Multi-purpose road slope finishing machine

A multi-purpose, refurbishment machine technology, applied in mechanically driven excavators/dredgers, earth movers/shovels, construction, etc., can solve the problems of single function, inconvenient movement, low work efficiency, etc. Low labor intensity, increase practicality, increase the effect of function

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

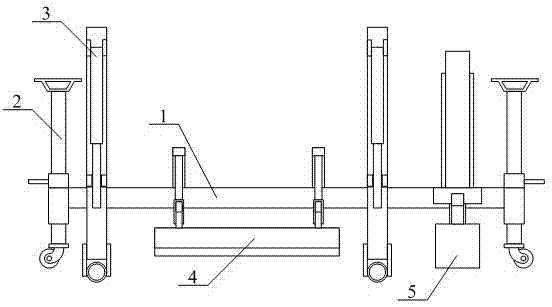

[0038] as attached figure 1 To attach Figure 6 shown

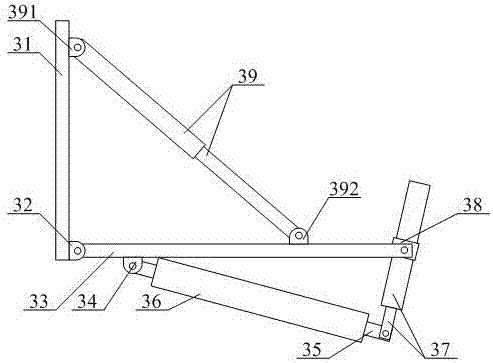

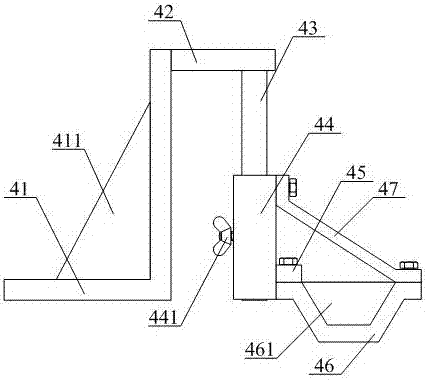

[0039]The present invention provides a multi-purpose road slope finishing machine, which includes a base 1, an adjustable moving wheel device 2, a slope compacting roller device 3, a ditching plate device 4 and an adjustable soil loosening wheel device 5. The adjustment moving wheel device 2 is welded to the left and right parts of the base 1 respectively, the slope compacting roller device 3 is bolted to the left and right parts of the front surface of the base 1, and the ditching plate device 4 is bolted to the base 1 In the middle of the front surface, the adjustable loosening wheel device 5 is bolted to the front surface of the base 1, and the slope compacting roller device 3 includes a support plate 31, a first-stage orifice plate 32, a folding plate 33, two Stage orifice 34, rotating shaft 35, roll 36, angle adjustment cylinder 37, rotating sleeve 38 and stretching cylinder 39, described primary orifice 32 is weld...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com