Magnesium sulfate heptahydrate producing process with fully-continuous method

A kind of technology of magnesium sulfate heptahydrate and full continuous method, which is applied in the technical field of producing magnesium sulfate heptahydrate by full continuous method, and can solve the problem of inability to meet the needs of large-scale industrial production, low efficiency of magnesium sulfate heptahydrate, crystallizer wall formation, etc. problems, to achieve the effect of improving the crystallization effect, reducing the floor space and improving the efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

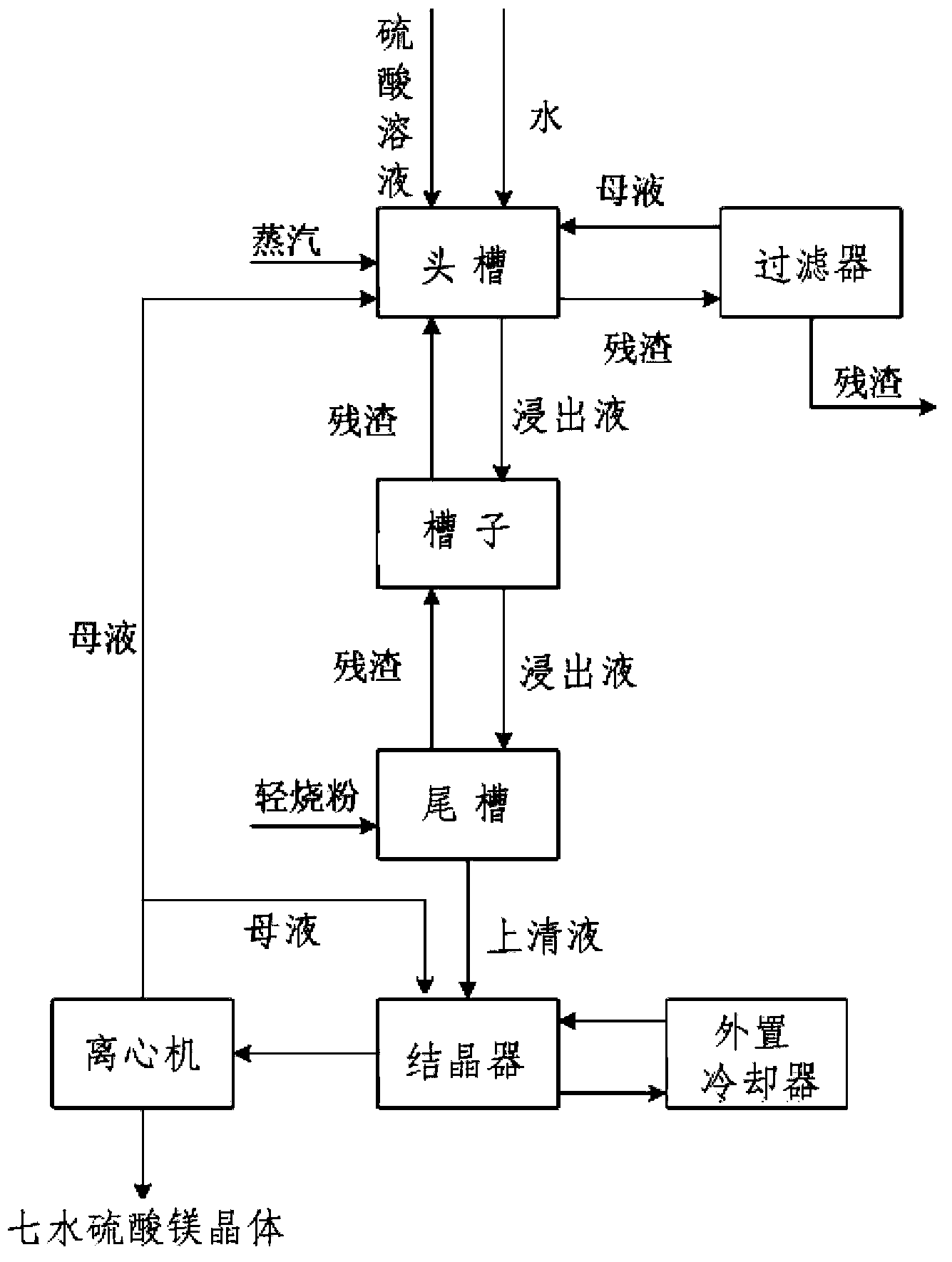

[0033] The technique for the production of magnesium sulfate heptahydrate by full continuous method of the present invention, the reactor is composed of three continuous tanks in series to form a continuous leaching tank, including a head tank, a middle tank and a tail tank, the head tank and the tail tank are located at two ends, each tank The conveying device is built in the bottom, and the upper part of the head tank, the middle tank and the tail tank are respectively provided with overflow ports corresponding to the middle tank, the tail tank and the crystallizer.

[0034]Continuously put lightly burned powder into the tail tank of the continuous leaching tank at a rate of 0.5t / h, and add sulfuric acid solution with a concentration of 80% at a rate of 1.5t / h in the head tank at a rate of 0.6t / h Tap water, steam at a rate of 0.4t / h, the reaction liquid overflowing from the head tank is the leachate, and the temperature of the leachate overflowing from the head tank is mainta...

Embodiment 2

[0037] The difference between the technique of the fully continuous production of the present embodiment and the embodiment 1 of magnesium sulfate heptahydrate is: in the tail tank of the leaching tank, the lightly burned powder is continuously dropped at a rate of 0.3t / h, and in the head tank at a rate of 1t / h The sulfuric acid solution with a concentration of 70% was introduced at a rate of 0.2t / h, tap water was added, and steam was added at a rate of 0.3t / h to maintain the leachate temperature at 70°C. The magnesium sulfate-containing supernatant obtained after the tail tank reaction had a specific gravity of 1.4 and a pH value of 6.5. The tail tank supernatant is continuously pumped into the DTB crystallizer at a speed of 3.7t / h, and the circulating water at 5°C is used as the cooling source to cool down instantaneously. After cooling, the temperature inside the crystallizer is kept constant at 10°C. The crystal slurry of 3.7t / h is continuously discharged from the crystall...

Embodiment 3

[0039] The difference of the technique and embodiment 1 of the full continuous method production magnesium sulfate heptahydrate of the present embodiment is: in the tail tank of continuous leaching tank, drop into light burnt powder continuously with the speed of 2.2t / h, in head tank with 9t / h Add sulfuric acid solution with a concentration of 55% at a rate of h, add tap water at a rate of 0.6t / h, deliver steam at a rate of 0.8t / h, and maintain the leachate temperature at 90°C. The magnesium sulfate-containing supernatant obtained after the tail tank reaction has a specific gravity of 1.3 and a pH value of 7.5. The tail tank supernatant is continuously pumped into the OSLO crystallizer at a rate of 17.4t / h, and the refrigeration unit is used as the cold source to cool down instantaneously. After cooling, the temperature inside the crystallizer is 22°C and remains constant. The crystal slurry of 32.4t / h is continuously discharged from the crystallizer, and after being dried by ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com