Building wood board cutting-off device

A technology for cutting devices and wood boards, which is applied to wood processing equipment, forming/shaping machines, manufacturing tools, etc. It can solve the problems of not collecting cut sawdust, and the cutting machine cannot automatically return to its original position, so as to achieve the effect of easy recycling

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

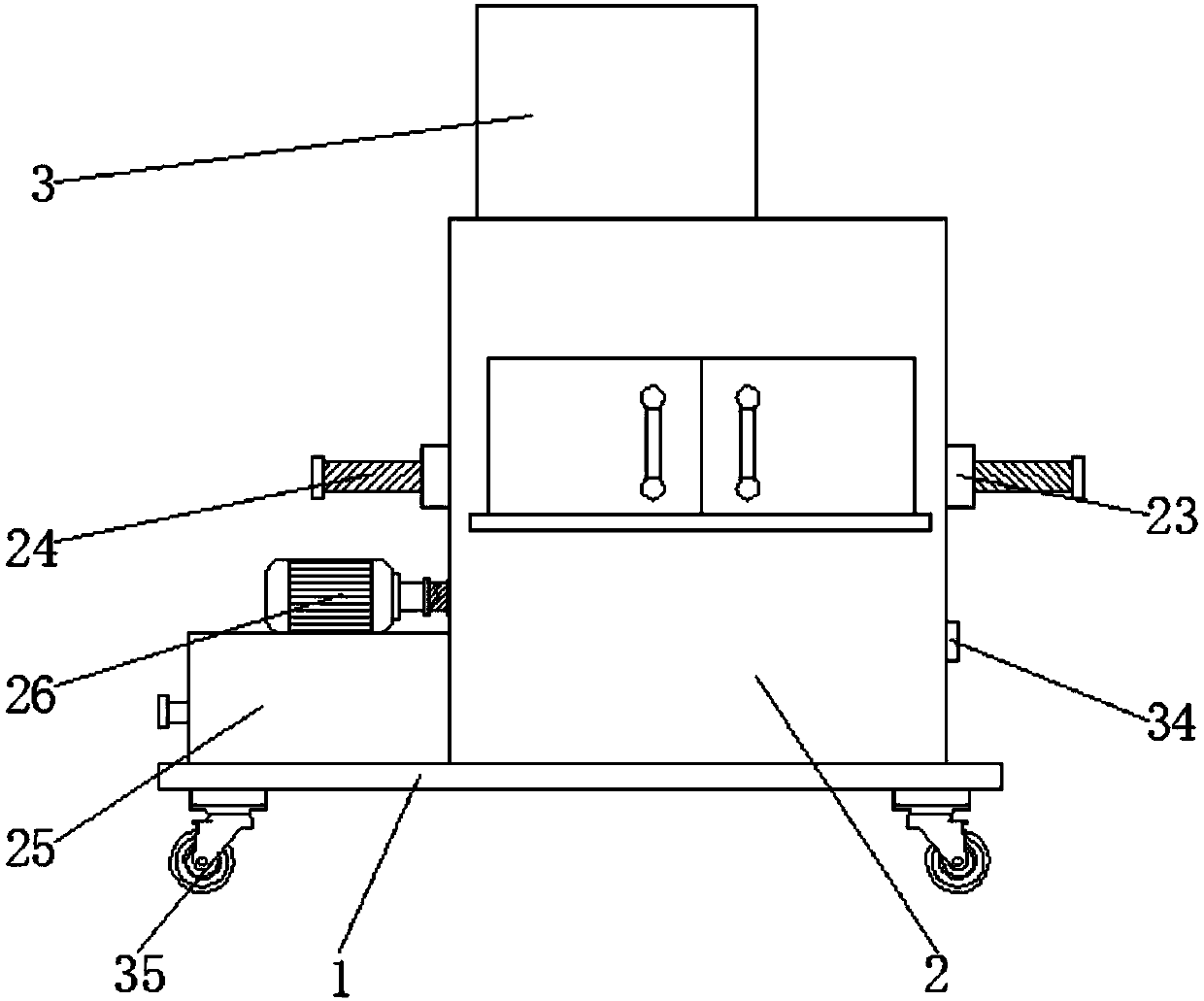

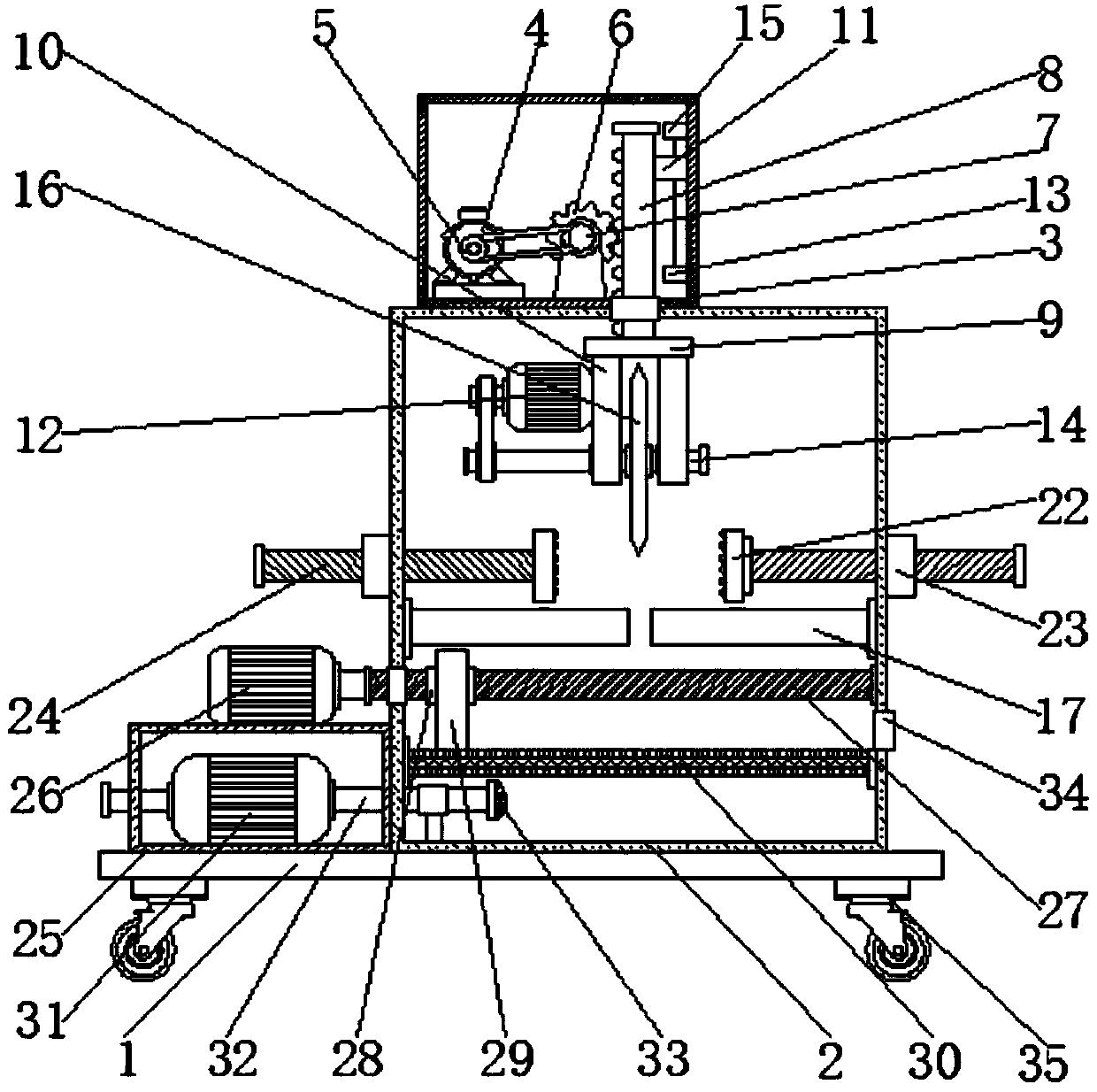

Embodiment 1

[0029] see Figure 1-2, a kind of building plank cutting device, comprises base 1 and box body 2, and cutting wheel 16 is installed on the top of box body 2 inner cavity, and fixing plate 17 is all fixed on the box body 2 inner wall of cutting wheel 16 both sides; Cutting wheel 16 and The moving parts are connected, and the moving parts take the cutting wheel 16 to move up and down. The moving parts include a motor box 3 and a first motor 4 , the motor box 3 is fixed on the top of the box body 2 , and the first motor 4 is fixed on the inner wall of the bottom of the motor box 3 . The outer surface of the output shaft of the first motor 4 is sheathed with the first pulley 5, the bottom of the motor case 3 inner wall and one side positioned at the first motor 4 are connected with a gear 6 through the support rod rotation, and the front of the gear 6 is fixedly connected with a second pulley. Pulley 7, the outer surface of the second pulley 7 is connected with the outer surface ...

Embodiment 2

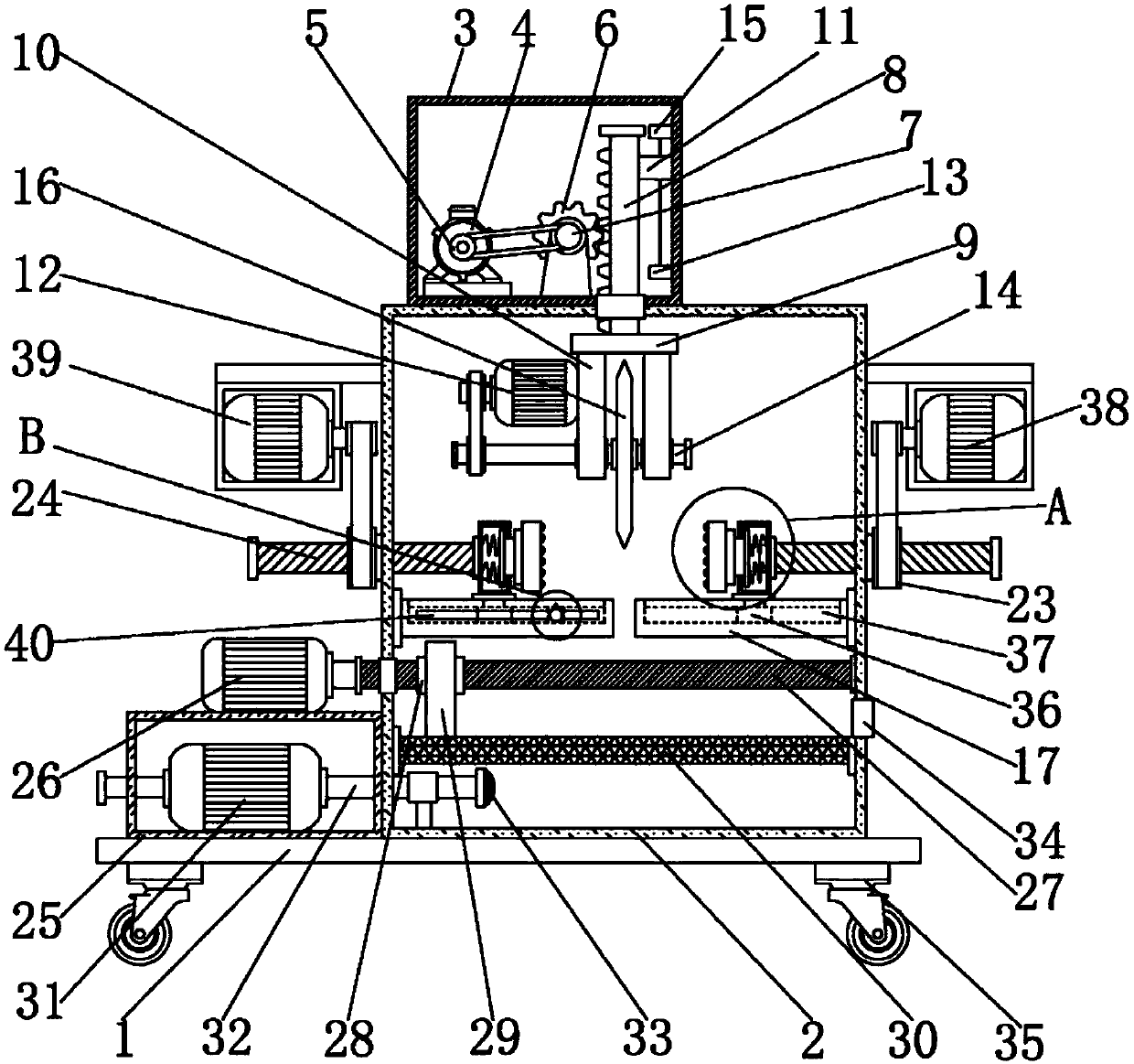

[0033] In addition to the technical features of Embodiment 1, the difference between this embodiment and Embodiment 1 is that: Please refer to Figure 3 ~ Figure 6 , the top of the fixed plate 17 is slidingly connected with a sliding frame 18, the sliding frame 18 is fixed with the clamping screw 24; one side of the sliding frame 18 is provided with a push rod 21, one end of the push rod 21 is fixed with the clamping block 22, and the other end penetrates into In the sliding frame 18, a first spring 20 is provided between the push rod 21 and the inner wall of the sliding frame 18; the fixed plate 17 is provided with a chute 37, and the lower end of the sliding frame 18 is fixed with a clamping sliding block 36 cooperating with the chute 37. Holding the sliding block 36 to slide in the chute 37 to realize the back and forth movement of the sliding frame 18. When the clamping block 22 clamps the plank to cut, the cutting wheel 16 will have a certain lateral vibration. Lateral v...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com