Patents

Literature

71 results about "Function problem" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

In computational complexity theory, a function problem is a computational problem where a single output (of a total function) is expected for every input, but the output is more complex than that of a decision problem. For function problems, the output is not simply 'yes' or 'no'.

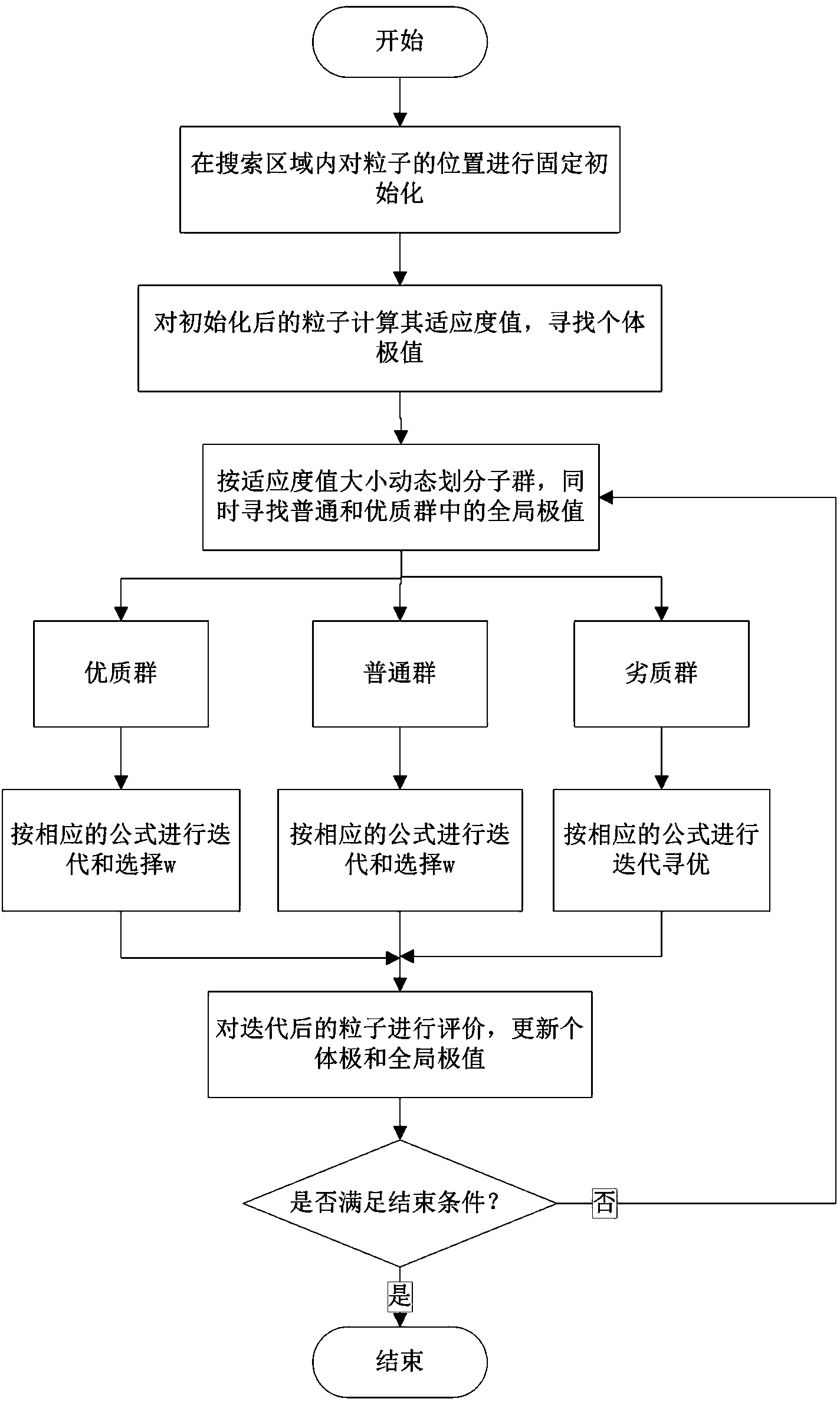

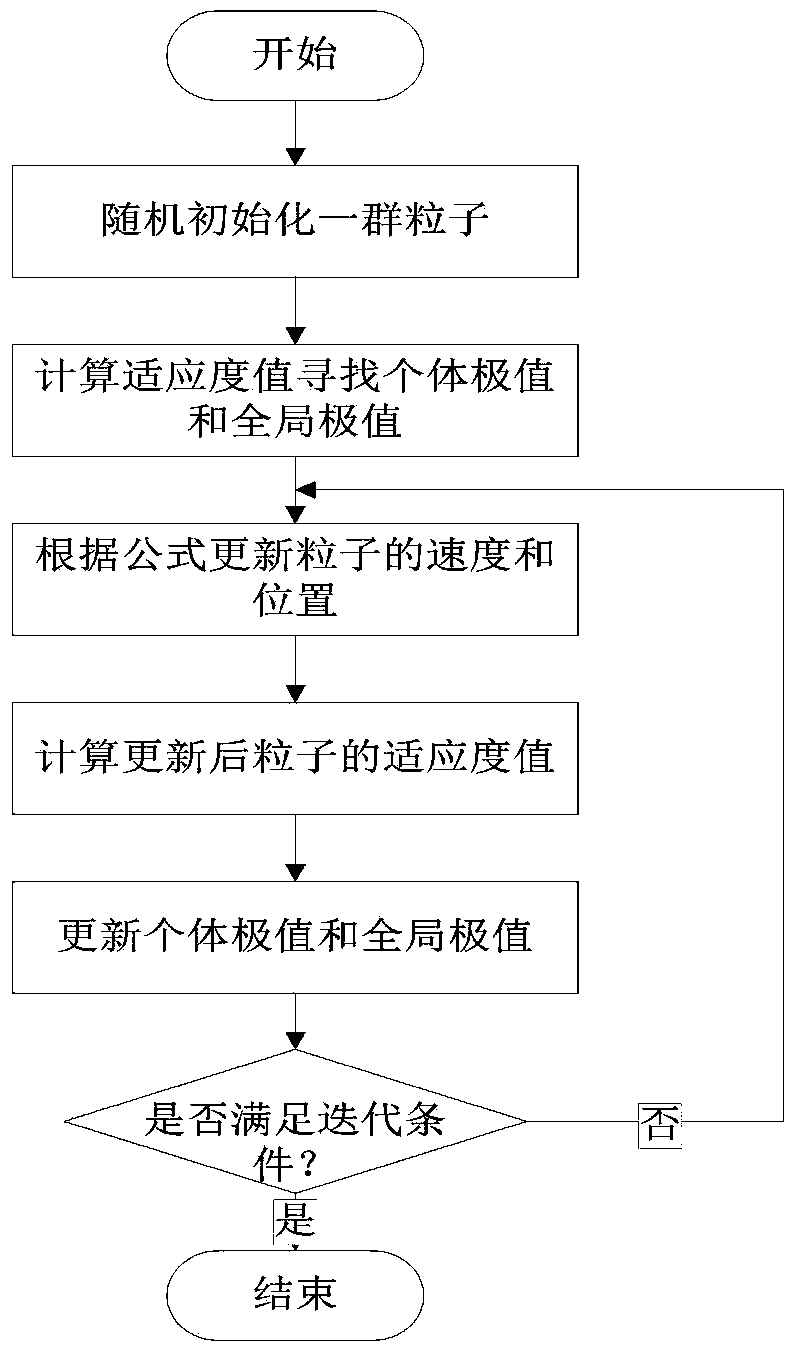

Cascade reservoir optimal operation method based on adaptive particle swarm optimization algorithm

InactiveCN103942612ADiversity guaranteedAvoid falling intoForecastingBiological modelsLocal optimumFunction problem

The invention discloses a cascade reservoir optimal operation method based on the adaptive particle swarm optimization algorithm. According to the method, aiming at the defect of the particle swarm method in cascade reservoir optimal operation, fixed initialization improvement is conducted firstly on particle random initialization to enable the algorithm to have the possibility of approaching the optimal value at the beginning, large-scale dead zones do not exist, convergence speed is increased, and the stability of the algorithm is improved; then according to the group cooperation idea and the cluster ecological niche idea, an initialized group is dynamically divided into three subgroups, optimization and parameter selection are conducted on each subgroup in an adaptive mode according to the difference of particles, and in this way, the particle diversity is improved, the information exchange model is changed, and local optimum of the algorithm is avoided. According to the improved algorithm, the function problems of nonlinearity and multiple local minima can be well solved, and an effective and feasible solution is provided for cascade reservoir optimal operation.

Owner:HOHAI UNIV

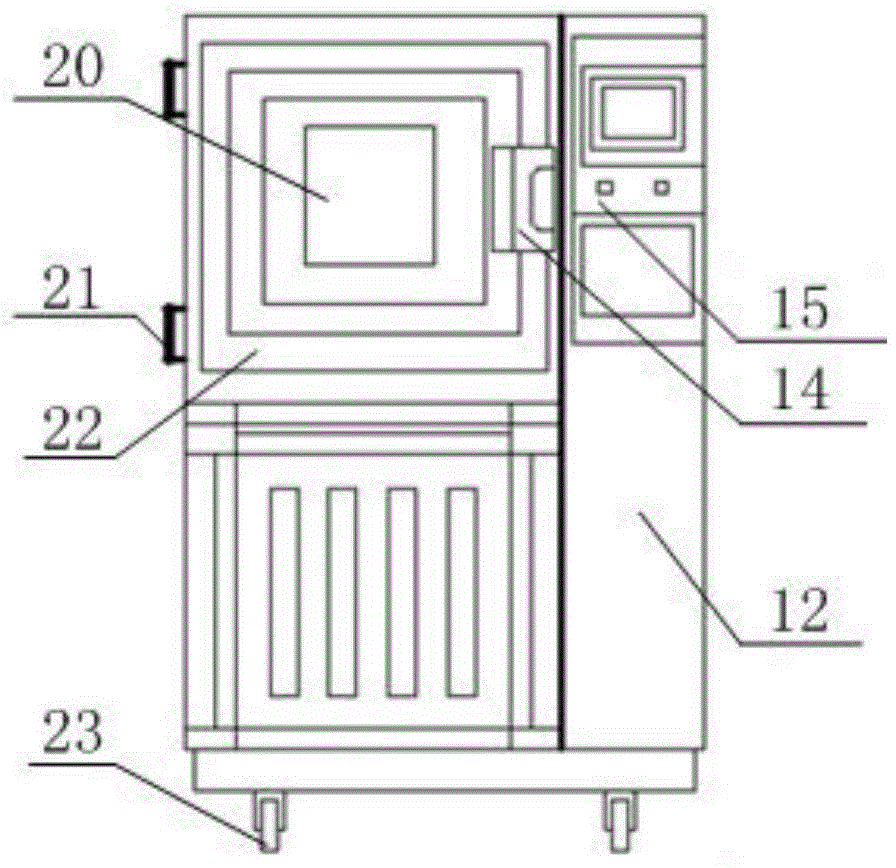

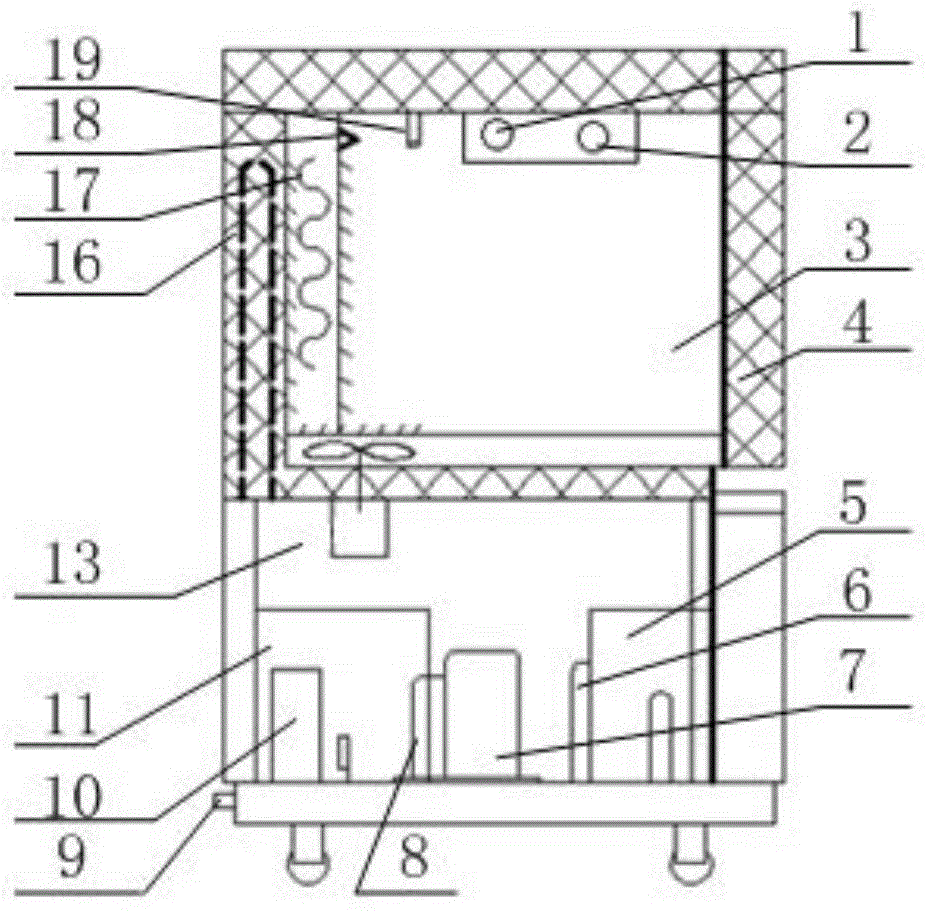

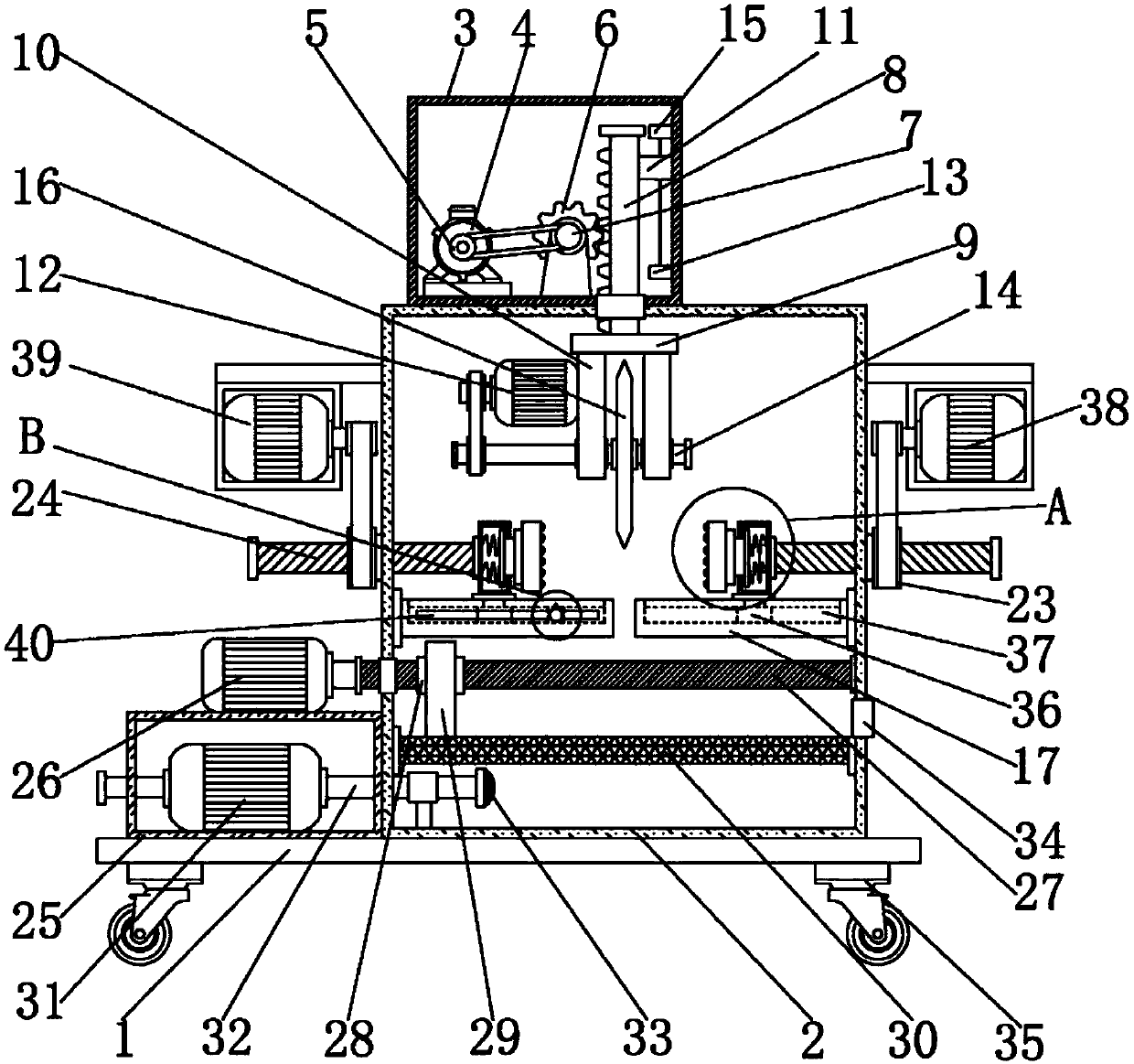

Reconfigurable modularized environment test box

InactiveCN104977244AImprove adaptabilityMeet the needs of environmental testingWeather/light/corrosion resistanceWeather resistanceModularity

The present invention discloses a reconfigurable modularized environment test box, which comprises a test box body, wherein an environment simulation function module is arranged inside the test box body and comprises a high temperature module, a low temperature module, a humidity module, an ultraviolet weathering resistance module, a xenon lamp weather resistance module, a low pressure module, an ozone aging module, a raining module, a salt mist module, a sand and dust module, and a control module. The reconfigurable modularized environment test box of the present invention has the following advantages that: the modules are subjected to combined use and the combination manner of the modules can be changed so as to achieve different environment tests, improve the adaptability of the equipment, and meet requirements of various environment tests; each module is corresponding to the one environment test, and the customer can selectively install a plurality of required environment modules, such that the single function problem of the existing environment test box is overcome; and the equipment utilization rate is high, and the environment test cost is low.

Owner:CHINA UNIV OF MINING & TECH

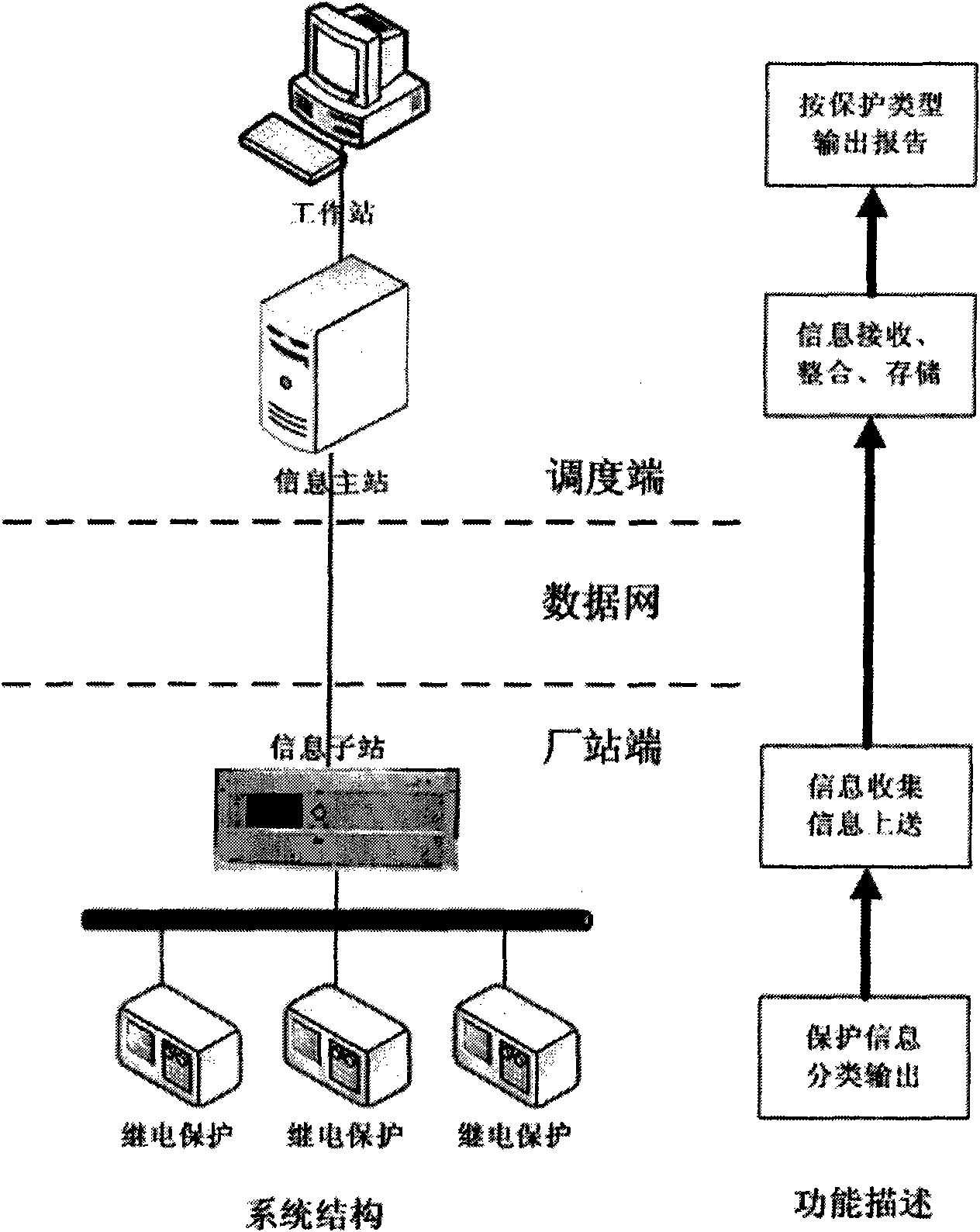

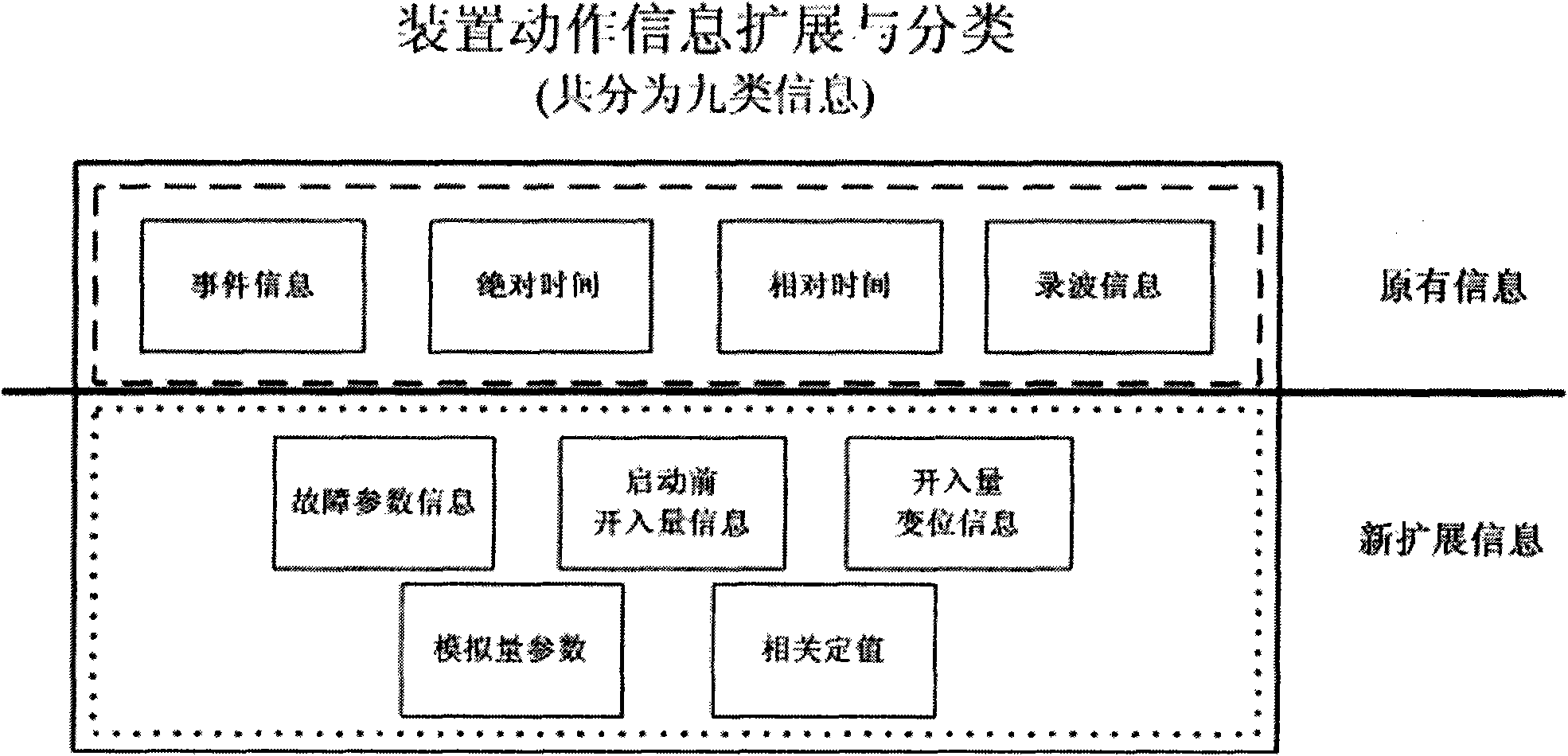

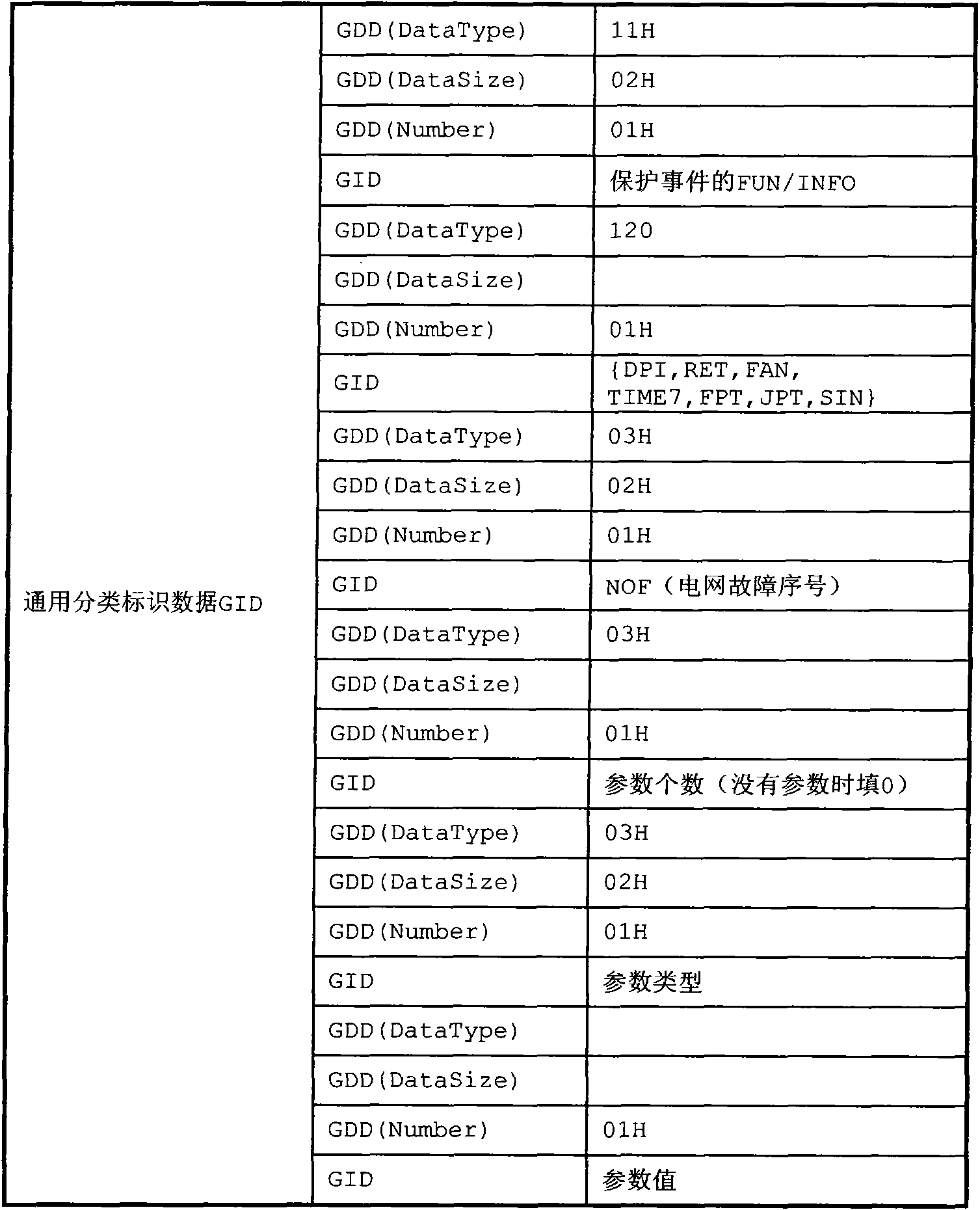

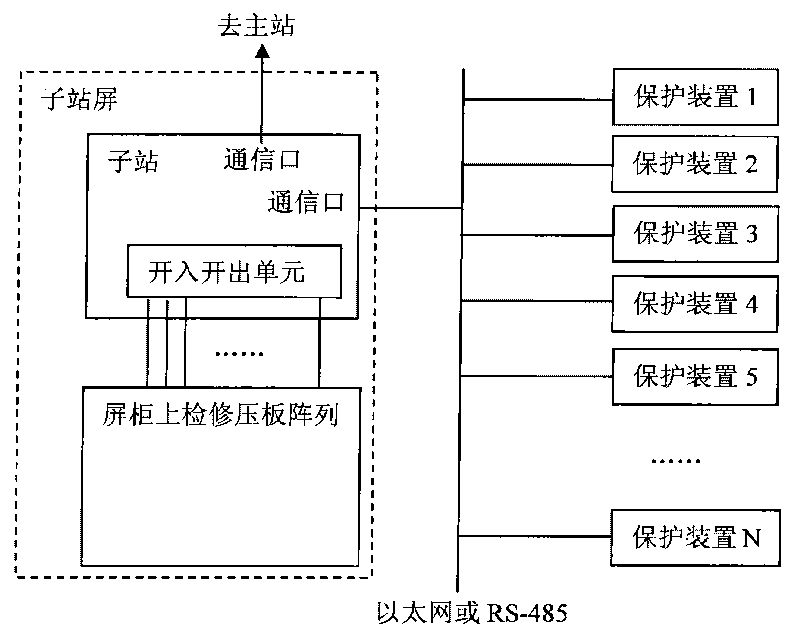

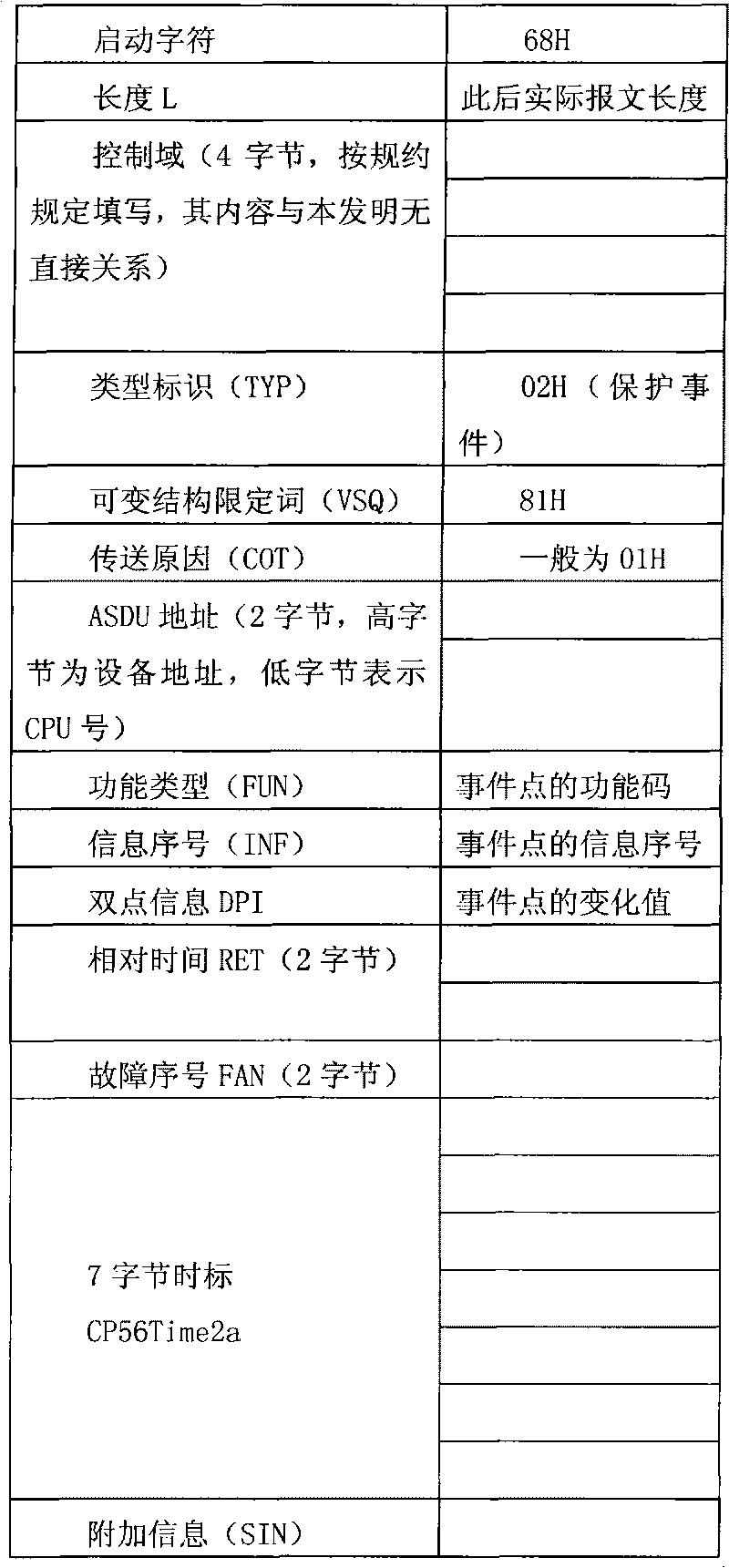

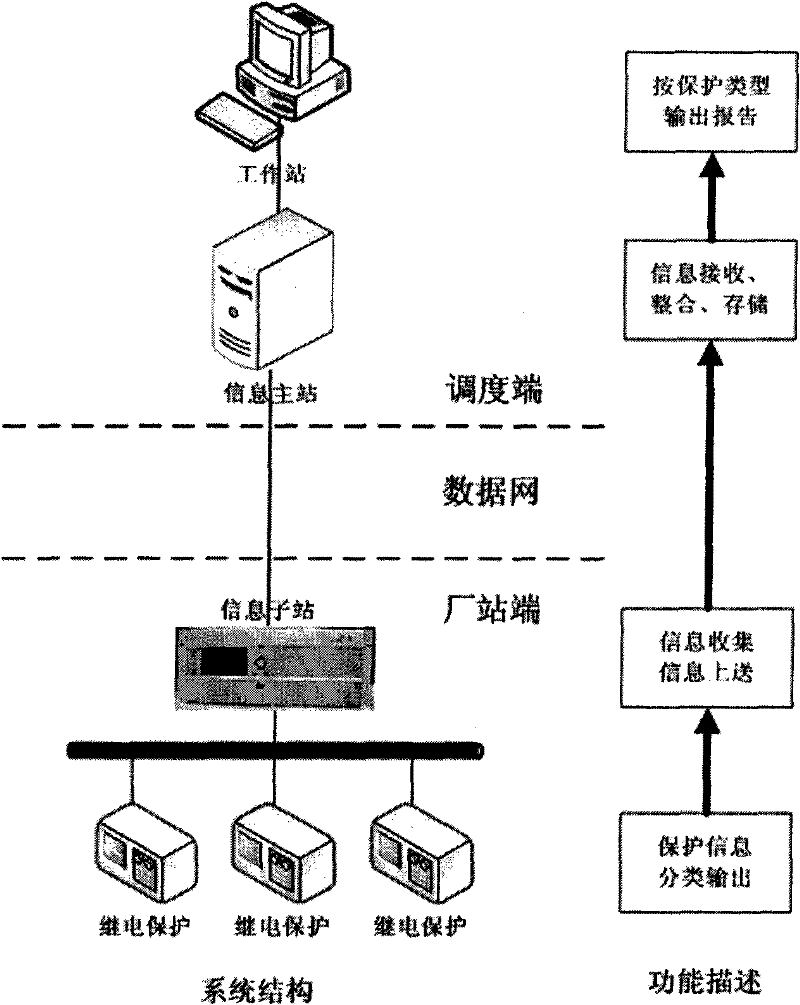

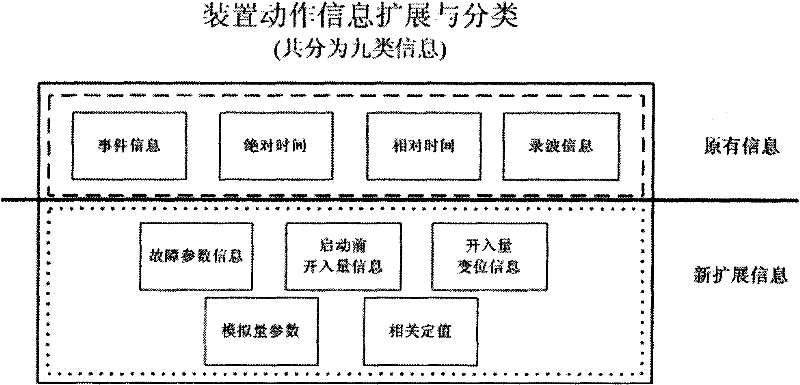

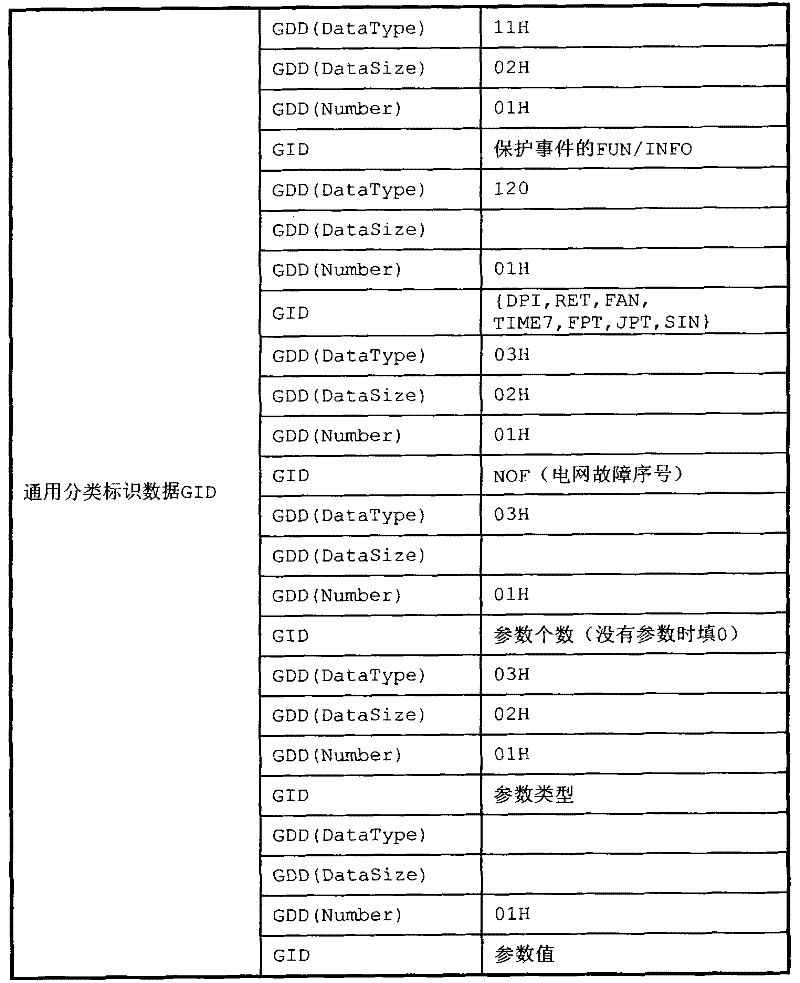

Reduction and generation method of action report of protection device at scheduling port

ActiveCN101640436AIncrease the level of automationImprove the level of practicalityCircuit arrangementsInformation technology support systemDevice typeMaster station

The invention provides a reduction and generation method of an action report of a relay protection device at a scheduling port, which is applied to a power network relay protection and failure information management system. The method comprises the following steps: normalizing output information of a relay protection device on a station port, and sending the information by classification; establishing a communication specification between a master station and a slave station to guarantee integral data transmission; and outputting corresponding action report at the scheduling port of the masterstation according to the device type to realize reduction and generation of the device report at the scheduling port. The method in the invention helps realize that the action report is basically consistent with the report form and the content printed on the spot by the relay protection device in an information display layer of a master station system. The method is completed and practical; and the method helps perfect the information content sent by the relay protection device, solve the long-standing functional problems of the domestic relay protection and failure information management system such as scattered information, shortage of the content and the like, meanwhile formally realize long pass of the relay protection action report, is beneficial to relay protection professional staffs to carry out protection action analysis, and improve the integral practicability level of the system.

Owner:STATE GRID ZHEJIANG ELECTRIC POWER +2

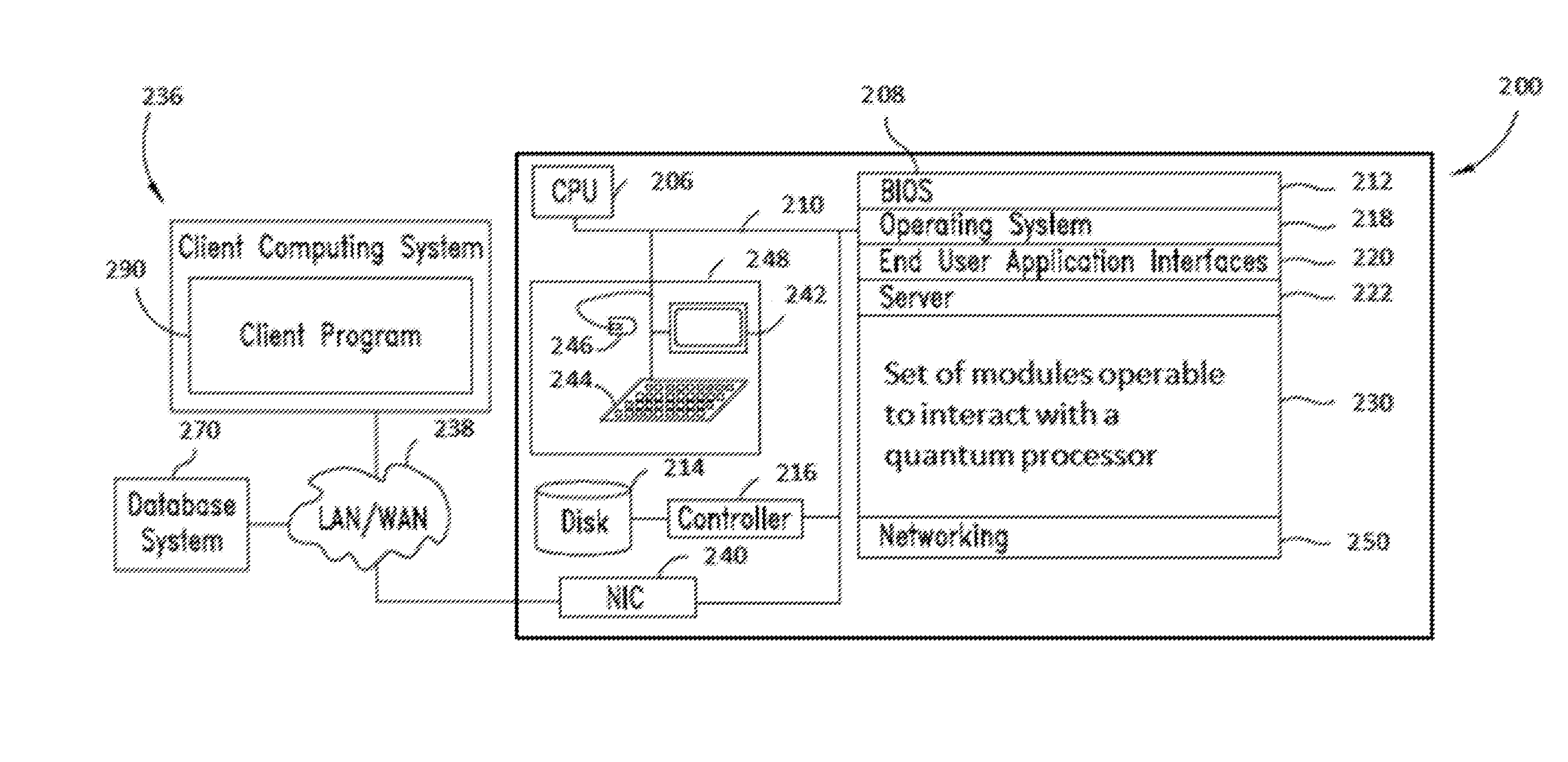

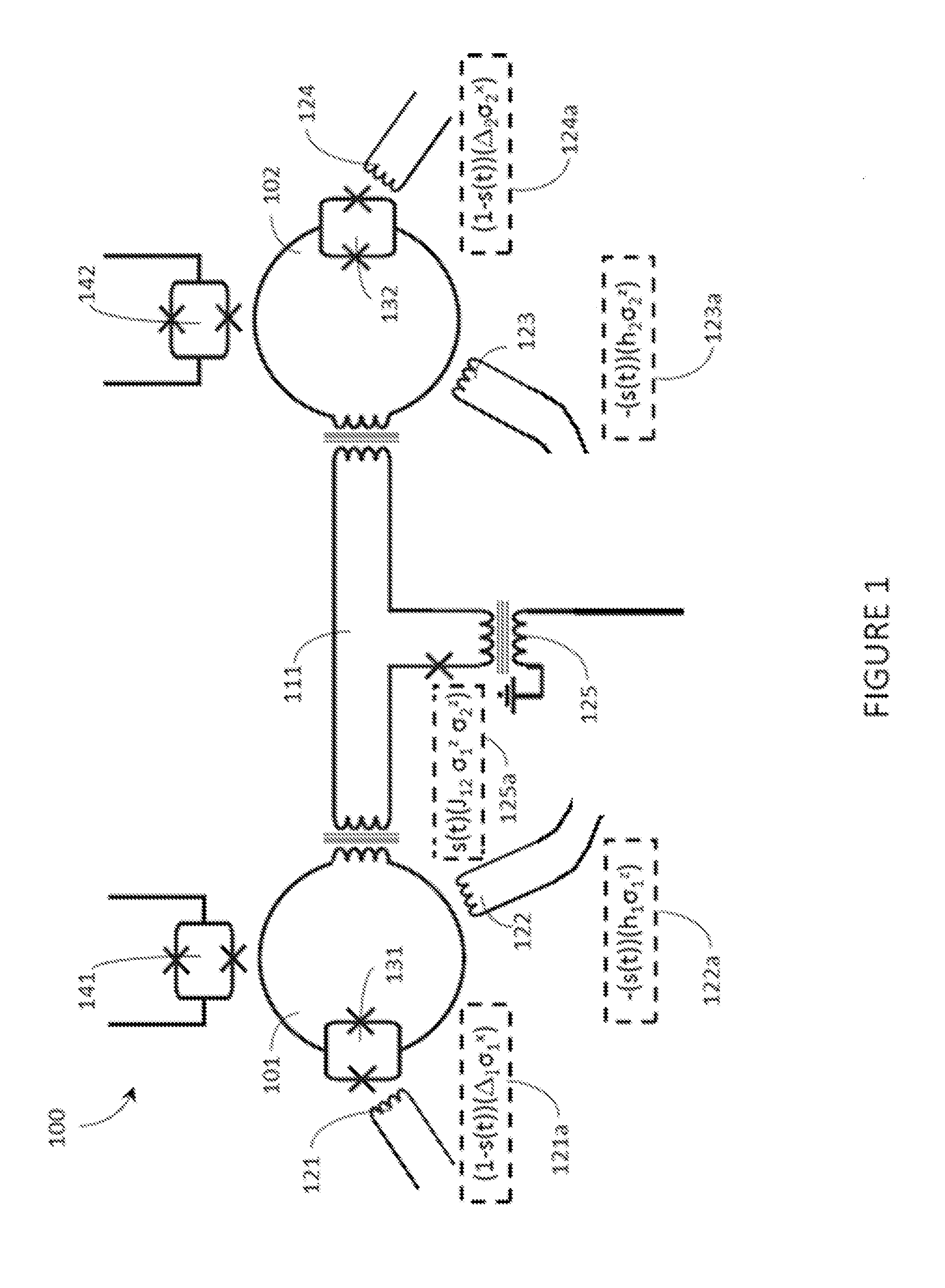

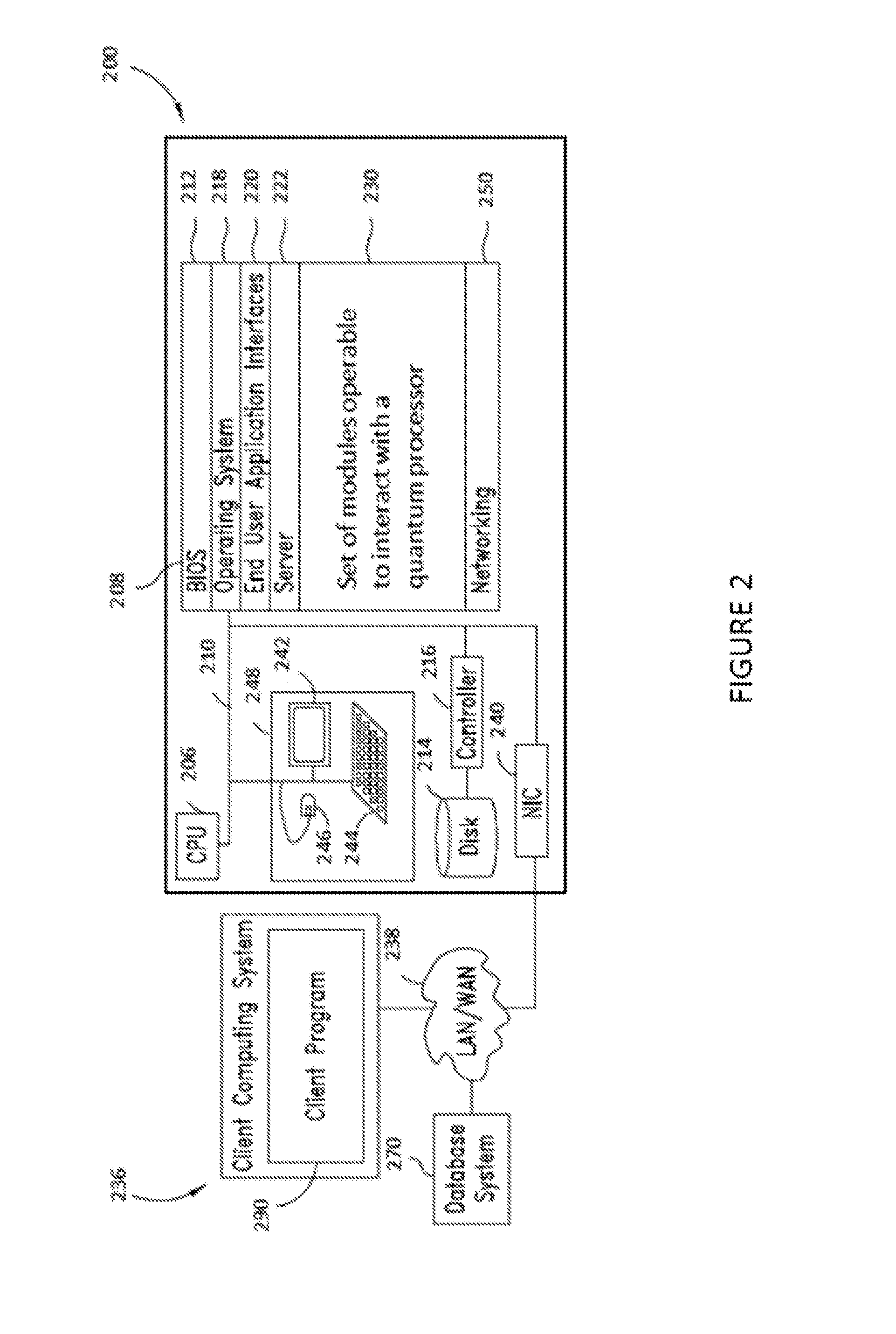

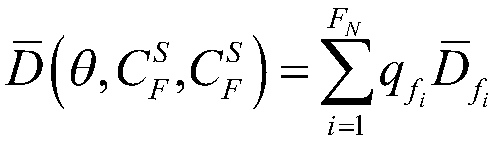

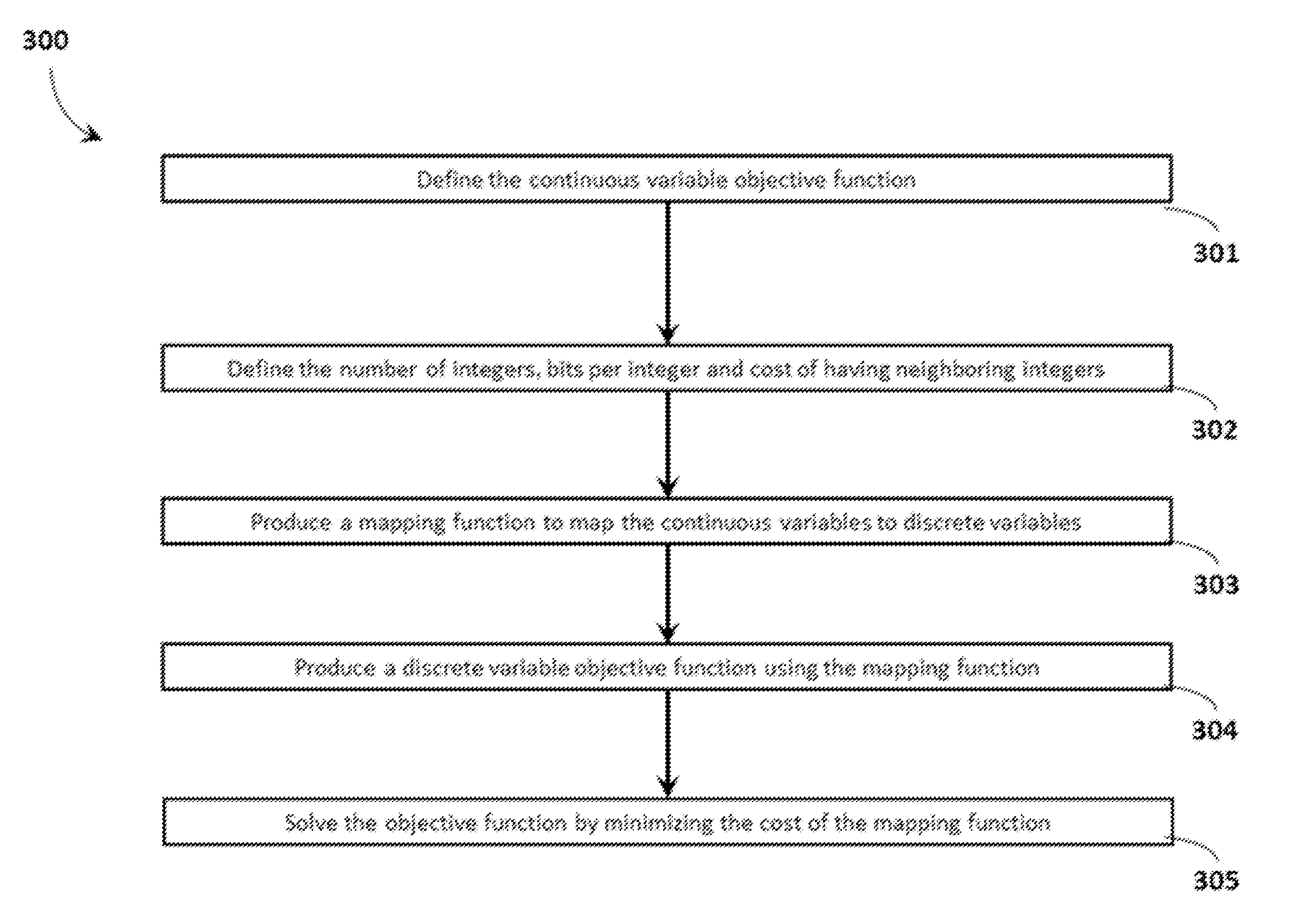

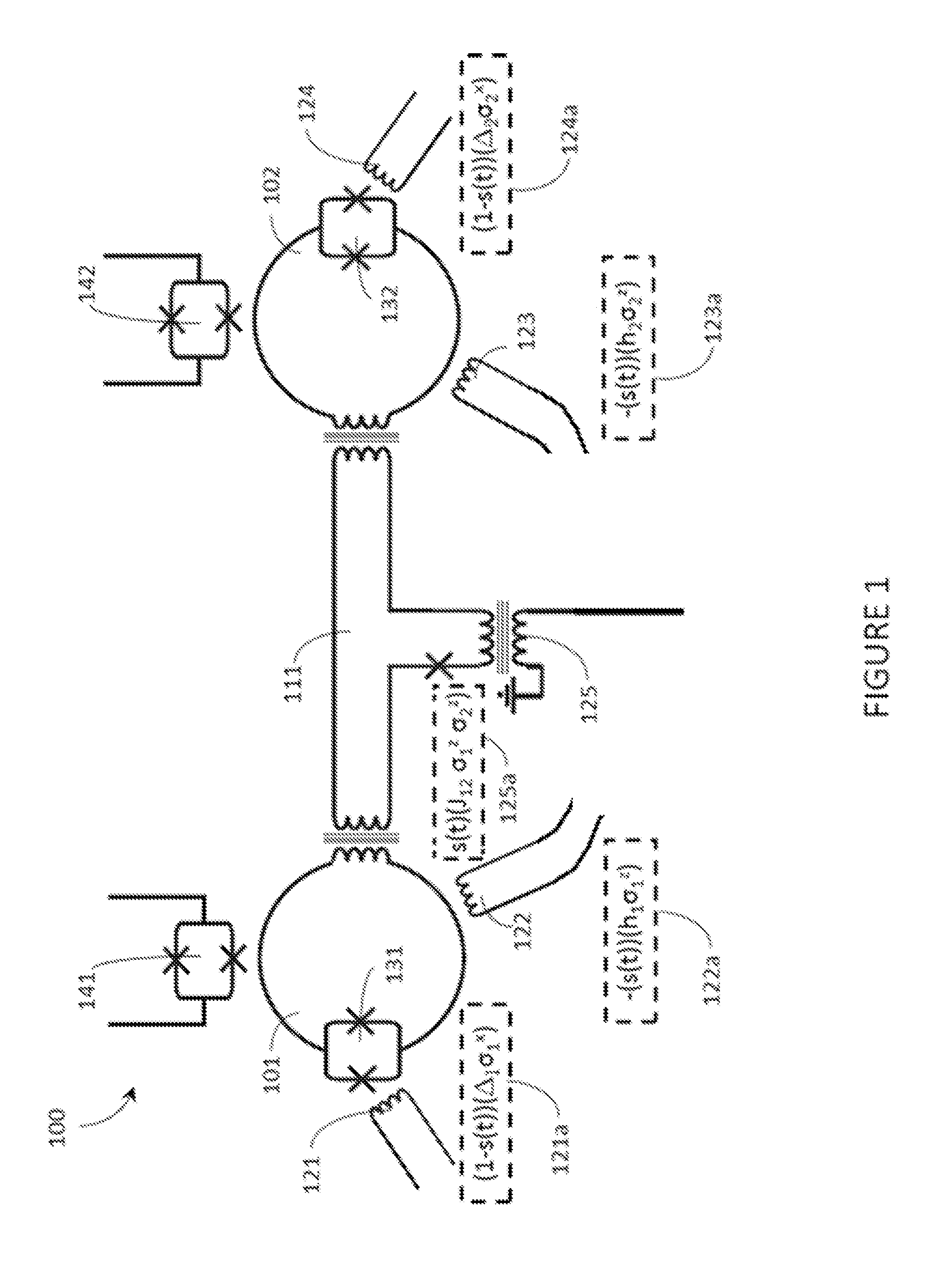

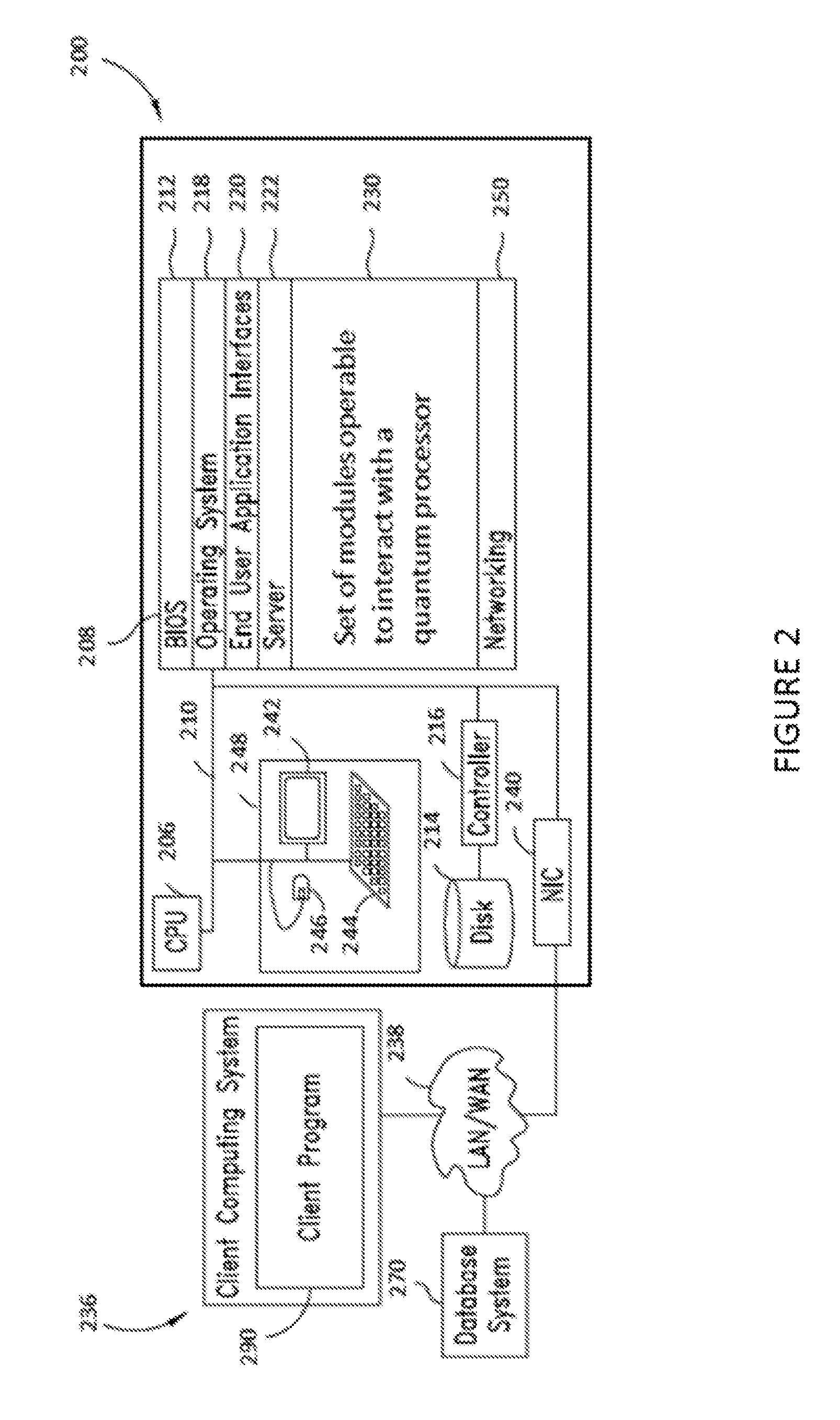

Quantum processor based systems and methods that minimize a continuous variable objective function

Computational techniques for mapping a continuous variable objective function into a discrete variable objective function problem that facilitate determining a solution of the problem via a quantum processor are described. The modified objective function is solved by minimizing the cost of the mapping via an iterative search algorithm.

Owner:D WAVE SYSTEMS INC

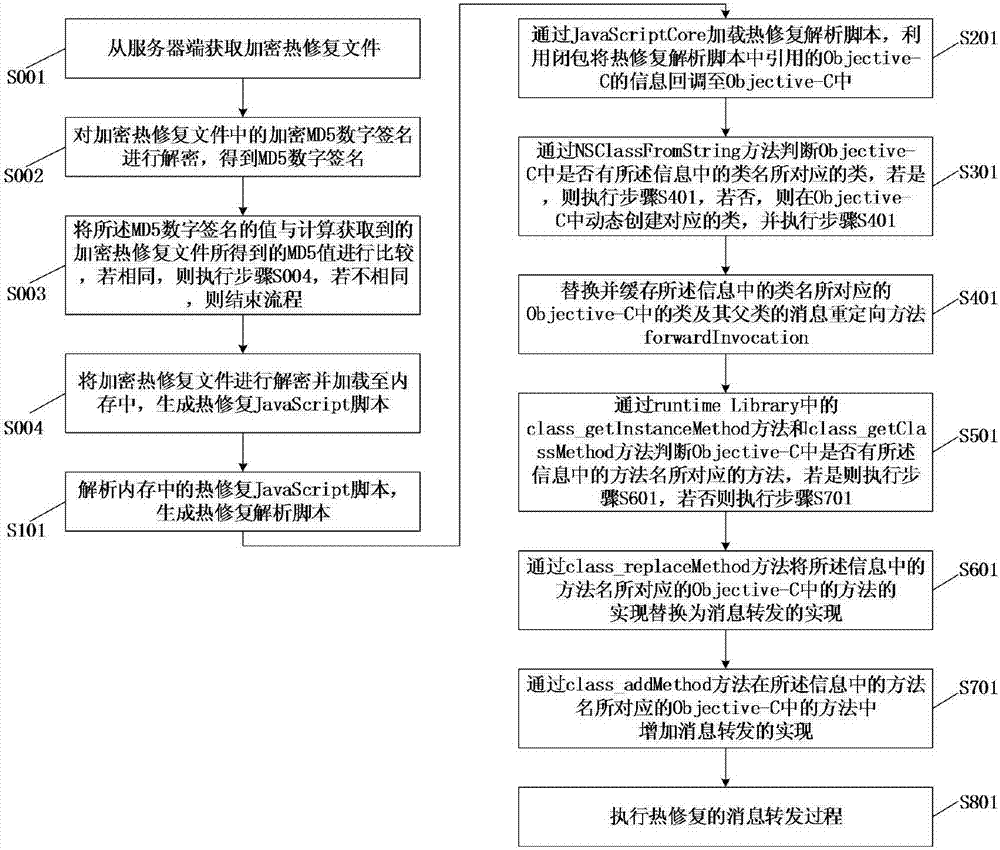

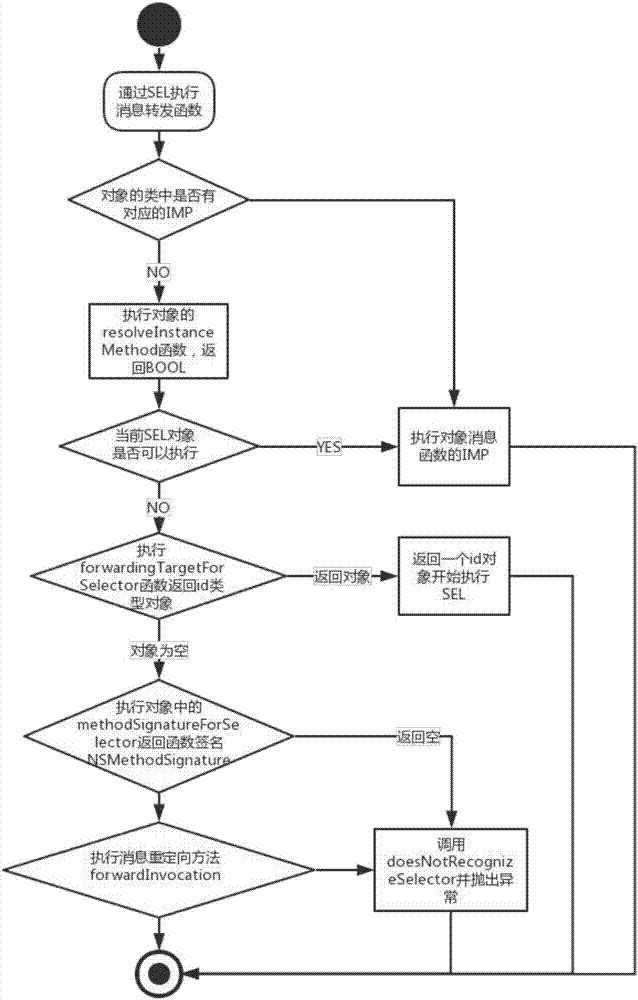

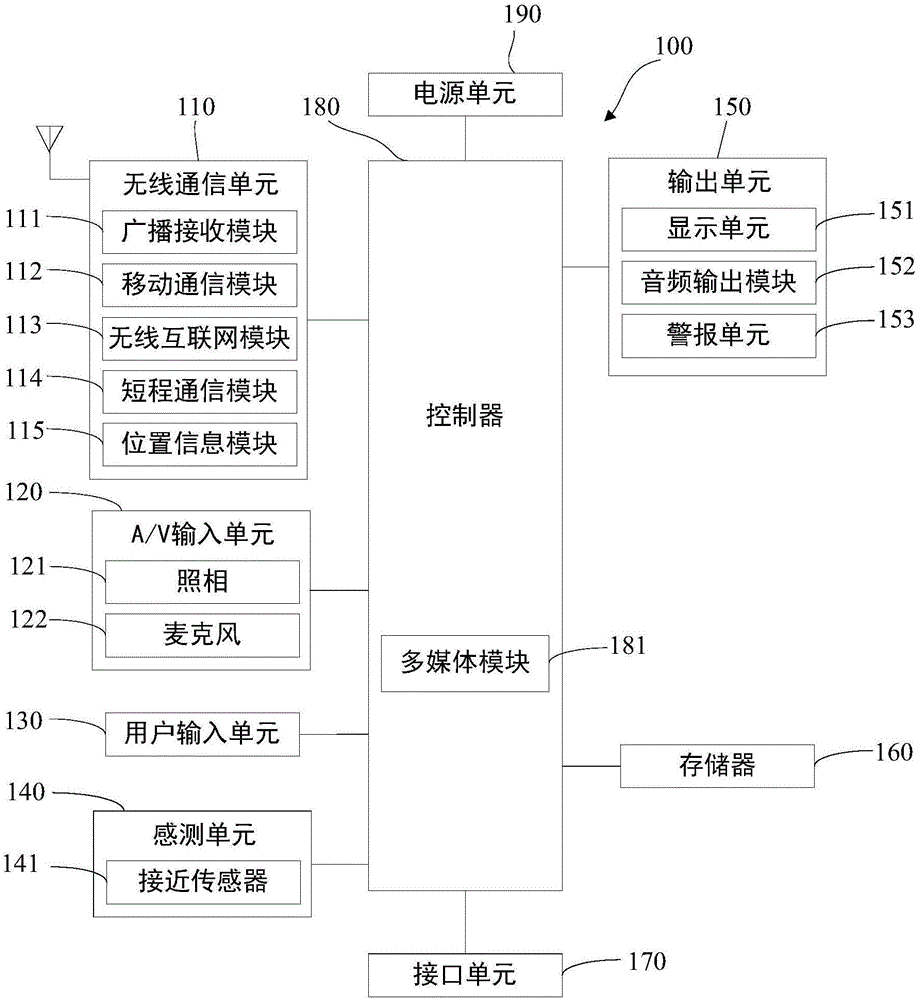

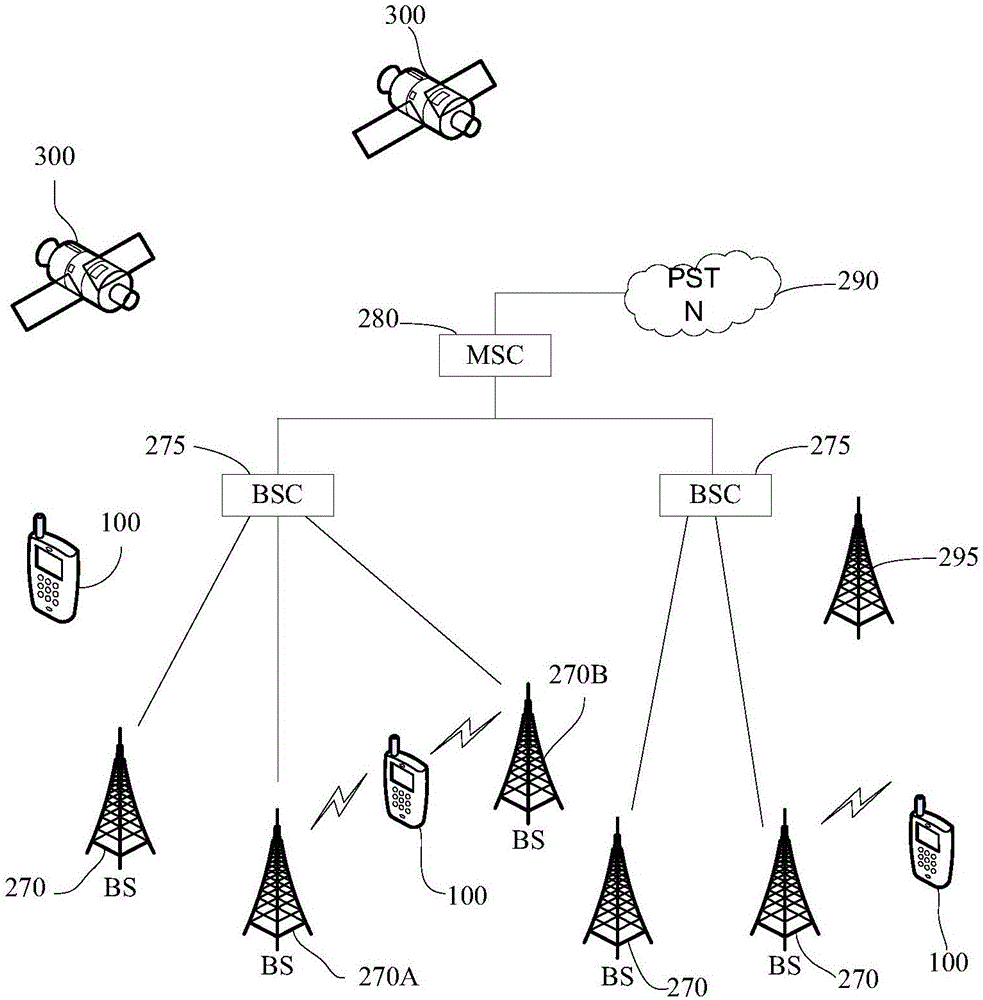

Method of solving iOS hot-fix problem of and user terminal

ActiveCN107391171AAddressing the Attack SituationResolve Review Denied IssuesSoftware engineeringUser identity/authority verificationFixed-functionAlgorithm

The invention discloses a method of solving an iOS hot-fix problem and a user terminal. According to the method, on the one hand, a method of querying whether an Objective-C class method exists is also realized through avoiding a respondsToSelector method and a performSelector method and using class_getInstanceMethod and class_getClassMethod methods in a runtime Library, and NSInvocation and forwardInvocation are applied to realize redirection of messages, and also to realize forwarding and invoking of the messages. Through relieving a sensitivity function problem existing in current open source technology, the method can enable a product with a hot-fix function to successfully pass strict examination and verification of Apple Inc..

Owner:GUANGDONG YOUMAI INFORMATION COMM TECH

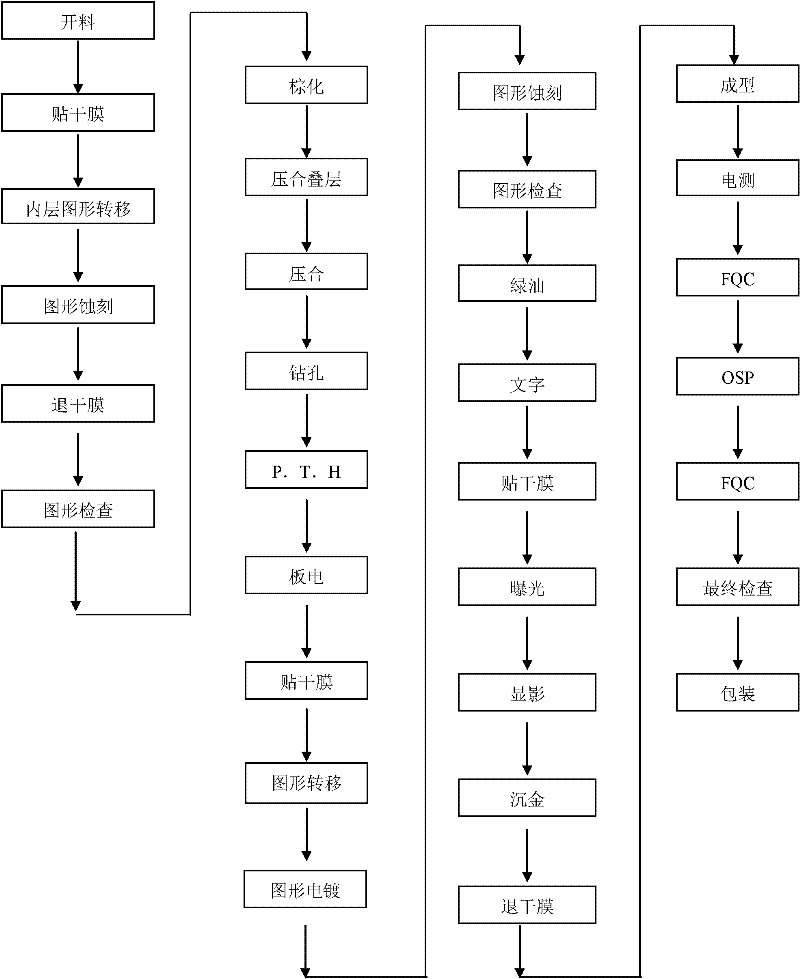

Manufacture method for multiple surface treatments on one board

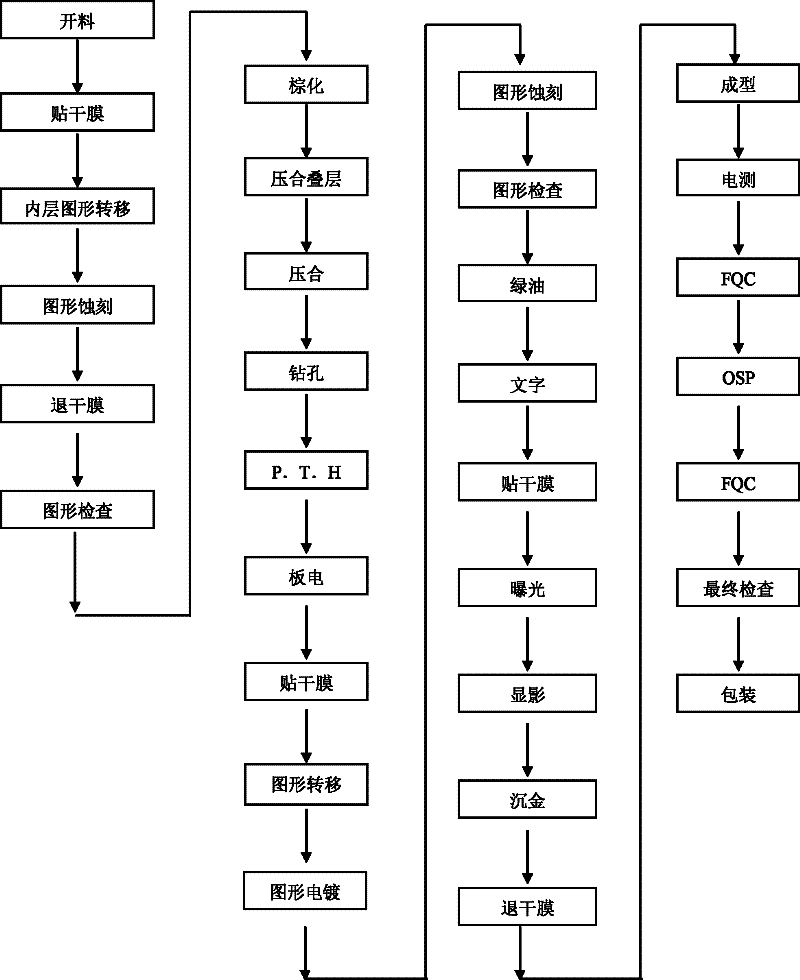

InactiveCN102365001AWin-win qualityPrinted circuit assemblingPrinted circuit secondary treatmentEtchingQuality assurance

The invention discloses a manufacture method for multiple surface treatments on one board. The manufacture method comprises the following steps of: cutting: cutting copper foils according to the design requirement of each layer; affixing of photosensitive dry films: affixing the photosensitive dry films to every internal layer except for the outmost top layer and bottom layer; pattern transfer: transferring the pattern of every internal layer to the surface of the board; pattern etching: fully etching off the unneeded positions with etching chemical liquid; removal of dry films: fully removing the affixed dry films; pattern checking: checking the open short and other bad phenomena of a circuit by using a scanning instrument; browning: mainly roughening the copper surfaces and circuit surfaces in every internal layer; lamination and pressing: completely laminating and pressing the internal / external layers together; mechanical drilling: drilling to form conduction holes of every layer and element holes; P.T.H (plating of through hole): depositing copper on the inner walls of each hole; electroplating: thickening the copper layers in the holes of the circuit board and the copper layers on the surface of the board; affixing of a photosensitive dry film: affixing a photosensitive dry film to the whole surface of the external layer; transferring of patterns: transferring the patterns of the external layer to the surface of the board; electroplating of patterns: electroplating the patterns for thickening the copper layers in the holes of the circuit board and the copper layers of the patterns; etching of the patterns: fully etching off the unneeded positions with etching chemical liquid; checking of the patterns: checking the open short and other bad phenomena of the circuit by the scanning instrument; application of green oil: endowing the board with insulation action; affixing of a photosensitive dry film: affixing the photosensitive dry film to the whole surface of the external layer; exposure: exposing the position to be gold-plated; development: developing the position to be gold-plated; gold deposition: fully plating gold on the developed positions of the photosensitive dry film, wherein the undeveloped positions of the dry film are protected by the dry film and can not be gold-plated; removal of the dry film: removing the dry film; shaping: finishing the produced circuit board until the size meets the finished product requirement; detection: testing the shaped circuit board to confirm that appearance and function problems are not existed; OSP (organic solderability preservatives) treatment: carrying out OSP treatment on the positions which are not gold-plated by forming an anti-oxidation film; FQC (final quality control): fully checking again to confirm that appearance and function problems are not existed; and final checking: checking after QA (quality assurance).

Owner:广东达进电子科技有限公司

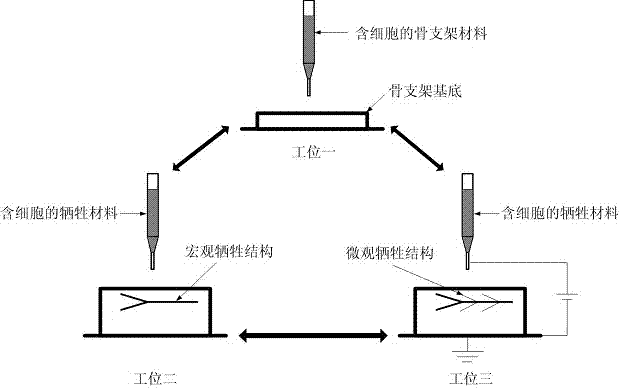

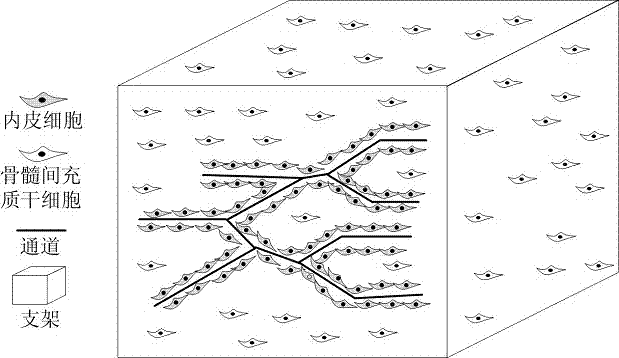

Building method of Pre-revascularizational large biological bone scaffold of composite cell

ActiveCN107412851AImplement the buildReduce harmAdditive manufacturing apparatusTissue regenerationOsteoblastDirect writing

The invention discloses a building method of a pre-revascularizational large biological bone scaffold of a composite cell which is used for the field of biological manufacturing. According to the building method of the pre-revascularizational large biological bone scaffold of the composite cell, composite biological 3D printing, electro-hydro dynamics direct writing, subtractive manufacturing and a cell assembly technology are adopted to build a functional pre-revascularizational network in the interior of the large biological bone scaffold to promote repairing of large bone defect. The key of the building method lies in the fact that sodium alginate which is a biological material and can be degraded in a body is adopted to serve as a sacrificial material, endothelial cells are loaded in the sodium alginate, and the sodium alginate is adhered to the surface of a prefabricated vessel network through migration of the endothelial cells. Meanwhile, the sodium alginate is degraded to form the prefabricated vessel network. In addition, human mesenchymal stem cells in a bone scaffold material are differentiated into osteoblasts, and synthesizes and secretes bone matrix under the mutual promotional effect of the endothelial cells, mineralization is conducted, so that the efficiency of bone tissue repair is improved, the functional problem of large bone tissue repair is solved, and the building method has important significance on solving the large bone tissue repair problem to clinical medicine.

Owner:SHANGHAI UNIV

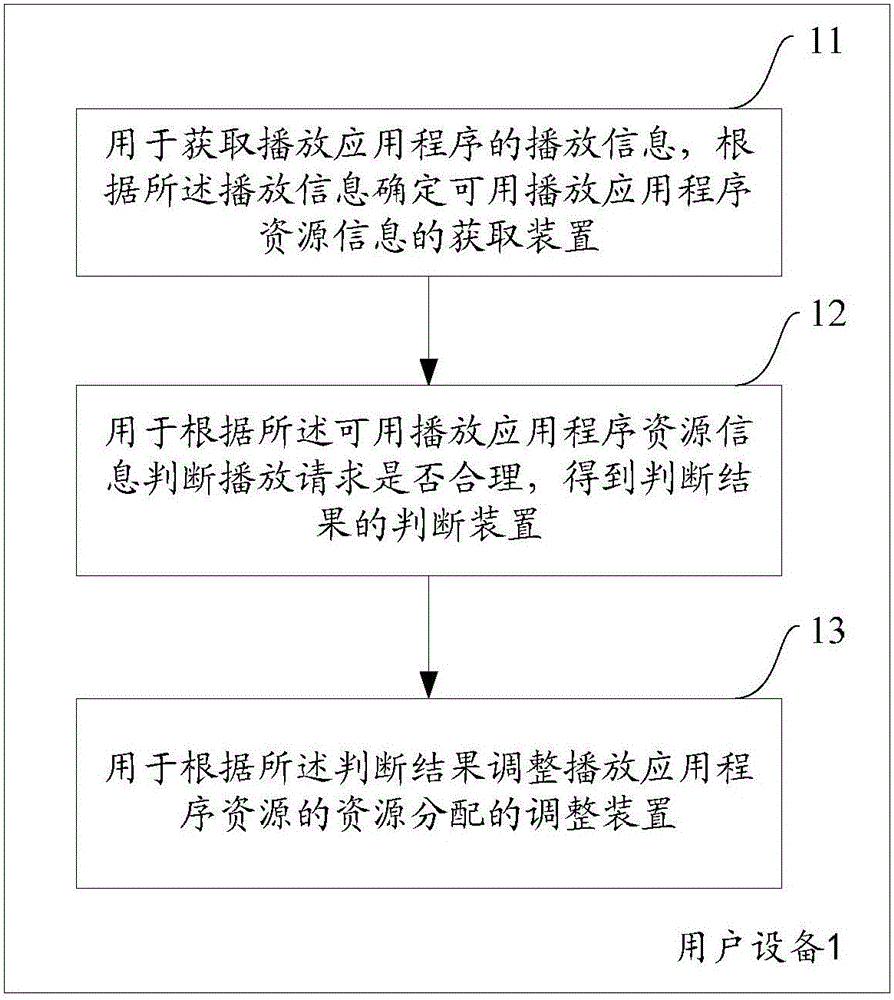

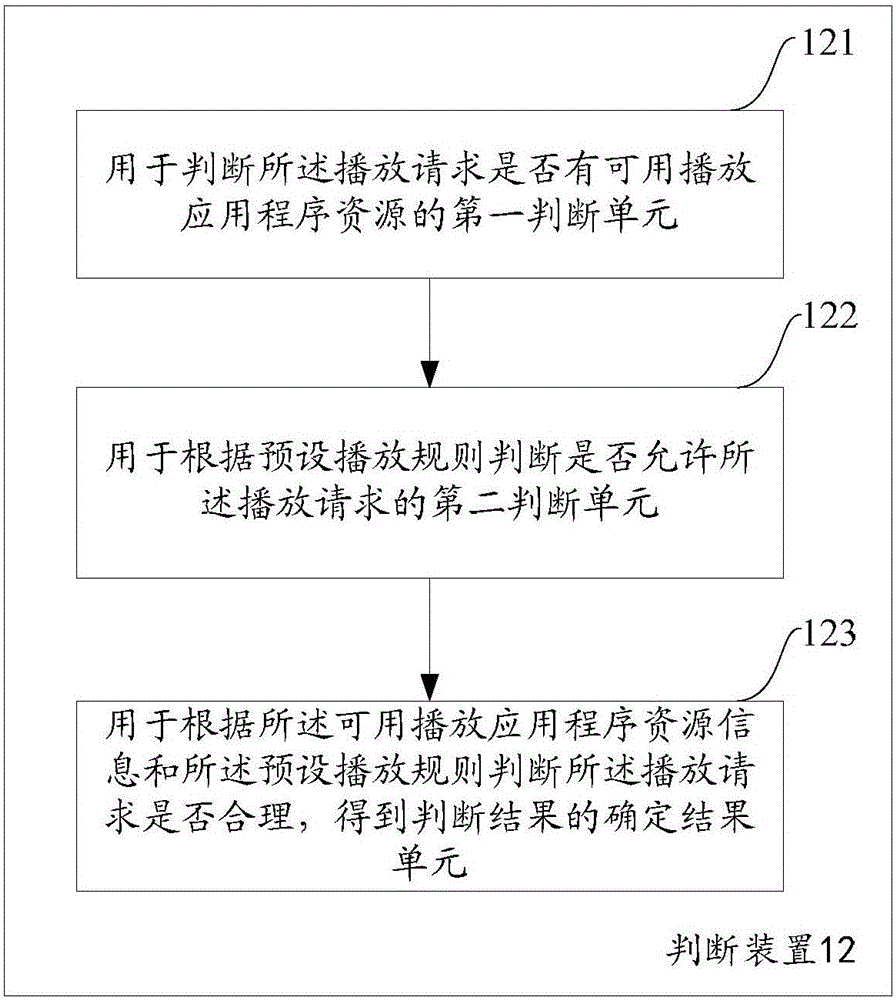

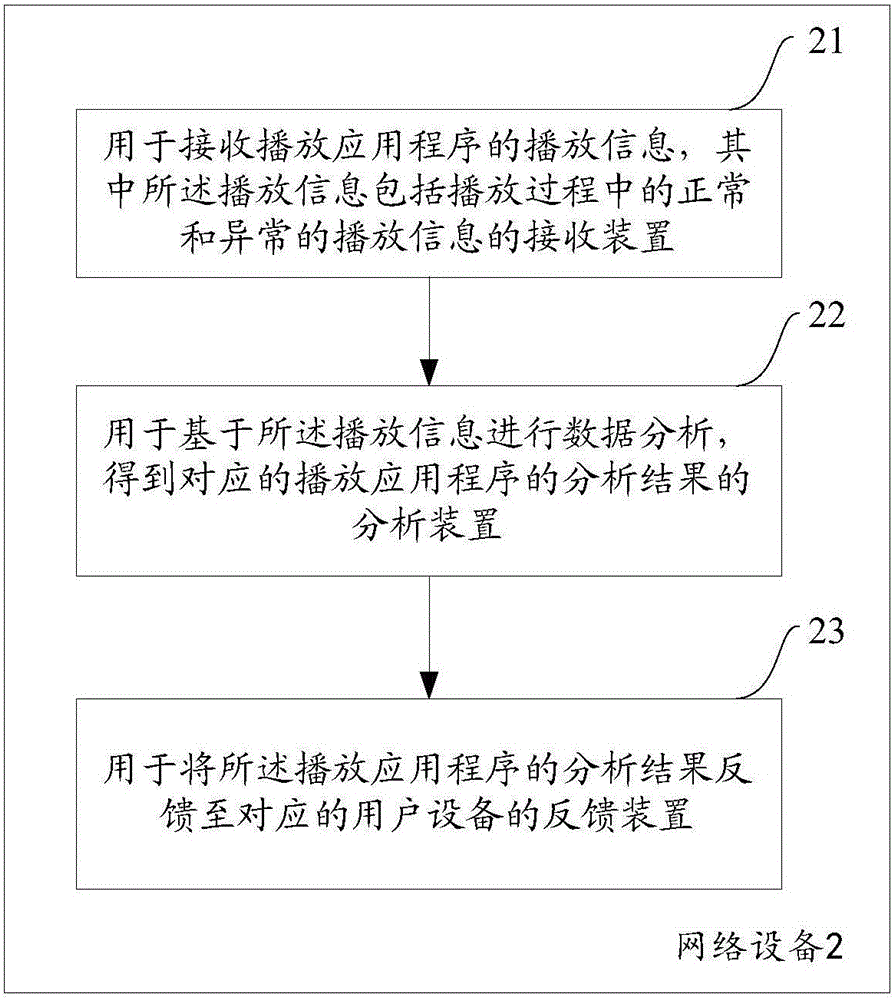

Method and equipment for controlling playing application program resources

InactiveCN106155828AResolve playback conflictsFind functional problems in timeResource allocationFault responseResource informationApplication programming interface

The invention aims at providing a method and equipment for playing application program resources. The method comprises the following steps of acquiring playing information of playing application programs at a user equipment end, and determining usable playing application program resource information according to the playing information; judging whether a playing request is reasonable or not according to the usable playing application program resource information to obtain a judgment result; adjusting resource allocation of the playing application program resources according to the judgment result. Therefore resource management on a programming interface level of the playing application programs is realized, and potential playing contradiction among all the playing application programs is overcome; besides, the playing information is uploaded to network equipment for big data analysis. Furthermore, the network equipment performs the big data analysis on stored system-level playing information, so that a function problem of the application programs can be found in time, and early diagnosis and optimization are performed.

Owner:WHALEY TECH CO LTD

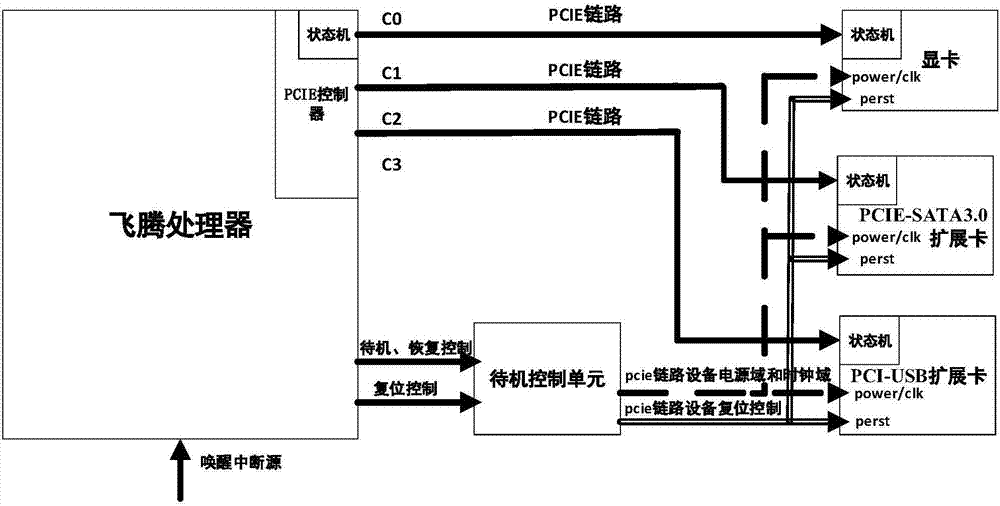

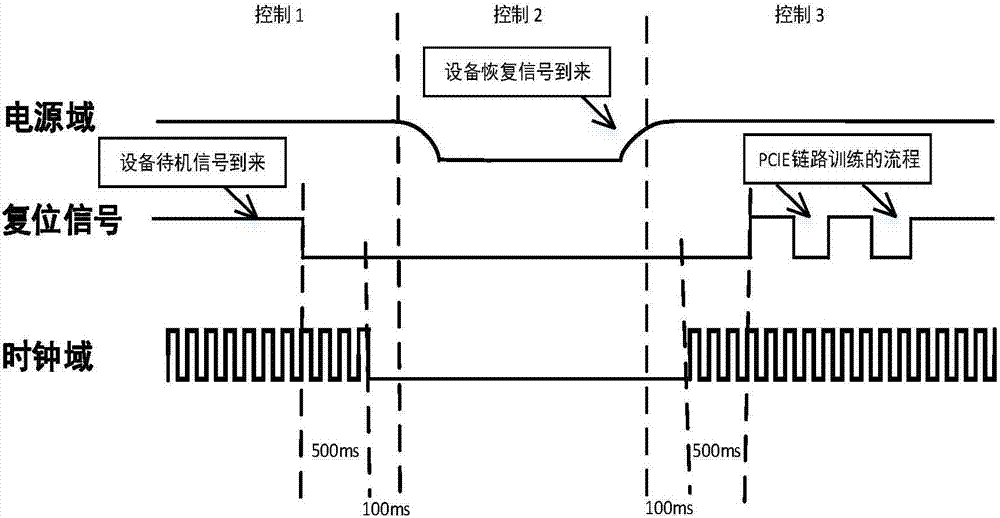

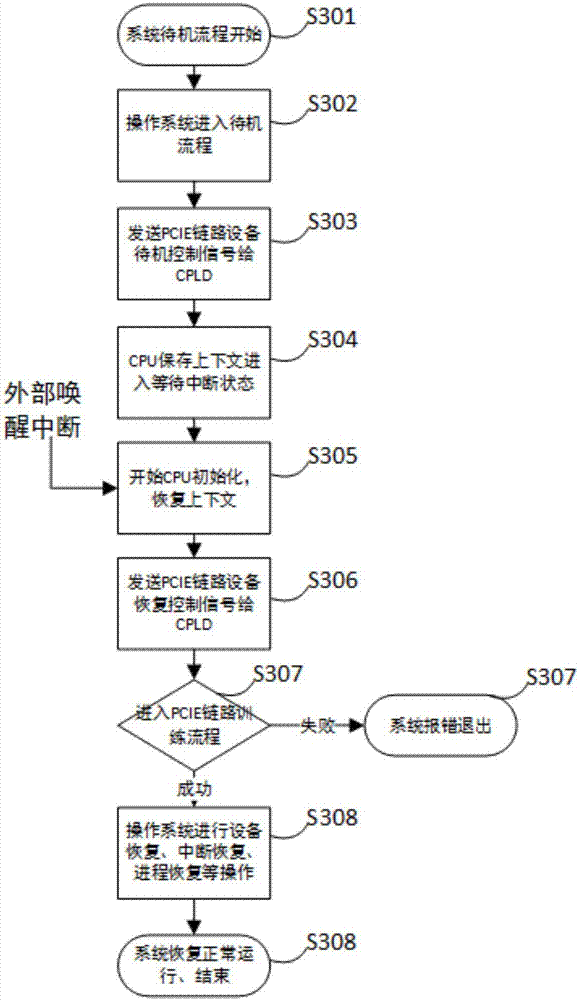

Phytium platform based PCIE link device standby and recovery method

ActiveCN107957885ASolve the problem of abnormal resident statusRealize power management standby recovery functionSpecific program execution arrangementsRecovery methodOperational system

The invention discloses a phytium platform based PCIE link device standby and recovery method. The method comprises the steps that an application layer is used for initiation, a system enters a standby process; a standby signal of the PCIE link device is sent to a CPLD complex programmable logic device; a CPU saves the context and enters the waiting interrupt state; after an awakening interrupt isreceived, the system recovery process is started; a recovery signal of the PCIE link device is sent to a CPLD; the PCIE link training process is entered, and link training is performed, and if failed, an error is reported, and exiting is performed; the system performs restorative operations, and then the operation system recovers to normal operation. The method has the advantages that for solvingthe PCIE bus based ARM64 platform standby function problem, the problem that the PCIE link state machine link status is abnormal and resident is solved, and therefore the power management standby recovery function of a phytium platform is achieved.

Owner:KYLIN CORP

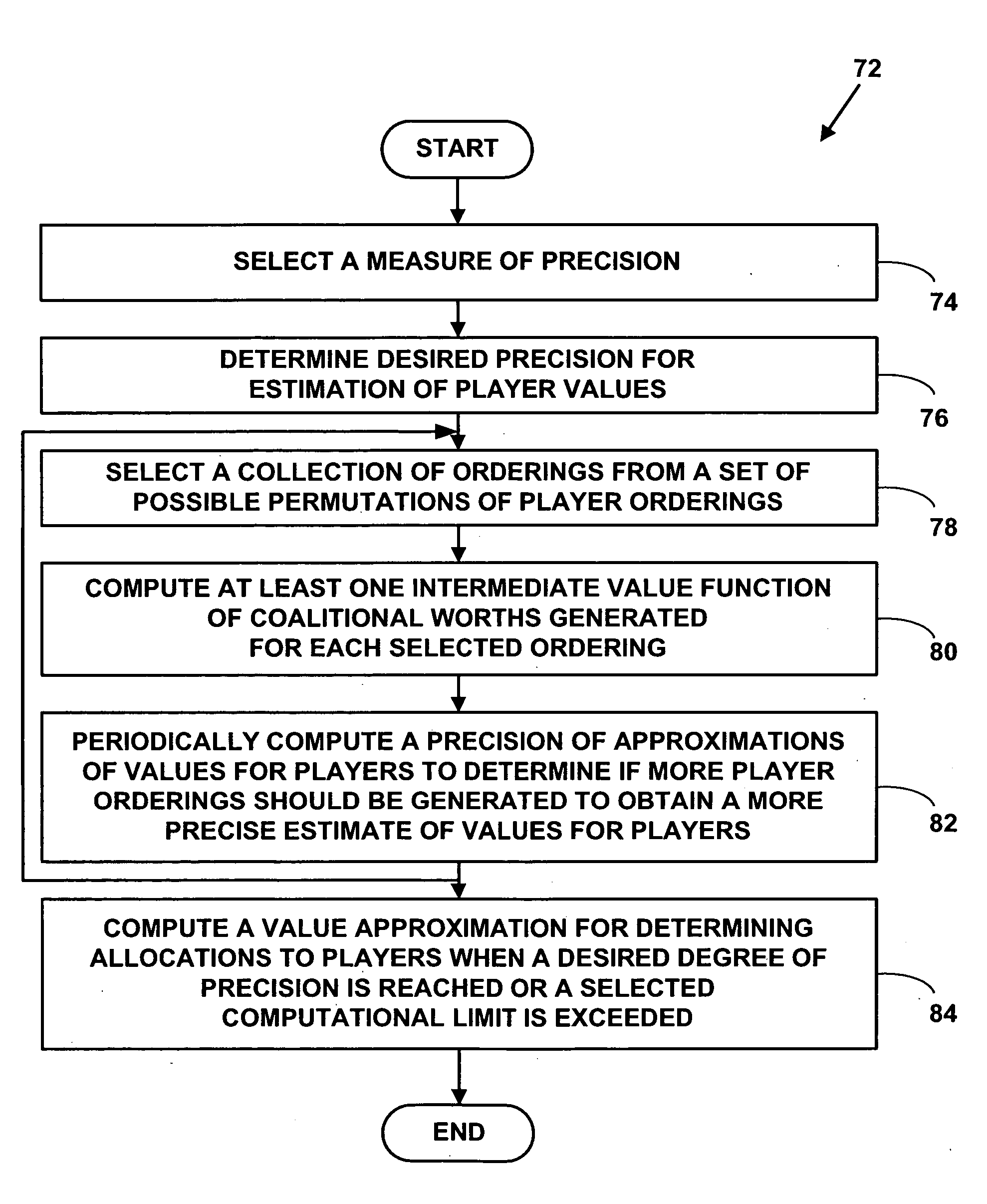

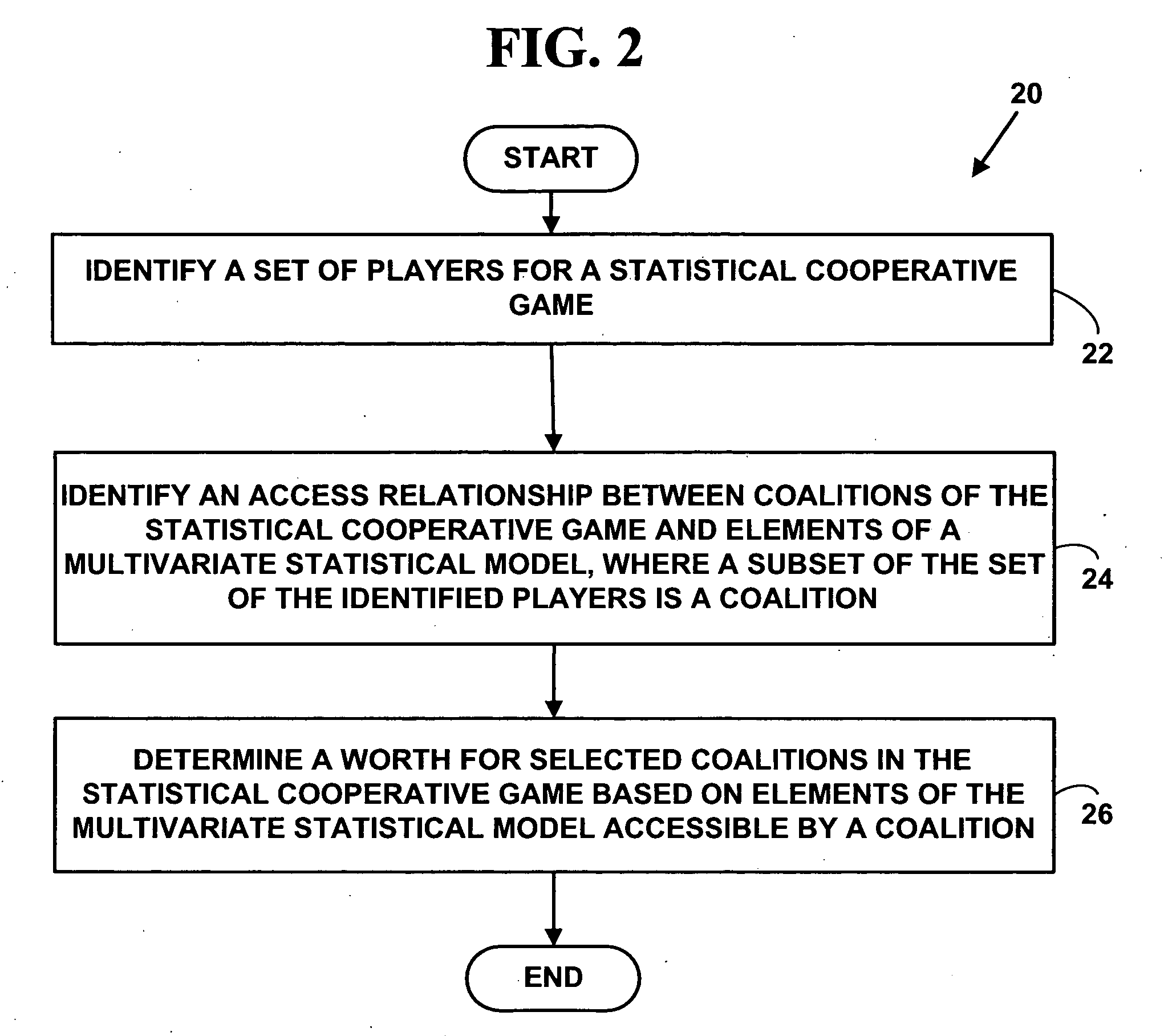

Method and system for approximating value functions for cooperative games

A method and system for approximating a value functions for cooperative games. The method and system include approximating value functions for large cooperative games. The method and the system may be applicable to other types of value function problems such as those found in engineering, finance and other disciplines.

Owner:FELDMAN BARRY E

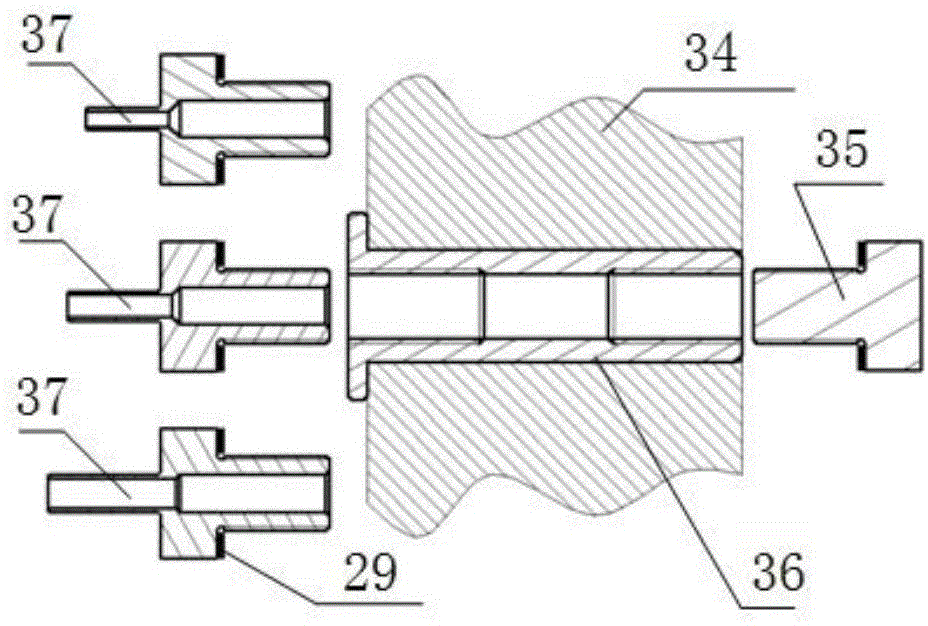

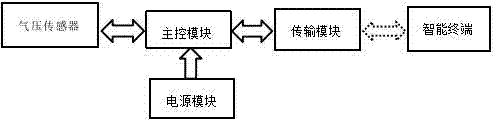

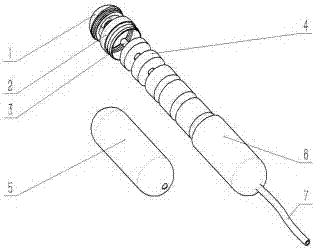

Novel pelvic diaphragm muscle rehabilitative apparatus externally connected with gas pressure sensor and use method

Provided is a rehabilitation type medical instrument for exercising the vagina muscle of females, improving the contractility of the pelvic diaphragm muscle, and relieving stress incontinence and bulging or prolapse and other symptoms of the vagina, the uterus and other organs. The equipment mainly comprises a balance weight rehabilitative apparatus body, a silica gel ventilating pipe and a gas pressure detector. The balance weight rehabilitative apparatus body and the gas pressure detector are mainly connected through the silica gel ventilating pipe. The silica gel ventilating pipe can be independently used in cooperation with the rehabilitative apparatus body, and training of different kinds of strength is achieved by adjusting the number of balance weights. Meanwhile, the rehabilitative apparatus body can achieve biological pressure feedback in combination with the gas pressure detector. Detected data can be sent to a smart mobile phone side through the gas pressure detector, the mobile phone side analyzes and processes the received data, therefore, the pelvic diaphragm muscle force is evaluated, the exercise time and muscle force effect oscillogram of each day can be recorded, and the final effect of relieving postpartum woman pelvic diaphragm muscle looseness, uracratia and other functional problems is achieved.

Owner:CHENGDU HEXU MEDICAL TECH CO LTD

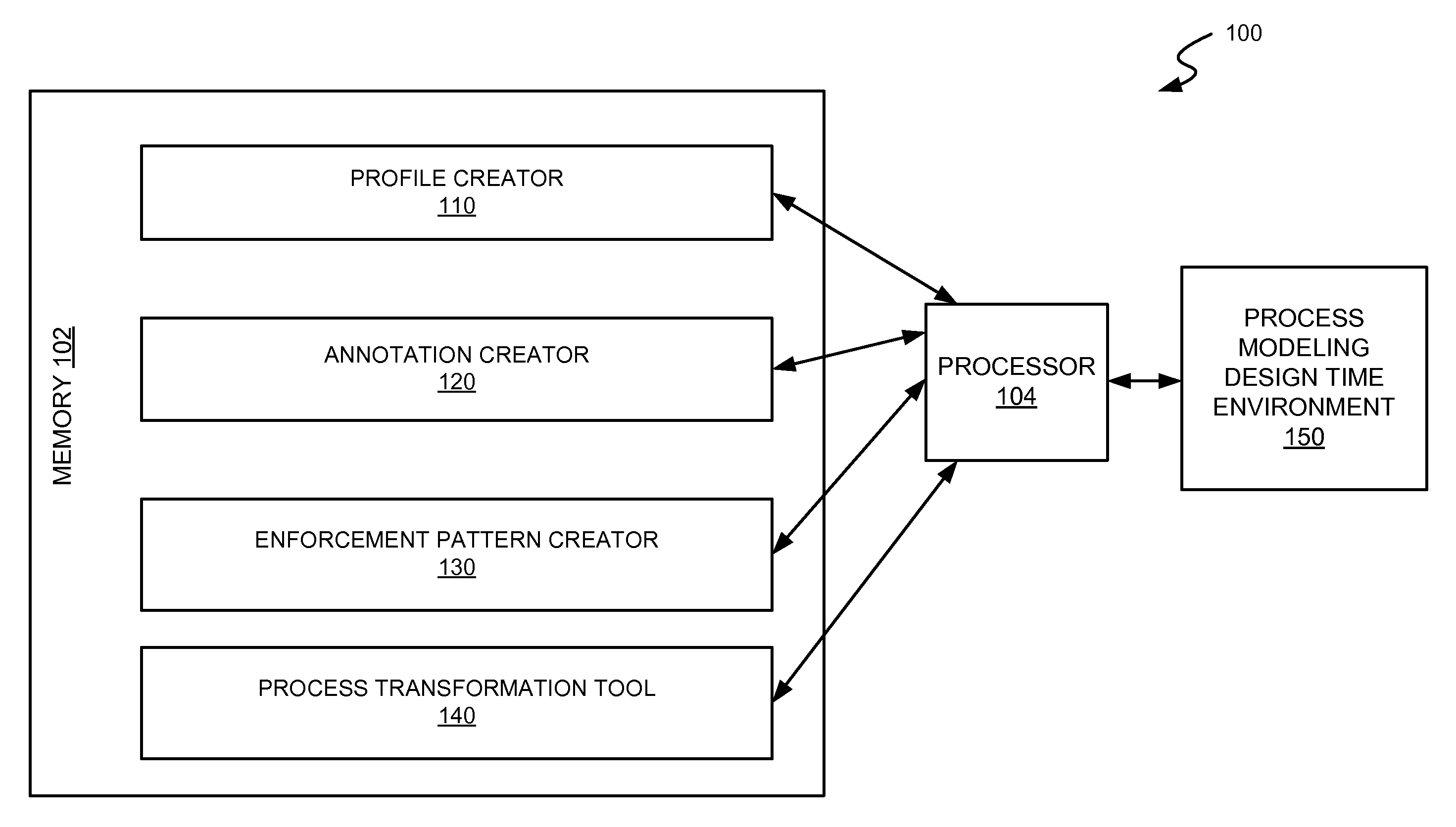

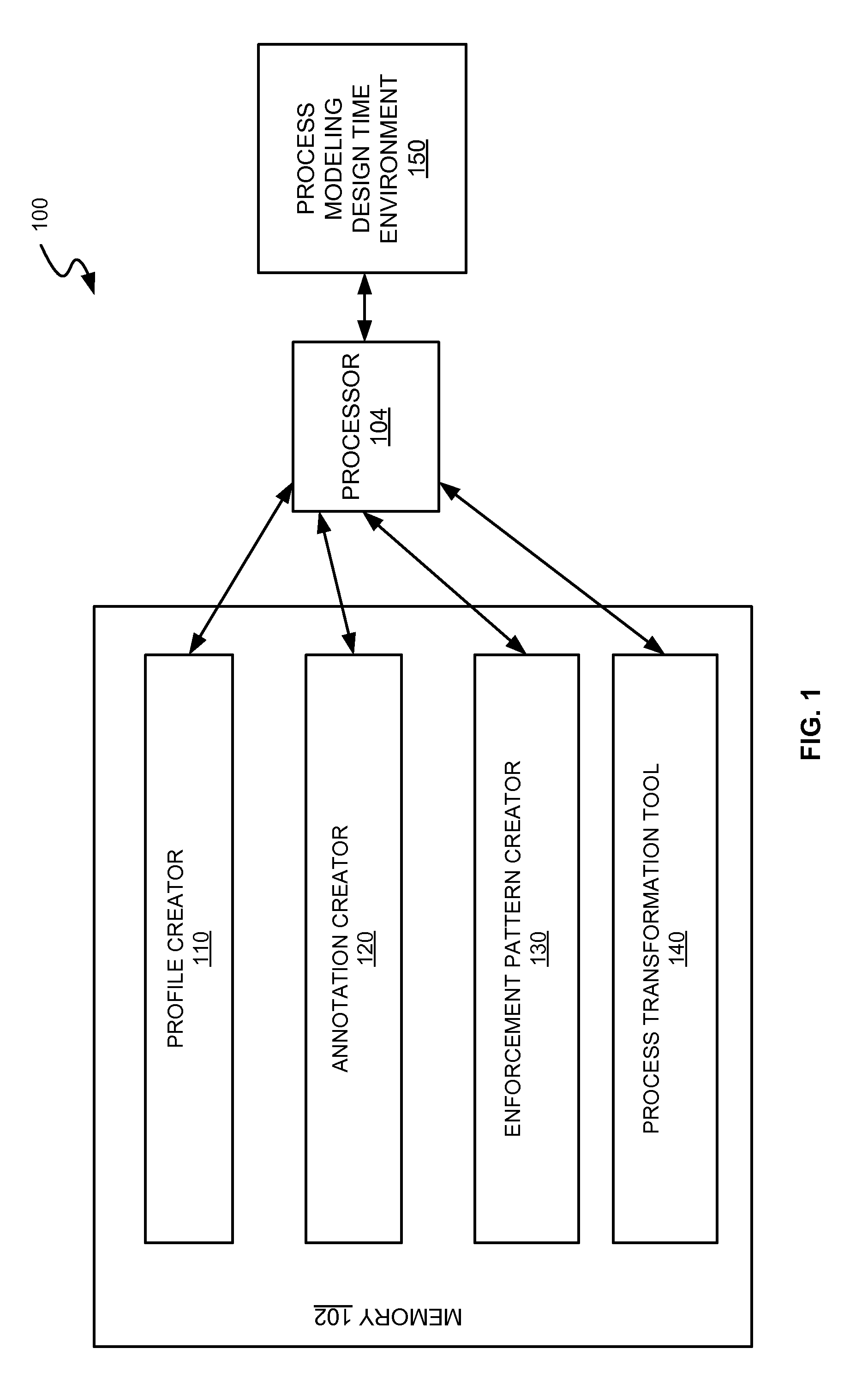

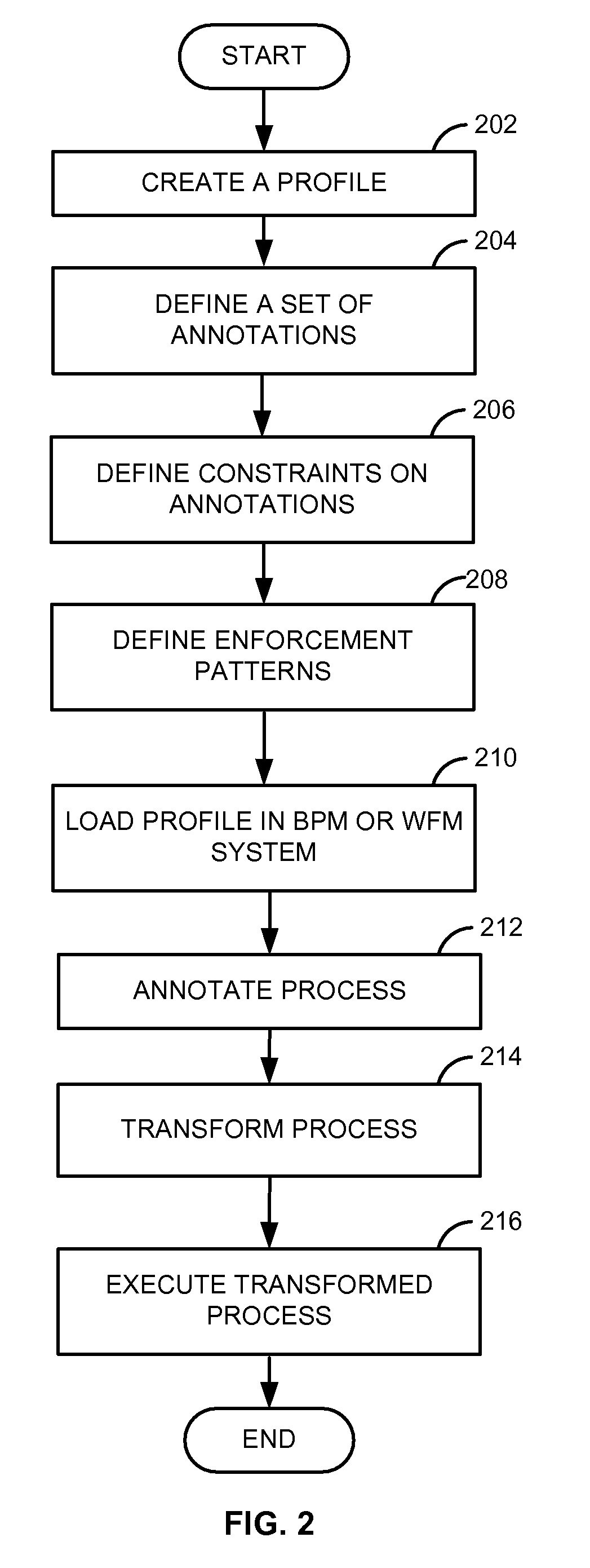

Method and system for expressing and enforcing non-functional concerns in business process management systems and workflow systems

InactiveUS20100218082A1ForecastingSpecial data processing applicationsFunction problemComputer science

A system and method to express and enforce non-functional properties in process management systems are described. Non-functional properties are expressed via annotations. Annotations and corresponding constraints are grouped in profiles. Further, non-functional properties are enforced via rules specified in enforcement patterns that are associated with the annotations. The enforcement patterns extend processes with additional process elements and logic for enforcing non-functional properties at runtime.

Owner:SAP AG

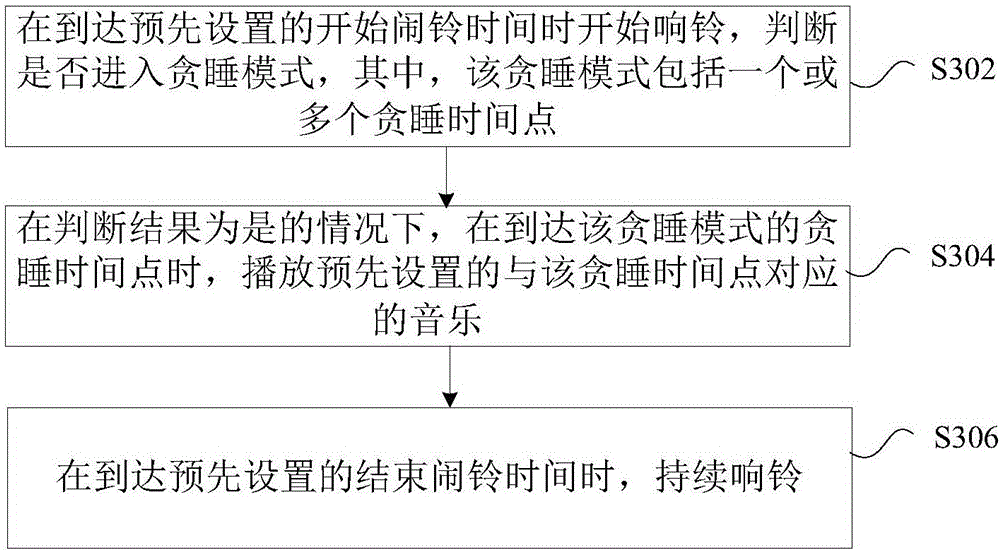

Method and device for managing alarm of intelligent watch

InactiveCN106357886ASolutionSolve functionDevices with bluetooth interfacesSubstation equipmentFunction problemAlarm management

The invention discloses an intelligent watch alarm management method, wherein the method comprises the following steps: start ringing before reaching the preset alarm time in snooze mode' play the preset music corresponding the snooze time point in snooze mode; continuous ringing till the end of the alarm time. In addition, the invention also discloses a smart watch alarm management device. The scheme provided by the invention solves single function problem of related technology for the alarm clock in the smart watch, start ringing at the beginning of the alarm time, play the corresponding music in snooze mode, and continuous ringing at the end of last time when the bell rings.Through different tones in a relatively long time, it becomes easier to wake up users, thus improve the user experience.

Owner:NUBIA TECHNOLOGY CO LTD

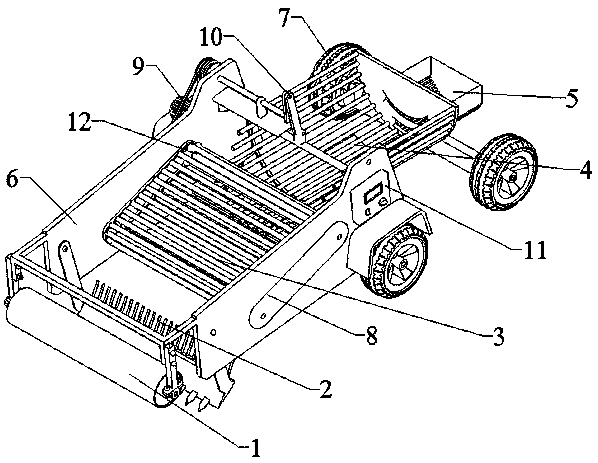

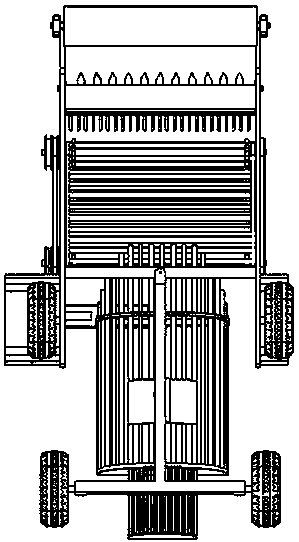

Harvesting-screening-integrated machine for potatoes

The invention discloses a harvesting-screening-integrated machine for potatoes. The harvesting-screening-integrated machine comprises a roller, a bulldozing blade, a conveying sieve, a vibration sieve, a classification collection tank, trapezoid iron plates, driven tires, conveying sieve mounting plates, a gear meshing system, a rotary connecting rod, a touch screen control device and drive tires.The harvesting-screening-integrated machine can be divided into a potato digging system, a potato branch and leaf removing system, a potato conveying system, a soil separating system, a traveling system and a potato collecting system, wherein the potato digging system comprises the bulldozing blade; the potato branch and leaf removing system comprises the roller; the soil separating system comprises the bulldozing blade, the conveying sieve and the vibration sieve; the traveling system comprises the drive tires, the driven tires, the touch screen control device, the gear meshing system and the trapezoid iron plates; the potato collecting system comprises the classification collection tank. The harvesting-screening-integrated machine is simple to operate, capable of integrating potato harvesting and potato screening, capable of solving the single function problem of an existing machine, high in automation level, capable of increasing potato collection level and capable of promoting thedevelopment of potato industry.

Owner:HAINAN UNIVERSITY

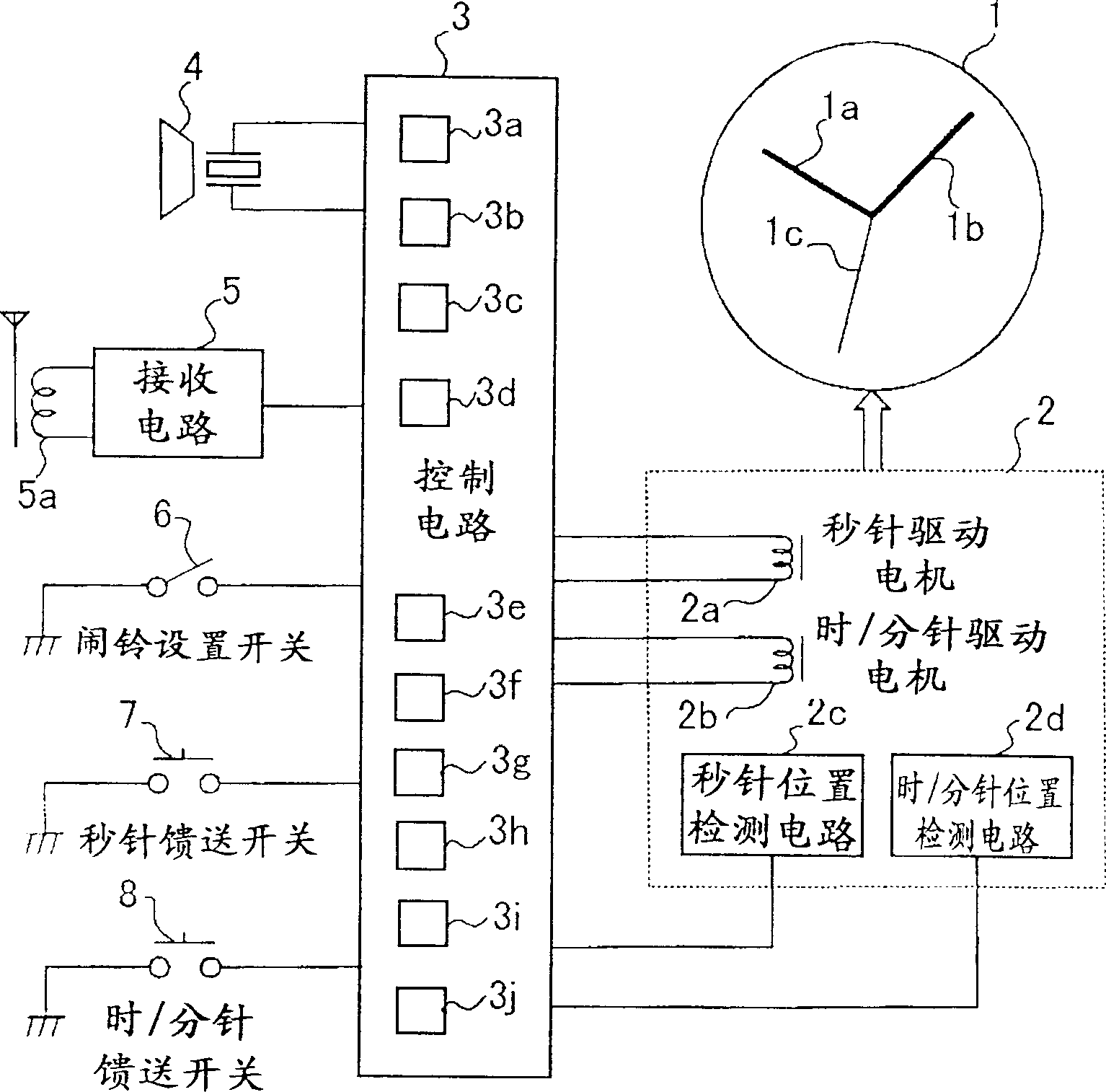

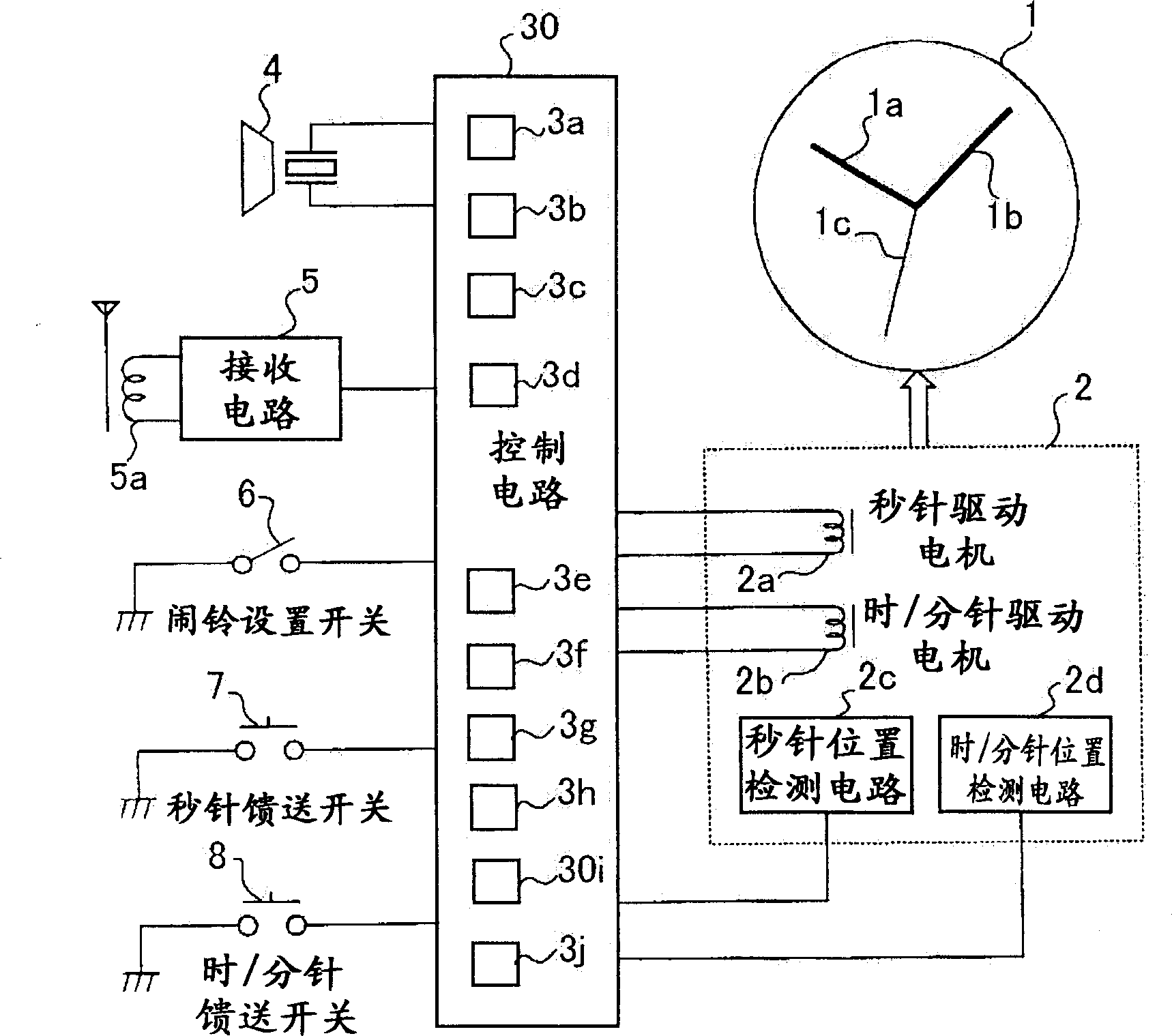

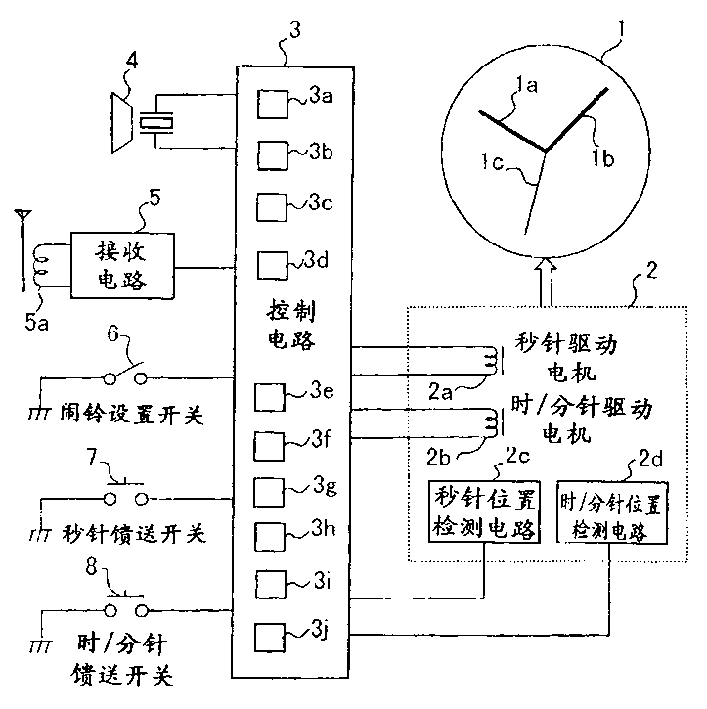

Clock and alarm clock corrected by radio wave with ringing function

InactiveCN1378108ALimit consumptionSimple structureElectric indicationElectric windingTime informationFunction problem

PROBLEM TO BE SOLVED: To provide a radio controlled clock, having alarm function, which simplifies the constitution by making the receiving function of long-wave standard waves satisfactory. SOLUTION: When an alarm setting switch 6 is at on state, the alarm time is displayed on a second hand 1c, so as to be stopped in a position corresponding to the alarm time. When 23 o'clock 57 minutes stored in a time-information reception-timing storage part 3e is reached in this situation, a reception circuit 5 starts to receive the long-wave standard waves containing time information, and the time information (a pulse signal) is detected, on the basis of the received long-wave standard waves. Since the second hand 1c is stopped, at this time, a magnetic noise generated from a second-hand drive motor 2a in the operation of the second hand 1c is not generated, and the receiving environment for the long-wave standard waves is made satisfactory, as compared with a case where the magnetic noise is generated. Since the second hand 1c is stopped in the on state of the switch 6, a detection part exclusively used to detect a state to stop the operation of the second hand is not required, and the constitution of the radio-controlled clock can be simplified.

Owner:SEIKO CLOCK INC

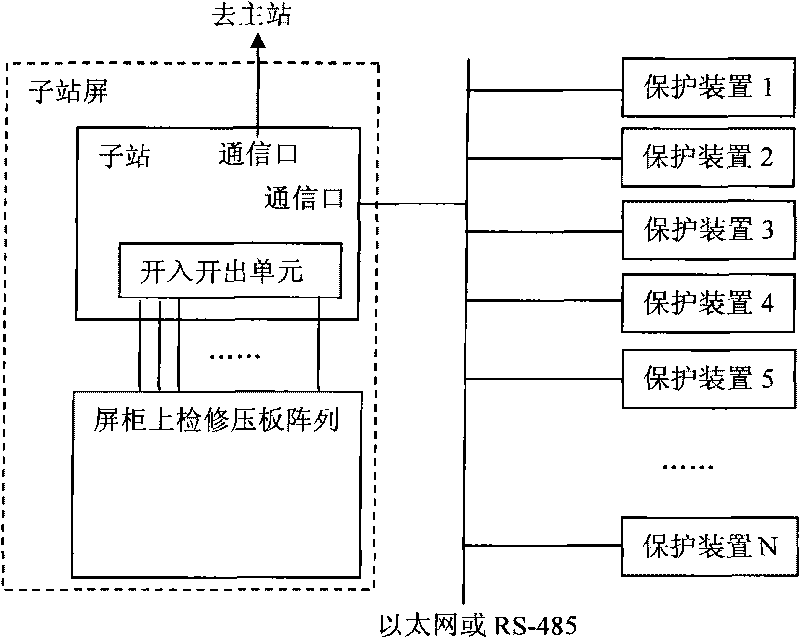

Treating method of fault information system sub-station for overhauling state of protective relaying device

ActiveCN101699706AConducive to the analysis of protective action behaviorThe method is complete and practicalCircuit arrangementsInformation technology support systemFunction problemEngineering

The invention provides a treating method of a fault information system sub-station for overhauling state of a protective relaying device, comprising the steps of installing a plurality of hard pressure pads on a sub-station cabinet with each pressure pad corresponding to one space, manually inputting the pressure pads corresponding to spaces when the device is overhauling, manually outputting the pressure pads corresponding to spaces when the overhauling is finished, and sending a state information of pressure pad to the sub-station in a communication mode by connecting to a device with a function of collecting input quantity, for identifying whether each space is at overhauling state. The sub-station identifies the protective relaying device at overhauling state according to the information of pressure pad. The method is complete and useful, perfects the content classification of information on the protective relaying device, solves the problem that the domestic protective relaying fault information management system can not identify the overhauling state and the function at running state of the protective relaying device, is beneficial for the professionals of relay protection to analyze the protecting action, and promotes the integrate practicability of the system.

Owner:STATE GRID ZHEJIANG ELECTRIC POWER +2

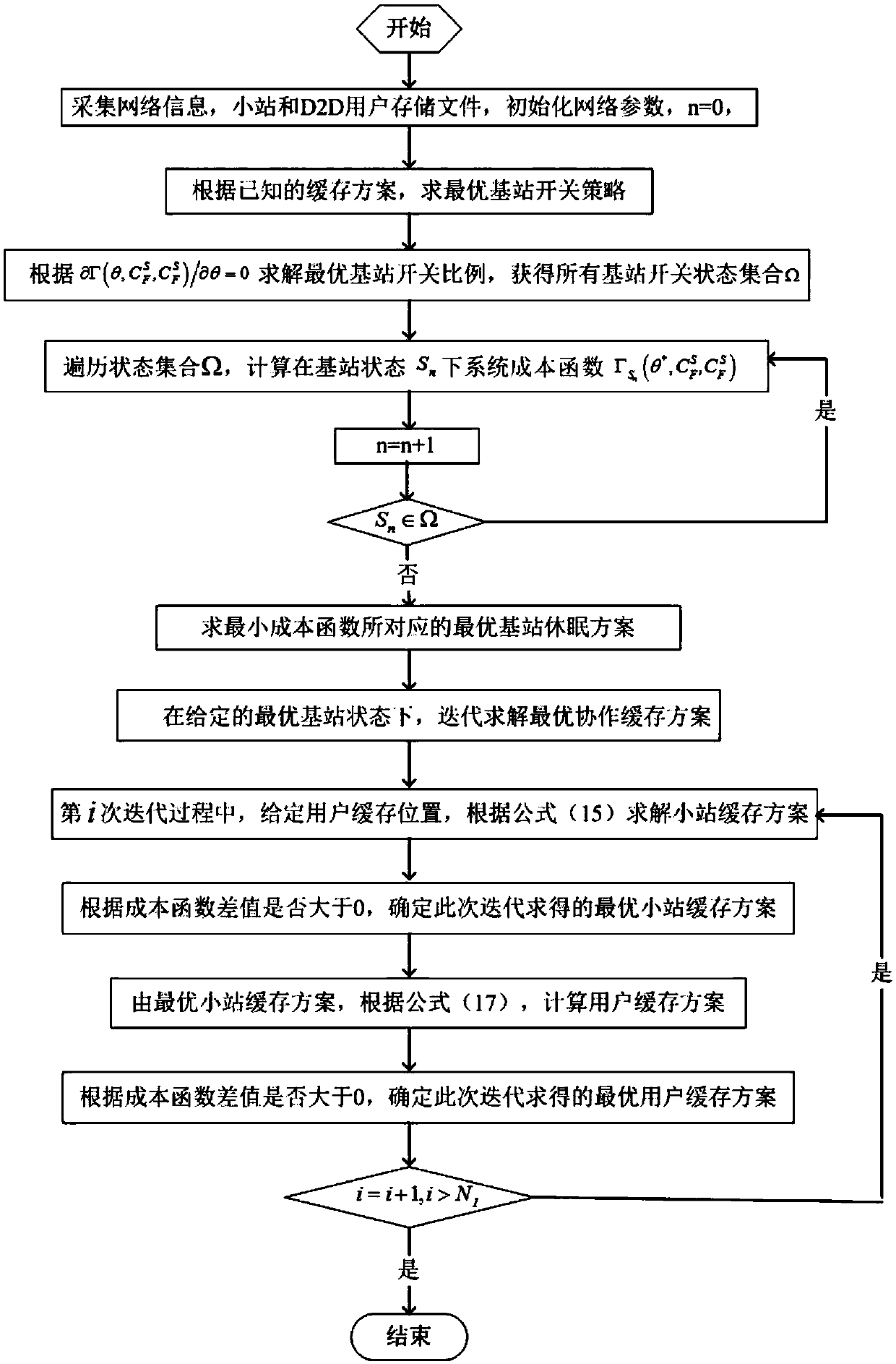

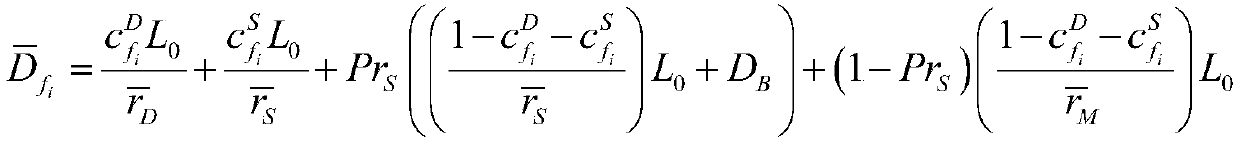

Joint optimization method for base station dormancy and cooperative cache in D2D-assisted ultra-dense network

ActiveCN109587776AGuaranteed Latency CharacteristicsGood performance gainPower managementNetwork traffic/resource managementQuality of serviceFile transmission

The invention discloses a joint optimization method for base station dormancy and cooperative cache in a D2D-assisted ultra-dense network. The method considers a caching scheme and a base station dormancy strategy at the same time. By analyzing the file transmission delay and the average system energy consumption, the energy consumption and delay weighing problem are described as the minimum costfunction problem. The minimum cost function problem is a complex combinatorial optimization problem. Since dormancy and caching are two independent processes, the original problem is decomposed into two sub-problems: first, the caching scheme is given, and the optimization base station dormancy scheme corresponding to the minimum cost function is found; and secondary, based on the optimization base station dormancy scheme, the optimal cooperative cache scheme is iteratively solved according to the combinatorial optimization algorithm, so that the system energy consumption is minimized under the condition that the user service quality is guaranteed.

Owner:SOUTHEAST UNIV

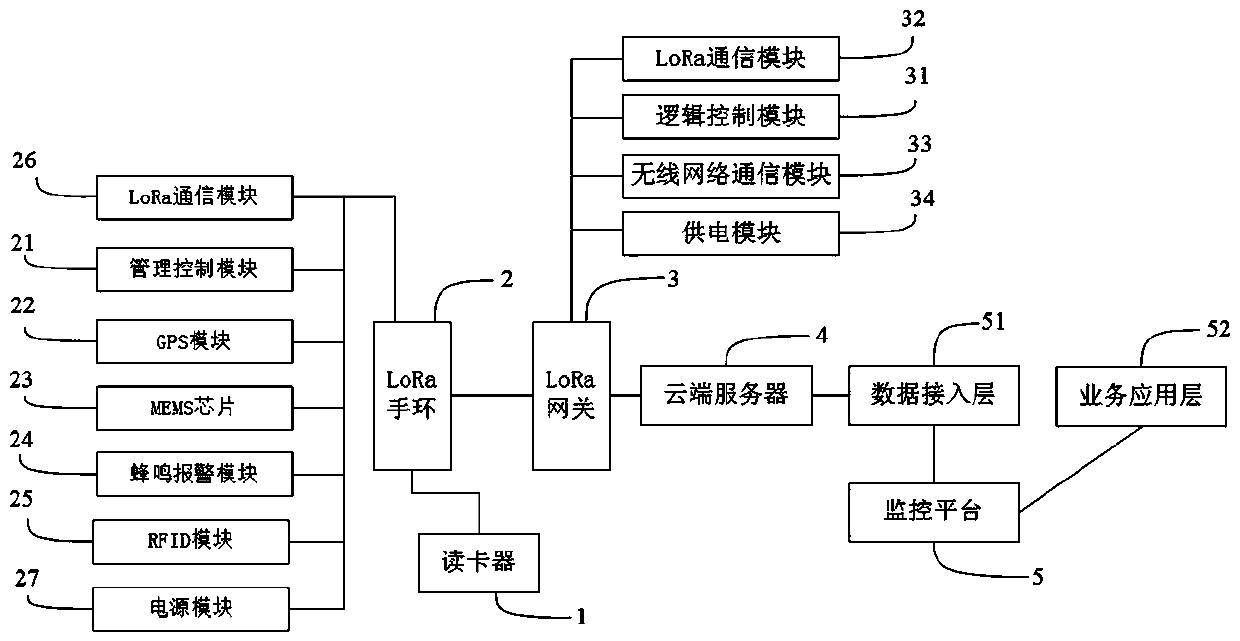

LoRa wristband-based student campus positioning system

PendingCN107736699AKeep abreast of trendsSolution to short lifeBraceletsSatellite radio beaconingNetwork connectionTreatment fever

The invention discloses an LoRa wristband-based student campus positioning system, and belongs to the technical field of remote monitoring. The LoRa wristband-based student campus positioning system comprises a card reader, LoRa wristbands, an LoRa gateway, a cloud server, and a monitoring platform. The card reader senses and reads LoRa wristband information by emitting low-frequency radio waves.The LoRa wristbands collect students' characteristics of body temperature, life, and movement. The LoRa gateway is connected with a plurality of LoRa wristbands based on an LoRaWAN network and sends students entry and exit records, positioning information, heart rate, temperature, and movement data to the cloud server. The monitoring platform is connected with the cloud server through a data access layer and displays abnormal wristband information, such as students' high fever, lack of attendance and the like. A school manager sends a short message or email to corresponding students' head teachers based on the promotions and receives feedback from the students' head teachers. The LoRa wristband-based student campus positioning system solves problems of high power consumption, small monitoring range and single function of a traditional campus positioning system.

Owner:TIANJIN YUNTUO NETWORK TECH CO LTD

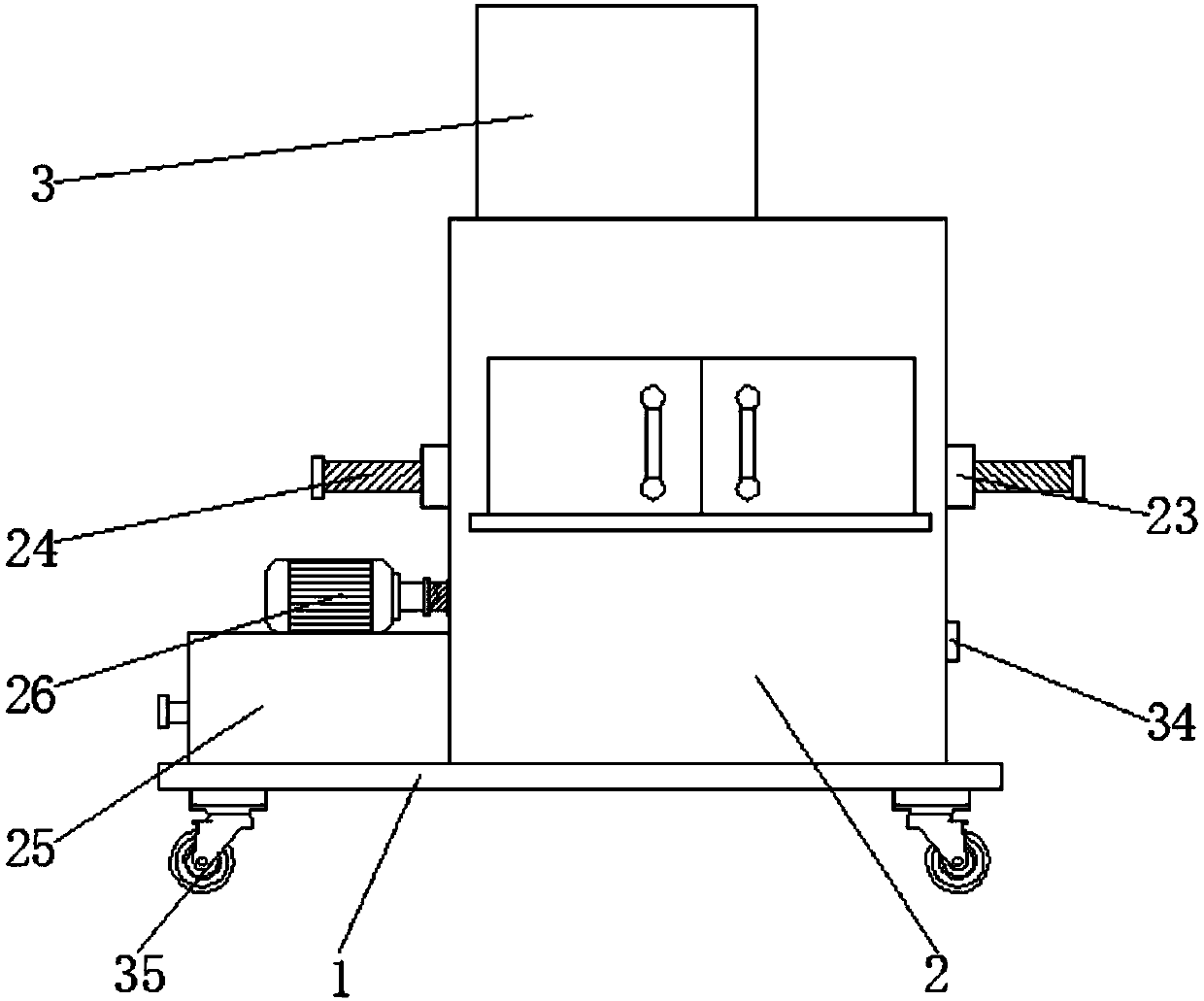

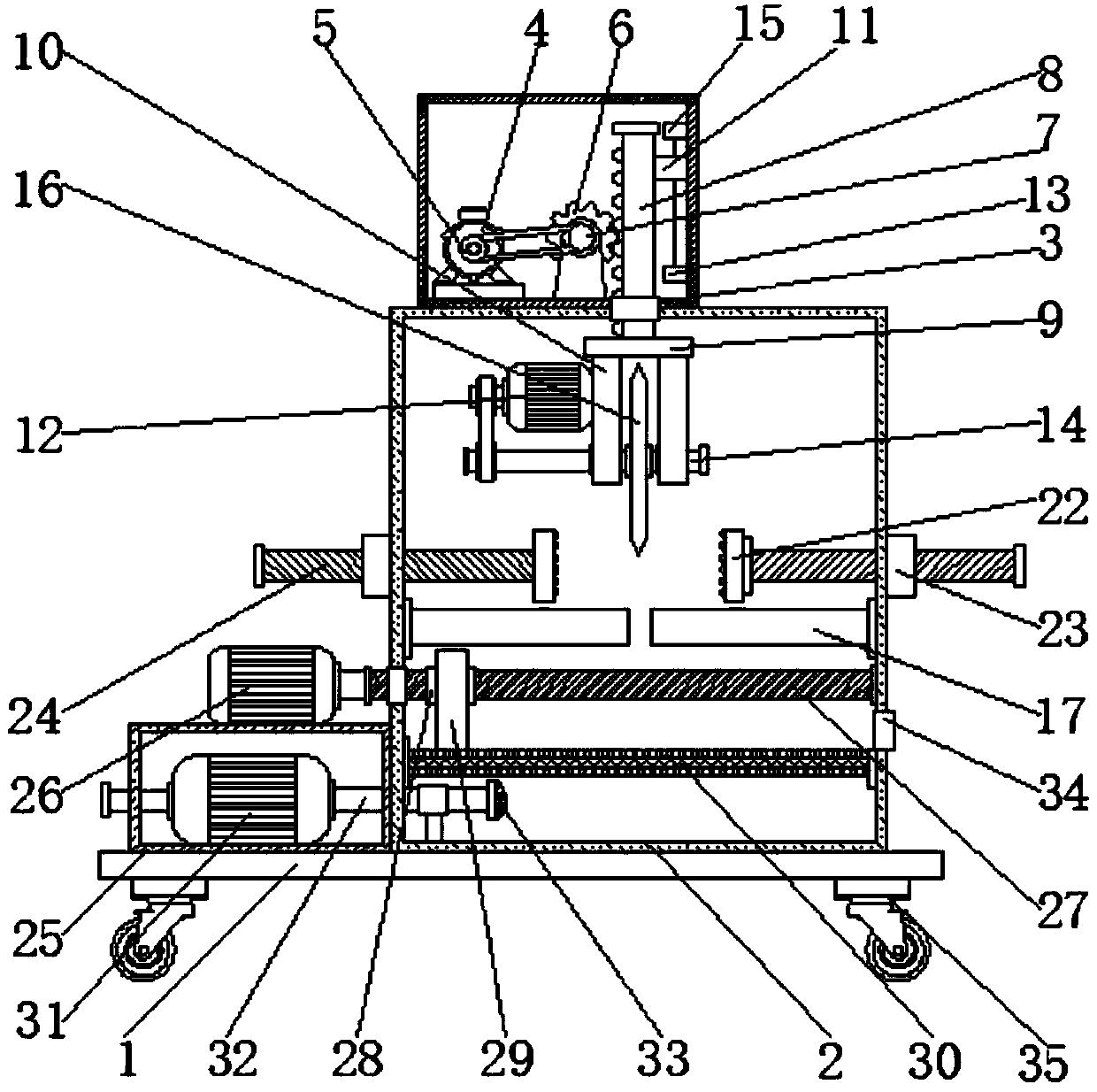

Building wood board cutting-off device

InactiveCN107856136AEasy to recycleAvoid pollutionProfiling/shaping machinesBark-zones/chip/dust/waste removalStopped workFunction problem

The invention discloses a building plank cutting device, which comprises a base and a box body. A cutting wheel is installed above the inner cavity of the box. Fixed plates are fixed on the inner walls of the box on both sides of the cutting wheel; the cutting wheel is connected with a moving part, and the moving part It moves up and down with the cutting wheel; there is a clamping block that moves back and forth on the fixed plate, and the clamping block clamps the wooden board; there is a filter plate under the fixed plate, and a push block that can move back and forth is arranged above the filter plate. The invention relates to the technical field of building plank cutting equipment, and solves the problem that the existing cutting machine cannot automatically return to the original position and stop working after cutting the plank, and does not have the function of collecting cut sawdust.

Owner:钟晓芳

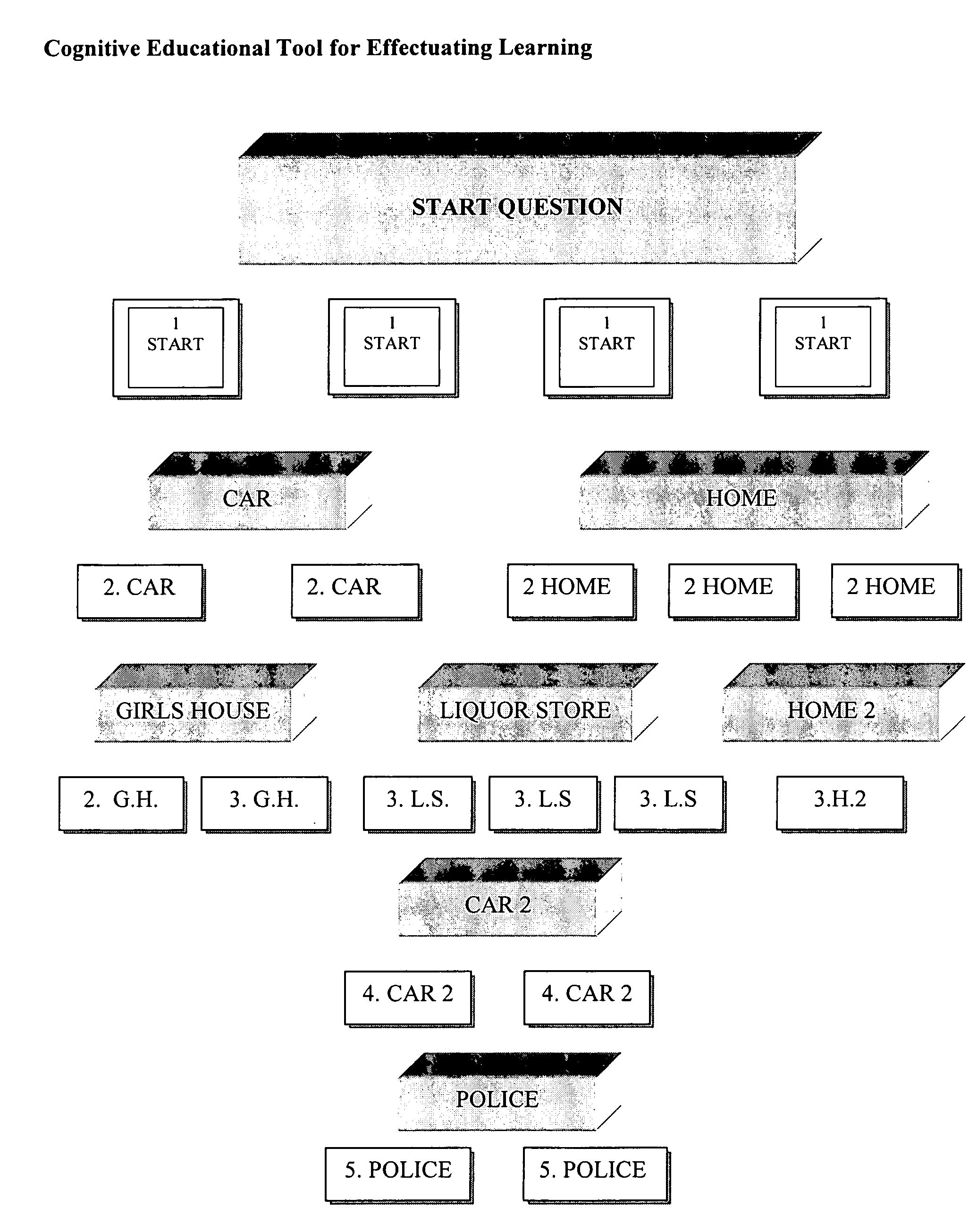

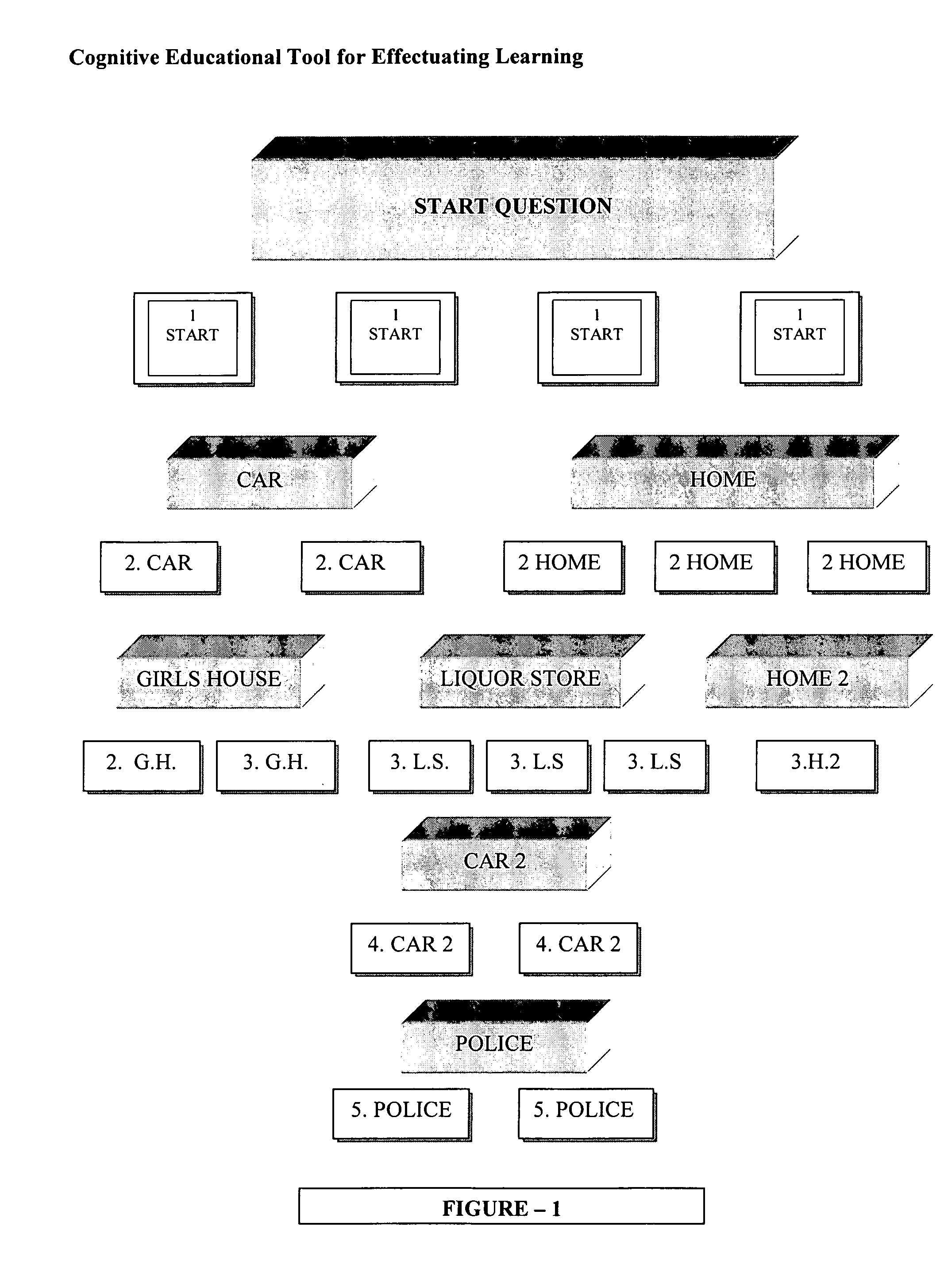

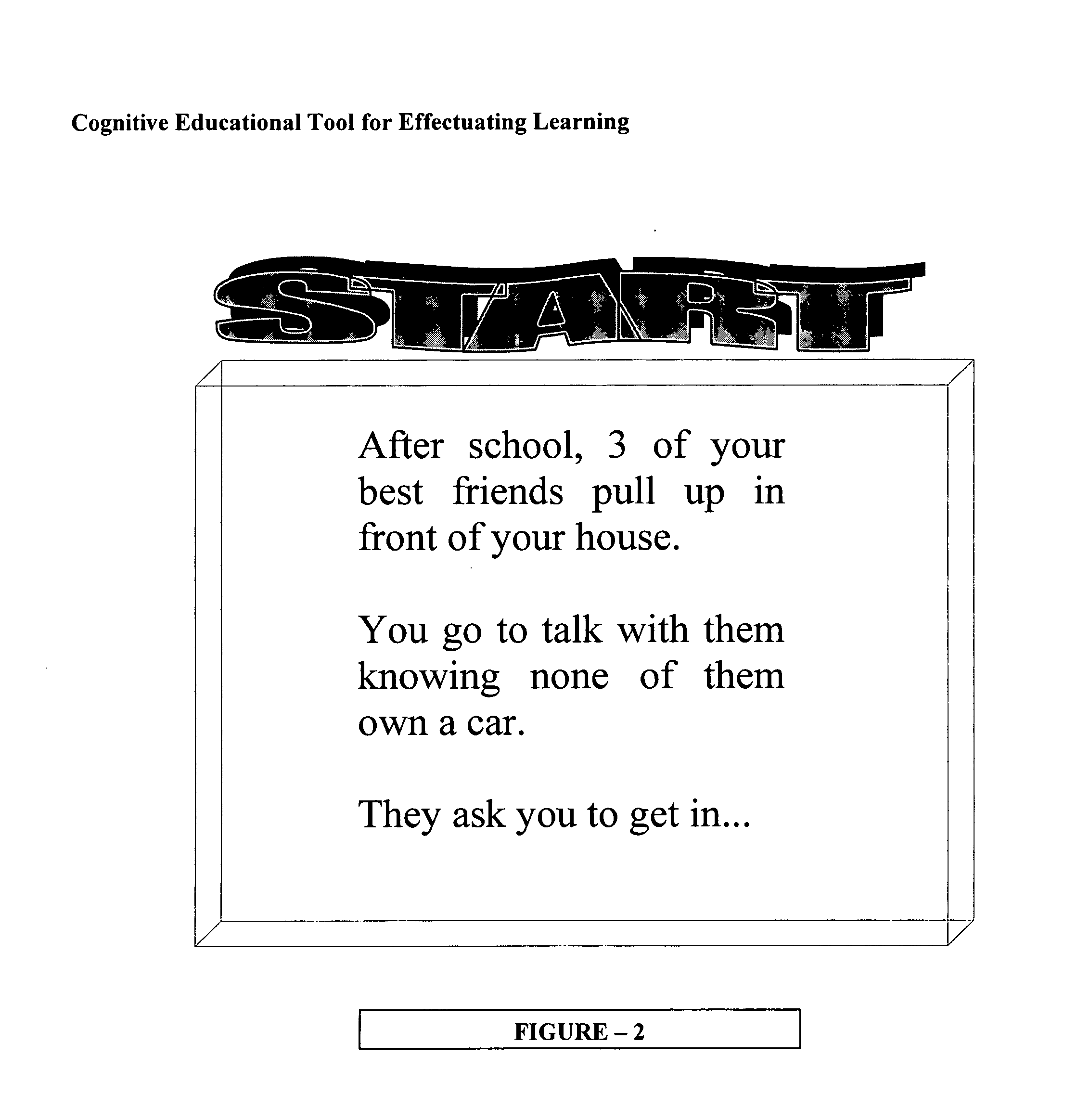

Cognitive educational tool for effectuating learning

InactiveUS20080220399A1Improve the level ofRaise the level of performanceTeaching apparatusMechanical appliancesProblem solveFunctional Technique

The following concept is to be utilized in the acquisition of information by combining various learning styles. Key areas addressed are the increment of student participation, increased levels of student honesty, and higher rates of student responsivity. The tool encourages the development of student-teacher rapport levels and thus promotes the ability to acquire and retain functional techniques and information. The concept addresses real life situations by creating functional problem solving strategies to be used at specific junctures in both the scenarios and everyday life. The tool is preventative in nature, and is also culturally, cognitively, age appropriate, gender and scenario flexible. The adaptability highlights the vast spectrum of issues the concept can resolve. Overall the process is designed to increase participants' level of competency when encountering situations, which impact their pro social development and / or success in real life situations. In doing so the likelihood of engaging in detrimental or negative behaviors is significantly reduced. The program focuses on enhancing social skills, responsibility, self-control, pro social cognition, and moral reasoning. All of the aforementioned skills are nurtured and developed through the alternative learning style used to engage the client, through the therapeutic process.

Owner:GIWA CHRISTOPHER KAYODE

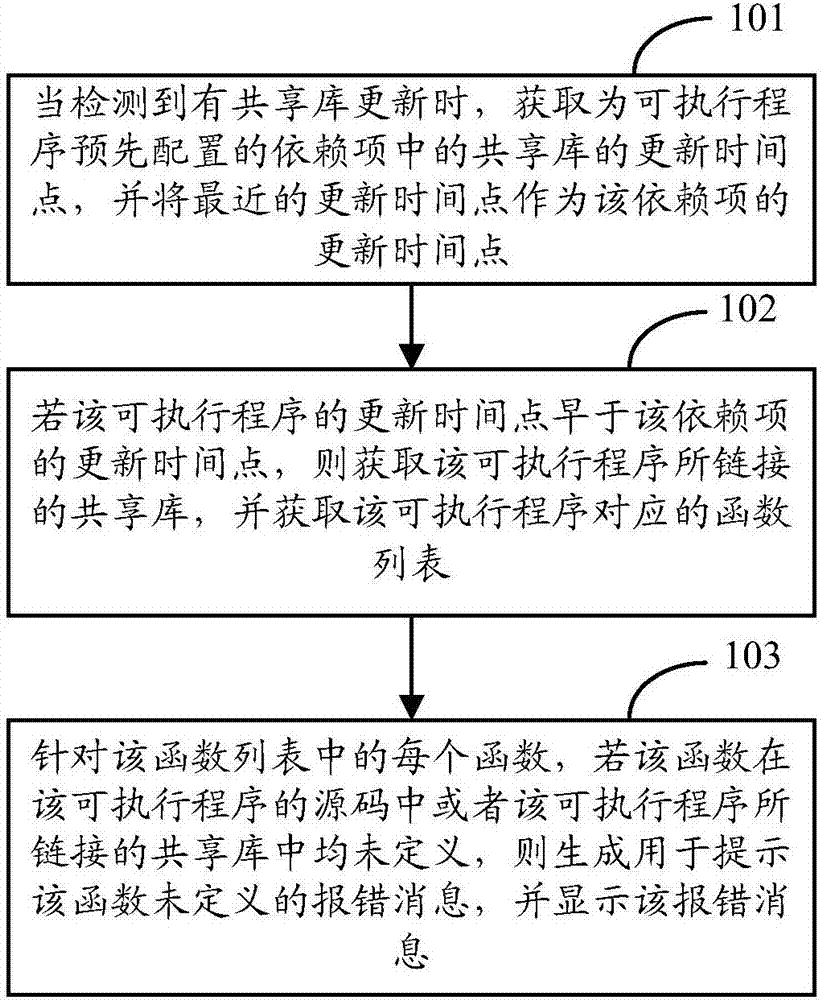

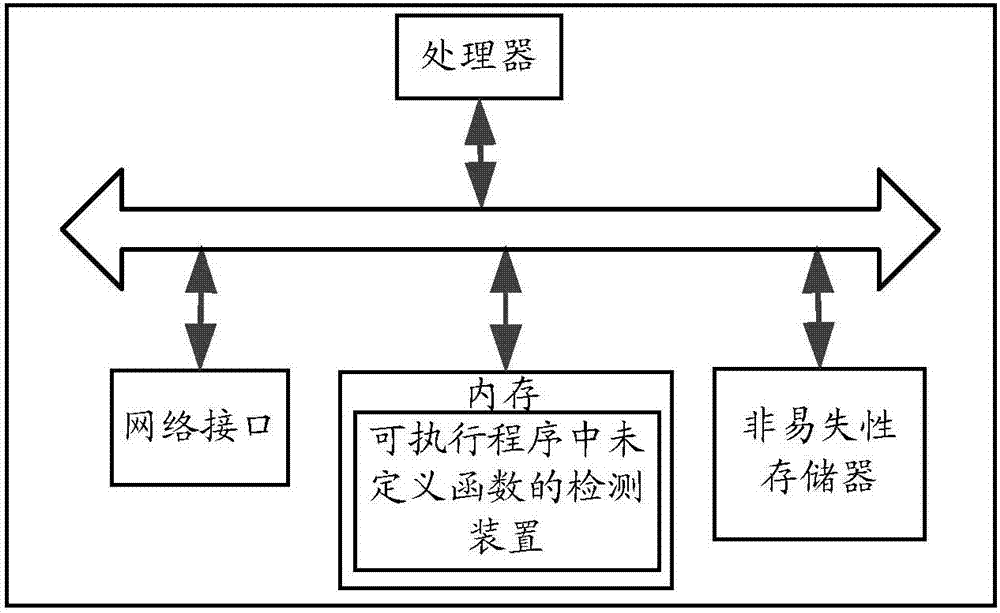

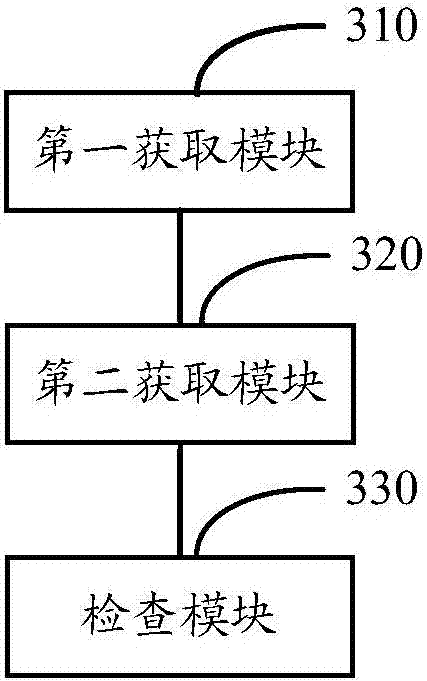

Detection method and device of undefined function in executable program

ActiveCN106909434AImplement dynamic dependenciesAvoid introducing other errorsProgram controlMemory systemsFunction problemSource code

The application provides a detection method and device of a undefined function in an executable program. The method comprises the following steps: when detecting the update of a sharing base, acquiring an updating time point of the sharing base in a dependency item configured for the executable program, and regarding the latest updating time point as the updating time point of the dependency item; if the updating time point of the executable program is earlier than the updating time point of the dependency item, acquiring the share base linked with the executable program and a corresponding function list; and generating an error report message aiming at each function in the function list if the function is undefined in a source code of the executable program or the sharing base linked with the executable program. When detecting the update of the sharing base, if the updating time point of the executable program is earlier than the latest updating time point of the sharing base in the dependency item configured for the executable program, the method disclosed by the invention comprises checking whether the function in the corresponding function list is defined or not, thereby enabling a technician to immediately find the undefined function problem and avoiding the introduction of other error due to the update of the sharing base, and the project development efficiency is improved.

Owner:HANGZHOU DPTECH TECH

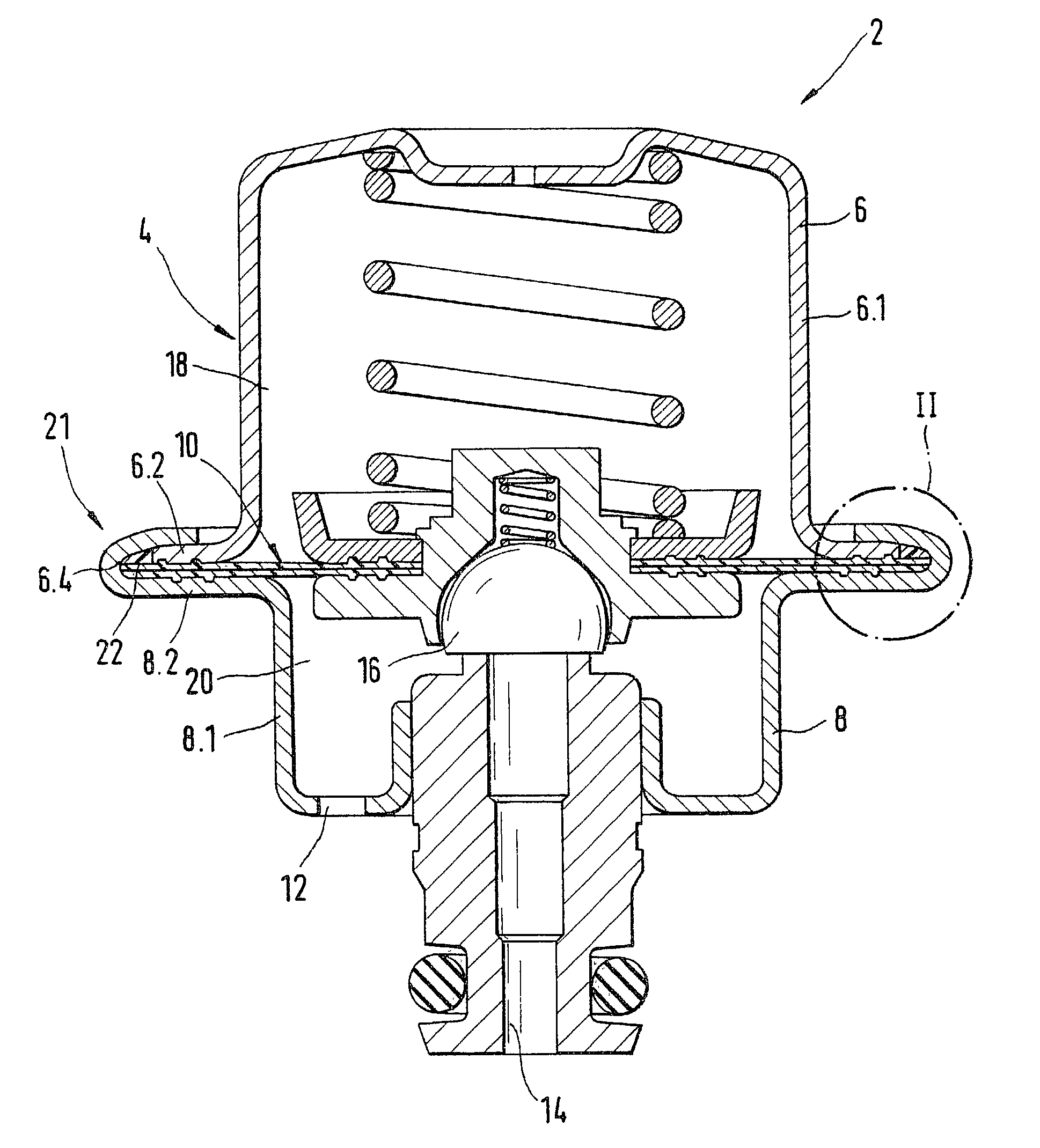

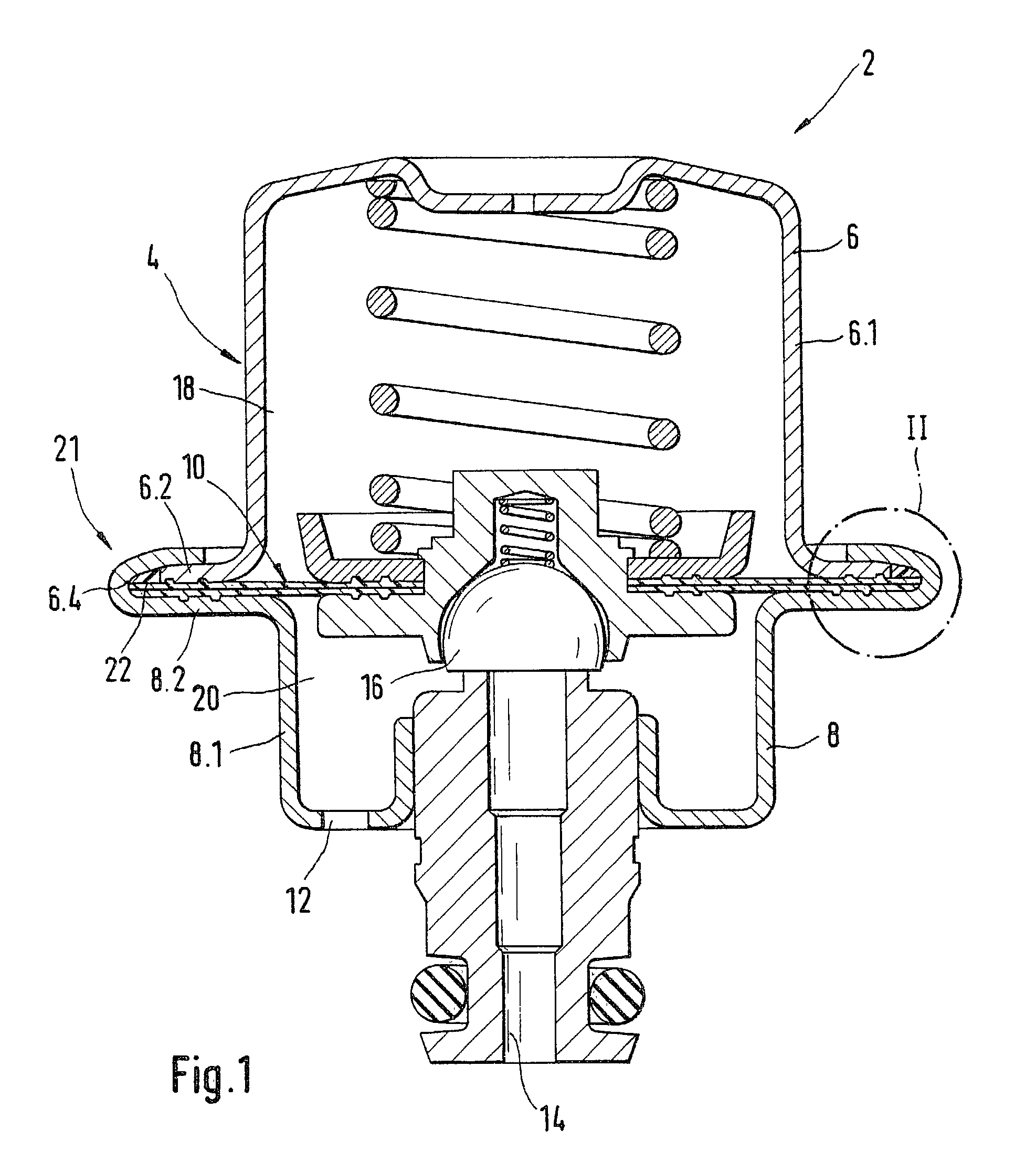

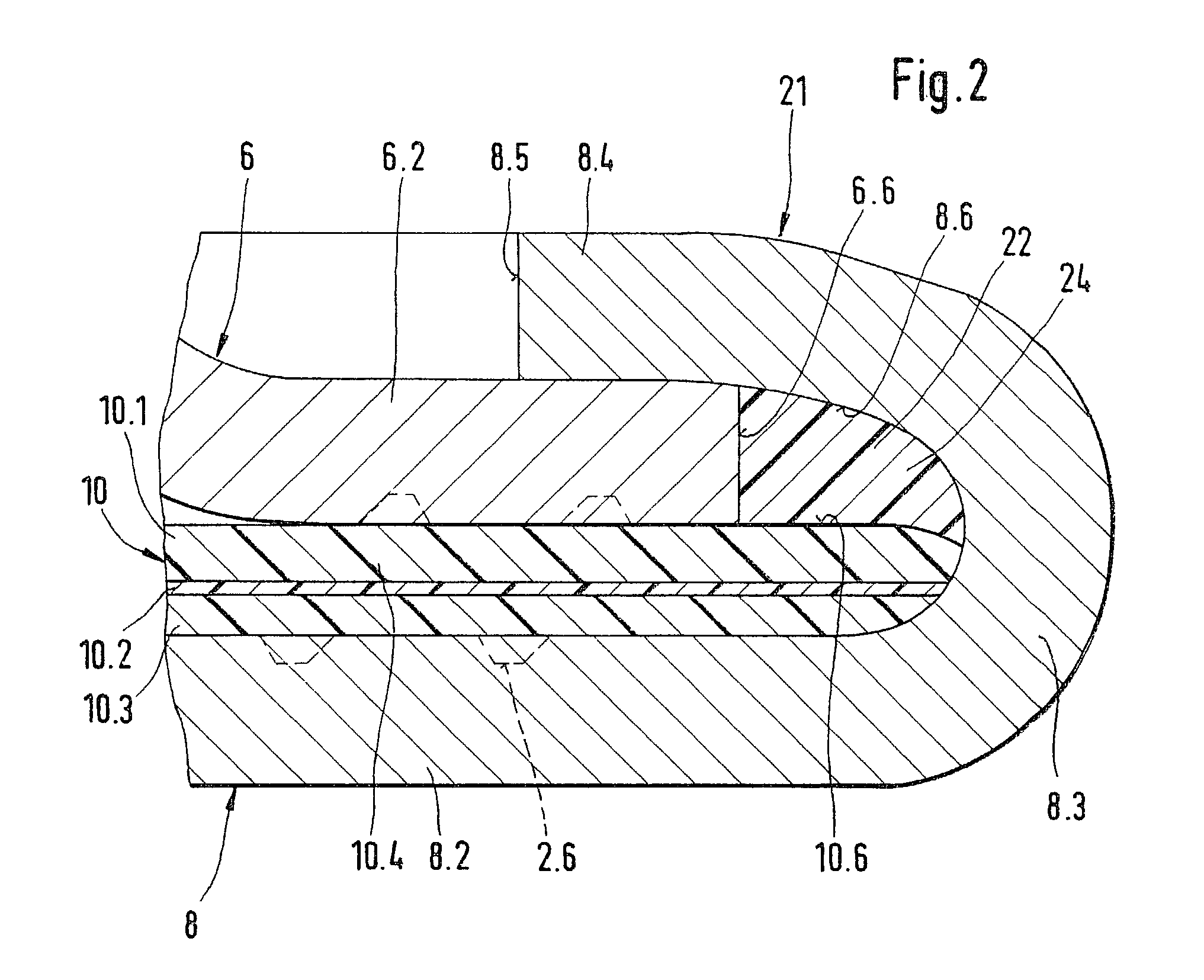

Device with a diaphragm arrangement

InactiveUS20020134433A1Little production effort and expenseEasy to operateSpindle sealingsOperating means/releasing devices for valvesElastomerFunction problem

In devices with a diaphragm arrangement crimped into place and dividing two chambers from one another, until now functional problems arose at elevated pressures, because in permanent operation the diaphragm arrangement shifted, or because of leaks. In the device (2) proposed here, with a diaphragm arrangement (10) retained via a crimped connection (21), excellent restraint of the diaphragm arrangement (10) and excellent sealing are attained with the aid of an elastomer material (22). The device is a pressure valve, for instance, and serves to vary a pressure of a fuel supply system of a motor vehicle.

Owner:ROBERT BOSCH GMBH

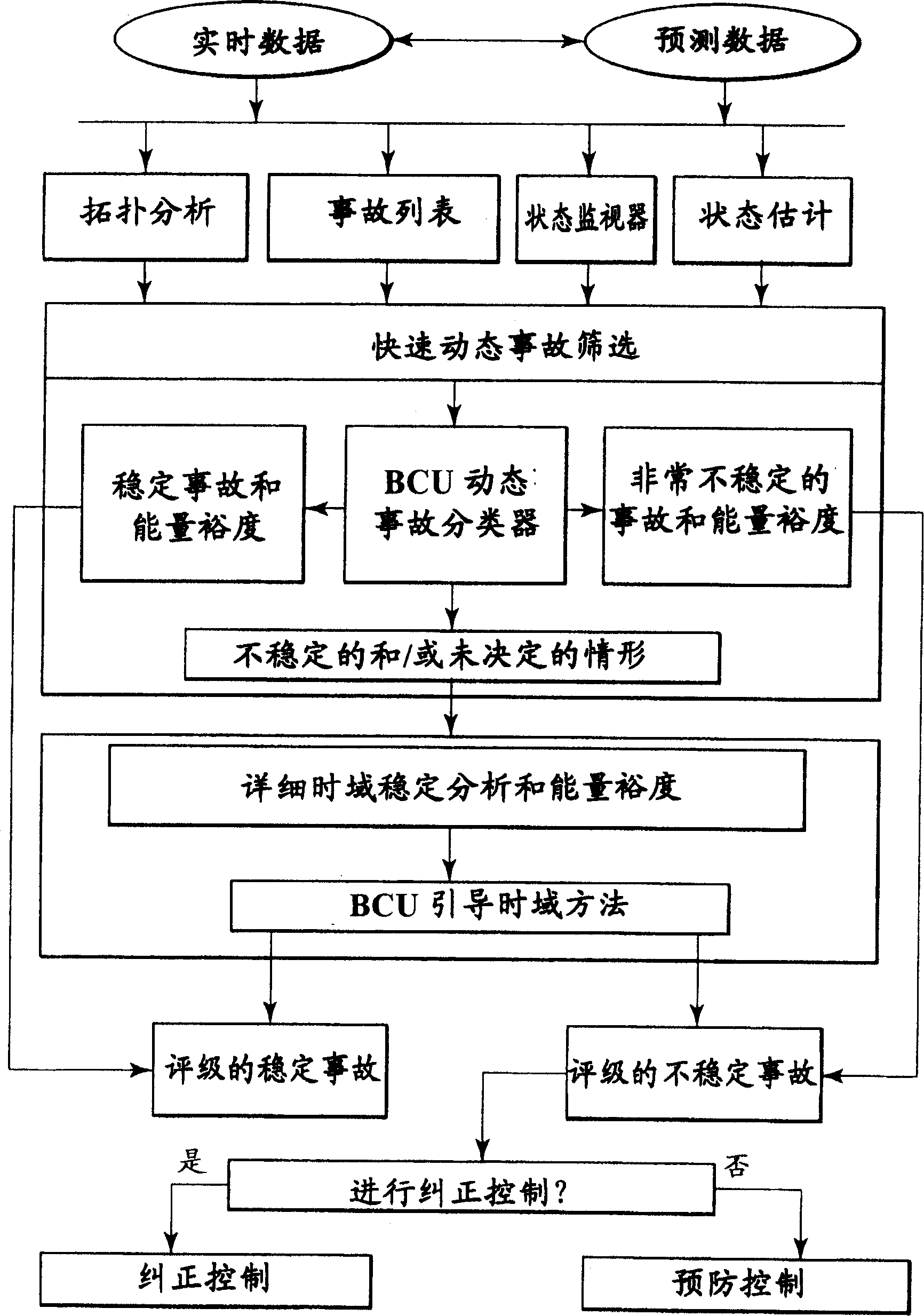

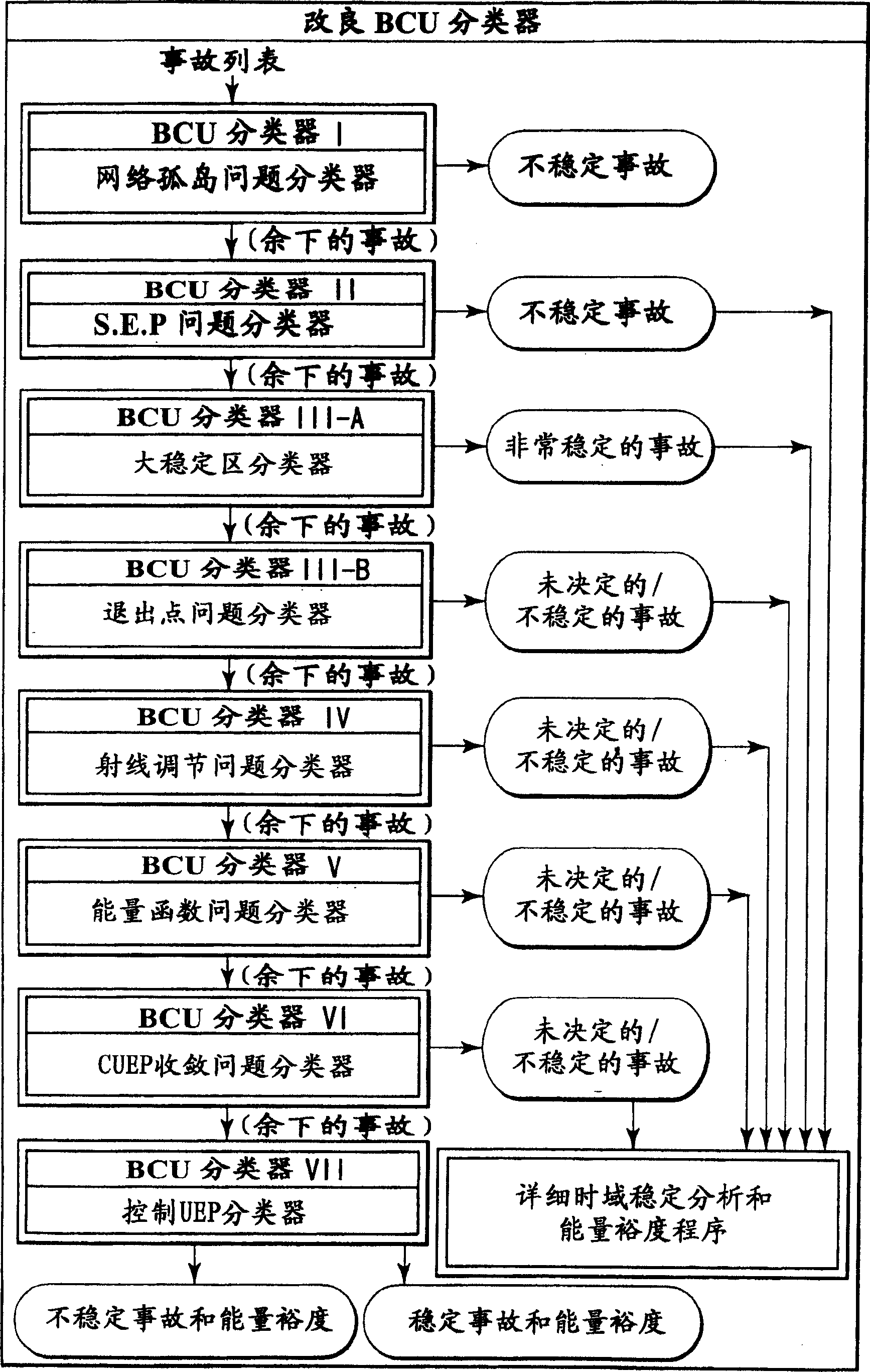

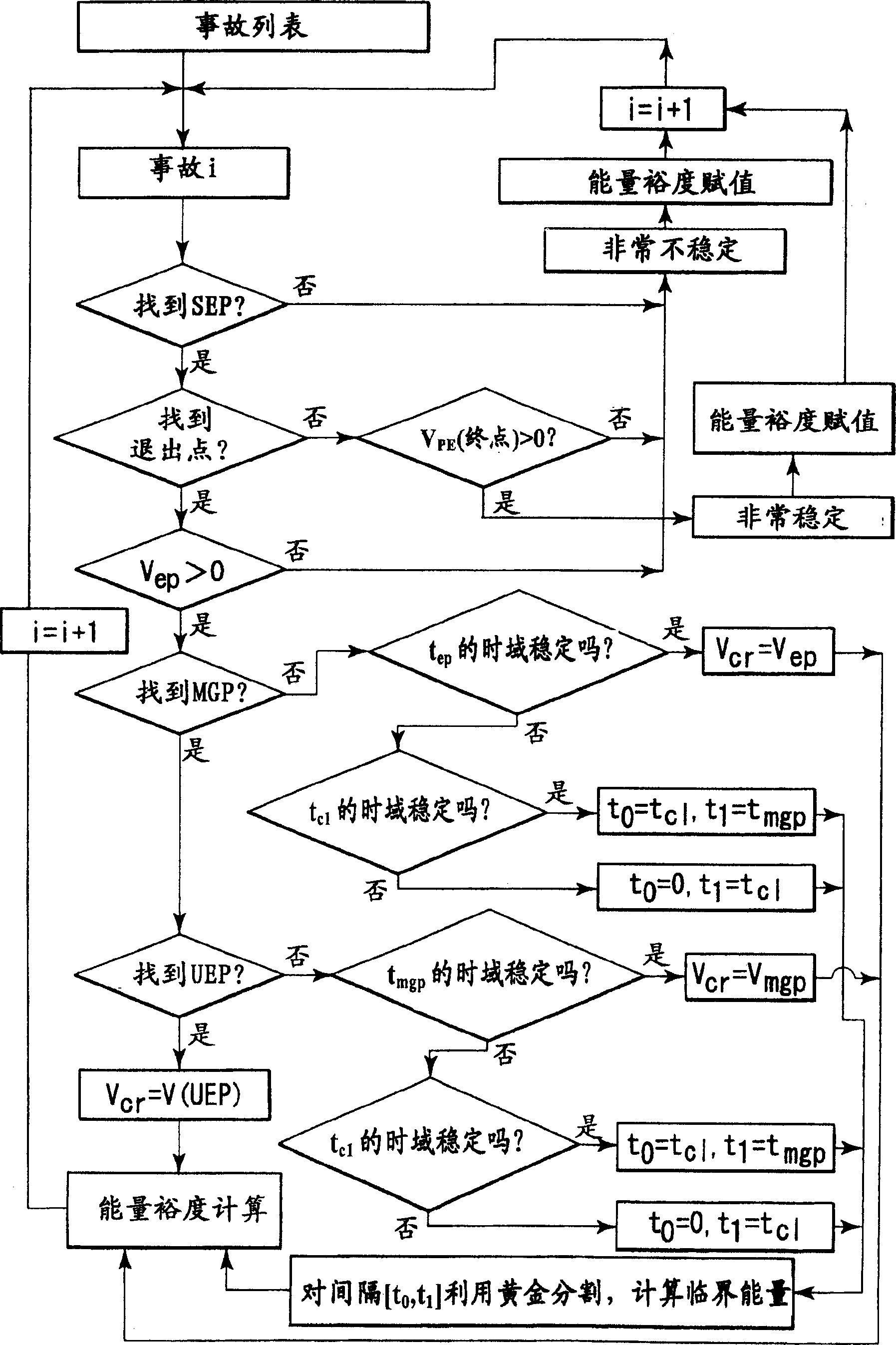

Method and system for on-line dynamical screening of electric power system

InactiveCN1647338AImprove reliabilityCalculation speedPower network operation systems integrationContigency dealing ac circuit arrangementsTime domainIslanding

Owner:TOKYO ELECTRIC POWER CO HLDG INC +1

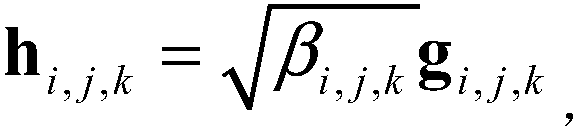

User access method for large-scale MIMO multi-cell network

InactiveCN108064070AReduce pollutionAssess restrictionRadio transmissionAccess methodSignal-to-noise ratio (imaging)

The invention discloses a user access method for a large-scale MIMO multi-cell network, and a dynamic user access scenario is introduced to alleviate the problem of pilot frequency pollution; considering the mobility of the user, some accessed users have the probability of leaving the network after the pilot frequency is distributed; at this time, the base station can allow a new user to access. The invention provides a novel user access scheme; the fairness degree of user access is measured by utilizing a harmonic progressive signal-to-noise ratio utility function comprising a pilot pollutionitem, the optimal user access problem is converted into a minimization ultra-mode function problem, and for the NP difficulty problem, an ultra-mode user access greedy algorithm is proposed to obtaina suboptimal user access scheme. By means of the user access scheme provided by the invention, pilot pollution between cells can be effectively reduced, and the base station does not need to re-allocate the pilot frequency to all the users.

Owner:CHINA UNIV OF MINING & TECH

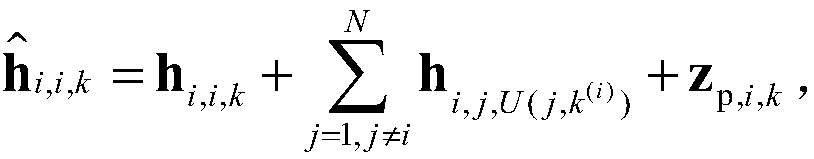

A picture quality detection method based on machine learning

InactiveCN109410203ASave human effortImprove efficiencyImage enhancementImage analysisFeature learningImaging quality

The invention discloses a picture quality detection method based on machine learning, and belongs to the field of picture recognition, and the method comprises the following steps: collecting data ofa problematic picture; performing analysis processing and classification processing according to the collected picture data; establishing a picture preliminary image quality comparison detection library for the pictures subjected to analysis processing and classification processing; extracting image quality characteristics of each image in the preliminary image quality library; establishing an image quality feature library according to the image quality features of the image; detecting the image according to the image quality feature library and the preliminary image quality library; detectingoutput results. The method comprises the following steps of: extracting feature learning from previous images with image quality function problems by using a machine learning method, quickly positioning which kind of problems belong to, performing feature learning on the images with the image quality function problems by using a deep learning technology, and classifying the learned features to obtain a deep learning model; and judging the image quality function picture of the camera by using the deep learning model and outputting a result.

Owner:LUSHAN COLLEGE OF GUANGXI UNIV OF SCI & TECH

Quantum processor based systems and methods that minimize a continuous variable objective function

Computational techniques for mapping a continuous variable objective function into a discrete variable objective function problem that facilitate determining a solution of the problem via a quantum processor are described. The modified objective function is solved by minimizing the cost of the mapping via an iterative search algorithm.

Owner:D WAVE SYSTEMS INC

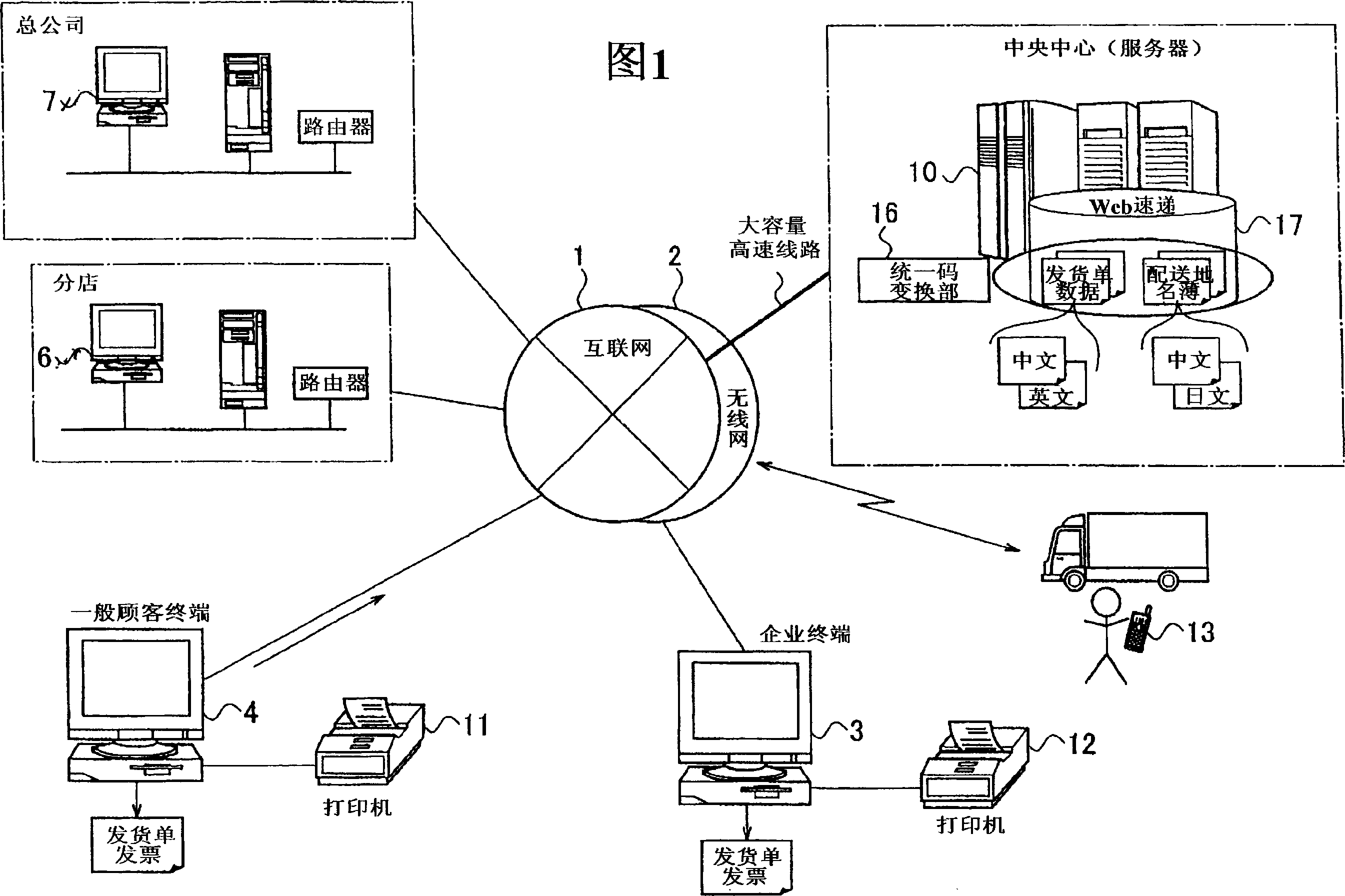

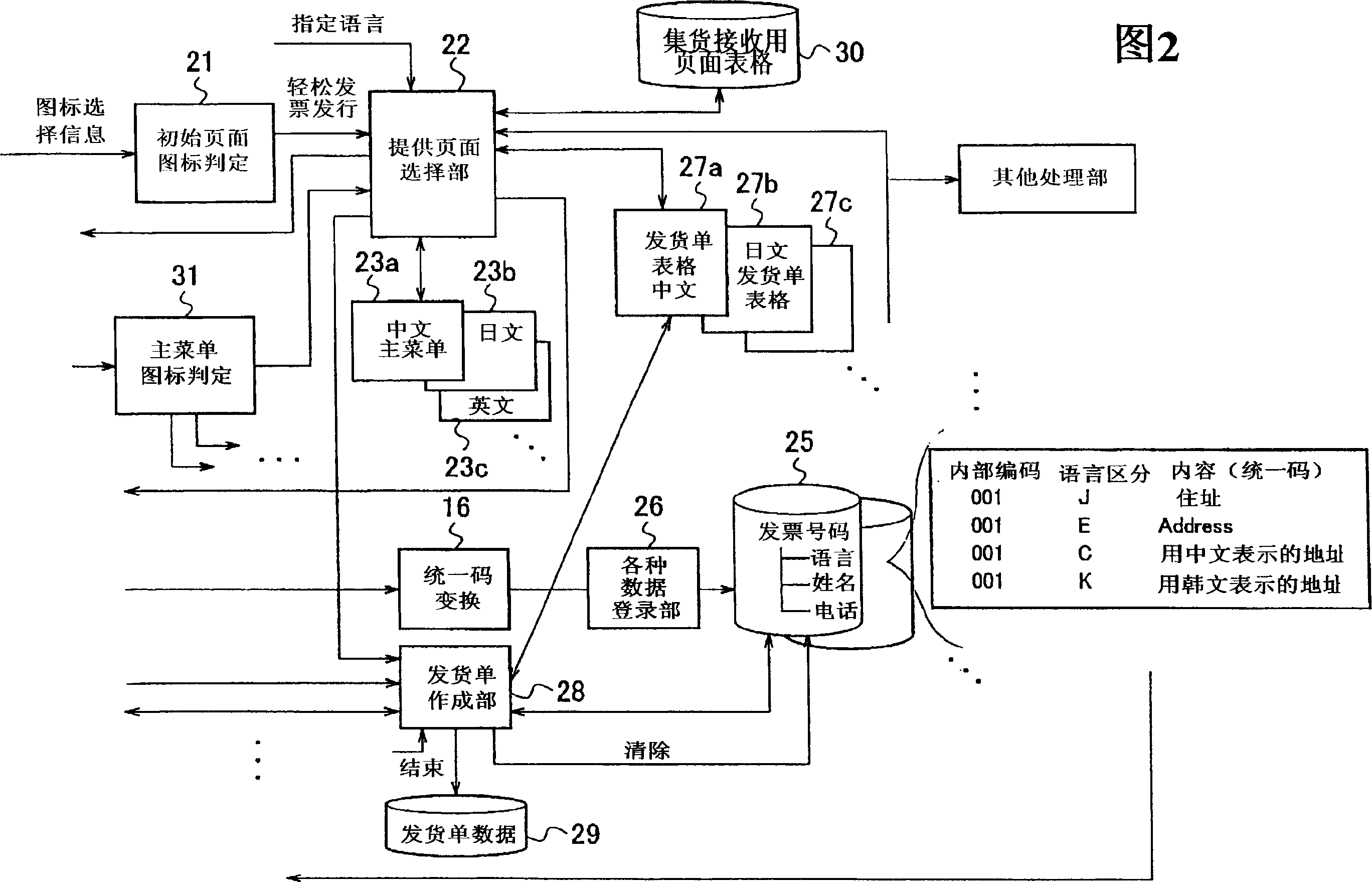

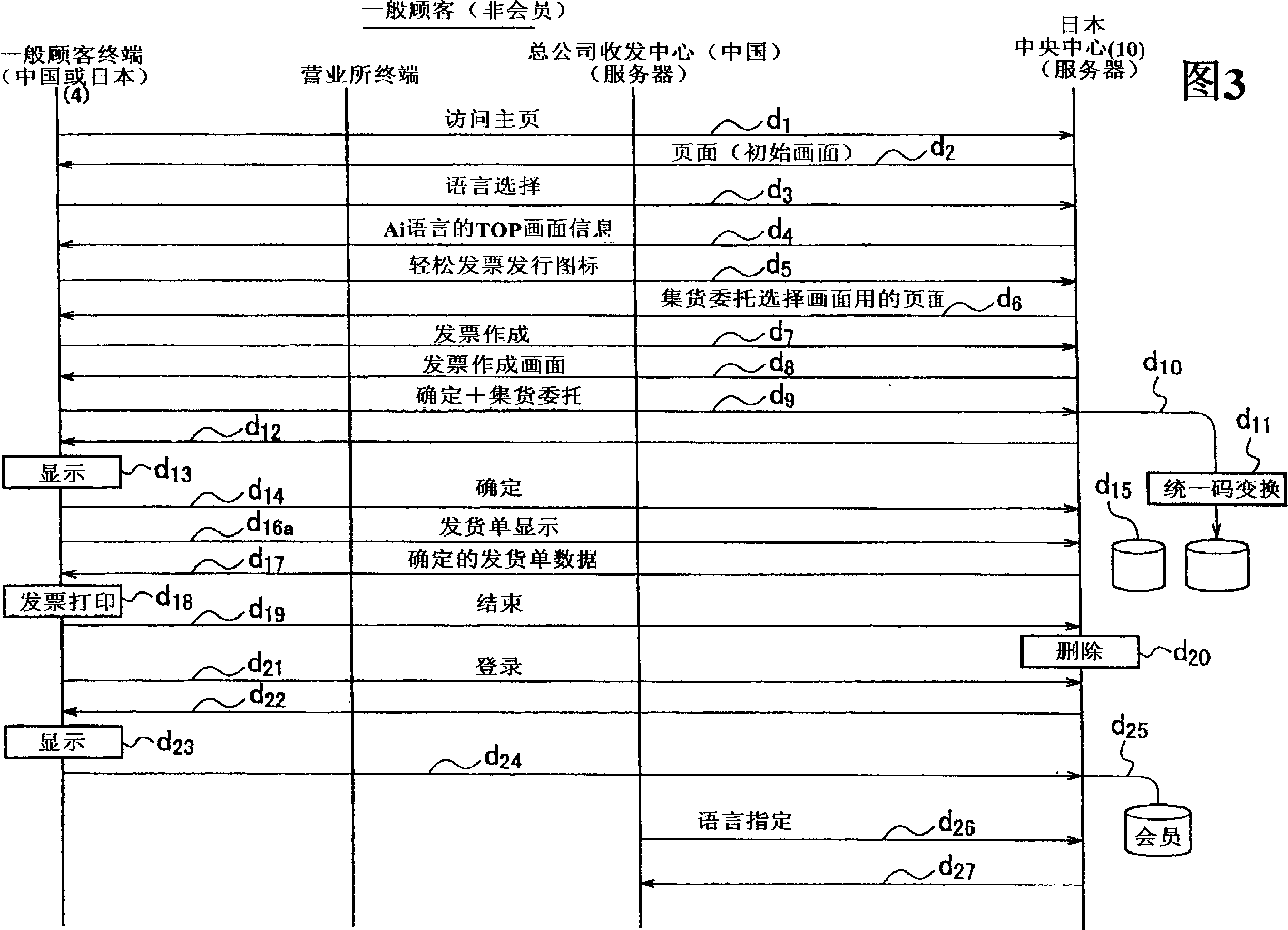

Web goods collecting system with multi-language corresponding function

InactiveCN1674016ARealize the popularization of electronicEnjoy the serviceData processing applicationsStacking articlesRadio networksMulti language

PROBLEM TO BE SOLVED: To obtain a web cargo booking system corresponding to multi-language for providing and managing screens of home delivery service in a language convenient to a user asking for cargo booking. ŽSOLUTION: In this web cargo booking system corresponding to multi-language, each of terminals (an enterprise terminal 3, a general user terminal 4, a branch terminal device 6 (formed of a server and multiple terminals) and a head office terminal device (formed of a server and multiple terminals)) accesses a central server 100 (formed of a server and various terminals) through the Internet 1 and a radio network 2, and an operator obtains various information related to a cargo booking request in a specified language (Chinese, Japanese, English, Korean, etc.), and prints the obtained information with a printer when necessary. Ž

Owner:SAGAWA EXPRESS +1

Reduction and generation method of action report of protection device at scheduling port

ActiveCN101640436BIncrease the level of automationImprove the level of practicalityCircuit arrangementsInformation technology support systemDevice typePower grid

The invention provides a reduction and generation method of an action report of a relay protection device at a scheduling port, which is applied to a power network relay protection and failure information management system. The method comprises the following steps: normalizing output information of a relay protection device on a station port, and sending the information by classification; establishing a communication specification between a master station and a slave station to guarantee integral data transmission; and outputting corresponding action report at the scheduling port of the master station according to the device type to realize reduction and generation of the device report at the scheduling port. The method in the invention helps realize that the action report is basically consistent with the report form and the content printed on the spot by the relay protection device in an information display layer of a master station system. The method is completed and practical; and the method helps perfect the information content sent by the relay protection device, solve the long-standing functional problems of the domestic relay protection and failure information management system such as scattered information, shortage of the content and the like, meanwhile formally realize long pass of the relay protection action report, is beneficial to relay protection professional staffs to carry out protection action analysis, and improve the integral practicability level of the system.

Owner:STATE GRID ZHEJIANG ELECTRIC POWER +2

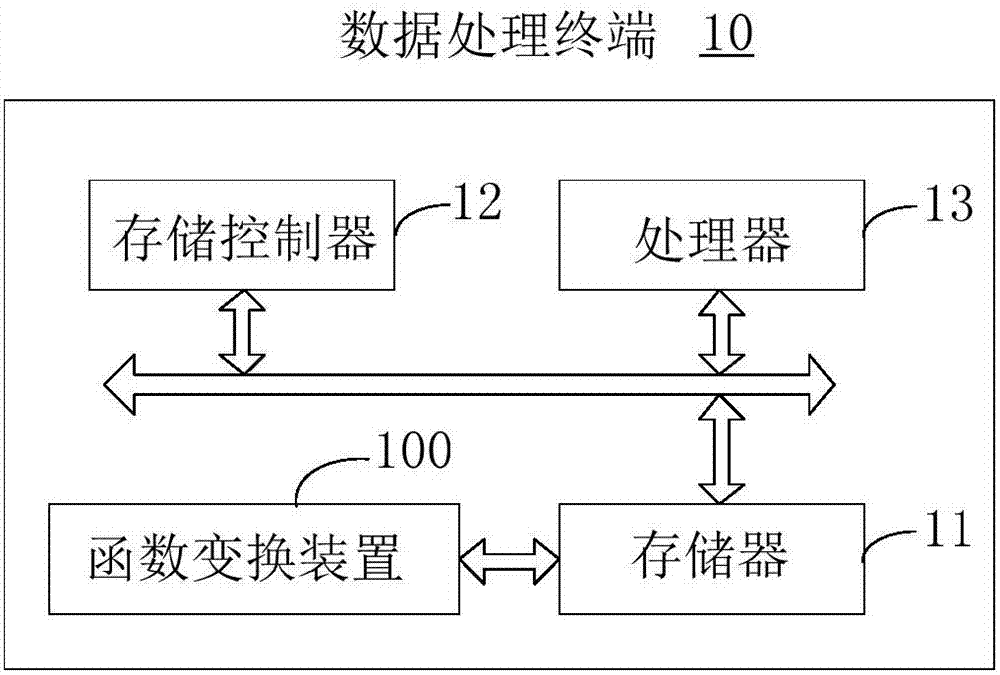

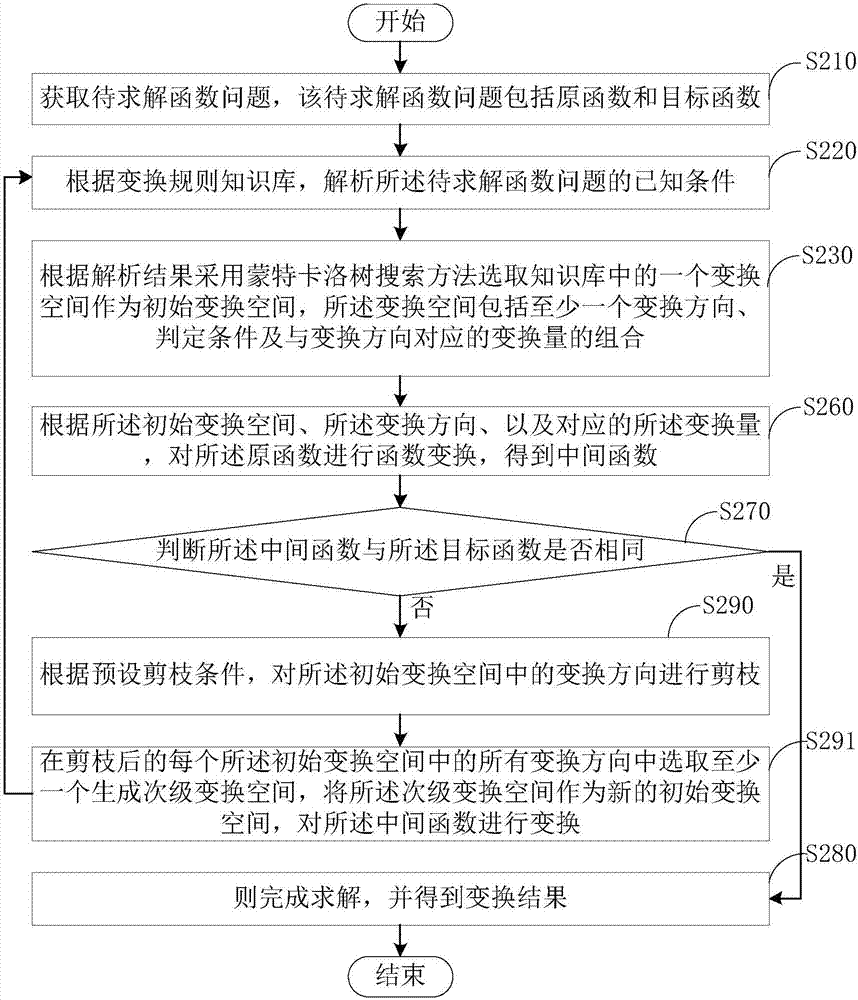

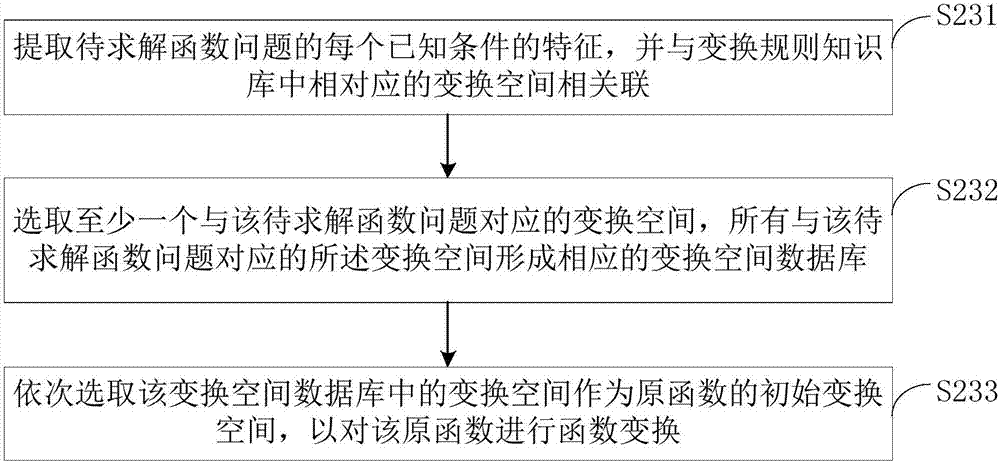

Function transformation method and device

InactiveCN107122334AQuick solveAccurate solutionComplex mathematical operationsFunction problemComputers technology

The present invention provides a function transformation method and device, and relates to the technical field of data processing based on computer technology. The function transformation method comprises: acquiring a to-be-solved function problem; according to a transformation rule knowledge library, analyzing a known condition of the to-be-solved function problem, and according to an analysis result, selecting a transformation space in the knowledge library as an initial transformation space by using a Monte Carlo tree search method; performing function transformation on an original function, to obtain an intermediate function; determining whether the intermediate function is the same as a target function; and if the intermediate function is the same as the target function, finishing solution and obtaining a transformation result. Compared with the prior art, the function transformation method and apparatus provided by the present invention reduce computation amount, improve computation speed and can rapidly and accurately solve function transformation problems by using Monte Carlo tree search and preset pruning conditions.

Owner:UNIV OF ELECTRONICS SCI & TECH OF CHINA

Entry-level construction engineering management system

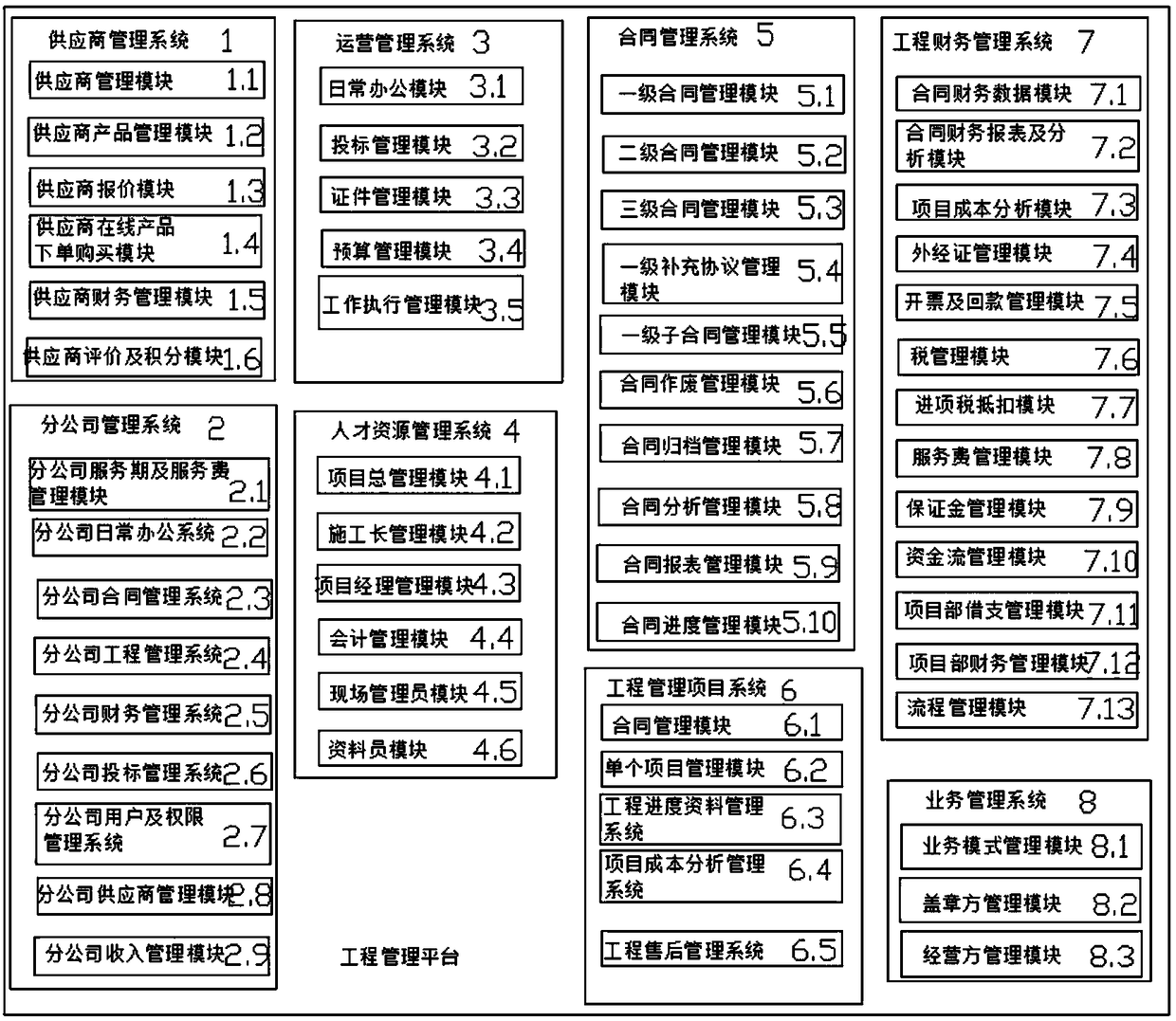

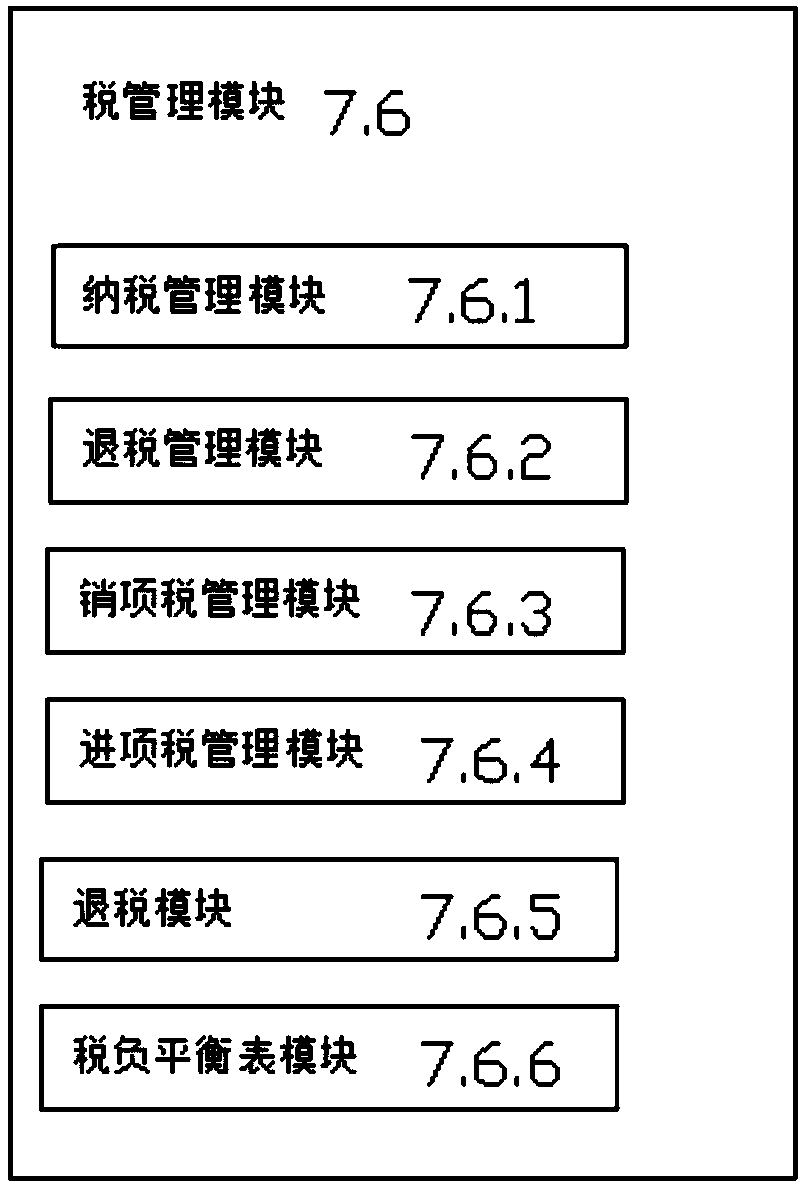

ActiveCN108765200AGood choiceEasy to implementResourcesResource Management SystemBusiness management

The invention provides an entry-level construction engineering management system. The entry-level construction engineering management system comprises a supplier management system, a branch managementsystem, an office management system, a talent resource management system, a contract management system, an engineering management project system, an engineering financial management system and a business management system which are in related connection, wherein the supplier management system is applied to a purchasing and supply management platform of construction industry material suppliers, the branch management system is for special full-platform management of each branch, the operation management system is for daily company operation management, the talent resource management system is an engineering and technical talent management and evaluation system, the contract management system is for management of all the engineering contracts, the engineering project management system is forwhole-process management of each project, the engineering financial management system is combined with the project management system to realize integrated financial project management, and the business management system is an engineering business form management system. The system is advantaged in that a single engineering management system function problem in the prior art is solved, and a problem that the system cannot be applied to a large number of engineering is solved.

Owner:HUBEI FUTAI BUILDING DECORATION ENG

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com