Eight-shaft-moving chip repairing and attaching device and method with visual positioning function

A technology of visual positioning and placement devices, which is applied in the direction of assembling printed circuits with electrical components, can solve problems that are not conducive to improving the quality of desoldering and placement, unfavorable work efficiency, labor costs, automatic adjustment of heating height, etc., to achieve saving Labor cost, wide application range, and the effect of improving work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0048] The following examples are further explanations and supplements to the present invention, and do not constitute any limitation to the present invention.

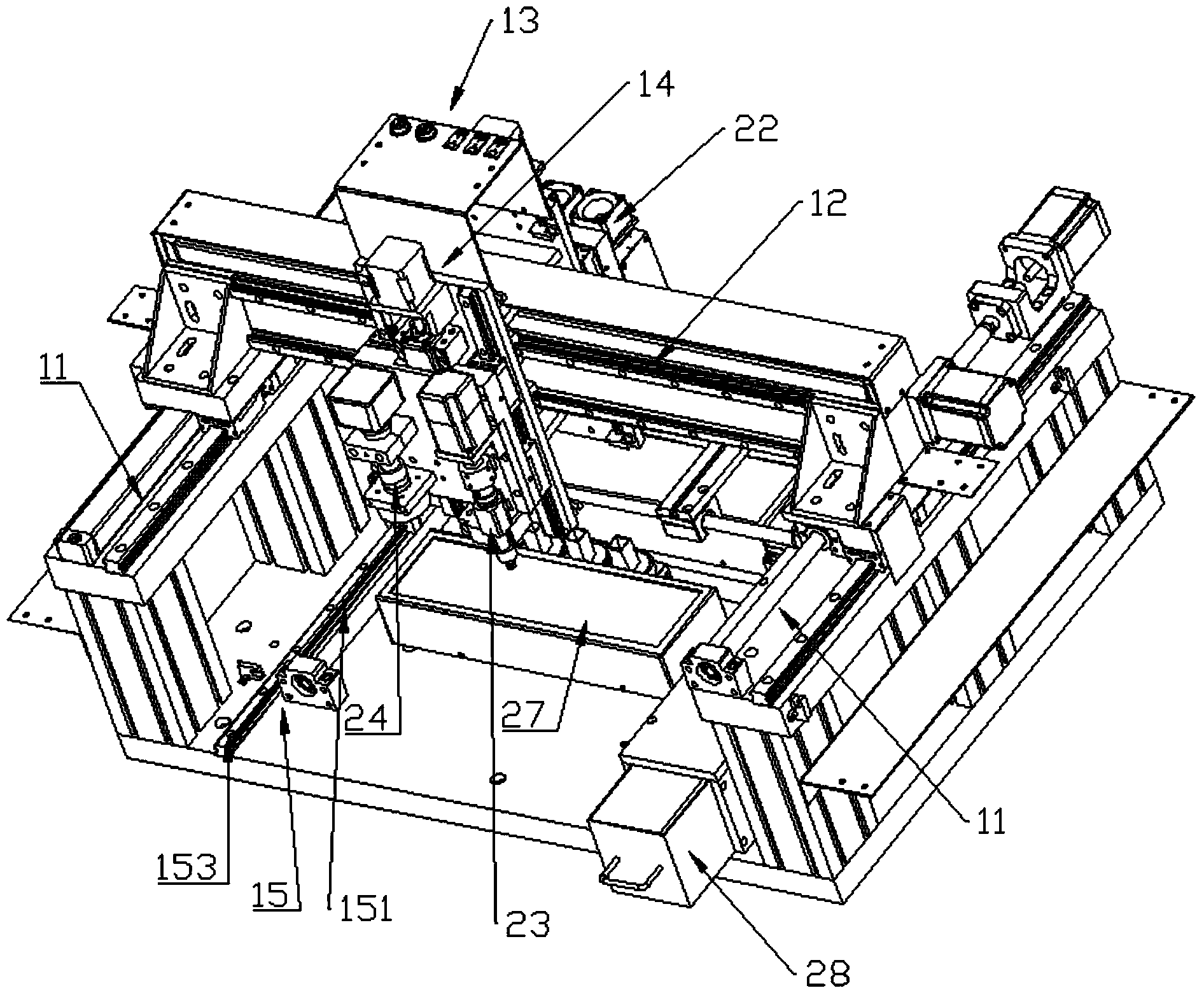

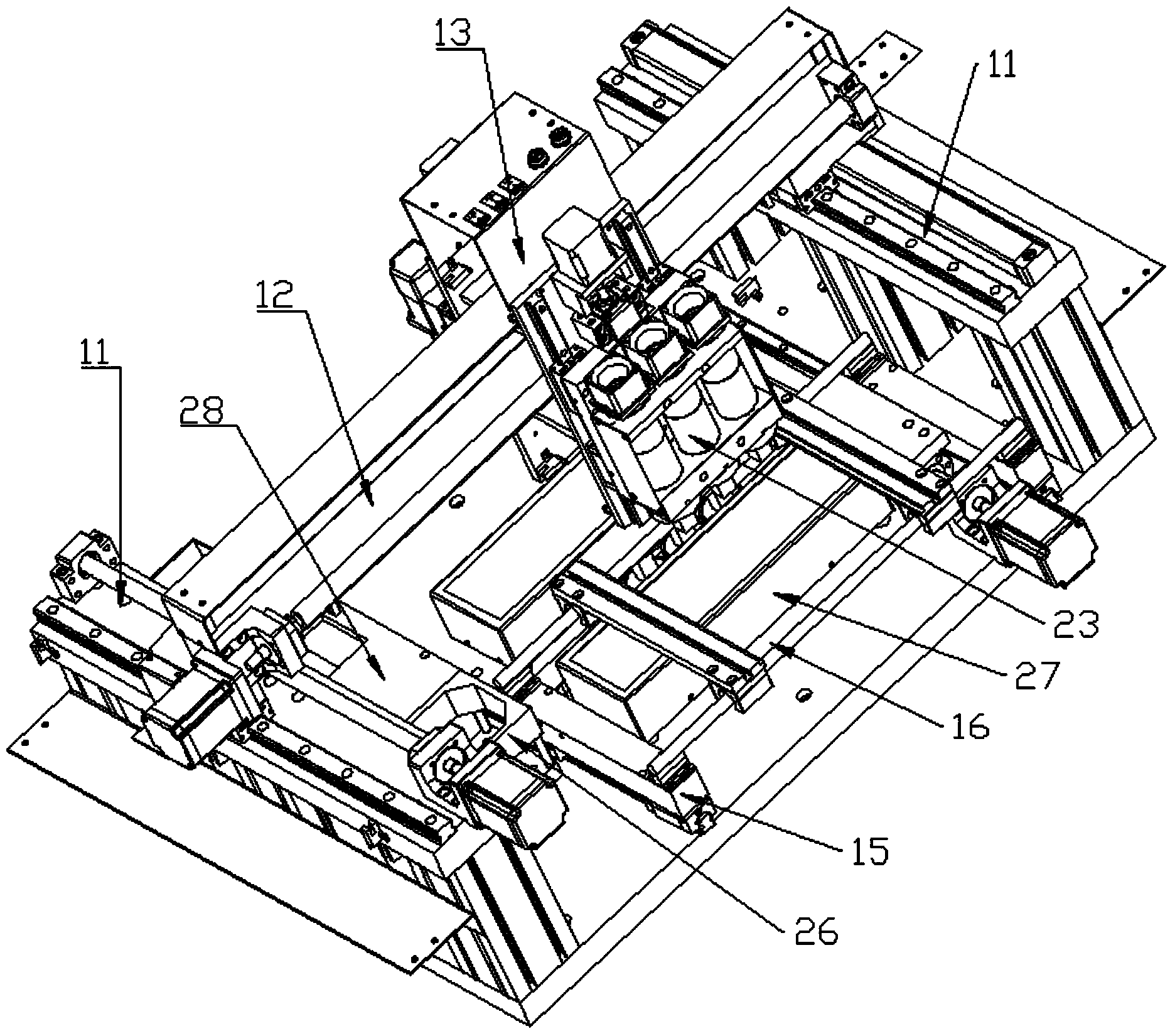

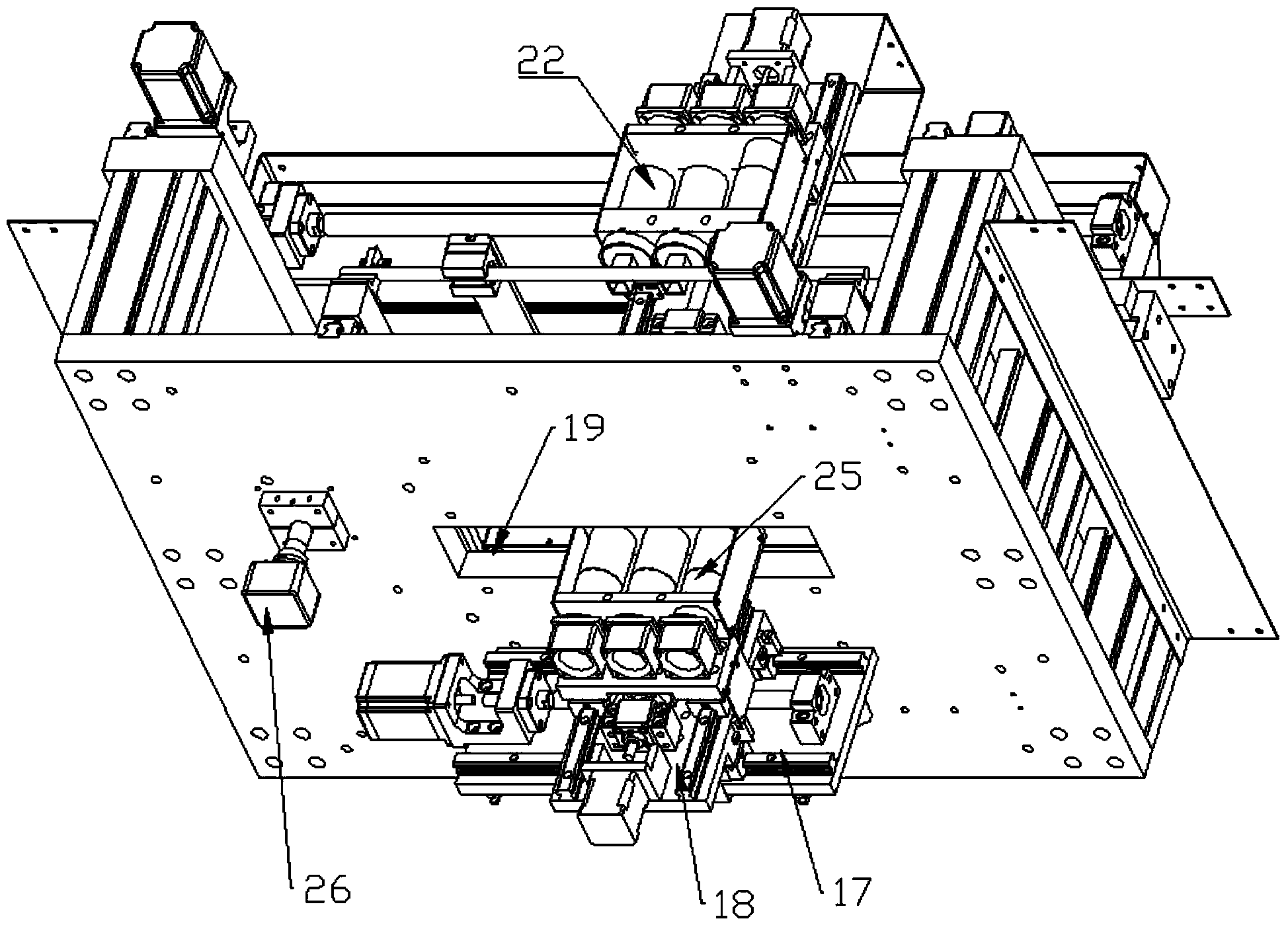

[0049] The eight-axis mobile chip rework and chip placement device with visual positioning of the present invention is equipped with eight linear moving guide rail pairs, which have moving tracks in eight directions, so it has high flexibility and can be used for a variety of chips packaged in BGA Desoldering and SMT operations, and can greatly improve work efficiency.

[0050] Specifically, as Figure 1 to Figure 13 As shown, the eight linear guide rail pairs include the first linear guide rail pair 11, the second linear guide rail pair 12, the third linear guide rail pair 13, the fourth linear guide rail pair 14, the fifth linear guide rail pair 15, the sixth linear guide rail pair The linear guide rail pair 16 , the seventh linear guide rail pair 17 and the eighth linear guide rail pair 18 .

[0051] Such as Fi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com