Patents

Literature

227results about How to "Meet the needs of large-scale industrial production" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

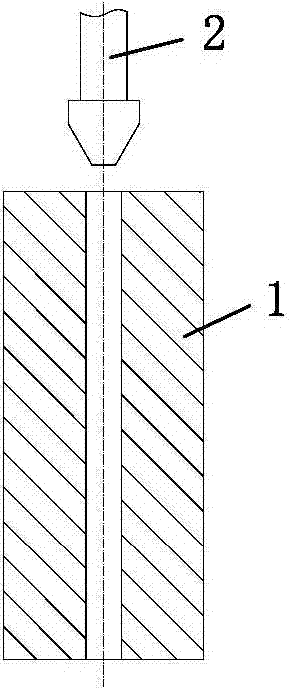

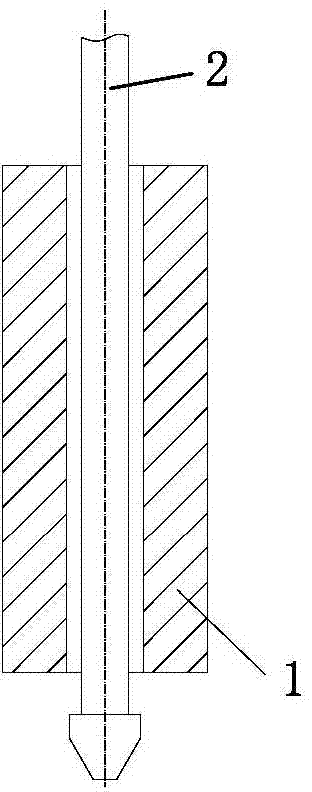

Method for manufacturing pure titanium seamless tubes

ActiveCN101708511ASimple processImprove efficiencyMetal rolling arrangementsRoll speed control devicePunchingTitanium

The invention relates to a method for manufacturing pure titanium seamless tubes. The method is characterized by comprising the following steps of: preparing tube blank bars; machining the tube blank bars; diagonally rolling and punching holes: heating blank to 700 to 980 DEG C, punching holes once or twice by utilizing a two-roll diagonally rolling mill group, wherein molybdenum mandrels or water-cooled mandrels are utilized, the inclined angle of punching roll is 8 degrees, the number of revolutions of the roll is 40 to 90 basic speed to 195 r / min; preparing the pierced billet after punching hole, wherein the specifications of the pierced billet are that the outside diameter is phi 72 to phi 125mm,the wall thickness is 5 to 20mm, and the length is; carrying out cold rolling; and carrying out heat treatment on finished product, detecting performance and entering warehouse. The invention has the characteristics of high production efficiency, low production cost, high material yield, short production period, low device investment, better product quality, and the like. The produced pure titanium seamless tubes have good quality, the mechanical properties accord with state requirements, and the pure titanium seamless tubes can meet the need for large-scale industrial production.

Owner:PANGANG GROUP SICHUAN CHANGCHENG SPECIAL STEEL

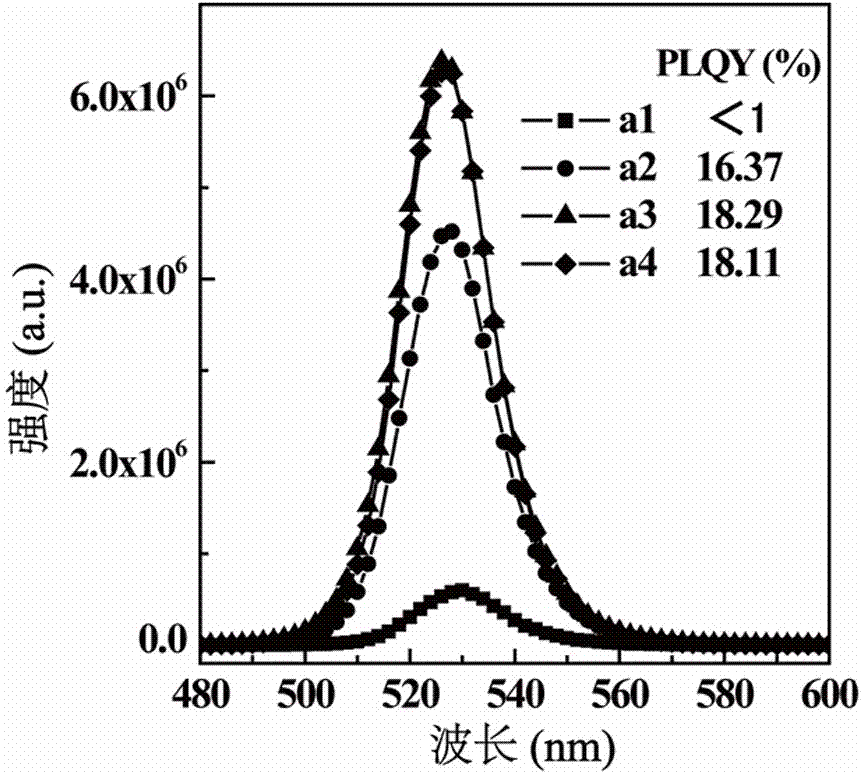

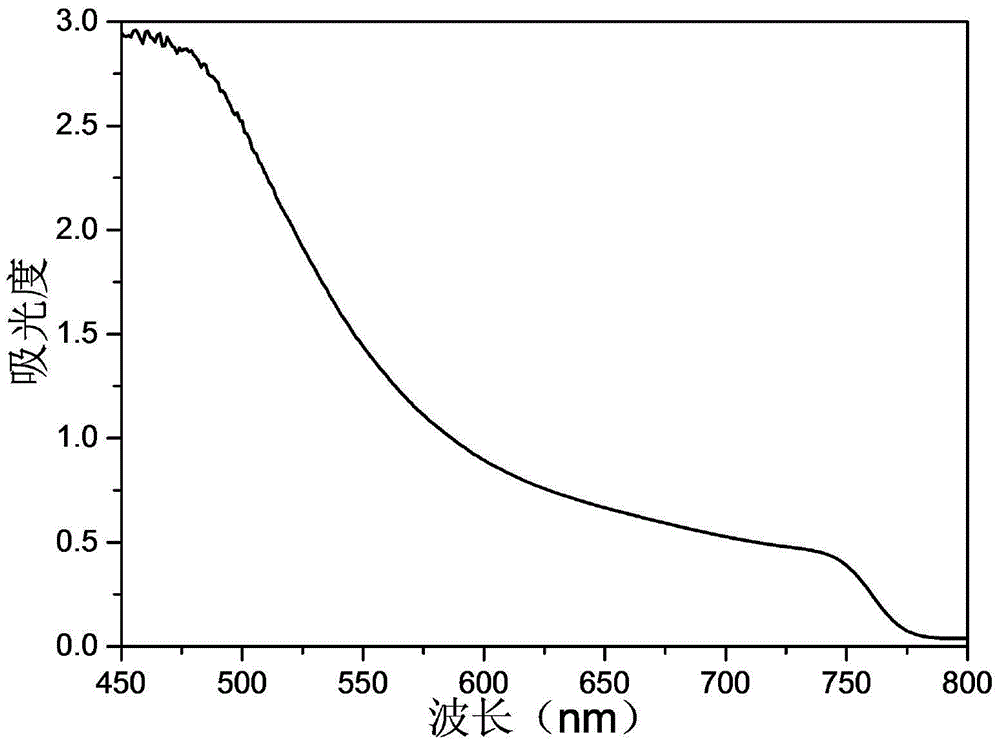

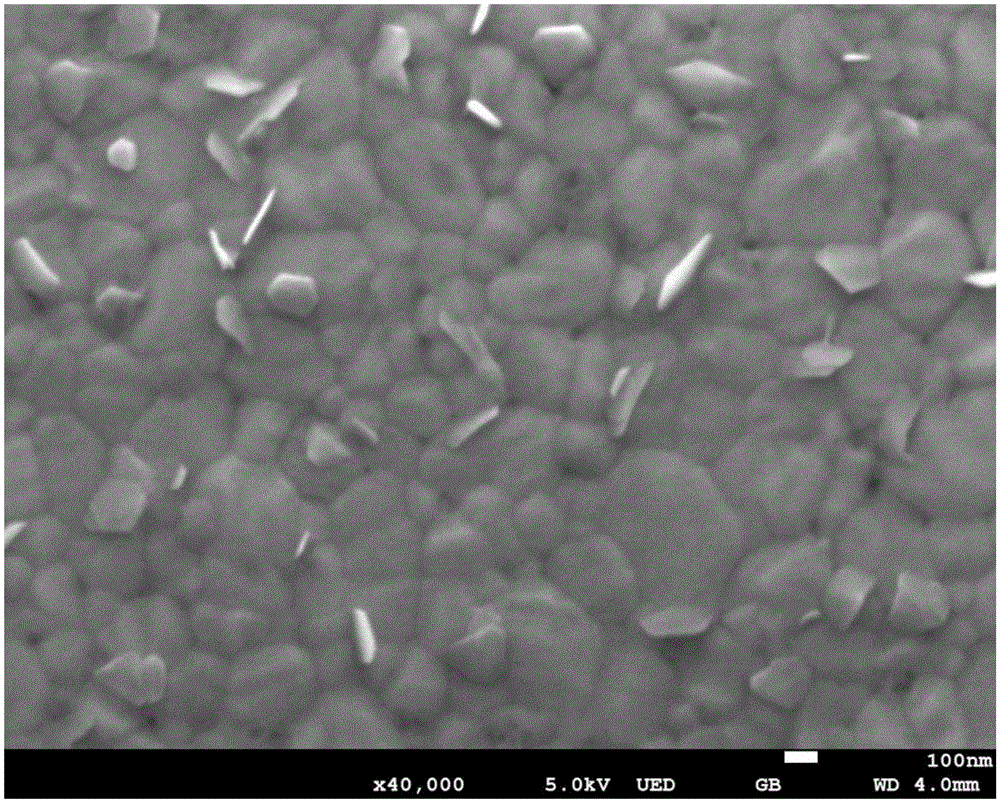

Method for preparing high-luminous-efficiency inorganic perovskite thin film on basis of one-step method

InactiveCN107195710AReduce processing costsEasy to operateLuminescent compositionsSemiconductor devicesSpinsSolvent

The invention provides a method for preparing a high-luminous-efficiency inorganic perovskite thin film on basis of a one-step method. The method comprises the steps of: dissolving lead halide and cesium halide into a solvent to obtain perovskite precursor solution; and then after spin-coating the precursor solution, heating to obtain the high-luminous-efficiency inorganic perovskite thin film, wherein a molar ratio of the lead halide to the cesium halide is 1:1 to 1:3. The method has the characteristics of low cost, easiness for operation, low requirement for thermal processing temperature and the like, and is convenient for large-scale production of the perovskite thin film; and by limiting a precursor ratio, in the premise of not changing a perovskite crystal phase, luminous efficiency of the thin film is obviously promoted.

Owner:SUZHOU UNIV

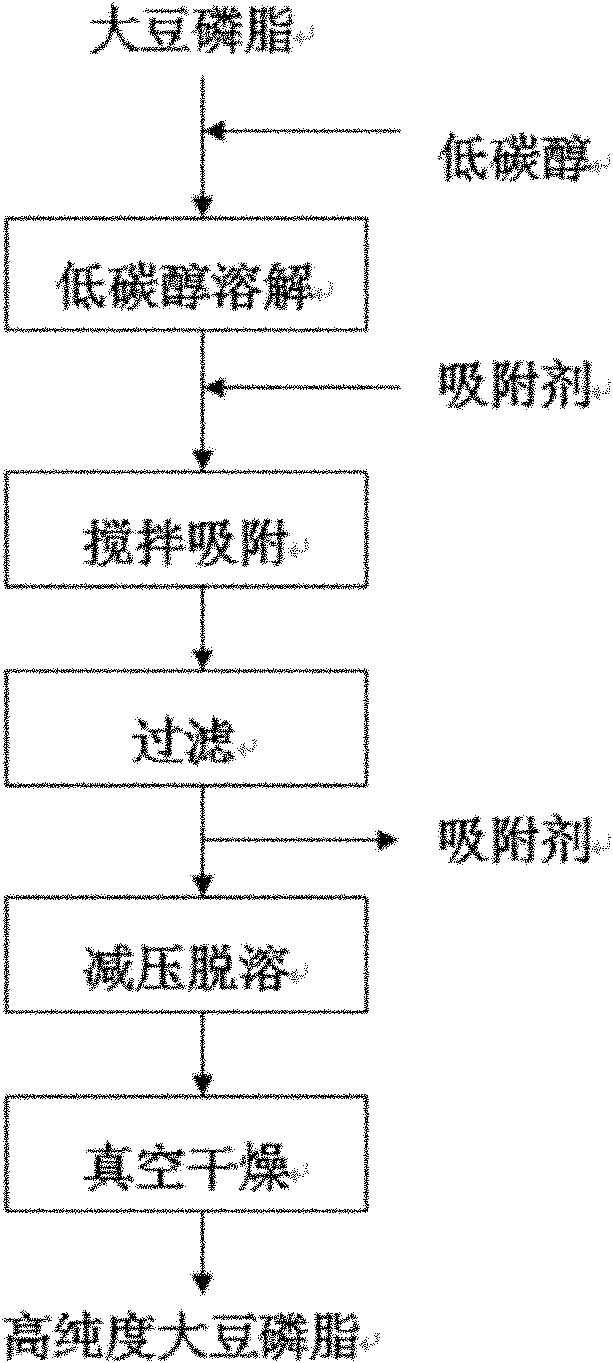

Adsorption method for preparing soybean lecithin

InactiveCN102146094AHigh adsorption selectivityAdsorption will notPhosphatide foodstuff compositionsAlcoholSeparation technology

The invention relates to an adsorption method for preparing soybean lecithin. Granulesten is taken as a raw material, C1-C4 alcohol is taken as a solvent, an adsorbent is added, the mixture is stirred, adsorbed and filtered, filtrate is subjected to desolvation under reduced pressure and vacuum drying to form a soybean lecithin product with over 80 percent of phosphatidylcholine, and the yield is over 85 percent. Compared with the conventional preparation method, the direct adsorptive separation technology has the advantages of simple process, short production period, high product purity, low consumption of solvent, simple equipment, low investment cost and the like, and is suitable for large-scale industrial production.

Owner:NANJING TECH UNIV

Production method of beta-glucan

ActiveCN105255964AAvoid dark colorsAvoid secretionMicroorganism based processesFermentationMonopotassium phosphateBiological activation

The invention discloses a production method of beta-glucan. The production method comprises the following steps of (1) schizophyllum commune activation; (2) seed activation; (3) fermentation culture; (4) coarse extraction; (5) purification. A colorless liquid culture medium prepared from 25 to 30g / L of glucose, 10 to 15g / L of sorbitol, 0.2 to 0.8g / L of monopotassium phosphate, 3 to 5g / L of epsom salt, 0.5 to 1g / L of ammonium sulphate, 0.1 to 0.5g / L of triethylamine hydrochloride, 1 to 2.2ml / L of trace element mixed solution and water is used as a fermentation culture medium for performing deep layer liquid fermentation culture on strains to obtain the colorless fermentation liquid. No pigment exists in the whole process; a decoloring step is not needed; loss due to adsorption is reduced; the problem of beta-glucan separation purification is overcome; high-purity white beta-glucan is obtained; the production method is suitable for mass industrial production.

Owner:NINGBO XINUOYA MARINE BIOTECH CO LTD

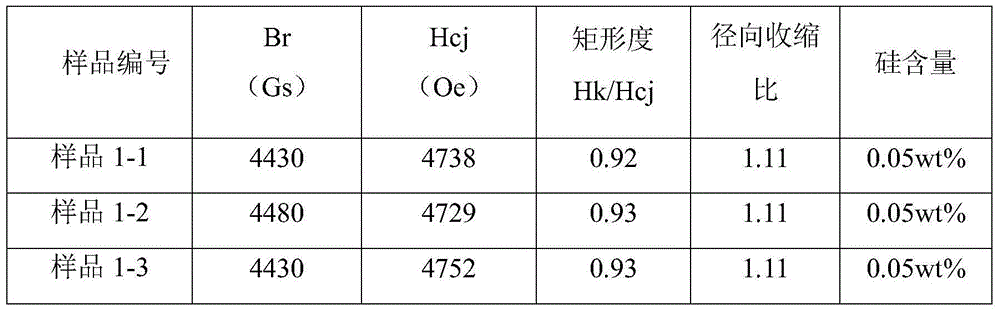

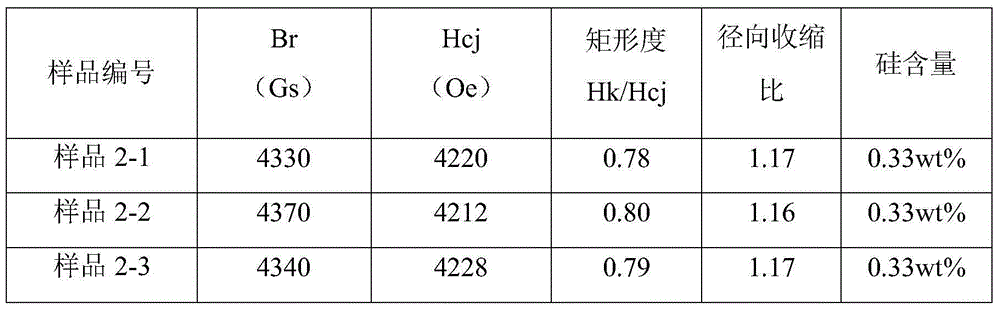

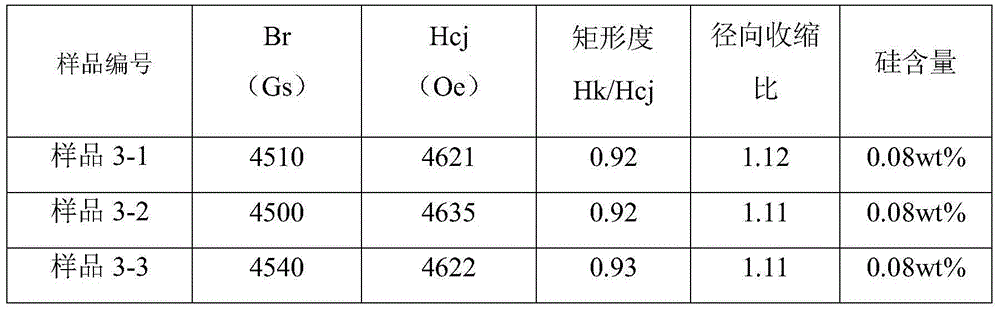

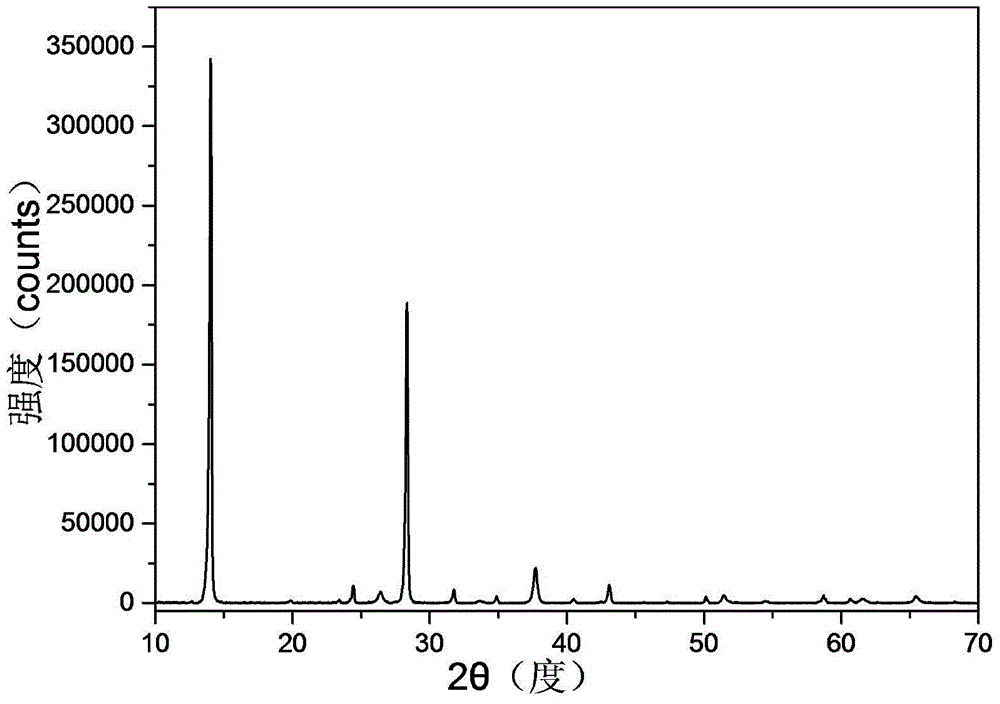

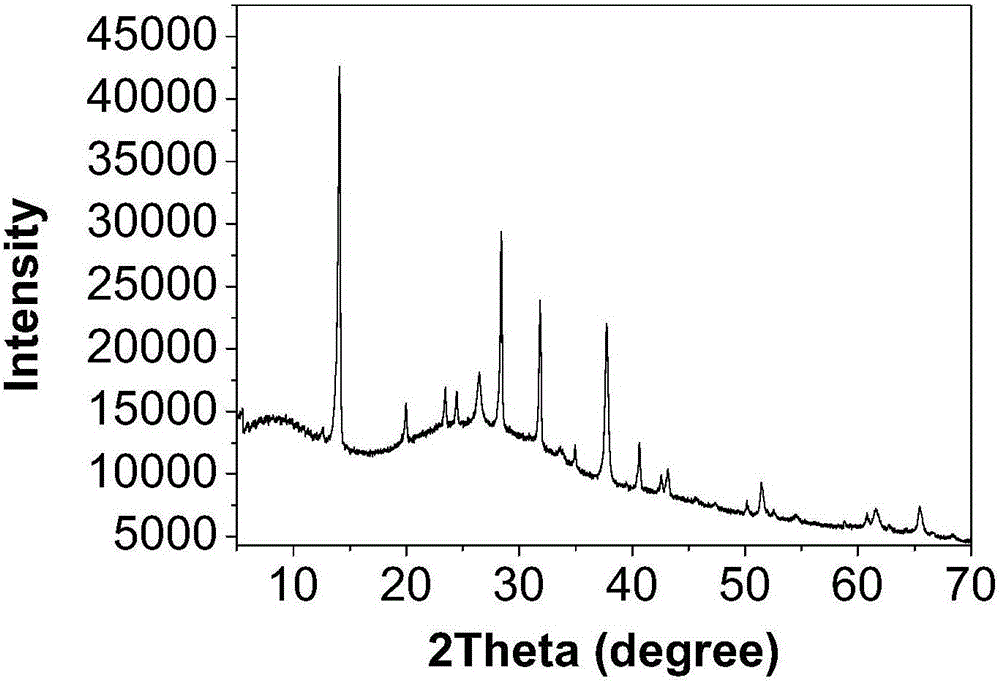

High performance strontium-calcium permanent magnetic ferrite magnet and preparation method thereof

The invention provides a high performance strontium-calcium permanent magnetic ferrite magnet and a preparation method thereof; and the invention belongs to the field of permanent magnetic materials. The magnet has a principal phase of a hexagonal crystal structure. The principal phase of the hexagonal crystal structure consists of metal elements represented by a formula of Sr(x)Ca(y)La1-x-yFe(z)Co(m), and the formula satisfies the conditions that: x is greater than or equal to 0.2 and less than or equal to 0.8; y is greater than or equal to 0.1 and less than or equal to 0.4; z is greater than or equal to 9.0 and less than or equal to 11.0; m is greater than or equal to 0.1 and less than or equal to 0.2; and y / m is greater than or equal to 1.5 and less than or equal to 2.0; meanwhile, by the cooperative use of a secondary additive, the magnet has a high magnetic performance that Br: 4200 Gs - 4600 Gs, Hcj: 4000 Oe - 5600 Oe, and a rectangle degree Hk / Hcj higher than 0.90. In the high performance strontium-calcium permanent magnetic ferrite magnet and the preparation method thereof, a radial shrinkage ratio of a sintered magnet is ranging from 1.10 to 1.12 by controlling the content of silicon in a primary pre-sintering powder material and the secondary additive, thus increasing the production efficiency of the sintering process, reducing the production cost, and meeting the requirements of a massive industrial production.

Owner:马鞍山市鑫洋永磁有限责任公司

Method for preparing thermal-stability perovskite CsPbI3 by dual-amino organic matter

ActiveCN106449979AEasy accessEasy to operateSolid-state devicesSemiconductor/solid-state device manufacturingOrganic matterThermal stability

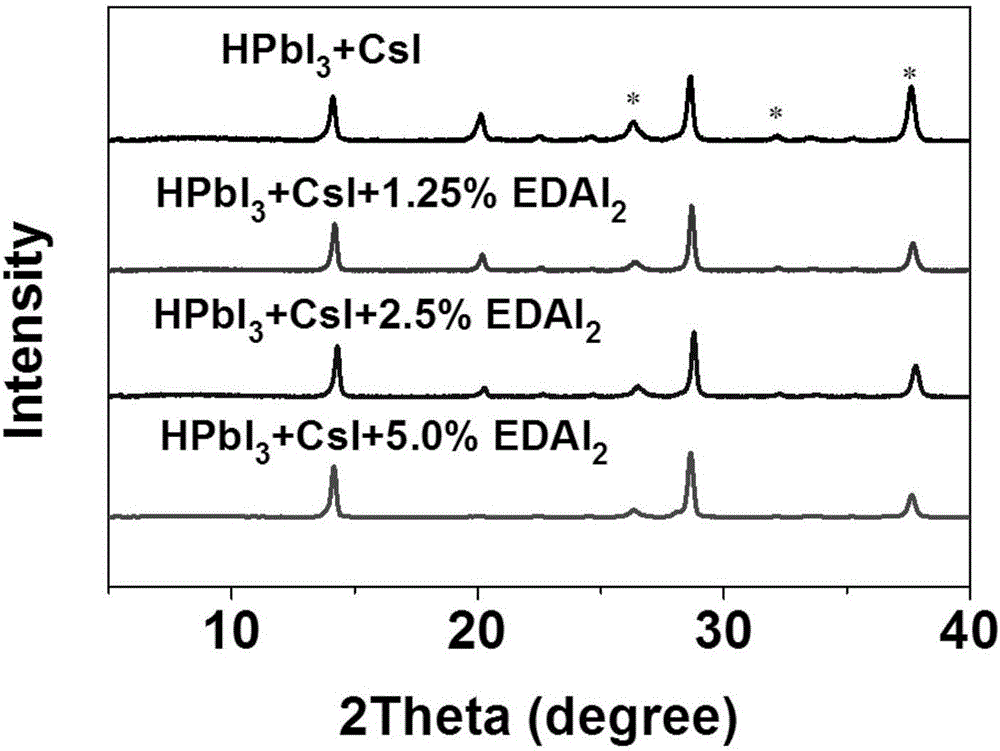

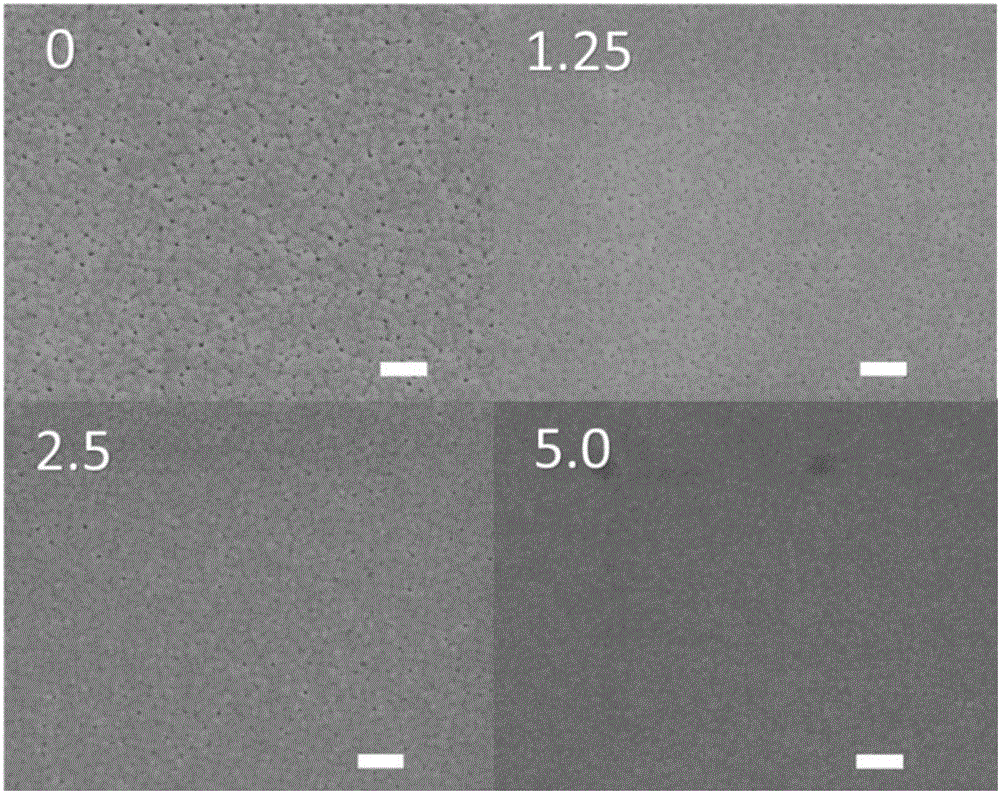

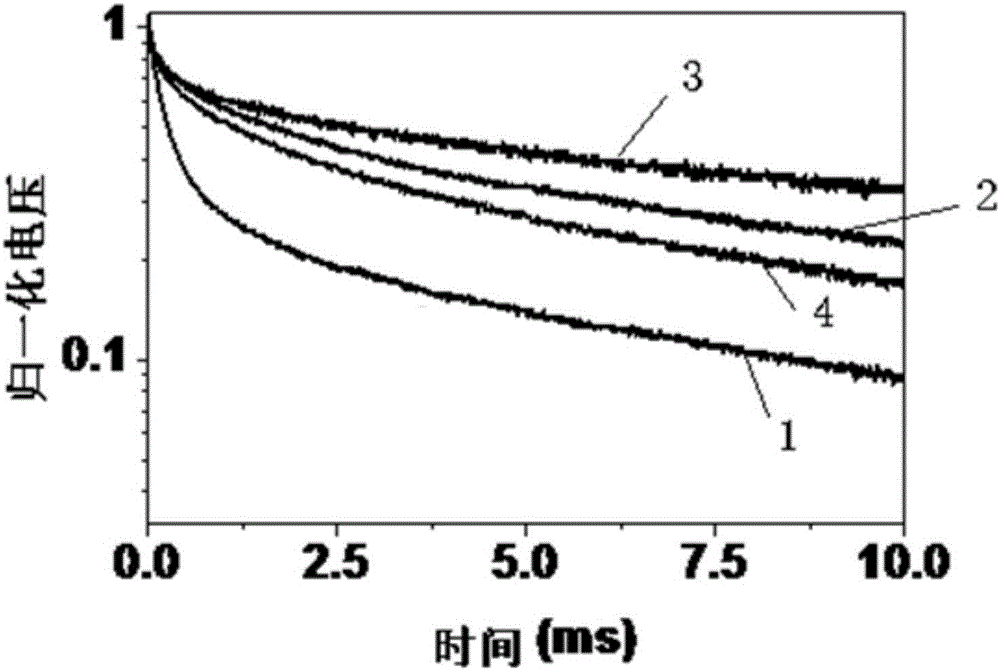

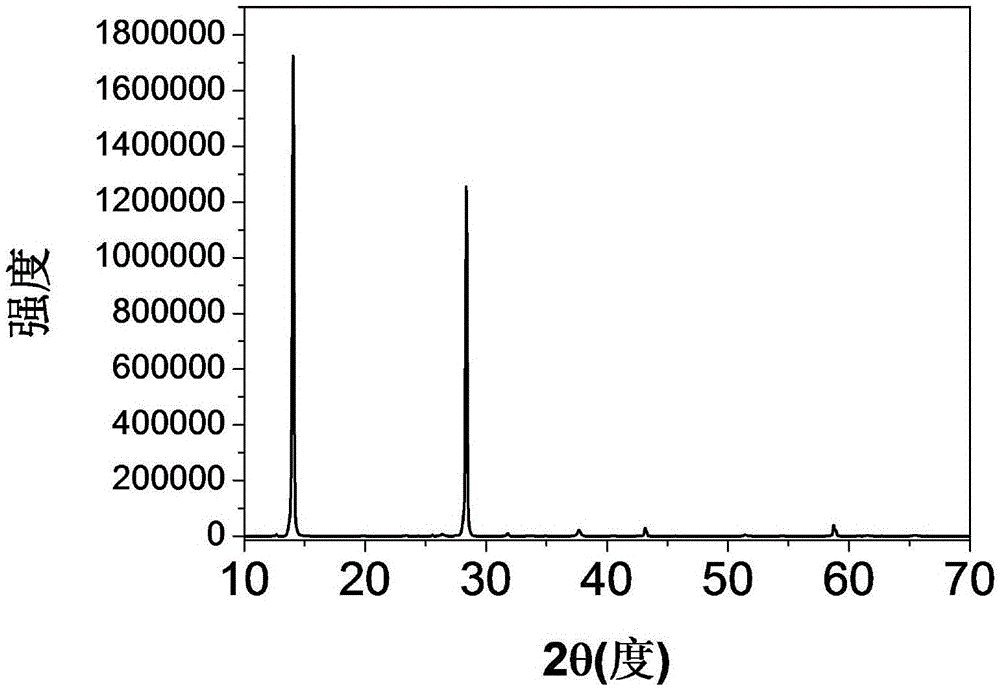

The invention discloses a method for preparing thermal-stability perovskite CsPbI3 by a dual-amino organic matter. The method comprises the following steps of dissolving HPbI3, CsI and EDA12 in a DMF solution according to a mole ratio being 1:1:(0.0125-0.05) to obtain a precursor solution A; and spin-coating the precursor solution A on a solar cell substrate, and afterwards performing low-temperature annealing to obtain a perovskite thin film with a smooth surface. Such a type of battery is relatively high in photoelectric conversion efficiency and also is excellent in thermal stability.

Owner:CONTEMPORARY AMPEREX TECH CO

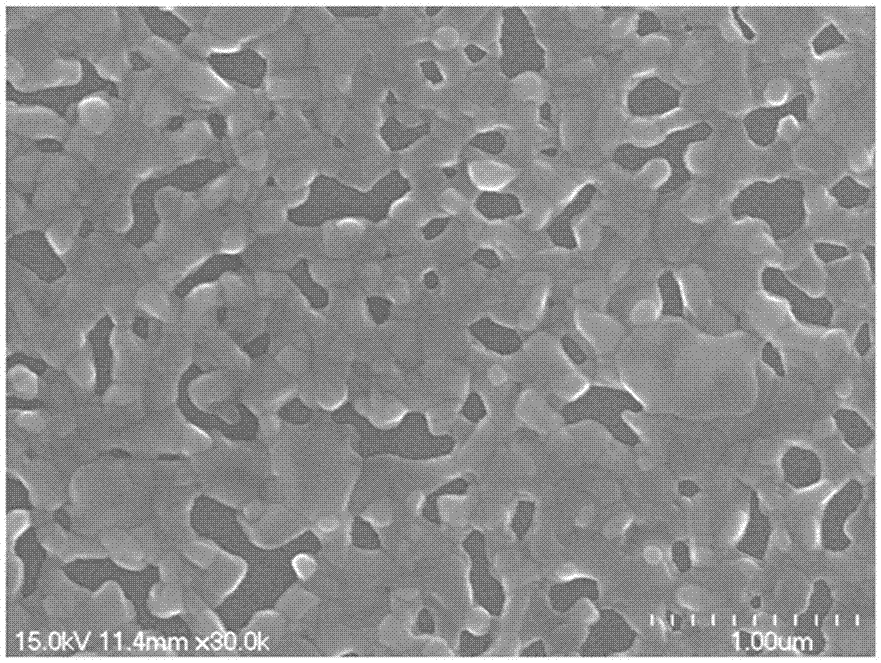

Method for preparing organic-inorganic hybrid perovskite material through gas-liquid or gas-solid two phase in-situ reaction

ActiveCN105481697AReduce the pre-production processRapid responseOrganic compound preparationOrganic chemistry methodsCrystallinityOrganic inorganic

The invention provides a method for preparing an organic-inorganic hybrid perovskite material through a gas-liquid or gas-solid two phase in-situ reaction. Through gas-liquid one-step spin coating or gas-solid in-situ reaction continuous sedimentation, the organic-inorganic hybrid perovskite material is prepared. The method comprises mixing halogen acid HX and lead halide PbX2 according to a certain ratio, coating a substrate with the mixture in an organic amine atmosphere and carrying out annealing to obtain a perovskite film, or comprises mixing halogen acid HX and lead halide PbX2 according to a certain ratio, coating a substrate with the mixture, carrying out drying to obtain a precursor film and carrying out organic amine vapor treatment so that the high-quality perovskite spin-coated film is obtained through a gas-solid in-situ reaction. The perovskite film prepared through gas-liquid and gas-solid in-situ reaction methods has good crystallinity and the compact and flat surface. The method can be carried out at the normal temperature, is free of halogenated methylamine precursor preparation, can be operated conveniently, has a low cost and good film forming ability and is convenient for industrial large-scale production.

Owner:CONTEMPORARY AMPEREX TECH CO

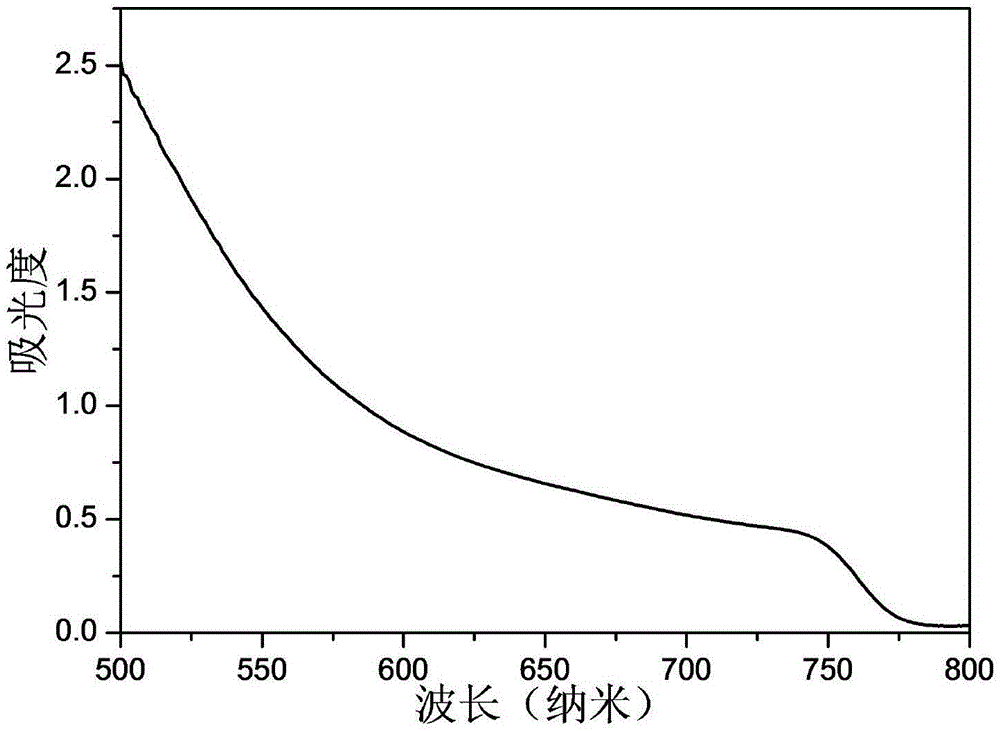

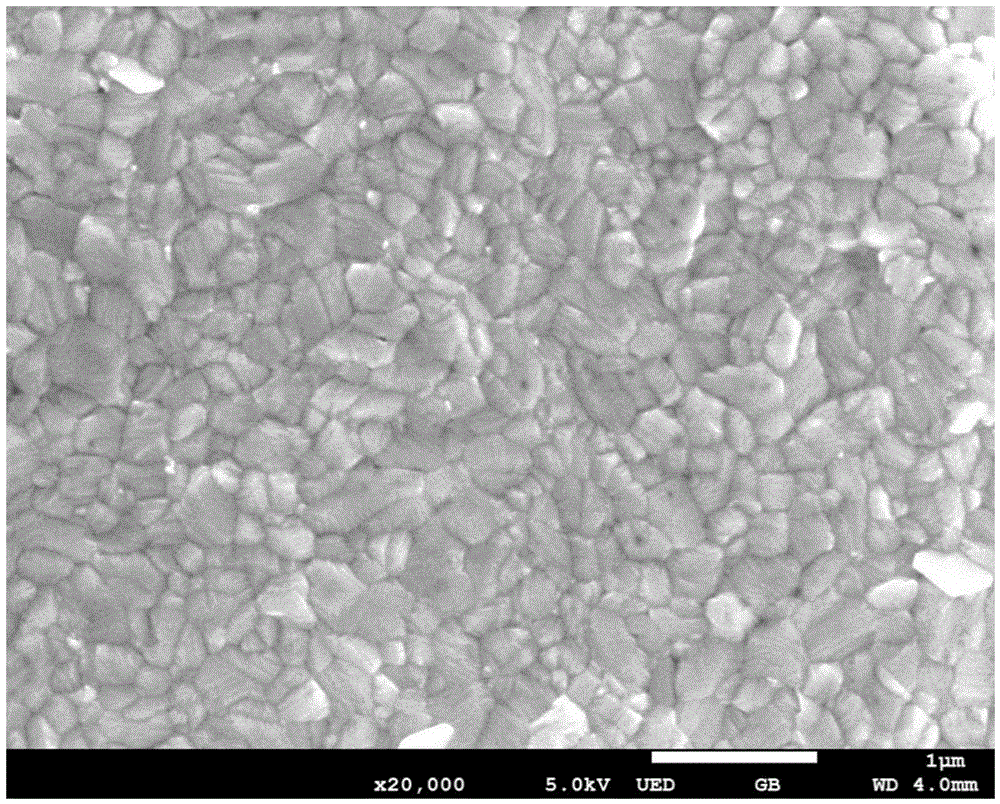

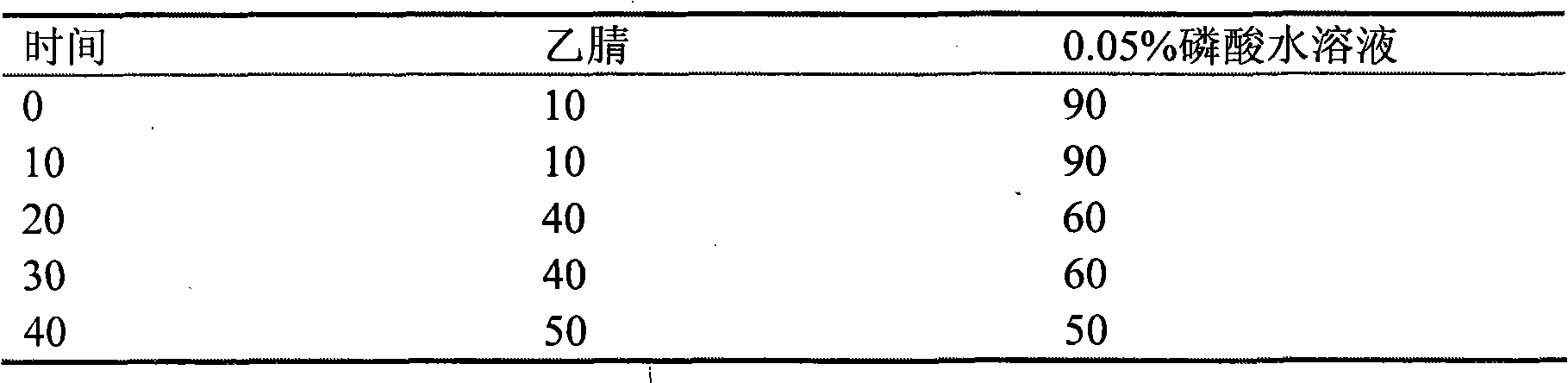

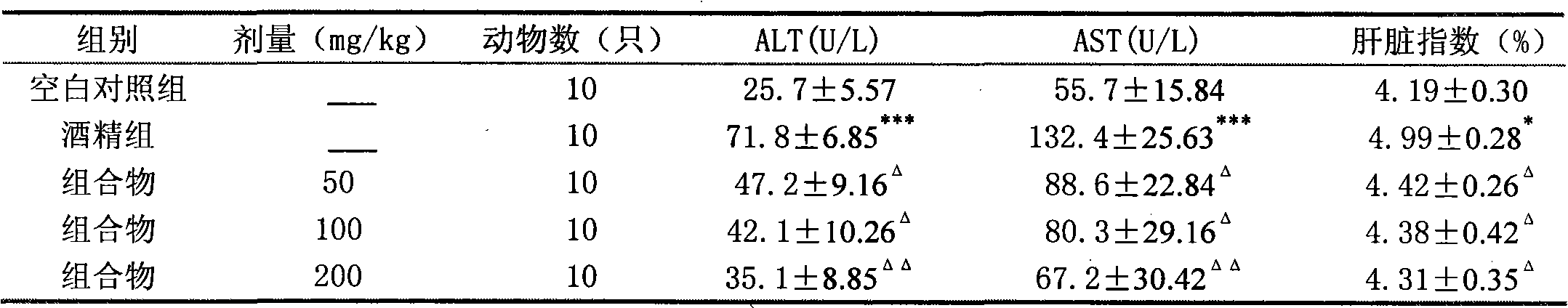

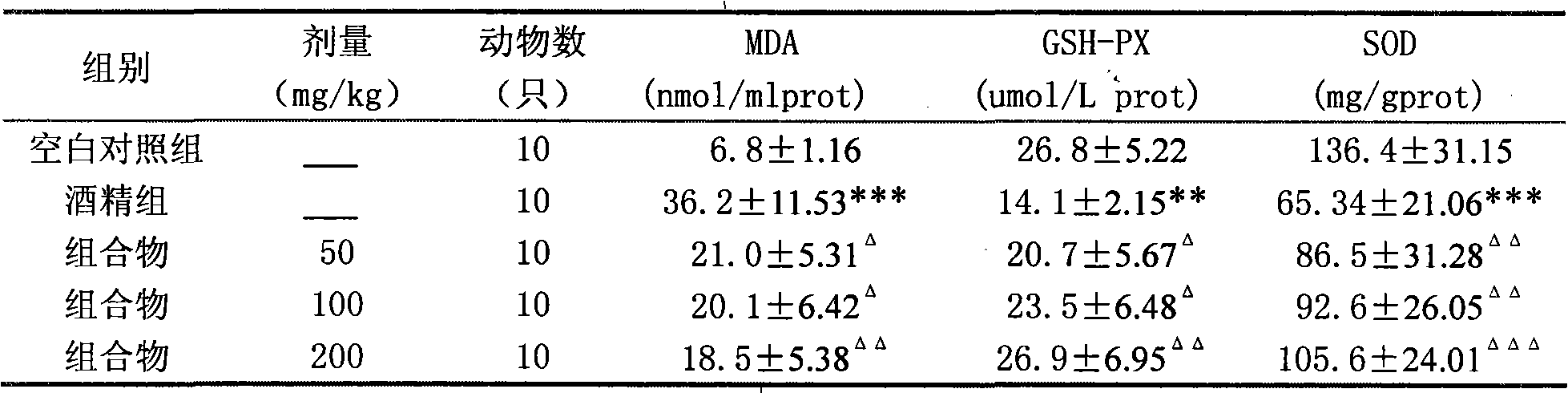

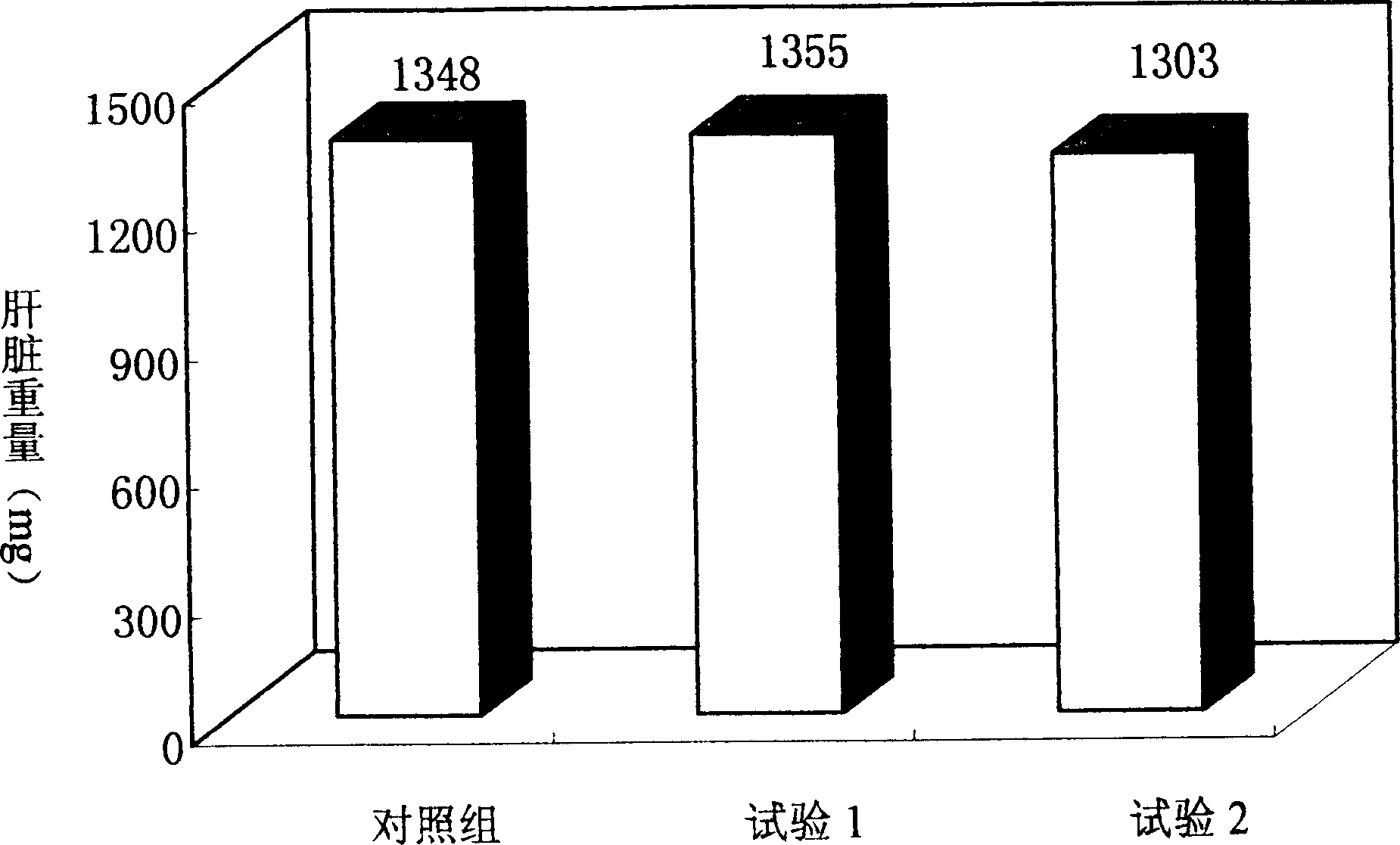

Application of medicinal composition to preparation of medicament for preventing and treating alcoholic liver damage and fatty liver and lowering blood fat

ActiveCN102058632AEasy to solveImprove development and utilization valueOrganic active ingredientsDigestive systemSecondary hyperlipidemiaAlcoholic liver damage

The invention discloses an ilicis routundae cortex medicinal composition for preventing and treating alcoholic liver damage, alcoholic fatty liver, non-alcoholic fatty liver and hyperlipidemia. The composition is extracted and refined from natural ilicis routundae cortex and is not chemically modified, and is characterized by comprising substances such as pedunculoside, syringin, rotundicacid and the like. The invention also discloses a preparation method of the ilicis routundae cortex composition and application to preparation of a medicament for preventing and treating the alcoholic liver damage, the alcoholic fatty liver and the non-alcoholic fatty liver and lowering blood fat.

Owner:吉林修正药业新药开发有限公司

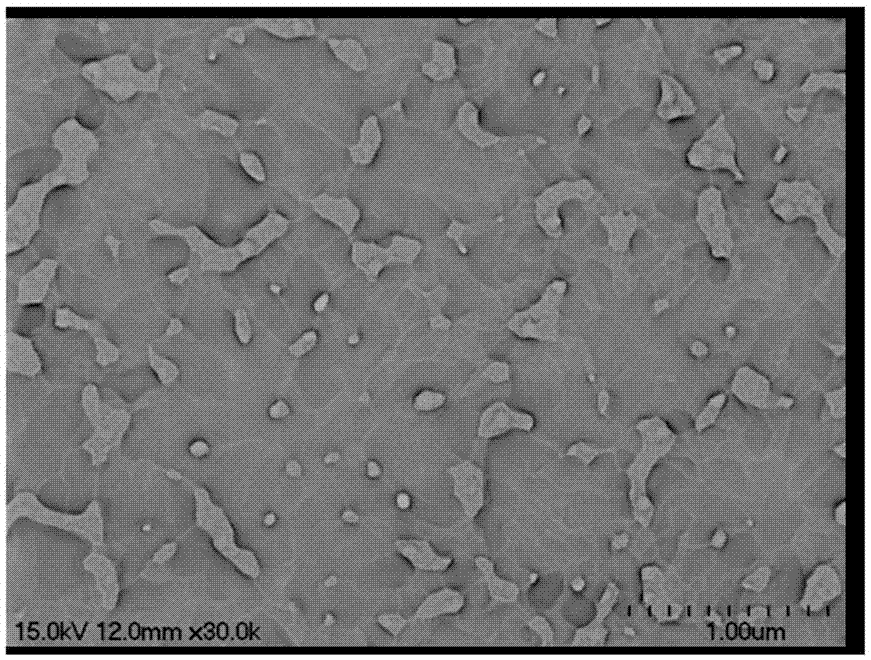

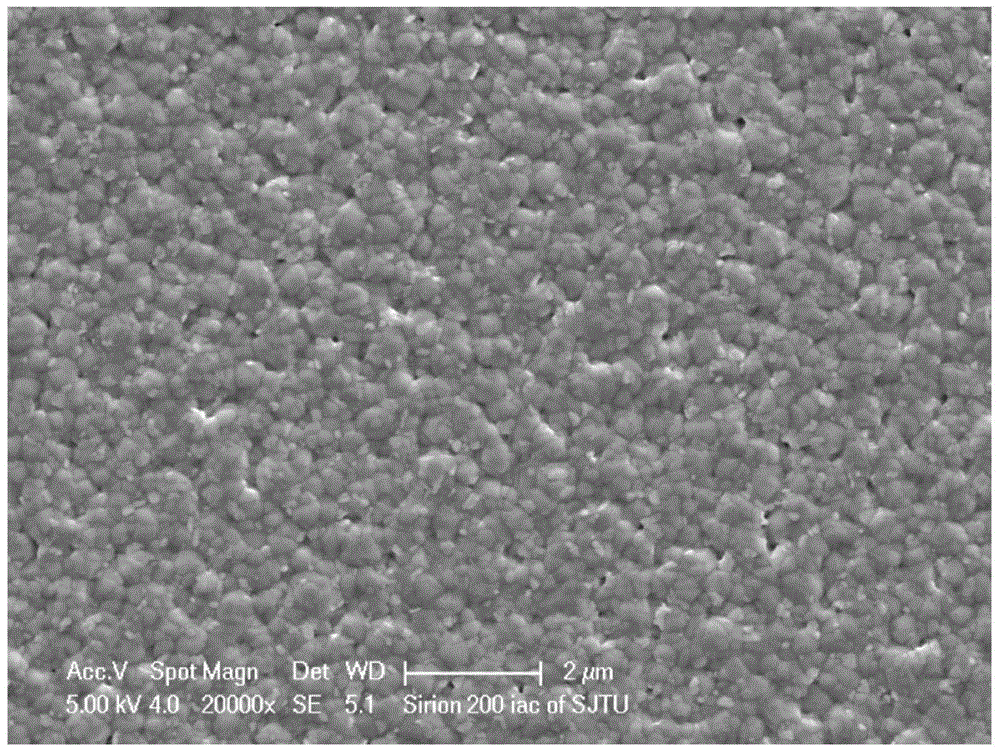

Hydrochloric acid-assisted method for preparing organic and inorganic hybrid perovskite material

InactiveCN105226196AFlat surfaceIncrease coverageSolid-state devicesSemiconductor/solid-state device manufacturingCrystallinityPerovskite

The invention provides a hydrochloric acid-assisted method for preparing an organic and inorganic hybrid perovskite material. The organic and inorganic hybrid perovskite material is prepared through a one-step spin-coating method or a continuous deposition method. The method comprises the following steps: mixing concentrated hydrochloric acid, lead halide PbX2 and corresponding halogenated methylamine MAX at a certain ratio, and then obtaining a high-quality perovskite spin-coating film through spin-coating and annealing; or mixing the concentrated hydrochloric acid with the lead halide PbX2 at the certain ratio and then preparing the high-quality perovskite spin-coating film through spin-coating film formation and soaking growth. By the hydrochloric acid-assisted method, the perovskite film which is good in crystallinity and compact and smooth in surface can be prepared. The preparation method can be carried out at normal temperature, and is convenient to operate, relatively low in cost and good in film-forming property; and large-scale factory production is convenient to achieve.

Owner:SHANGHAI JIAO TONG UNIV

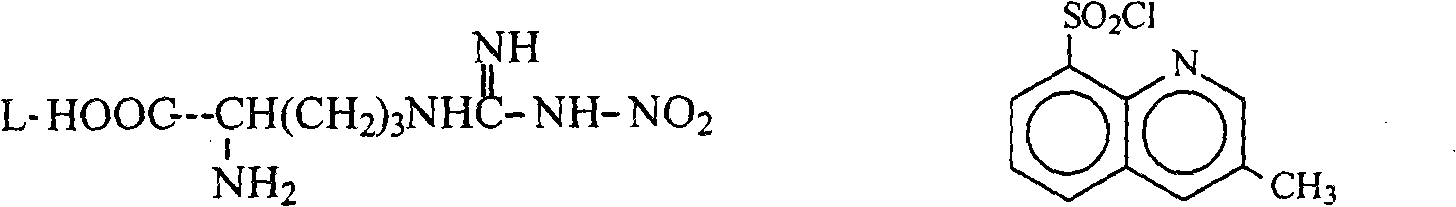

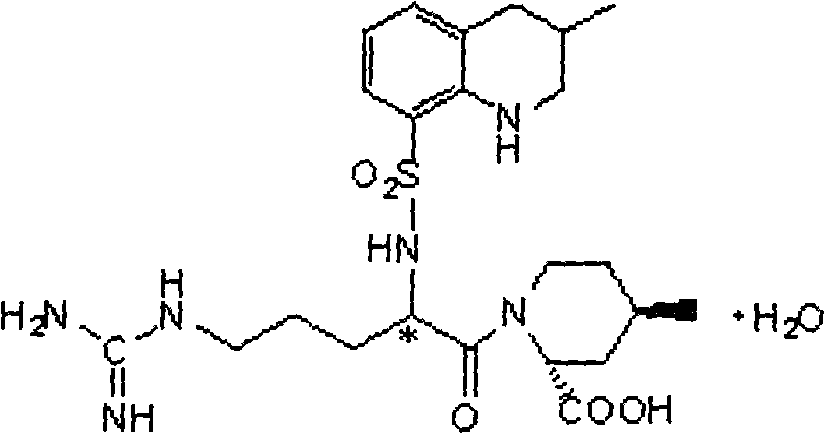

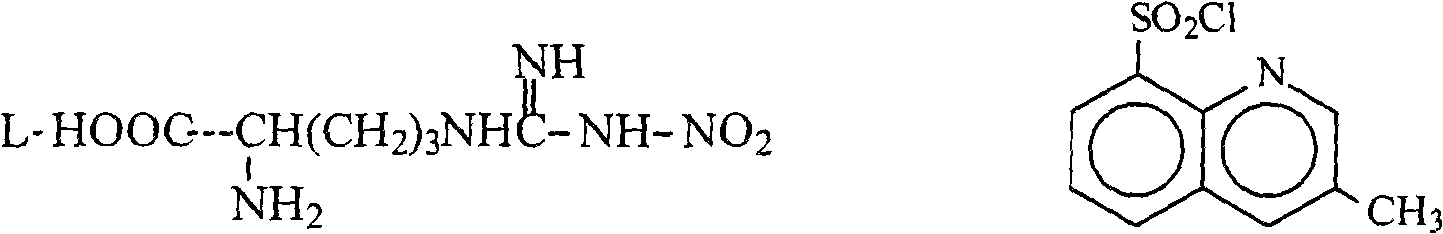

Synthetic method of argatroban and intermediate thereof

ActiveCN101348463ASolve tough problems that are hard to get rid ofMeet the needs of large-scale industrial productionOrganic chemistrySulfonyl chlorideArginine

The invention relates to a method for preparing N<2>-(3-methyl-8-quinoline sulfonyl)- N-nitryl-L-arginine as the intermediate of argatroban. The method comprises the following steps that the reaction of N-nitryl-L-arginine and a 3-methyl-8-quinoline sulfonyl chloride-THF solution is carried out in an aqueous solution of sodium carbonate ; after the reaction ends, THP is collected through evaporation, and the water layer is extracted with an organic solvent, then THF is added with pH adjusted to 2-3, and then a solid saturated water layer of inorganic salt is added; THF is separated and a desiccant is added and stirred for 10-24 hours, with water content of THF measured to be less than 1 percent, then a molecular sift is added for drying, with the water content of THF controlled within 0.2 percent, and then THF reacts with (2R, 4R) 4MPE directly. The invention solves well the control on the water content of N<2>-(3-methyl-8 quinoline sulfonyl)-N N-nitryl-L-arginine, ensures the successful implementation of amide acylation, and satisfies the requirement of the large-scale industrial production.

Owner:天津药物研究院药业有限责任公司 +1

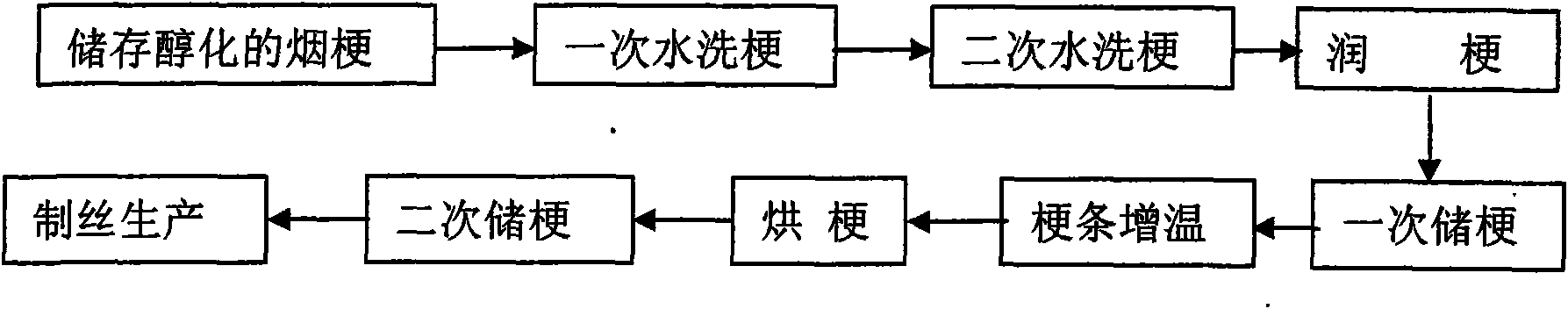

Pretreatment method for improving cigarette adaptability of tobacco stems

ActiveCN101589846AImprove inner qualityGood compatibility with cigarettesTobacco treatmentPretreatment methodChemical composition

The invention discloses a pretreatment method for improving cigarette adaptability of tobacco stems. The tobacco stems which are not fully alcoholized and have poor adaptability with tobacco shred are subjected to warm water washing, hot water soaking and washing, moistening, storage, stem heating, drying and secondary storage to complete the pretreatment. The technology comprehensively utilizes principles such as intermediate temperature biodegradation, high temperature non enzymatic browning reaction and the like, fully exploits the potential of chemical components in the tobacco stems, and promotes the chemical components to generate beneficial conversion to obtain the tobacco stems which have similar luster with the tobacco shred, improve inner quality and have good cigarette adaptability. The technological process of the method is concise and smooth, and the equipment for the method has the characteristics of simple and easy implementation, and low investment; and the method has obvious technical effect, and can fully meet the requirement of industrial mass production.

Owner:HONGYUN HONGHE TOBACCO (GRP) CO LTD

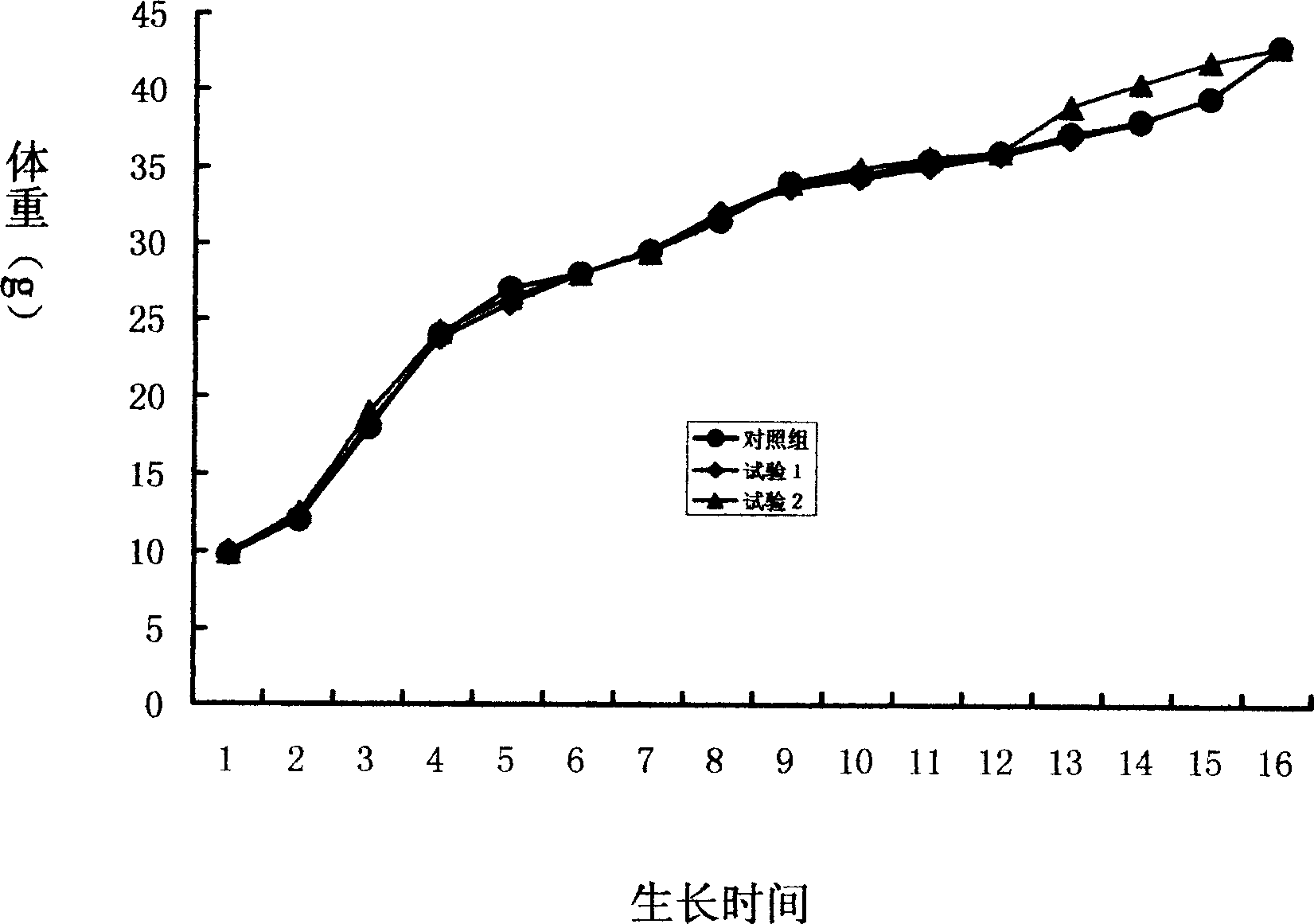

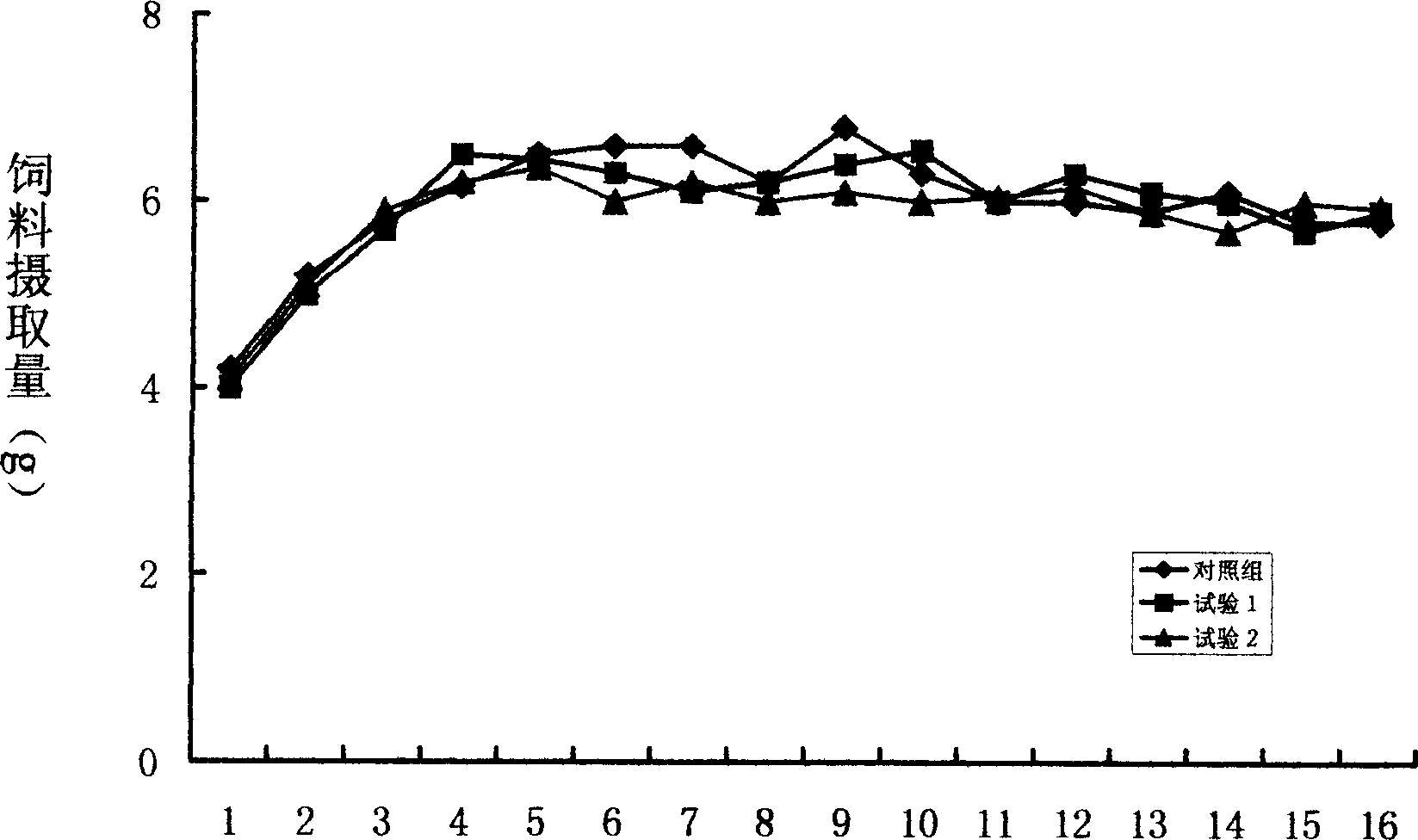

Zymophyte liquid, liquid spirit stillage fermented feed and fermentation method of liquid spirit stillage fermented feed

InactiveCN103074284AGrowth inhibitionMaintain balanceFungiBacteriaBacillus subtilis var. nattoBacilli

The invention discloses a zymophyte liquid, a liquid spirit stillage fermented feed and a fermentation method of the liquid spirit stillage fermented feed. The zymophyte liquid is prepared by mixing, at a preset proportion, liquids of lactobacillus, bacillus subtilis, bacillus natto and candida utilis bacteria which are obtained by enlarged culture. The fermented feed is prepared by fermenting a liquid complete feed with the zymophyte liquid. The fermentation method comprises the steps of inoculating the zymophyte liquid with the liquid complete feed at 3-5%wt, adjusting the moisture content to be 68-72%, sufficiently mixing into a liquid, and loading into a sealer for sealing and fermentation. The shelf life of the liquid spirit stillage fermented feed fermented by the zymophyte liquid is over 6 months at a room temperature. The liquid spirit stillage fermented feed is easier to digest, low in thallus activity loss and ideal in using effect, a culture proportion and a complete feed formula balance essential amino acid, and the liquid spirit stillage fermented feed is suitable for a whole postweaning growth stage of a commercial pig.

Owner:四川国凤生物科技有限公司

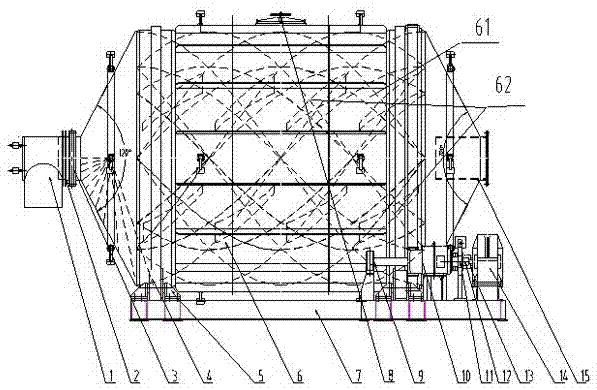

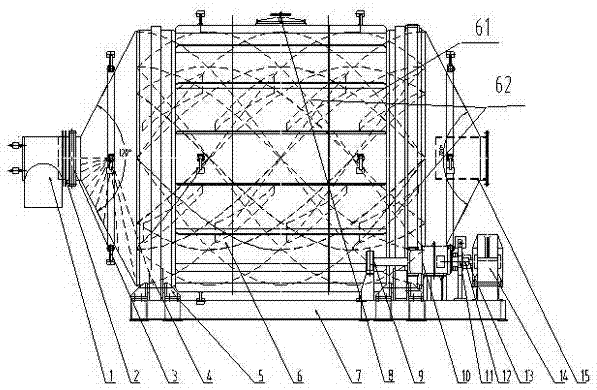

Powder material and granular material mixing device

InactiveCN102294191AImprove liquidityLow costRotating receptacle mixersTransportation and packagingEngineeringSupport plane

The invention discloses a mixing device for powder materials and granular materials, which comprises a mixing cylinder body; a grabing plate is disposed on the inner wall of the mixing cylinder body; the grabing plate comprises main grabing plates and assistant grabing plates, wherein the main grabing plate comprises multiple groups of internal helical ribbons; one end of each group of internal helical ribbons is directly mounted on the inner wall of the mixing cylinder body; the multiple groups of internal helical ribbons are distributed uniformly; a group of assistant grabing plates is mounted in a mounting gap between every two groups of main grabing plates; the assistant grabing plates are blades arranged in a direction reverse to that of the main grabing plates; the assistant grabingplates are mounted on the inner wall of the mixing cylinder body by a bracing frame, that is, the assistant grabing plates and the main grabing plates are staggeredly mounted, and the height of the assistant grabing plates is within 0.1-0.6 m. Compared with the prior art, the invention has the beneficial effect that self-falling mixing of the powder materials is realized by the internal grabing plate through the rotation of the rotary cylinder body; the device is simple, has low cost, stable operation, high efficiency, low failure rate, low power consumption, and more stable and reliable product quality.

Owner:四川华铁钒钛科技股份有限公司

Active quick dissolving full valued bone powder, and preparation method

InactiveCN1915092AMeet nutritional needsDoes not affect processabilityFood preparationFood additiveGranularity

An instant active whole-value bone powder with nano-class granularity contains collagen (more than 13%), Ca (more than 15%) and minerals (more than 45%). Its preparing process is also disclosed.

Owner:大连础明生物科技有限公司

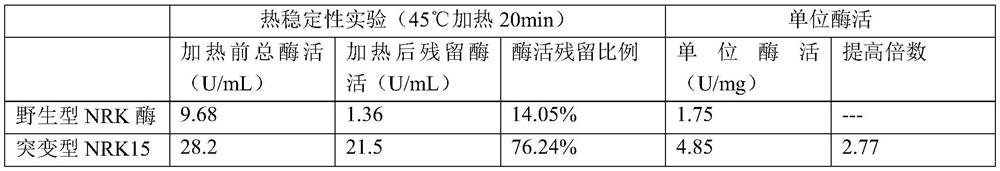

Nicotinamide riboside kinase mutant with enhanced thermal stability and activity, encoding gene of nicotinamide riboside kinase mutant, and application

ActiveCN112553178AImprove thermal stabilityRaise the reaction temperatureBacteriaTransferasesMutantRibosomal RNA Genes

The invention belongs to the technical field of biological enzyme engineering, and particularly relates to a nicotinamide riboside kinase mutant with enhanced thermal stability and activity, an encoding gene of the nicotinamide riboside kinase mutant, and application. Compared with wild nicotinamide riboside kinase of which the amino acid sequence is disclosed by SEQ ID NO:4, the amino acid sequence of the nicotinamide riboside kinase mutant is characterized in that one-point or multiple-point combined mutation is carried out on any one or a plurality of sites in 15 pieces of sites of the amino acid sequence disclosed by SEQ ID NO:4. The nicotinamide riboside kinase mutant provided by the invention can be used for synthesis and preparation of [beta]-nicotinamide mononucleotide. Compared with wild enzymes, the nicotinamide riboside kinase mutant constructed by the invention is characterized that the thermal stability and the unit enzyme activity of the mutant are greatly improved, so that the reaction temperature of the enzyme can be obviously improved, a reaction rate is quickened, reaction time is shortened, production cost is lowered, an NMN yield is improved, and the nicotinamide riboside kinase mutant has a wide prospect of large-scale industrial application.

Owner:中山俊凯生物技术开发有限公司

Manufacturing method of alloy steel section tubes

The invention provides a manufacturing method of alloy steel section tubes. The method comprises the following steps: (1) forging steel ingots of alloy steel to a bar material; (2) after removing surface defects of the bar material, cutting the bar material to blank materials with predetermined lengths; (3) drilling the blank materials to manufacture tube blanks; (4) preheating the tube blanks to 600-900 DEG C, and broaching the tube blanks after the tube blanks are heated to 1000-1200 DEG C; (5) after the broached tube blanks are heated to 1100-1300 DEG C, performing extrusion molding to obtain the section tubes. By adopting the manufacturing method of the alloy steel section tubes, the production process can be simplified, the production cost can be largely reduced, the requirements of large-scale industrial production can be met, and the section tubes with the good quality are obtained.

Owner:PANGANG GROUP JIANGYOU CHANGCHENG SPECIAL STEEL

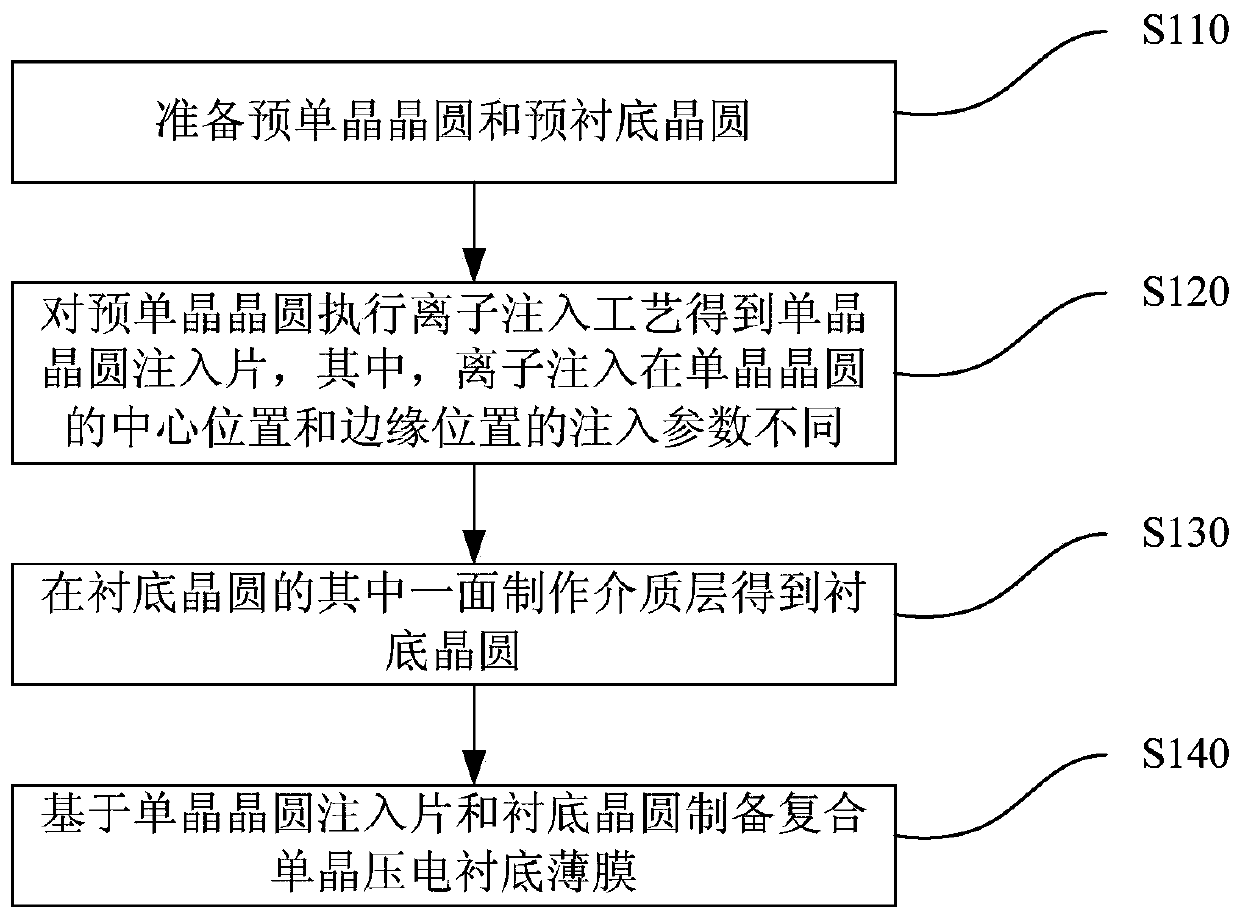

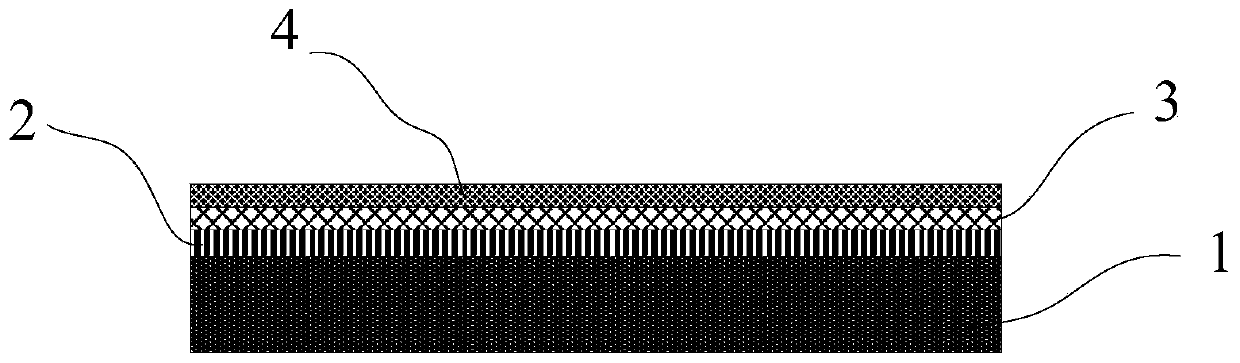

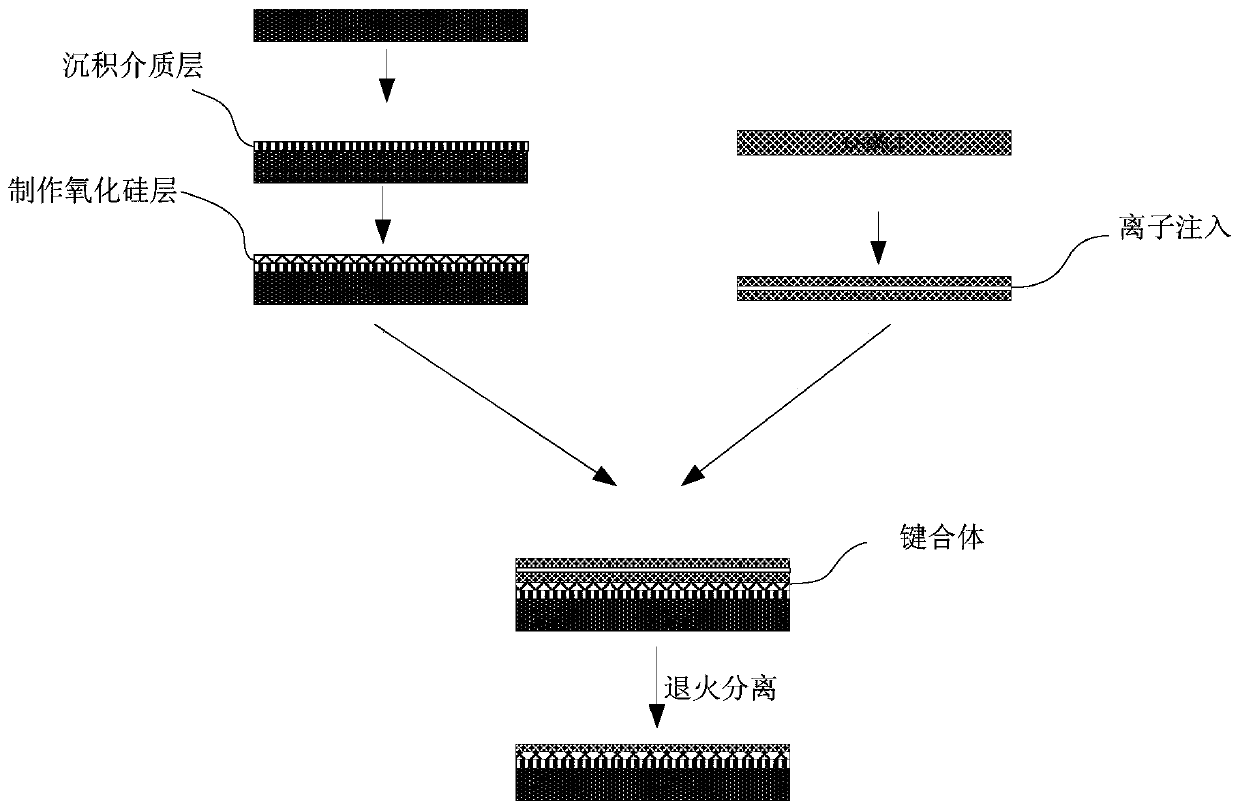

Composite single crystal piezoelectric substrate film and preparation method thereof

ActiveCN111128699AGuaranteed separation effectReduce lossSemiconductor/solid-state device manufacturingSocial benefitsWafering

The invention discloses a composite single crystal piezoelectric substrate film and a preparation method thereof. The preparation method comprises the steps that when He+ or H+ is implanted into a polished and cleaned single crystal wafer through an ion implantation method, implantation dose parameters and / or temperature parameters of a center position and an edge position of the single crystal wafer are / is regulated and controlled, and a single crystal wafer implantation piece is obtained; the preparation method of the composite single crystal piezoelectric substrate film is simple and easy to implement, gluing pressurization or mechanical separation is not needed during annealing separation, and the problems of mechanical tearing and wafer scratching in the prior art can be avoided; thewafer obtained by adopting the preparation method is low in defect rate, the rate of finished products can reach 99% or above, and the rate of finished products in the prior art is generally 80% or below; and the preparation process for completely separating a lithium niobate / lithium tantalate thin film under the condition that a substrate is not broken can meet the requirements of large-scale industrial production, and has good economic benefits and social benefits.

Owner:JINAN JINGZHENG ELECTRONICS

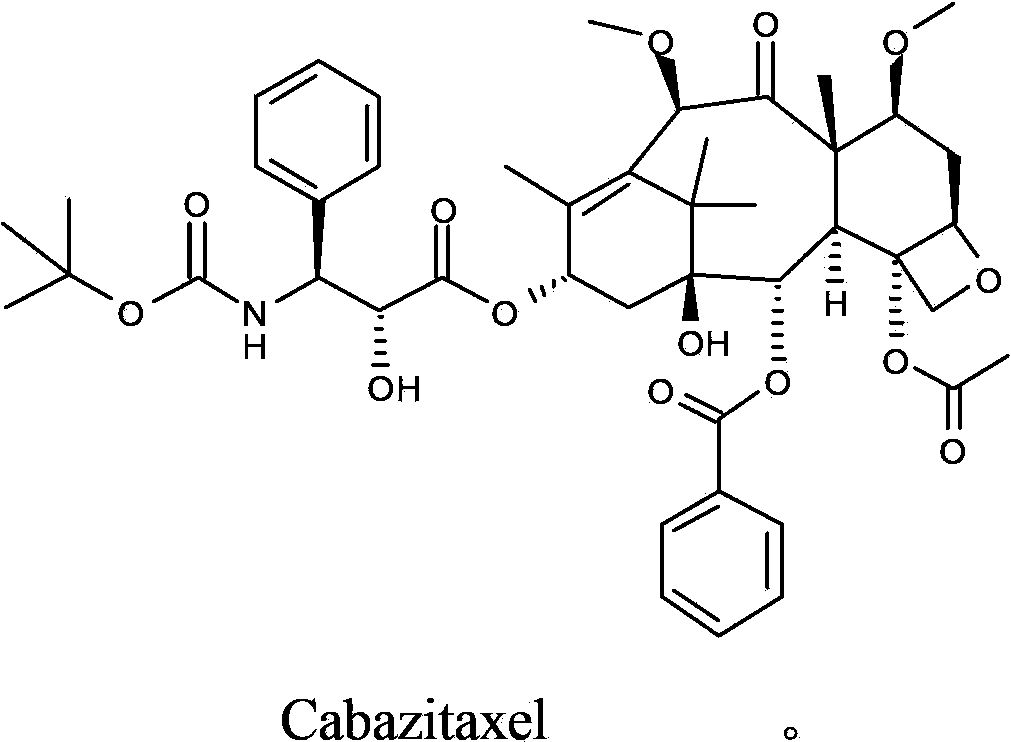

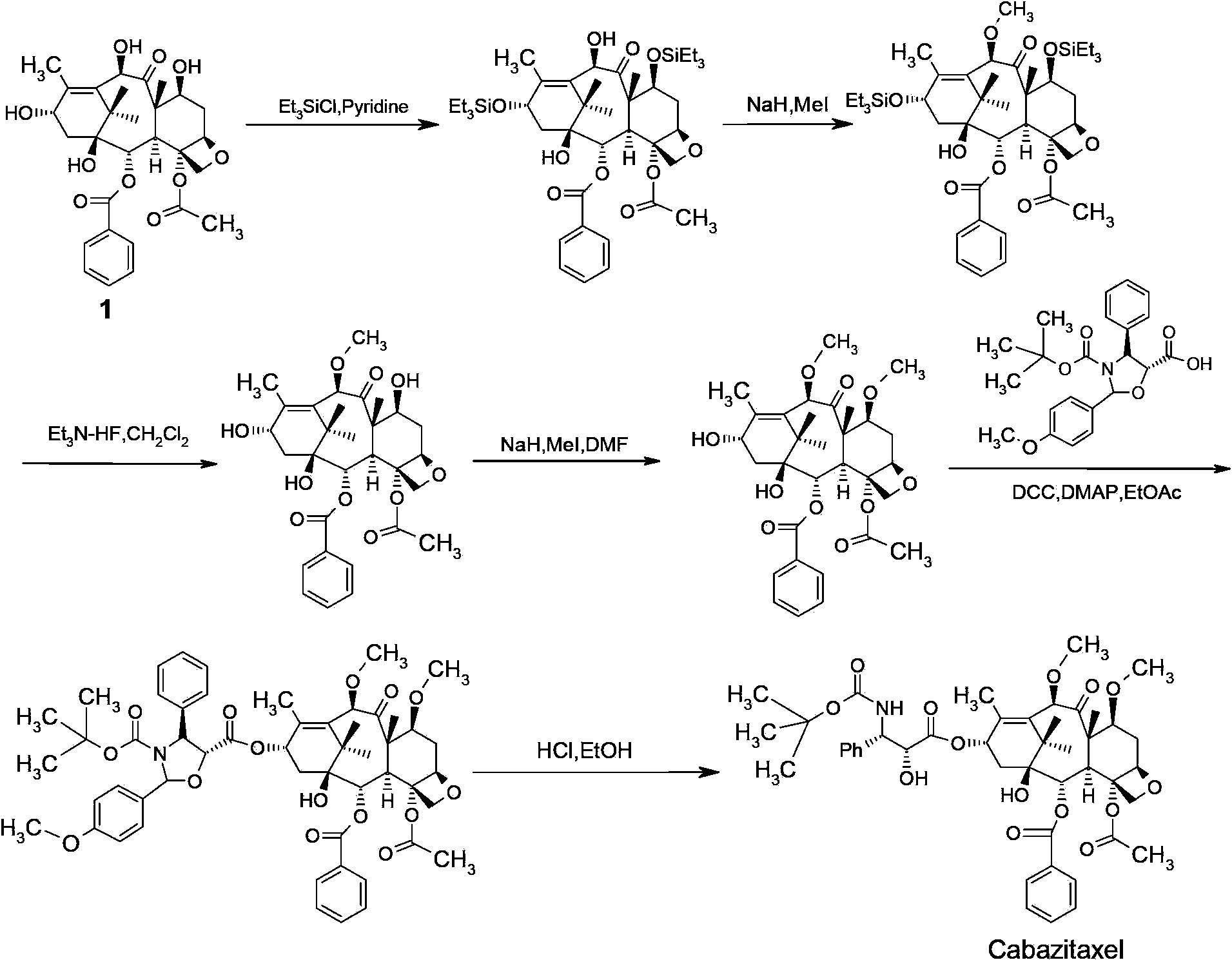

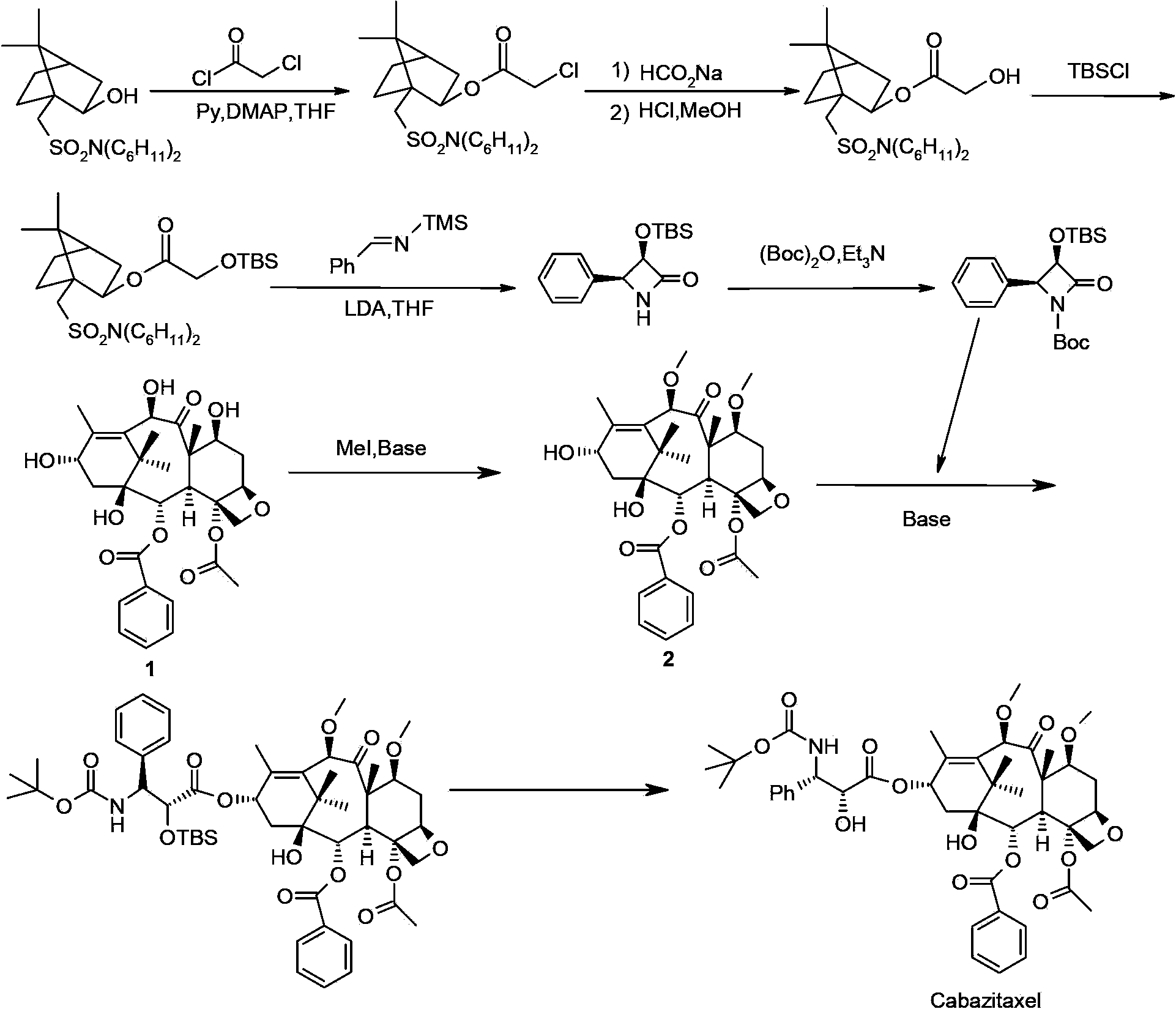

Cabazitaxel intermediate as well as preparation method and application thereof

ActiveCN103421036AMild reaction conditionsEasy to operateGroup 4/14 element organic compoundsBulk chemical productionChemical structureCabazitaxel

The invention discloses a cabazitaxel intermediate as well as a preparation method and an application thereof. The intermediate has a chemical structure formula shown as formula I shown in the description, and TES in the formula is the abbreviation of triethylsilane. The preparation method of the intermediate comprises a step B or a step A and the step B in the following synthetic route shown in the description, wherein the step A means that the compound of a formula 1 is subjected to a methylation reaction with a methylation agent for preparation of the compound of a formula 2; and the step B means that the compound of the formula 2 is subjected to a condensation reaction with the compound of a formula 3 for preparation of the intermediate I. The intermediate is subjected to hydrolysis under an acidic condition for removing the triethylsilane protective group, and thus cabazitaxel is prepared. According to the technical scheme, high-purity cabazitaxel can be synthesized by utilizing cheap and easily-available raw materials and with a low cost, large-scale industrialized production requirement on cabazitaxel is satisfied, and the preparation method is applicable to industrial application and has practical value.

Owner:SHANGHAI ACEBRIGHT PHARMA CO LTD +1

Cake riched in full-valence animal bone powder

InactiveCN1849894AUnique preparation methodDoes not affect processabilityDough treatmentBakery productsFood additiveAdditive ingredient

The present invention relates to a cake richly containing complete animal bone powder. It includes flour for making cake and additive, in which the animal bone powder is added. It is characterized by that its calcium content is high, and its animal bone powder grain size is up to nano-grade, so that it contains rich nutrients.

Owner:大连础明生物科技有限公司

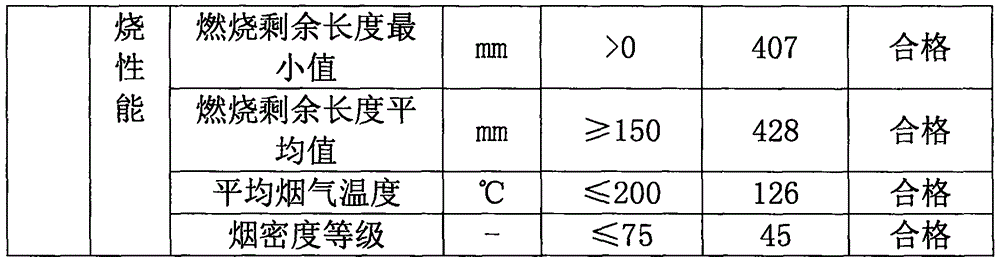

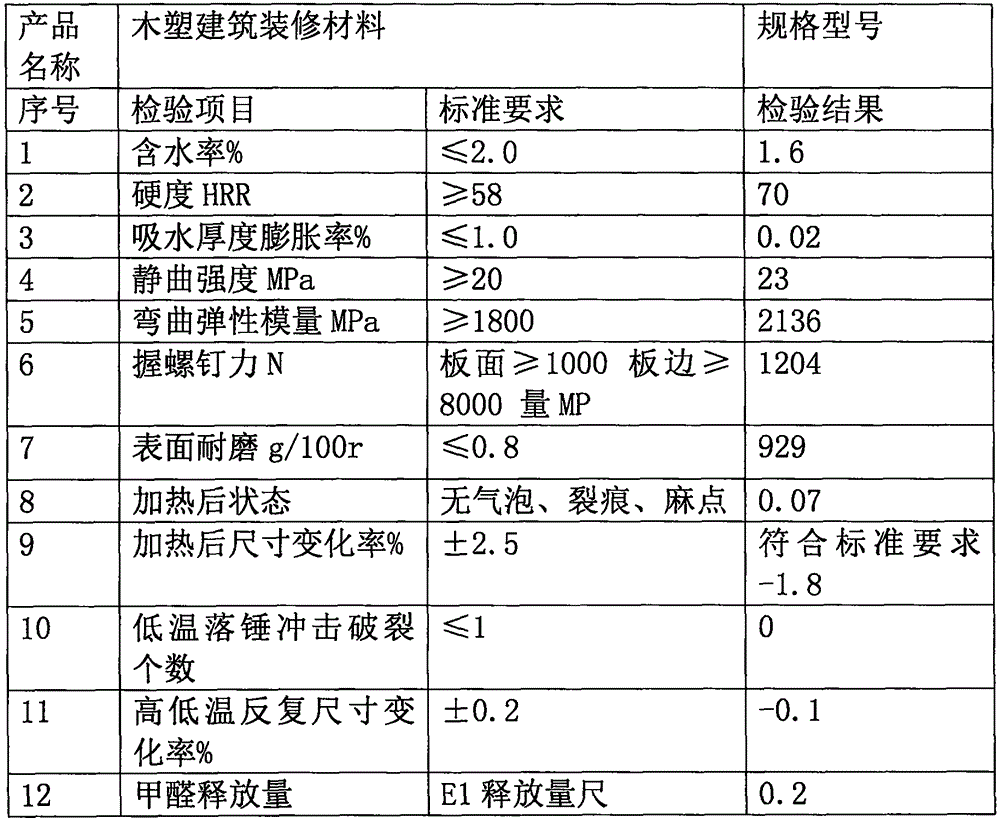

Energy-saving and environment-friendly wood plastic material

The invention discloses an energy-saving and environment-friendly wood plastic material, which consists of the following raw materials by mass: 40-60 parts of polyvinyl chloride resin powder, 30-40 parts of wood powder, 20-30 parts of calcium carbonate powder, 2-3 parts of a modifier, 3-5 parts of a processing aid, 2-3 parts of a foaming agent, 1-2 parts of a stable solvent, 1-2 parts of a foaming aid, 1-1.5 parts of a lubricant, and 0.5-1 part of a colorant. The wood plastic material has the characteristics of moisture protection, waterproofness, insect prevention, termite prevention, low carbon and energy saving, the product does not contain benzene, has a formaldehyde content of 0.2, which is lower than the EO level standard and meets the European grading standard, can realize recycling, greatly saves wood usage, is suitable for the national policy of sustainable development, and benefits the society. The whole production process does not generate industrial waste gas and waste water, is low in noise, and is in line with various national industrial production environmental protection requirements, thus being suitable for large-scale promotion and application.

Owner:高智慧

Nicotinamide ribokinase mutant as well as coding gene and application thereof

The invention belongs to the technical field of biological enzyme engineering and particularly relates to a nicotinamide ribokinase mutant as well as an encoding gene and application thereof. Comparedwith wild nicotinamide ribokinase with the amino acid sequence shown as SEQ ID NO: 2, the amino acid sequence of the nicotinamide ribokinase mutant is subjected to single mutation, pairwise joint mutation, three joint mutations or any one of four joint mutations at the 9th site, the 102nd site, the 52nd site and the 146th site of the amino acid sequence shown as SEQ ID NO: 2. The nicotinamide ribokinase mutant provided by the invention can be used for synthesizing and preparing beta nicotinamide mononucleotide. Compared with a wild type enzyme, the nicotinamide ribokinase mutant constructed by the invention has the advantages that the enzyme activity is improved by 3.86-4.53 times, the reaction time is shortened, the use amount of the enzyme can be remarkably reduced, the fermentation capacity and the cost are reduced, the NMN yield is improved, and the nicotinamide ribokinase mutant has a wide prospect of large-scale industrial application.

Owner:中山俊凯生物技术开发有限公司

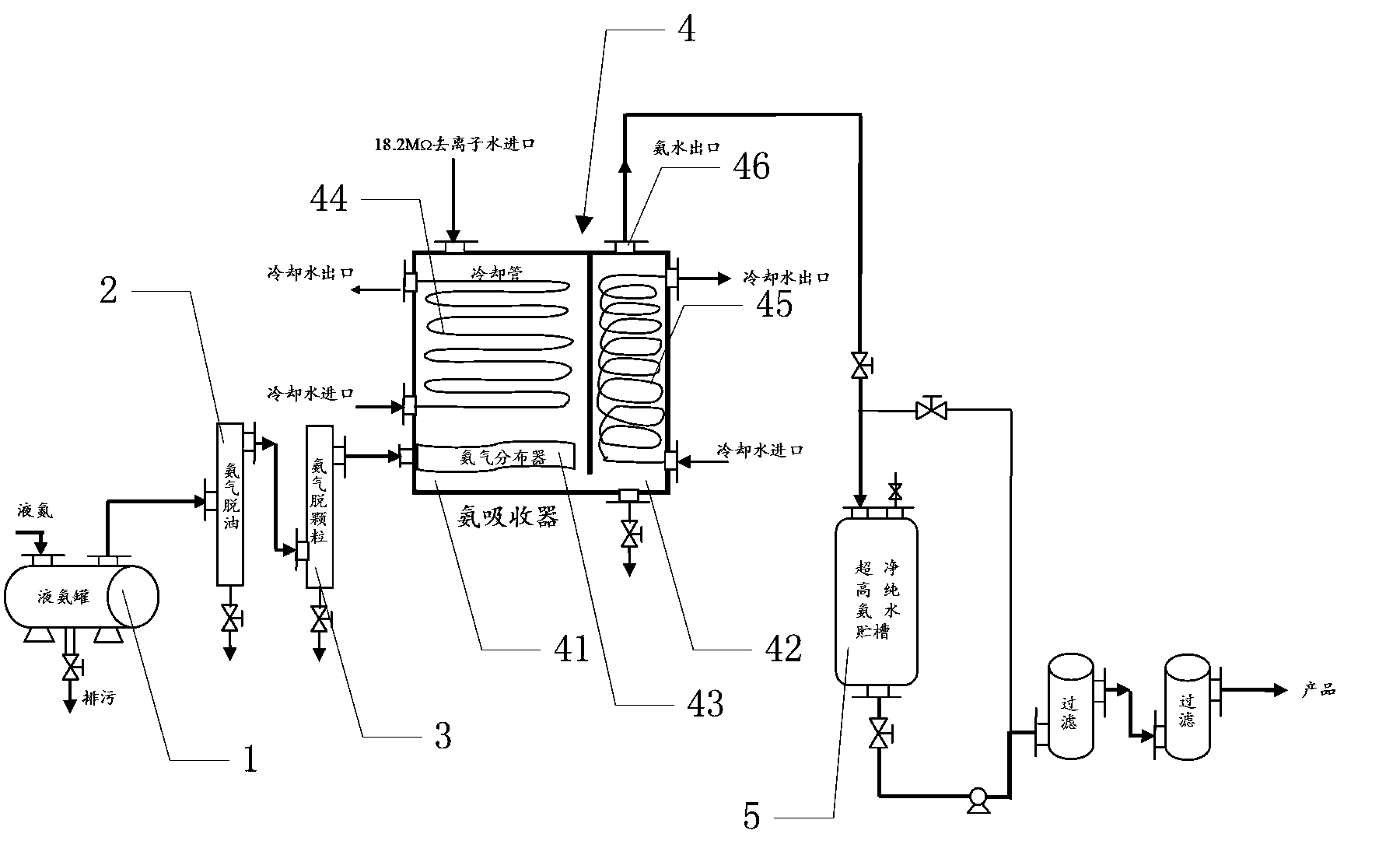

Ammonia absorption device and method for preparing ultra-clean high-purity ammonium hydroxide

ActiveCN103466655AGood technical effectIncrease productionChemical industryAmmonia preparation/separationDevice formPhysical chemistry

The invention relates to a high-purity ammonium hydroxide absorption device and technology, and discloses an ammonia absorption device formed by high-purity materials. The high-purity ammonium hydroxide absorption device comprises a liquid ammonia tank, an ammonia gas deoiling device, an ammonia gas degranulation device, an ammonia absorption device and an ultra-clean high-purity ammonium hydroxide storage tank which are sequentially connected. The invention further discloses a method for preparing the ultra-clean high-purity ammonium hydroxide. The ammonia absorption device and the method for preparing the ultra-clean high-purity ammonium hydroxide have the advantages that the ultra-clean high-purity ammonium hydroxide can be prepared, the device is simple in structure, the number of needed processing procedures is small, the absorption is fast, the yield is high, the energy is saved, the efficiency is high, three wastes cannot be discharged, the requirement for environmental protection is met, the demand for industry large-scale manufacturing is met, and the device has good application value.

Owner:ZHEJIANG JIANYE CHEM +2

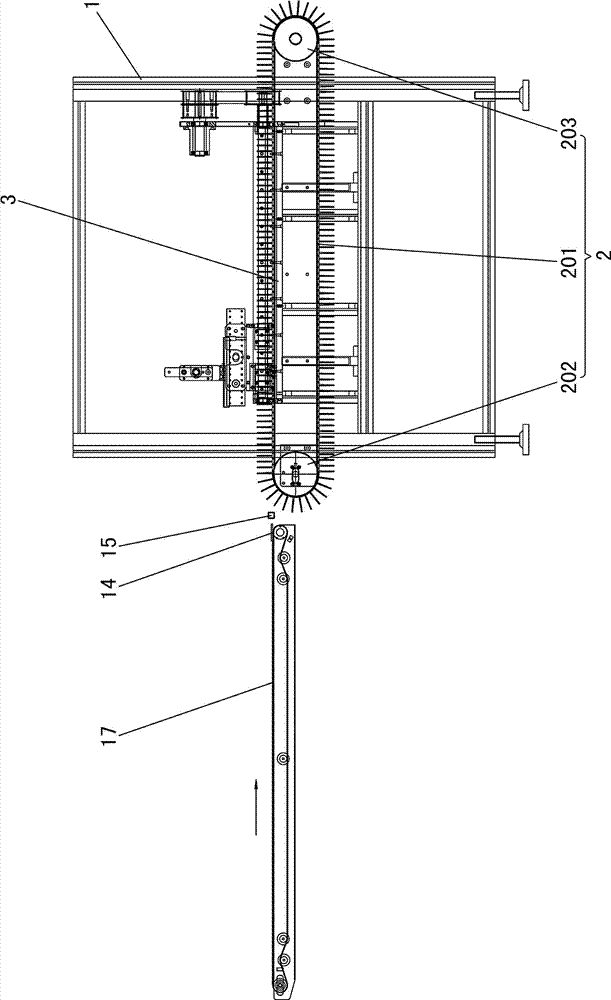

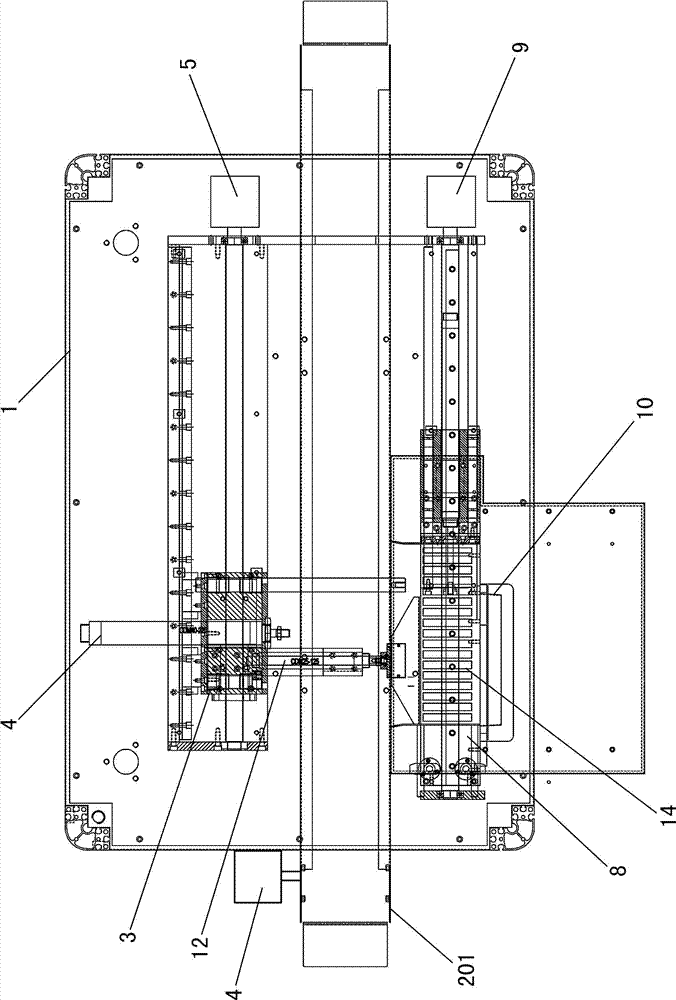

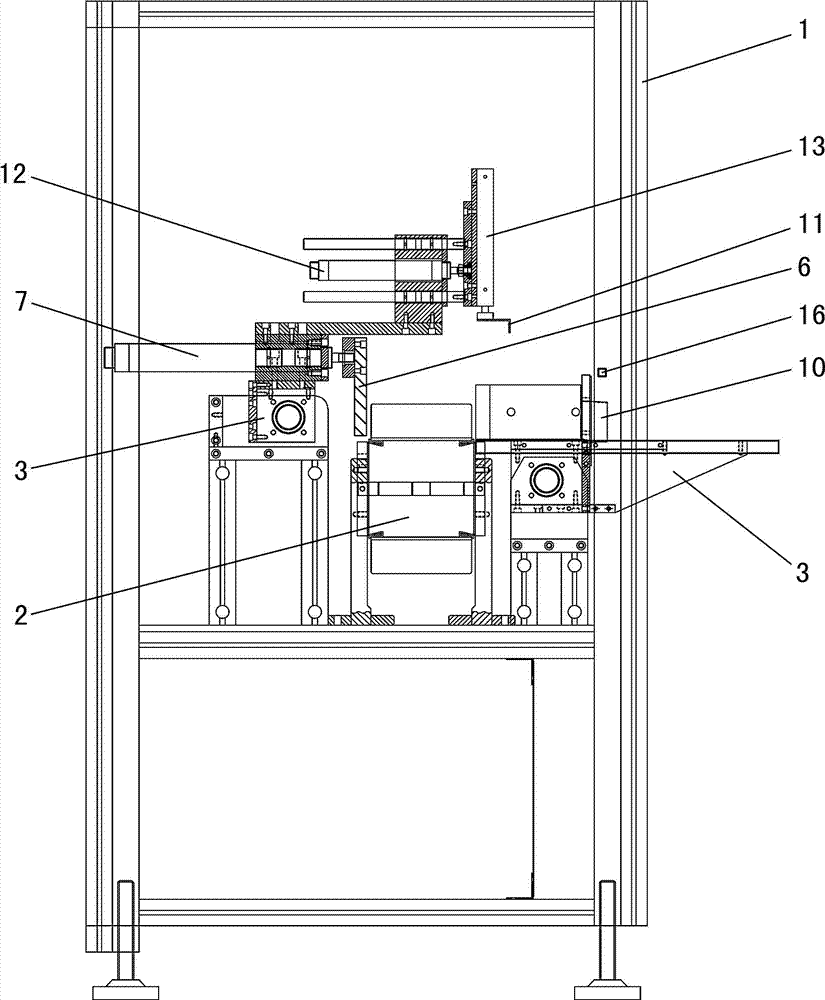

Boxing production line for packing bag

InactiveCN102963576AImprove work efficiencyLabor savingPackaging automatic controlEngineeringManufacturing line

A boxing production line for a packing bag relates to a boxing production line and comprises a stand as well as a chain plate type conveying mechanism, a first driving mechanism, a packing bag extruding and boxing mechanism and a second driving mechanism which are respectively mounted on the stand, wherein the packing bag extruding and boxing mechanism comprises synchronous worktables, a packing bag removing mechanism, a packing bag extruding mechanism and a packing bag boxing mechanism; the synchronous worktables can be longitudinally mounted on the stand along the stand in a sliding way and are positioned on the front side and the back side of the chain plate type conveying mechanism; the second driving mechanism is connected with the synchronous worktables; and the packing bag removing mechanism, the packing bag extruding mechanism and the packing bag boxing mechanism are respectively mounted on the synchronous worktables. According to the boxing production line disclosed by the invention, the packing bags can be automatically finished and counted; the bagging bags with the preset quantity are arranged into a row; one row of packing bags are extruded and subjected to width reduction and are loaded into the packing box for work; and in addition, the work efficiency is greatly improved, the labor force can be greatly saved and the production cost is effectively reduced.

Owner:汕头市高雄海包装机械有限公司

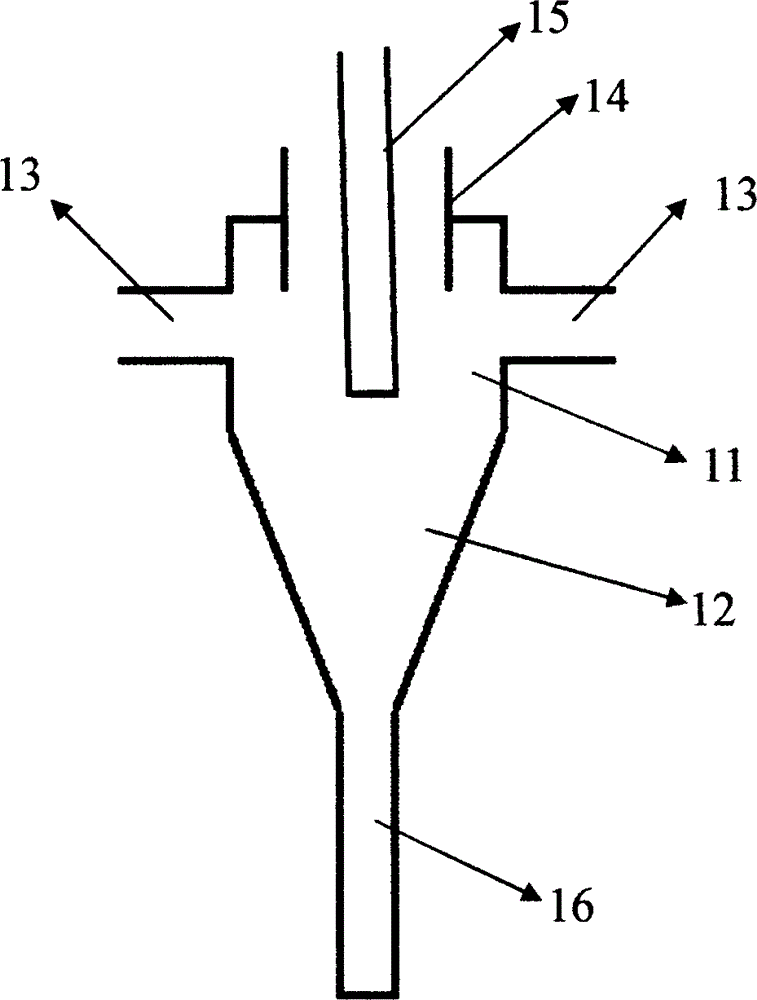

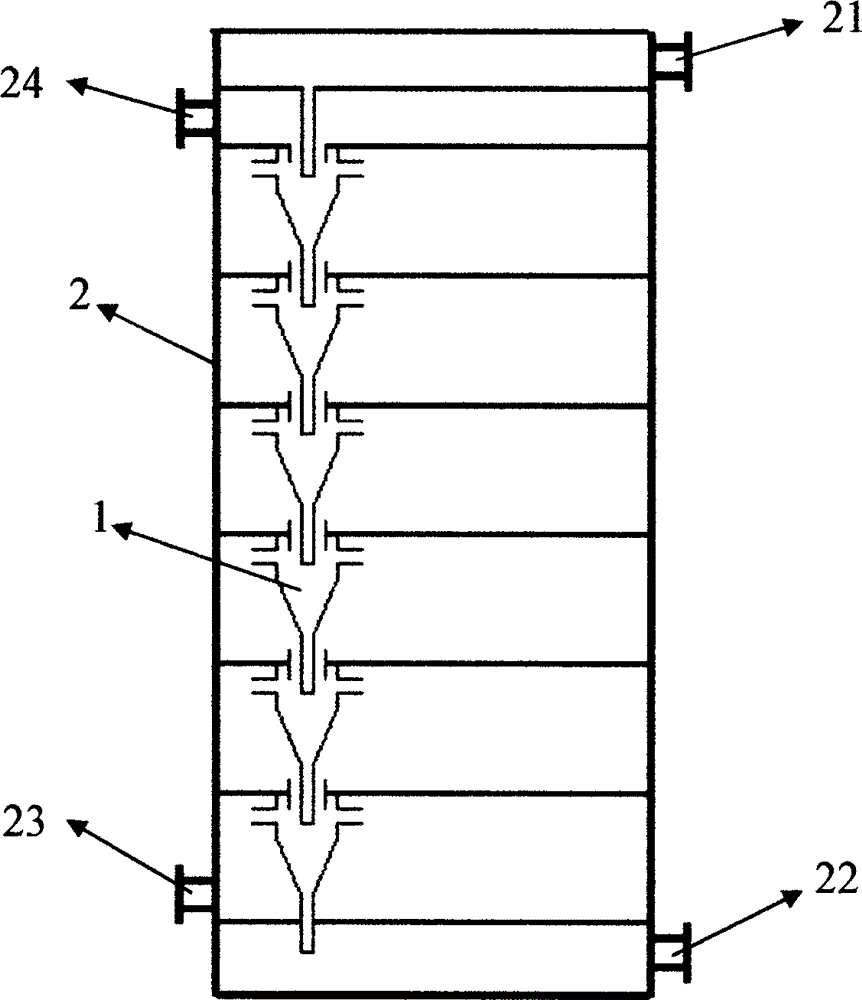

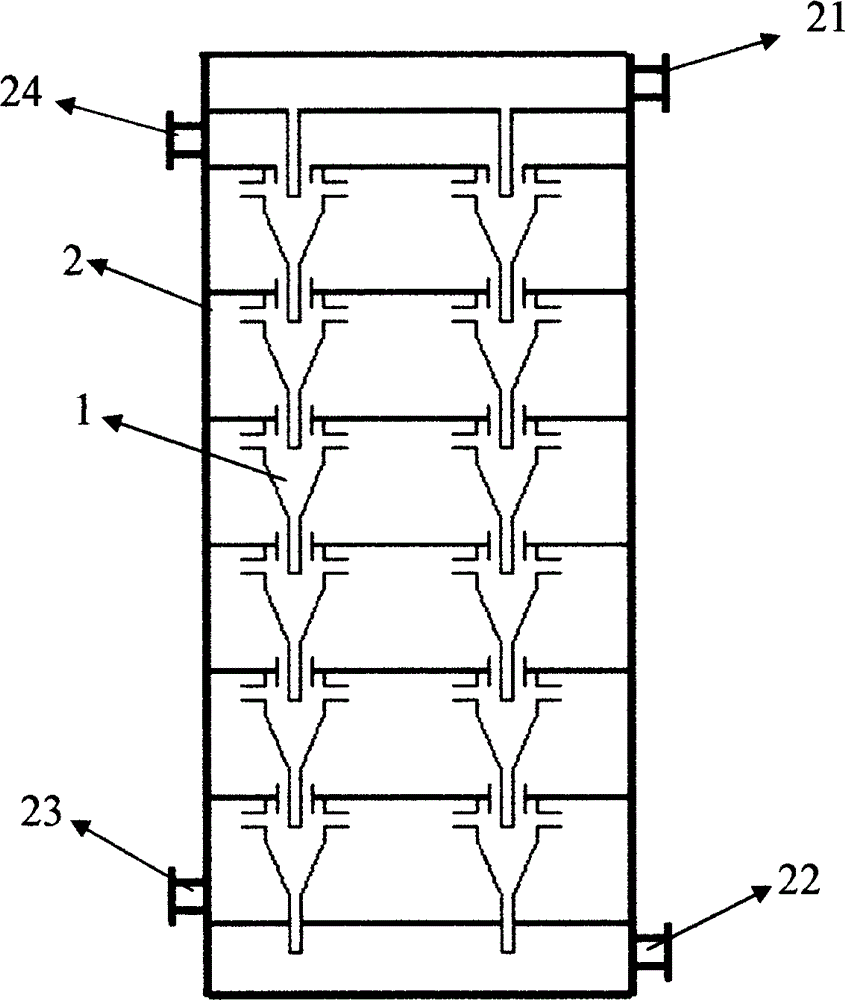

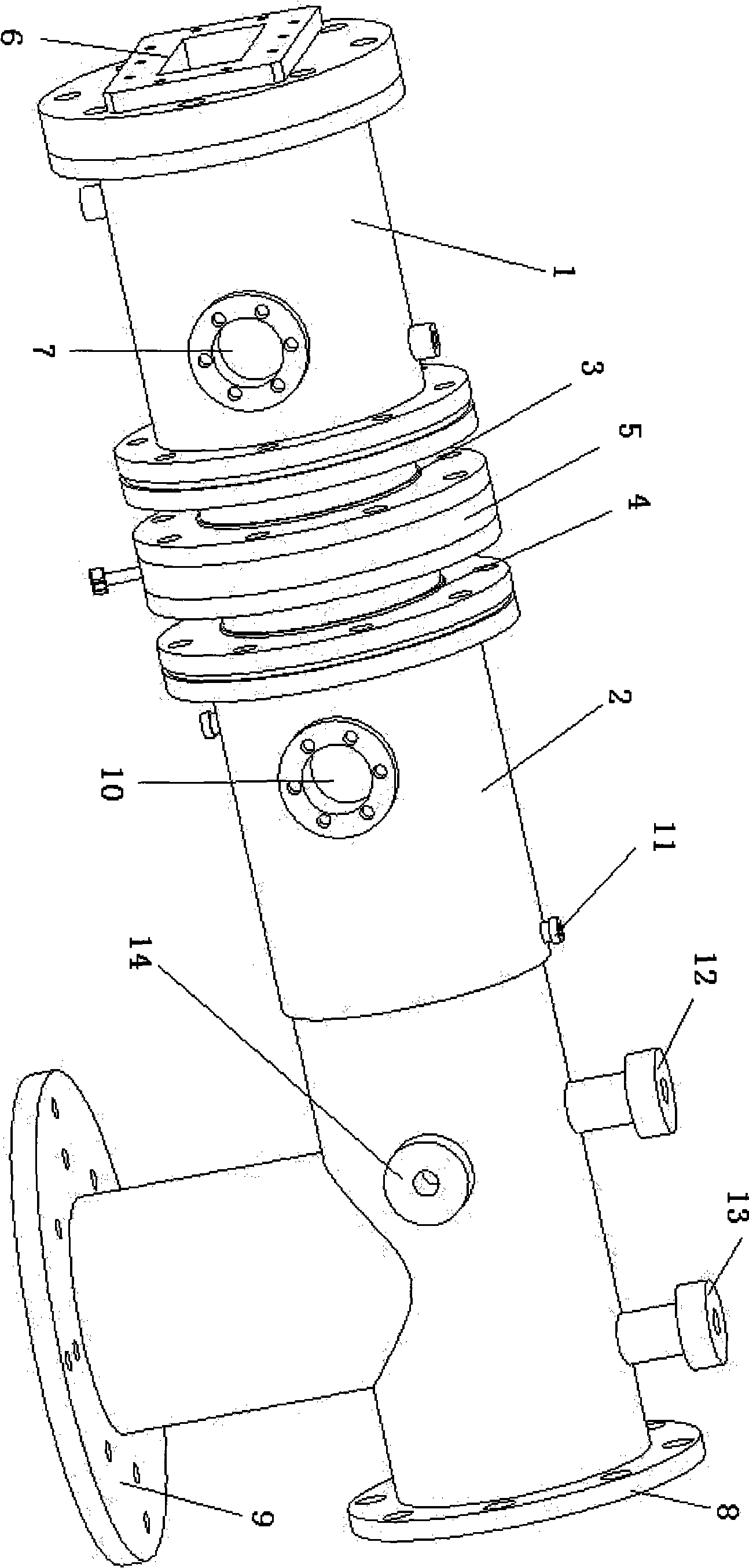

Cyclone-shaped mass transfer component and static supergravity mass transfer separation device

InactiveCN104525394ACheap manufacturingEasy to handleReversed direction vortexEngineeringCentrifugal force

The invention discloses a cyclone-shaped mass transfer component which comprises a cavity and a tail tube, wherein the upper part of the cavity is provided with a light phase feeding tube along the tangent direction of the cavity, a circumferential outlet at the upper part of the cavity is provided with a light phase overflow tube, the center of the light phase overflow tube is provided with a heavy phase feeding tube, and the heavy phase feeding tube is inserted in the cavity along the center of the light phase overflow tube; and the center of the lower end of the cavity is provided with the tail tube, and through the formation of a static supergravity field without rotatable parts, two-phase materials with different densities simultaneously implement a two-phase uniform mixing and separating process. The invention also discloses a static supergravity mass transfer separation device containing the mass transfer components, which comprises multiple mass transfer components which are connected in series, the tail tube of the (N+1)th-stage mass transfer component is a heavy phase feeding tube of the Nth-stage mass transfer component, the mass transfer components are connected in a similar fashion, and through the reasonable structure design of the multiple mass transfer components, a static centrifugal force field is formed for realizing the multistage countercurrent operation of two phases with different densities.

Owner:李中 +1

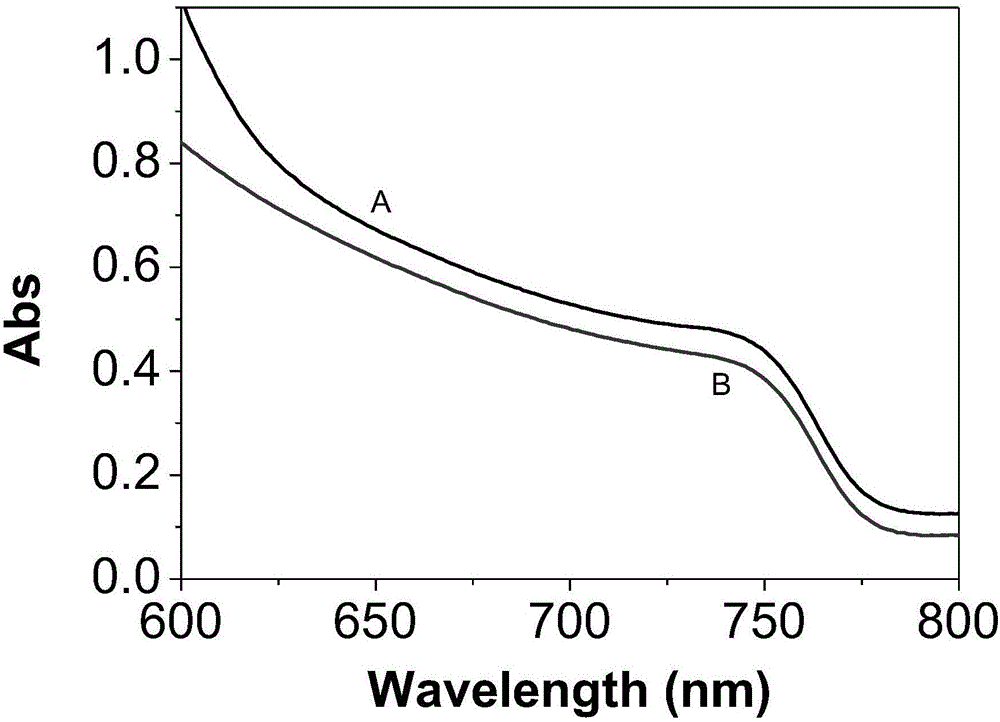

Method for improving stability of perovskite film through sulphuring treatment

ActiveCN105932164AFlat surfaceImprove stabilitySolid-state devicesSemiconductor/solid-state device manufacturingIonSulfur containing

The invention provides a method for improving stability of a perovskite film through sulphuring treatment. The perovskite film is processed by sulfur-containing inorganic salts to form a protection layer on the surface of the perovskite film, thereby improving stability of the film. The method comprises the following steps: applying a solution containing sulfur ions to a lead halide perovskite film under a certain condition, and then, carrying out annealing processing to obtain the perovskite film wrapped by the lead sulfide. The method can improve humidity resistance and stability of the perovskite film obviously, and has great significance to practical application.

Owner:SHANGHAI JIAO TONG UNIV

Extraction process of polysaccharide in poria cocos

The invention relates to an extraction process of traditional Chinese medicine, in particular to an extraction process of polysaccharide in poria cocos. The extraction process of polysaccharide in poria cocos is low in time consumption and high in extraction rate. The extraction process includes the process steps of performing pretreatment; performing extraction, wherein distilled water is added into degreased poria cocos powder at the material-liquid ratio of 1:15-1:25, and ultrasonic extraction is performed for 25-30 min at 60-80 DEG C at the ultrasonic power of 200-280 w; performing suction filtration, decoloration and concentration; performing deproteinization, wherein crude polysaccharide is dissolved in double-distilled water, the mixture is added into mixed liquor of chloroform and n-butyl alcohol at the mass ratio of 4:1-5:1 after even mixing, the ratio of m chloroform to m n-butyl alcohol in the mixed liquor is 5:1, supernatant liquor is taken after shaking, 3-5-volume fold ethyl alcohol with the mass fraction of 95% is added, the mixture is placed in a refrigerator for 24 h of standing, and then deproteinized poria cocos polysaccharide is obtained through centrifugation; performing washing to obtain poria cocos polysaccharide.

Owner:NINGGUO THOUSAND SQUARE TCM DEV

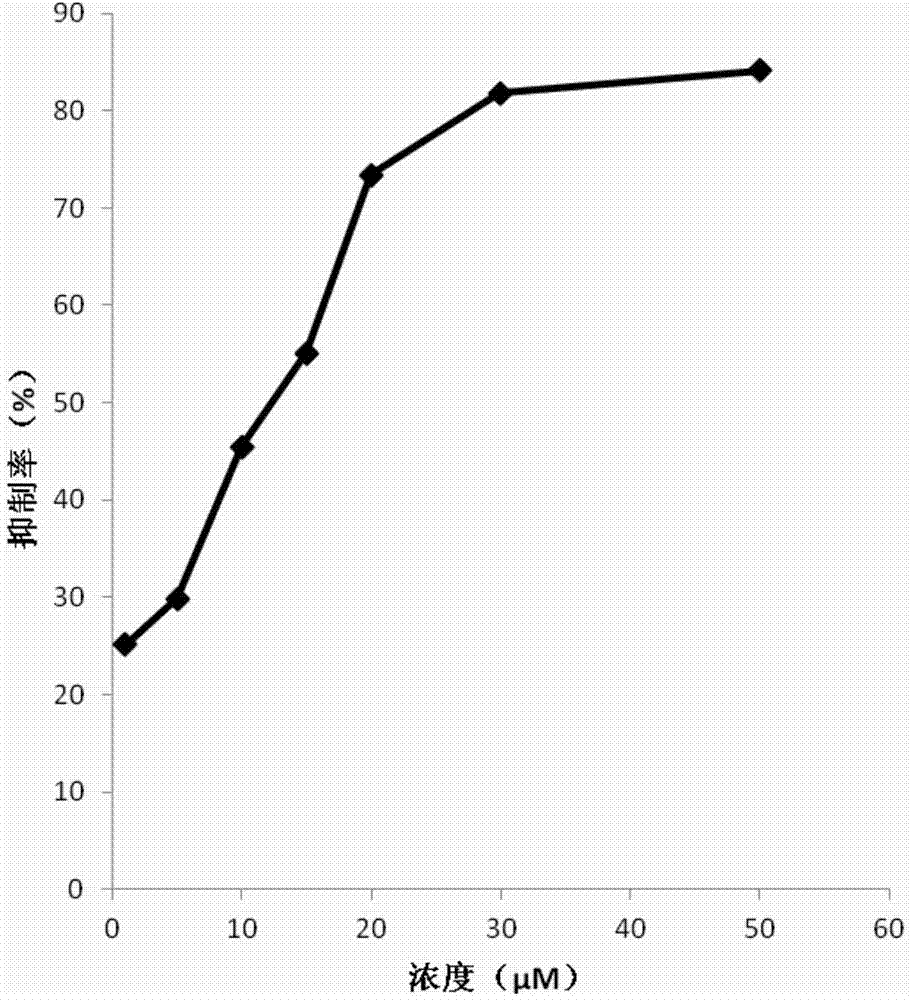

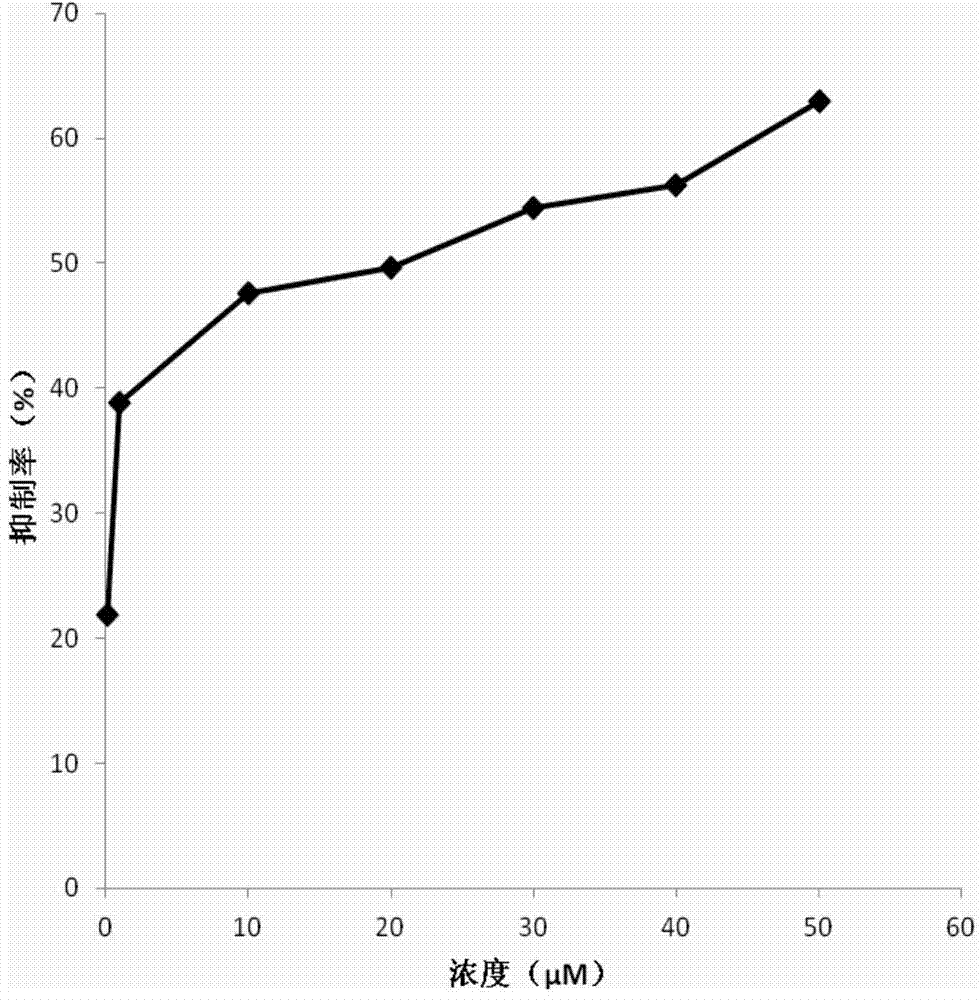

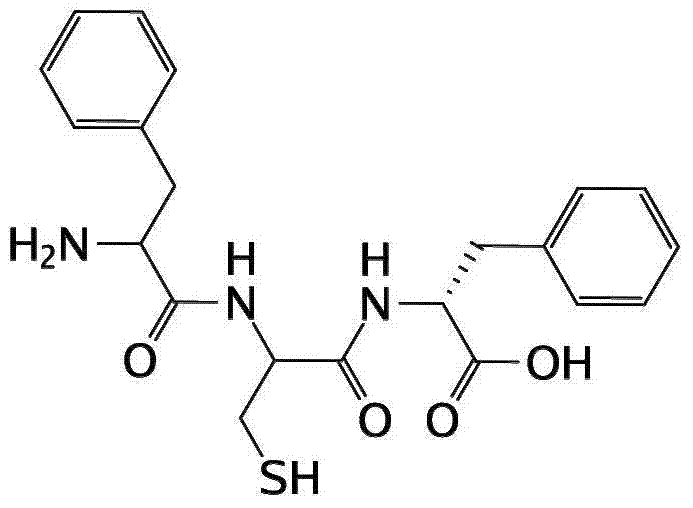

New Delhi metallo-beta-lactamase inhibitory peptide and application thereof

InactiveCN103588861ASimple structureSimple methodAntibacterial agentsOrganic active ingredientsDrug resistanceNew Delhi metallo-beta-lactamase

The invention belongs to the field of biological medicament, and specifically relates to a NDM-1 type metallo-beta-lactamase tripeptide inhibitor with an amino acid sequence of Phe-Cys-D-Phe. Pharmacodynamical experiments prove that the peptide provided by the invention is applicable to preparation of antibacterial medicaments for preventing and treating drug-resistance bacterial infection.

Owner:CHINA PHARM UNIV

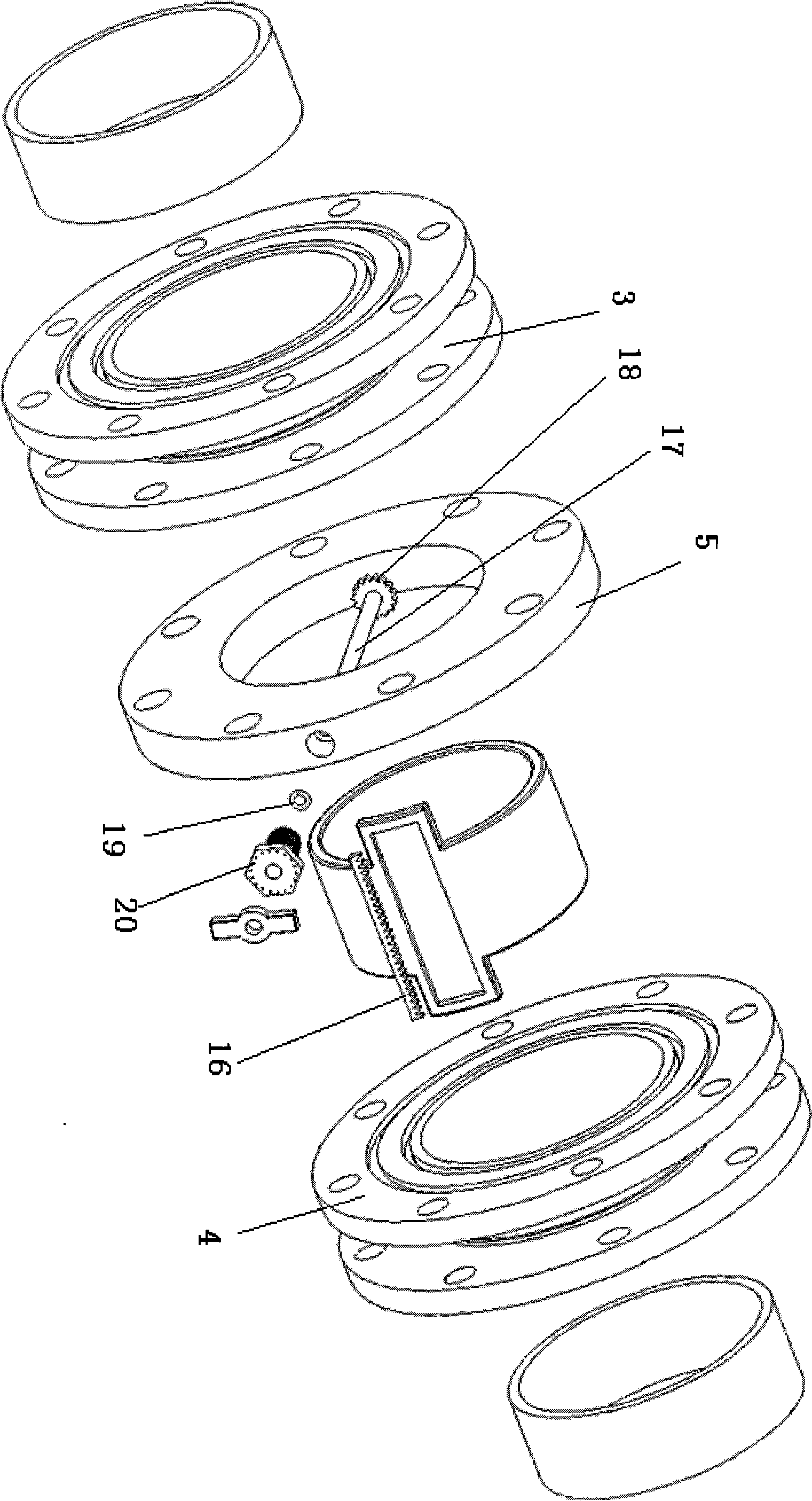

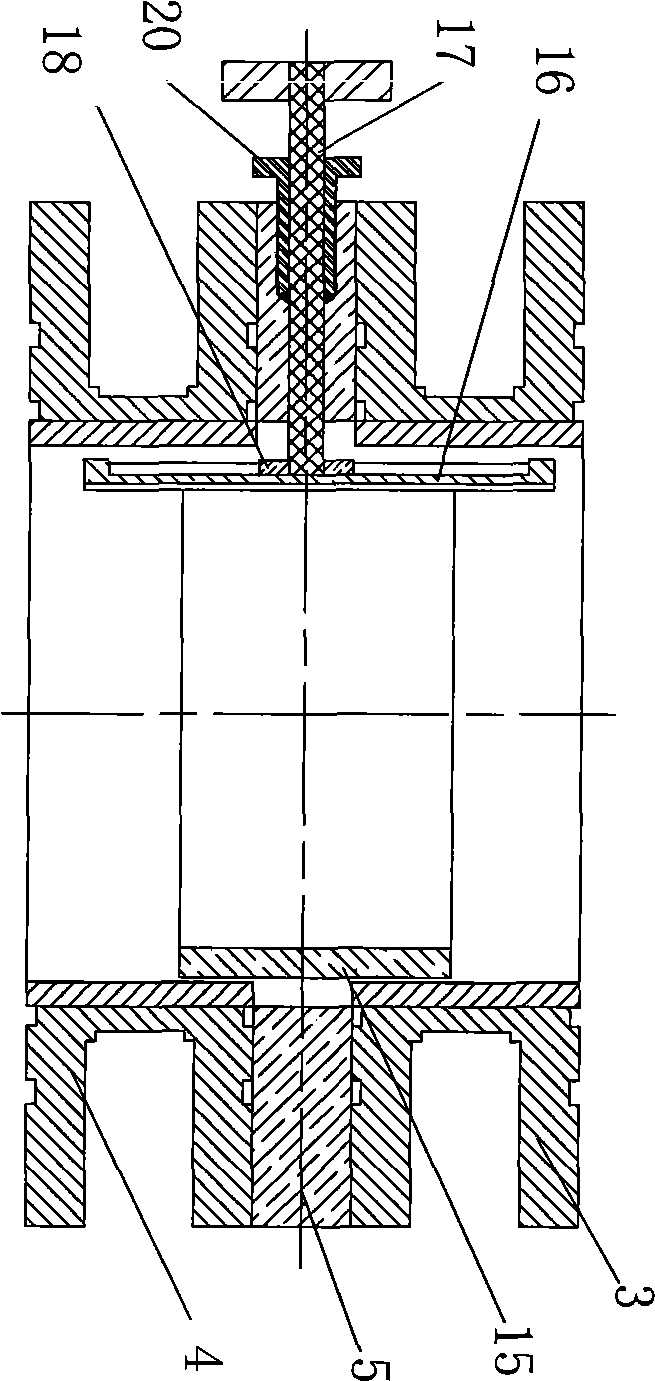

Cavity structure of ECR plasma sputtering apparatus

InactiveCN101509124AAutomate operationThe cavity structure is simpleVacuum evaporation coatingSputtering coatingSputteringElectron cyclotron resonance

The invention relates to an electron cyclotron resonance (ECR) plasma sputtering device and discloses a cavity structure of the ECR plasma sputtering device, which is capable of conveniently changing particle sources. The cavity structure comprises a left vacuum cavity (1), a right vacuum cavity (2) and at least two target cavities (3, 4); wherein, the target cavities (3, 4) are connected between the left vacuum cavity and the right vacuum cavity (1, 2) and are internally provided with targets. The cavity structure is characterized in that a washer (5) is arranged between adjacent target cavities (3, 4) and is provided with a driving rod (17) in the radial direction; the inner end of the driving rod (17) is provided with a gear (18); a sliding check ring (15) is arranged in the adjacent target cavities (3, 4); the outer wall of the check ring (15) is inlaid with a rack (16) in the axial direction; the rack (16) is meshed with the gear (18) and a dynamic sealing equipment is arranged between the washer (5) and the driving rod (17).

Owner:XI AN JIAOTONG UNIV

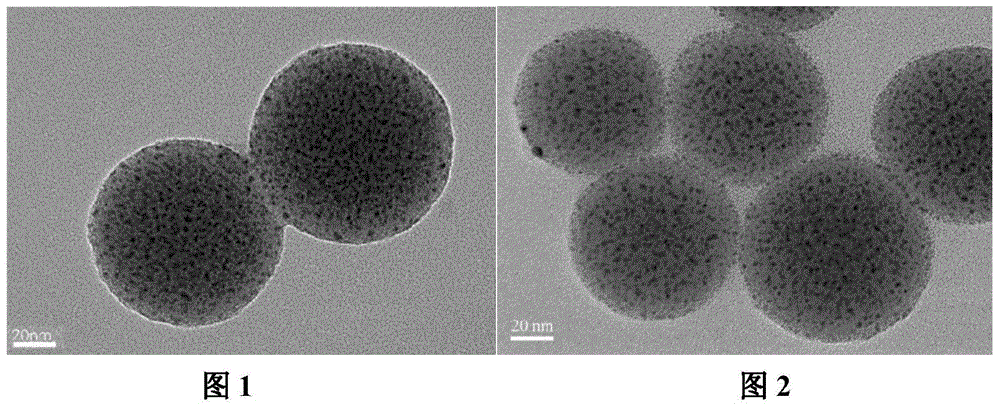

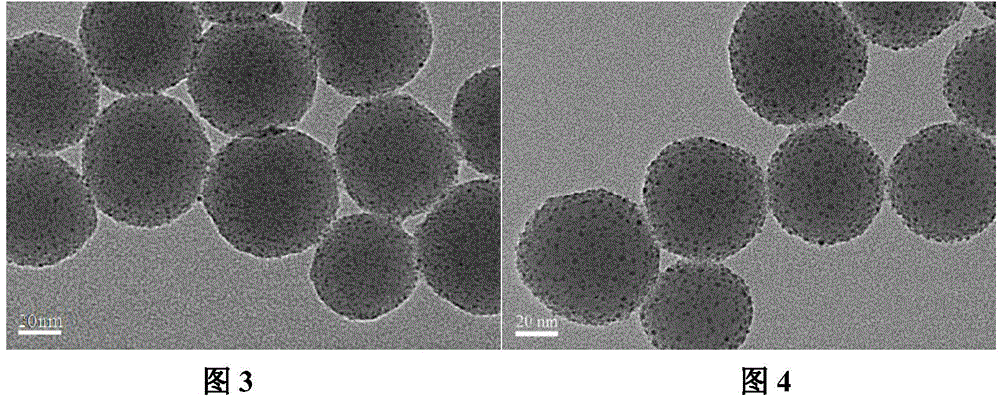

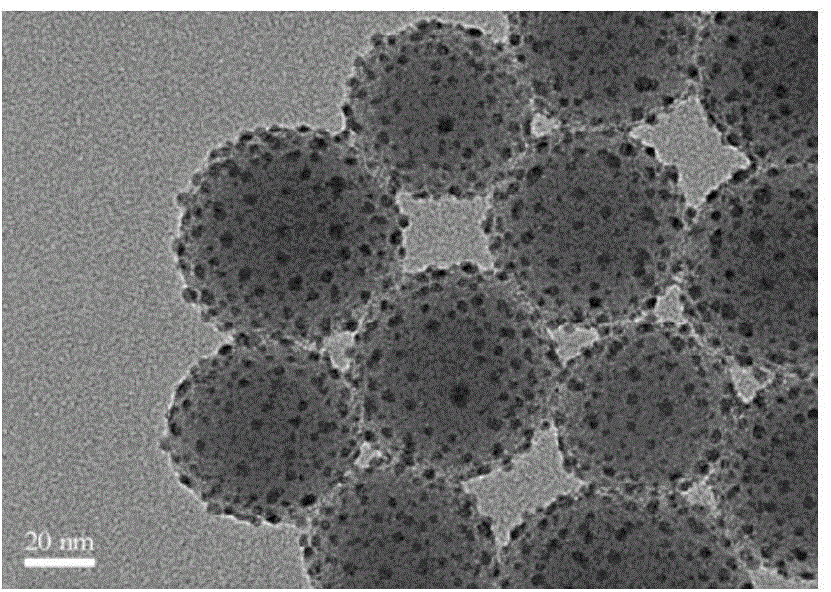

Method for preparing simple and controllable nanoscale silver-loaded monox

InactiveCN104959623AEvenly distributedControllable particle sizeMaterial nanotechnologyProduct systemNano sio2

The invention provides a method for preparing simple and controllable nanoscale silver-loaded monox. The method comprises the specific steps that (1) monodispersed spherical nanometer SiO<2> particles are prepared through a Stober method; (2) a reducibility group is decorated on the surface of a nanometer SiO<2> sphere; (3) silver particles with the diameter of 1-3 nm are reduced on the surface of the nanometer SiO<2> sphere. The obtained silver-loaded monox is regular in form and even in particle size, and the particle size and density of the silver particles on the surface of the silver-loaded monox can be regulated and controlled easily; the overall preparation technology is easy and feasible, a product system is stable, and the industrial preparation potential is achieved.

Owner:SHANGHAI JIAO TONG UNIV +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com