Self-weighing hopper of loading and unloading device

A technology for loading and unloading equipment and hoppers, applied in the directions of loading/unloading, packaging, transportation and packaging, which can solve the problems of large impact on load-bearing conveying equipment, affecting production efficiency, high failure frequency and maintenance frequency, etc., and achieve effective vibration and blockage. , to ensure the effect of continuity and high efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] The present invention will be described in further detail below in conjunction with the accompanying drawings and embodiments.

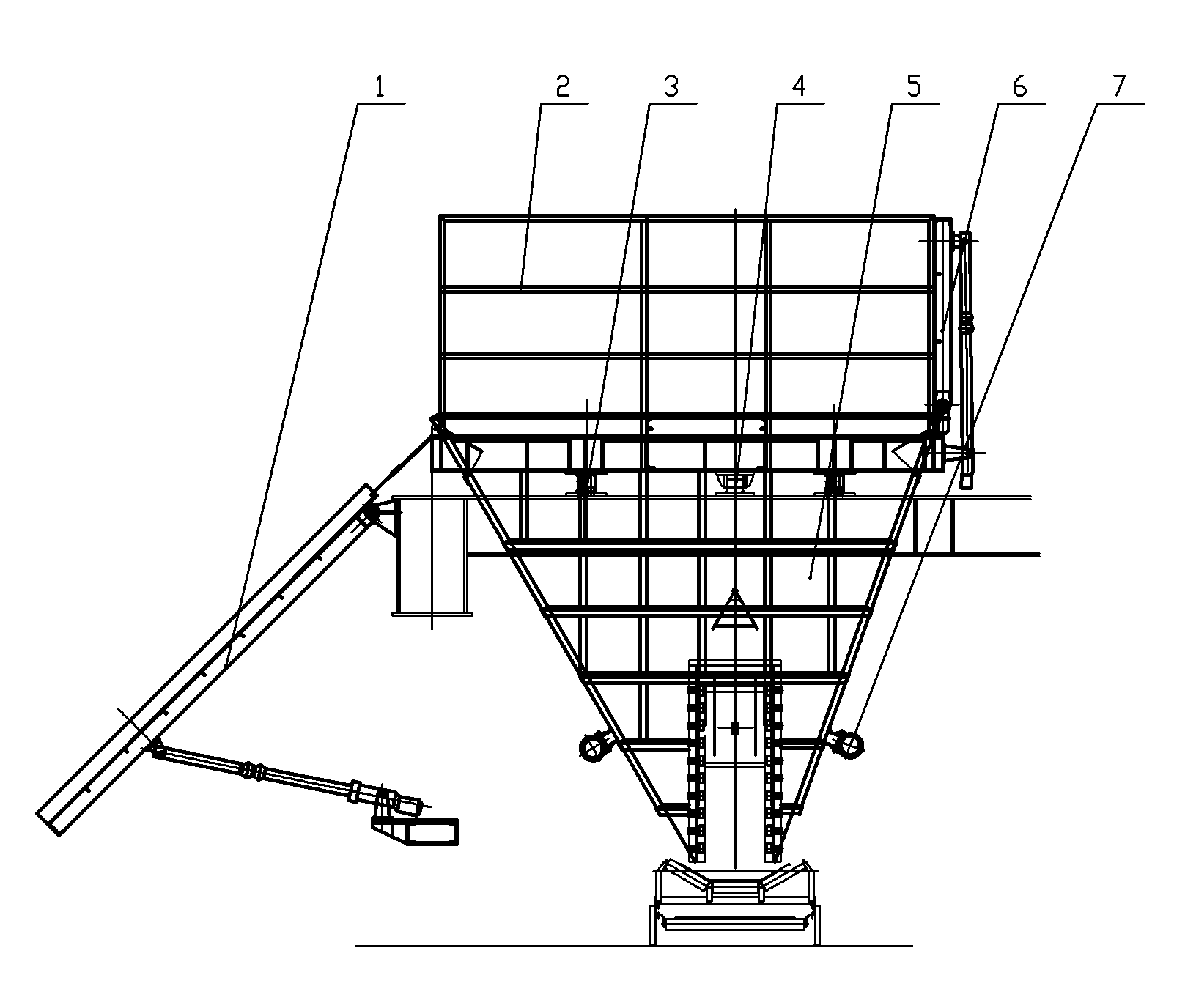

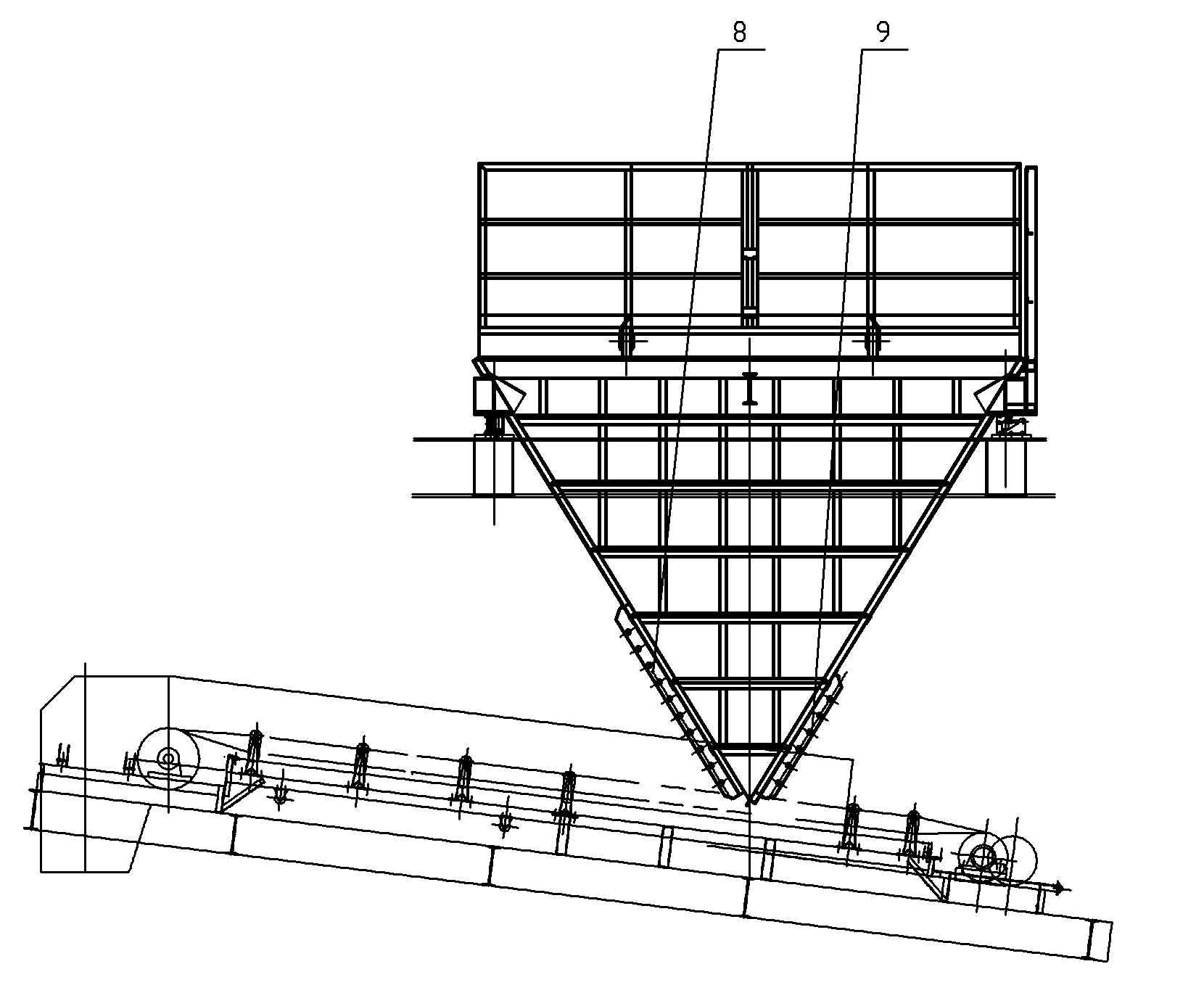

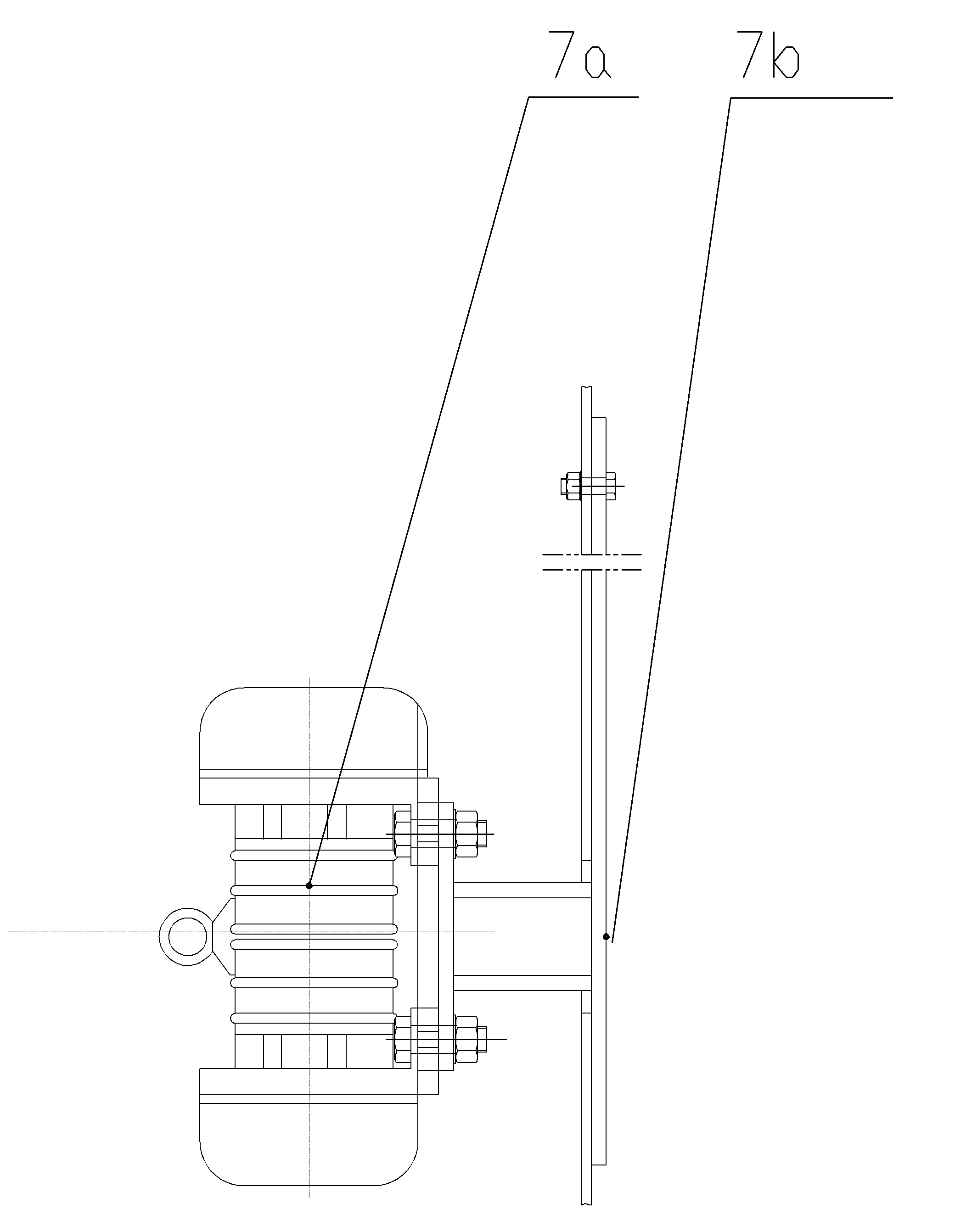

[0018] Figure 1 to Figure 6 As shown, it includes material receiving plate 1, side windshield 2, weighing load unit 3, anti-deflection device 4, hopper body 5, rear windshield 6, bin wall vibrator 7, main bucket door 8, auxiliary bucket door 9 .

[0019] like figure 1 As shown, the material receiving plate 1 is arranged at the upper mouth of the hopper body 5; the side windshields 2 are respectively fixed on both sides of the edge perpendicular to the shoreline at the upper mouth of the hopper body 5; the weighing load unit 3 and the anti-deflection device 4 are all arranged under the support beam of the hopper body 5; the rear windshield 6 is arranged on the upper opening of the hopper body 5; And auxiliary bucket door 9 are respectively arranged on both sides of the hopper discharge opening.

[0020] Wherein said weighing load unit 3 is...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com