Oil storage tank cleaning device

A technology for cleaning devices and oil storage tanks, which is applied in the direction of cleaning hollow objects, cleaning methods and utensils, chemical instruments and methods, etc., which can solve problems such as low work efficiency, safety accidents, and low cleaning pressure of cleaning machines, and achieve improved cleaning effects , good practicability and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

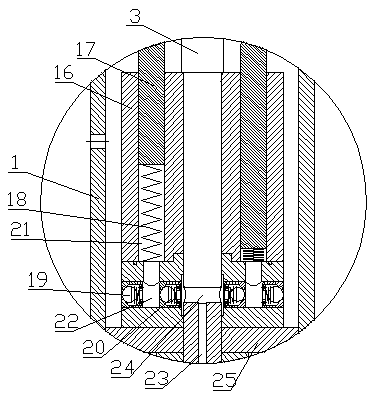

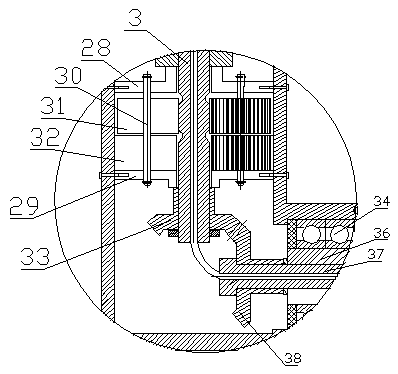

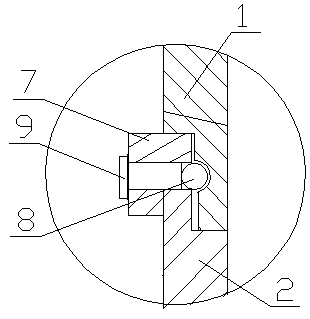

[0025] The oil storage tank cleaning device is composed of an upper casing 1, a lower casing 2, a booster pump, a main shaft 3 and a cleaning nozzle 4. The top end of the upper shell 1 is fixedly mounted with an upper joint 6 through a threaded intermediate joint 5 , and the bottom end of the upper shell 1 is mounted with an L-shaped lower shell 2 through a sealed joint. The sealing connector is composed of a connecting sleeve 7, a ball 8 and a ball ejector rod 9. The connecting sleeve 7 is symmetrically provided with an assembly hole, and the ball ejector rod 9 installed through the thread in the assembly hole is equipped with a ball 8, and the lower end of the upper shell 1 is The reducing body, the upper housing 1 corresponding to the ball 8 is provided with a ring groove, the sealing connector is threadedly connected with the lower housing 2 through the connecting sleeve 7, and the sealing connector is matched with the upper housing 1 through the cooperation of the ball 8 a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com