Building method of Pre-revascularizational large biological bone scaffold of composite cell

A construction method and technology of bone scaffolds, applied in the field of biomanufacturing, can solve the problems of unsatisfactory prefabricated vascular network scaffolds and inability to perform cell assembly tests, etc., to achieve rapid repair, improve repair efficiency, and high flexibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

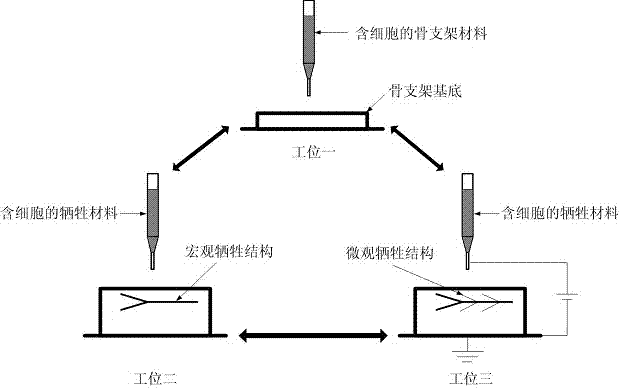

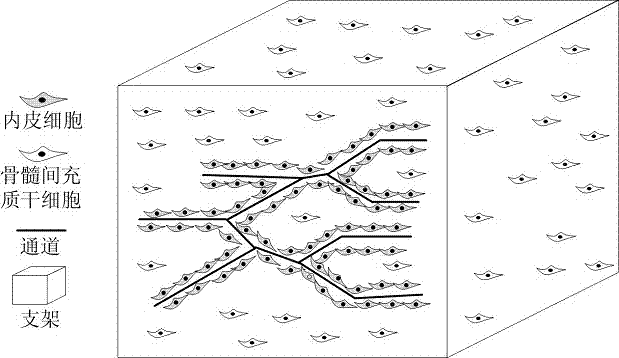

[0029] In this example, see Figure 1~Figure 2 A method for constructing a pre-vascularized bulk biological bone scaffold of composite cells, comprising the steps of:

[0030]a. Preparation of gelatin loaded with human bone marrow mesenchymal stem cells as raw material for printing bone scaffolds and sodium alginate loaded with human umbilical vein endothelial cells as sacrificial material, gelatin and sodium alginate powder baked at high temperature and sterilized by ultraviolet light Pour into the cell culture medium, and prepare gelatin solution and sodium alginate solution with the concentrations that meet the conditions of macroscopic printing and electrohydrodynamic direct writing; respectively, the third-generation human bone marrow mesenchymal stem cells and the third-generation human umbilical cord The venous endothelial cells were taken out from the incubator, after trypsin digestion, centrifugation and other steps, the supernatant was discarded to obtain human bone ...

Embodiment 2

[0036] This embodiment is basically the same as Embodiment 1, especially in that:

[0037] In this embodiment, a method for constructing a pre-vascularized bulk biological bone scaffold of composite cells, the bone scaffold material adopts chitosan, comprising the following steps:

[0038] a. Preparation of chitosan loaded with human bone marrow mesenchymal stem cells as raw material for printing bone scaffolds and sodium alginate loaded with human umbilical vein endothelial cells as sacrificial material: chitosan and The sodium alginate powder was poured into the cell culture medium, and the chitosan solution and the sodium alginate solution with the concentrations meeting the conditions of macroscopic printing and electrohydrodynamic direct writing were respectively prepared; respectively, the third-generation human bone marrow mesenchymal stem cells under cultivation were and third-generation human umbilical vein endothelial cells were taken out from the incubator, digested...

Embodiment 3

[0044] This embodiment is basically the same as the previous embodiment, and the special features are:

[0045] In this embodiment, a method for constructing a prevascularized bulk biological bone scaffold of composite cells, the bone scaffold material is a mixture of gelatin and hydroxyapatite, including the following steps:

[0046] a. Preparation Use gelatin loaded with human bone marrow mesenchymal stem cells as raw material for printing bone scaffolds and sodium alginate loaded with human umbilical vein endothelial cells as sacrificial material, weigh hydroxyapatite, and the quality of gelatin and hydroxyapatite The ratio is 5:1, the gelatin and hydroxyapatite powder that has been baked at high temperature and sterilized by ultraviolet light are mixed and poured into the cell culture medium with sodium alginate powder respectively, and the concentrations are prepared to meet the requirements of macroscopic printing and electrohydrodynamics Gelatin solution and sodium algi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com