Self-weighing garbage compression box

A technology for compressing and compressing garbage, which is used in trash cans, garbage conveying, garbage collection, etc. It can solve the problem that garbage cannot be poured into the feeding port normally, and achieve the effect of preventing left and right shaking, improving service life and improving utilization rate.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] In order to fully understand the technical content of the present invention, the technical solutions of the present invention will be further introduced and illustrated below in conjunction with specific examples, but not limited thereto.

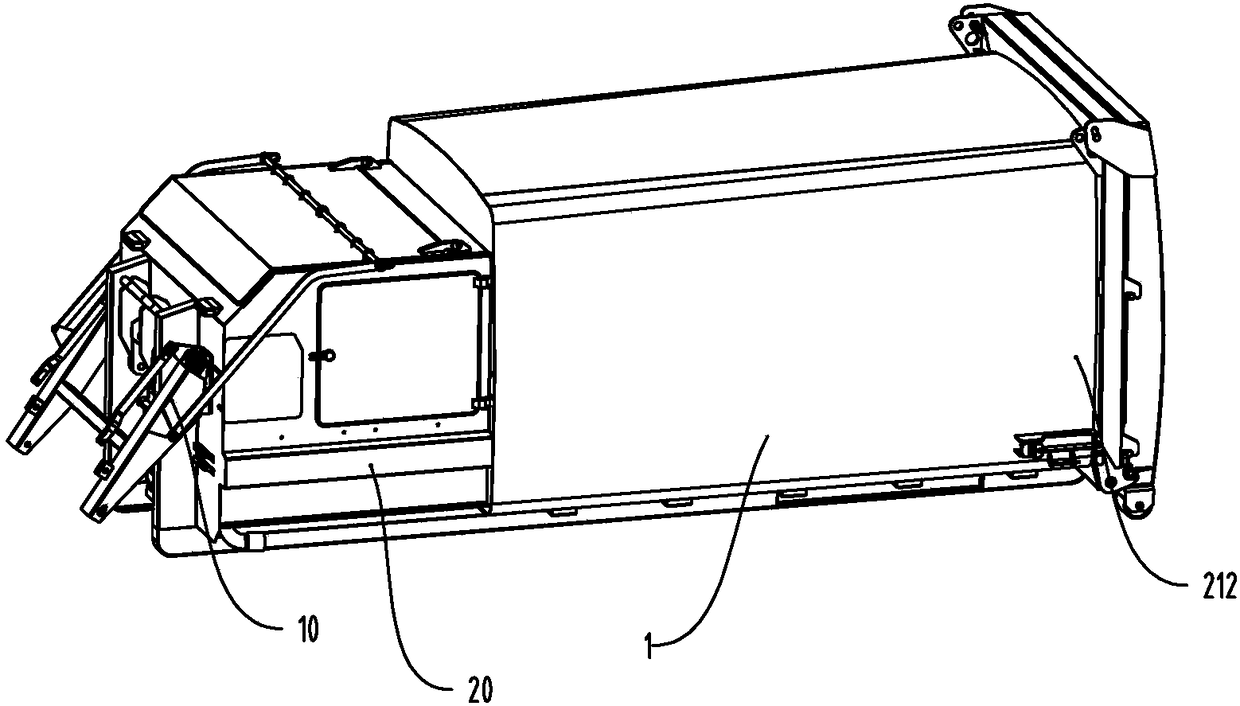

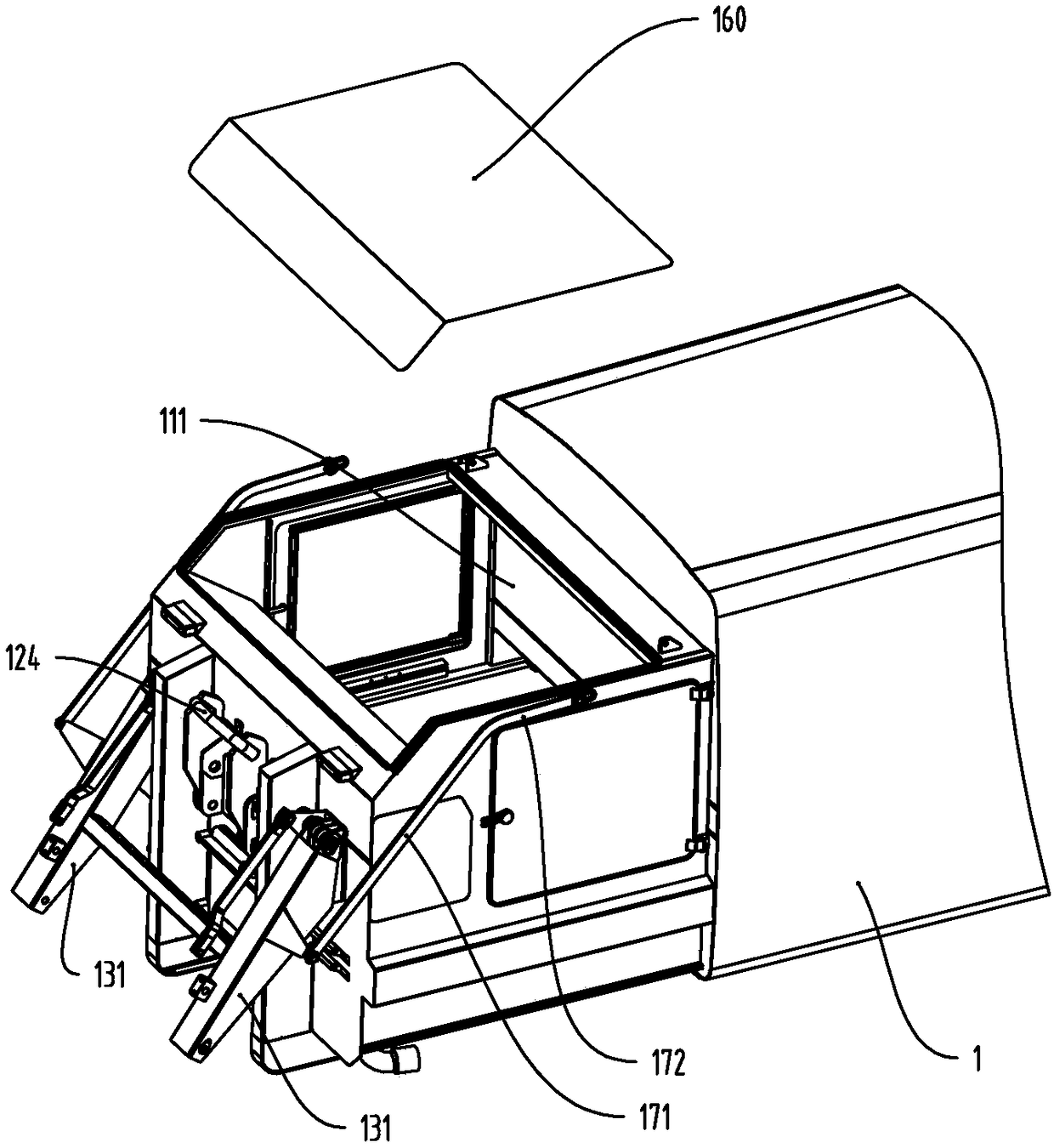

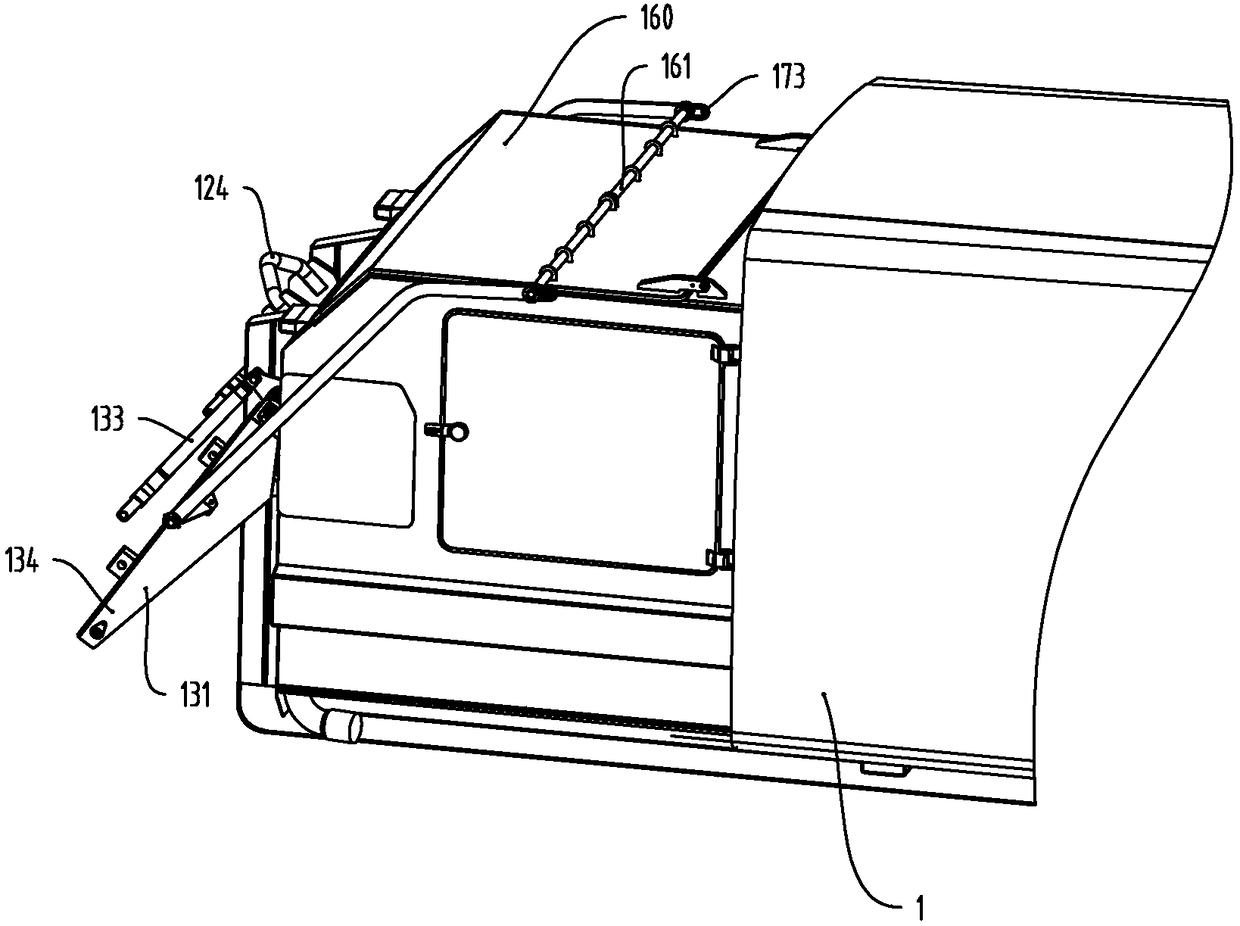

[0027] Such as Figure 1 to Figure 8 As shown, a self-weighing garbage compression box includes a compression box body 1. One end of the compression box body 1 is connected with a turning mechanism 10 for dumping garbage, and the other end is provided with a garbage outlet 212. The bottom of the cavity of the compression box body 1 is close to the turning mechanism. One side of the 10 is provided with a drainage device 20, and the turning mechanism 10 includes a garbage turning bucket 120, a lifting arm 130 and a locking member 140; the upper surface of the front end of the compression box body 1 is provided with a garbage feeding port 111, and the garbage turning bucket 120 is located The front end of the compression box body 1, one...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com