Patents

Literature

430results about How to "Solve low work efficiency" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

City-level intelligent traffic simulation system

ActiveCN110164128ASolve low work efficiencyDetection of traffic movementForecastingState predictionFeature extraction

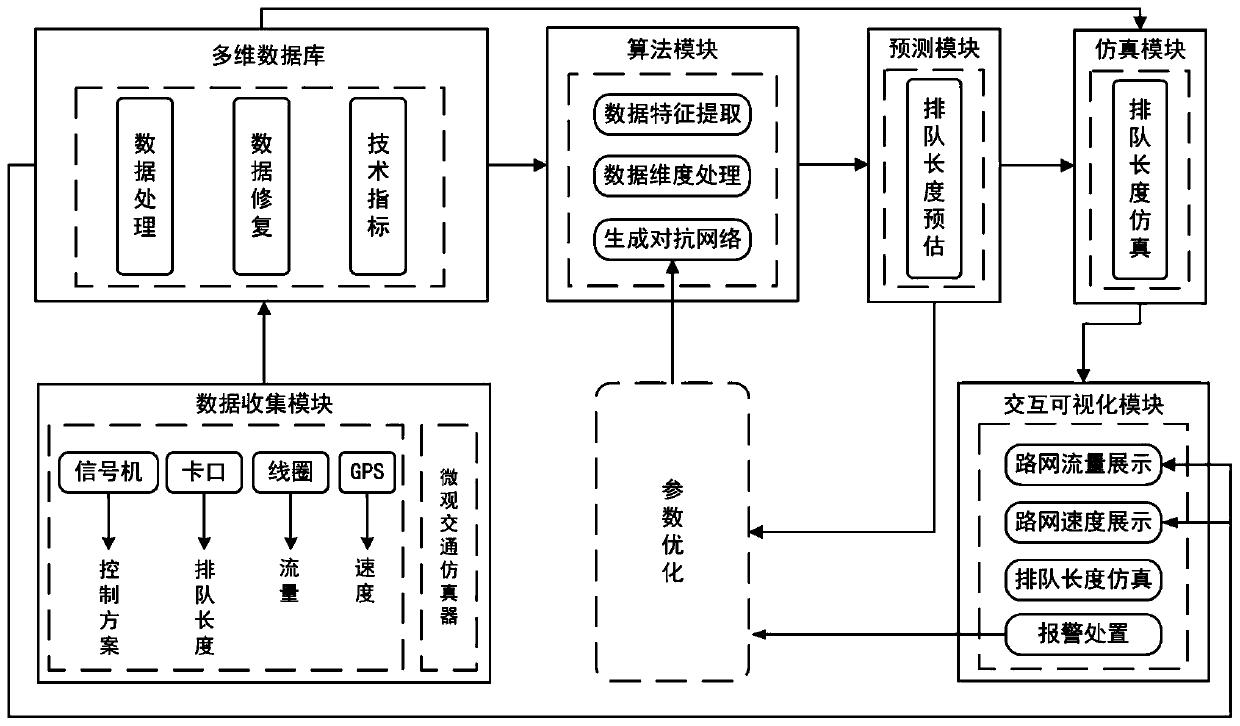

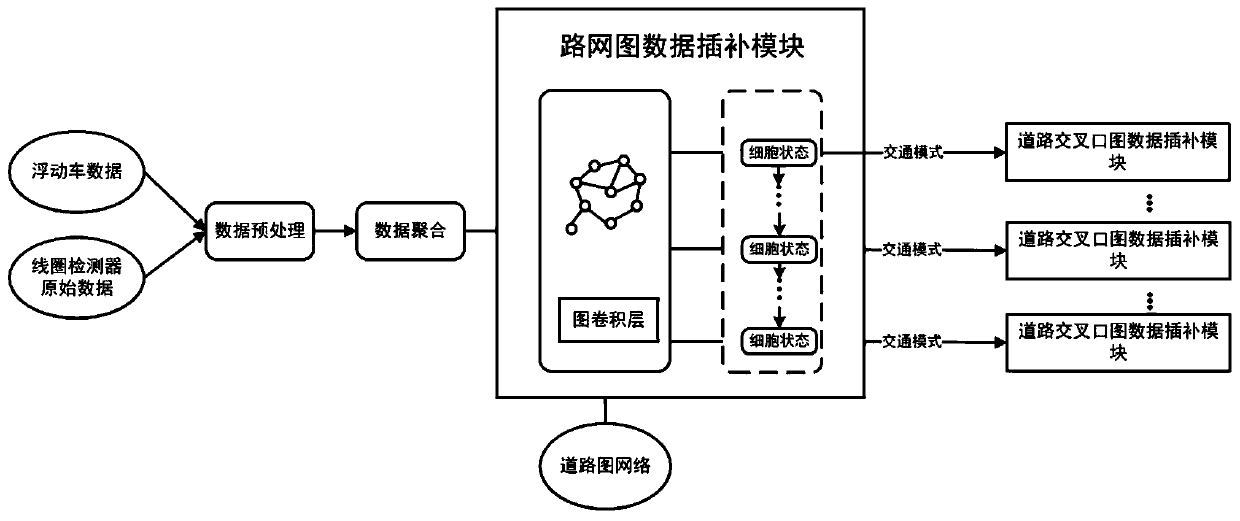

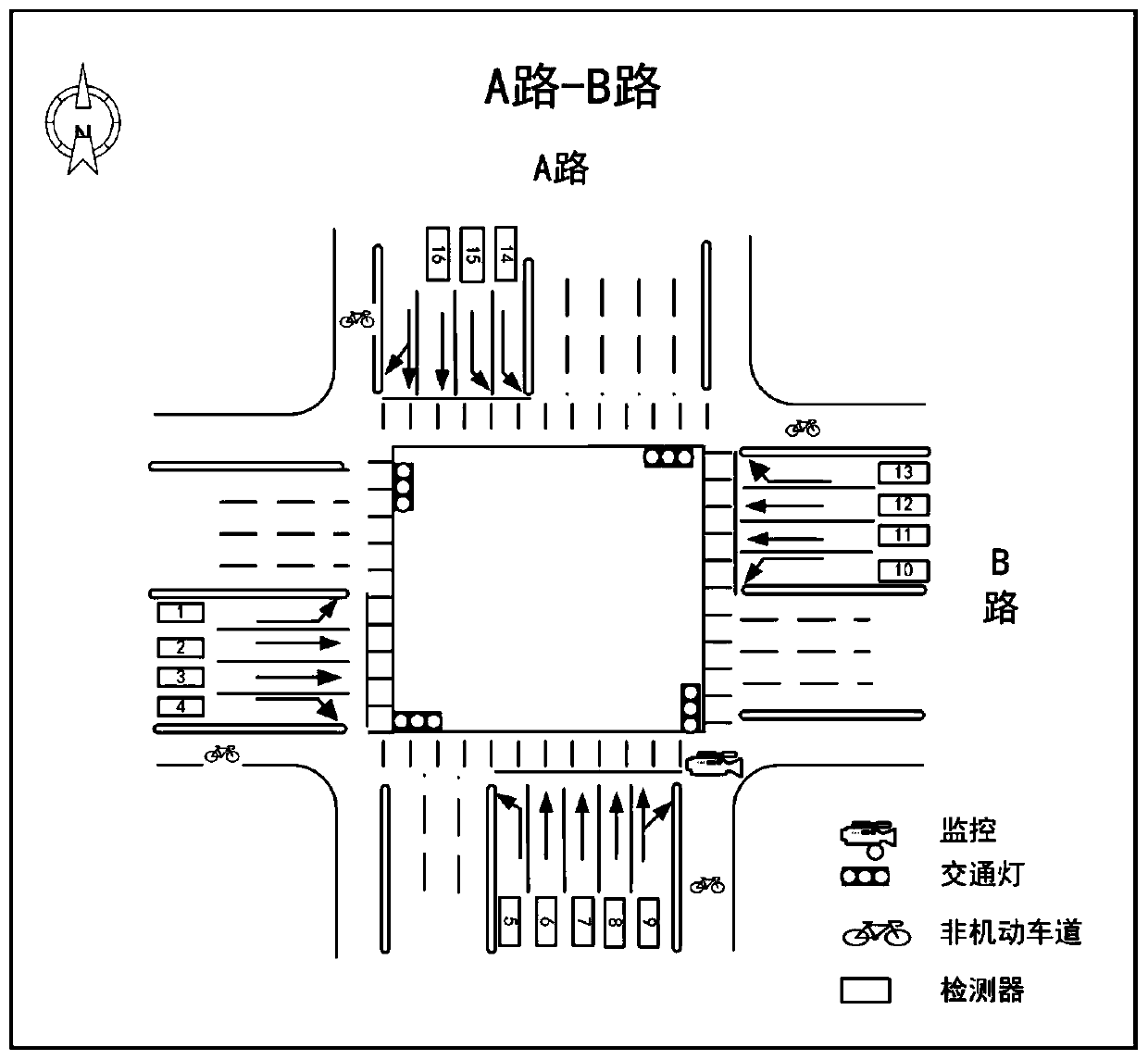

The invention discloses a city-level intelligent traffic simulation system. With multi-source heterogeneous data as input, the vehicle queue length of each lane at an intersection can be predicted, the evolution of the vehicle queue length is further dynamically simulated, and the simulation system comprises a data collection module, a multidimensional database, an algorithm module, a traffic state prediction module, a traffic simulation derivation module and an interaction visualization module. In the data collection module, the collected data comprise traffic dynamic data and static data. The multidimensional database is used for receiving various traffic dynamic information in real time and storing road infrastructure configuration information. In the algorithm module, a generated confrontation network is used for data generation and state prediction on the vehicle queue length, and the processing process comprises data feature extraction, data dimension processing, confrontation network generation, and hyperparameter optimization. The vehicle queue length of each lane at the intersection can be predicted, and the evolution of the vehicle queue length is further dynamically simulated.

Owner:ENJOYOR COMPANY LIMITED

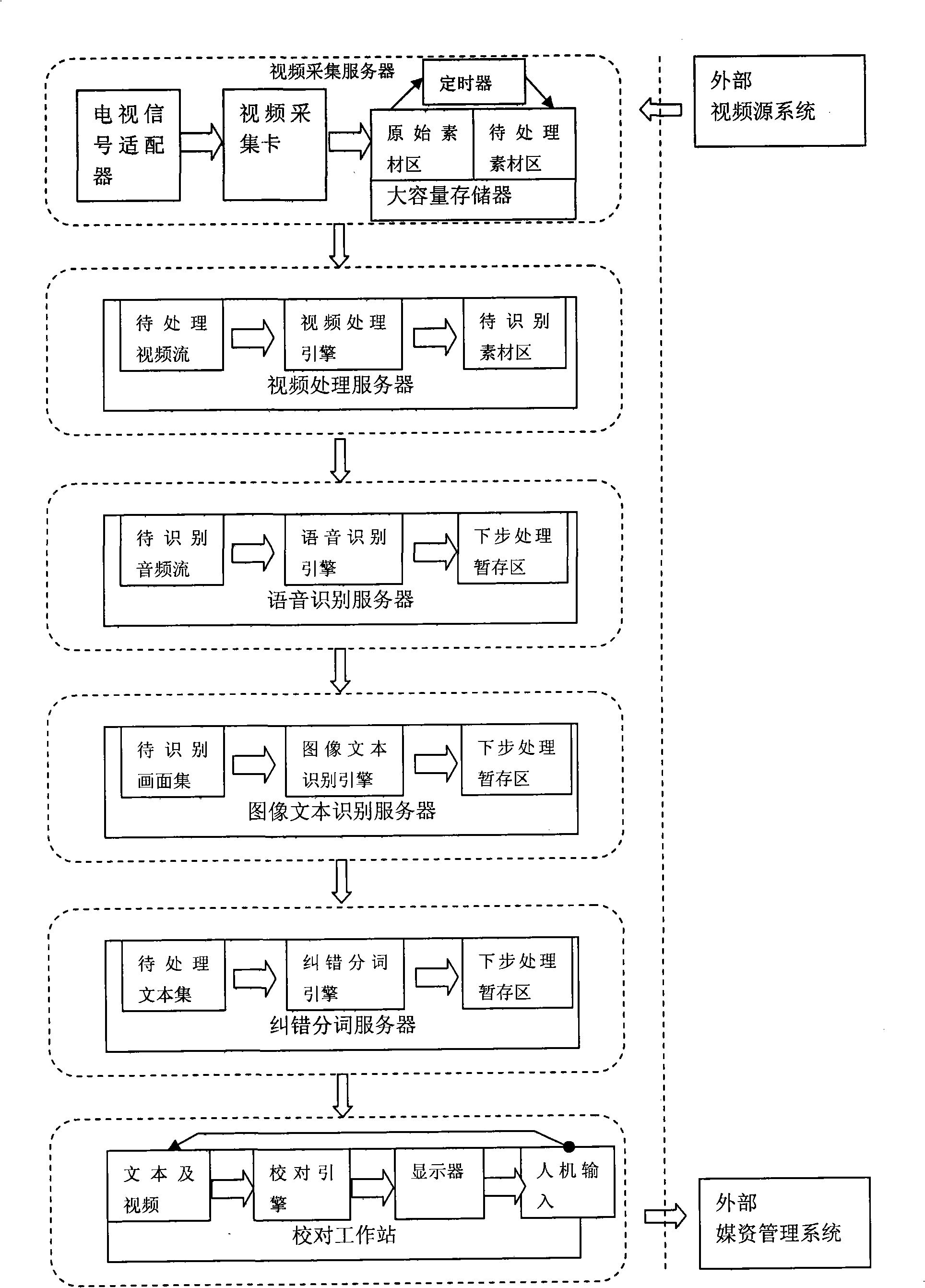

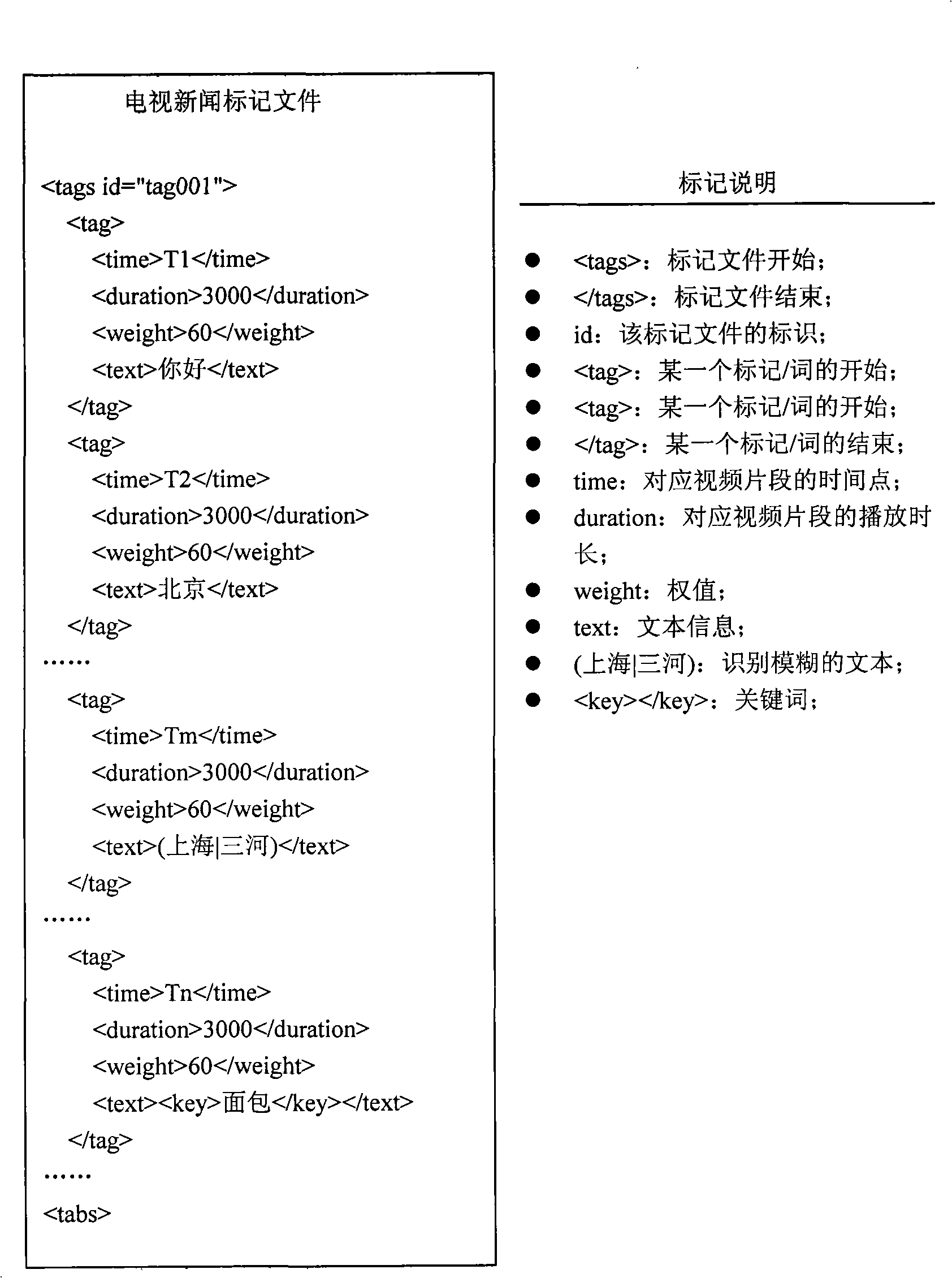

Method for indexing TV news by utilizing computer system

InactiveCN101539929ASolve low work efficiencyEasy to handleCharacter and pattern recognitionSpeech recognitionImage identificationText recognition

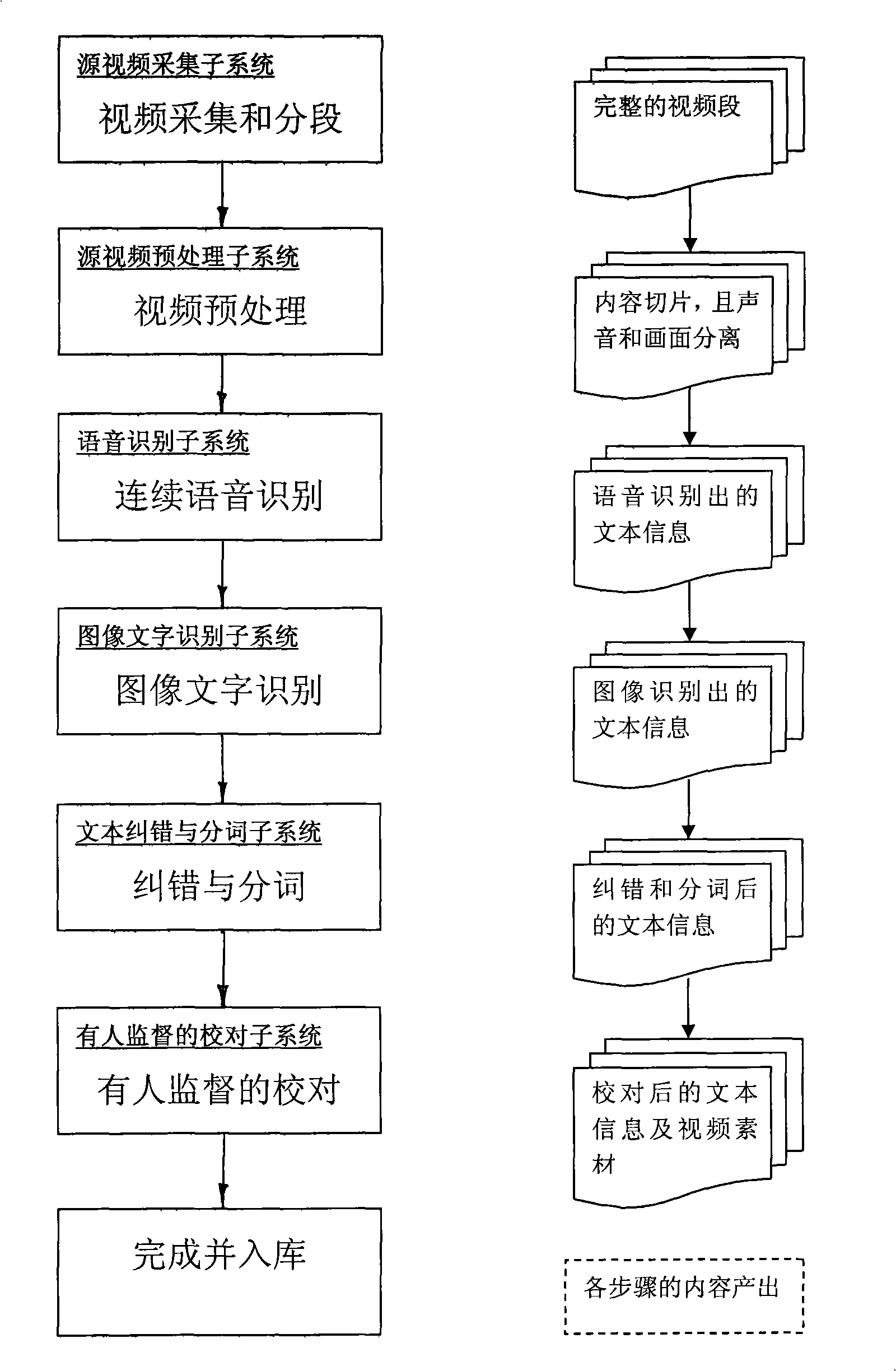

The invention discloses a method for indexing TV news, which introduces artificial intelligence method such as speech recognition, image recognition, and the like into traditional TV news indexing work. The method comprises the following steps: (1) video capture and video segmentation; (2) video preprocessing; (3) continuous speech recognition; (4) image and text recognition; (5) text error correction and word segmentation; and (6) human-supervised proofreading. The method redefines the indexing process and indexing mode of TV new programs and solves the problems of low working efficiency, insufficient indexing and information mining, and the like.

Owner:WUXI TVMINING MEDIA SCI & TECH

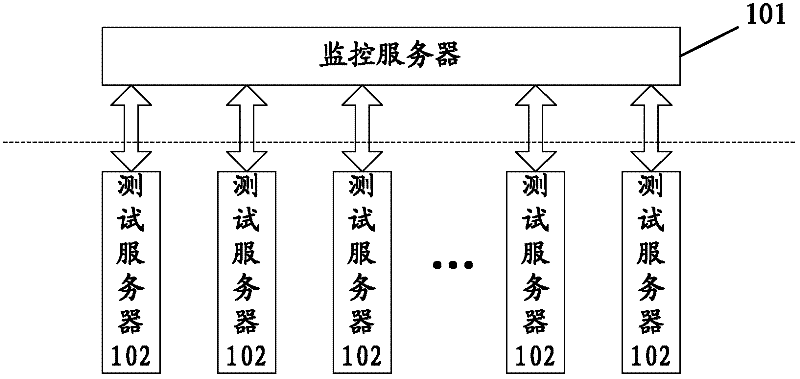

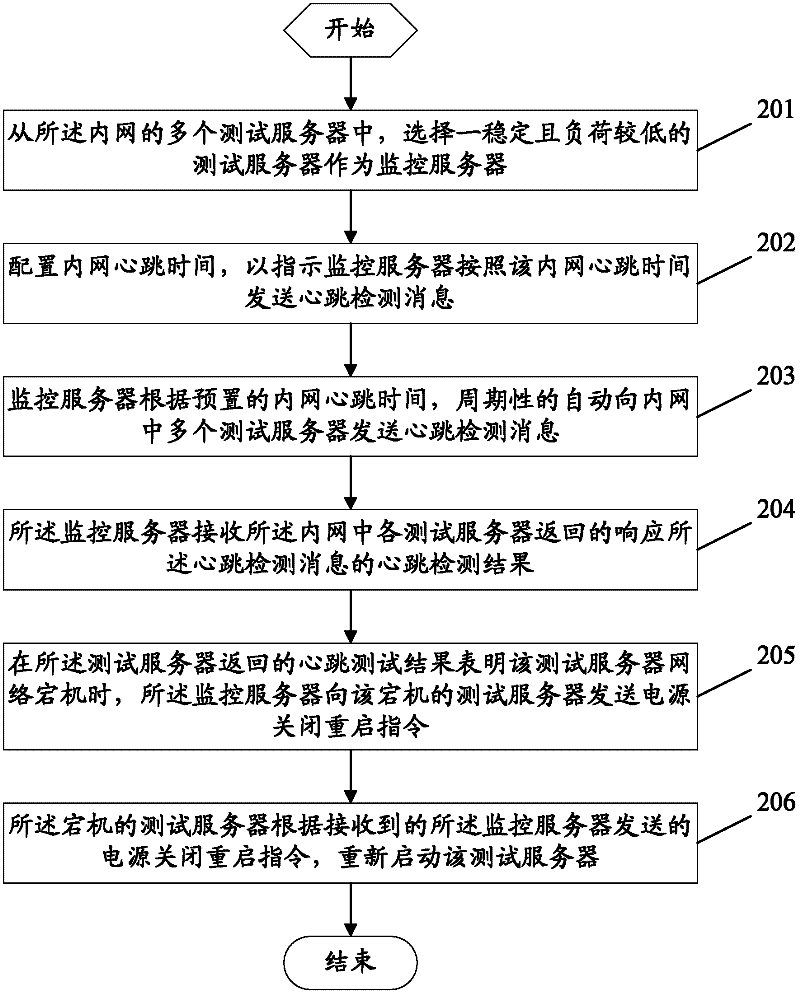

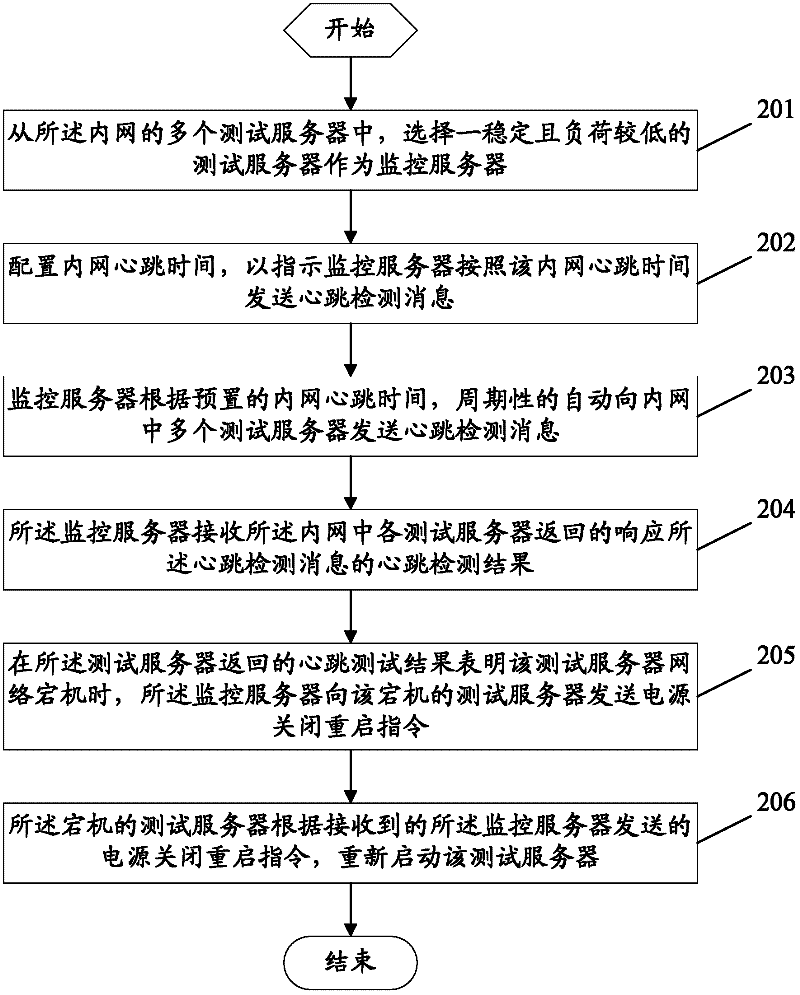

Downtime recovery method and system

InactiveCN102394791ARealize automatic real-time detectionShort response timeData switching networksRecovery methodRestoration method

The invention provides downtime recovery method and system, relates to the communication field, and solves the problem that the working efficiency of the system is low because the requirement for fast system failure response can not be satisfied by manual detection. The method comprises the following steps: a monitoring server periodically and automatically sends heartbeat detection messages to a plurality of detection servers in an intranet according to the preset intranet heartbeat time; the monitoring server receives heartbeat detection results responding to the heartbeat detection messages and returned by the detection servers in the intranet; and when the heartbeat detection result returned by the detection server shows that the network of the detection server is down, the monitoring server sends a power supply switch-off and re-start command to the detection server which is down. The technical scheme provided by the invention is suitable for a multi-server network, and achieves automatic and efficient downtime detection and recovery.

Owner:INSPUR BEIJING ELECTRONICS INFORMATION IND

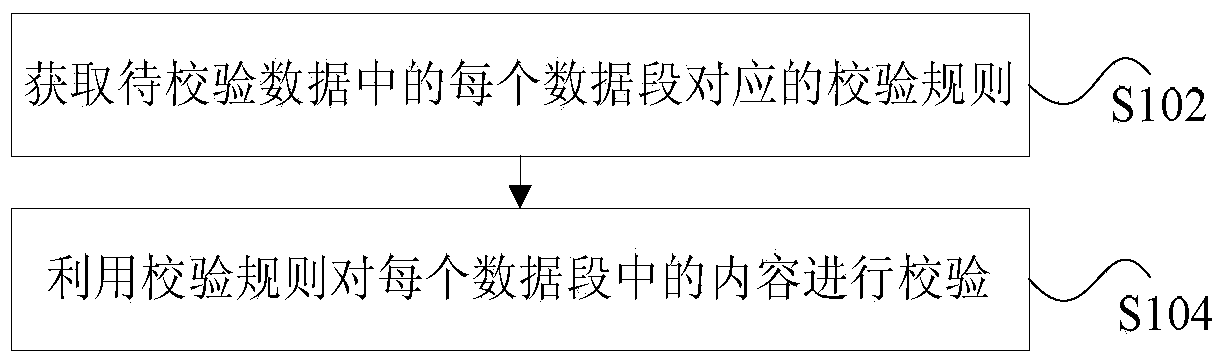

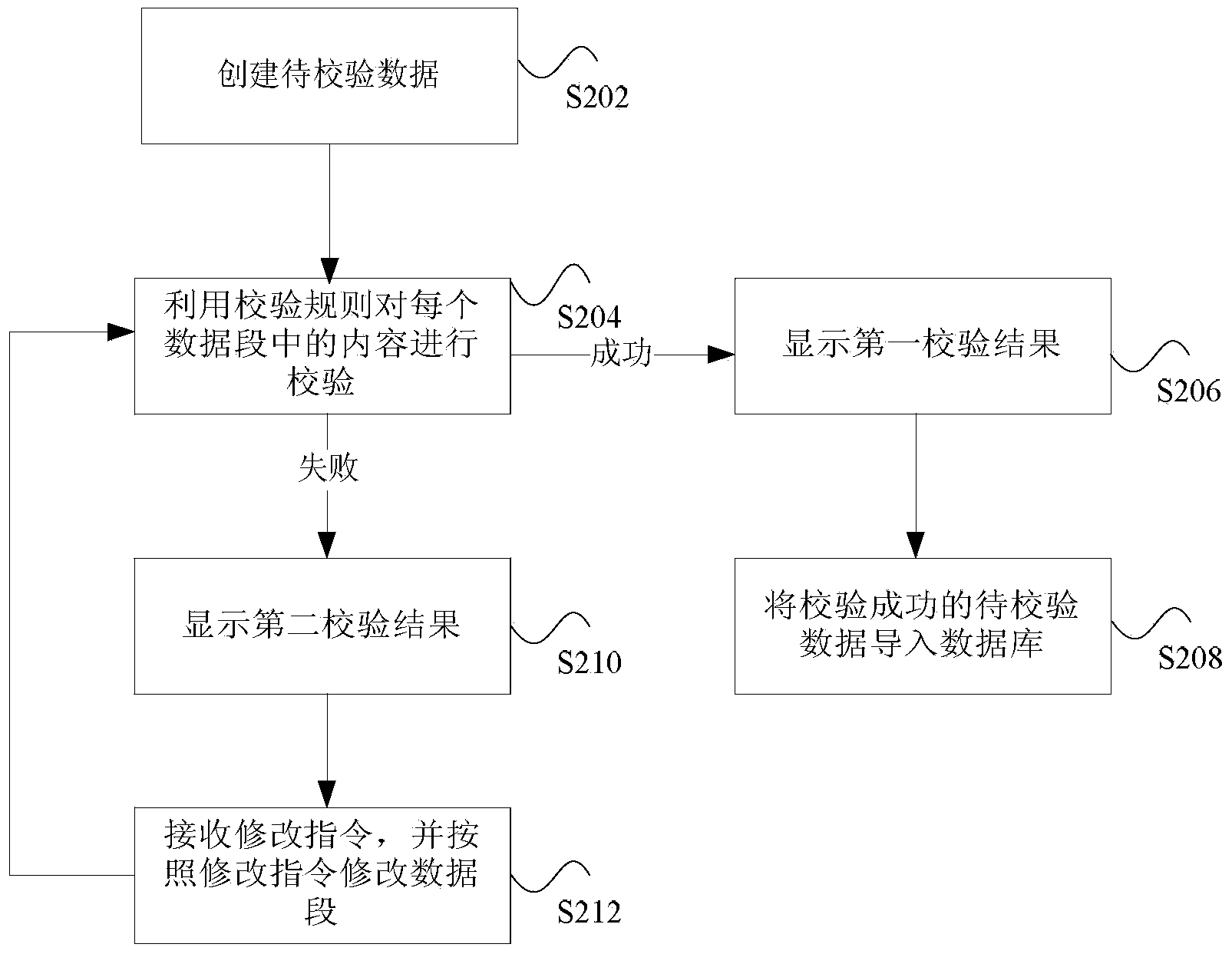

Data check method and data check device

InactiveCN104239162ASolve low work efficiencyImprove work efficiencyFault responseData segmentDatabase

The invention discloses a data check method and a data check device, wherein the data check method comprises the following steps that a checking rule corresponding to each data segment in data to be checked is obtained, wherein the data to be checked include a number of data segments; the checking rules are utilized to check the content in each data segment. By means of the data check method and the data check device, the problem of low working efficiency caused by artificial check is solved, and therefore the effect of increasing working efficiency is achieved.

Owner:BEIJING GRIDSUM TECH CO LTD

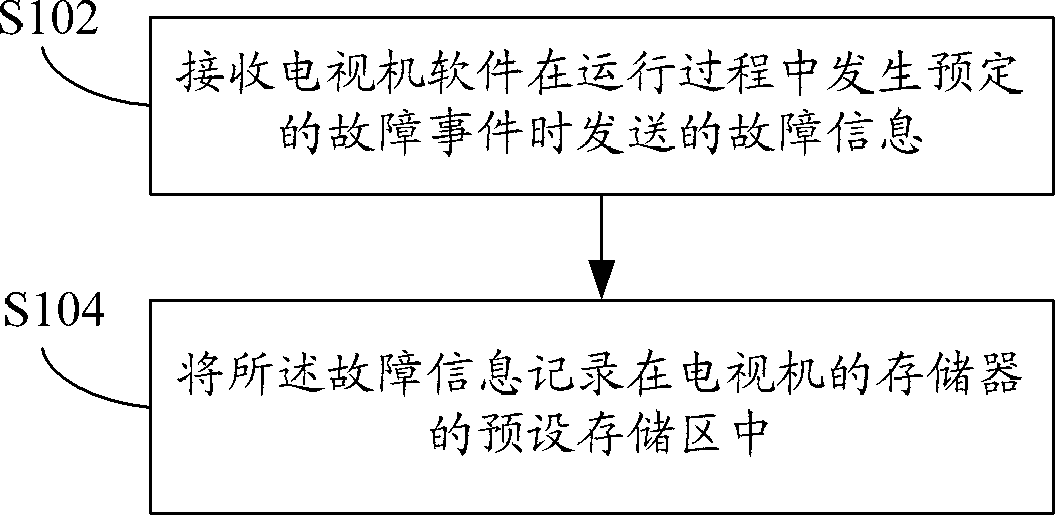

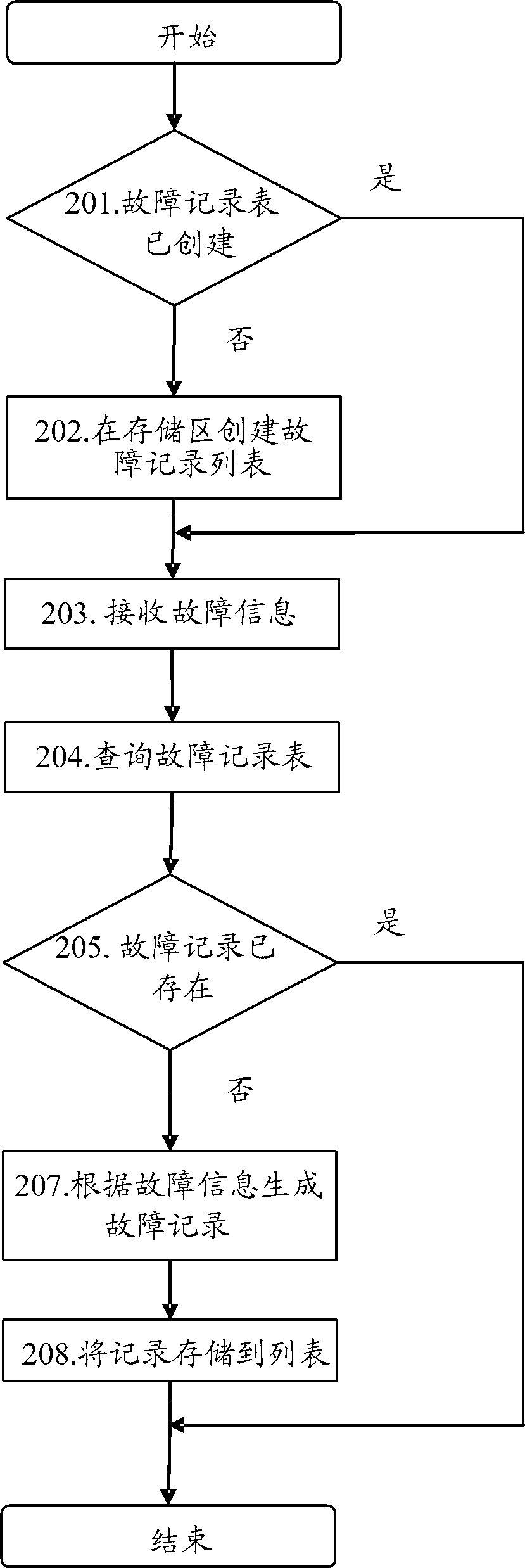

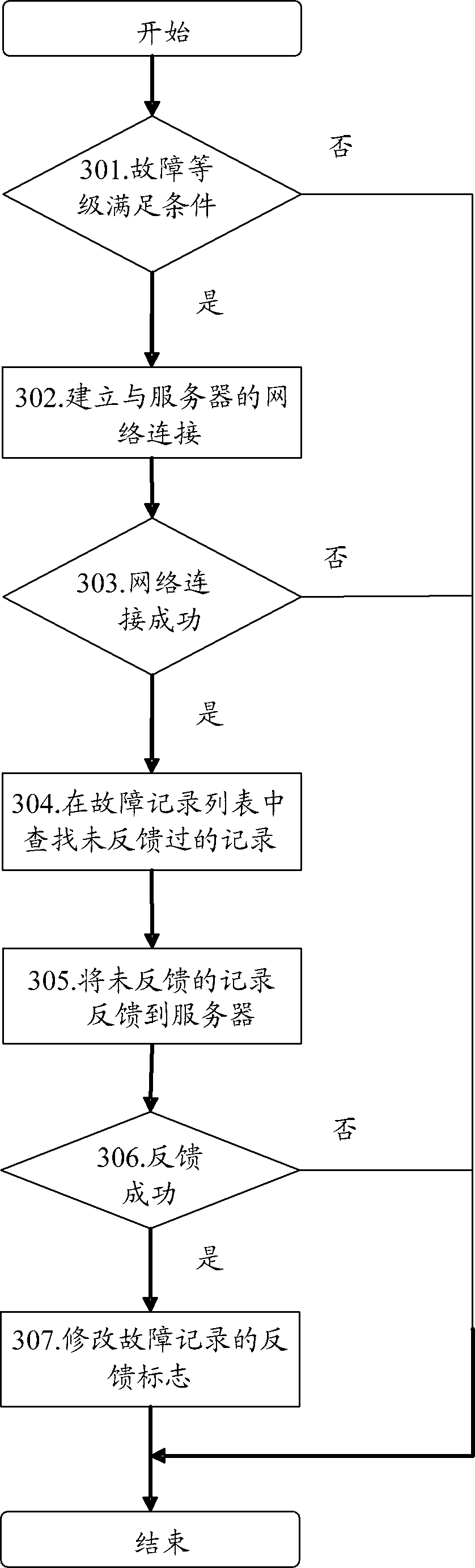

Method and apparatus for recording failures of television software

InactiveCN102740160AImprove experienceSolve low work efficiencyHardware monitoringSelective content distributionSoftwareMemory block

The invention discloses a method and an apparatus for recording failures of television software The method comprises: receiving a failure message sent when a scheduled failure occurs in a running process of the software; recording the failure message in a preset memory block of television storage. The method and the apparatus enable the initiative recording of failure messages in the running process of the television software, so that the efficiency of problem solving is improved.

Owner:HISENSE VISUAL TECH CO LTD

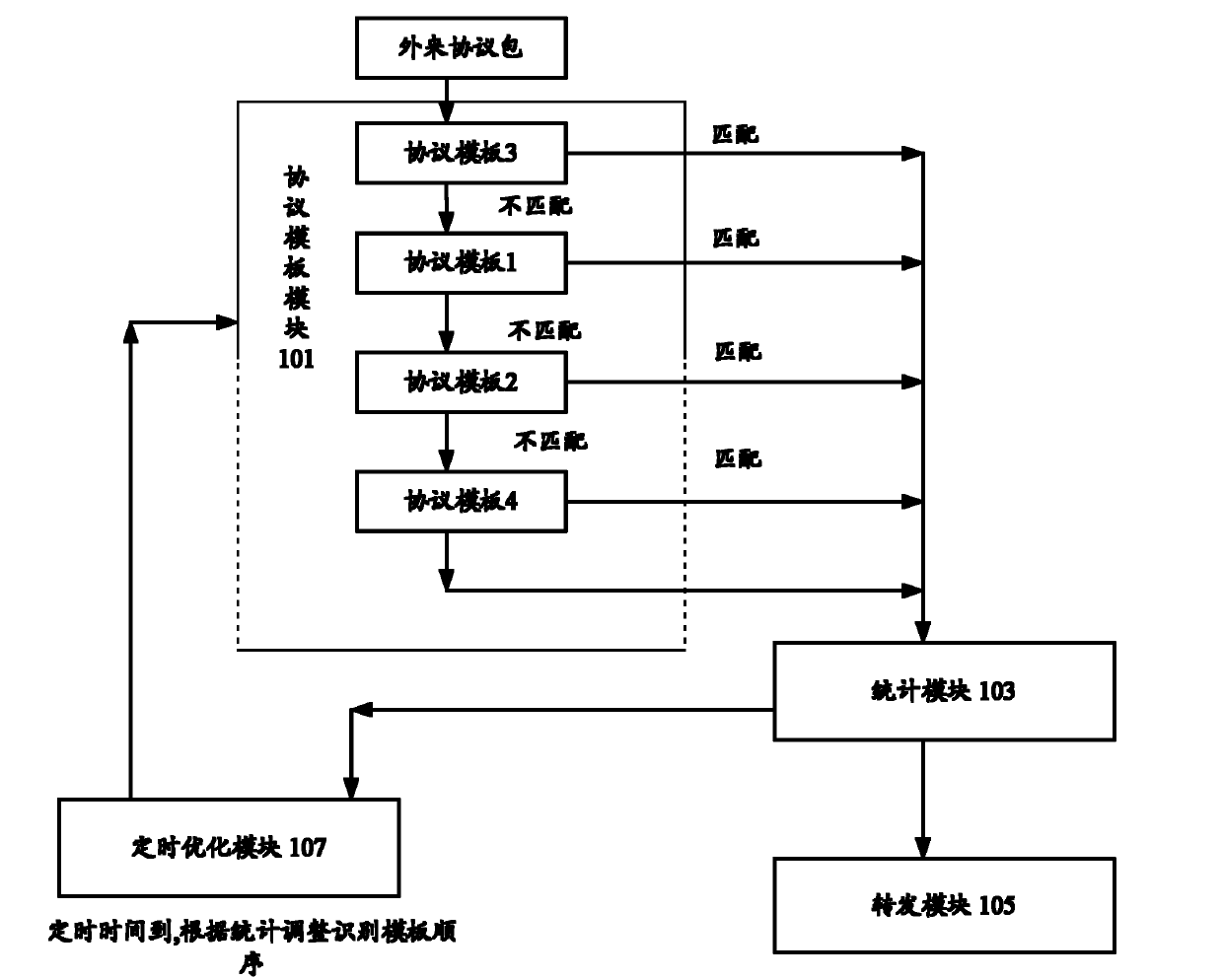

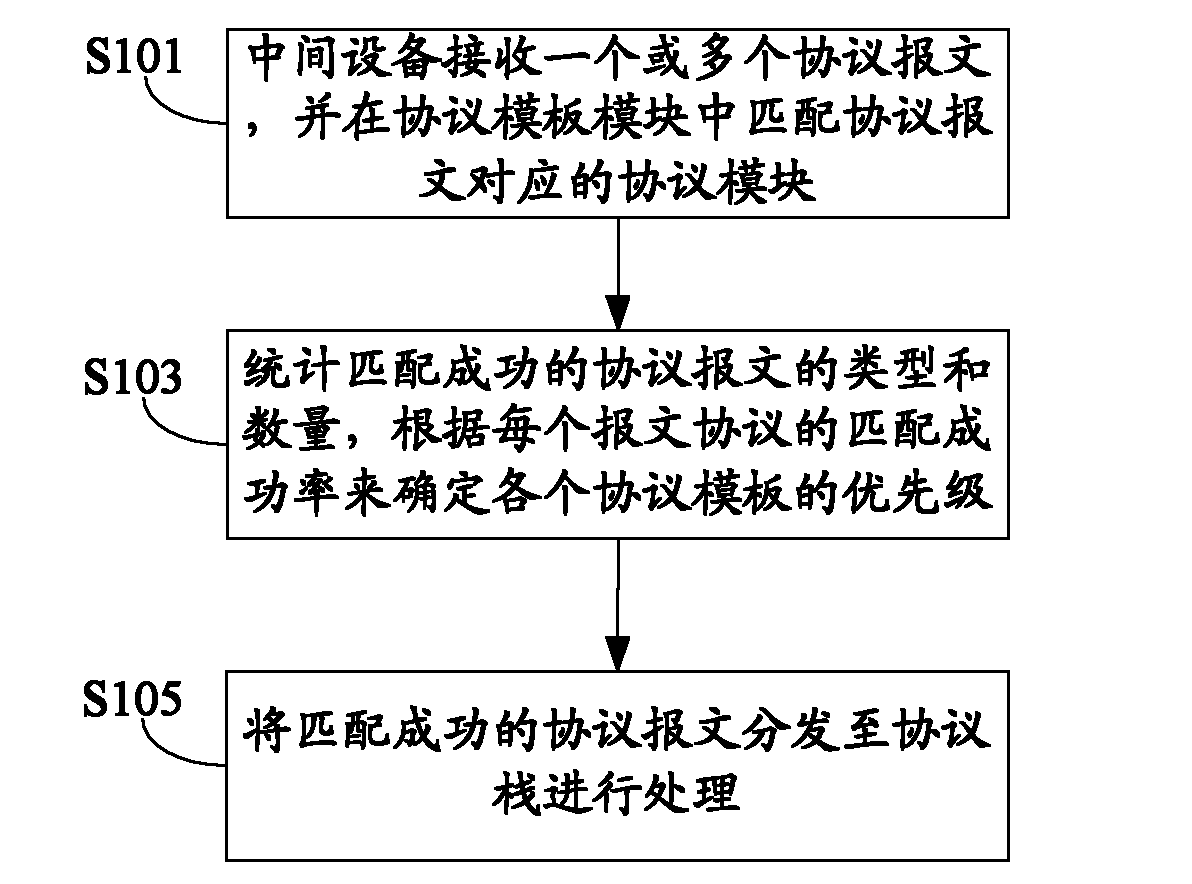

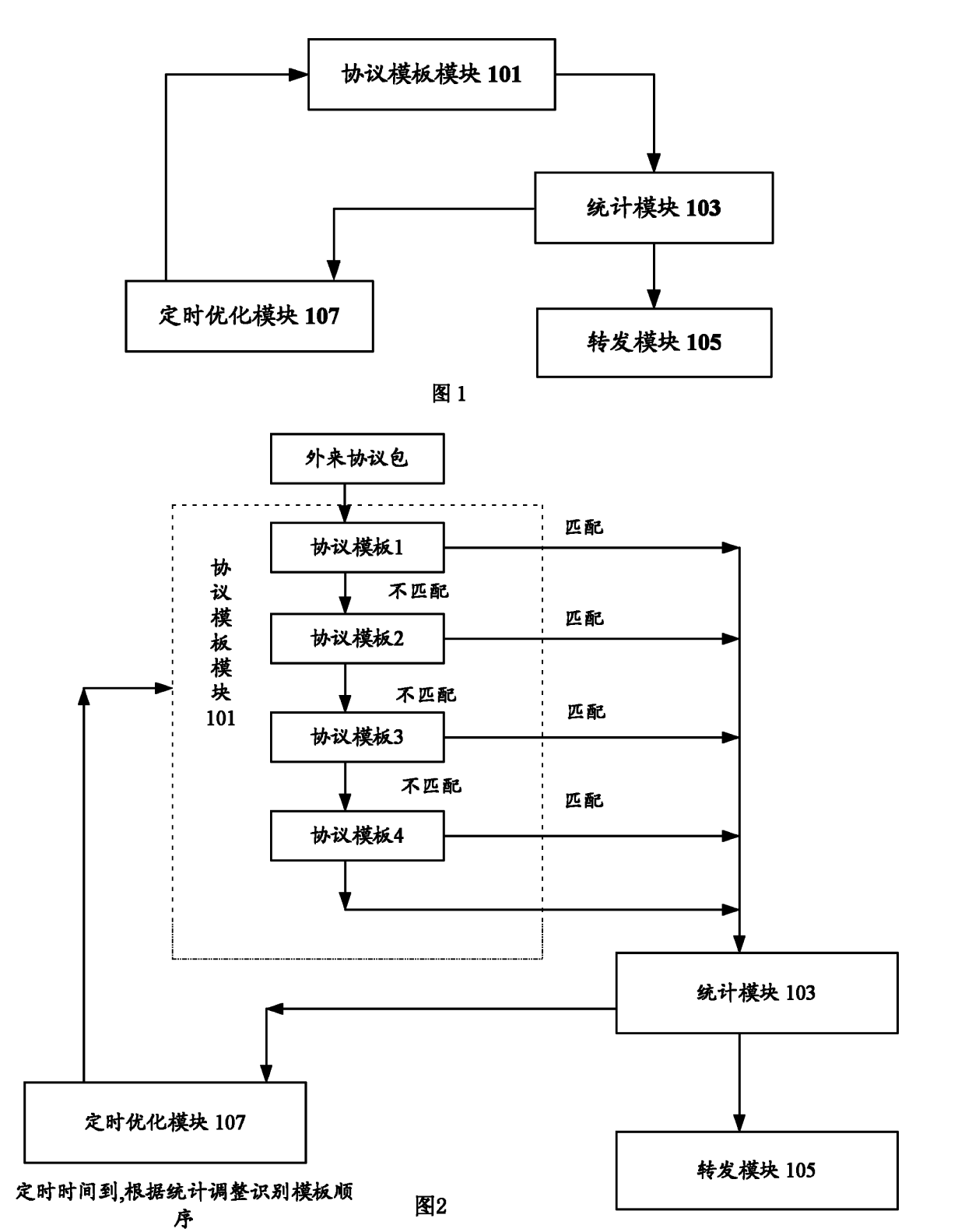

Protocol processing method for intermediate device and device thereof

ActiveCN102158414ASolve low work efficiencyImprove work efficiencyData switching networksProtocol processingComputer science

The invention discloses a protocol processing method for an intermediate device and a device thereof, wherein the method comprises the steps of: receiving one or more protocol messages by the intermediate device, and matching a protocol module corresponding to the protocol message in the protocol template module, wherein the protocol template module comprises one or more protocol modules; counting the type and number of the successfully matched protocol messages, and determining the priority of each protocol template according to the matching success rate of each message protocol; distributing the successfully matched protocol messages to a protocol stack for processing. Through the invention, a pre-processing operation is distributed to CPU (Central Processing Unit) protocol identification with less cost so that the work efficiency of the CPU is improved.

Owner:如东县升泰新农村开发建设有限公司

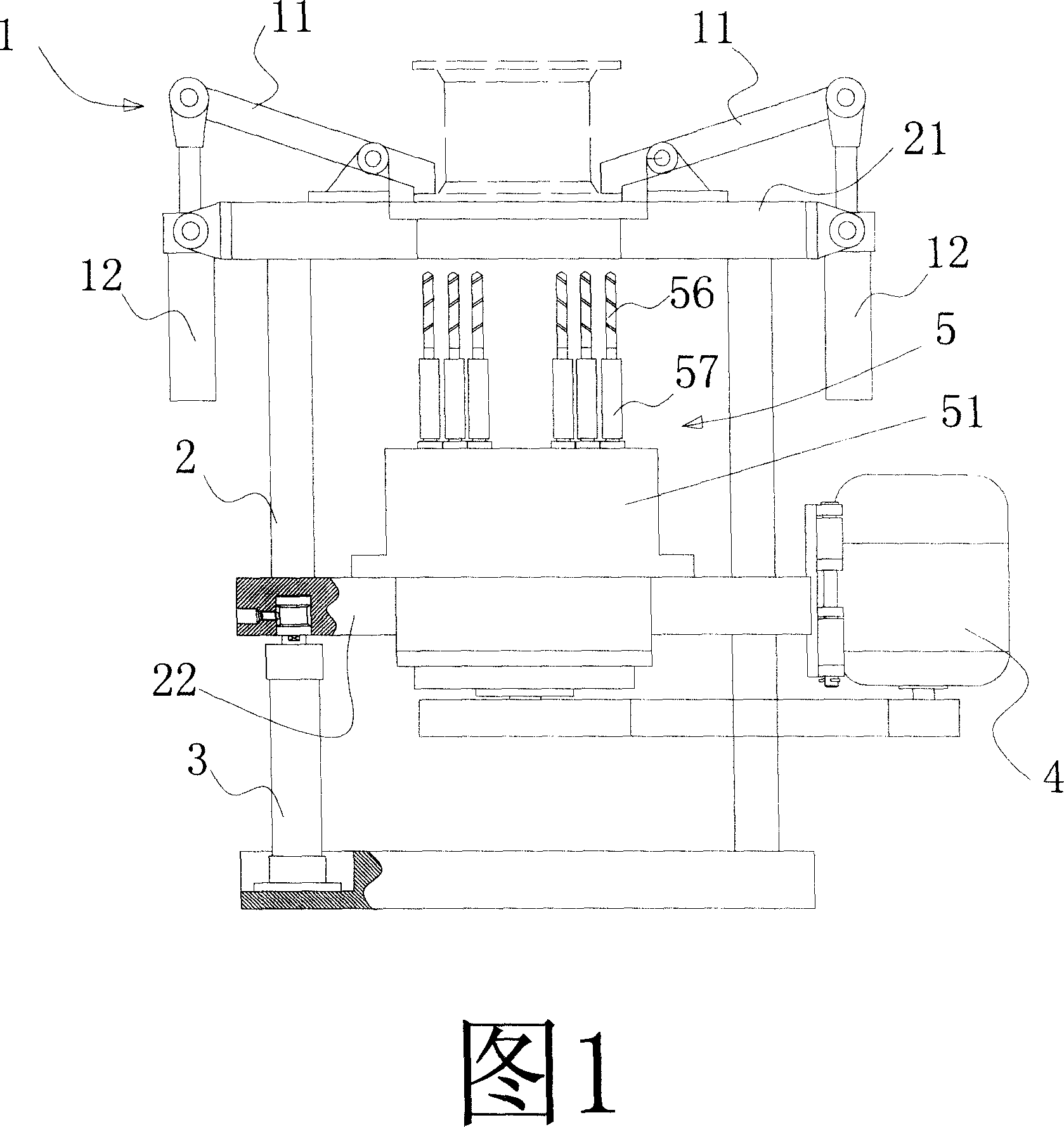

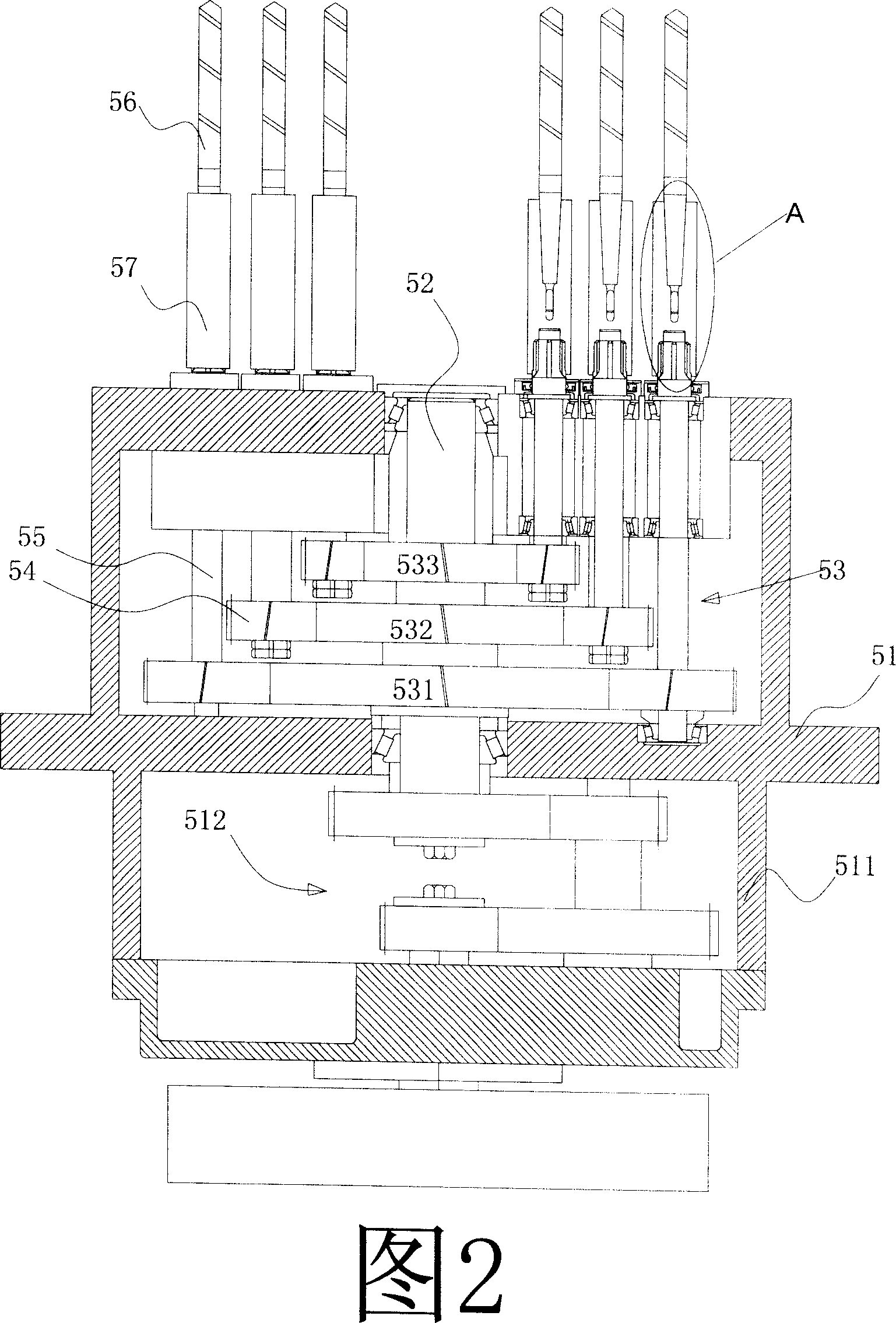

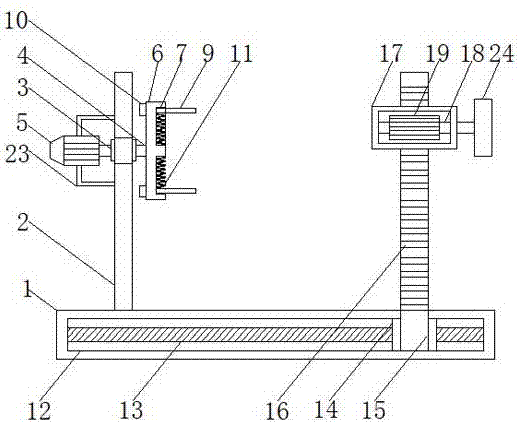

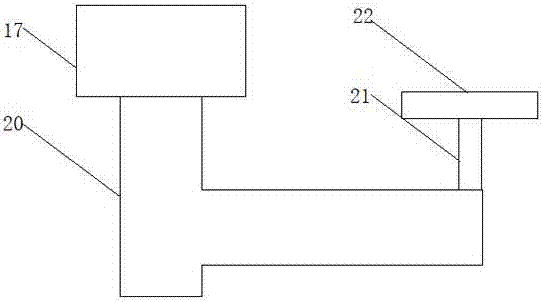

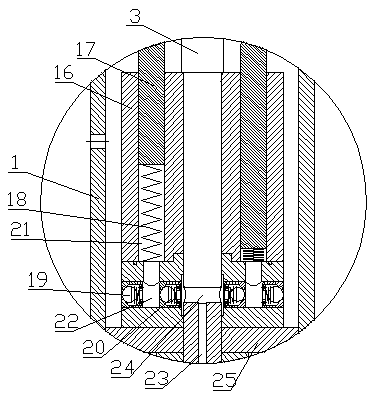

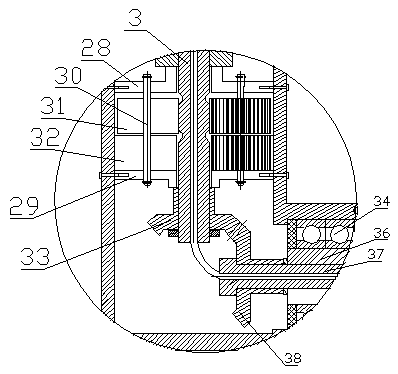

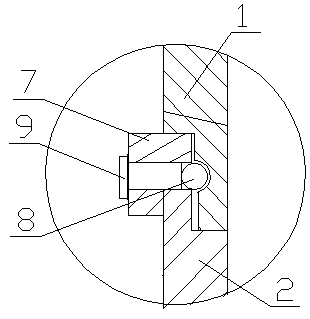

Lathe dedicated for boring on pipe fittings flange

InactiveCN1994640ASimple processing and assembly processSolve low work efficiencyPositioning apparatusBoring/drilling componentsAutomotive engineeringDrill hole

The invention relates to a tube flange drill machine, which comprises support, mechanical transmitter, clamper, hydraulic system, and electric system, wherein it also comprises multi-axle power head with main axle box at the middle plate of support; a tower gear group on the transmission axle in main axle box with several active wheels on the transmission axle; several planet wheel symmetry distributed on the circumference of active wheels to mesh active wheels; several main axles on the planet wheels; the transmitter drives the main transmission axle via tower gear group to drive the main axles of planet wheels to rotate. The invention can process several holes at one time, with high efficiency and quality.

Owner:北京通州宋庄铸造厂

Leather manufacture and production process thereof

InactiveCN104846127ASolve low work efficiencyThe process is simple and clearSkins/hides/leather/fur manufacturing apparatusLeather softeningSizingWork performance

The invention relates to a leather manufacture and production process thereof, mainly solving the problems that the current leatherworking is not environment-friendly and the working performance is low. The leather manufacture and the production process thereof are characterized by comprising the following steps: (1) carrying out physical squeeze and vacuum adsorption on leather blank; (2) air drying; (3) fixing leather on vertical toggling and feeding the toggling into an oven to carry out hot wind baking; (4) trimming manually, and mending blemishes; (5) leather fluffing; (6) leather blank starching; (7) utilizing an atomization sizing agent principle to carry out spraying; (8)embossing or printing; (9)milling or staking the leather;(10) ironing and sizing;(11)measuring the leather, detecting and warehousing. The technological process of the leather manufacture has the advantages of being simple and clear, material-saving, environment-friendly, high in efficiency and strong in practicality and the safe operation by an operator is guaranteed.

Owner:ZHEJIANG LIYUAN LEATHER IND

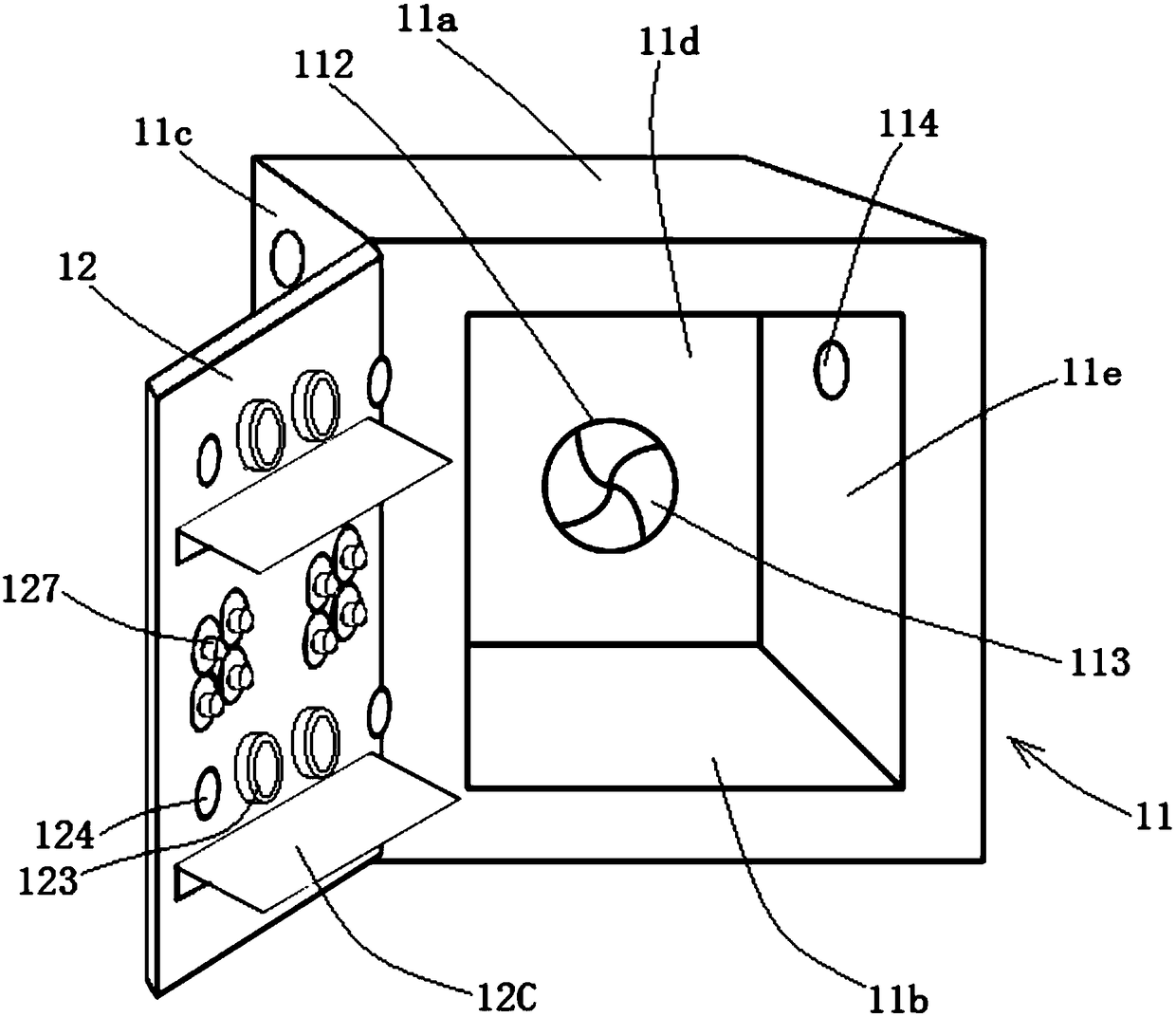

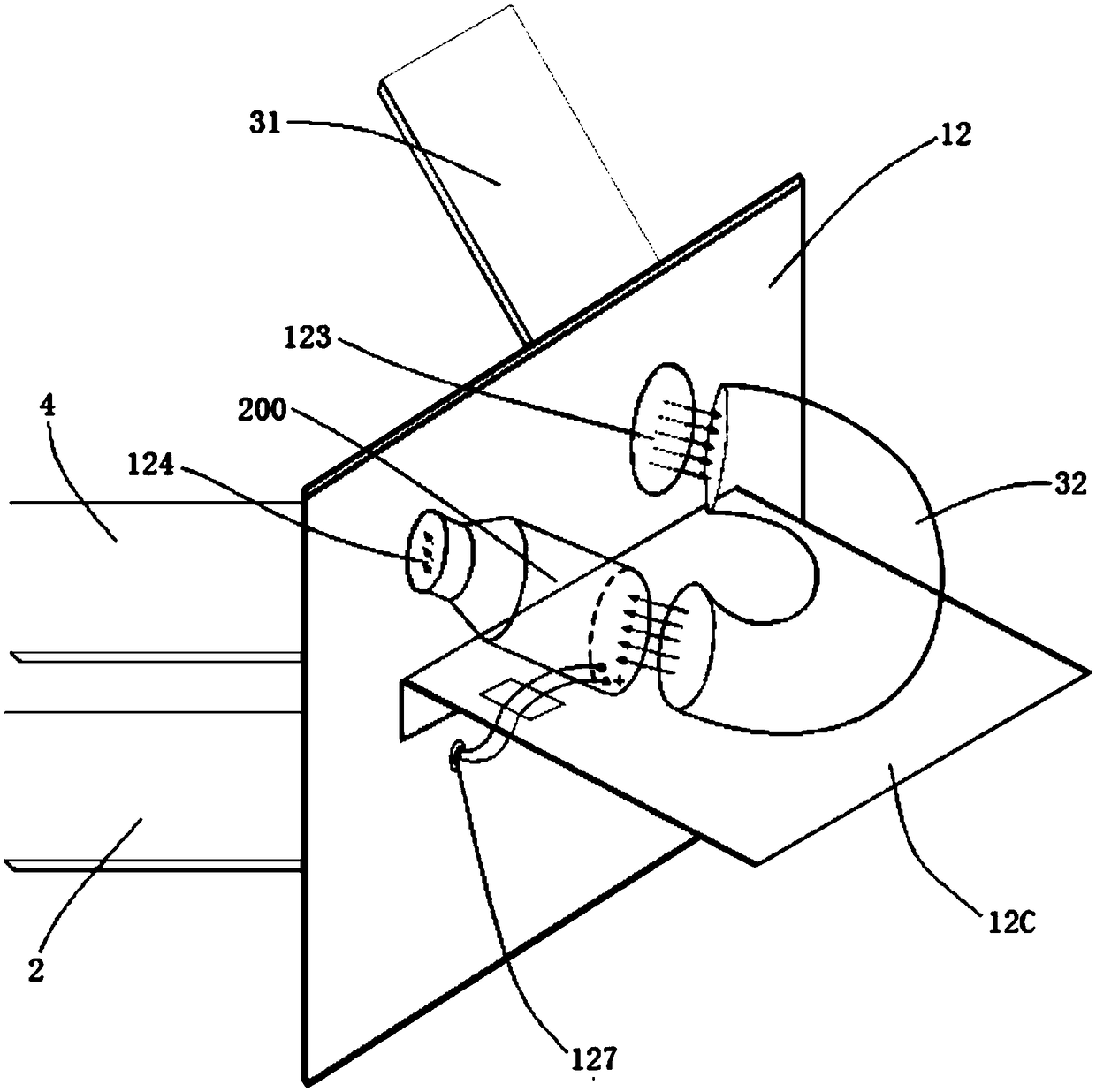

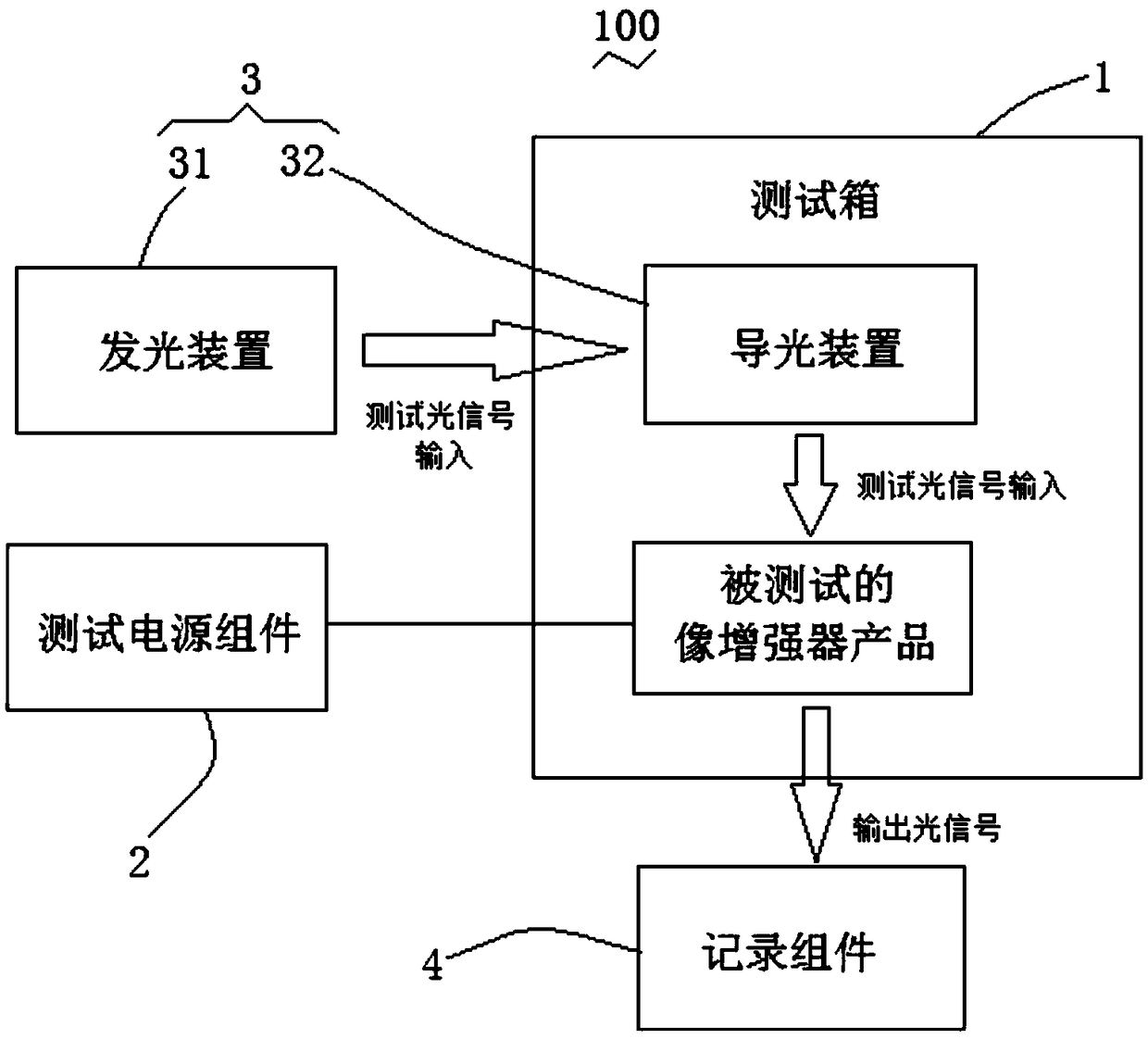

Low light level image intensifier test system

ActiveCN109489941ASolve frostingSolve the record depth problemTesting optical propertiesTest powerElectricity

The invention discloses a low light level image intensifier test system which comprises a test box for containing the tested low light level image intensifier, a test power supply assembly for providing a working power supply to the tested low light level image intensifier, an illumination assembly for providing a test optical signal input to the tested low light level image intensifier, and a recording assembly for receiving an output optical signal generated by the tested low light level image intensifier based on the test optical signal input and converting the output optical signal into atest electrical signal and recording the voltage data of the test electrical signal. The illumination assembly comprises a light emitting device for emitting the test optical signal and a light guidedevice for transmitting the test optical signal; the test power supply assembly, the light emitting device and the recording assembly are all arranged outside the test box, the light guide device is arranged inside the test box and is used for transmitting the test light signal emitted by the light emitting device to the tested low light level image intensifier as the input of the test light signal.

Owner:NORTH NIGHT VISION TECH

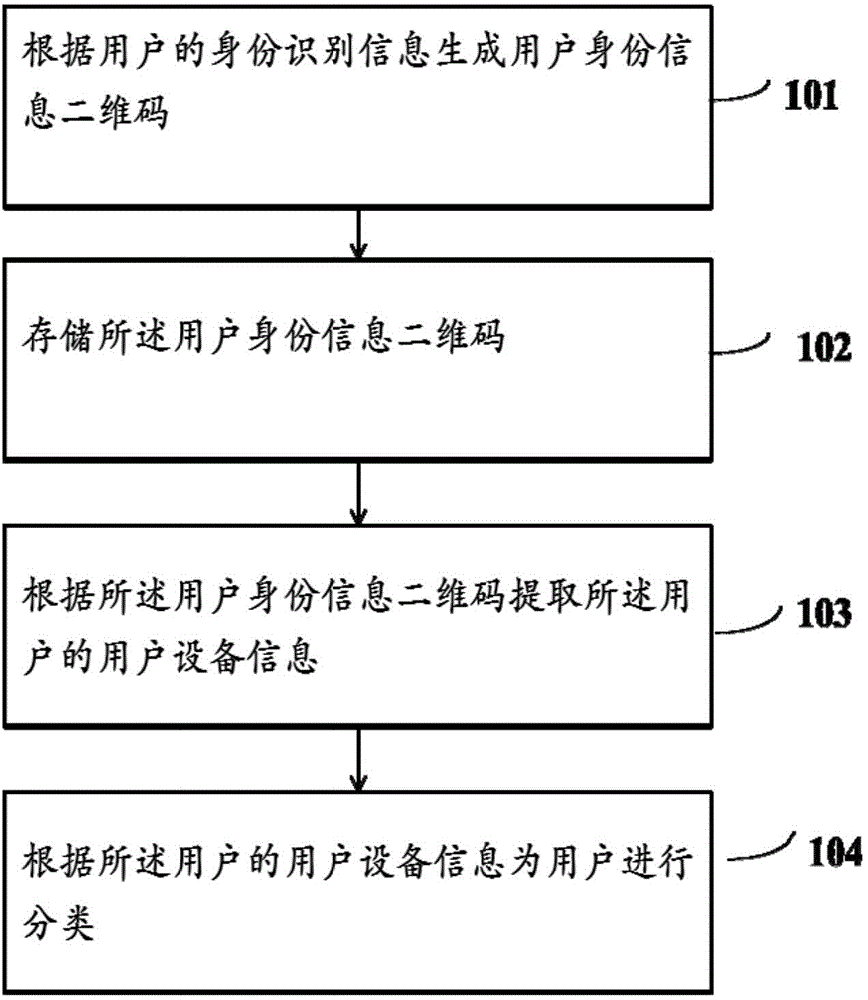

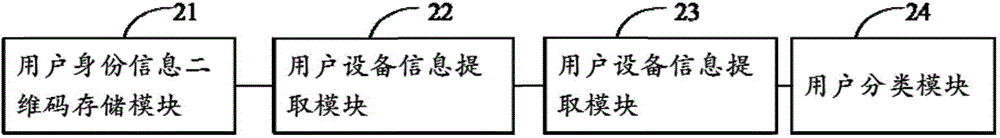

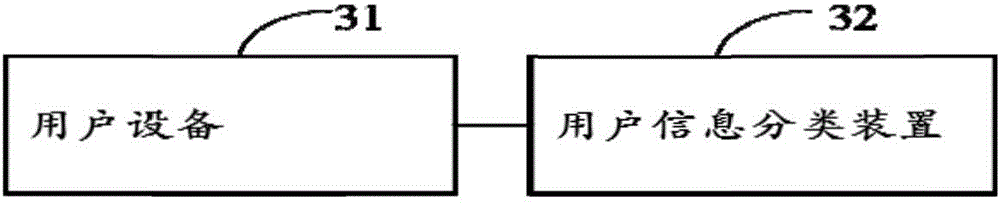

Method, device and system using two-dimension code to distinguish user type

The invention discloses a method, device and system using a two-dimension code to distinguish user types; when users belong to different types, the method, device and system can use a corresponding relation between the two-dimension code and user equipment to automatically distinguish users; the method comprises the following steps: using user ID information to generate a user ID information two-dimension code; storing the user ID information two-dimension code; extracting user equipment information according to the user ID information two-dimension code; classifying the users according to the user equipment information. In addition, the invention also provides the corresponding device and system embodiments. The method, device and system can prevent resource waste caused by work people to artificially register user information, thus improving user classification and register work efficiency, saving work time for user artificial classification, and saving time for the users as well.

Owner:上海天脉聚源文化传媒有限公司

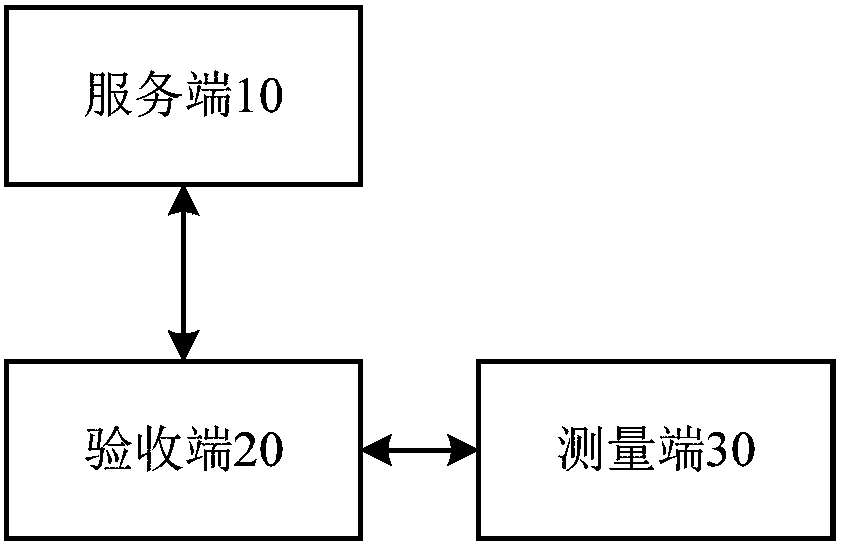

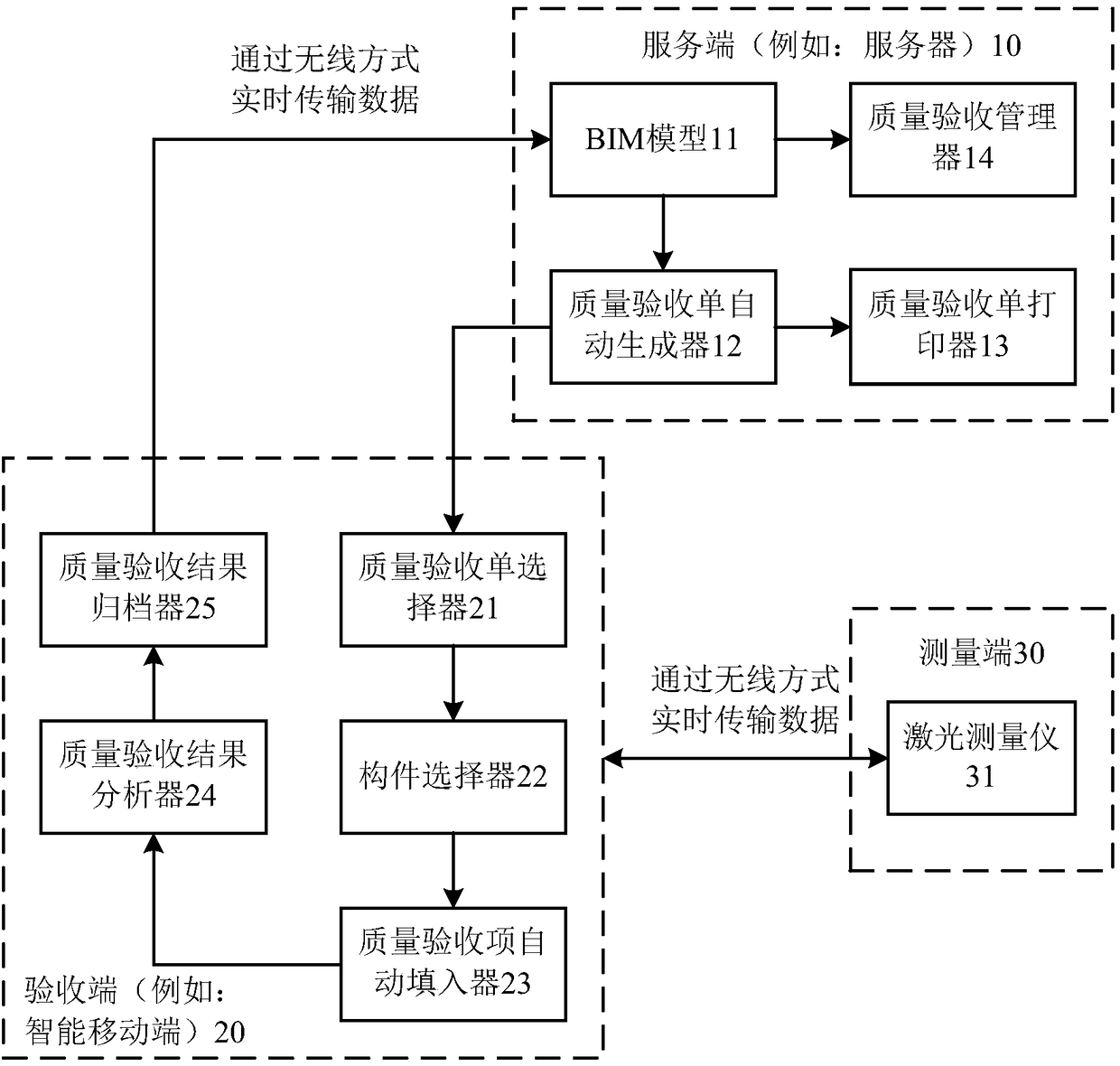

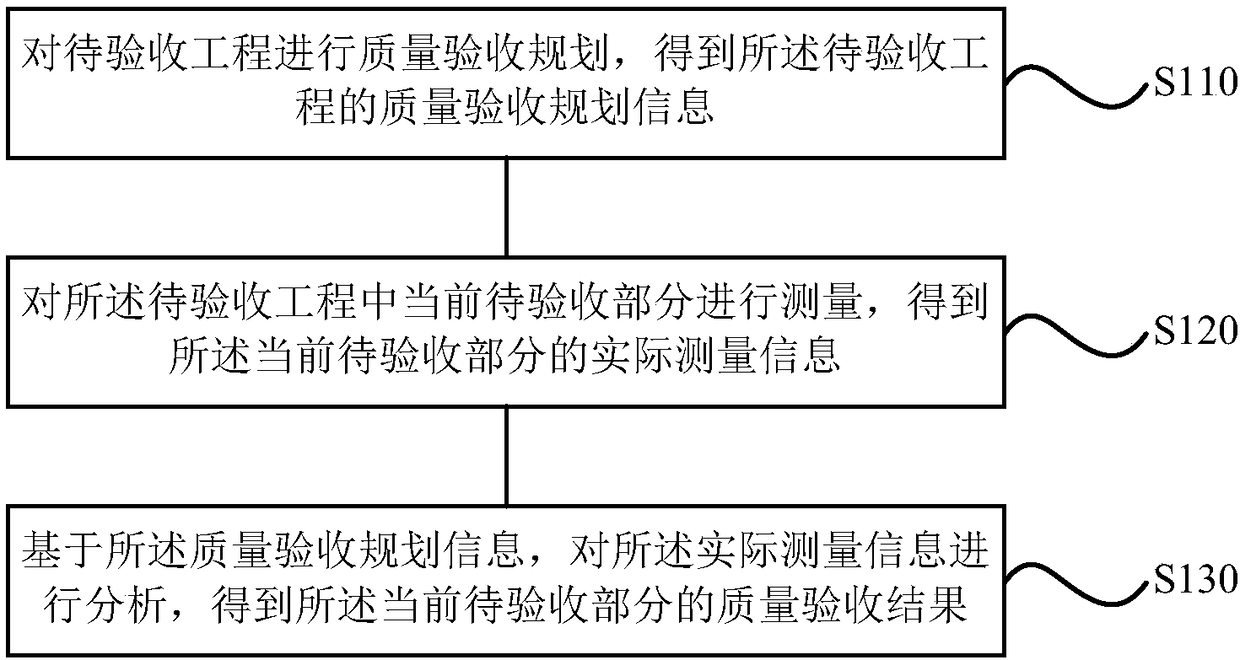

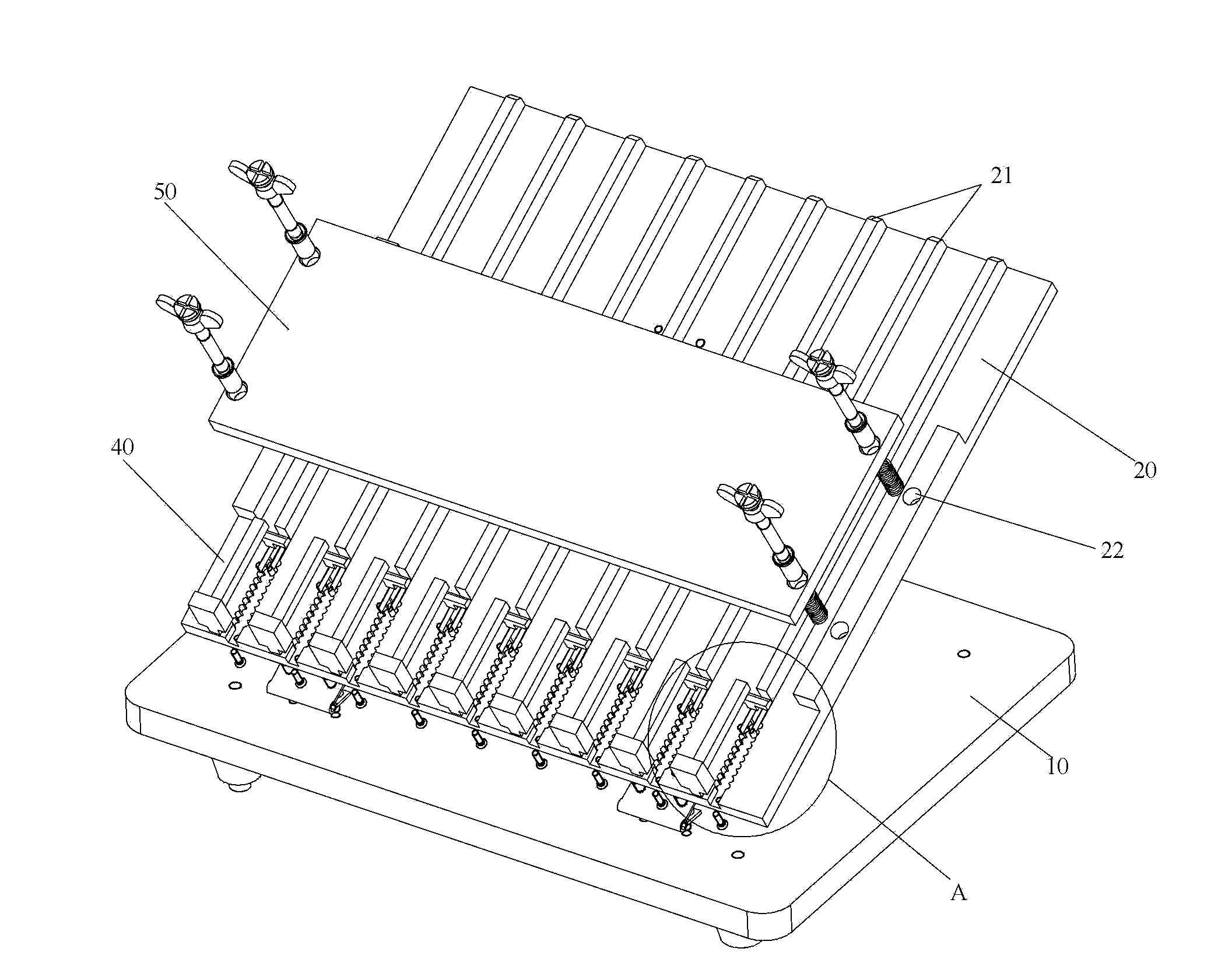

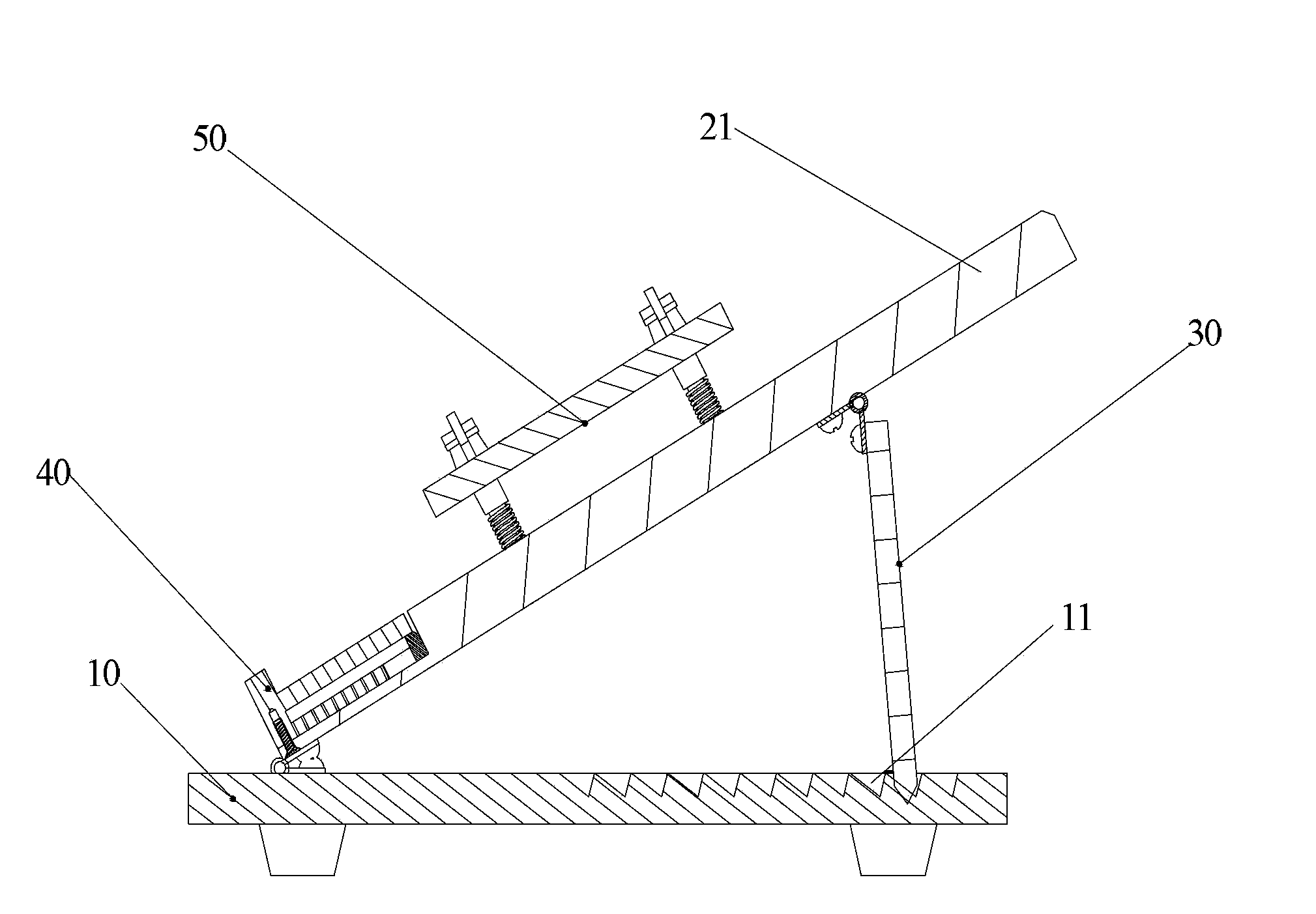

Project quality acceptance device and method

ActiveCN108074032AQuickly generate quality acceptance resultsAchieve the effect of remote supervision quality acceptance workResourcesWork qualityAcceptance testing

The invention discloses a project quality acceptance device and method. The device comprises a service end (10), a measuring end (30) and an acceptance end (20); the service end (10) is used to make aquality acceptance plan for a to-be-accepted project and obtain quality acceptance plan information of the to-be-accepted project; the measuring end (30) is used to measure a part to be accepted at present in the to-be-accepted project and obtain practical measurement information of the part to be accepted at present; and on the basis of the quality acceptance plan information, the acceptance end(20) analyzes the practical measurement information and obtains a quality acceptance result of the part to be accepted at present. Via schemes of the invention, defects including that the working efficiency is low, data is hard to track, and the data accuracy and project quality are hard to ensure in the prior art are overcome, and the working efficiency is high, data can be traced, and the dataaccuracy and project quality can be ensured.

Owner:SHANGHAI NO 4 CONSTR

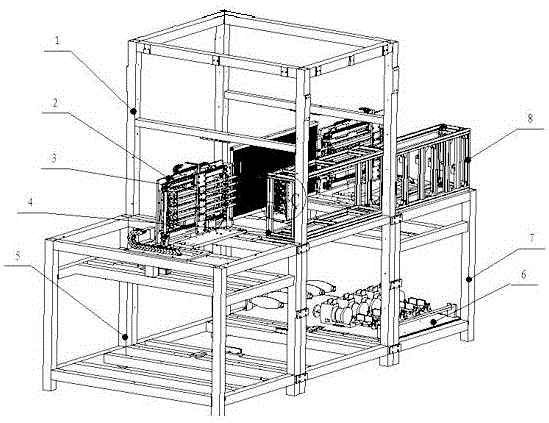

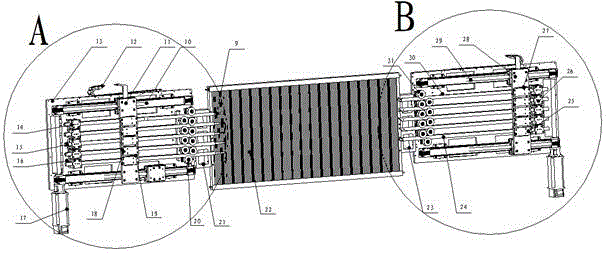

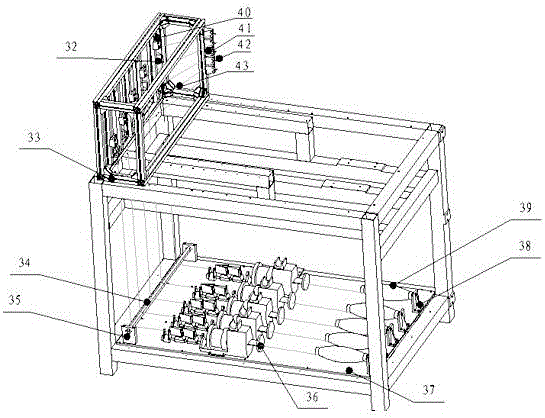

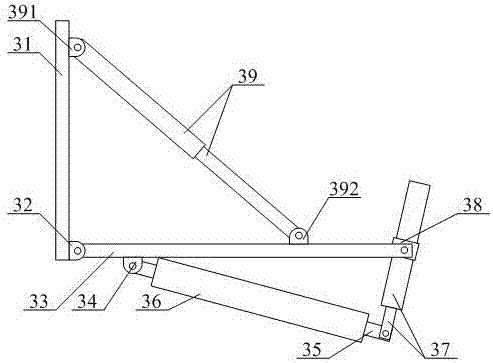

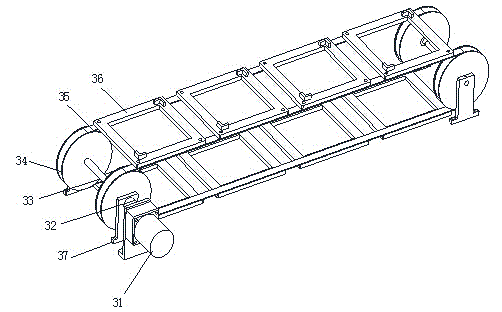

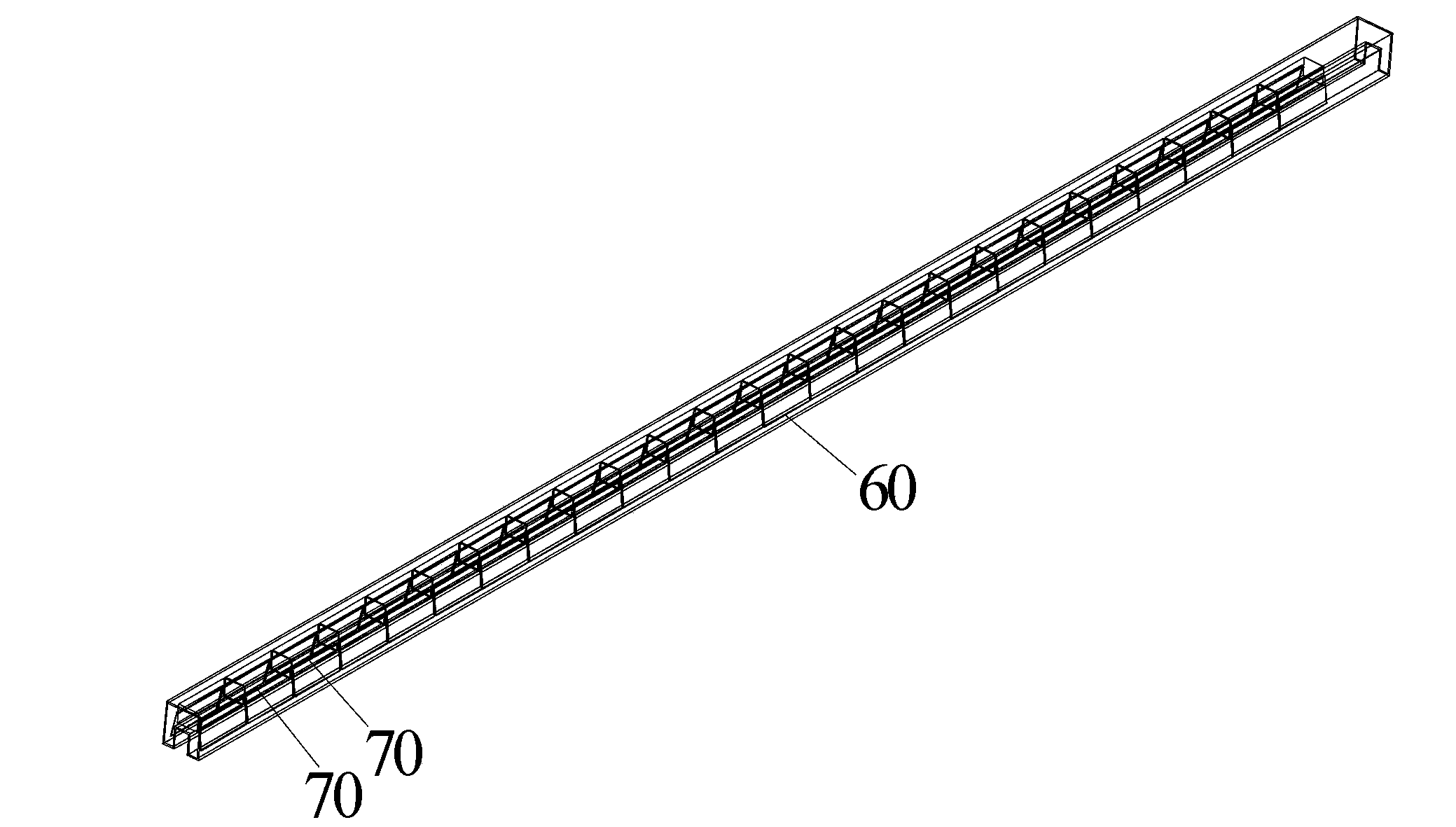

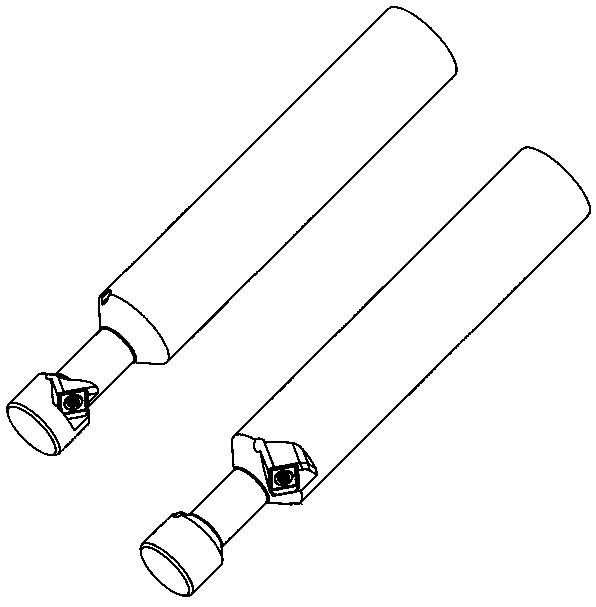

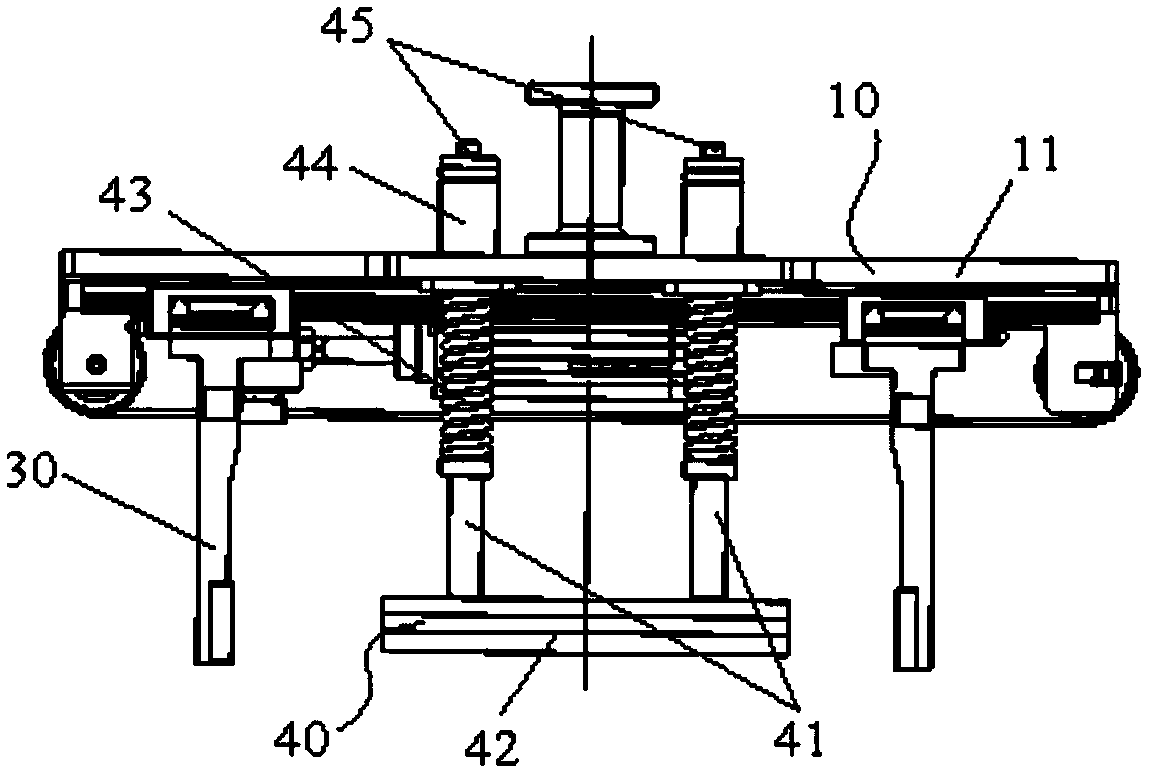

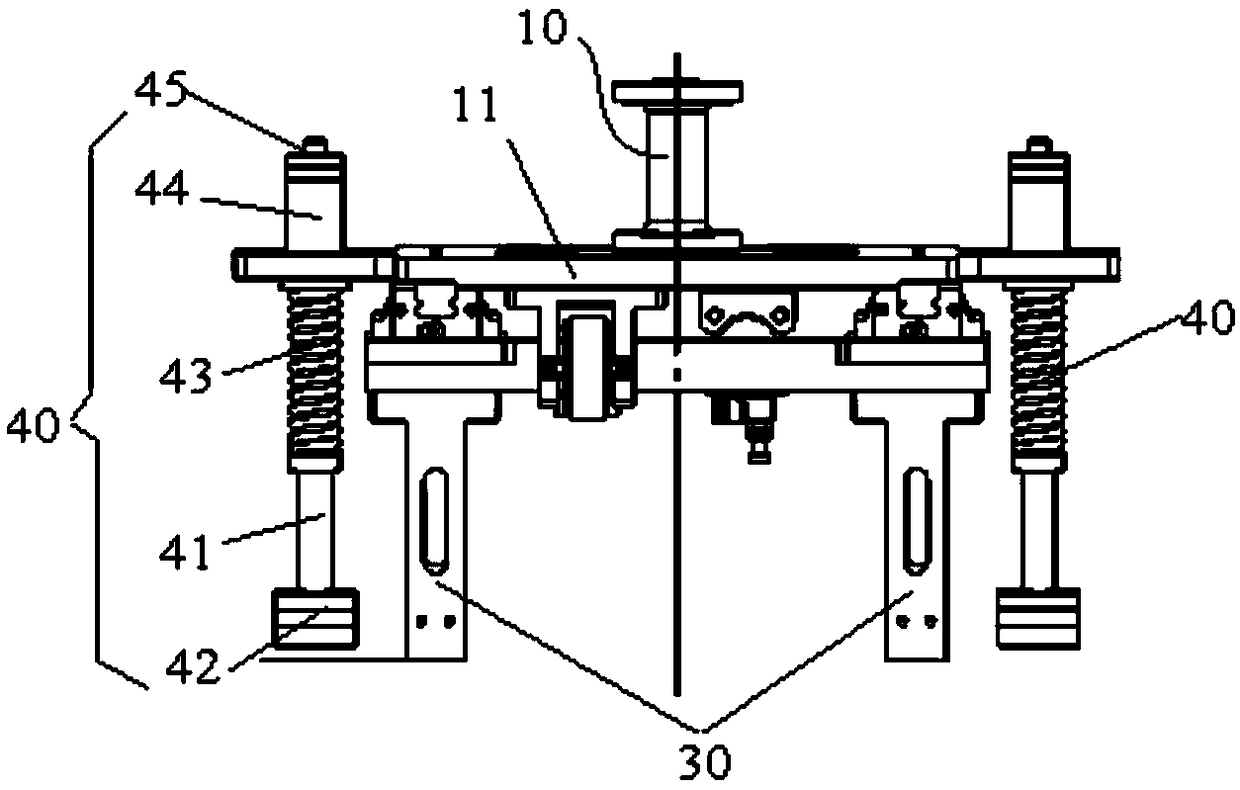

Novel multi-rapier weft insertion equipment of three-dimensional fabric loom and weaving method of novel multi-rapier weft insertion equipment

The invention discloses novel multi-rapier weft insertion equipment of a three-dimensional fabric loom and a weaving method of the novel multi-rapier weft insertion equipment. The novel multi-rapier weft insertion equipment comprises: a multi-rapier weft insertion and weft hooking assembly, an edge thread mechanism and a weft yarn guiding and tensioning mechanism, wherein the multi-rapier weft insertion and weft hooking assembly and the edge thread mechanism are arranged in parallel and oppositely; the weft yarn guiding and tensioning mechanism is arranged below the multi-rapier weft insertion and weft hooking assembly, wherein the multi-rapier weft insertion and weft hooking assembly further comprises a multi-rapier weft insertion mechanism and a multi-rapier weft hooking mechanism, which are arranged oppositely; the multi-rapier weft insertion mechanism is used for conveying weft yarns into the multi-rapier weft hooking mechanism; the multi-rapier weft hooking mechanism is used for hooking the weft yarns and conveying the weft yarns. The weaving method of the novel multi-rapier weft insertion equipment sequentially comprises a weft yarn guiding and tensioning procedure, a multi-rapier weft insertion procedure, a multi-rapier weft hooking procedure and an edge thread self-weaving procedure. By adopting the novel multi-rapier weft insertion equipment of the three-dimensional fabric loom and the weaving method of the novel multi-rapier weft insertion equipment, the blank of a weft insertion technology for weaving a three-dimensional fabric in the prior art is filled, and the technical problem that the working efficiency of weaving the three-dimensional fabric through a traditional technological process is low is solved.

Owner:FOSHAN CIHUI TONGDA SCI & TECH

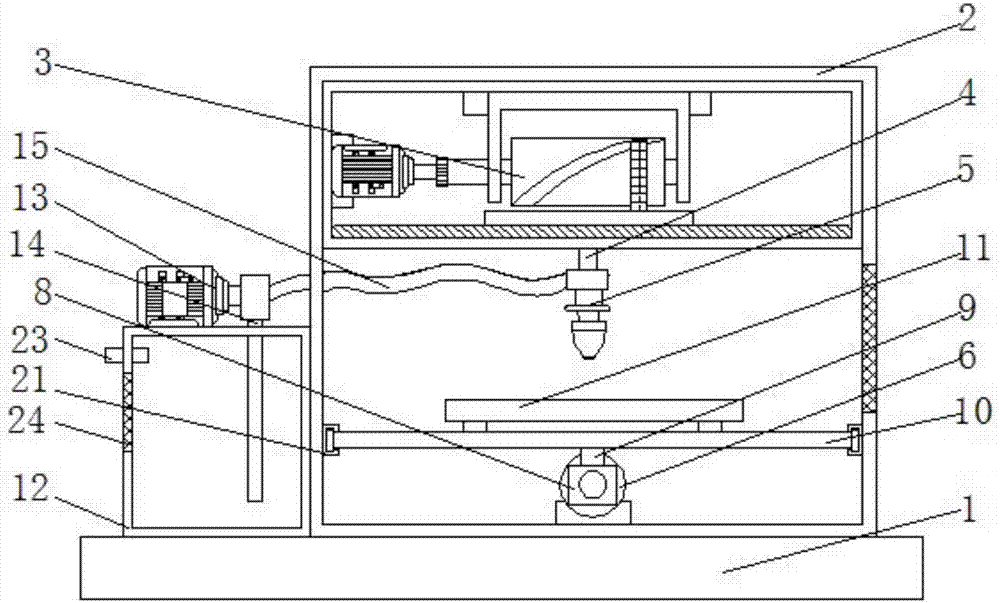

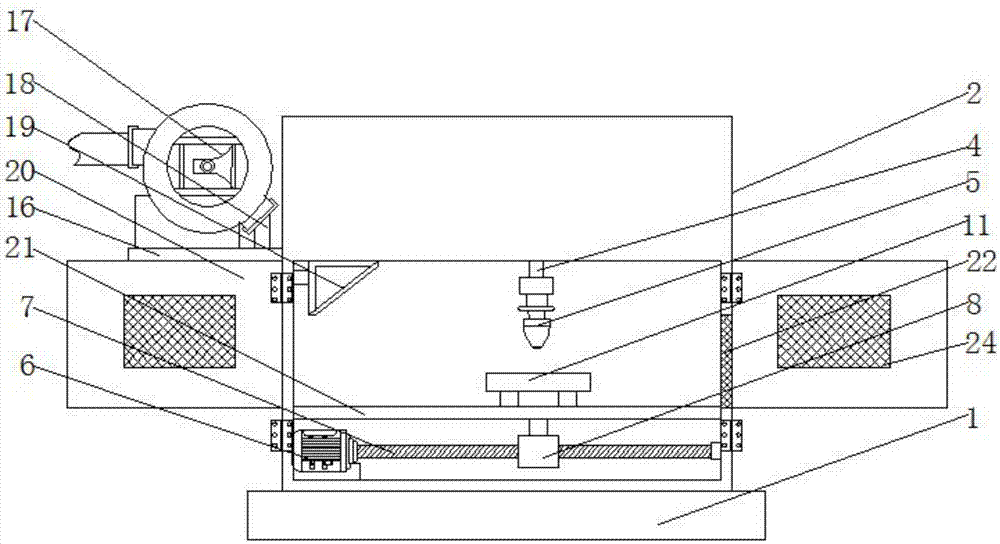

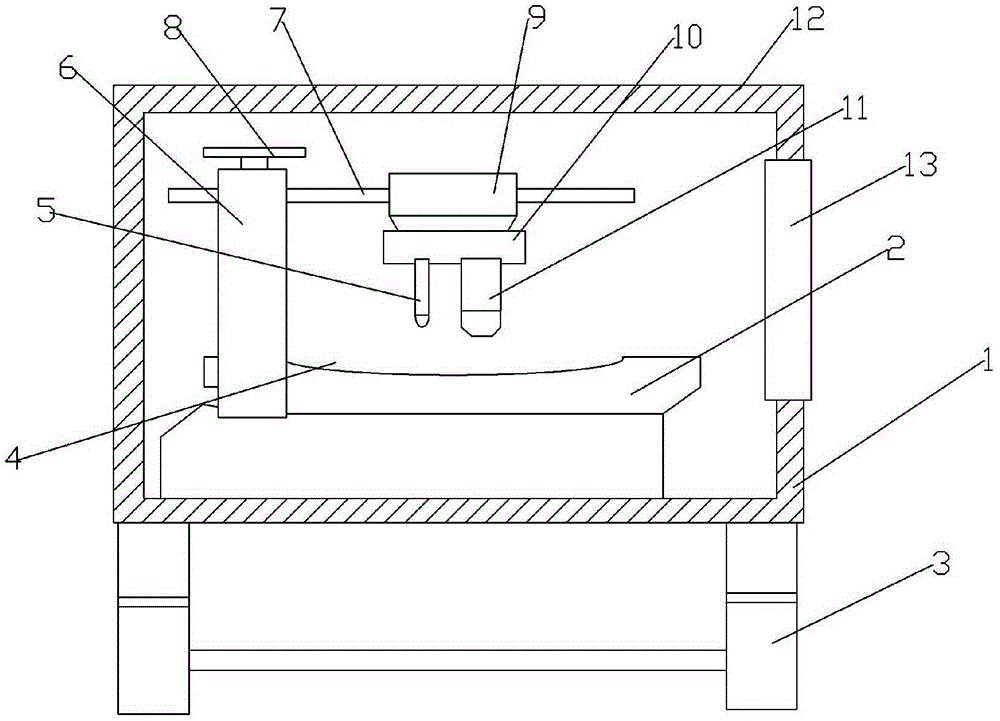

Paint spraying device for computer circuit board

InactiveCN107214026ASolve the problem of poor painting effectImprove work efficiencyLiquid surface applicatorsSpraying apparatusCouplingEngineering

The invention discloses a paint spraying device for a computer circuit board. The paint spraying device for the computer circuit board comprises a base; the top of the base is fixedly connected with a box body; the top of an inner cavity of the box body is fixedly connected with a transmission device; a supporting rod penetrates through the bottom of the transmission device; the bottom end of the supporting rod is fixedly connected with a paint spraying head; one side of the bottom of the inner cavity of the box body is fixedly connected with a first motor; an output shaft of the first motor is fixedly connected with a threaded rod through a coupling; the other end of the threaded rod is rotatably connected with one side of the inner cavity of the box body. The invention relates to the field of computers. According to the paint spraying device for the computer circuit board, the problem of poor paint spraying effect in the traditional paint spraying device for the computer circuit board is solved; the work efficiency of the paint spraying device is improved; a using effect of a user is achieved; the production efficiency of a factory is improved; the problem that the environment is poor when the conventional computer circuit board is subjected to paint spraying; the body health of working personnel is ensured; the work efficiency of the working personnel is indirectly improved.

Owner:合肥万伟达信息科技有限公司

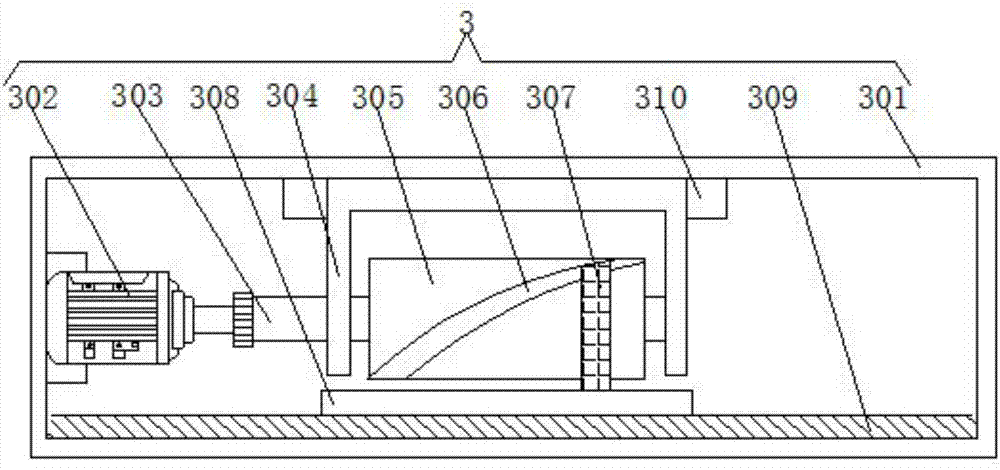

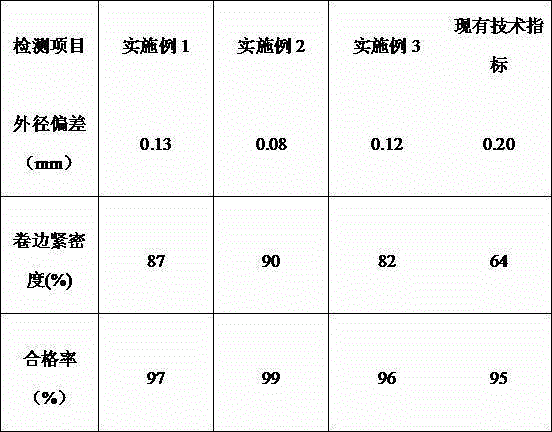

Production process of electric rice cooker

The invention discloses a production process of an electric rice cooker. The production process is characterized in that lubricating oil is added based on the mixing ratio to lubricate during the stretching process, and thus a strip-shaped stainless steel plate and a die can be sped up to slide. The production process has the advantages of inhibiting the thinning speed and preventing temperature from increasing. The heat sealing area of a rim-crimping machine can be controlled so as to control the size of a crimped circular arc; the temperature and humidity in rim crimping can be controlled, thereby reducing the phenomenon of poor rim crimping effect due to the deformation of the strip-shaped stainless steel plate; the temperature of a punch can be controlled during punching, thus the aperture of a formed hole meets the standard, and as a result, pressed ribs can be conveniently formed in the next step; the ribs are pressed in a combination manner, so that the problem of low working efficiency can be solved. The production process has the advantages of being consistent in product specification, high in working efficiency, huge in market potential and broad in prospect.

Owner:HUIZHOU UNIV

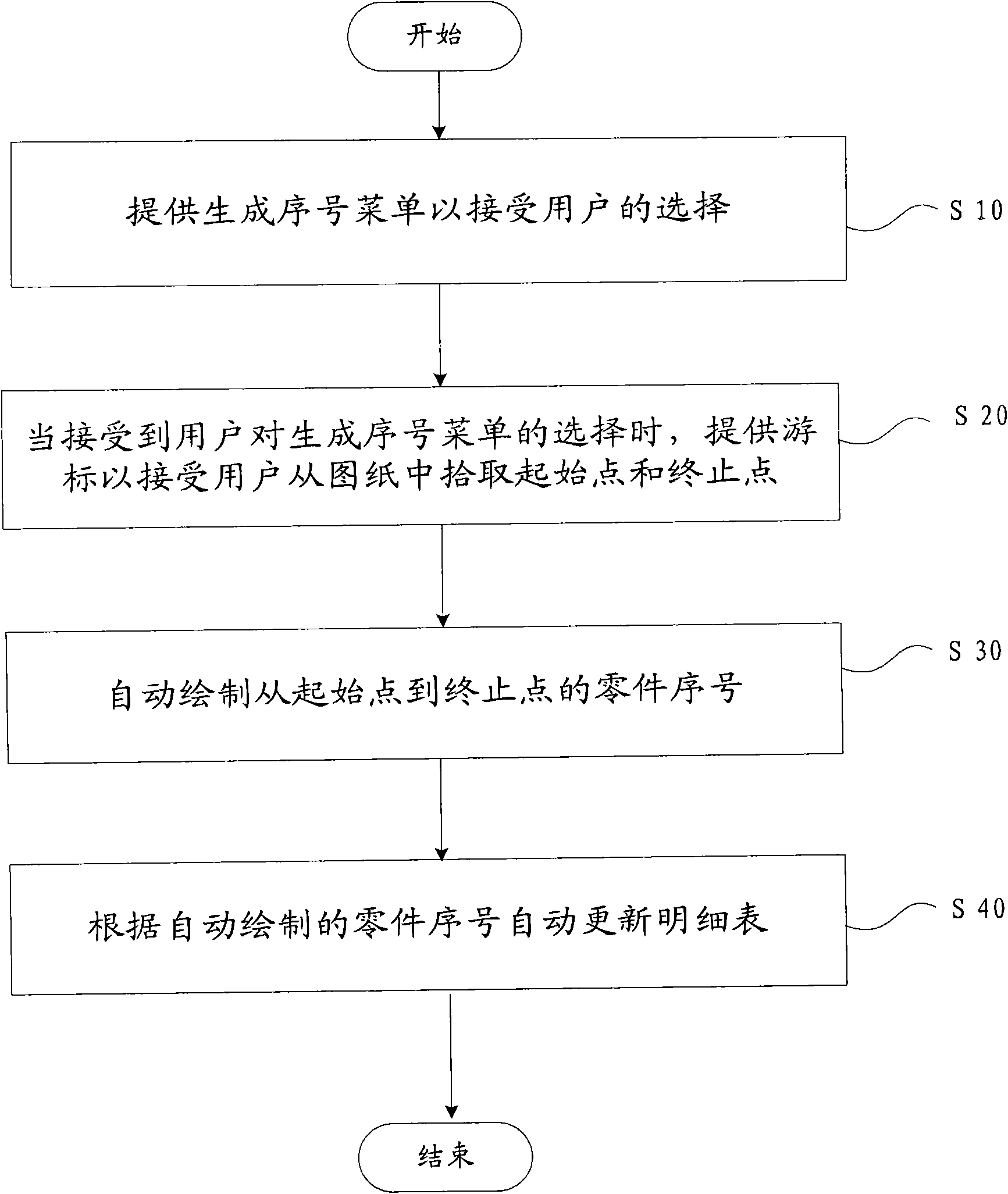

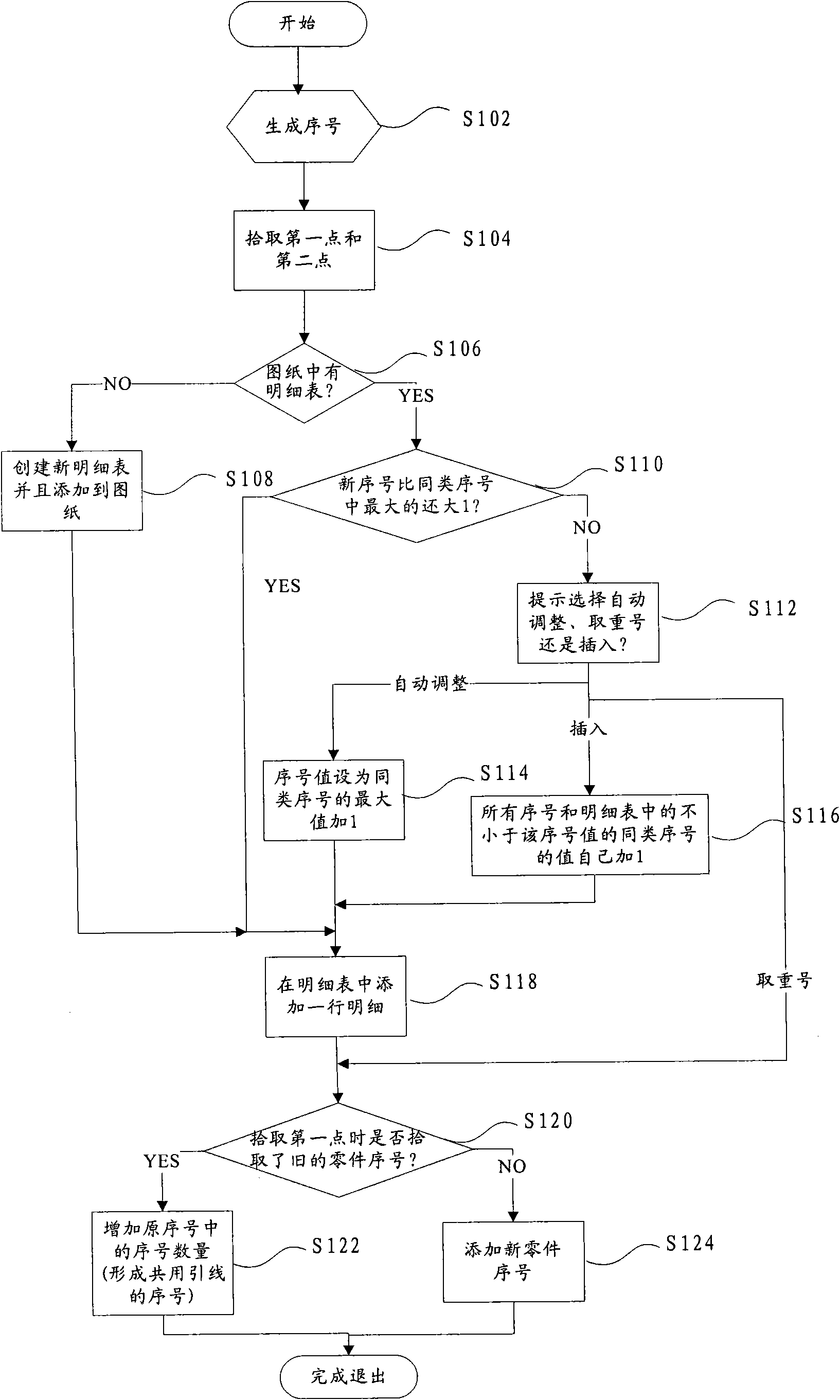

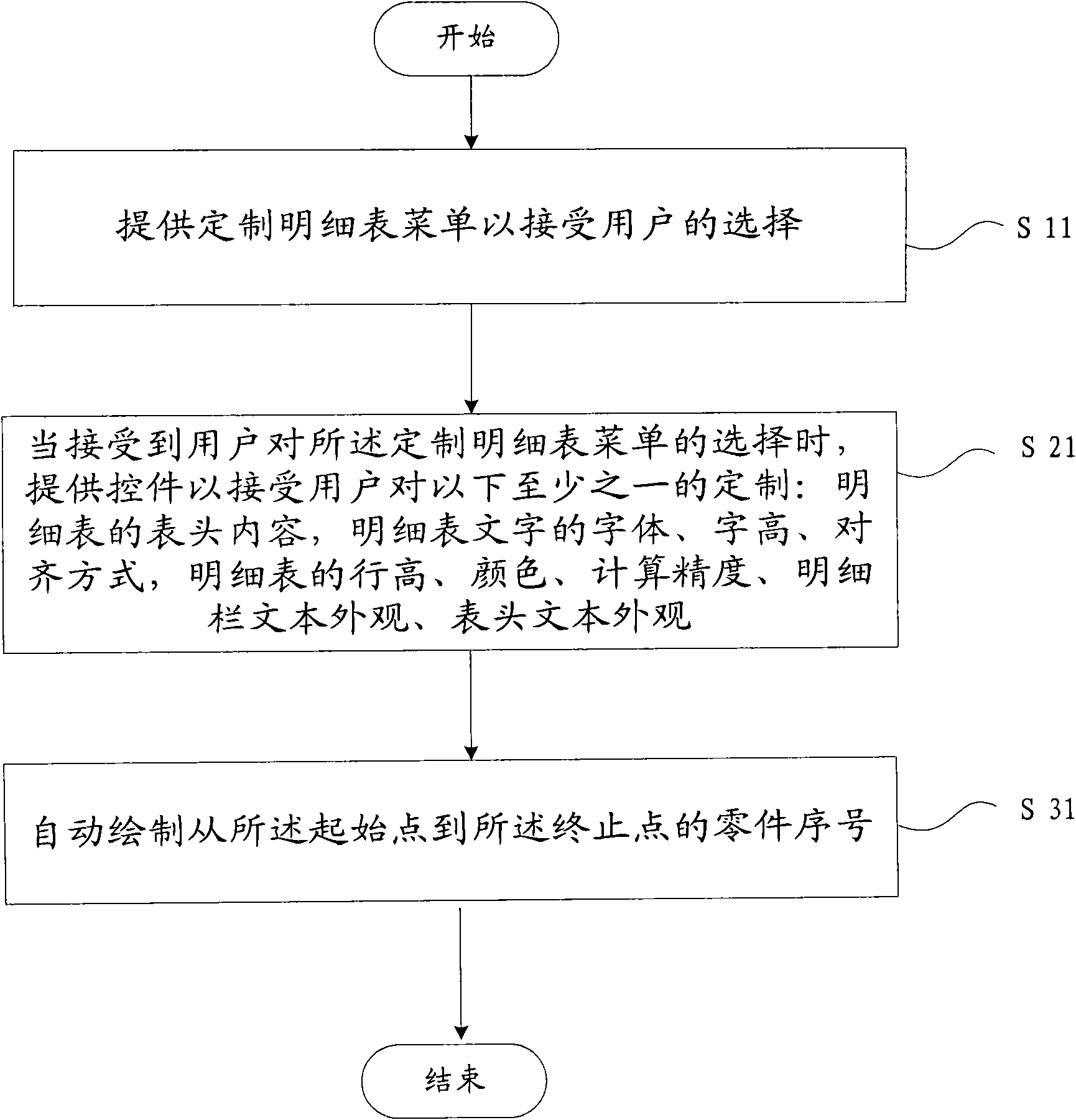

Method for processing part sequence number and list of CAD

InactiveCN101661516ASolve low work efficiencyDrawing shortcutSpecial data processing applicationsWorkloadHand operations

The invention provides a method for processing a part sequence number and a list of CAD, which comprises the following steps: providing a generation sequence number menu to receive selection of a user; when the selection of the generation sequence number menu by the user is received, providing a cursor to accept the user to pickup a start point and an end point from a drawing; drawing the part sequence number from the start point to the end point automatically; and updating the list automatically according to the part sequence number drawn automatically. The method solves the problems of low work efficiency, high labour intensity and high error probability in manual operation, thereby achieving the effect of fast drawing, lightening the workload of a designer, and reducing the probabilityof errors.

Owner:CAXA TECH

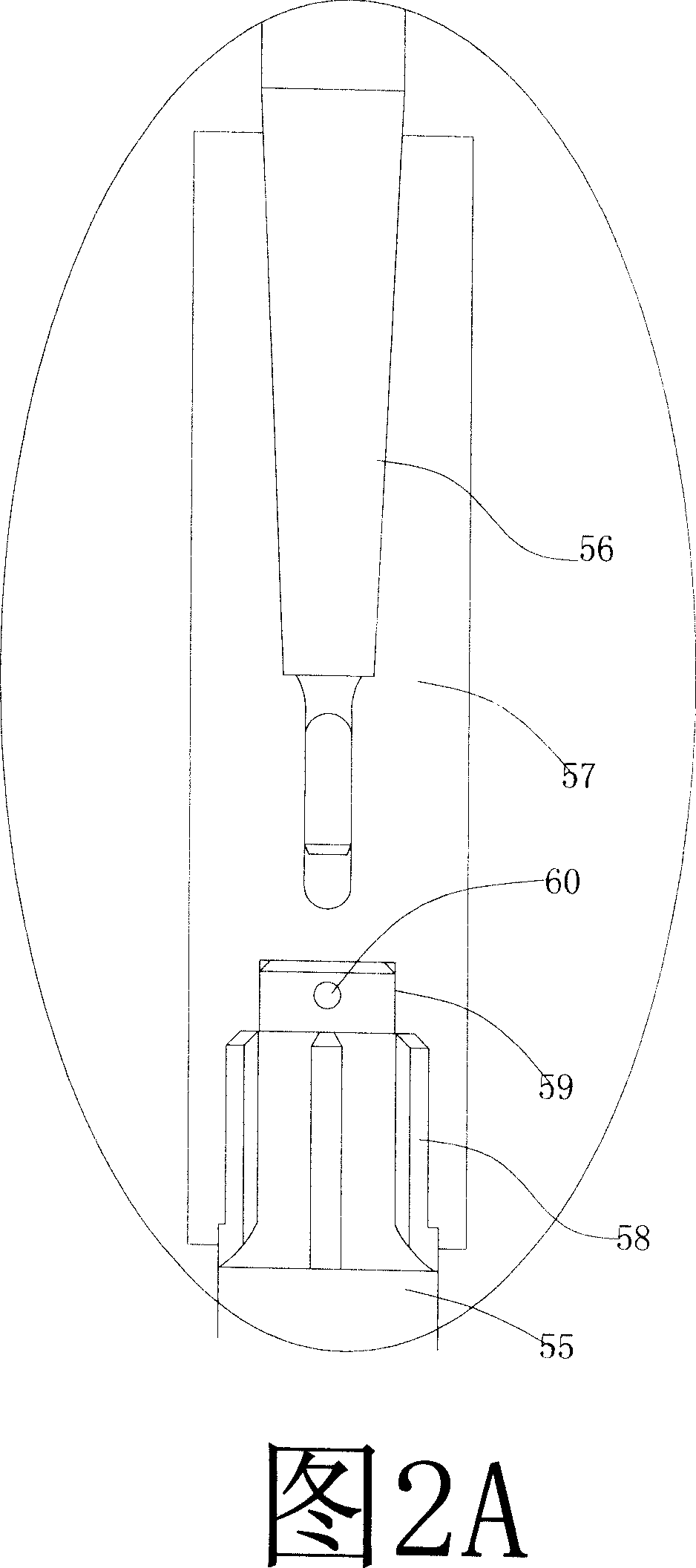

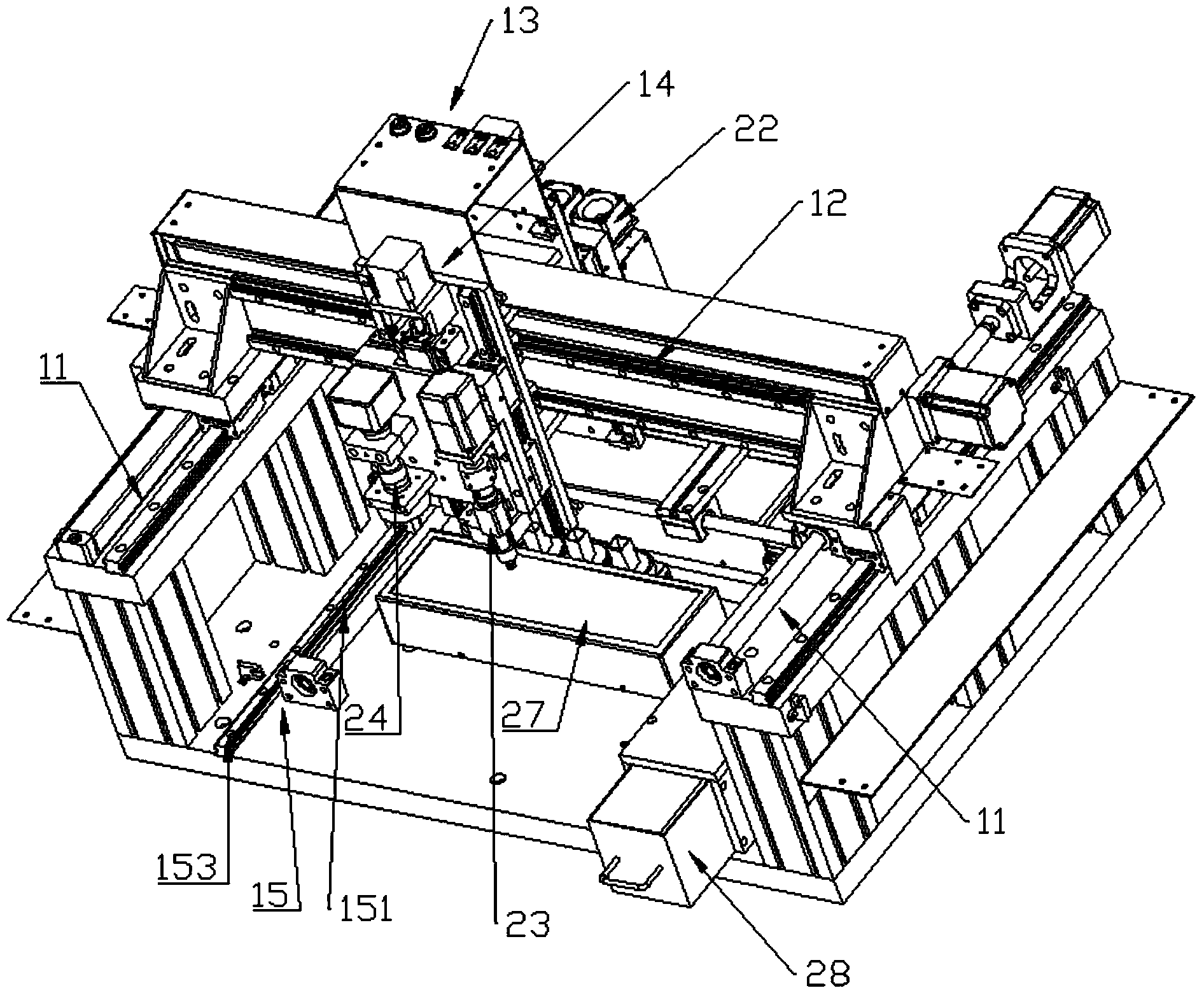

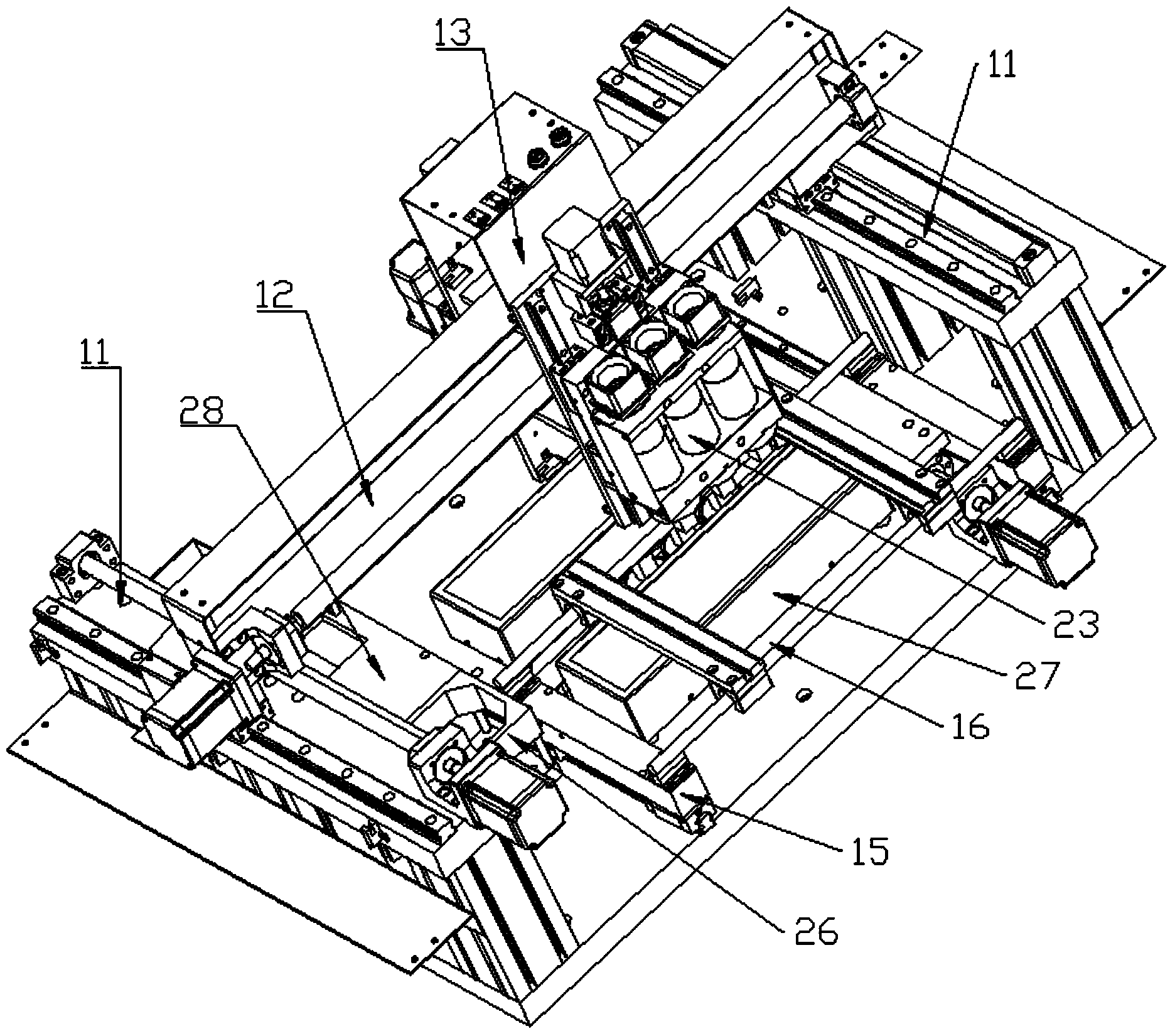

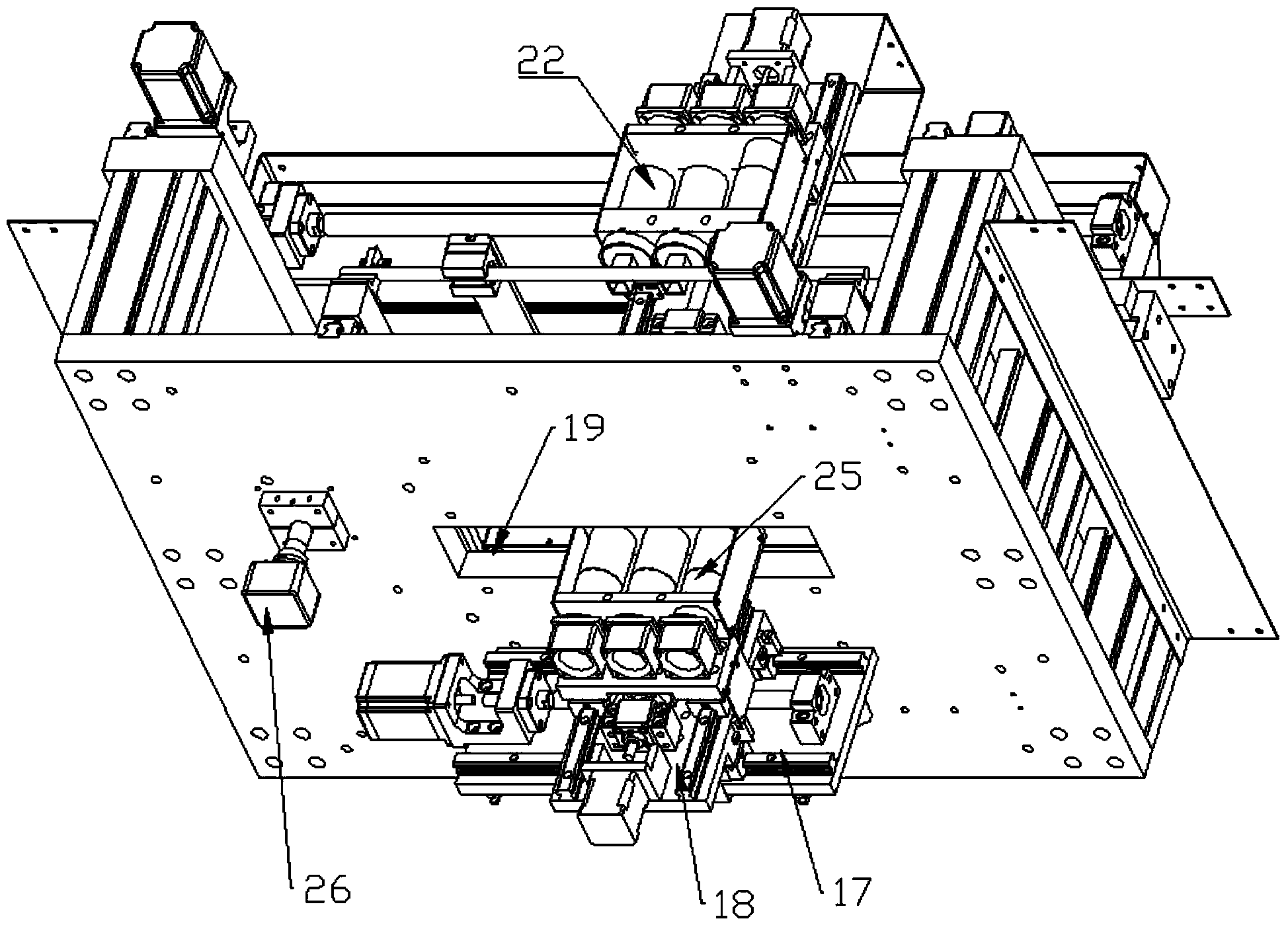

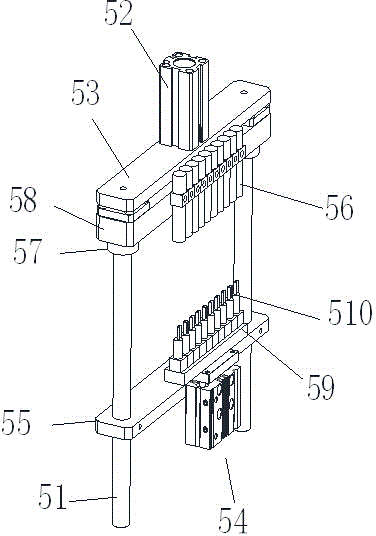

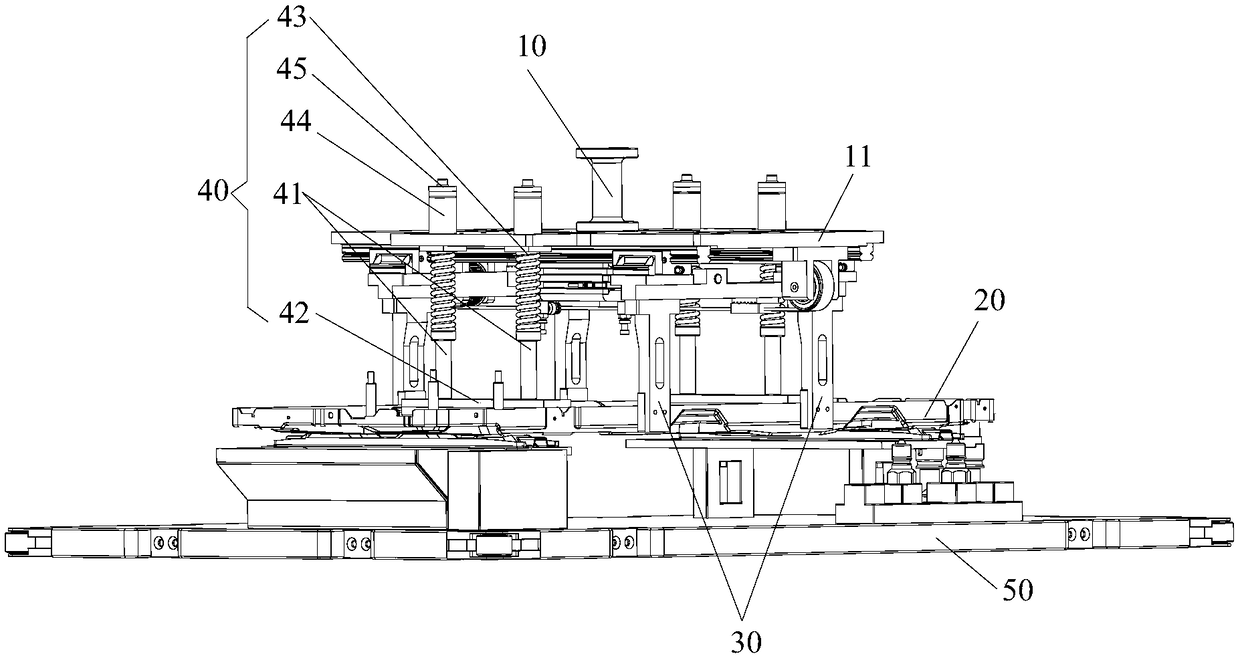

Eight-shaft-moving chip repairing and attaching device and method with visual positioning function

InactiveCN103717005ASolve low work efficiencyImprove work efficiencyPrinted circuit assemblingEngineeringVisual perception

The invention discloses an eight-shaft-moving chip repairing and attaching device and method with a visual positioning function. The device is provided with a first linear guide rail pair, a second linear guide rail pair, a third linear guide rail pair, a fourth linear guide rail pair, a fifth linear guide rail pair, a sixth linear guide rail pair, a seventh linear guide rail pair, an eighth linear guide rail pair, a tray assembly, a first heating assembly, a second blowing assembly, a third heating assembly, a first visual positioning assembly, a second visual positioning assembly and a chip taking and attaching assembly. Multi-dimensional motion trails are provided by the several linear guide rail pairs so that the tray assembly, the heating assemblies, the visual positioning assemblies and the chip taking and attaching assembly can be controlled by a controller to achieve positioning, heating, taking and placing flexibly, and therefore the sealing-off and chip attaching function can be achieved. Because the several linear guide rail pairs and the heating assemblies are arranged, a plurality of PCBs or chips can be operated at the same time, and accordingly the sealing-off and chip attaching efficiency can be greatly improved, and human cost can be greatly reduced as well.

Owner:古国柱

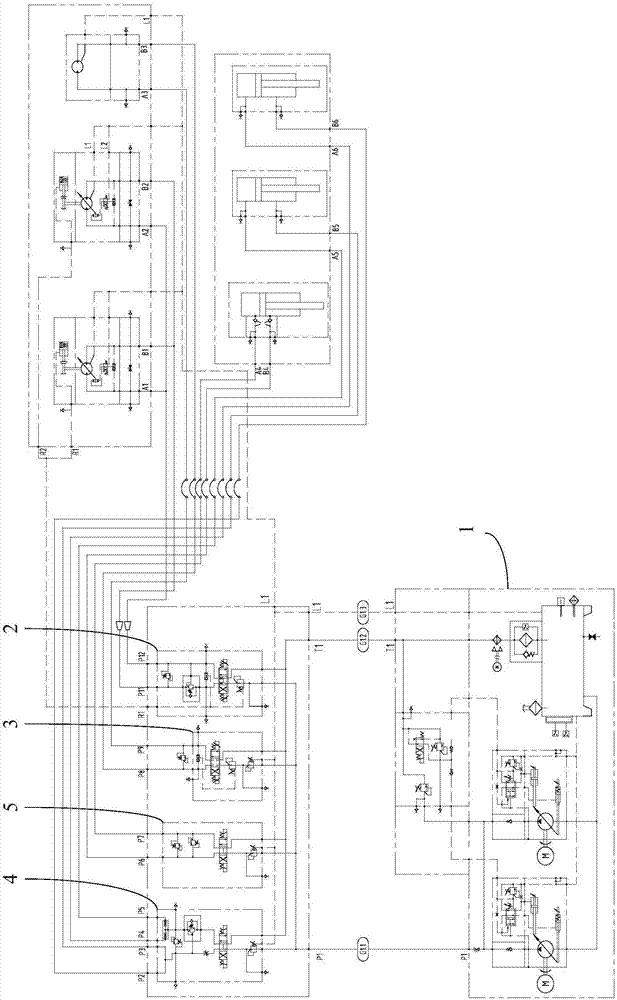

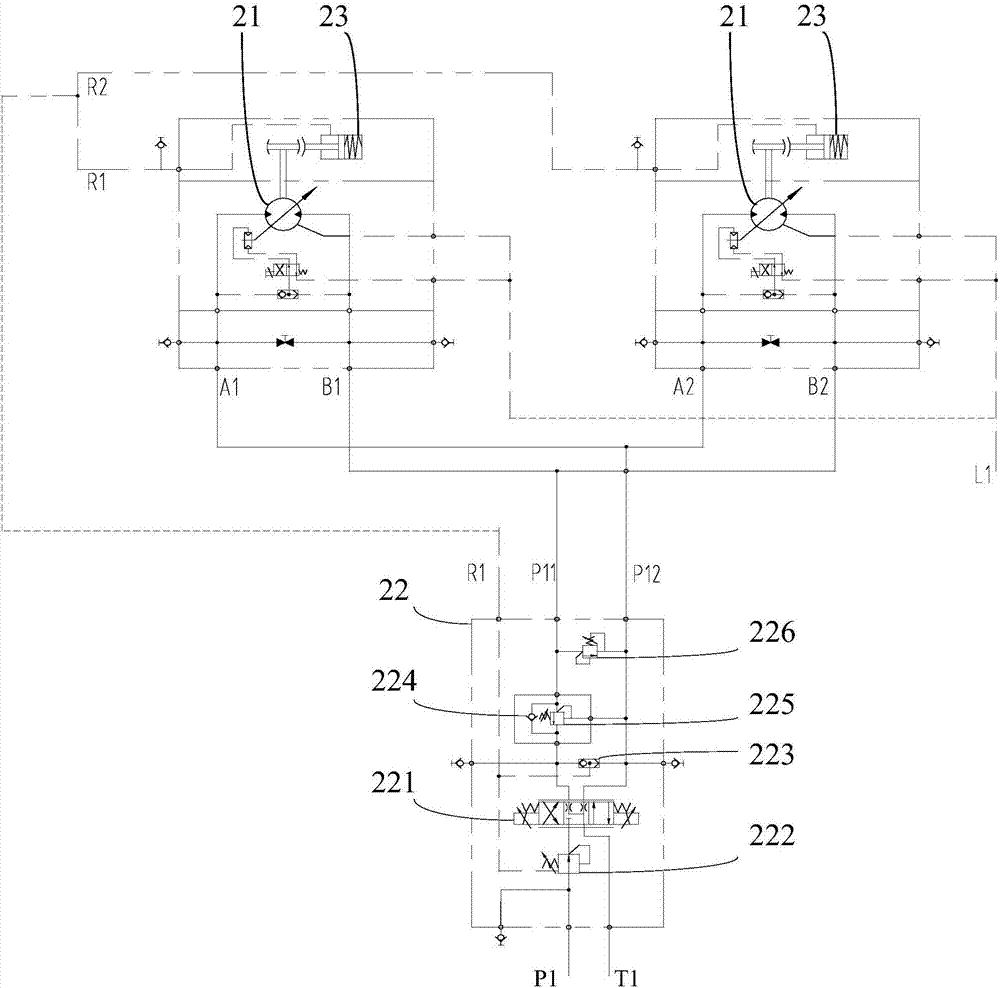

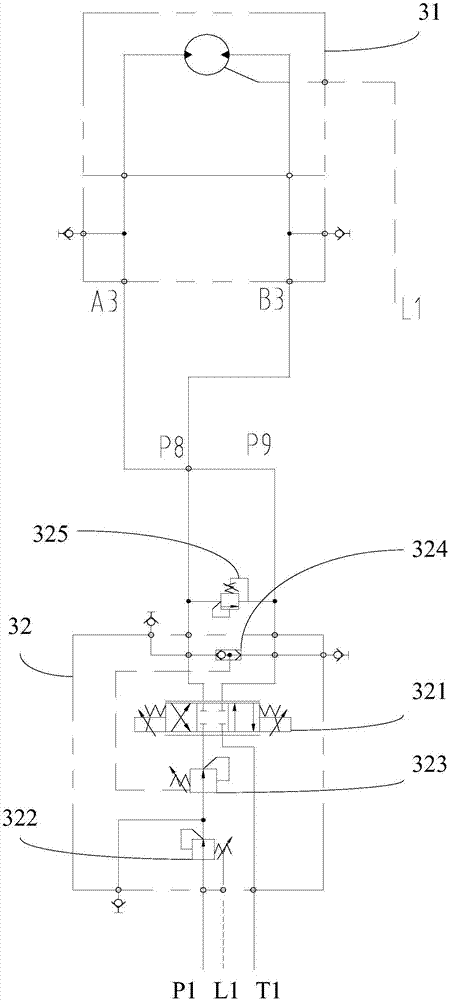

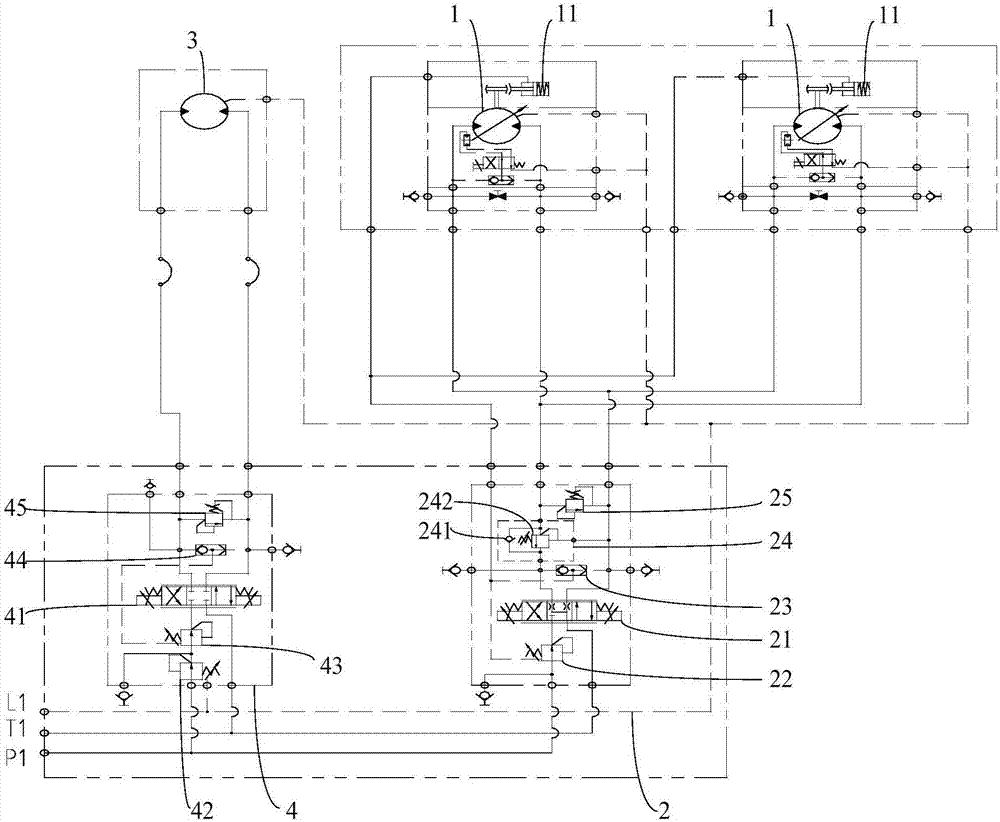

Hydraulic system of crude oil outward transportation device

ActiveCN107013516AAvoid cooperatingSolve low work efficiencyServomotor componentsServomotorsElectricityControl engineering

The invention discloses a hydraulic system of a crude oil outward transportation device and belongs to the field of hydraulic control. The hydraulic system of the crude oil outward transportation device comprises a hose winch hydraulic system, a discharging pipe extending and retracting hydraulic system and a discharging pipe lifting hydraulic system. The hose winch hydraulic system comprises winch motors and a winch control module. The discharging pipe extending and retracting hydraulic system comprises a discharging pipe motor and a discharging pipe extending and retracting control module. The discharging pipe lifting system comprises a first discharging pipe oil cylinder, a second discharging pipe oil cylinder and a discharging pipe lifting control module. The hydraulic system further comprises a controller. The controller is electrically connected with a first three-position four-way electromagnetic reversing valve and a second three-position four-way electromagnetic reversing valve. The controller is arranged to achieve that when the controller controls the first three-position four-way electromagnetic reversing valve through a first electrical signal to enable the winch motor to work, the controller controls the second three-position four-way electromagnetic reversing valve through a second electrical signal to enable the discharging motor to work. The hydraulic system of the crude oil crude oil outward transportation solves the problem that synchronous working of the crude oil outward transportation device is difficult.

Owner:WUHAN MARINE MACHINERY PLANT

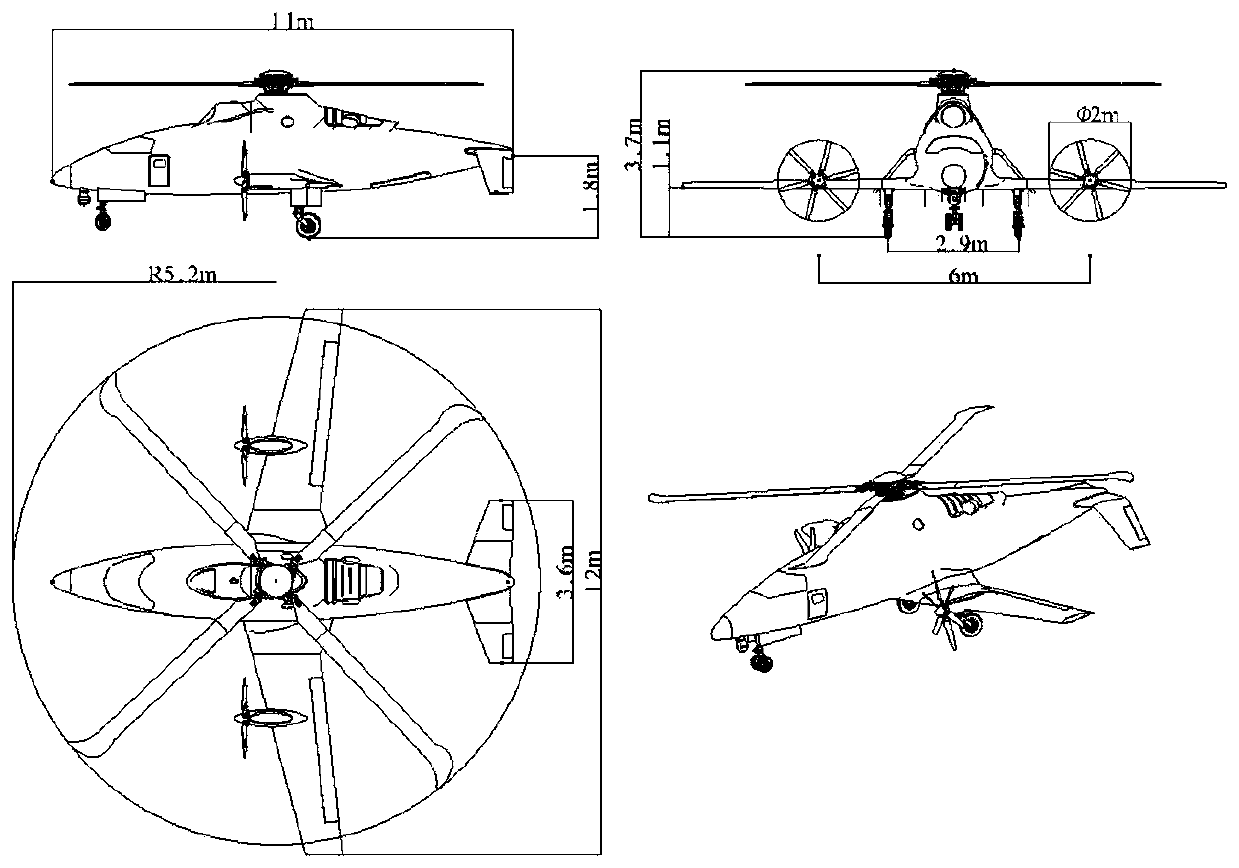

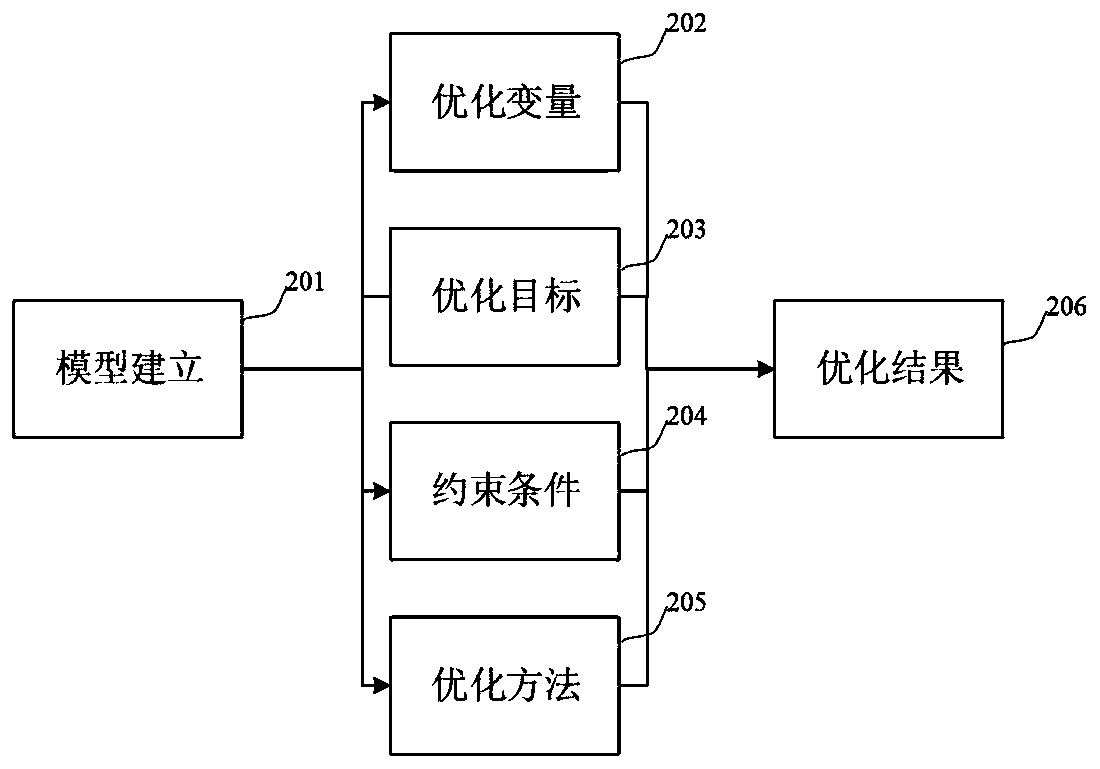

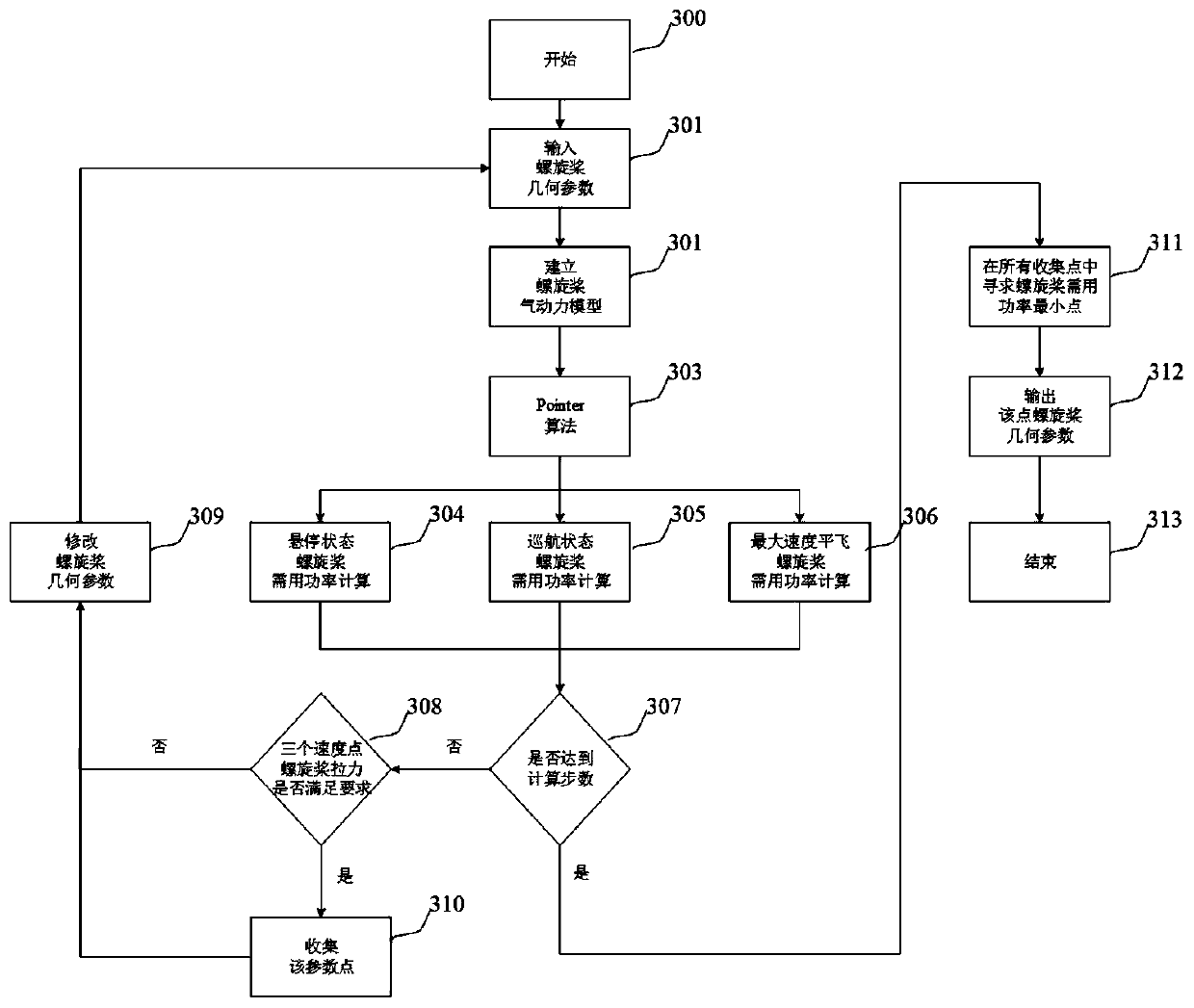

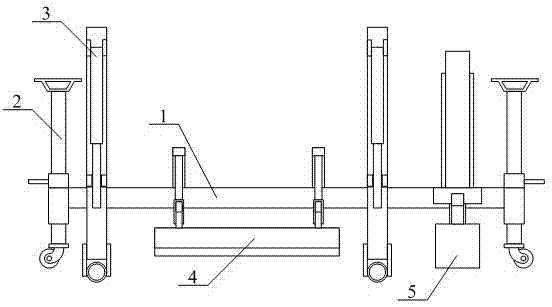

Method for optimizing propulsion propellers on both sides of composite thrust configuration helicopter

ActiveCN109969425ASolve low work efficiencyImprove work efficiencyPropellersSustainable transportationPropellerForward flight

The invention discloses a method for optimizing propulsion propellers on both sides of a composite thrust configuration helicopter. The method comprises: the preset propeller geometric parameters areinputted, a aerodynamic model of the propellers on both sides is established, by introducing a pointer algorithm, the required power of the propellers in hover state, cruise state and maximum speed forward flight state is calculated respectively, and then the parameter points satisfying the two constraints are searched by changing the geometric parameters within a reasonable range, after the preset calculation steps are completed, the geometric parameters at the minimum power point of the collection point are output. The method and a system can conveniently solve the problem that the working efficiency of the propellers on both sides of the composite thrust configuration helicopter is low under different flight states, thereby further improving the flight performance.

Owner:NANJING UNIV OF AERONAUTICS & ASTRONAUTICS

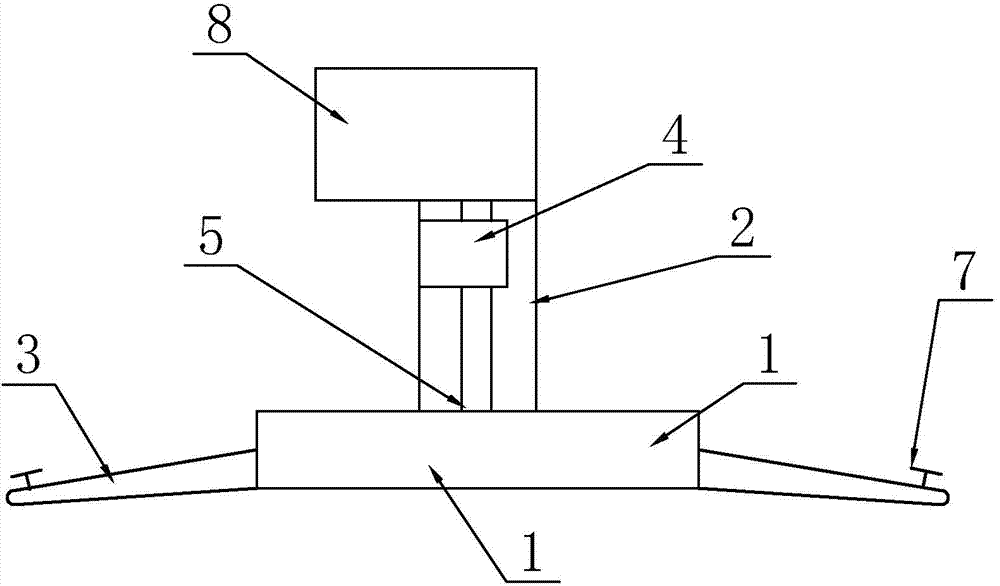

Multi-purpose road slope finishing machine

ActiveCN107326949AImprove practicalityEasy to moveMechanical machines/dredgersTerrainAgricultural engineering

The invention provides a multi-purpose road slope finishing machine. The multi-purpose road slope finishing machine comprises a base, adjustable movable wheel devices, slope compacting roller devices, a ditching plate device and an adjustable soil loosening wheel device, wherein the adjustable movable wheel devices are separately welded on the left part and the right part of the base; the slope compacting roller devices are separately in bolt connection on the left part and the right part of the front surface of the base; and the ditching plate device is in bolt connection on the middle position of the front surface of the base. The multi-purpose road slope finishing machine has the beneficial effects that: the slope compacting roller devices are arranged, so that road slopes of different angles are conveniently finished, and practicability of the road slope finishing machine is improved, and therefore, the multi-purpose road slope finishing machine is suitable for finishing road slopes of various terrains, and the solves the single function problem; and the adjustable movable wheel devices are arranged, so that the road slope finishing machine conveniently moves, labor intensity of working staff is reduced, and the problem that the road slope finishing machine is inconvenient to move is solved.

Owner:海安五一家庭农场

Hydraulic system for automatic hose arrangement device for crude oil exportation winch

ActiveCN107188062ASolve low work efficiencyReduce errorsWinding mechanismsMagnetic exchangeElectricity

The invention discloses a hydraulic system for an automatic hose arrangement device for a crude oil exportation winch and belongs to the field of hydraulic control. The hydraulic system comprise a hose winch hydraulic system and a hose arrangement device hydraulic system. The hose winch hydraulic system comprises a winch motor and a winch control module. The hose arrangement device hydraulic system comprises a hose arrangement motor and a hose arrangement control module. The hydraulic system further comprises a controller. The controller is electrically connected with a first three-position four-way magnetic exchange valve and a second three-position four-way magnetic exchange valve. The controller is configured that the winch motor and the hose arrangement motor operate synchronously by controlling the first three-position four-way magnetic exchange valve and the second three-position four-way magnetic exchange valve. The hydraulic system solves the problem that the work efficiency of a crude oil exportation device is low.

Owner:WUHAN MARINE MACHINERY PLANT

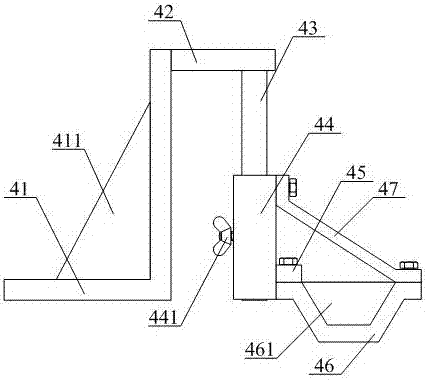

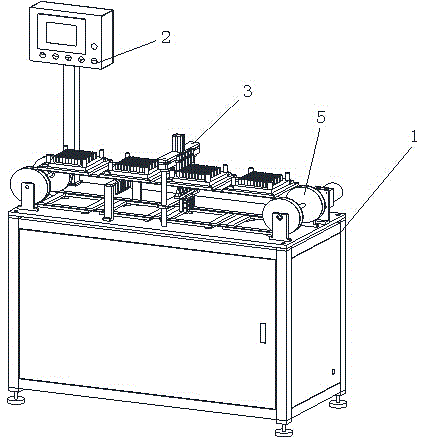

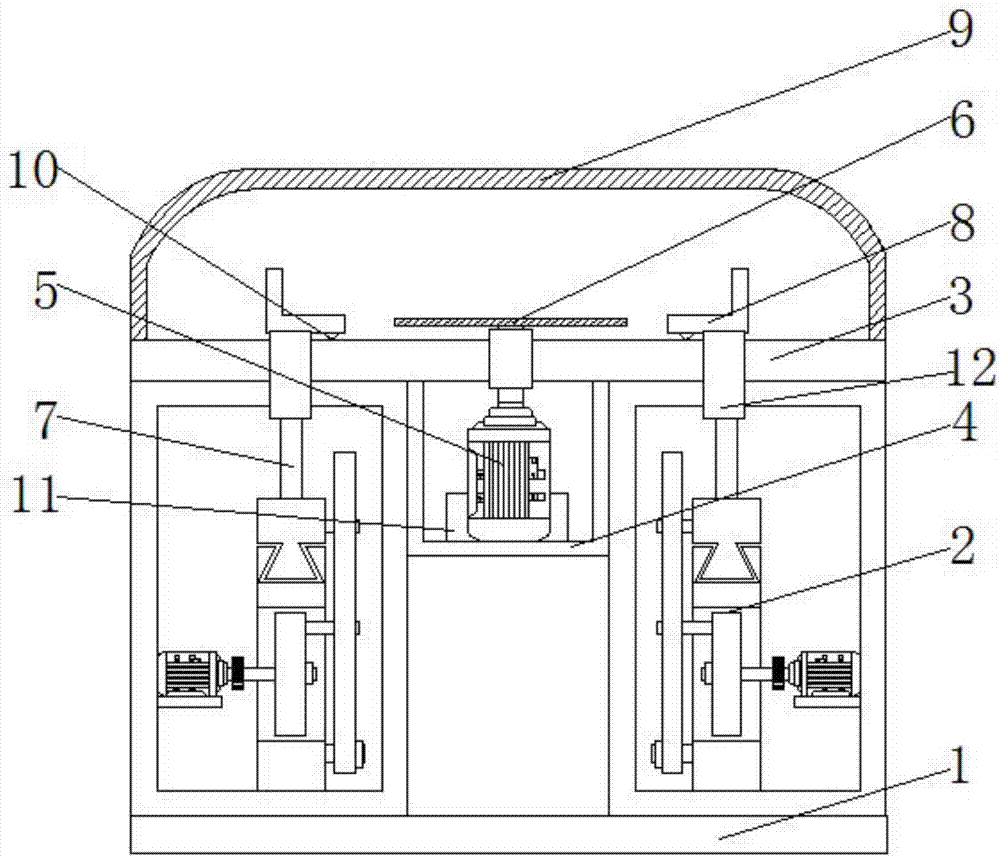

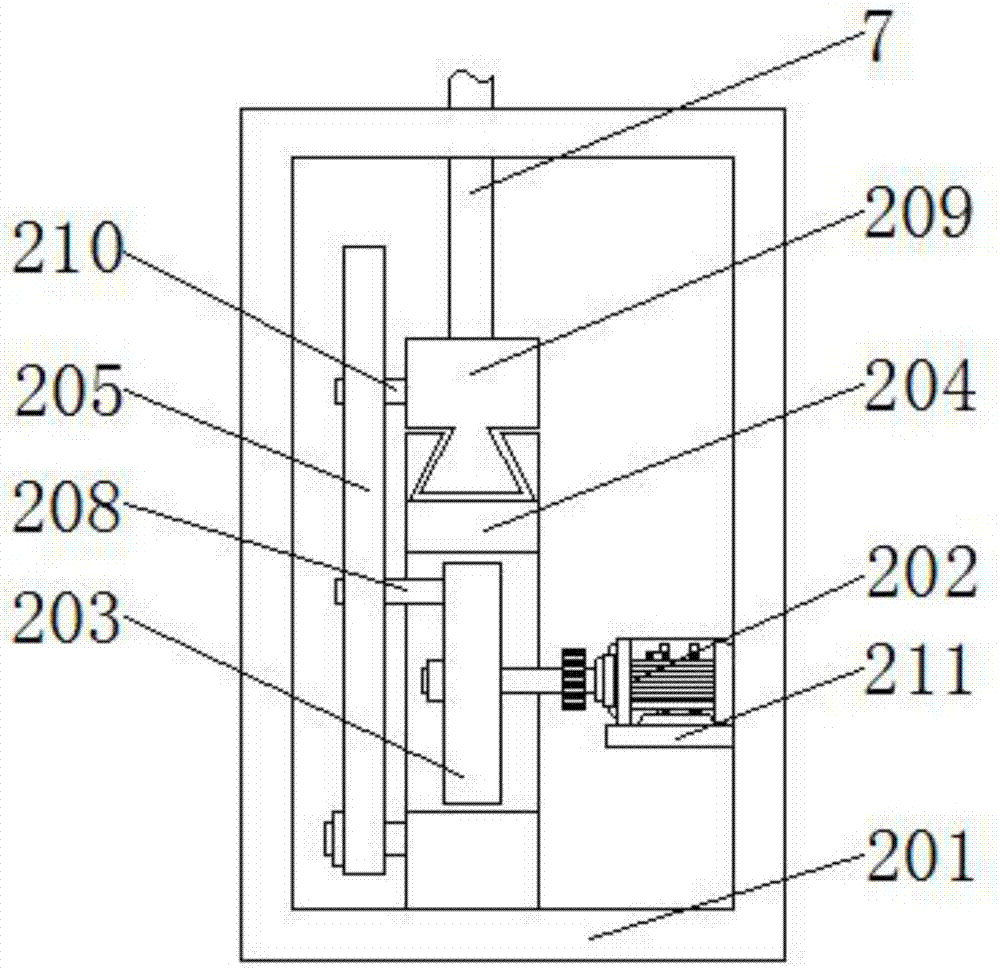

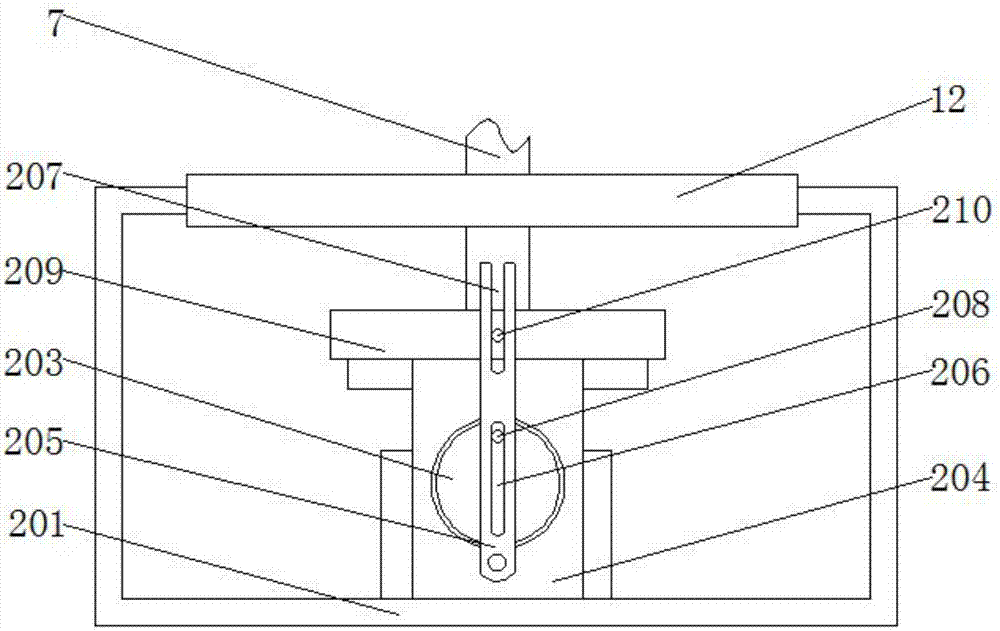

Smoke testing machine for electronic cigarette

The invention belongs to the field of machinery and electronic cigarettes and provides a smoke testing machine for an electronic cigarette. The smoke testing machine for the electronic cigarette comprises a machine frame assembly, a control assembly, a transmission assembly, a test assembly and a gas suction assembly, wherein the control assembly, the transmission assembly and the test assembly are all arranged on the machine frame assembly; the control assembly is electrically connected with the transmission assembly and the test assembly and is used for controlling the transmission assembly and the test assembly. The technical scheme provided by the invention has the advantages of high working efficiency and full mechanical automated operation.

Owner:SHENZHEN KINGRAY LASER EQUIP

Machining grinding tool for metal tube

PendingCN107971840AEasy to fixSolve the problem of easy damage to metal pipesRevolution surface grinding machinesGrinding drivesEngineeringGrinding wheel

The invention discloses a machining grinding tool for a metal tube. The machining grinding tool comprises a base, a stand column is connected to the right side of the top of the base, a rotating shaftis connected to the inner side of the bearing in a penetrating manner, a motor is connected to the left side of the rotating shaft, a clamping plate is connected to the inner side of a strip-shaped groove in a penetrating manner, a spring is connected between the clamping plate and the inner wall of the groove, a supporting column is connected to the front face of a sliding block, a movable box is connected to the top of the outer side of the supporting column in a sleeving manner, a transverse rod is connected to the right side of the movable box in a penetrating manner, a gear is connectedto the outer side of a transverse rod in a sleeving manner, and a sanding wheel is connected to the top of the connecting rod. Through matched use of the clamping plate, the clamping block, the groove, the strip-shaped groove and the spring, the problem that the metal tube is prone to being damaged when the metal tube is fixed through a traditional grinding device is solved; and through matched use of the rotating shaft, the motor, the rotary disc, a sliding groove, a sliding rail, the sliding block and a sanding wheel, the problem that traditional grinding equipment needs to be repeatedly ground, and consequently the working efficiency is low is solved.

Owner:郑州博尔德磨料磨具有限公司

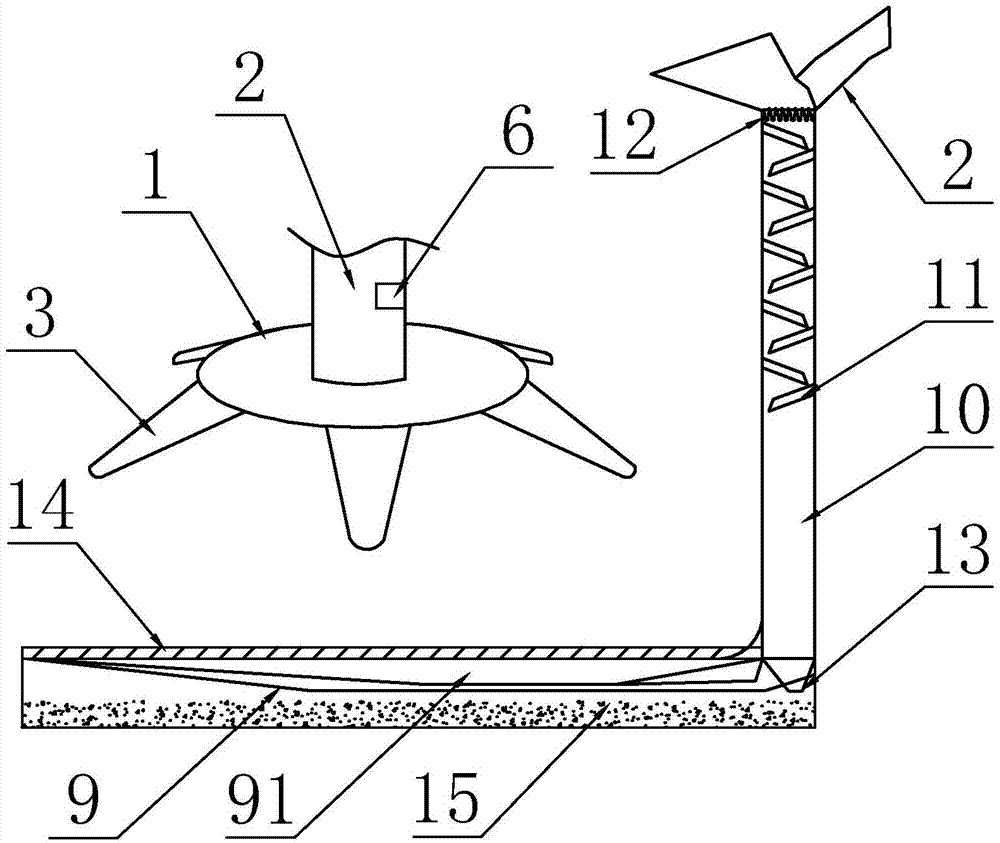

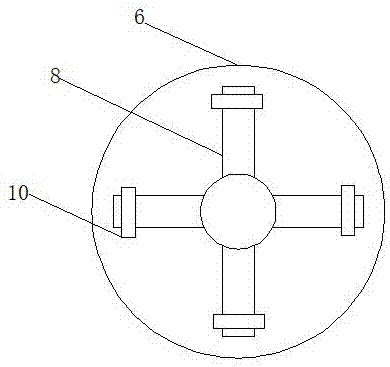

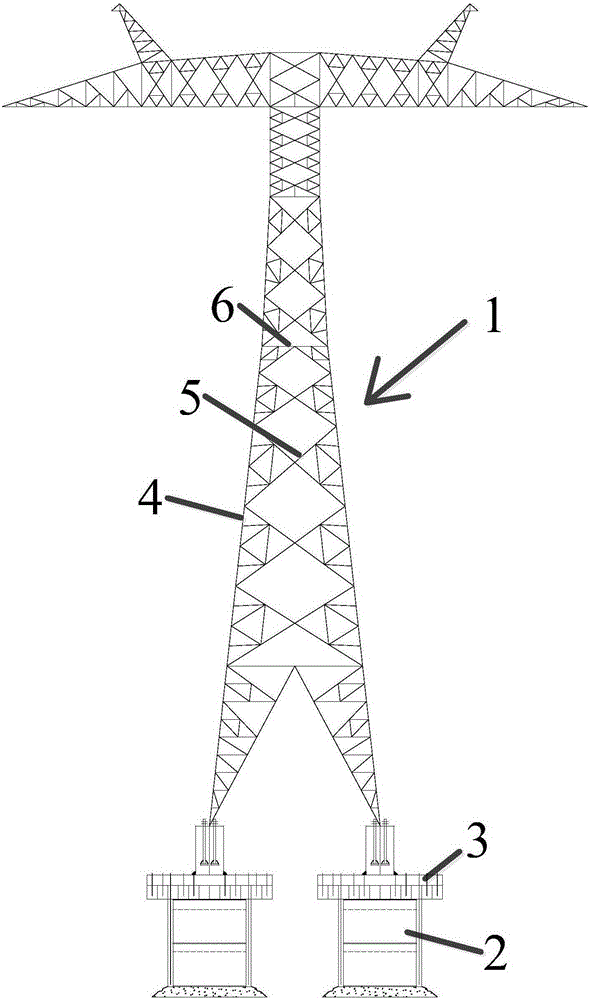

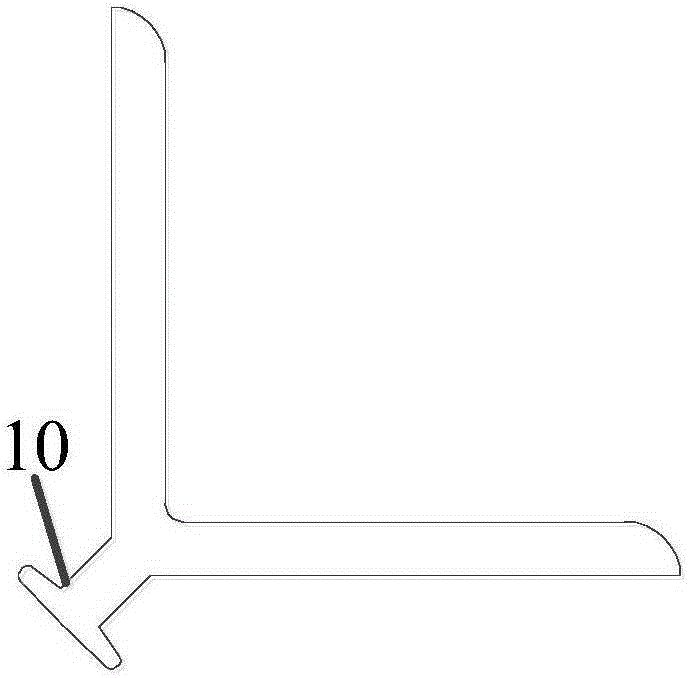

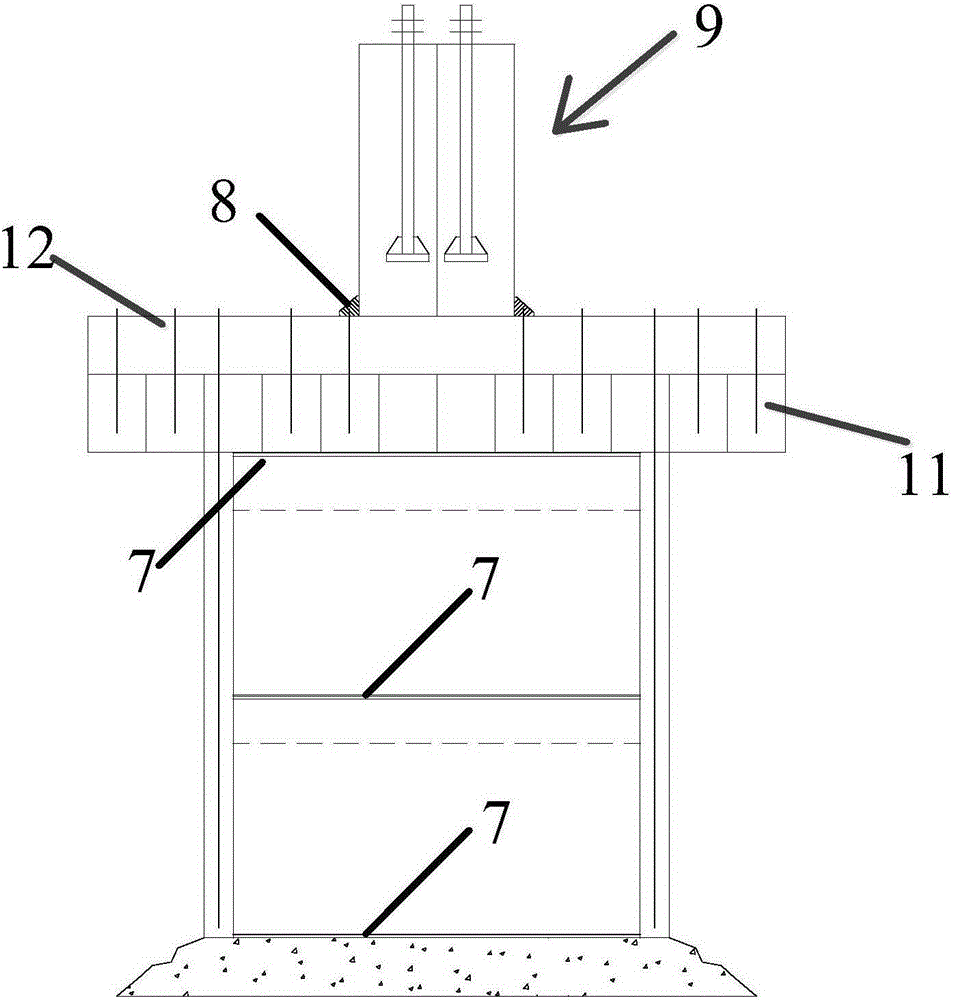

Assembly type micro open caisson foundation for power transmission tower in soft soil area

ActiveCN105350561AMeet fixed requirementsEasy to transportFoundation engineeringTowersTowerPower transmission

The invention relate to an assembly type micro open caisson foundation for a power transmission tower in a soft soil area. The power transmission tower comprises a vertically-arranged tower body and a cross arm which is arranged at the upper end of the tower body and is perpendicular to the axial direction of the tower body. The foundation is composed of a micro open caisson and a bearing table arranged at the upper end of the micro open caisson. The tower body is of a truss structure formed by connecting a main material, inclined materials and a cross material perpendicular to the main material in a staggered manner, and the main material is angle steel with a Y-shaped cross section. The foundation is arranged at the four tower feet of the power transmission tower. A fixing assembly for fixing the tower body is arranged at the upper end of the bearing table. The assembly type micro open caisson foundation for the power transmission tower in the soft soil area has the beneficial effects of meeting the fixing requirement of the power transmission tower, and being low in production cost, convenient to mount, firm and low in environment pollution.

Owner:CHINA ELECTRIC POWER RES INST +2

Automatic discharging device

ActiveCN103625827AAvoid clutterAvoid the problem of pins locking each otheChutesElectrical polarityEngineering

Owner:GREE ELECTRIC APPLIANCES INC

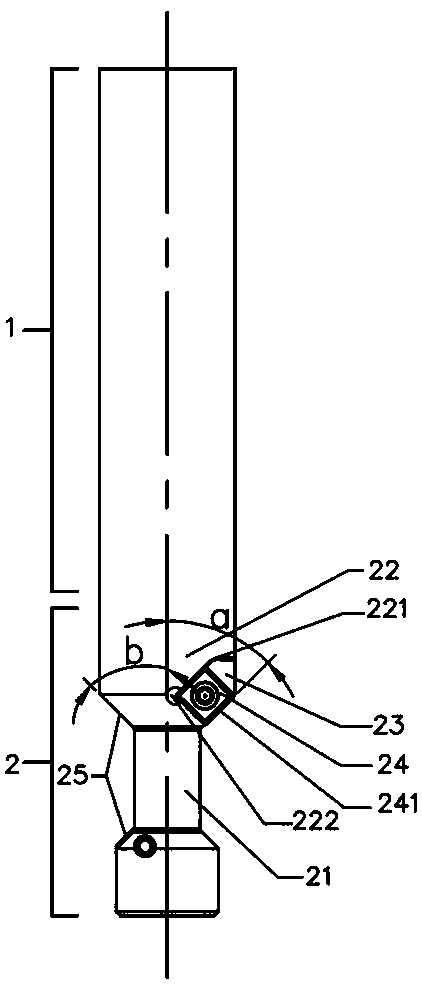

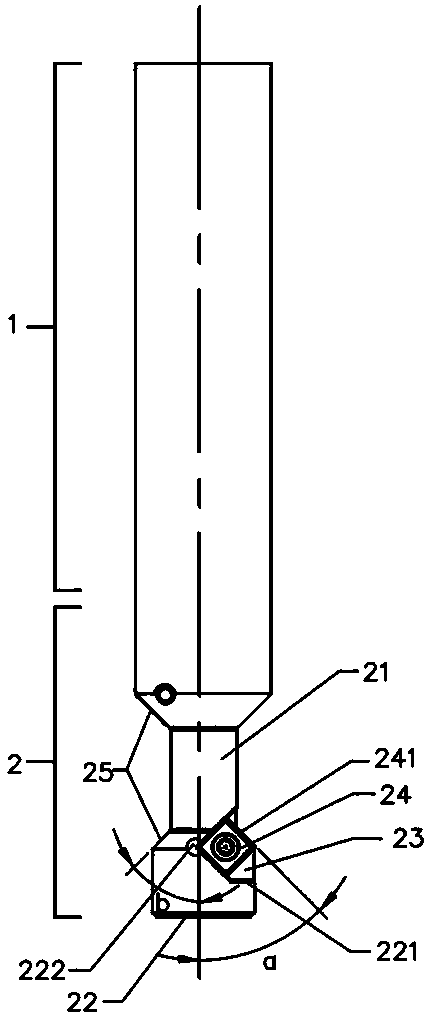

Non-eccentricity type through hole double-face chamfering tool and chamfering process using chamfering tool

PendingCN107790799ASimple structureEasy to useMilling cuttersMilling equipment detailsMachine partsMaterial resources

The invention relates to a non-eccentricity type through hole double-face chamfering tool. The non-eccentricity type through hole double-face chamfering tool comprises a clamping part and a machiningpart which are integrally molded, and the central axis of the clamping part and the central axis of the machining part are located on one straight line; and the machining part comprises an upper chamfering part, a lower chamfering part and a chamfering anti-interference part located between the upper chamfering part and the lower chamfering part, and the central axes of the chamfering anti-interference part, the upper chamfering part and the lower chamfering part are located on one straight line. The tool is simple in structure, convenient to use and complete in function; in cooperation with acorresponding chamfering process, the number of tool walking steps is reduced, the process is simplified, and the production period is shortened; and on the basis of guaranteeing the accuracy and stability, the machining efficiency is improved, the structure strength is good, manpower and material resources are saved, production is safe and reliable, and the non-eccentricity type through hole double-face chamfering tool is worthy of application and popularization.

Owner:ZHEJIANG 81 PRECISION MACHINERY CO LTD +1

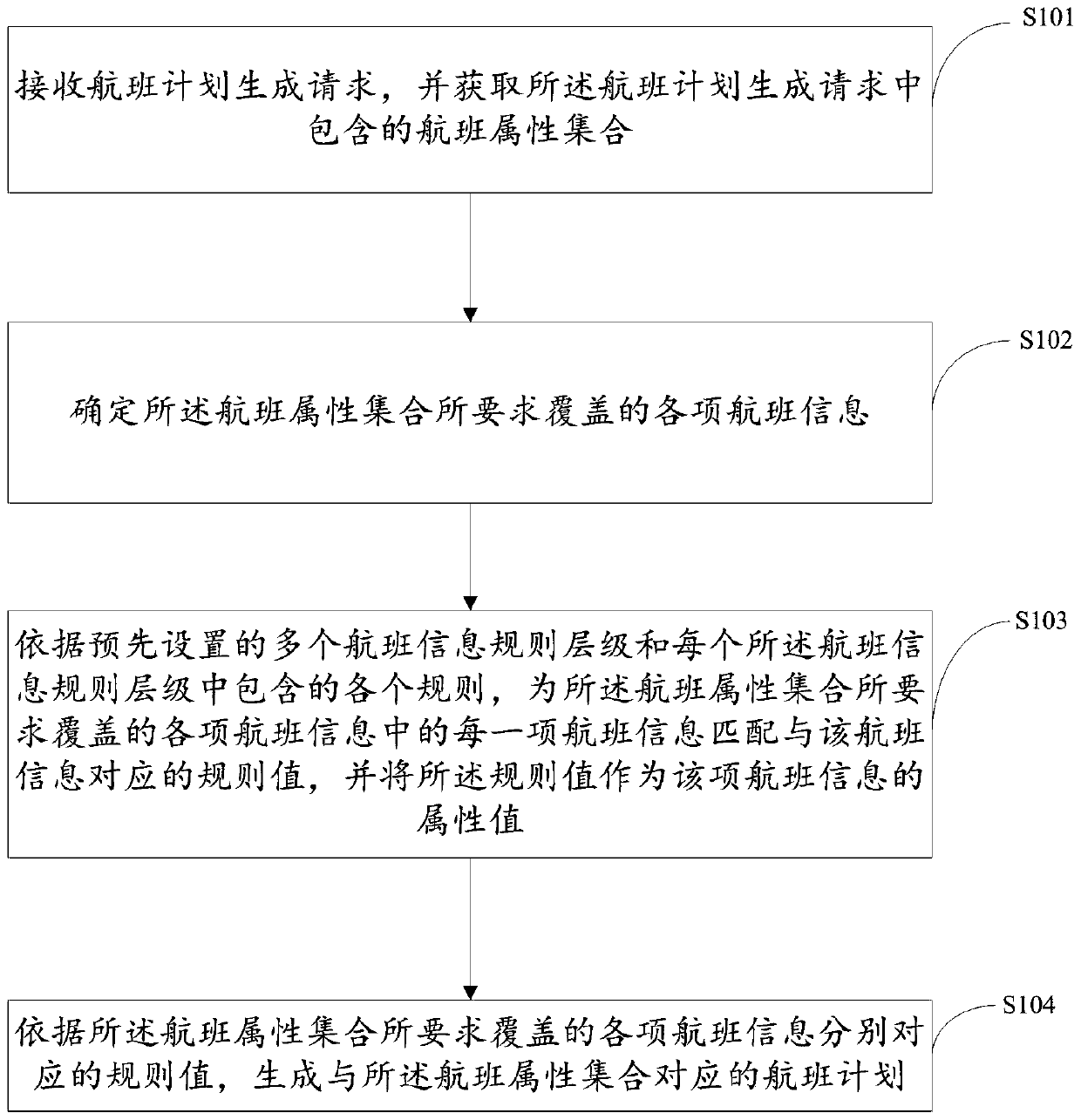

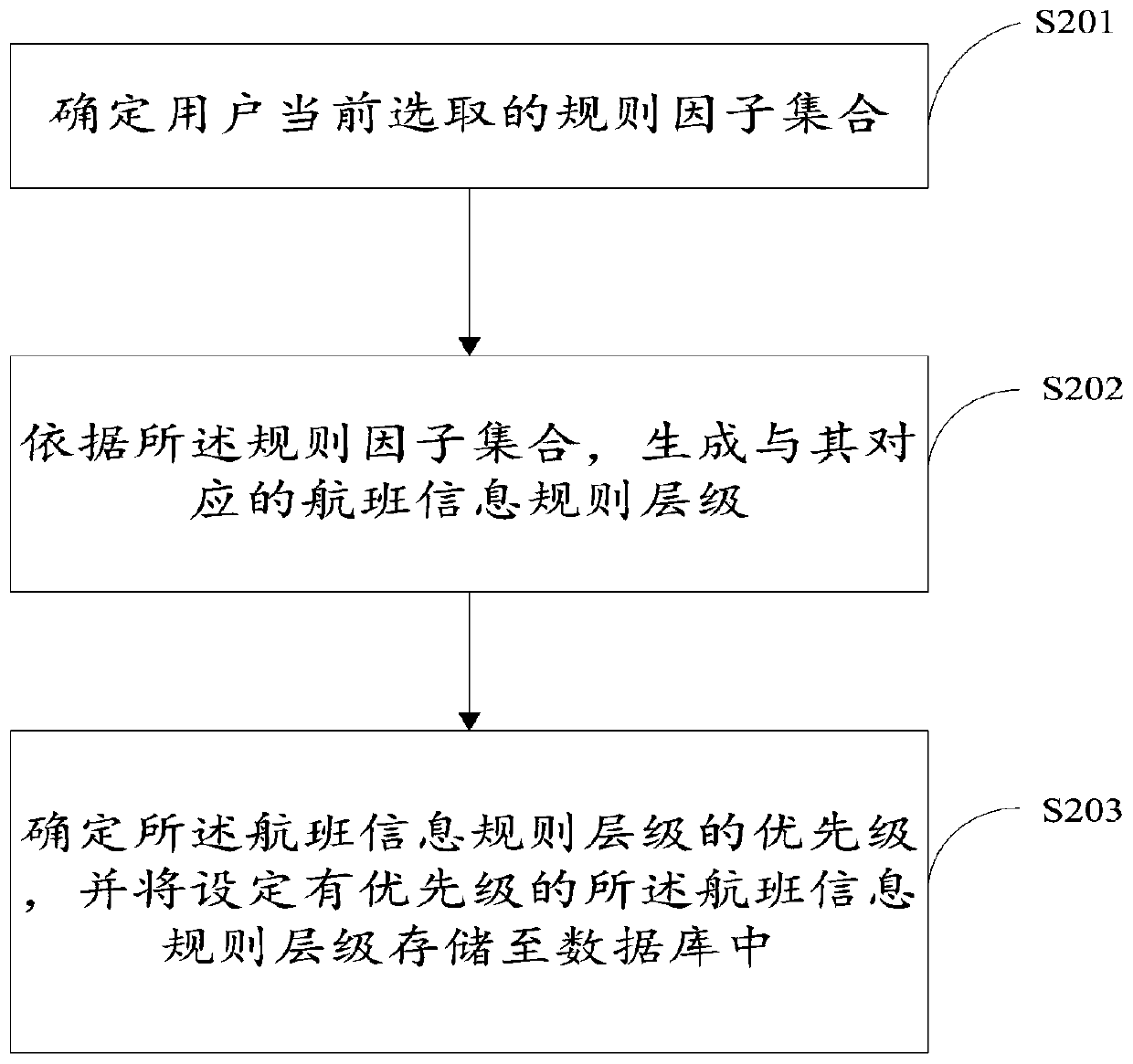

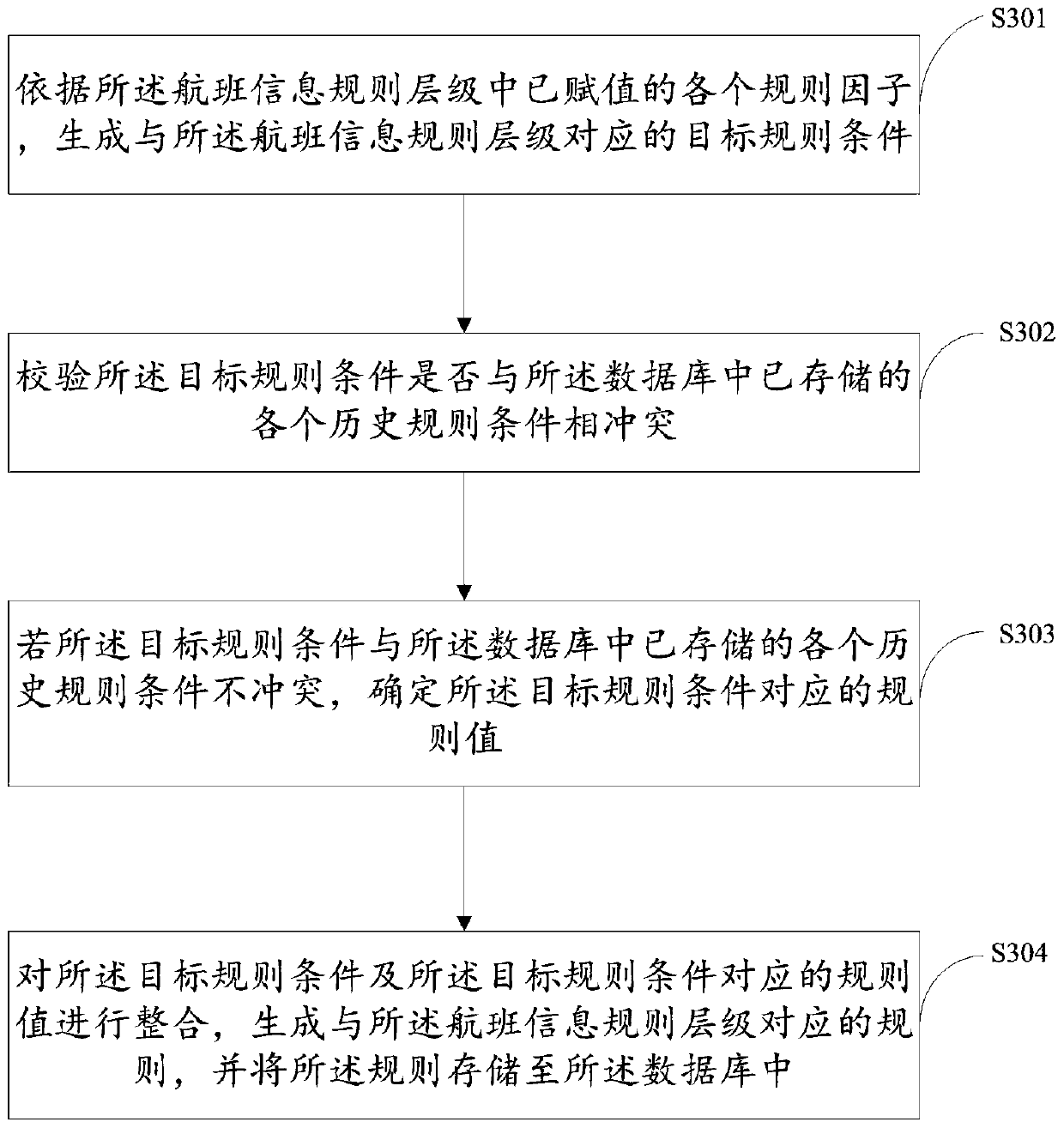

Flight plan generation method and device

ActiveCN110298604ASave manpower and material resourcesSolve low work efficiencyResourcesProgram planningMaterial resources

According to a flight plan generation method provided by the invention, when the flight plan generation request is received, each piece of flight information required to be covered by the flight planis determined as each piece of flight information to be matched with the flight attribute set; and according to a preset flight information rule level and a rule corresponding to the flight information rule level, a flight attribute set is matched to obtain a plurality of different rule values, and according to the different rule values matched by the flight attribute set, a flight plan corresponding to the flight attribute set is generated. In the method provided by the invention, a user can flexibly set flight information rule levels and rules; according to the flight information rule hierarchy and rule, corresponding rule values are matched for all pieces of flight information respectively, the flight plan can be rapidly generated, a large amount of manpower and material resources are saved, and the problem that in the prior art, the work efficiency is low due to the fact that all pieces of flight information are manually added is solved.

Owner:TRAVELSKY

Oil storage tank cleaning device

The invention relates to an oil storage tank cleaning device and belongs to the technical field of oil storage tank cleaning devices. The oil storage tank cleaning device comprises an upper shell, a lower shell, a booster pump, a main shaft and a cleaning spray head. The bottom end of the upper shell is provided with the lower shell, a turbine shaft is installed in the upper shell, the main shaftis arranged below the turbine shaft, the main shaft is fixedly connected with the turbine shaft, a cylindrical cam is fixedly installed inside the upper shell below a bearing of the main shaft, the booster pump is installed below the cylindrical cam, and the booster pump is in sliding contact connection with the cylindrical cam. In the working process of the cleaning device, the main shaft drivesthe lower shell to rotate at 360 degrees, and meanwhile drives the cleaning spray head to rotate at 360 degrees, so that all-around cleaning is carried out on an oil storage tank, and the cleaning effect is greatly improved. The problems that existing manual operation ways are low in working efficiency, existing cleaning machines are low in cleaning pressure, most machines are mechanical and electrical products, and therefore safety accidents are likely to occur once static electricity or electric sparks are produced in the working process are solved. The oil storage tank cleaning device is particularly applicable to cleaning the interior of the oil storage tank.

Owner:CHINA PETROLEUM & CHEM CORP +1

Corner cutting device for manufacturing computer circuit board

ActiveCN107297777ASolve human-driven problemsImprove work efficiencyMetal working apparatusEngineering

The invention discloses a corner cutting device for manufacturing a computer circuit board, and relates to the technical field of computers. The corner cutting device comprises a base. Transmission devices are fixedly connected to the two sides of the top of the base, a supporting plate is fixedly connected to the tops of the transmission devices, one opposite sides of the two transmission devices are fixedly connected, a first motor is fixedly connected between the two transmission devices through a motor box, an output shaft of the first motor sequentially penetrates through the top of the motor box and the supporting plate from bottom to top and is fixedly connected with a cutting knife, supporting rods penetrate through the tops of the transmission devices, the top ends of the supporting rods penetrate through the supporting plate and are fixedly connected with containing frames, a protection cover is movably connected to the top of the supporting plate, and the transmission devices comprise shells. By means of the corner cutting device for manufacturing the computer circuit board, the problem that a traditional corner cutting device needs to be manually pushed is solved, the working efficiency of workers is improved, utilization of labor resources is saved, and the using effect of users is achieved.

Owner:宜兴市旭航电子有限公司

Clamp

ActiveCN108994561AImprove work efficiencySolve low work efficiencyWork holdersMetal working apparatusBiomedical engineering

The invention provides a clamp. The clamp is used for assembling a clamped part and a part to be assembled together. The clamp comprises a clamp body, a clamping jaw and a tightly-pressing assembly, wherein the clamping jaw is used for clamping the clamped part, the clamping jaw is movably arranged on the clamp body; and the tightly-pressing assembly is arranged on the clamp body, and at least part of the tightly-pressing assembly is telescopically arranged to enable the tightly-pressing assembly to apply acting force towards the part to be assembled to the clamped part after the clamping clawplaces the clamped part on the part to be assembled so as to press the clamped part tightly on the part to be assembled. The clamp effectively solves the problem of low working efficiency of a clampin the prior art.

Owner:GREE ELECTRIC APPLIANCES INC +1

Automatic cutting device for plaster

InactiveCN105232237ASolve low work efficiencyPrecise positioningBandagesIndustrial engineeringInfrared detector

The invention provides an automatic cutting device for plaster. The automatic cutting device comprises a frame and a working table arranged on the frame and used for holding plaster. The middle portion of the working table is provided with a groove matching plaster in size. An infrared detector is arranged above the working table and is fixed to be above the working table through a base. The top of the base is provided with a horizontal support rod. The support rod is provided with a horizontal slide rail. A slider driven by a motor is connected to the sliding rail slidingly. A telescopic cylinder is installed on the slider and the output end of the telescopic cylinder is provided with a plaster saw. The infrared detector is fixed on the slider. The telescopic amount of the telescopic cylinder is determined through the infrared detector. The automatic cutting device for plaster can automatically cut plaster off and solve the problem of low working efficiency of plaster cutting.

Owner:CHONGQING QIULU GYPSUM PROD FACTORY

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com