Self-weighing type slab straddle carrier

A straddle vehicle and weighing technology, applied in the straddle vehicle field, can solve the problems of high operator requirements and low weighing accuracy, and achieve the effect of improving efficiency and facilitating tracking control.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

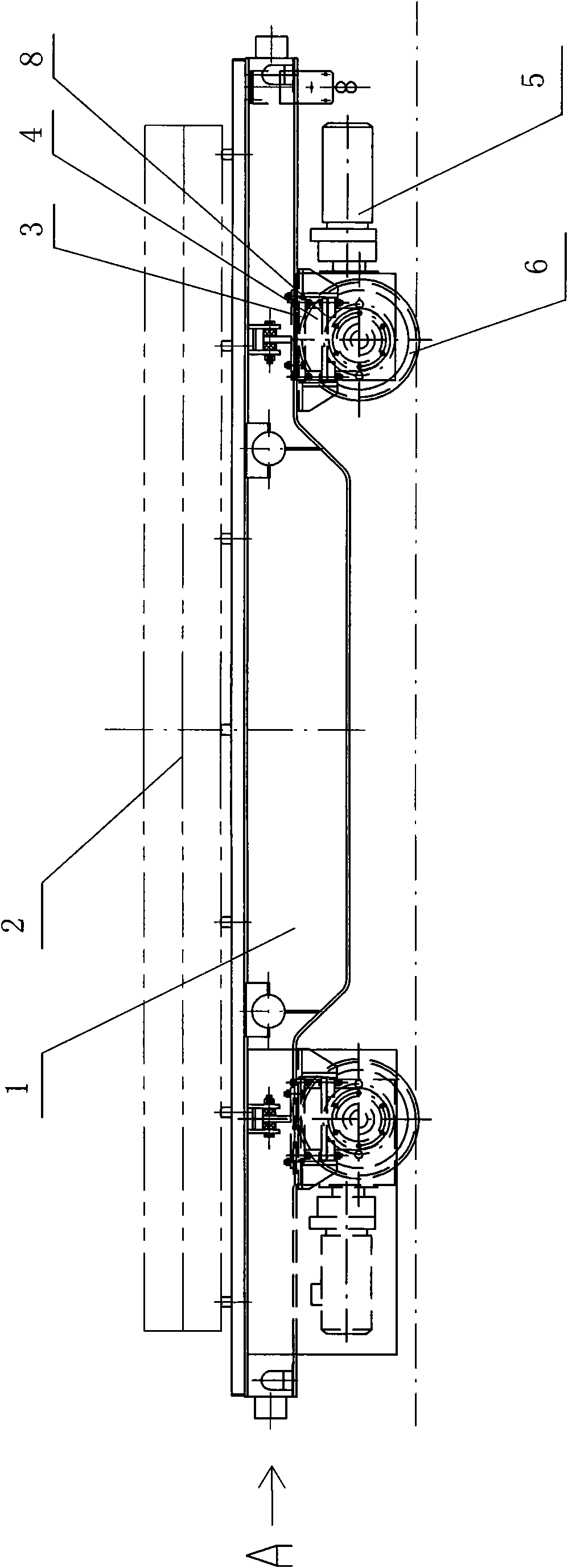

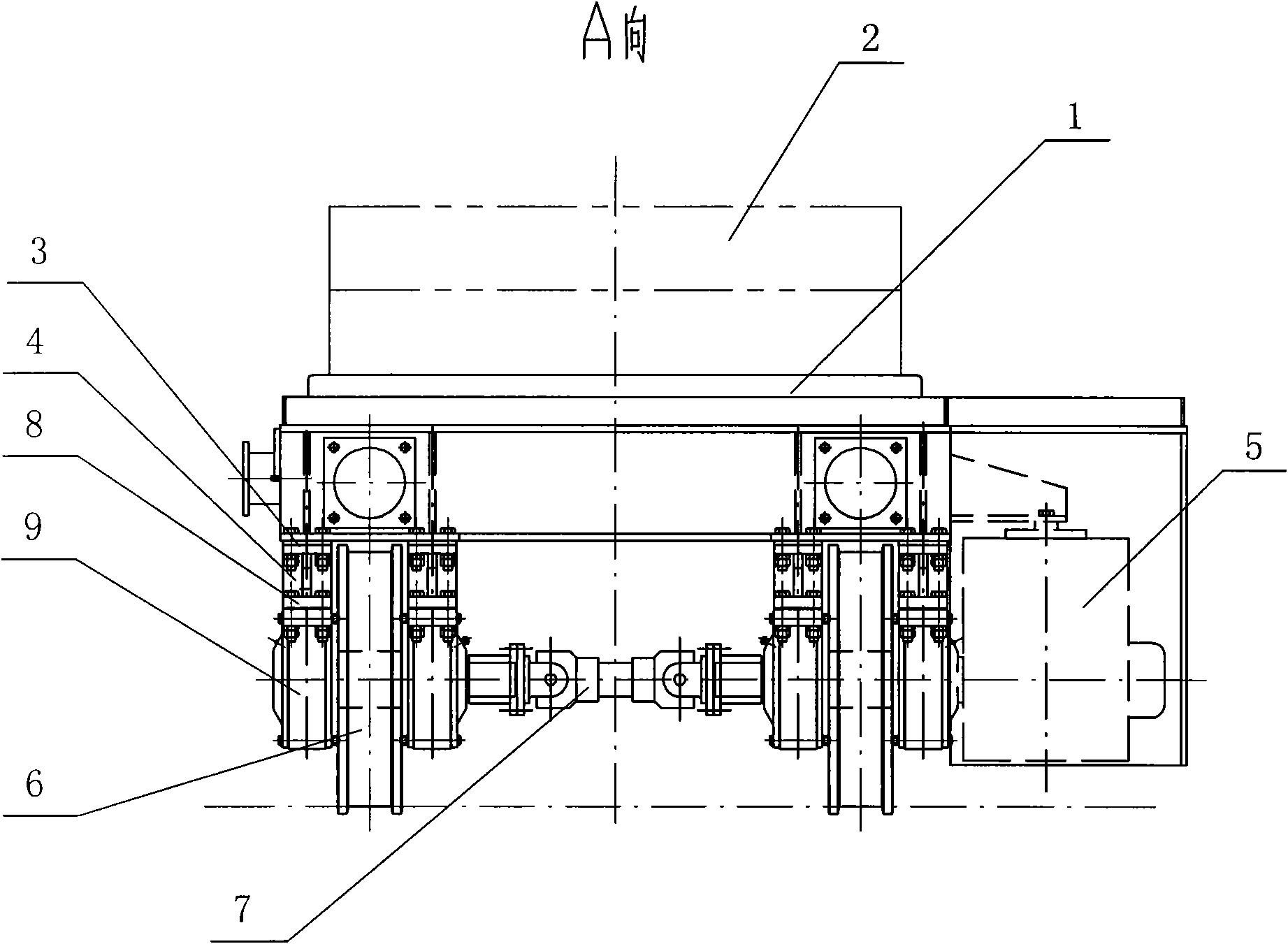

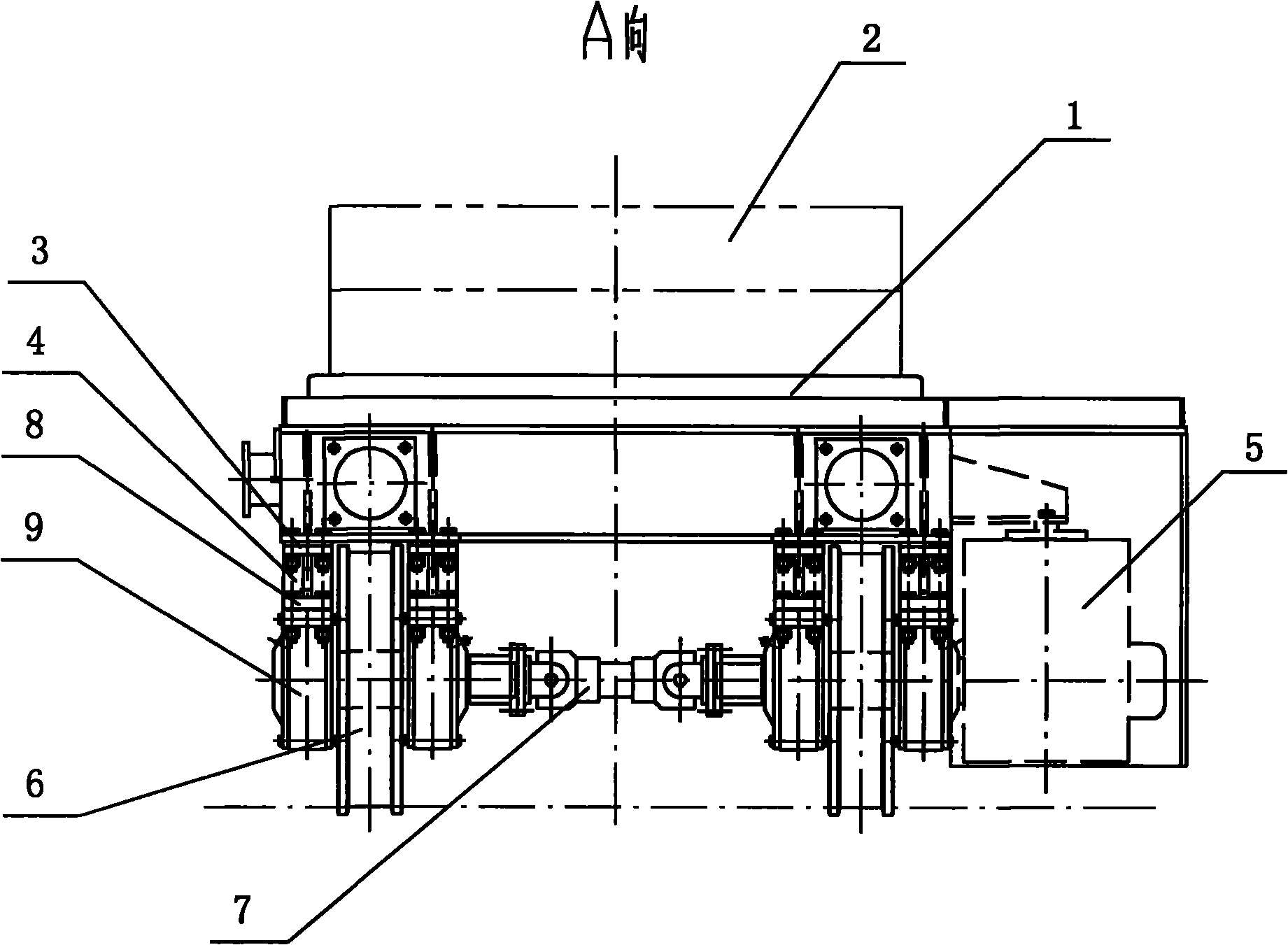

[0009] Such as figure 1 , 2 As shown, the self-contained weighing type slab over straddle vehicle includes a frame 1, a slab 2 is placed on the top of the frame 1, and two transmission wheel sets are arranged under the frame 1, and each drive wheel set includes two Wheels 6, two wheels 6 are respectively arranged on the left and right sides below the vehicle frame 1, and the two wheels 6 of each transmission wheel group are connected by a universal joint 7, and two wheels are respectively arranged on the same side of the vehicle frame 1. A group of motor reducers 5, each group of motor reducers 5 is connected to the main shaft of a wheel 6 in a group of transmission wheels, each motor reducer 5 is equipped with a brake, and the main shaft of each wheel 6 is equipped with a bearing, and the bearing is fixed to the bearing In the seat 9, the bottom of the vehicle frame 1 above each wheel 6 is respectively connected to the upper connecting plate 3, and the bottom of the upper co...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com