Manufacture method for multiple surface treatments on one board

A technology of surface treatment and manufacturing method, applied in the direction of printed circuit manufacturing, secondary processing of printed circuits, electrical components, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

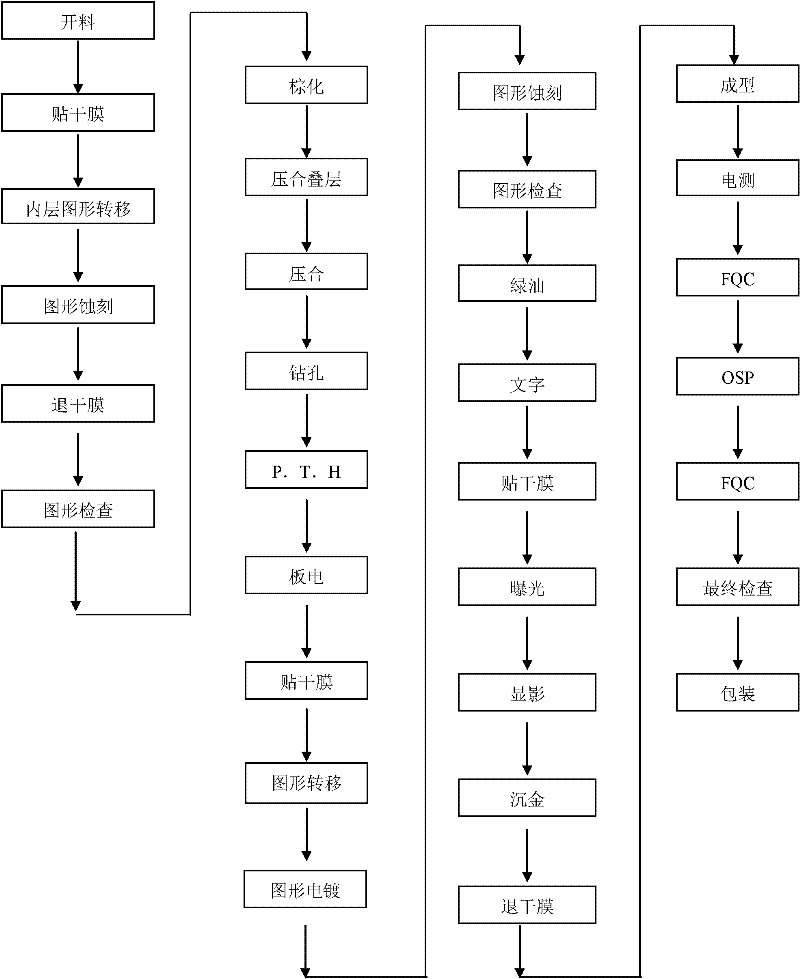

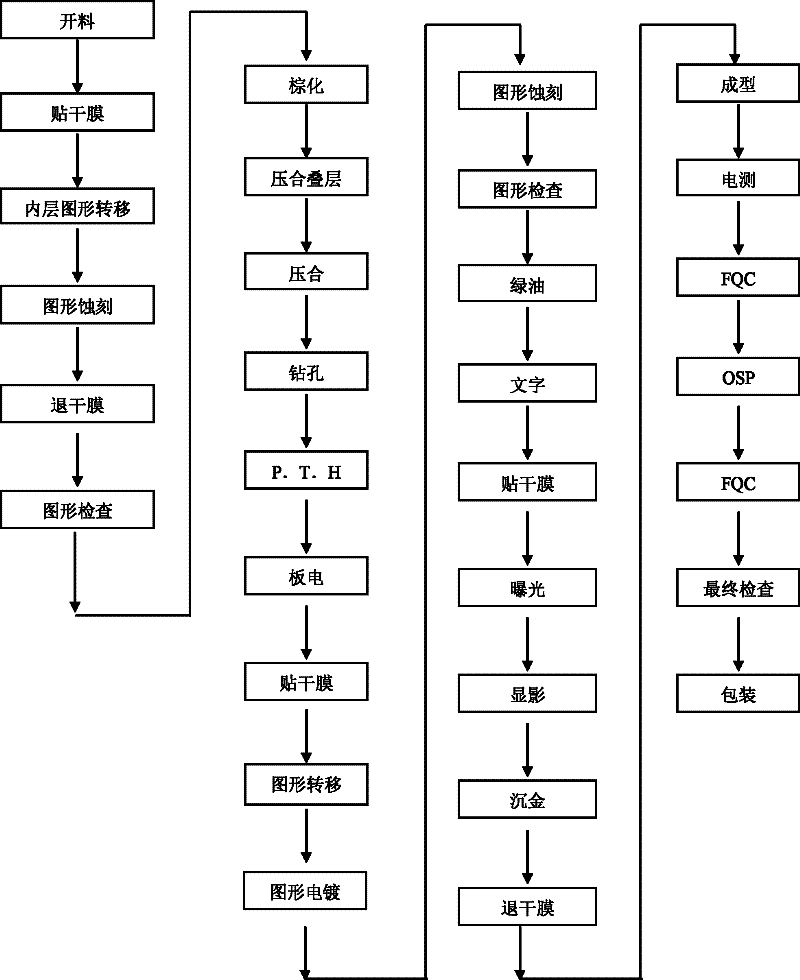

[0041] A manufacturing method for multiple surface treatments on the same board, specifically comprising the following steps:

[0042] BB, material cutting: according to the copper foil of each layer that meets the design requirements.

[0043] CC, paste the photosensitive dry film of each inner layer: except the outermost top layer and bottom layer, paste the photosensitive dry film on each inner layer.

[0044] DD. Inner layer graphics transfer: use the technology of film exposure to transfer the graphics of each inner layer to the board.

[0045] EE, graphic etching: use etching potion to etch away all unnecessary positions, and keep the required positions.

[0046] FF, dry film removal: remove all the pasted dry film, and expose the copper surface and lines.

[0047] GG, graphic inspection: Use a scanning instrument to check out the open and short circuits of the circuit and other defects, and complete the circuit production of each inner layer.

[0048] HH, Browning: I...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com