Manufacturing method for magnesium-based organic binding agent used for iron making pellet ore

The technology of an organic binder and a manufacturing method, applied in the field of metallurgical binders, can solve problems such as the output of sintered ore, the influence of quality indicators, etc., and achieve the effects of relieving pressure, reducing the dosage, and reducing the dosage.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

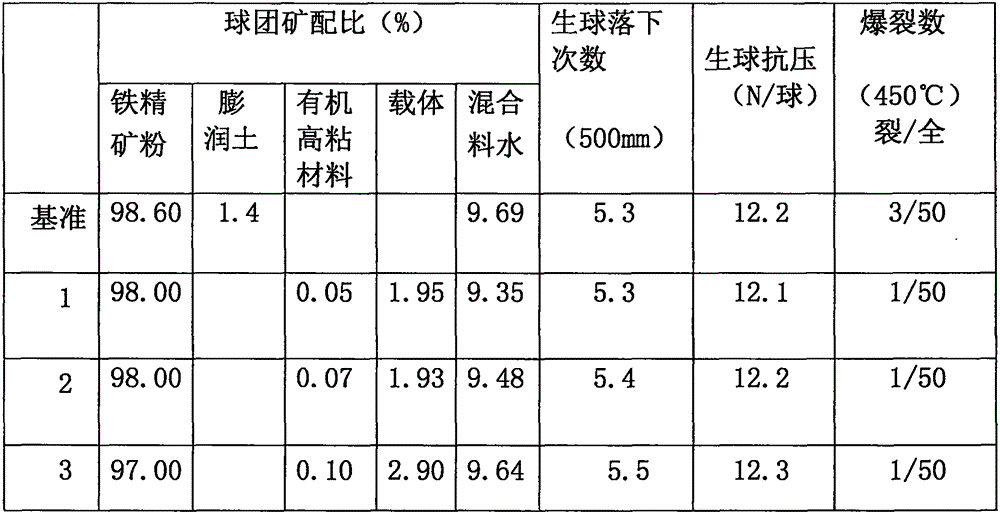

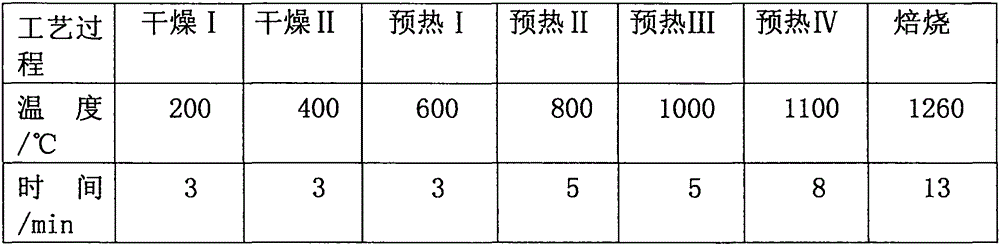

[0013] The present invention is further described in conjunction with above-mentioned technical scheme and embodiment:

[0014] Below is the detailed embodiment of specific implementation mode:

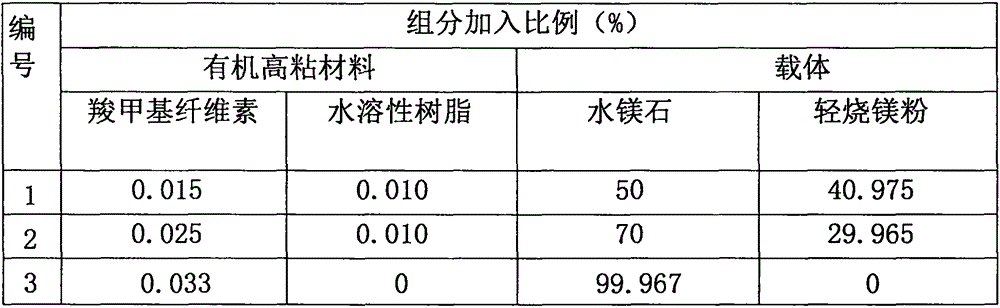

[0015] 1. A magnesium-based organic binder for ironmaking pellets, characterized in that its components by weight percentage are: organic high-viscosity material 0.025-0.075.0%; carrier 99.975-99.925%.

[0016] 2. The organic high-viscosity material is composed of one or a mixture of carboxymethyl cellulose and water-soluble resin. When the concentration of carboxymethyl cellulose is 1%, the viscosity is ≥300mpa.s; when the concentration of water-soluble resin is 1%, the viscosity is ≥350mpa.s. These highly viscous materials are highly hydrophilic and have strong adhesion to ferrous materials.

[0017] 3. The carrier is brucite {Mg(OH) 2} and a combination of one or two mixtures of lightly burned magnesium powder.

[0018] 4. The carrier is brucite {Mg(OH) 2} and one or two mixtu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com