Patents

Literature

41 results about "Caustic Burn" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Method for preparing lightweight microporous magnesium raw material

InactiveCN106747594AReduced alkali corrosion resistanceImprove mechanical propertiesCeramicwareBrickGranularity

The invention relates to a method for preparing a lightweight microporous magnesium raw material, and belongs to the technical field of refractory materials. The steps and parameters are as follows: preparingcaustic-burned magnesia powder with granularity smaller than 0.080mm, magnesite powder granularity not greater than 0.080mm and pulp waste raw material with specific gravity of 1.0-1.6g / cm3; performing ball grinding on 5-95wt% of caustic-burned magnesia powder and 5-95wt% of magnesite powder for 1-5h in a ball mill, and mixing the mixture with the pulp waste accounting for 3-8% of the total weight; pressing green bricks by using a press machine; and drying, sintering and cooling to the room temperature, and discharging the finished products from the kiln. The lightweight microporous magnesium raw material has the advantages of having good mechanical properties under normal temperature and high temperature while on the premise of ensuring no obvious reduction of the alkali erosion resistance of the material; reducing the load of the cylinder body while reducing the temperature of the cylinder body of the high-temperature kiln, and thus realizing the purposes of saving energy and reducing the consumption.

Owner:TONGDA REFRACTORY TECH CO LTD +2

Aging-resistant PVC tubular product and preparation method thereof

InactiveCN104140617AGood anti-ultraviolet aging performanceImprove mechanical propertiesPhosphateCadmium Cation

The invention discloses an aging-resistant PVC tubular product and a preparation method thereof. The aging-resistant PVC tubular product is prepared from the following raw materials in parts by weight: 100-150 parts of SG-3 PVC, 30-60 parts of an acrylonitrile-styrene-acrylate copolymer, 2-4 parts of triglycidyl isocyanurate, 10-15 parts of titanium dioxide, 15-20 parts of sericite in powder, 25-45 parts of polyether sulfone, 3-6 parts of polytetrafluoroethylene micropowder, 2-3 parts of tribasic aluminum sulfate, 1.5-2.5 parts of a barium cadmium zinc liquid compound stabilizer, 3-5 parts of erucyl amide, 4-7 parts of Fischer Tropsch wax, 1-2 parts of pyrithione zinc, 1-2 parts of bisphenol A phosphate, 5-10 parts of caustic-burned magnesia powder and 3-4 parts of auxiliaries. The PVC tubular product prepared by the preparation method disclosed by the invention not only has excellent ultraviolet aging resistance and mechanical property, but also has good heat resistance, corrosion resistance, wear resistance, impact resistance, environmental stress crack resistance and the like, and is free from deformation and cracking when being exposed to the sun for a long time and durable.

Owner:安徽玉发塑业有限公司

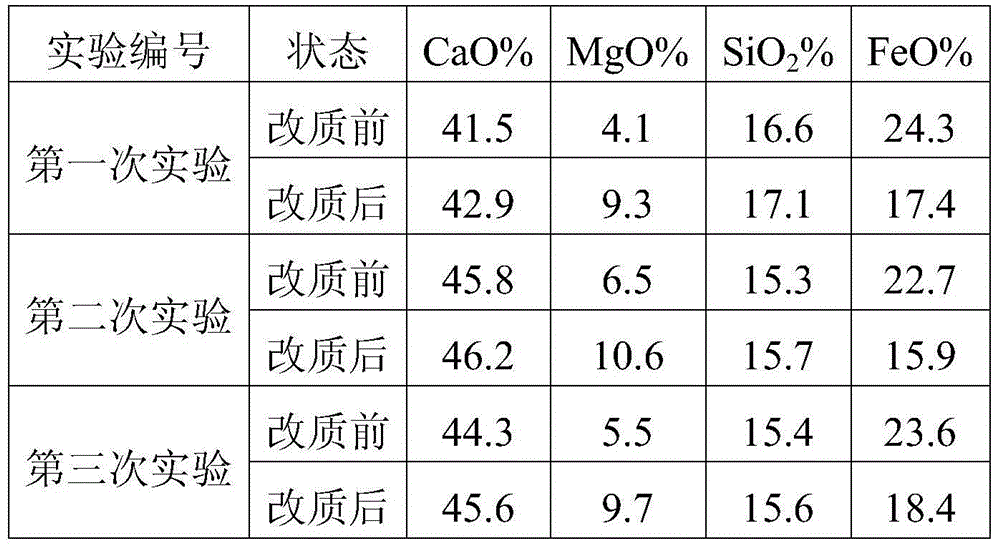

Resource utilization method of waste magnesia powder after treating oriented silicon steel

ActiveCN104099469AEfficient use ofHigh viscosityManufacturing convertersEnvironmental resistanceSlag

The invention discloses a resource utilization method of waste magnesia powder after treating oriented silicon steel. The resource utilization method comprises the following steps: (1) the waste magnesia powder after treating the oriented silicon steel is collected, and is evenly mixed with carbon powder and asphalt powder to obtain a mixed raw material by the following weight percentages: the waste magnesia powder is 60-95%, the carbon powder is 0-30%, and the asphalt powder is 5-10%; (2) the mixed raw material is prepared to green pellets with the diameter of 10-15 mm; and then the temperature of the green pellets is kept at 190-210 DEG C for 0.8-1.2 hours to prepare magnesium carbon pellets; and (3) the cooled magnesium carbon pellets are used as a slag splashing furnace protecting material. The resource utilization method uses the waste magnesia powder after treating the oriented silicon steel to replace the magnesium carbon pellets for the slag splashing furnace protection of a caustic-burned magnesia powder production converter; and the magnesium carbon pellets have high mechanical strength, can effectively enhance the viscosity of furnace slag, and can improve the slag splashing effect, so that the waste magnesia powder is effectively used, the stacking place is saved, the groundwater pollution is prevented, and the dual effects of environmental protection and economy are achieved.

Owner:武汉钢铁有限公司

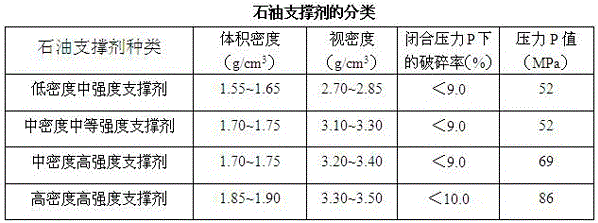

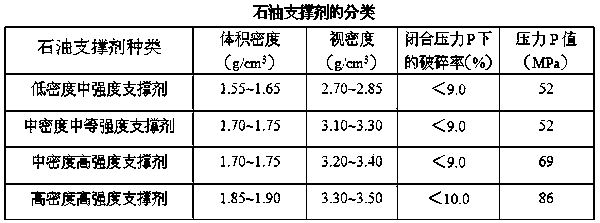

Ultralow-density cordierite petroleum fracturing propping agent and preparation method thereof

ActiveCN106431349AHigh hardnessHigh mechanical strengthFluid removalDrilling compositionCordieriteManganese oxide

The invention provides an ultralow-density cordierite petroleum fracturing propping agent and a preparation method thereof. A principal crystalline phase of the popping agent is of a cordierite structure and is formed by firing coal ash, caustic-burned magnesia powder, Jiaozuo clay and a composite mineralizer, and the composite mineralizer is formed by mixing manganese oxide and barium carbonate according to the equal weight ratio. A large amount of high-silicone, low-aluminum, low-calcium and low-ignition-loss neutral coal ash is adopted as a main raw material, and the density index of the popping agent is effectively reduced; through the special processing and treating processes such as special pre-sintering on an important raw material magnesite and ultrafine grinding on batches and the composite mineralizer technology, it is effectively guaranteed that high-hardness and low-density principal crystalline phase minerals are formed in a system at high temperature, therefore, and it is guaranteed that the finished ultralow-density popping agent has high mechanical strength; the firing temperature of the popping agent is reduced, and the purposes of energy saving and consumption reduction are achieved.

Owner:洛阳赛罗帕陶瓷科技有限公司 +1

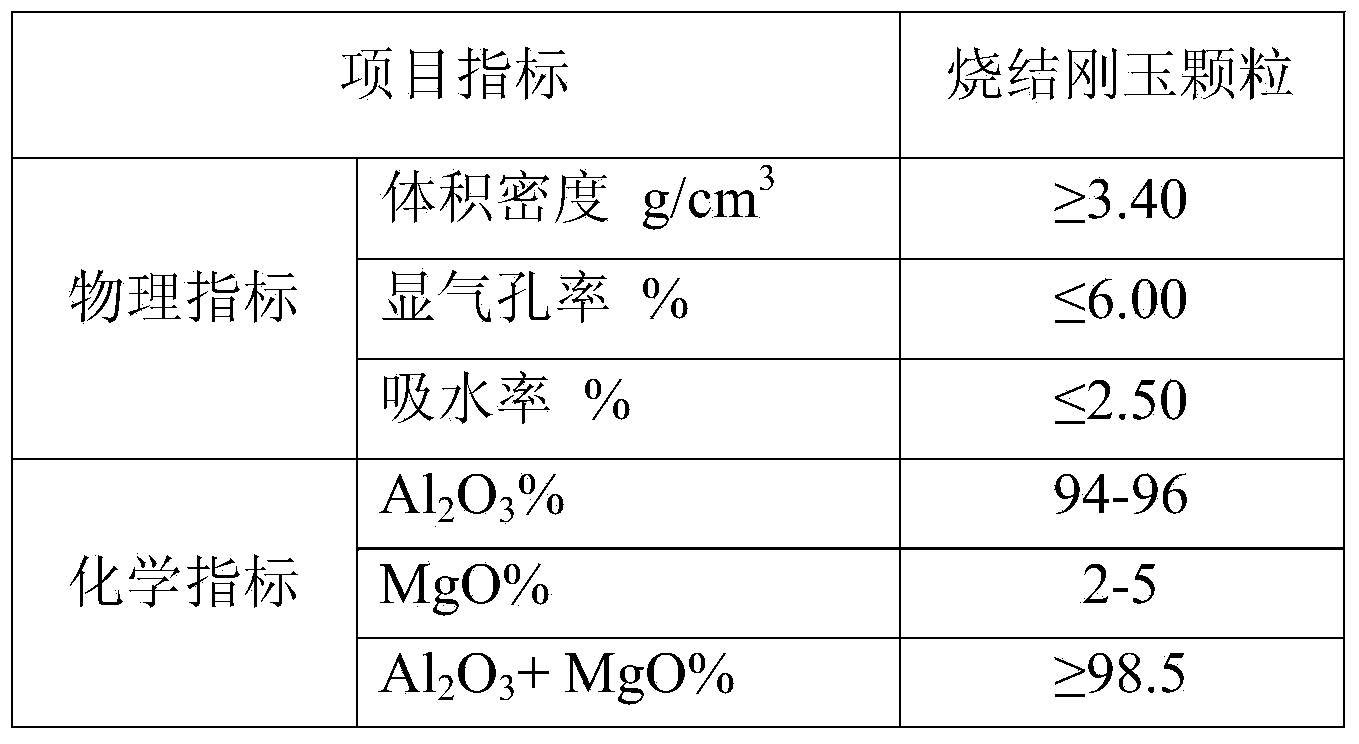

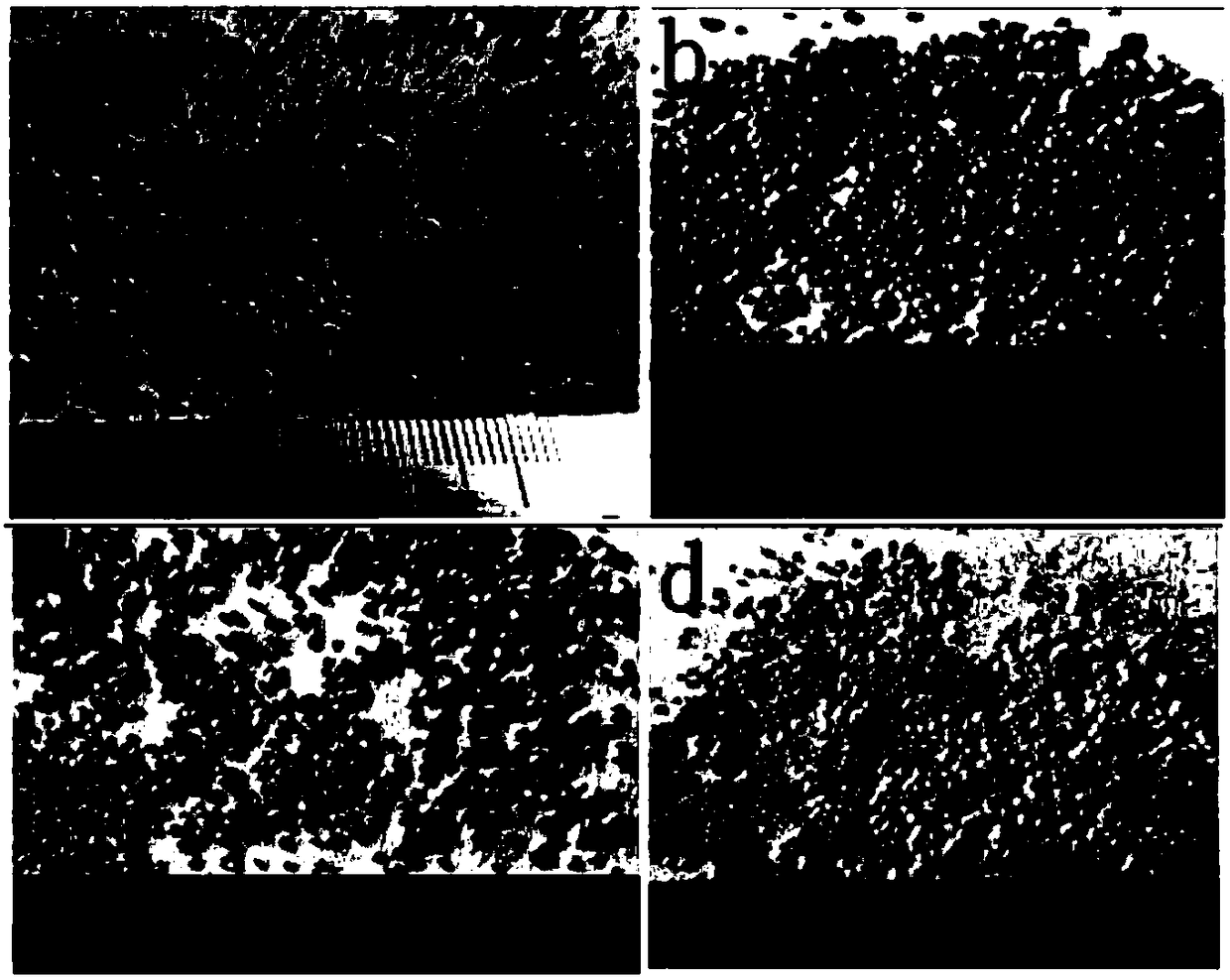

Preparation method for sintered corundum

The invention discloses a preparation method for sintered corundum. The method comprises the following steps: (1) uniformly mixing gamma-Al2O3 and caustic-burned magnesia powder and carrying out crushing so as to obtain mixed powder, wherein a weight ratio of gamma-Al2O3 to caustic-burned magnesia powder is 94-96: 3-6; (2) subjecting the mixed powder prepared in the step (1) to balling twice so as to obtain a pre-sintered material; and (3) drying the pre-sintered material prepared in the step (2) and carrying out calcining and cooling molding so as to obtain sintered corundum. Preferably, the weight ratio of gamma-Al2O3 to caustic-burned magnesia powder is 95: 3-6. The method is energy saving and environment-friendly; the prepared sintered corundum has high volume density and low impurity content; a microstructure shows that crystal grain of the sintered corundum is of a sheet structure and has a size of 10 to 200 mu m, pores in the crystal exist in an enclosed form, and a crystal structure is compact; and the sintered corundum is widely applicable to production of high-grade shaped or shapeless refractory products.

Owner:浙江自立新材料股份有限公司

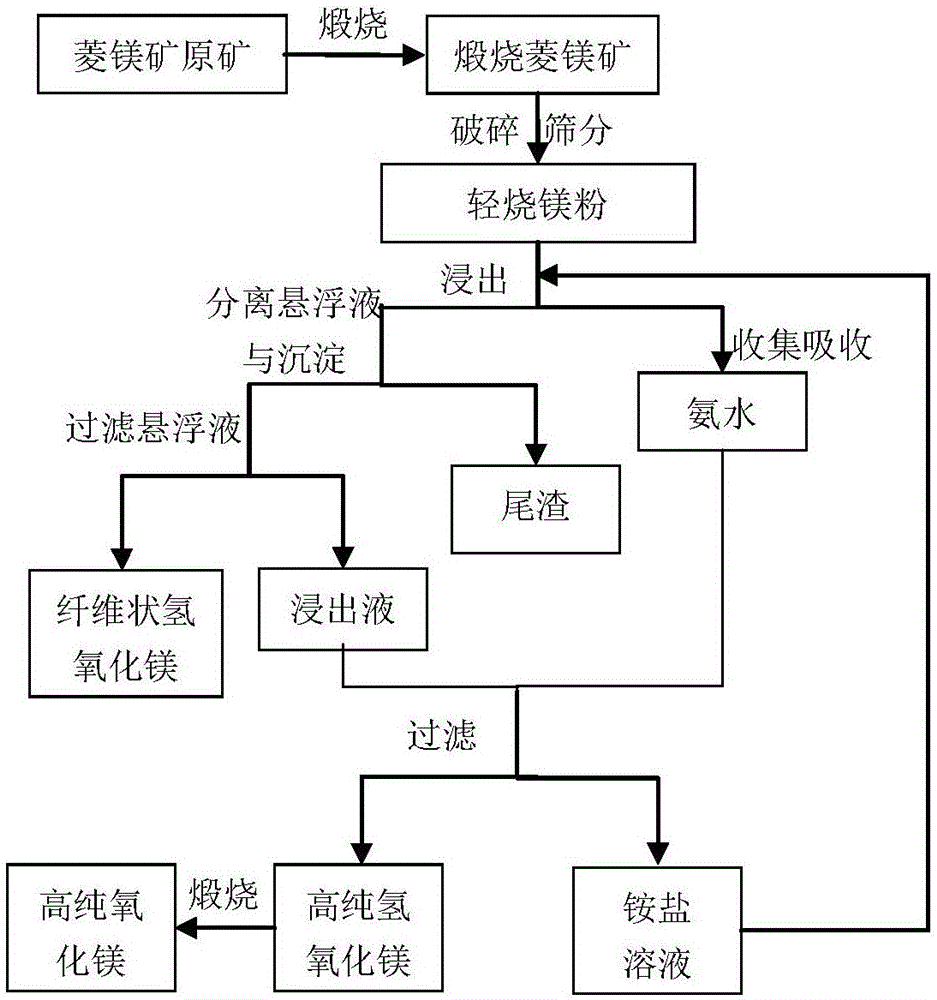

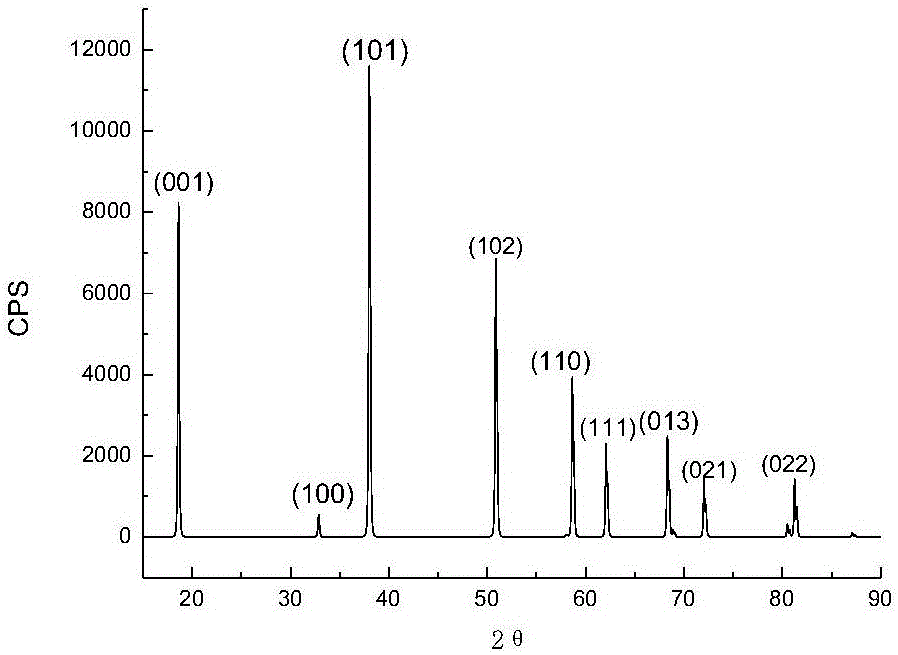

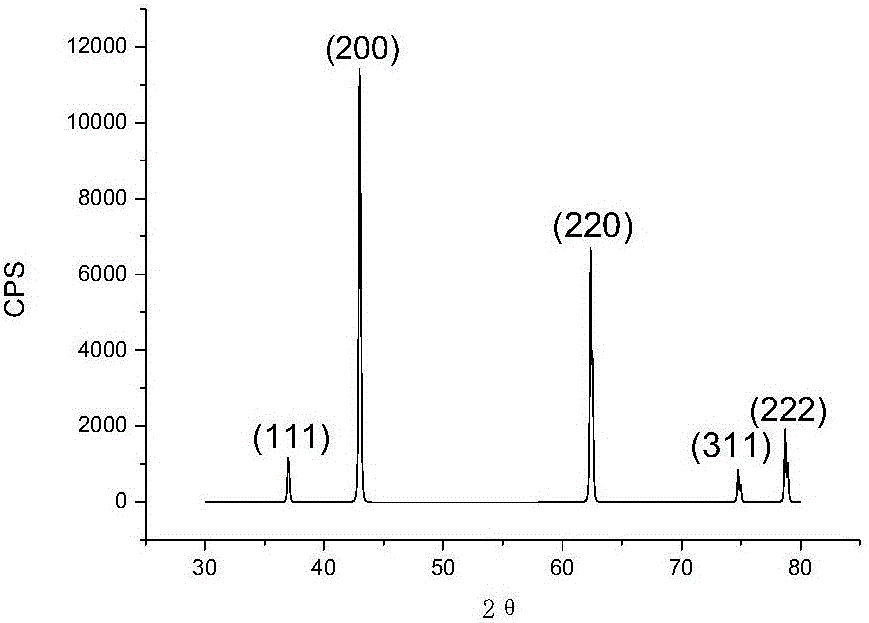

Method for preparing magnesium oxide or magnesium oxide and fibrous magnesium hydroxide from magnesite

InactiveCN106745103AWide variety of sourcesLow costMagnesiaMagnesium hydroxideWater bathsMagnesium salt

The invention discloses a method for preparing magnesium oxide from magnesite. The method comprises the following steps: 1) calcining magnesite to obtain caustic-burned magnesia powder; 2) adding the caustic-burned magnesia powder into an ammonium salt solution for leaching, wherein the leaching process is performed under the conditions of reduced pressure, water bath heating and stirring; and 3) filtering to obtain magnesium salt leachate; 4) enabling the magnesium salt leachate to react with ammonia water to obtain magnesium hydroxide precipitate, and calcining to obtain magnesium oxide. The invention also discloses a method for preparing magnesium oxide and fibrous magnesium hydroxide from magnesite, which comprises the following steps: 1) calcining magnesite to obtain caustic-burned magnesia powder; 2) adding the caustic-burned magnesia powder into an ammonium salt solution for leaching, wherein the leaching process is performed under the conditions of reduced pressure, water bath heating and stirring; 3) extracting upper- and middle-layer suspension of the solid-liquid mixed system and performing suction filtration to obtain filtrate and a filter cake; drying the filter cake to obtain fibrous magnesium hydroxide; and combining the precipitate slag washing liquid with the filtrate to obtain magnesium salt leachate; and 4) enabling the magnesium salt leachate to react with ammonia water to obtain magnesium hydroxide precipitate, and calcining to obtain magnesium oxide.

Owner:张旭

Preparation method of tundish eco-friendly dry vibration material

The invention discloses a preparation method of a tundish eco-friendly dry vibration material. The preparation method comprises the following steps of 1, putting 15-17 parts of fused magnesia particles having the sizes of 5-7mm, 20-22 parts of fused magnesia particles having the sizes of 2-5mm and 7-9 parts of fused magnesia particles having the sizes of 0.5-1mm into a mixer, carrying out mixing for 4-6min, adding 1.5-2.5 parts of polyvinyl alcohol and 2-4 parts of bentonite into the mixture, and carrying out mixing for 9-11min, 2, adding 4-6 parts of caustic-burned magnesia powder of -200 meshes, 1-3 parts of alpha-Al2O3 powder of -200 meshes, 1-3 parts of silicon oxide powder of -200 meshes and 2-4 parts of calcium oxide powder of -200 meshes into the mixture, carrying out mixing for 9-11 min, adding 0.5-1.5 parts of sodium tripolyphosphate, 0.5-1.5 parts of sodium hexametaphosphate and 0.1-0.3 parts of dextrin into the mixture and carrying out mixing for 14-16min, and 3, carrying out blank film vibration molding on the mixture obtained by the step 2, carrying out baking at a temperature of 260-280 DEG C and carrying out demolding.

Owner:无锡市华瑞渔机厂

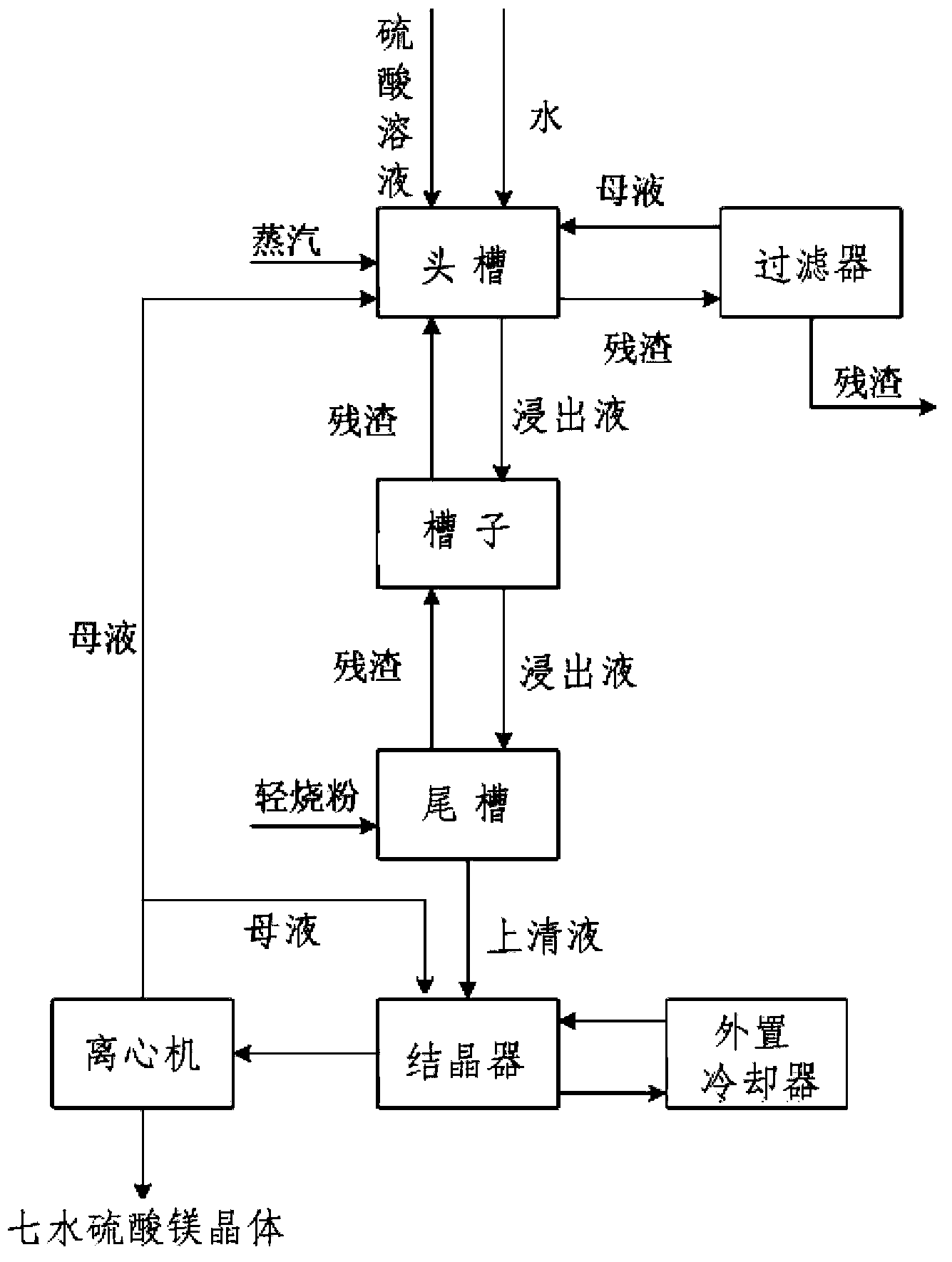

Magnesium sulfate heptahydrate producing process with fully-continuous method

ActiveCN103382035AOvercome the disadvantages of heat transferRealize continuous productionMagnesium sulfatesMagmaDirect heating

The invention provides a magnesium sulfate heptahydrate producing process with a fully-continuous method. The magnesium sulfate heptahydrate producing process with the fully-continuous method comprises continuously adding caustic-burned magnesia powder into the tail tank of a continuous leaching tank; continuously adding sulfuric acid solution, water and steam into the head tank, directly heating the head tank with the steam so as to enable the temperature inside the continuous leaching tank to be stable; controlling the material adding speed to obtain magnesium sulfate supernatant of a certain concentration, specific weight and pH value; continuously sending the supernatant into a crystallizer from the tail tank, continuously and steadily discharging magma through the crystallizer, obtaining magnesium sulfate heptahydrate products after solid-liquid separation, and sending mother liquor back to the head tank of the continuous leaching tank after the separation. The magnesium sulfate heptahydrate producing process with the fully-continuous method has the advantages of small device space occupation, no crystallizer wall attachment, small labor intensity, high utilization rate of magnesium-contained mineral in the caustic-burned magnesia powder and continuous operation capability.

Owner:HEBEI NUODA CHEM EQUIP

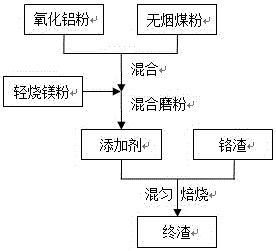

Dry process for detoxicating chromium slag

The invention relates to a dry process for detoxicating chromium slag and belongs to the fields of dry chromium slag detoxication technology and treatment of harmful solid wastes. The process comprises the following steps: preparing additives by using 30-50 wt% of alumina powder with Al2O3 content of 96% or above, 30-50 wt% of caustic-burned magnesia powder at the grade of QM-95 or more and 0-40 wt% of anthracite culm, mixing and roasting with chromium slag, reducing hexavalent chromium in the chromium slag into trivalent chromium, and fixing the trivalent chromium at the normal temperature. According to the method, the component materials are commercial commodities, are low in manufacturing cost and small in doping amount in the dry chromium slag detoxication technology, the temperature needed in the dry detoxication process can be effectively reduced, formation of a final magnesium slag-containing spinel structure is promoted, the chromium slag can reach the standard when treated by a one-stage process, and the final slag does not become yellow.

Owner:KUNMING UNIV OF SCI & TECH

Long-acting compound fertilizer specially used for maize and preparation method thereof

InactiveCN108586164ANo side effectsLow dosage of growth regulating substancesSuperphosphatesMagnesium fertilisersMicrobial agentPhosphoric acid

The invention relates to a long-acting compound fertilizer specially used for maize, which includes, by weight, 20-30 parts of urea, 15-20 parts of triple superphosphate, 5-10 parts of potassium chloride, 25-35 parts of active humic acid powder, 1-8 parts of caustic-burned magnesia powder, 1-5 parts of long-acting slow-releasing agent, 0.5-2 parts of microelements, 0.1-1 part of a compound microbial agent, and 5-15 parts of decayed organics. According to the ratio of required nutrients in a production period, a development period and a mature period of maize, the components are compounded reasonably; meanwhile, by adding the long-acting slow-releasing agent, the active humic acid powder, the microelements, the compound microbial agent and the like, problems of short acting time, low utilization rate and environment pollution in conventional single fertilizers, composite fertilizer and special fertilizer for maize as well as topdressings of the three fertilizers are solved.

Owner:广西亿润生物科技有限公司

Magnesium hydroxide preparation method

A method for preparing magnesium hydroxide belongs to the field of chemical industry, and is characterized in that it comprises the following steps: (1) weigh light-burned magnesium powder and ammonium chloride and add them to a three-necked flask, then add water to obtain a clarified magnesium chloride solution; ( 2) Fully dissolve the surfactant in the magnesium chloride solution; (3) Add ammonia water dropwise to carry out the precipitation reaction, and finally filter, wash and dry the solution to obtain a white powder of magnesium hydroxide; (4) Take magnesium hydroxide for hydrothermal modification. (5) After the reaction is completed, it is fully washed with water by natural cooling, and suction filtration to obtain a white precipitate of hydrothermally modified magnesium hydroxide. The dispersion effect of magnesium hydroxide is improved, the morphology of magnesium hydroxide is improved, and the recycling of ammonium chloride solution in the synthesis process is realized, which reduces environmental pollution on the one hand, and saves production cost on the other hand.

Owner:SHAANXI HUANKE BIOLOGICAL TECH CO LTD

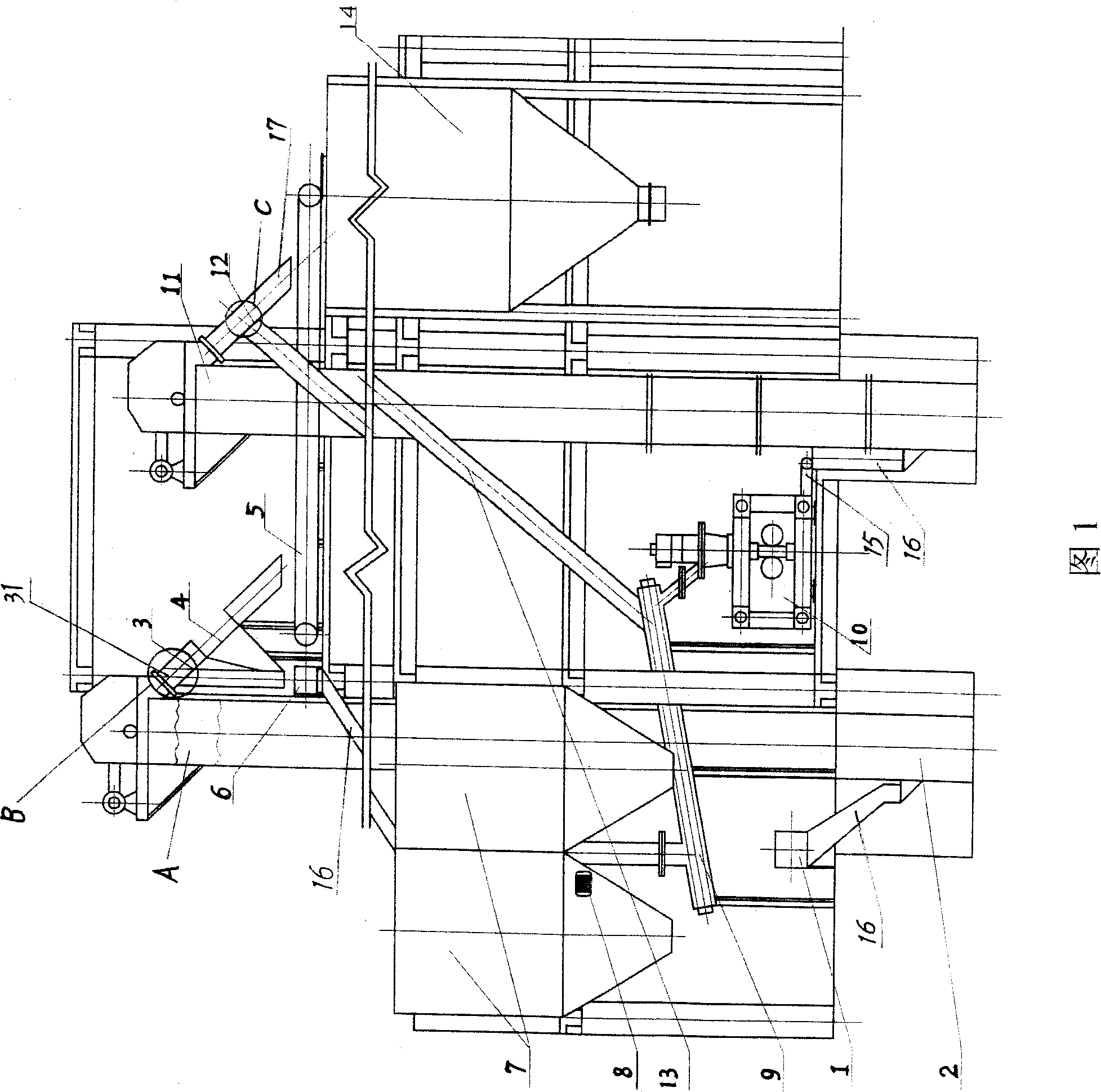

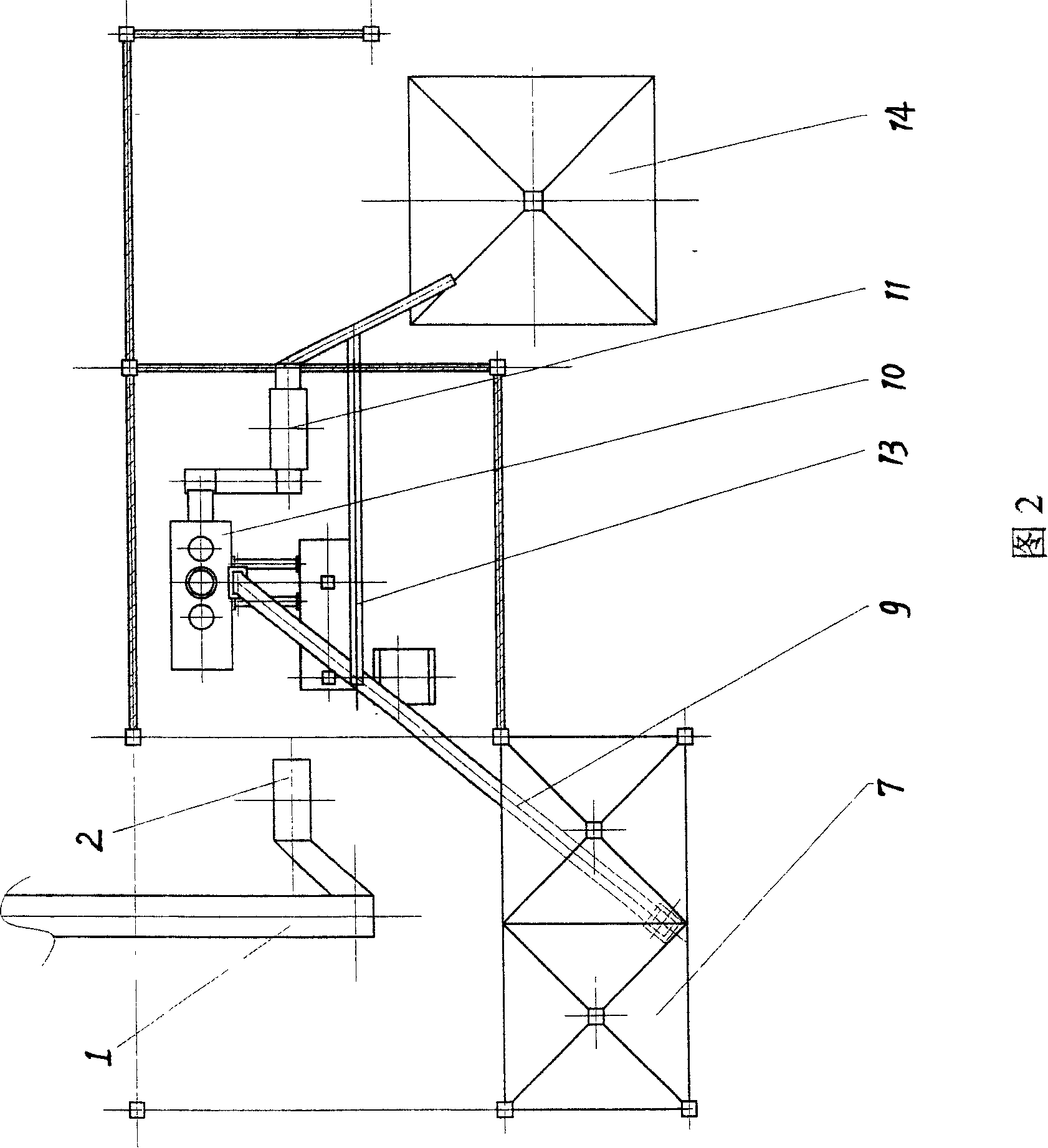

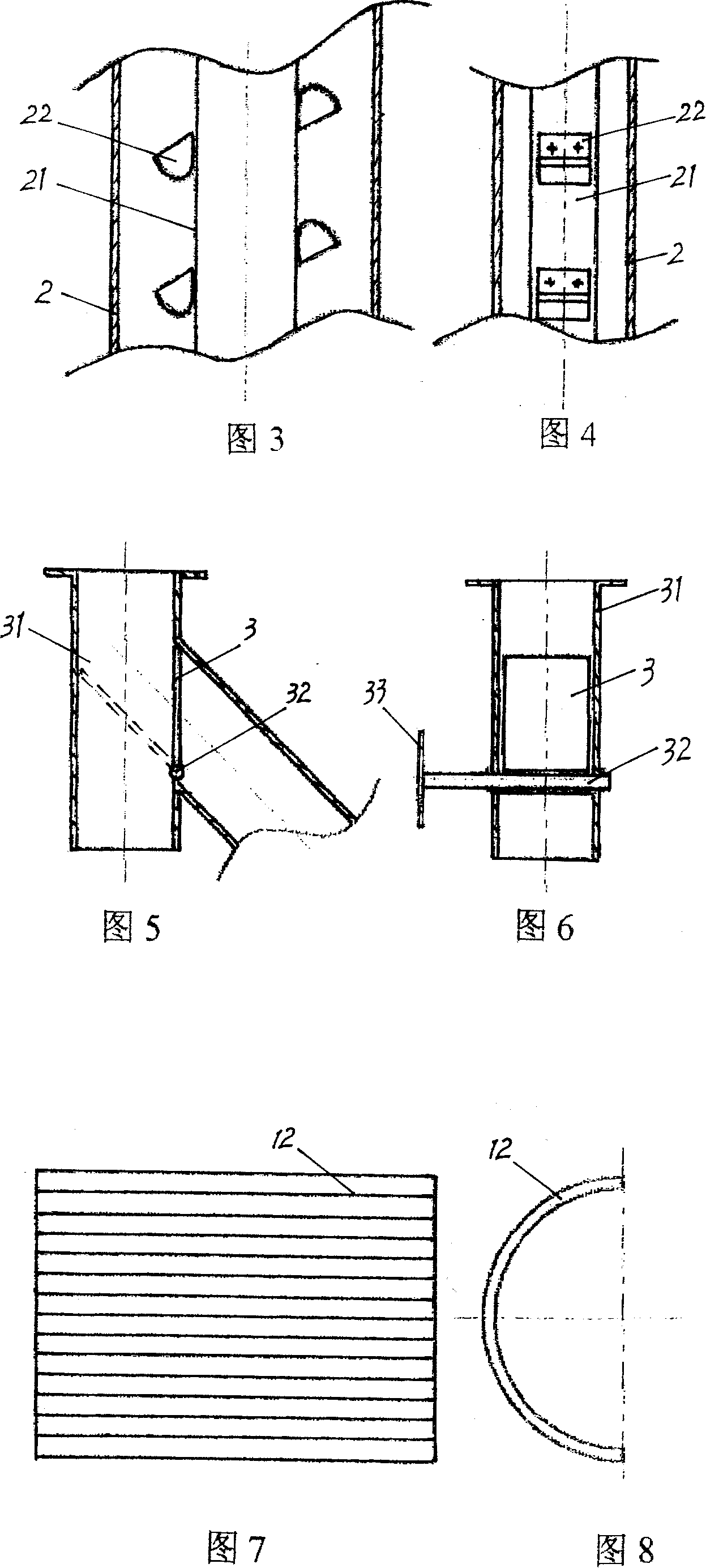

Comprehensive utilization technique and system for soft-burned dolomite fines

The invention provides a technique for integrally utilizing caustic-burned dolomite flour, and a relative system, which can directly press and shape the dolomite powder calcined from shaft furnace, the de-dust smoke generated in the calcinations, and flour screened from the dolomite, to be used in steel production, thereby fully utilizing dolomite, save material, and effectively prevent environment pollution. And the invention utilizes the character that caustic-burned dolomite flour and relative flour are easy to be separated, to arrange a tube screen on a Y-shape blanking tube, to secondary reclaim and utilize the flour generated in transmission palletizing process, and reduce the investment and energy consumption of screen device. And the invention arranges a micro external vibrator at the outlet of flour chamber to blank uniformly and successfully, and uniformly feed the flour of following helical conveyer into pelletizer to confirm the shaping quality of flour.

Owner:KUNMING IRON & STEEL GRP CO LTD

Industrial anti-piercing sole material and preparation method thereof

InactiveCN106009097AReduce manufacturing costImprove penetration resistanceSolesSlagAdditive ingredient

The invention discloses an industrial anti-penetration shoe sole material and a preparation method thereof, relating to the technical field of shoe sole materials, mainly composed of butadiene rubber, acrylic rubber, p-polystyrene, carbon black N660, zinc stearate, erucic acid Amide, petroleum coke residue, niobium diselenide, light-burned magnesium powder, perfluoropolyether, triisopropylphenyl phosphate, nano-diamond, ramie fiber, zinc oxide powder, antioxidant GM, anti-aging agent A, silane coupling Joint agent KH-590, made of nano-tungsten powder. The sole material of the present invention adopts butadiene rubber, acrylic rubber, and p-polystyrene as main raw materials, has good wear resistance, excellent elasticity, light weight, and low production cost. It is matched with nano-diamond, ramie fiber, nano-tungsten powder, and petroleum coke Slag and other ingredients greatly improve the anti-penetration ability, corrosion resistance and wear resistance of the sole material, especially suitable for workers' sole materials.

Owner:WENZHOU RENHE EDUCATION TECH CO LTD

Forsterite coating

The invention discloses a forsterite coating which comprises the following raw materials in percentage by mass: 25%-35% of forsterite, 50%-60% of magnesia, 4%-6% of high aluminum powder, 2%-3% of silica powder, 4%-6% of caustic-burned magnesia powder, 0.15%-0.25% of borax, 0.15%-0.25% of sodium tripolyphosphate, 0.4%-0.5% of pure aluminate cement and 0.8%-1.2% of fibers. According to the forsterite coating, the suspension property, stability, flowability and bonding property are remarkably improved.

Owner:浙江攀盛冶金材料有限公司

Glass-plastic composite geogrid

The invention discloses a glass-plastic composite geogrid. The glass-plastic composite geogrid is prepared from the following raw materials in parts by weight: 107-120 parts of high-density polypropylene, 2-3 parts of perchloro-ethylene resin, 2-4 parts of caustic-burned magnesia powder, 6-10 parts of blast furnace slag, 0.3-1 part of polyacrylamide, 2-3 parts of rare earth auxiliaries, 3-5 parts of glass powder, 0.6-1 part of saturated stearamide, 1-2 parts of barium metaborate, 0.5-1 part of potassium tetraborate, 1-2 parts of polyether glycol, 0.1-0.4 part of simethicone, 0.3-1 part of monobutyltin oxide, 1-2 parts of anhydrous calcium chloride and 1-2 parts of methyl ester nylon acid. According to the glass-plastic composite geogrid, the rare earth auxiliaries, which are formed by thoroughly mixing high-strength boron carbide with attapulgite and rare earth elements and further combining the mixture with a preservative calcium acetate and a stabilizer polyvinylpyrrolidone under the treatment action of a silane coupling agent, have excellent surface strength, toughness, weather fastness and corrosion resistance and good stability, and are capable of effectively improving the comprehensive quality of the finished product, the adaptability to the soil and the resistance to the ambient pressure.

Owner:ANHUI JIEAOMAKE SYNTHETIC MATERIAL TECH

Isometric spherical magnesium material as well as preparation method thereof and application in producing dispersion-type magnesium ventilated plug

The invention relates to an isometric spherical magnesium material as well as a preparation method thereof and an application in producing dispersion-type magnesium ventilated plug. The isometric spherical magnesium material with granularity respectively of 1 to 0.5mm, 0.5 to 0.3mm and less than 0.3mm is prepared by mixing 97 percent high-purity magnesia with the granularities of 40 meshes, 100 meshes and 200 meshes and 95 percent caustic-burned magnesia powder with the granularity of 200 meshes and calcium lignosulphonate and dextrin aqueous solution. The dispersion-type magnesium ventilatedplug produced by adopting the obtained isometric spherical magnesium material as a raw material has the following performance: the air permeability is 29 to 36 Nm<3> / h, the volume density is 2.57 to 2.62 g / cm<3>, and the pressure-resisting strength is 42.5 to 56.3MPa. Compared with the conventional raw material, the porosity of the isometric spherical magnesium material prepared by the invention is increased by 10 to 15 percent, and the prepared dispersion-type ventilated plug is more uniform in ventilated channels and better in ventilated effect.

Owner:营口市瑞福来耐火材料有限公司

Unshaped refractory material and preparation method thereof

The invention provides an unshaped refractory material and a preparation method thereof. The unshaped refractory material contains the components in parts by weight: 5-30% of magnesia particles, 5-15% of caustic-burned magnesia powder, 20-45% of corundum, 10-20% of silicon carbide, 10-18% of cokes, 6-12% of clay, 2-8% of ferro-silicon nitride, 3-10% of graphitisable coal tar pitch and aromatic hydrocarbon solvents. The preparation method comprises the steps of mixing the magnesia particles, the caustic-burned magnesia powder, the corundum, silicon carbide, the cokes, the clay, ferro-silicon nitride and the graphitisable coal tar pitch according to a certain proportion; and then, grinding and mixing after adding the aromatic hydrocarbon solvents to obtain the unshaped refractory material.

Owner:CENT RES INST OF BUILDING & CONSTR CO LTD MCC GRP +1

Brick made of rubbish and manufacturing method thereof

The invention discloses a brick made of rubbish. The brick is composed of a surface layer and a base layer. The surface layer comprises fine stone particles or sand particles, caustic-burned magnesia powder and a blending agent. The base layer comprises plastic rubbish which is cured after being melted or waste plastic which is cured after being melted and sand particles. The invention further discloses a method for manufacturing the brick by the rubbish. The manufacturing method comprises the following steps that: in the preparation process of a base layer material, the sand particles are firstly added into a stirring kettle for one time, and stirred while being heated, so that moisture in the sand particles is easily evaporated and discharged out from the top of the stirring kettle; when the temperature inside the stirring kettle is 95-105 DEG C, the plastic rubbish or the waste plastic is successively added into the stirring kettle, the successively added plastic rubbish or waste plastic is successively melted and successively mixed with the sand particles so that the plastic rubbish or waste plastic can be uniformly mixed with the sand particles; and when the temperature inside the stirring kettle is 135-145 DEG C, the plastic rubbish or waste plastic is completely melted and completely and uniformly mixed with the sand particles to form the base layer material, wherein no bubbles are formed in the base layer material.

Owner:张玉 +3

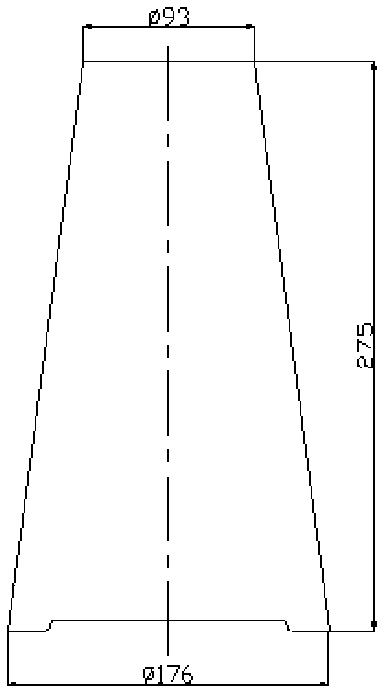

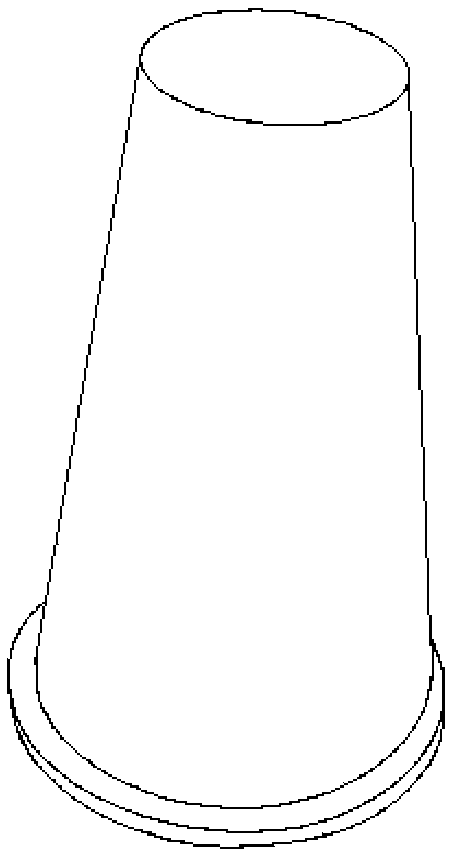

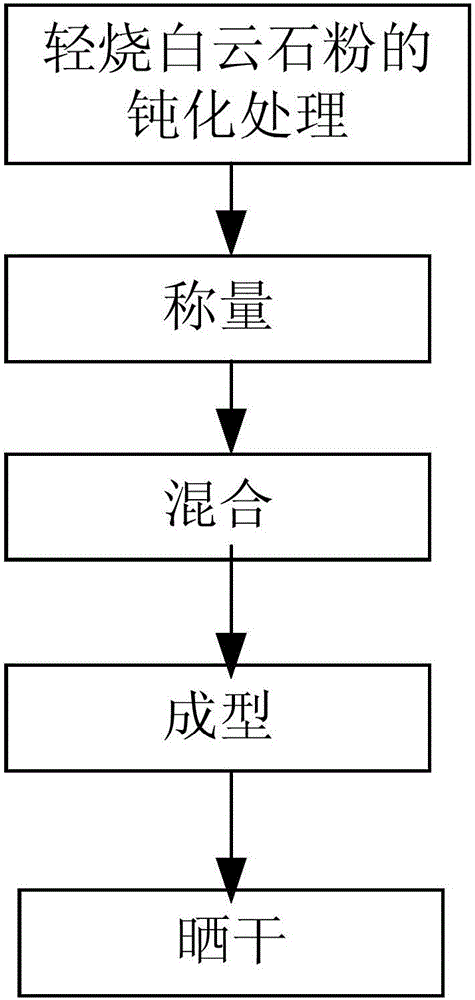

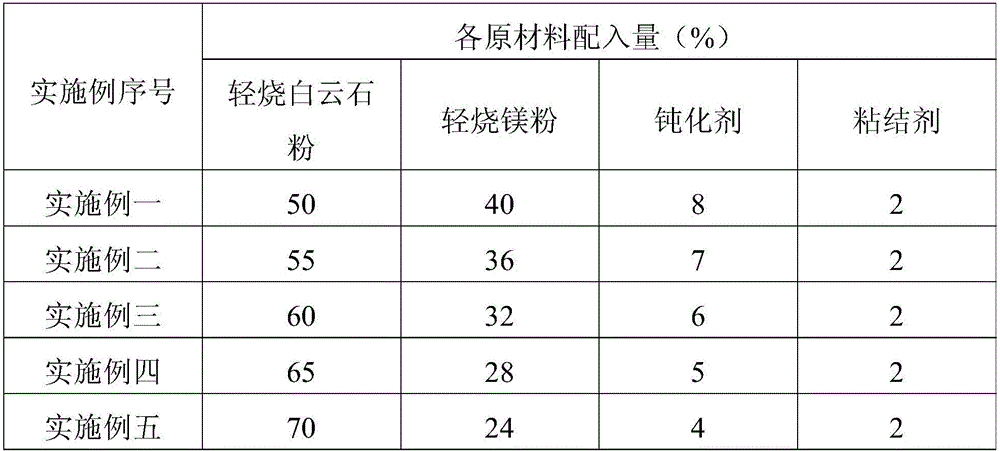

Light roasting pressing ball for converter steelmaking and preparation method of light roasting pressing ball

The invention discloses a light roasting pressing ball for converter steelmaking and a preparation method of the light roasting pressing ball. The light roasting pressing ball is prepared from the following raw materials in parts by weight: 50-80 parts of light roasting dolomite dust, 20-40 parts of caustic-burned magnesia powder, 5-20% of a passivator and 0.5-10 parts of an adhesive. By adopting the light roasting pressing ball, the light roasting dolomite dust can be processed and treated by using a simple, energy-saving, economic and environment-friendly method, not only can the light roasting pressing ball, which is stable in component and good in use effect, be obtained, but also mineral resources are sufficiently utilized, and the environment pollution is avoided.

Owner:ZHANJIANG SHENGBAO TECH CO LTD

Boric sludge pellet binder/iron smelting auxiliary and preparation method of boric sludge pellet binder/iron smelting auxiliary

The invention relates to a boric sludge pellet binder / iron smelting auxiliary and a preparation method of the boric sludge pellet binder / iron smelting auxiliary, and belongs to the technical field of metallurgy. The boric sludge pellet binder / iron smelting auxiliary comprises the following raw materials in percentage by weight: 75-84% of boric sludge, 6-10% of boric ore powder and 10-15% of caustic-burned magnesia powder, wherein the content of boron in the boric ore powder is 10-16%, and the content of magnesium in the boric ore powder is 70-90%. The boric sludge pellet binder / iron smelting auxiliary can completely replace bentonite usually used and solve the problems that the calcination temperature of pellets is too high and the compressive strength of the pellets is lower because the magnesium component (the iron smelting auxiliary) in pellet ore is difficult to compound and add; the boric sludge is used as the main raw material, besides iron smelting auxiliaries such as the magnesium component are added, so that the content of noxious constituent such as silicon dioxide is greatly reduced, and the fluidity of molten iron and slag is obviously improved during blast-furnace iron smelting; the boric sludge pellet binder / iron smelting auxiliary has a good desulfurization effect, so that the smooth and stable furnace condition is obviously improved.

Owner:YINGKOU LINHEMAO TECH DEV CO LTD

Magnesia castable taking forsterite as main raw material and preparation method of magnesia castable

The invention relates to magnesia castable taking forsterite as a main raw material and a preparation method of the magnesia castable. The technical scheme is that the preparation method comprises thefollowing steps: uniformly mixing forsterite fine powder, magnesite fine powder, caustic-burned magnesia powder, quartz sand fine powder, silica powder, ferrosilicon nitride, magnesium citrate and thermosetting phenolic resin, molding, carrying out heat treatment at 900 to 1200 DEG C in a neutral atmosphere for 3 to 5 hours, crushing, carrying out ball milling and screening to obtain a ball abrasive with the particle size less than 0.088 mm and a granular material with the particle size of 0.088 to 0.25mm; uniformly mixing the silica powder, the ferrosilicon nitride, citric acid, elemental silicon powder, the forsterite fine powder, hydroxyethyl cellulose and water and carrying out ball milling to obtain slurry; uniformly mixing forsterite particles, magnesite particles, the granular material, the ball abrasive, the slurry, polyvinyl alcohol fiber and a water reducing agent, thus obtaining the magnesia castable with the forsterite as the main raw material. A product produced by the preparation method disclosed by the invention has high strength and excellent slag corrosion resistance.

Owner:WUHAN UNIV OF SCI & TECH

Self-flow refractory castable

The invention relates to a self-flow refractory castable which is prepared from the following raw materials in parts by weight: 10-25 parts of kyanite, 10-20 parts of wollastonite, 10-20 parts of caustic-burned magnesia powder, 5-10 parts of alumina hollow balls, 5-10 parts of zirconium oxide hollow balls, 10-20 parts of alumina micro powder, 5-10 parts of silicon dioxide micropowder, 5-10 parts of aluminum phosphate and 5-10 parts of graphite, wherein kyanite, wollastonite, caustic-burned magnesia powder, alumina hollow balls and zirconium oxide hollow balls are aggregates; alumina micro powder, silicon dioxide micropowder, aluminum phosphate and graphite are powder.

Owner:宁夏胜金水泥有限公司

Nanometer magnesium hydroxide slurry as well as preparation method and application thereof

ActiveCN110357131ARealize comprehensive utilizationGood dispersionMaterial nanotechnologyWater contaminantsSlurryCaustic Burn

The invention provides nanometer magnesium hydroxide slurry as well as a preparation method and application thereof. The preparation method of the nanometer magnesium hydroxide slurry comprises the following steps: 1) uniformly mixing caustic-burned magnesia powder as a raw material, a dispersing agent and water according to the mass ratio of 1:(0.01-0.04):(4-6), controlling that the pH is not higher than 12 and adding a grinding medium for grinding, wherein the grinding temperature is 70-80 DEG C, the grinding time is 150-190 min, the grinding speed is 1200-1500 revolutions / minute, and the average particle size of the grinding medium is 0.5-3 mm; 2) adding a surface modifier into a system in the step 1) and performing full modification to obtain the nanometer magnesium hydroxide slurry; the mass ratio of the surface modifier to the caustic-burned magnesia powder is (0.03-0.05):1. The preparation method provided by the invention can directly convert the low-purity caustic-burned magnesium oxide into the magnesium hydroxide, thereby improving the utilization value of magnesium oxide wastes.

Owner:CHINA UNIV OF GEOSCIENCES (BEIJING) +1

Unshaped refractory material and preparation method thereof

The invention provides an unshaped refractory material and a preparation method thereof. The unshaped refractory material contains the components in parts by weight: 5-30% of magnesia particles, 5-15% of caustic-burned magnesia powder, 20-45% of corundum, 10-20% of silicon carbide, 10-18% of cokes, 6-12% of clay, 2-8% of ferro-silicon nitride, 3-10% of graphitisable coal tar pitch and 12-14 parts of a graphitisable binder which is liquid at normal temperature. The preparation method comprises the steps of mixing the magnesia particles, the caustic-burned magnesia powder, the corundum, silicon carbide, the cokes, the clay, ferro-silicon nitride and the graphitisable coal tar pitch according to a certain proportion; and then, grinding and mixing after adding the liquid graphitisable binder to obtain the unshaped refractory material.

Owner:CENT RES INST OF BUILDING & CONSTR CO LTD MCC GRP +1

Magnesium oxychloride cement-based straw light composite material and preparation method thereof

InactiveCN107540334AImprove flexural strengthLow densitySolid waste managementFiberThermal insulation

The invention belongs to the technical field of building heat-preservation materials and in particular relates to a magnesium oxychloride cement-based straw light composite material and a preparationmethod thereof. According to the technical scheme of the invention, the magnesium oxychloride cement-based straw light composite material comprises the following raw material components in parts by mass: 43-51 parts of caustic-burned magnesia powder, 10-15 parts of magnesium chloride, 40-44 parts of water, 0.40-0.53 part of phosphoric acid, 0.5-1.85 parts of hydrogen peroxide, and a straw fiber, wherein the volume ratio of the straw fiber to a cement paste is 0.75:1.25; the content of magnesium oxide of the caustic-burned magnesia powder is 95%; the activity of the caustic-burned magnesia powder is 68%. The magnesium oxychloride cement-based straw light composite material provided by the invention has the advantages of being green and environmentally friendly and good in heat preservationand thermal insulation.

Owner:SHENYANG JIANZHU UNIVERSITY

Preparation technology of inorganic foaming partition plate

InactiveCN108214919ALow priceReduce manufacturing costConstruction materialSurface layering apparatusFiberGlass fiber

The invention relates to a preparation technology of an inorganic foaming partition plate. The preparation technology comprises the following steps that magnesium chloride and water are mixed, prepared to be bittern and added into a stirring machine, and PP fiber is added into the bittern; caustic-burned magnesia powder and modifying agent are added and continue to be stirred for 30s; efficient chemical foaming agent is added, the mixture continues to be stirred to be uniform, and slurry with completely-dissolved solid materials and uniform liquid surface foams is prepared; the bottom layer ofa die is coated with a plastic film, a layer of glass fiber gridding cloth is fully laid on the film on the bottom layer of the die, the prepared slurry is rapidly poured into the die, the surface ofthe die is also coated with a layer of glass fiber gridding cloth after the die is filled and coated with a layer of plastic film again, the die is locked, and standing is carried out at indoor temperature for 24h; and the die is removed, the upper surface, lower surface and periphery of the cured partition plate are each spread with a layer of anti-crack mortar. According to the technology, operation is easy, operation steps are simplified, building requirements are met, and meanwhile working efficiency is improved. The inorganic foaming partition plate prepared through the technology is lowin cost, and the manufacturing cost of enterprises is reduced.

Owner:宜宾市叙州区伍益砖厂

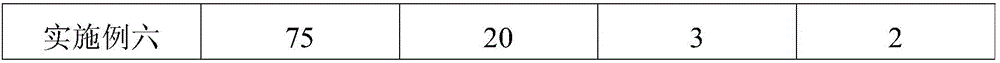

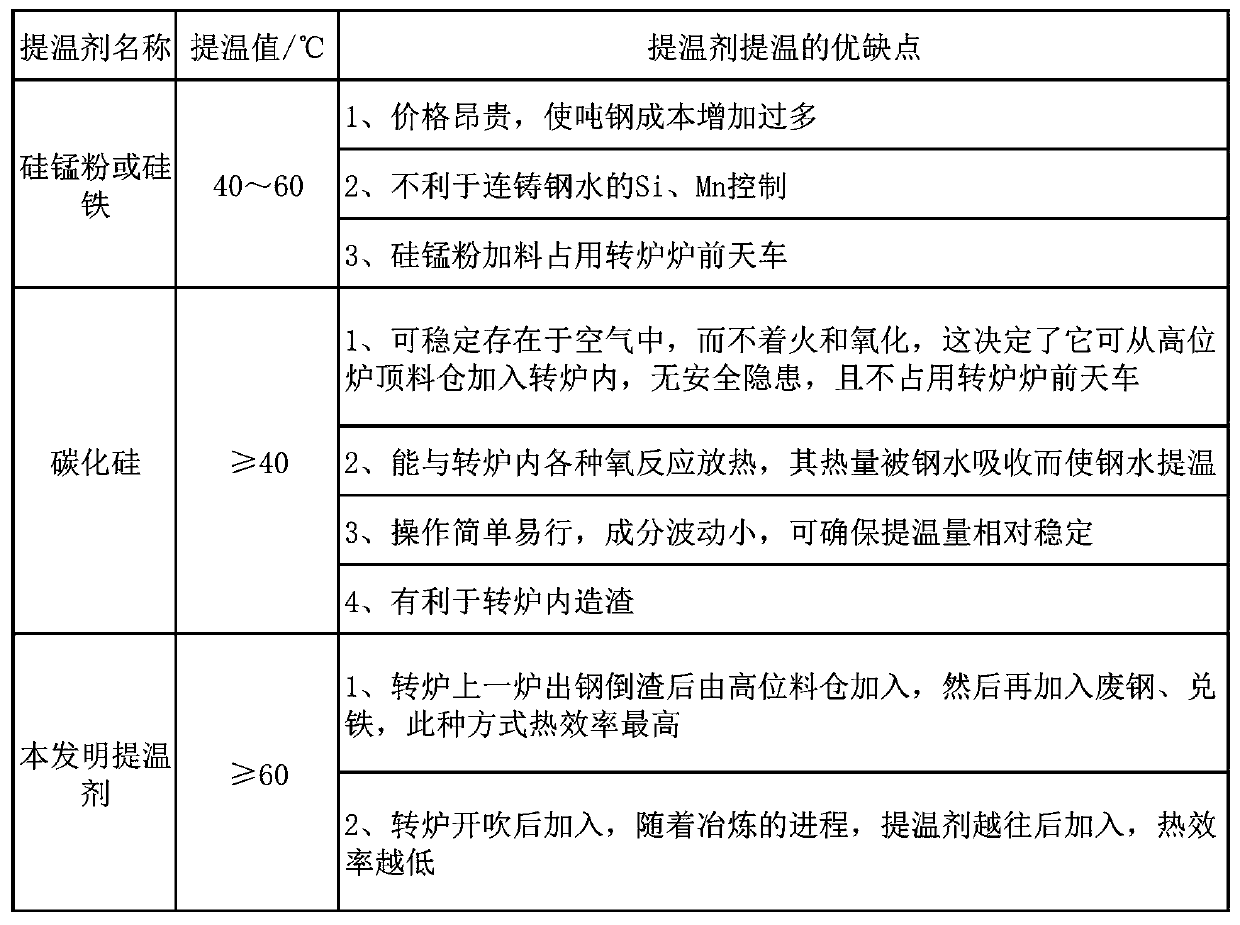

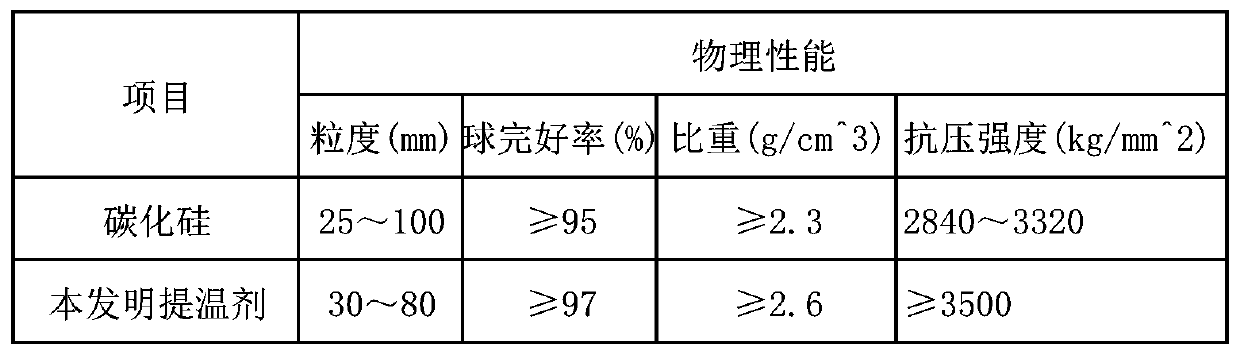

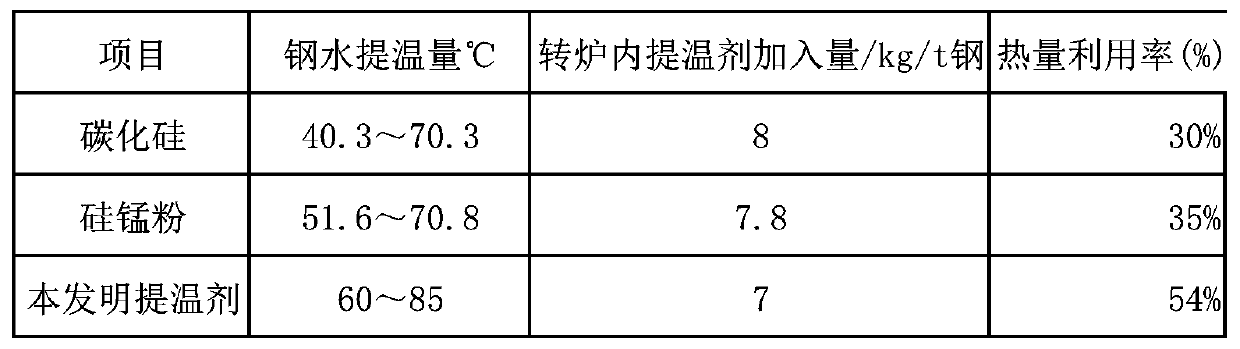

Slow-release high-efficiency carbon-based converter temperature-raising agent and preparation method thereof

The invention relates to the technical field of temperature-raising agents, in particular to a slow-release high-efficiency carbon-based converter temperature-raising agent and a preparation method thereof. The temperature-raising agent is mainly prepared from the following raw materials in parts by weight: 70 to 85 percent of pulverized coal, 10 to 20 percent of caustic-burned magnesia powder, 10to 15 percent of aluminum ash, and an adhesive necessary for forming the temperature-raising agent; the particle size of the temperature-raising agent is 30mm to 60mm; and the temperature-raising agent is in a spherical shape or an ellipsoidal shape. The temperature-raising agent provided by the invention is prepared through adding the caustic-burned magnesia powder, selecting the appropriate adhesive, and using a ball press machine, so that the strength of the temperature-raising agent is greatly improved, the compactness of the temperature-raising agent is improved, and the problem of pooreffect in use caused by low strength and density of an existing temperature-raising agent is solved; and according to the temperature-raising agent provided by the invention, through adding the caustic-burned magnesia powder, the corrosion speed of the temperature-raising agent in molten iron and semisteel is effectively delayed.

Owner:李付霞

Heat-resistant flexible composite filter material prepared by blending melt-blown polypropylene with modified caustic-burned magnesium powder and used for sewage treatment and preparation method thereof

InactiveCN104759150AImprove surface propertiesImprove mechanical propertiesOther chemical processesFiltration separationFiberSilica gel

The invention relates to a filter material used in sewage treatment and particularly relates to a heat-resistant flexible composite filter material prepared by blending melt-blown polypropylene with modified caustic-burned magnesium powder and used for sewage treatment and a preparation method thereof. The filter material is prepared from following raw materials, by weight: 5-8 parts of soft silica gel, 1-2 parts of nano clay, 2-3 parts of nano-hydroxyapatite, 12-15 parts of carbonized crop straw powder in 300-400 meshes, 30-40 parts of polypropylene, 15-20 parts of the caustic-burned magnesium powder in 200-300 meshes, 0.3-0.4 parts of sodium citrate, 0.5-0.8 parts of sodium carbonate, 2-3 parts of rosin and 1-2 parts of a silane coupling agent KH-550. In the invention, the modified conventional filter material composite body is supported onto the modified polypropylene master batch melt-blown fiber thin filaments to prepare the high-efficient filter material in a stereoscopic network structure. The filter material is convenient to use, is heat-resistant and fold-resistant, is stable in performance and is high-efficient and durable.

Owner:BENGBU PIONEER FILTER

A kind of ultra-low density cordierite oil fracturing proppant and preparation method thereof

ActiveCN106431349BHigh hardnessHigh mechanical strengthFluid removalDrilling compositionCordieriteManganese oxide

The invention provides an ultralow-density cordierite petroleum fracturing propping agent and a preparation method thereof. A principal crystalline phase of the popping agent is of a cordierite structure and is formed by firing coal ash, caustic-burned magnesia powder, Jiaozuo clay and a composite mineralizer, and the composite mineralizer is formed by mixing manganese oxide and barium carbonate according to the equal weight ratio. A large amount of high-silicone, low-aluminum, low-calcium and low-ignition-loss neutral coal ash is adopted as a main raw material, and the density index of the popping agent is effectively reduced; through the special processing and treating processes such as special pre-sintering on an important raw material magnesite and ultrafine grinding on batches and the composite mineralizer technology, it is effectively guaranteed that high-hardness and low-density principal crystalline phase minerals are formed in a system at high temperature, therefore, and it is guaranteed that the finished ultralow-density popping agent has high mechanical strength; the firing temperature of the popping agent is reduced, and the purposes of energy saving and consumption reduction are achieved.

Owner:洛阳赛罗帕陶瓷科技有限公司 +1

Method for producing magnesium sulfate and magnesium fertilizer by utilizing alkylated waste sulfuric acid

InactiveCN106745114ASimple processLow costCalcareous fertilisersMagnesium fertilisersCaustic BurnPollution

The invention relates to treatment of waste sulfuric acid, in particular to a method for producing a magnesium sulfate and magnesium fertilizer by utilizing alkylated waste sulfuric acid. The method comprises the following steps: (1) adding the alkylated waste sulfuric acid into a reaction kettle and preheating to 90 DEG C; (2) adding magnesite powder while stirring until no bubble occurs; (3) adding caustic-burned magnesia powder and reacting until the pH value is 6.8 to 7.0 to obtain mixed liquid; (4) performing filter-pressing separation on the mixed liquid to obtain primary mother liquid and primary waste residues; (5) adding sodium percarbonate into the primary mother liquid and stirring; (6) filter-pressing to obtain secondary mother liquid and secondary waste residues; (7) crystallizing, centrifuging and drying the secondary mother liquid to obtain magnesium sulfate heptahydrate; (8) mixing the primary waste residues and the secondary waste residues uniformly, drying and crushing to obtain silicon calcium sulfur magnesium fertilizer. The method for producing the magnesium sulfate and magnesium fertilizer by utilizing the alkylated waste sulfuric acid, provided by the invention, is simple in process and low in cost, and avoids secondary pollution.

Owner:广西防城港五星环保科技股份有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com