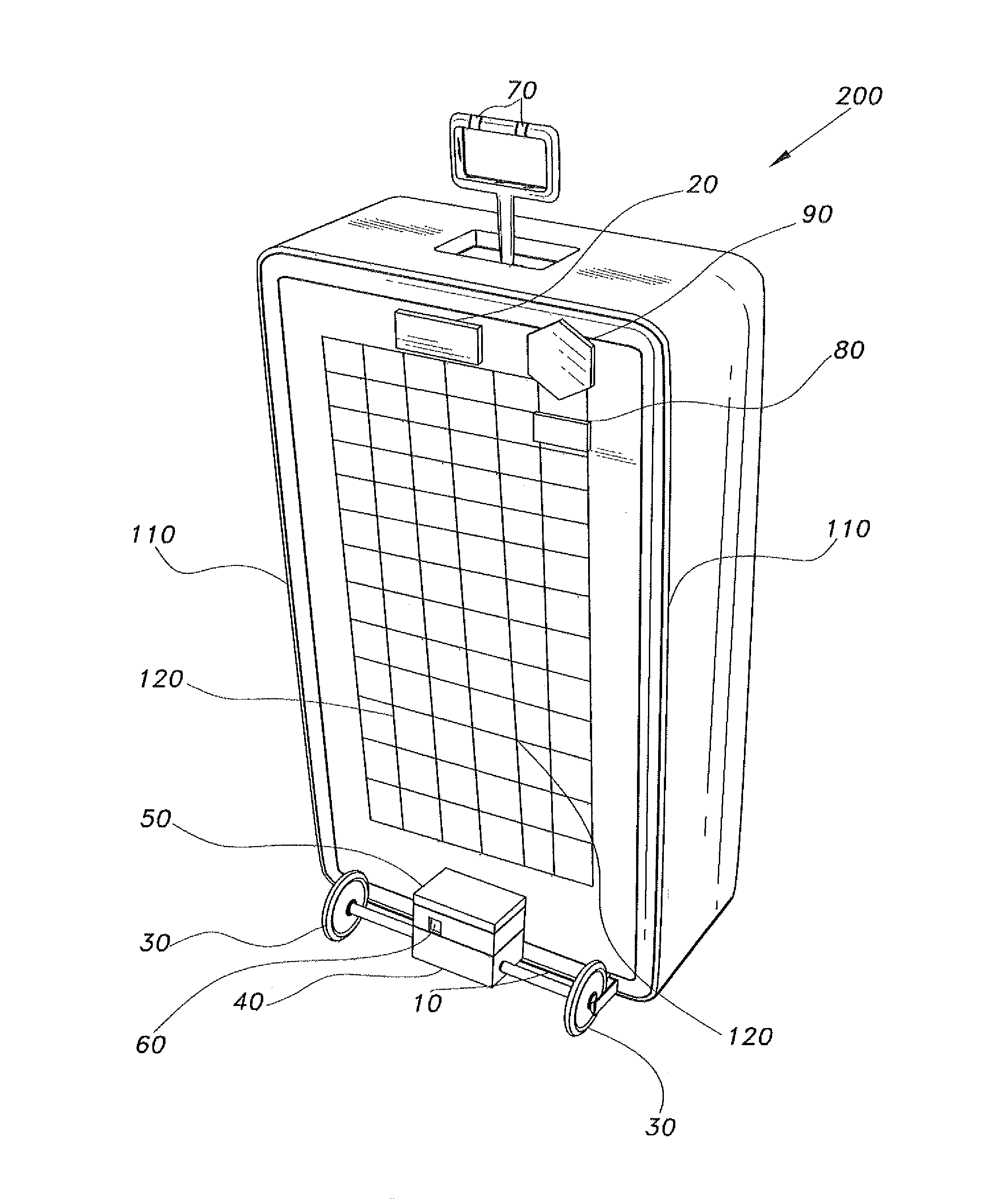

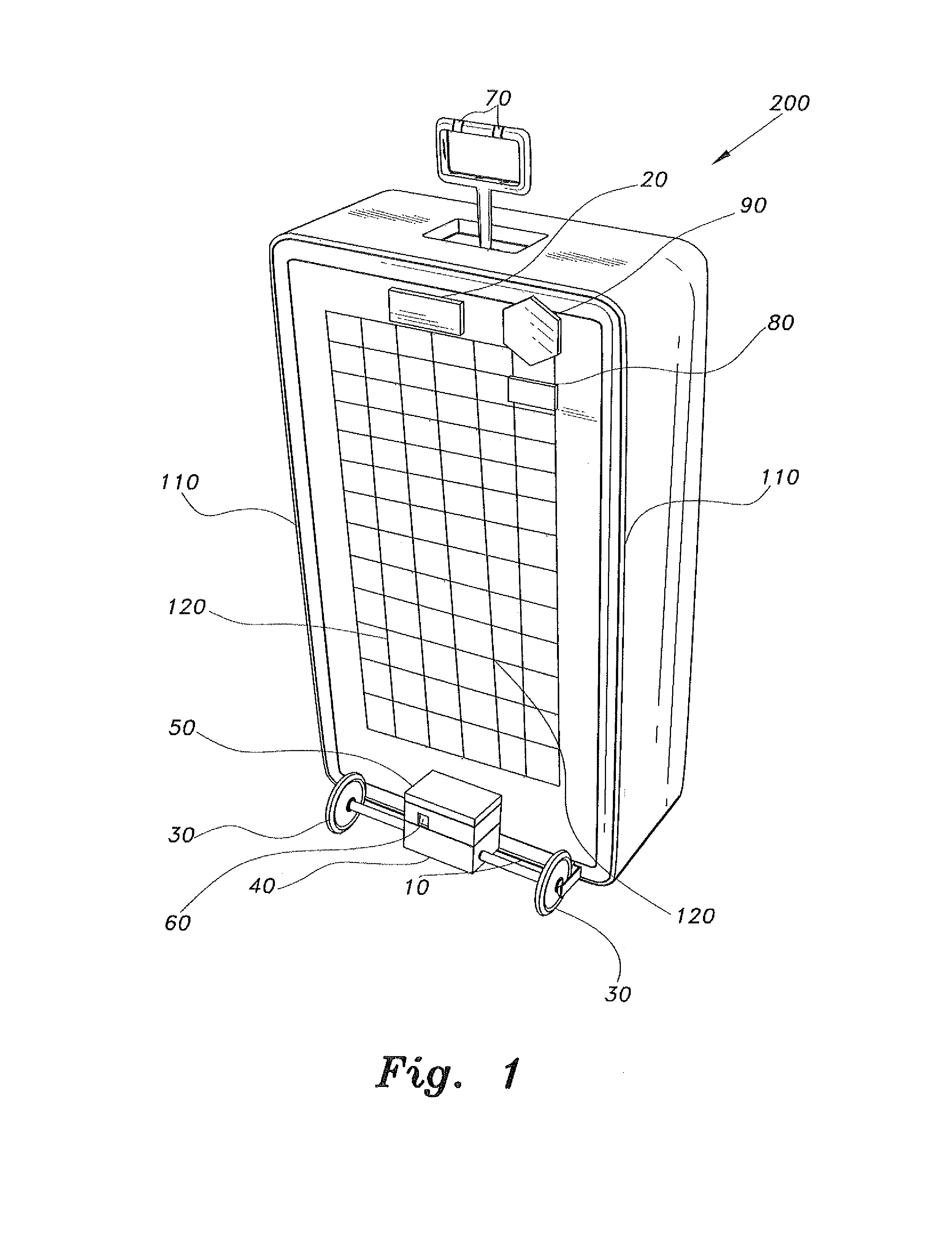

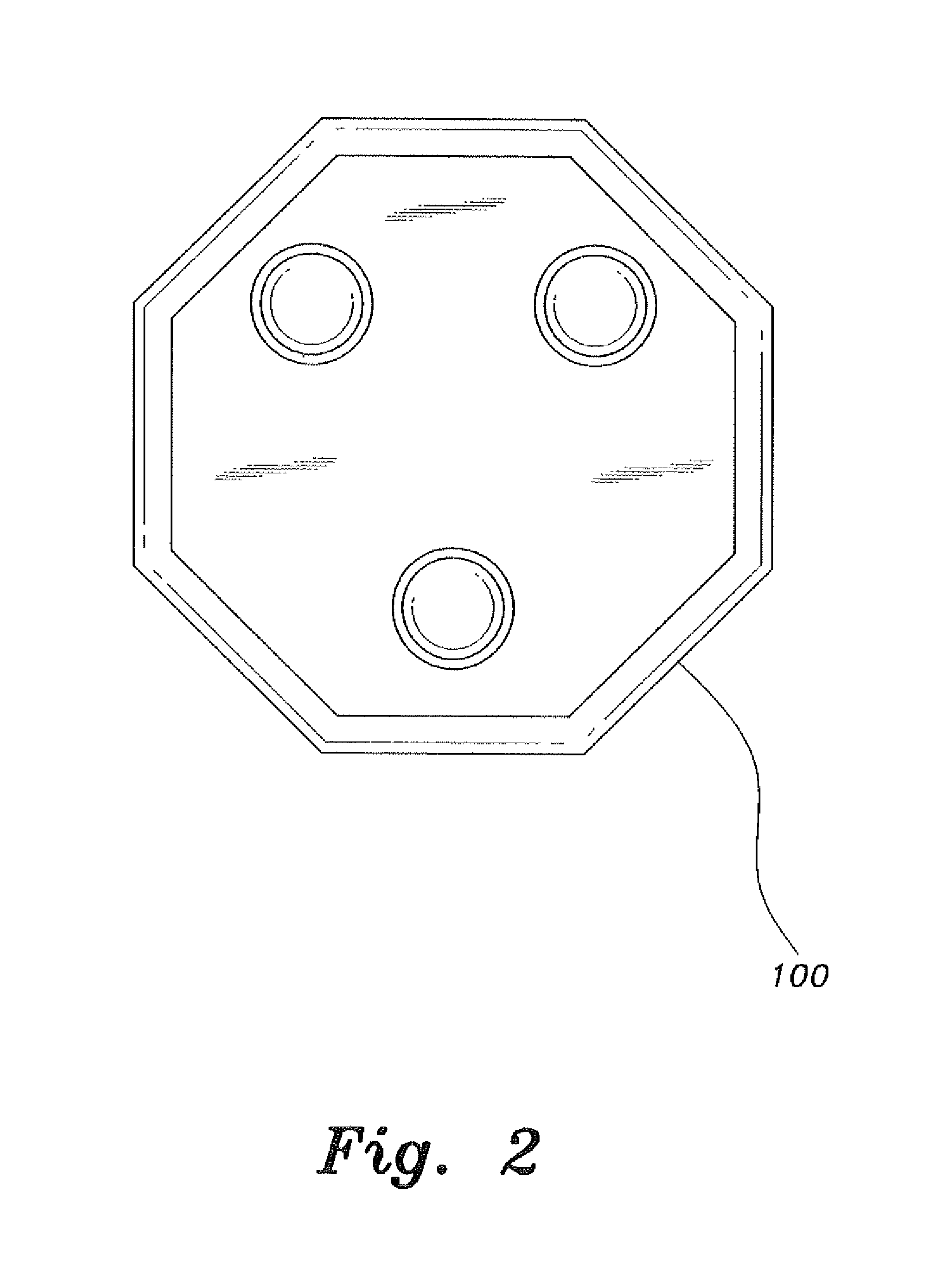

Self-weighing luggage device

ActiveUS20170325561A1Convenient ArrangementPrecise positioningPursesLuggageLiquid-crystal displayMechanical engineering

A self-weighing luggage device comprises a housing with a towing handle at one end and four wheel units mounted at the other end. Four weight determining sensors are incorporated into the wheel units, respectively. Each weight determining sensor is wired to a central circuit board, which is mounted on the inner surface of other end at position. The central circuit board is connected to a Liquid Crystal Display (LCD) mounted in a recess in the handle end of the housing, which recess is adapted to receive the handle in a stowed position, such that the LCD is protected by the handle. In use, the self-weighing luggage device is stood on the ground on the four wheel units and the weight readings from each weight determining sensor are combined to give the total weight of the self-weighing luggage device, which total weight is displayed on the LCD.

Owner:SELFWEIGHING SUITCASE CO LTD

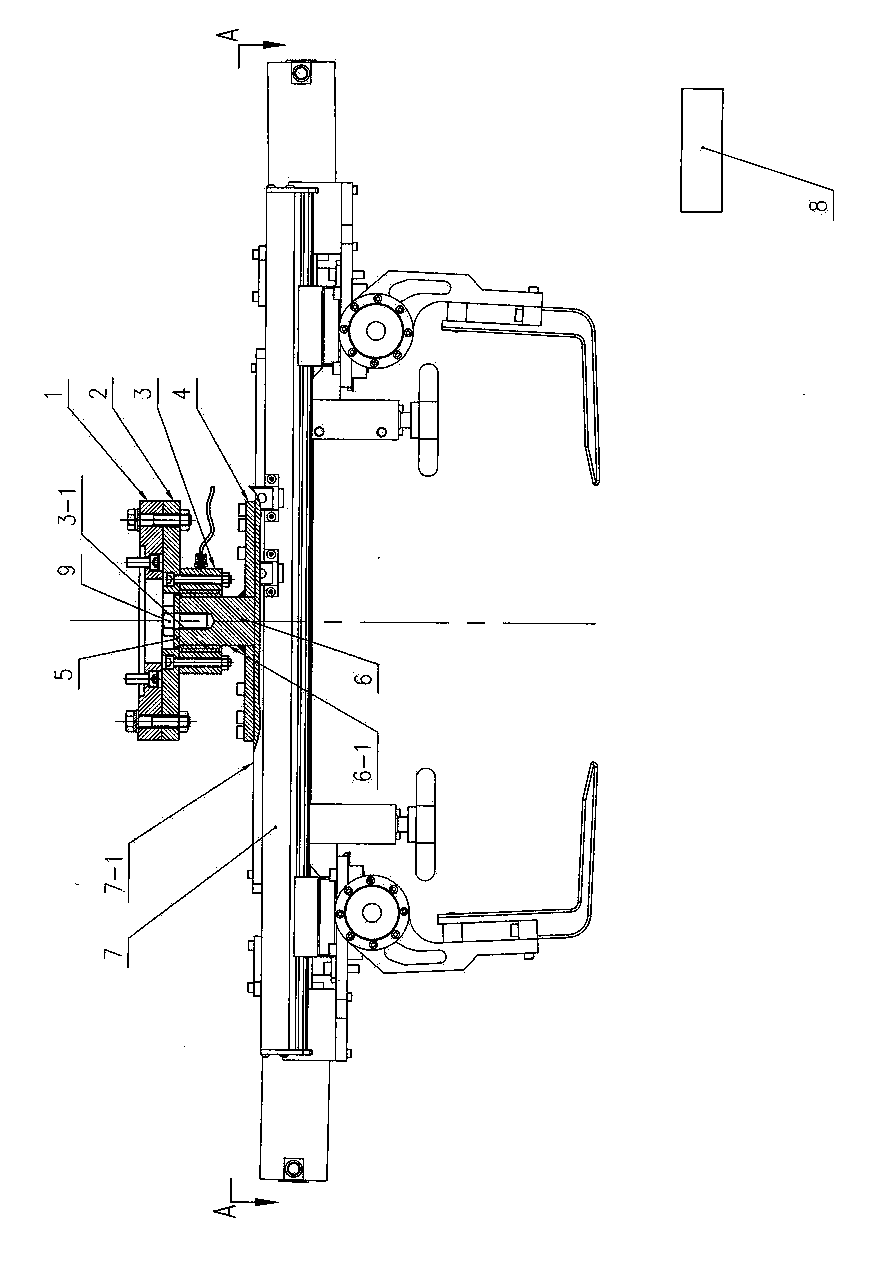

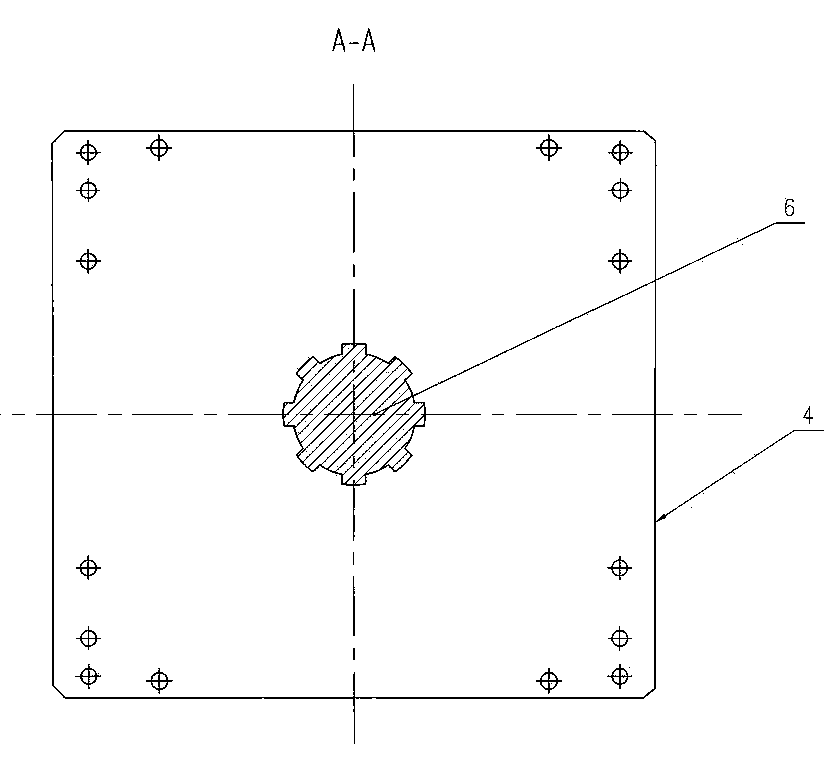

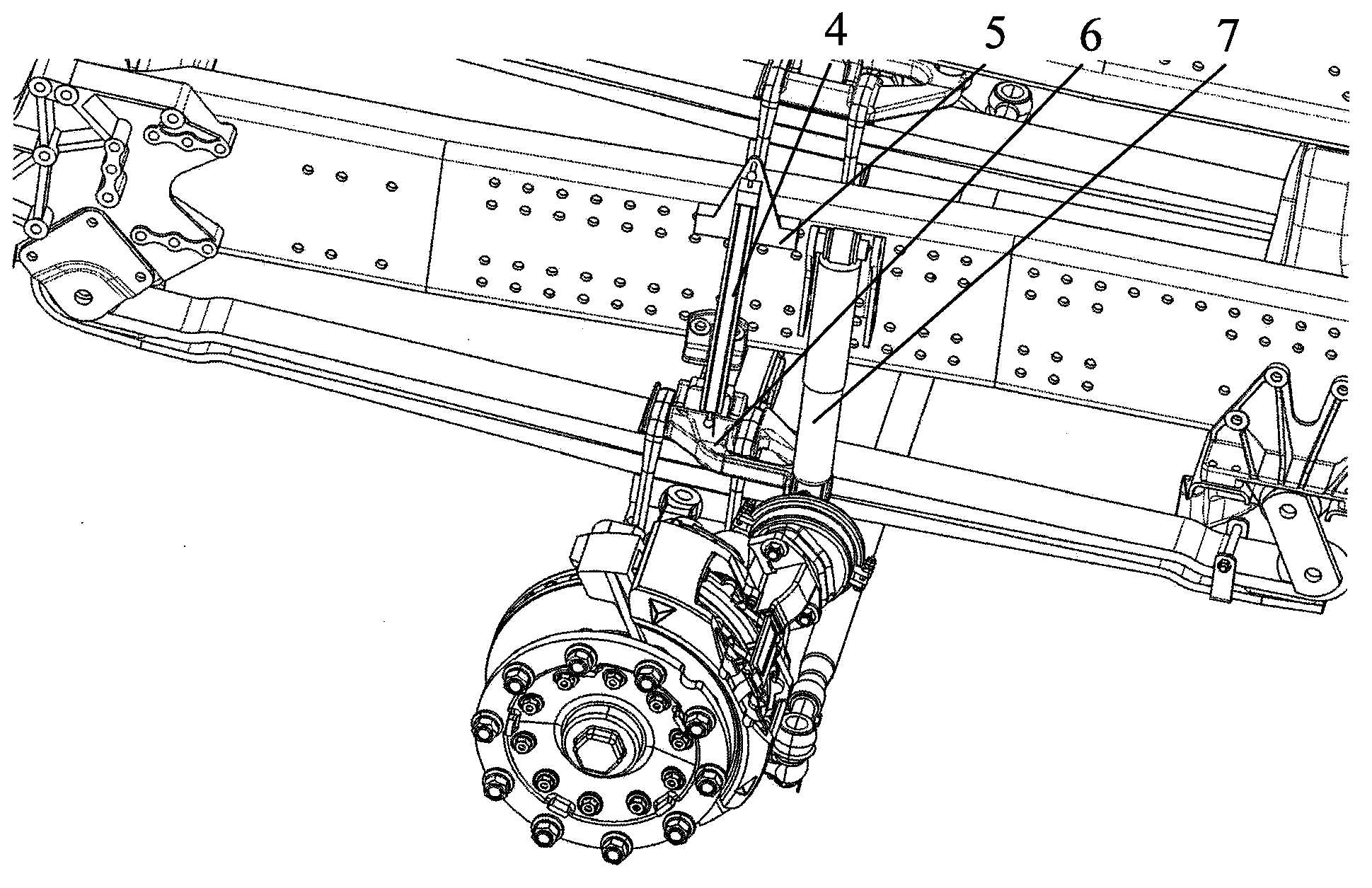

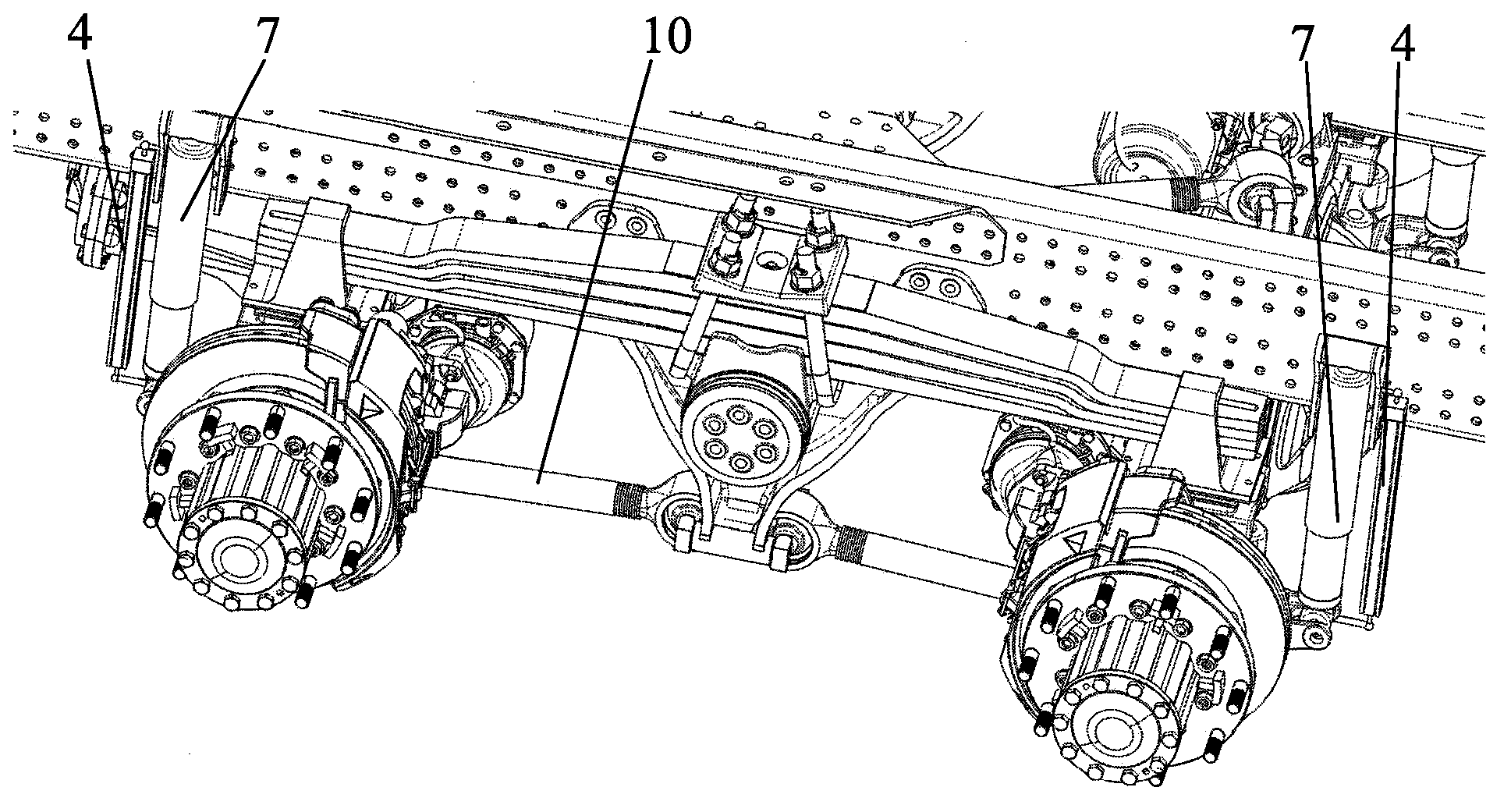

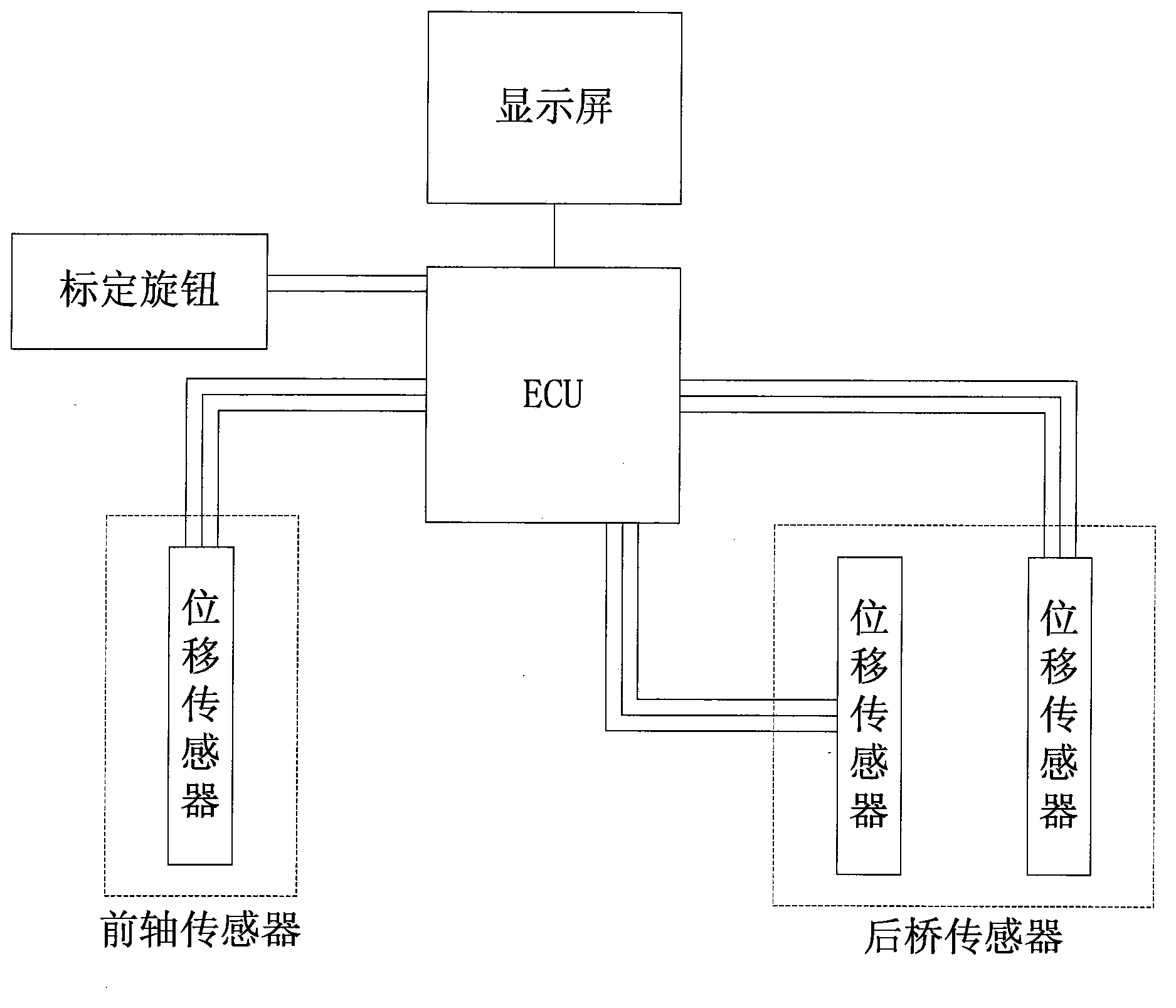

Plate spring suspension vehicle self-weighing system

Disclosed is a plate spring suspension vehicle self-weighing system. The plate spring suspension vehicle self-weighing system comprises displacement sensors (4), an electronic control unit and a display screen which are connected through wires. For a single-shaft plate spring suspension, the displacement sensors (4) are arranged on a plate spring pressing plate (6) in the middle of a vehicle axle; for a balanced suspension, the displacement sensors (4) are distributed at both ends of a single-side plate spring; the electronic control unit process signals transmitted by the displacement sensors (4) to calculate the total weight of the whole vehicle. The plate spring suspension vehicle self-weighing system can display the total weight of the whole vehicle in real time according to the loading status of the vehicle, and the weight measured in real time is displayed on the display screen to facilitate observation of a driver at any time.

Owner:SHAANXI HEAVY DUTY AUTOMOBILE

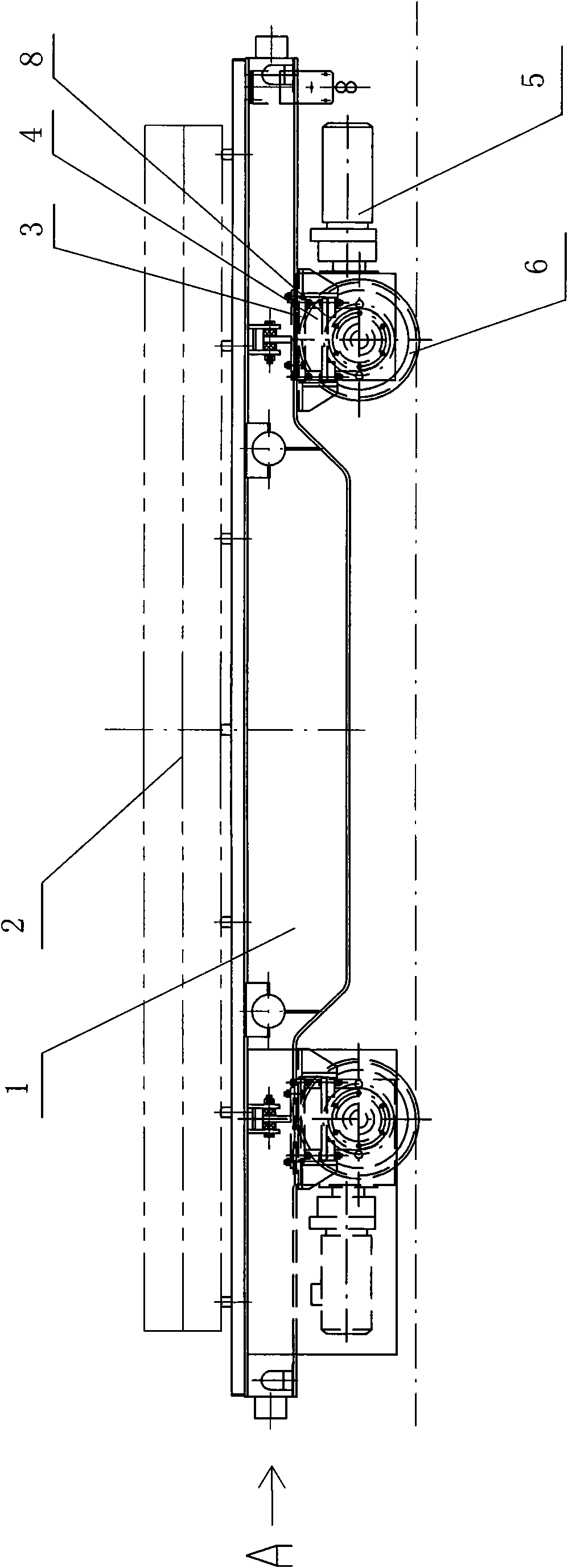

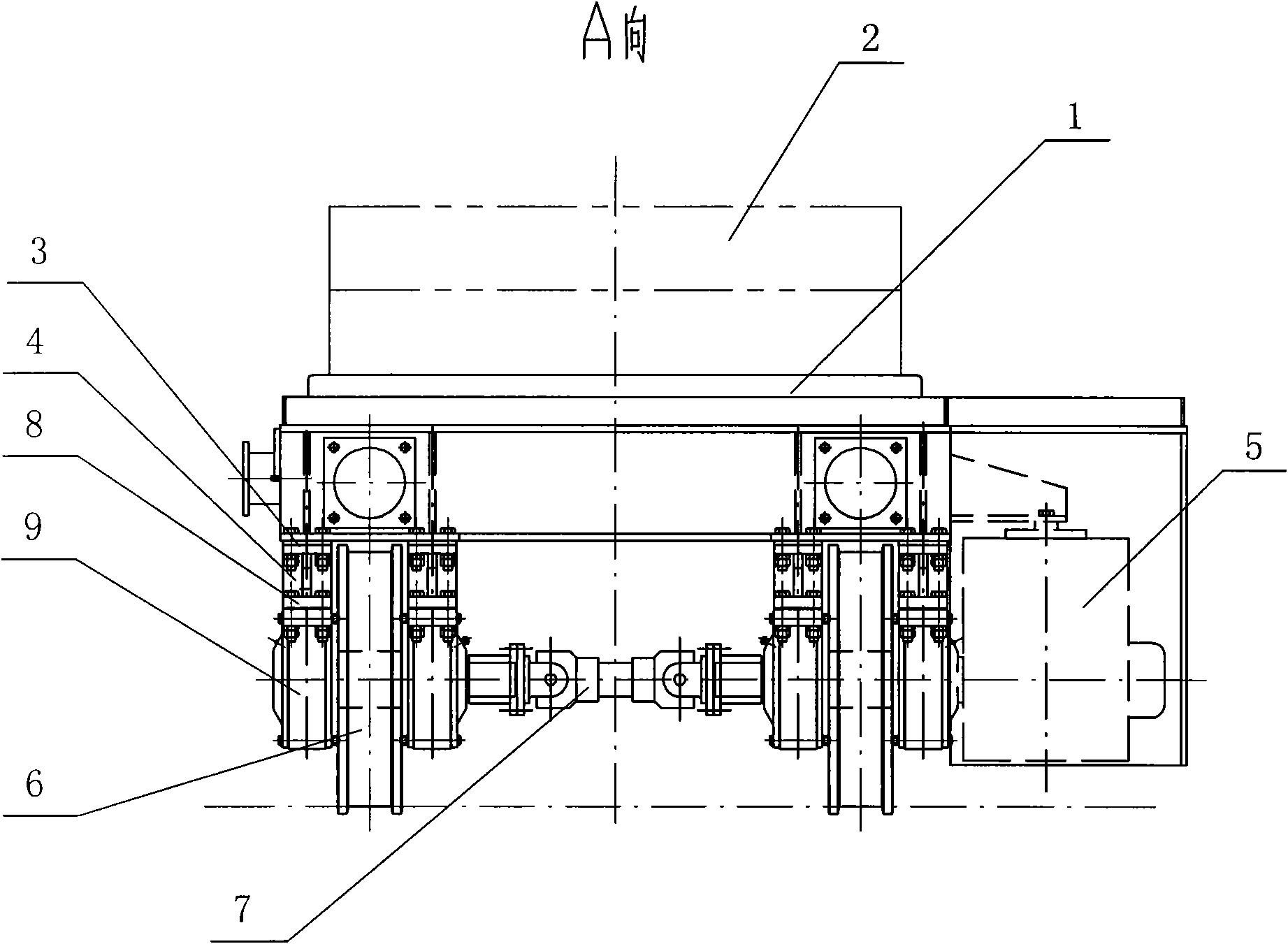

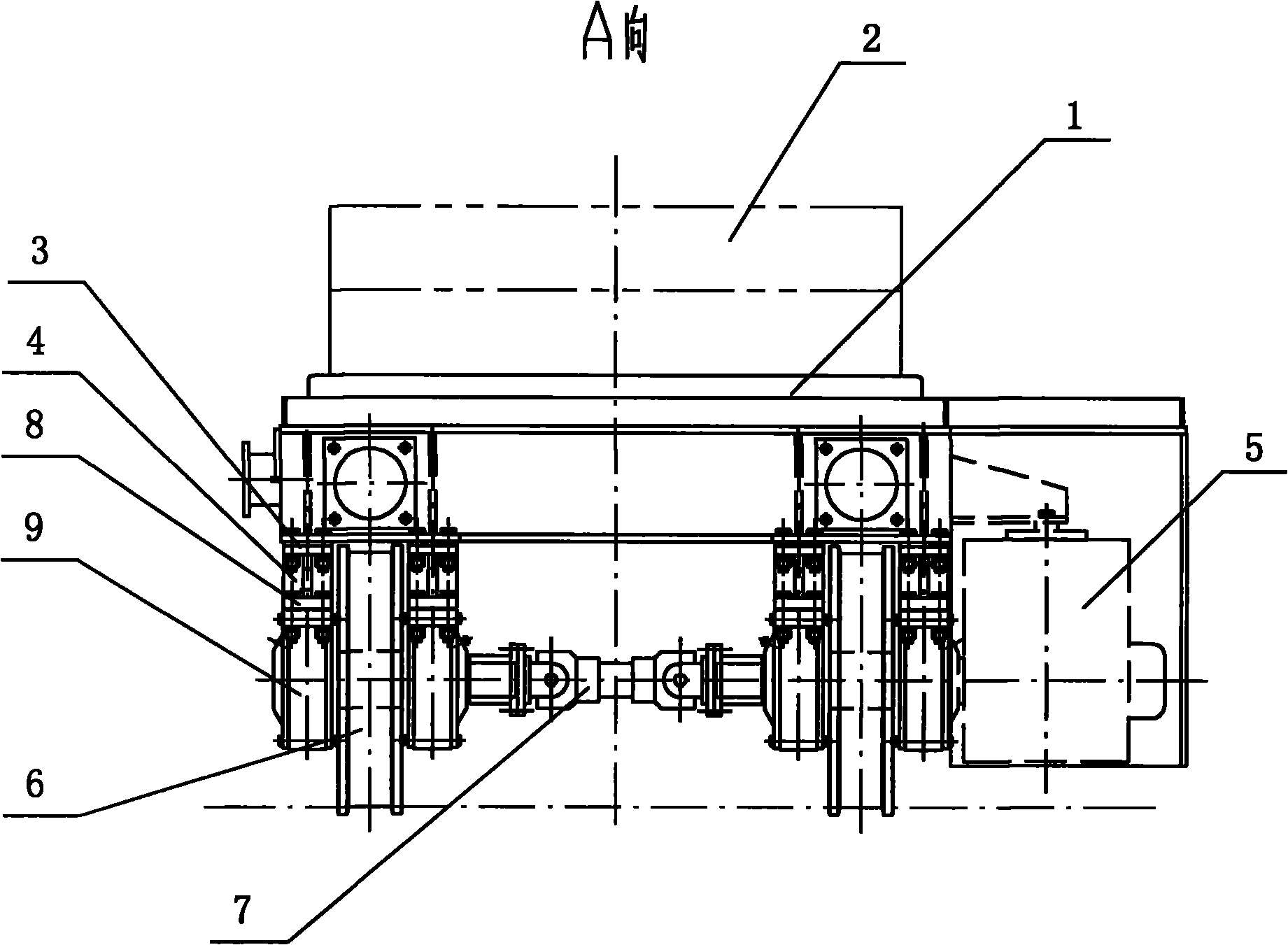

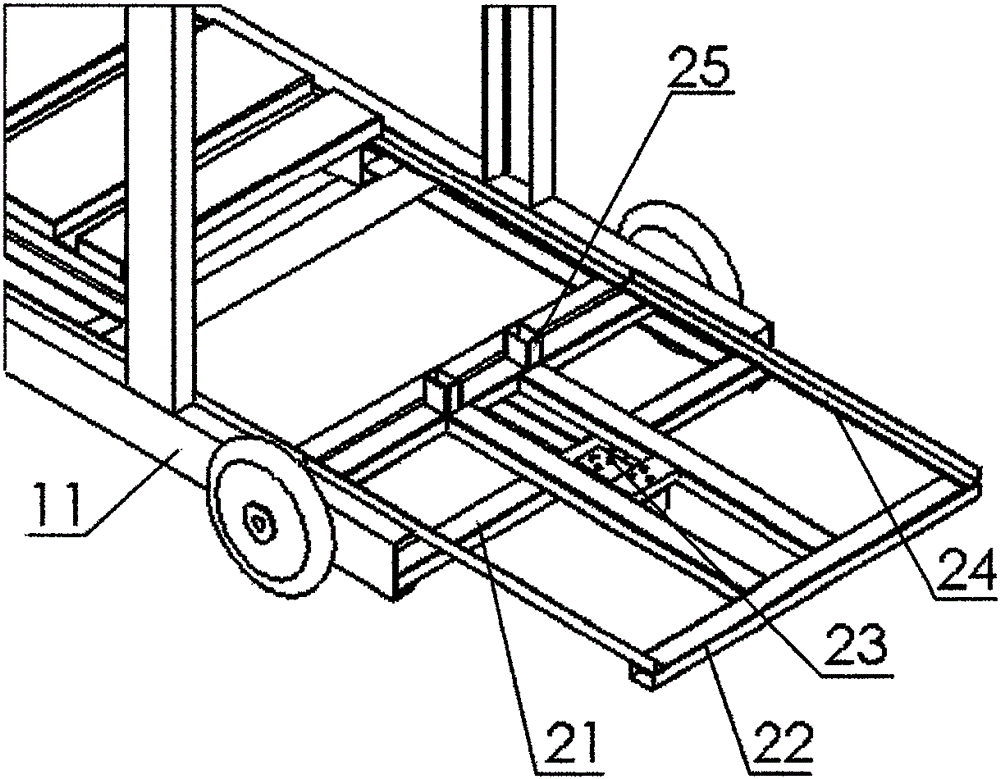

Self-weighing type slab straddle carrier

InactiveCN101992787AEasy to track and controlImprove efficiencyElectric motor propulsion transmissionUnderframesVehicle frameCoupling

The invention discloses a self-weighing type slab straddle carrier and relates to a transport means. The slab straddle carrier comprises a stand, wherein two transmission wheel sets are arranged below the stand, and each transmission wheel set comprises two wheels which are respectively arranged at the left side and the right side below the stand; the two wheels of each transmission wheel set are connected through a universal coupling; two sets of motor reducing gears are respectively arranged at the same side of the stand, and each set of motor reducing gears are connected with a spindle of a wheel of one transmission wheel set; the spindle of each wheel is sleeved with a bearing which is fixed in a bearing seat; the bottoms of the stand above each wheel are respectively connected with an upper connecting plate, and a weighing sensor is connected below each upper connecting plate; the lower ends of the weighing sensors are respectively connected with lower connecting plates; and the lower connecting plates are connected with the bearing seats. In the invention, a weighing device is arranged between the stand and each wheel to form a whole, thus the weighing device not only can achieve a weighing effect, but also can run along with the integral carrier and have the effect of crossing and transporting slabs.

Owner:沈剑

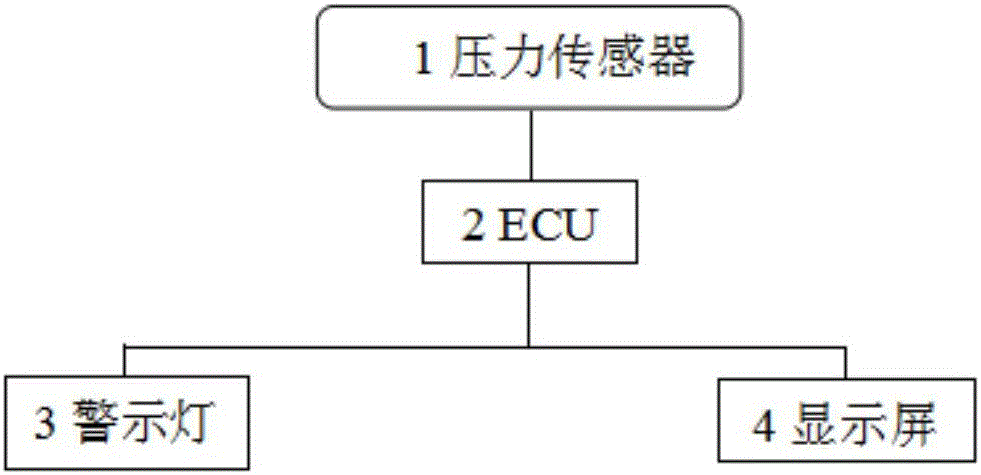

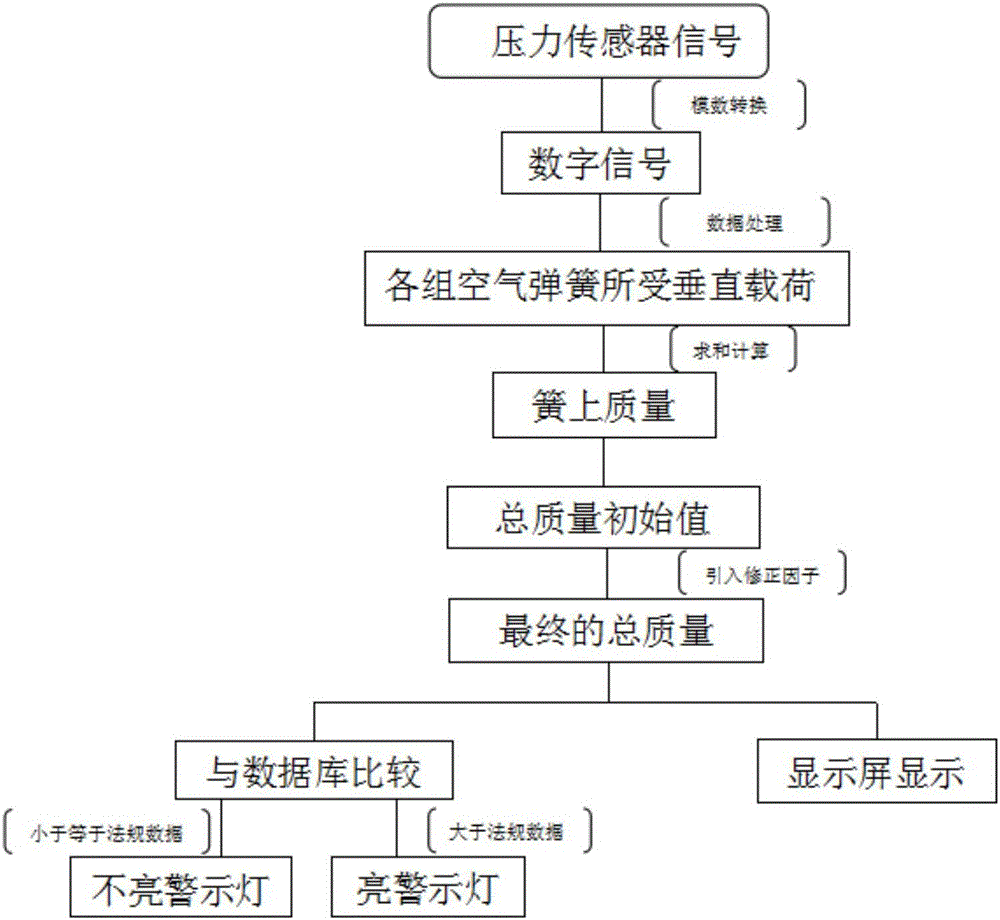

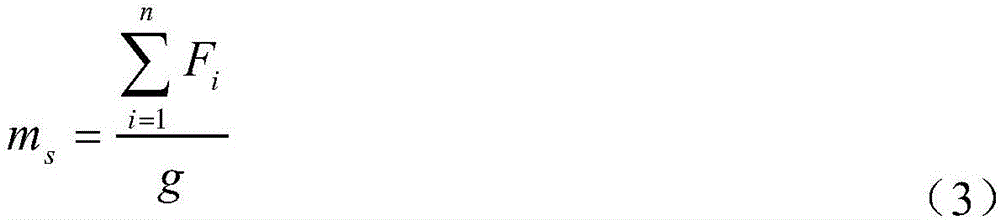

Self-weighing device of air suspension truck and method thereof

The invention discloses a self-weighing device of an air suspension truck and a method thereof. The method comprises the following steps: collecting inner air pressure of air springs via a pressure sensor, converting the inner air pressure into analogue electrical signals, transmitting the analogue electrical signals to an analogue-to-digital converter connected with the pressure sensor, then carrying out data processing on digital signals subjected to analogue-to-digital conversion via an electronic control unit ECU, calculating corresponding vertical load applied to each group of air springs, carrying out summation calculation on the data so as to obtain sprung mass, and primarily calculating to obtain the total mass of the truck because unsprung mass is a constant value. In view of the system errors, compared with a fixed on-ground weigher, correction factors are introduced into the algorithm, so that the more accurate total mass can be obtained; a driver can more conveniently obtain the total weight of the truck in real time; the occurrence of overweight phenomenon is effectively controlled.

Owner:CHANGAN UNIV

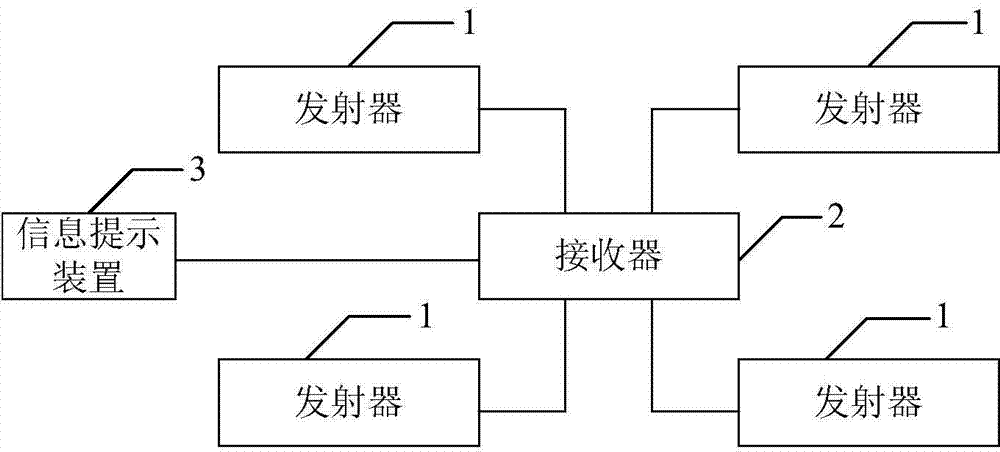

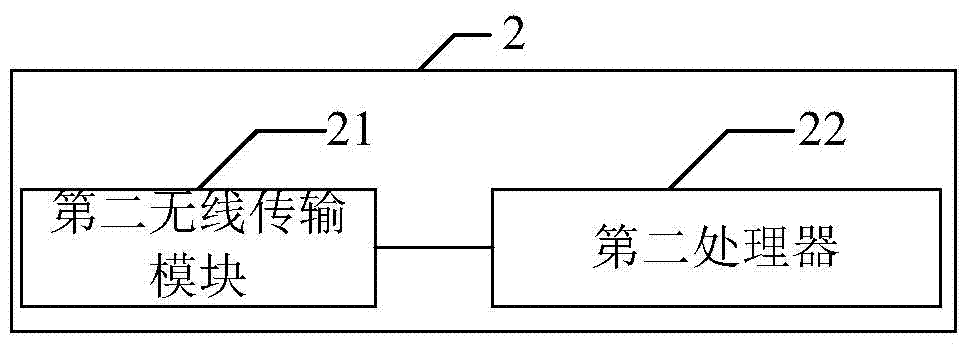

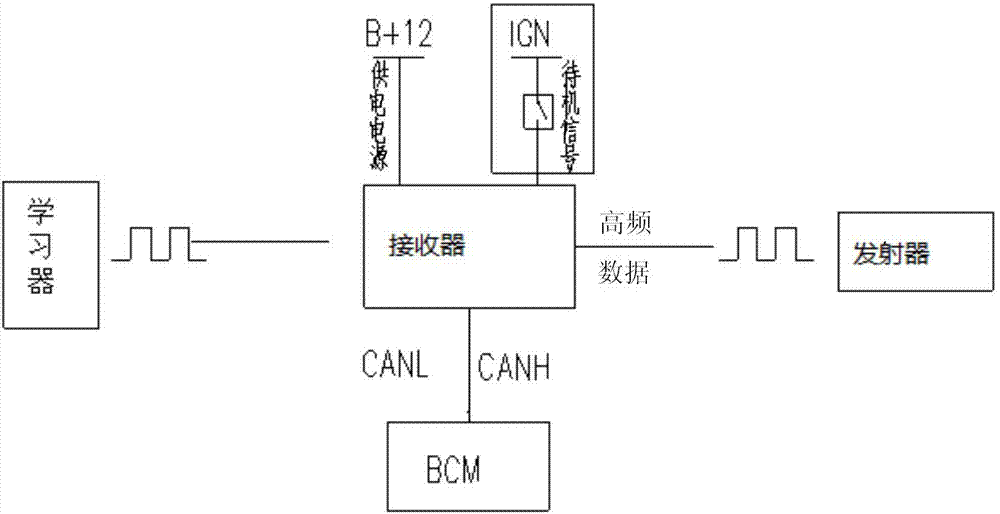

Vehicle self-weighing system and corresponding vehicle

InactiveCN104842856ATo achieve the purpose of self-weighingImprove securityTransmission systemsSpecial purpose weighing apparatusWireless transmissionSelf weighing

The invention discloses a vehicle self-weighing system and a corresponding vehicle. The vehicle self-weighing system comprises an emitter integrated with a displacement sensor and used for acquiring displacement data of a vehicle suspension through the displacement sensor and converting the displacement data to a digital signal to send to a receiver in a wireless transmission manner, the receiver used for receiving the digital signal transmitted by the emitter and calculating a vehicle load value according to the digital signal and to send to an information prompt device, and the information prompt device used for displaying the vehicle load value. The vehicle comprises the vehicle self-weighing system. The vehicle self-weighing system can precisely return the position change of different plate springs under different load conditions, is suitable for a chassis position, and can enhance the vehicle use safety to prevent the violation of application regulations to suffer the economic loss after the vehicle cargo capacity is definite.

Owner:BEIQI FOTON MOTOR CO LTD

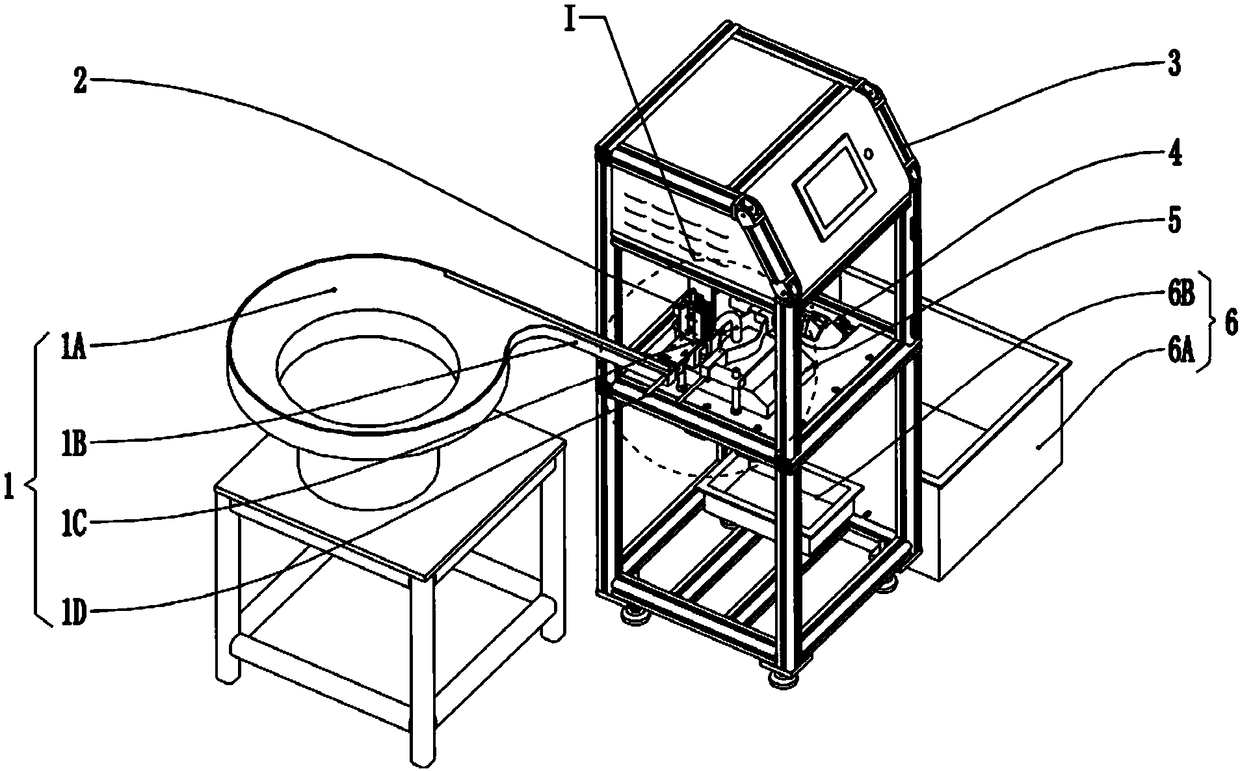

Self-weighing, picking and selling system and method for orchard

PendingCN109285290AReduce labor costsEasy to findApparatus for meter-controlled dispensingIndividual entry/exit registersEngineeringSelf weighing

The invention discloses a self-weighing, picking and selling system for an orchard, comprising a selling platform, a user client, an administrator terminal, a deliveryman terminal, orchard picking boxes and an orchard picking cabinet. The invention has the following advantages: a user can rent an empty orchard picking box by scanning a two-dimensional bar code of any storage compartment on the orchard picking cabinet through the client; a deliveryman can open a storage compartment of an orchard picking box selected on a deliveryman client by scanning the two-dimensional bar code of any storagecompartment on the orchard picking cabinet through the deliveryman client, so that the user and the deliveryman can get the orchard picking box easily; the picking cabinet will automatically detect the weight of the picking box and offer a fair price quickly and openly after the user picks fruits and puts the picking box into the picking cabinet.

Owner:盐城子渊机电科技有限公司

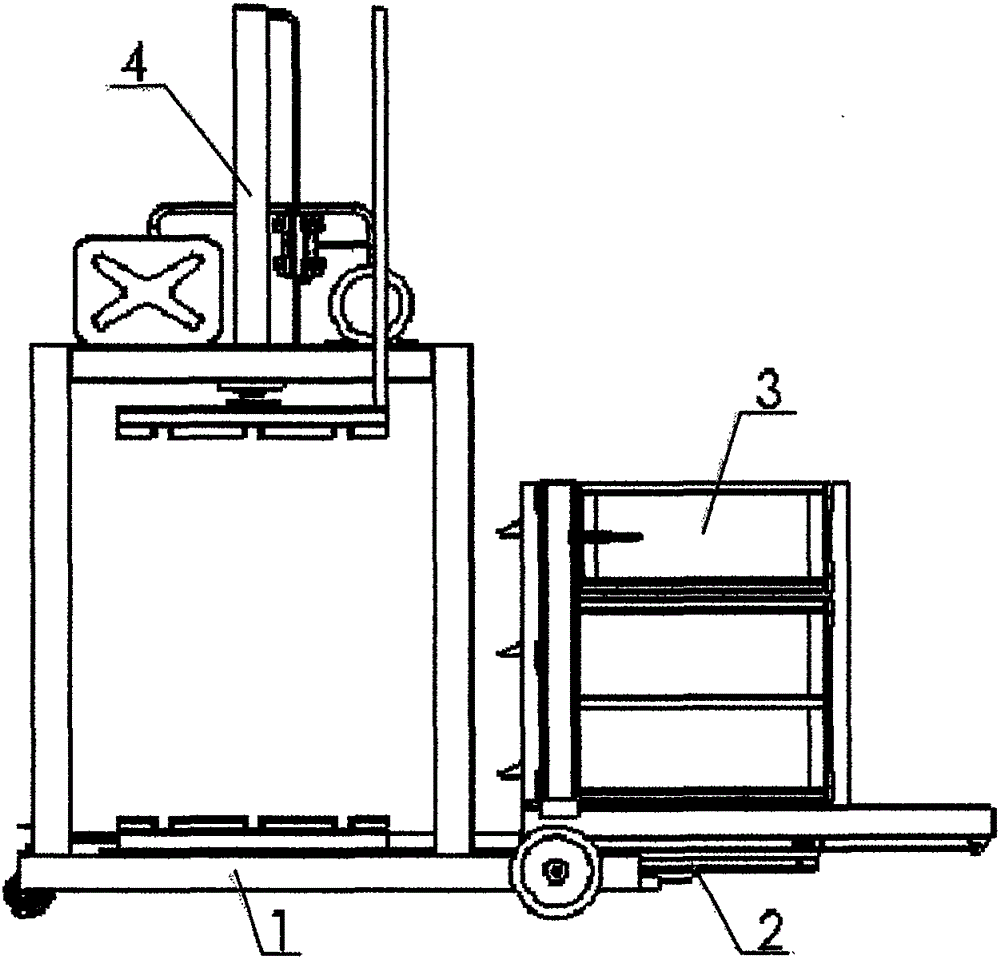

Self-weighing hydraulic baler with rotary bales

ActiveCN105584662ASolve low work efficiencyReduce labor intensityWrappingPackaging automatic controlHydraulic pumpFuel tank

A self-weighing hydraulic baler with rotary bales is characterized in that moving wheels are installed under a moving bottom frame, a locating device is installed on the moving bottom frame, and an upper frame is connected to the moving bottom frame through a frame stand column and a rotary stand column; a weighing mechanism is installed on the moving bottom frame and is located on the outer side of the rotary stand column; the two rotary bales are symmetrically distributed on the two sides of the rotary stand column; a bale rotating mechanism is installed on the rotary stand column in a sleeving mode and can rotate around the rotary stand column or vertically slide along the rotary stand column; a bale lifting mechanism is installed on the upper frame; a piston rod of a hydraulic oil cylinder in a hydraulic system is installed in the middle of the upper frame downwards, an upper pressing head is installed at the lower end of the piston rod, and a hydraulic pump station and a hydraulic oil tank are installed at the appropriate positions of the baler according to needs.

Owner:佛山市名赫机械有限公司

Material screening device

The invention provides a material screening device, and relates to the technical field of detecting. The screening device is provided with a control mechanism, a weighing mechanism which is used for detecting the weight of a material, a first discharging channel, a second discharging channel and a sorting mechanism; the control mechanism is used for controlling the sorting mechanism to sort materials according to detecting information of the weighing mechanism; the sorting mechanism comprises a switching component and a first driving component; the control mechanism is used for controlling theswitching component to communicate with the weighing mechanism and the first discharging channel when the detecting information is in accord with preset weight information, and controlling the switching component to communicate with the weighing mechanism and the second discharging channel when the detecting information is not in accord with preset weight information; and the first driving component is used for driving a material self-weighing mechanism to discharge along the first discharging channel when the weighing mechanism communicates with the first discharging channel, and driving thematerial self-weighing mechanism to discharge along the second discharging channel when the weighing mechanism communicates with the second discharging channel.

Owner:XIAMEN MAIFENG SEAL PRODS

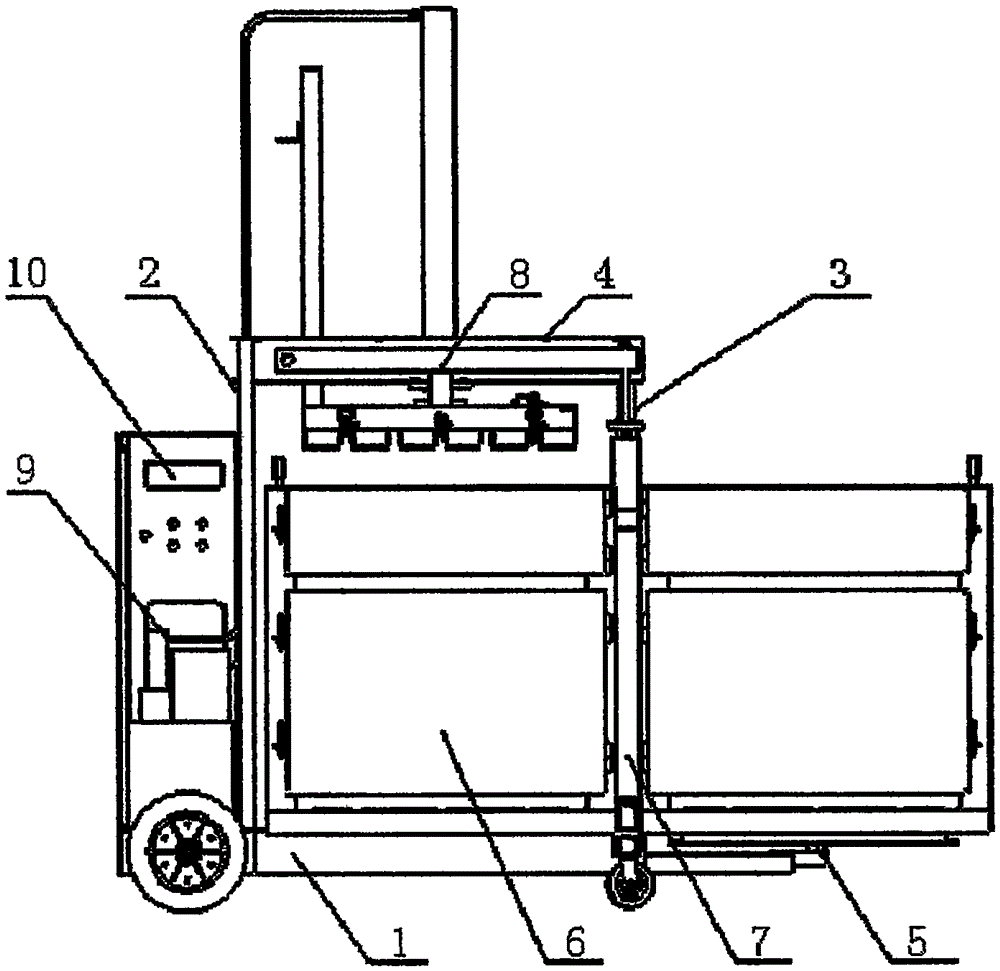

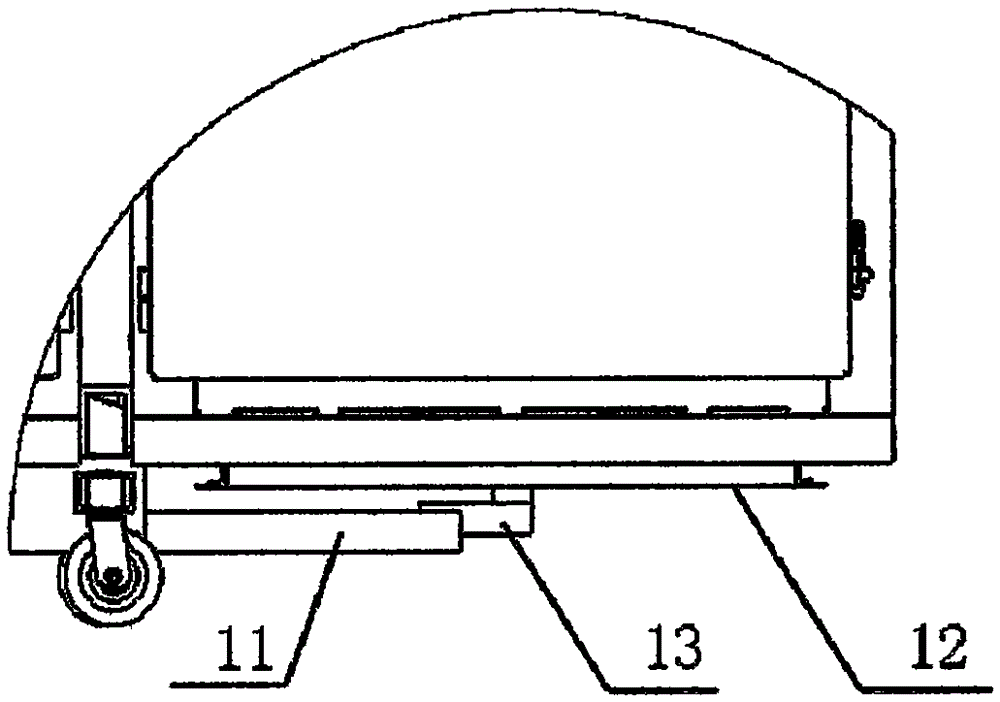

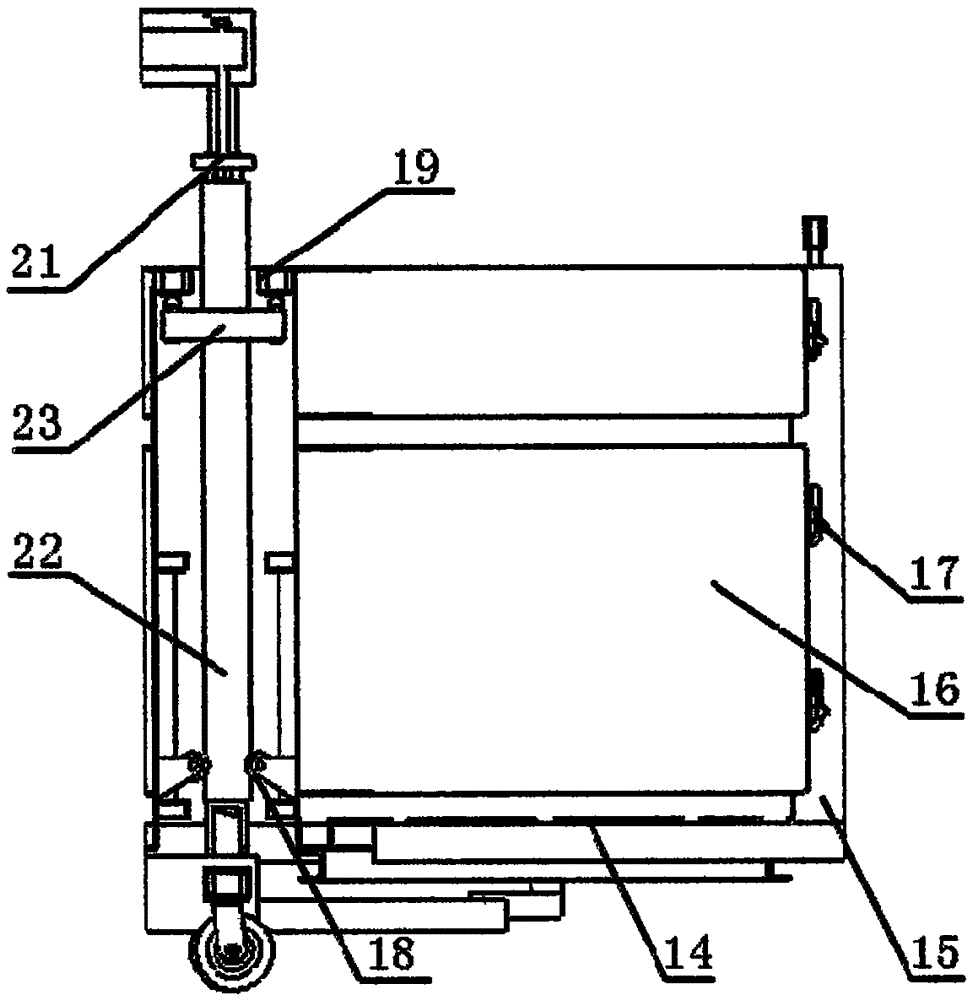

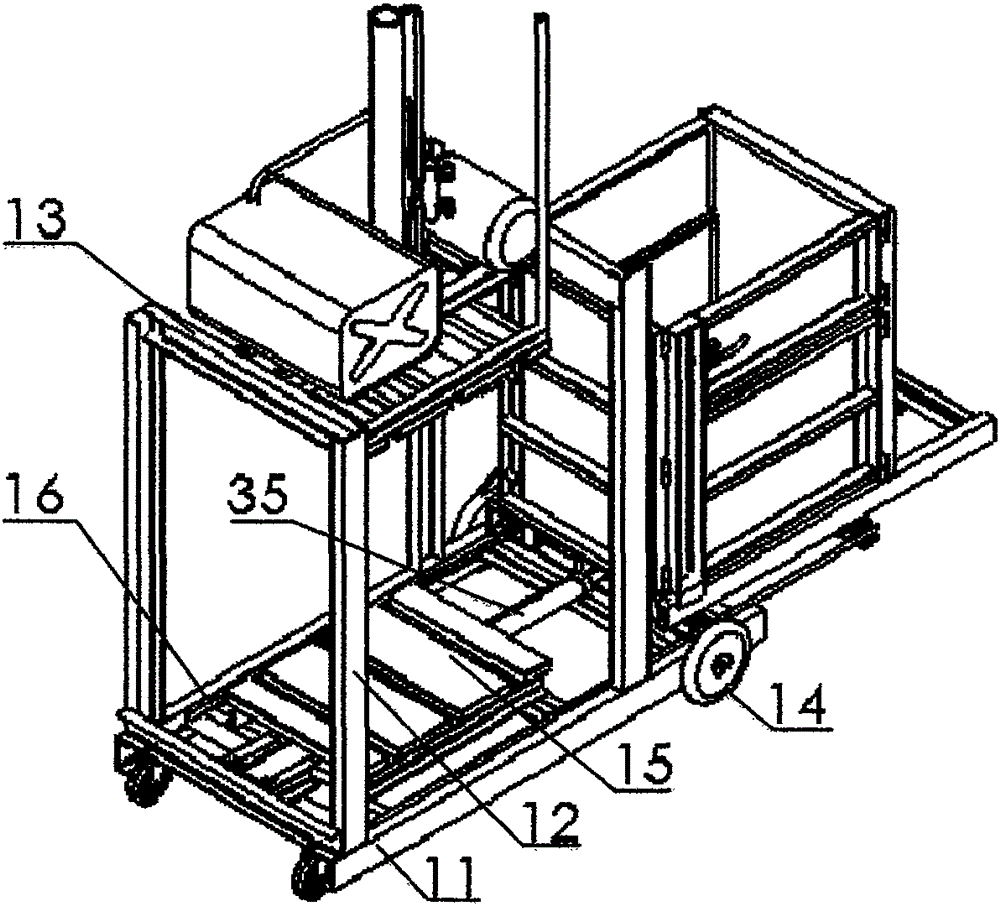

Moving container type self-weighing hydraulic packing machine

InactiveCN105192870ASolve labor intensitySolve efficiency problemsTobacco preparationPressesHydraulic cylinderFuel tank

The invention discloses a moving container type self-weighing hydraulic packing machine which mainly comprises a moving framework, a weighing mechanism, a moving container and a hydraulic system, wherein moving wheels are mounted on the lower surface of a bottom framework in the moving framework; a lower pressing head is arranged on the upper surface of the bottom framework; rails are arranged on the front side and the rear side of the lower pressing head; the weighing mechanism is mounted on one side of the bottom framework; rollers are arranged on the two sides of a bottom frame of the moving container; a telescopic oil cylinder is mounted below the moving container; one end of the telescopic oil cylinder is connected with the moving framework, and the other end of the telescopic oil cylinder is connected with the moving container; a piston rod of a hydraulic oil cylinder in the hydraulic system is downwards mounted at the middle part of an upper framework; an upper pressing head is mounted at the lower end of the piston rod; a guide rod is arranged on the upper surface of the upper pressing head; a hydraulic pump station and a hydraulic oil tank are mounted above the upper framework; the hydraulic oil cylinder, the hydraulic pump station and the hydraulic oil tank are connected with one another through a hydraulic pipeline, thus forming a working loop.

Owner:薛航

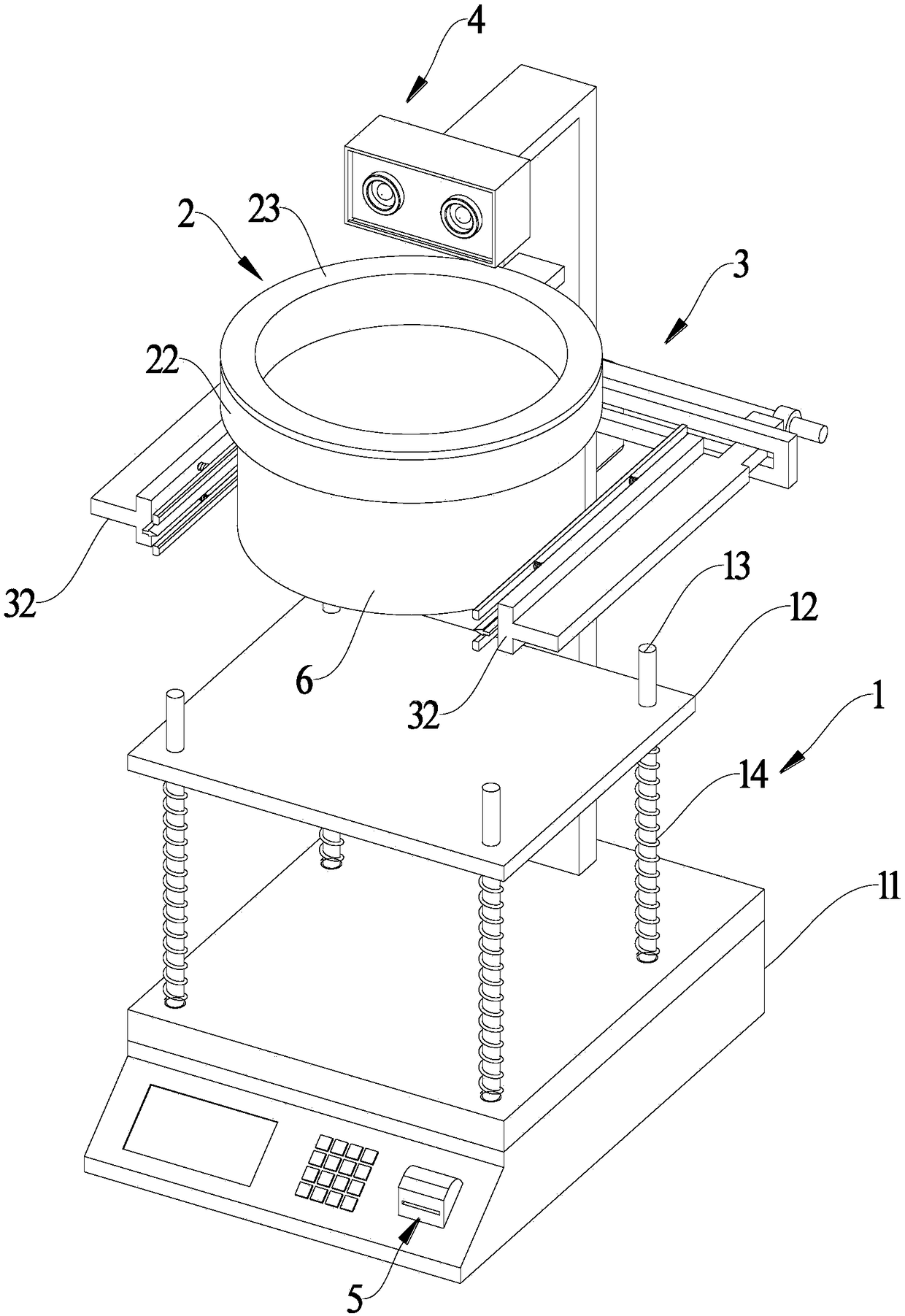

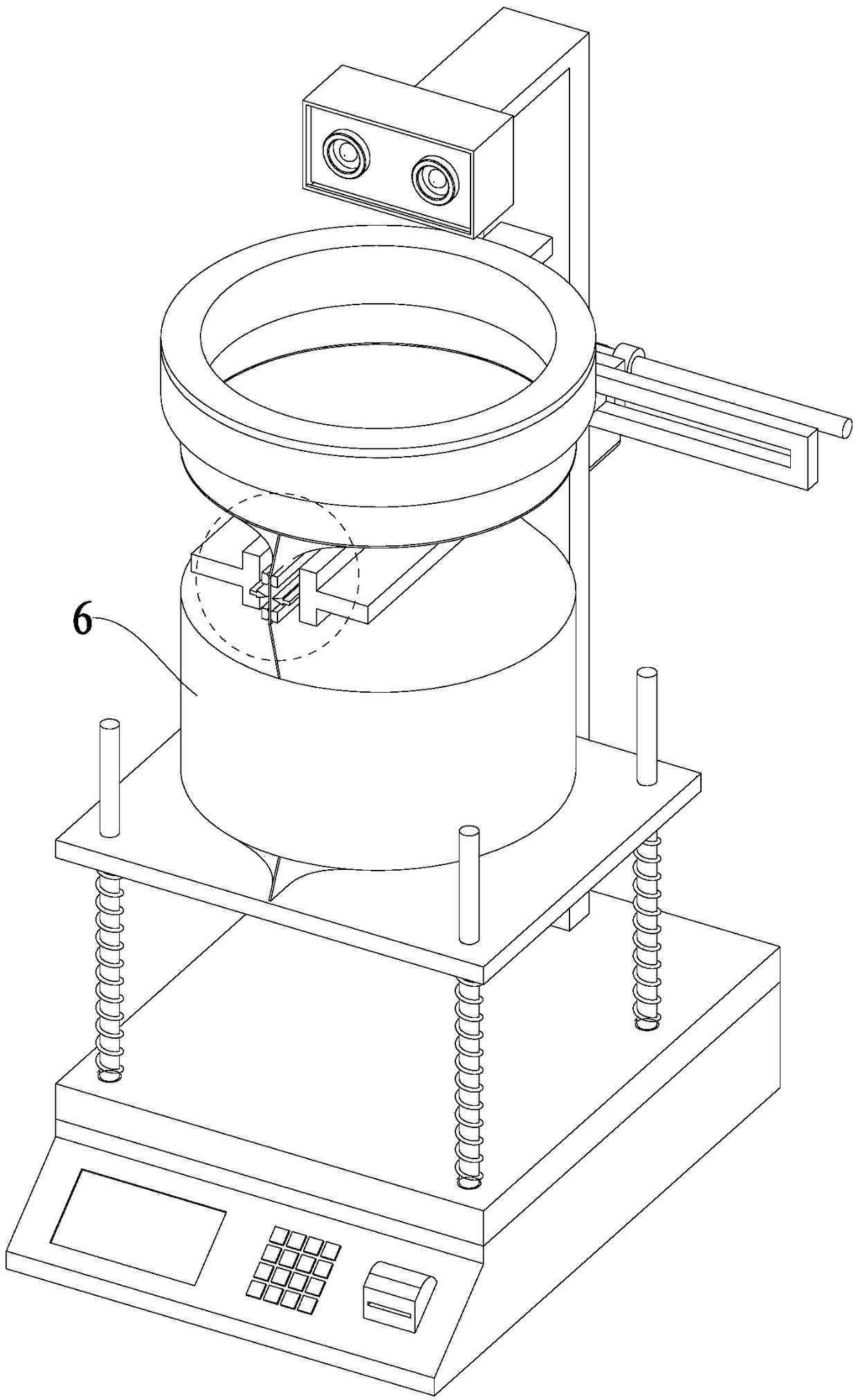

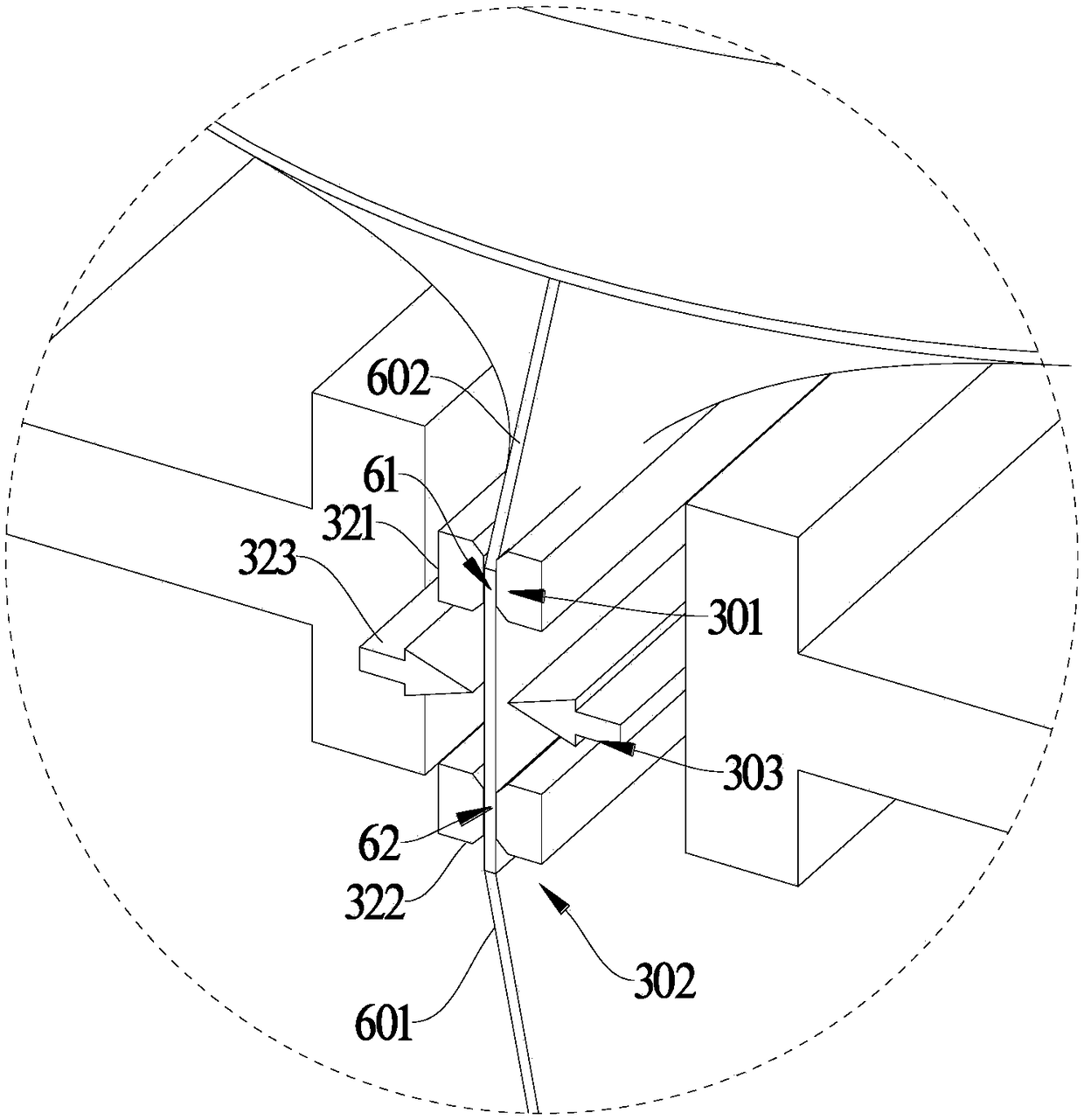

Self-weighing device

ActiveCN108639412AReduce wasteImprove weighing efficiencyTelevision system detailsColor television detailsEngineeringTotal price

The invention discloses a self-weighing device. The self-weighing device comprises a weighing unit, a packaging material mounting unit, a sealed mouth shearing unit, an intelligent identification unit, a control unit and a label unit, wherein the packaging material mounting unit is arranged above the weighing unit and is provided with a circular storage cavity; cylinder-shaped packaging materialsare suitable for being arranged in the storage cavity in a folding manner; a circular material outlet is also formed in the lower end of the packaging material mounting unit and communicates with thestorage cavity; the sealed mouth shearing unit is used for sealing and shearing the packaging materials which are pulled out of the storage cavity; the intelligent identification unit is arranged above the packaging material mounting unit and is suitable for identifying objects which are put in the packaging materials and judging the categories and the prices of the objects which are put in the packaging materials; the control unit is used for controlling the sealing and shearing operations of the sealed mouth shearing unit and calculating the total price of the weighed objects; and the labelunit is connected with the control unit in a communication manner and is used for printing the total price of the weighed objects and / or identification codes containing the prices of the objects on alabel.

Owner:徐州双驰消防器材有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com