Energy-saving and environment-friendly wood plastic material

A wood-plastic material, energy-saving and environmentally friendly technology, applied in the field of new materials, can solve the problems of non-universal utilization, non-renewable natural resources, destruction of natural resources, etc., to save later repair and maintenance costs, no need for repairs and maintenance, and prolong service life Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

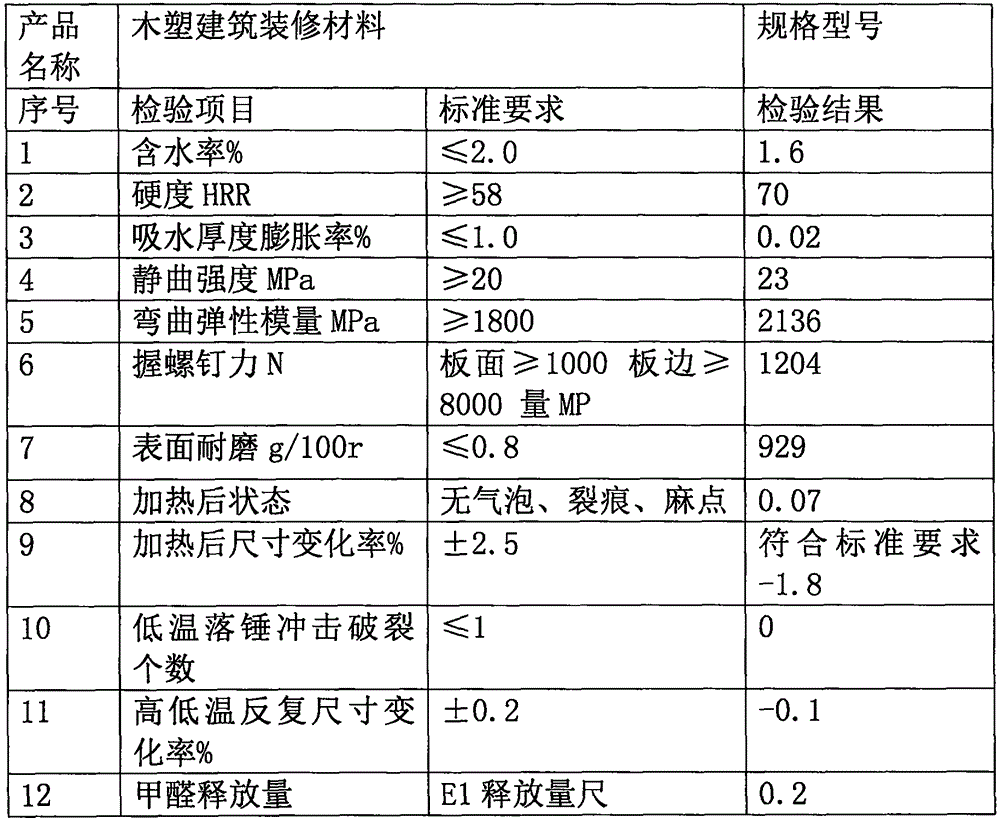

[0033] Weigh 40 parts of polyvinyl chloride resin powder (S-500 type), 30 parts of wood powder (80-120 mesh pine wood powder), 20 parts of calcium carbonate powder (ultrafine carbon light calcium powder 1000-1200 mesh), modifier 2 parts (for PVC impact modifier CPE-135A), 3 parts of processing aid (PVC processing aid ACR-401), 2 parts of foaming agent (NH-213 type), 1 part of stabilizing solvent (21F photothermal calcium zinc stabilizer), 1 part of foaming aid (PVC foam regulator HL-100), 1 part of lubricant (oxidized polyethylene wax OPE), 0.5 part of colorant (iron red).

[0034] The preparation method of the above-mentioned energy-saving and environment-friendly wood-plastic material is as follows:

[0035] 1) Ingredients: mix the above raw materials evenly;

[0036] 2) Hot mixing: Put the uniformly mixed raw materials into the hot mixing pot of the mixer and heat for 20 minutes. After the temperature reaches 120°C, put it into the cold mixing pot for cooling for 20 minute...

Embodiment 2

[0040] An energy-saving and environment-friendly wood-plastic material, comprising the following raw materials in parts by weight: 50 parts of polyvinyl chloride resin powder, 35 parts of wood powder, 28 parts of calcium carbonate powder, 2.4 parts of modifier, 4.7 parts of processing aid, and 2.3 parts of foaming agent , 1.5 parts of a stable solvent, 1.8 parts of a foaming aid, 1.3 parts of a lubricant, and 0.8 parts of a colorant. The model of the polyvinyl chloride resin powder is S-500, S-650, S-700 or waste plastic powder.

[0041] The wood powder is straw powder with a fineness of 120 mesh; the calcium carbonate powder is ultra-fine carbon light calcium powder with 1000 mesh; the modifier is PVC impact modifier ACM-J9; the The processing aid is PVC processing aid HL-175S; the foaming agent is NH-213 type; the stabilizing solvent is (lead-free type) 21F photothermal calcium zinc stabilizer; the foaming aid PVC foam regulator ACR-530; the lubricant is epoxy soybean oil D...

Embodiment 3

[0048] An energy-saving and environment-friendly wood-plastic material, comprising the following raw materials in parts by weight: 60 parts of polyvinyl chloride resin powder, 25 parts of wood powder, 20 parts of calcium carbonate powder, 3 parts of modifier, 5 parts of processing aid, and 3 parts of foaming agent , 2 parts of stabilizing solvent, 2 parts of foaming aid, 1.5 parts of lubricant, and 1 part of colorant.

[0049] The model of the polyvinyl chloride resin powder is S-700; the wood powder is straw powder with a fineness of 80 mesh; the calcium carbonate powder is ultra-fine carbon light calcium powder with 1200 mesh; the modified The neutralizer is PVC impact modifier CPE-135A; the processing aid is PVC processing aid HL-175S; the foaming agent is NH-213 type; the stable solvent is (lead-free type ) 21F photothermal calcium-zinc stabilizer; the foaming aid is PVC foam regulator ACR-530; the lubricant is epoxy soybean oil DOP; the colorant is purple.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com