Low light level image intensifier test system

A technology of low-light image intensifier and testing system, which is applied in the direction of optical instrument testing, machine/structural component testing, and optical performance testing. It is convenient for data comparison and statistical analysis, solves the problem of recording depth, and eliminates the effect of measurement error

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] In order to make the object, technical solution and advantages of the present invention clearer, the present invention will be further described in detail below with reference to the accompanying drawings and embodiments.

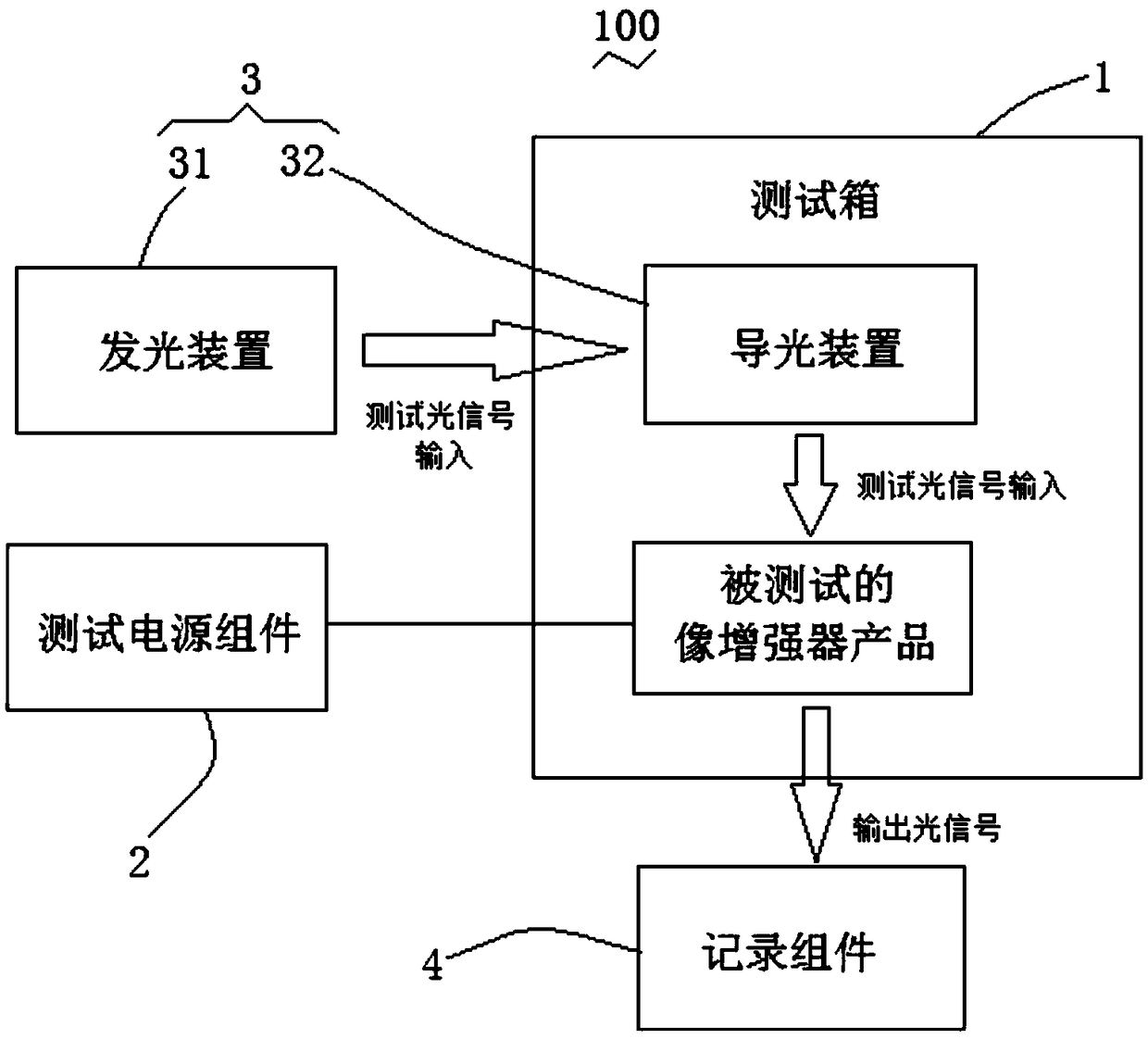

[0027] see figure 1 , a preferred embodiment of the present application provides a low-light image intensifier testing system 100, which can be used for performing performance tests on existing low-light image intensifiers, such as high and low temperature illumination tests. The micro-light image intensifier test system 100 includes a test box 1 , a test power supply component 2 , an illumination component 3 , and a recording component 4 .

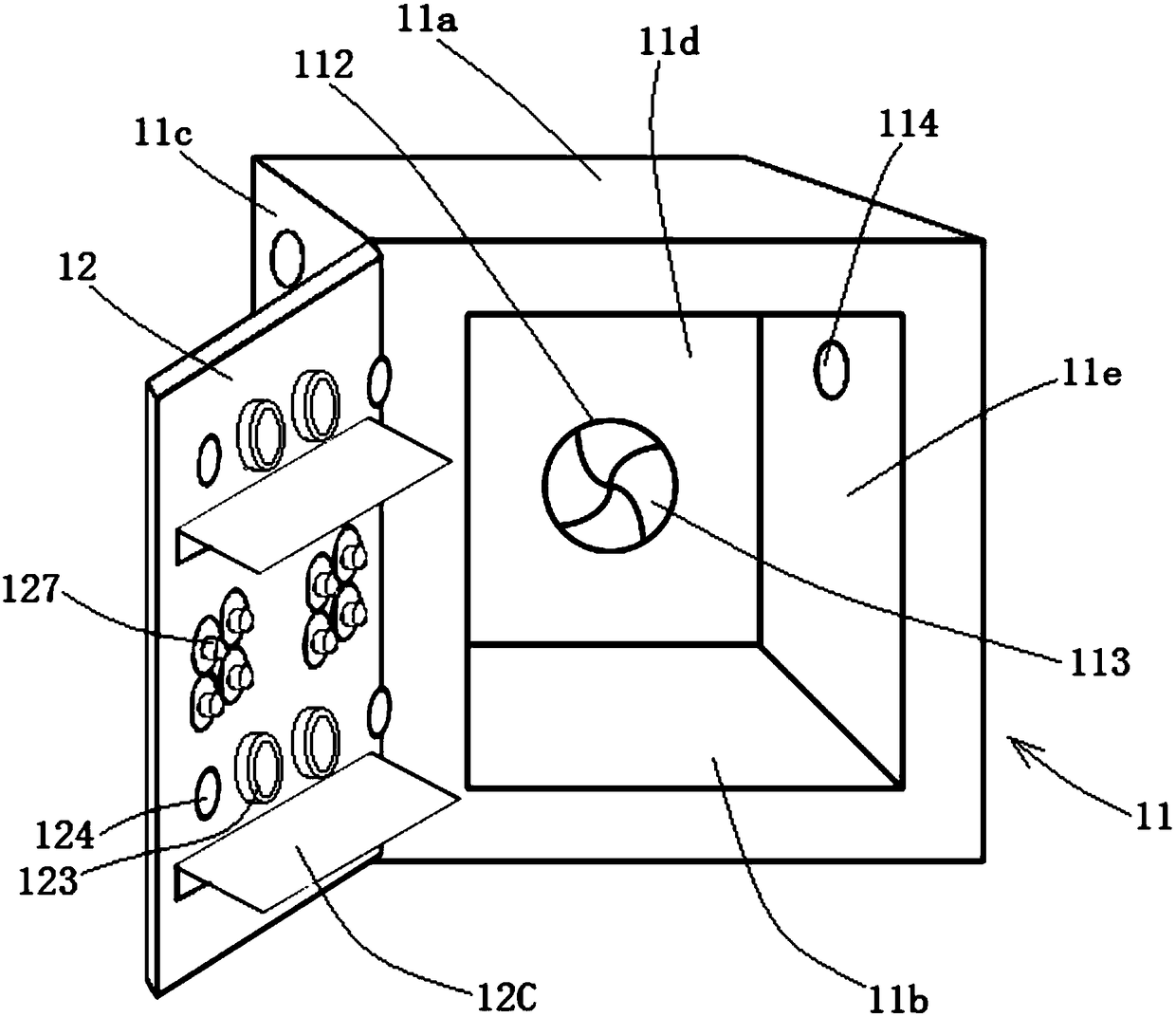

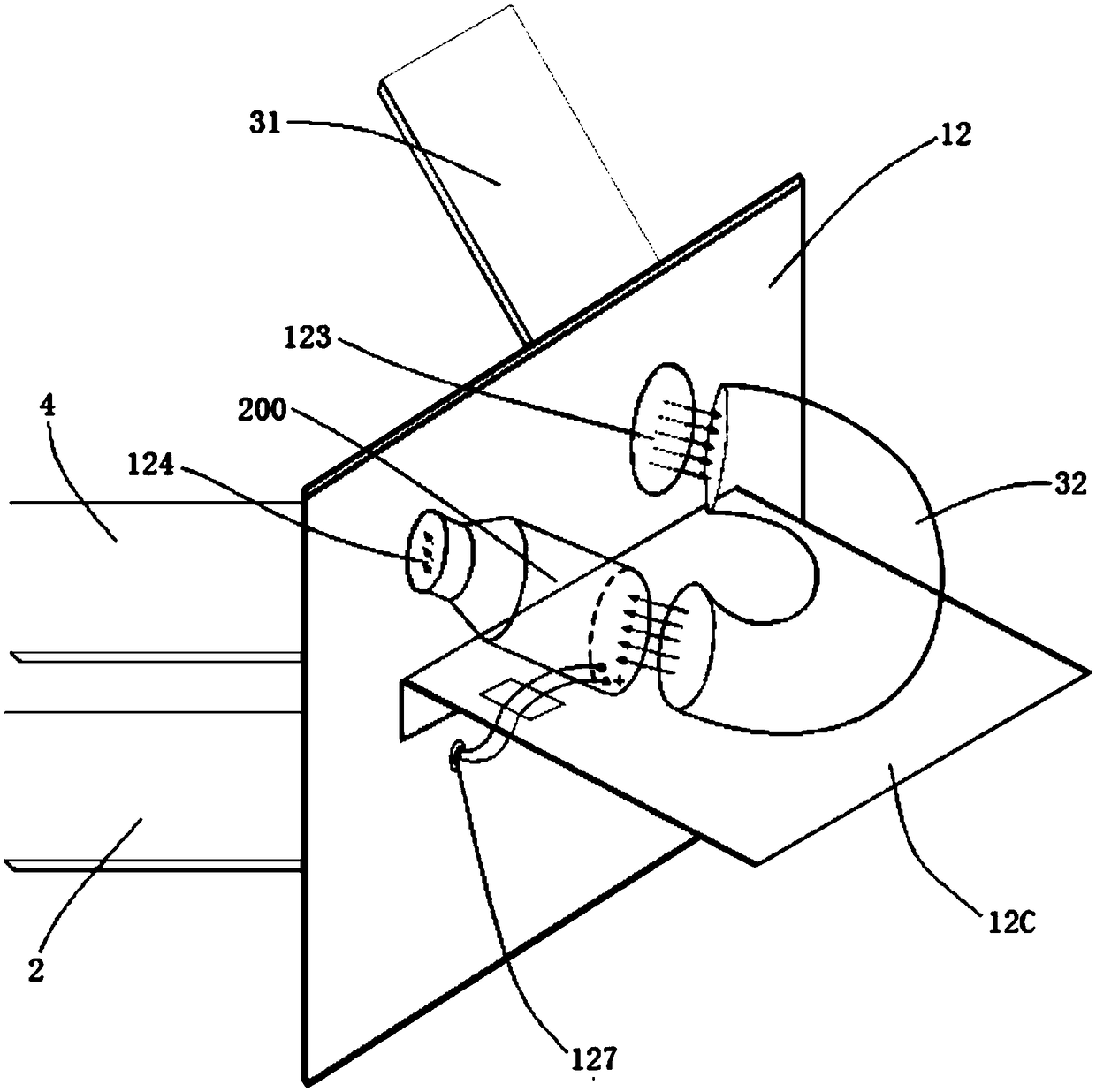

[0028] Please also refer to figure 2 , image 3 and Figure 4, the test box 1 includes a box body 11 and a box door 12, and the box body 11 and the box door 12 are preferably made of light-shielding and insulating materials. The shape of the box body 11 is roughly a rectangular parallelepiped or a cube with...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com