Patents

Literature

92results about How to "More color" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

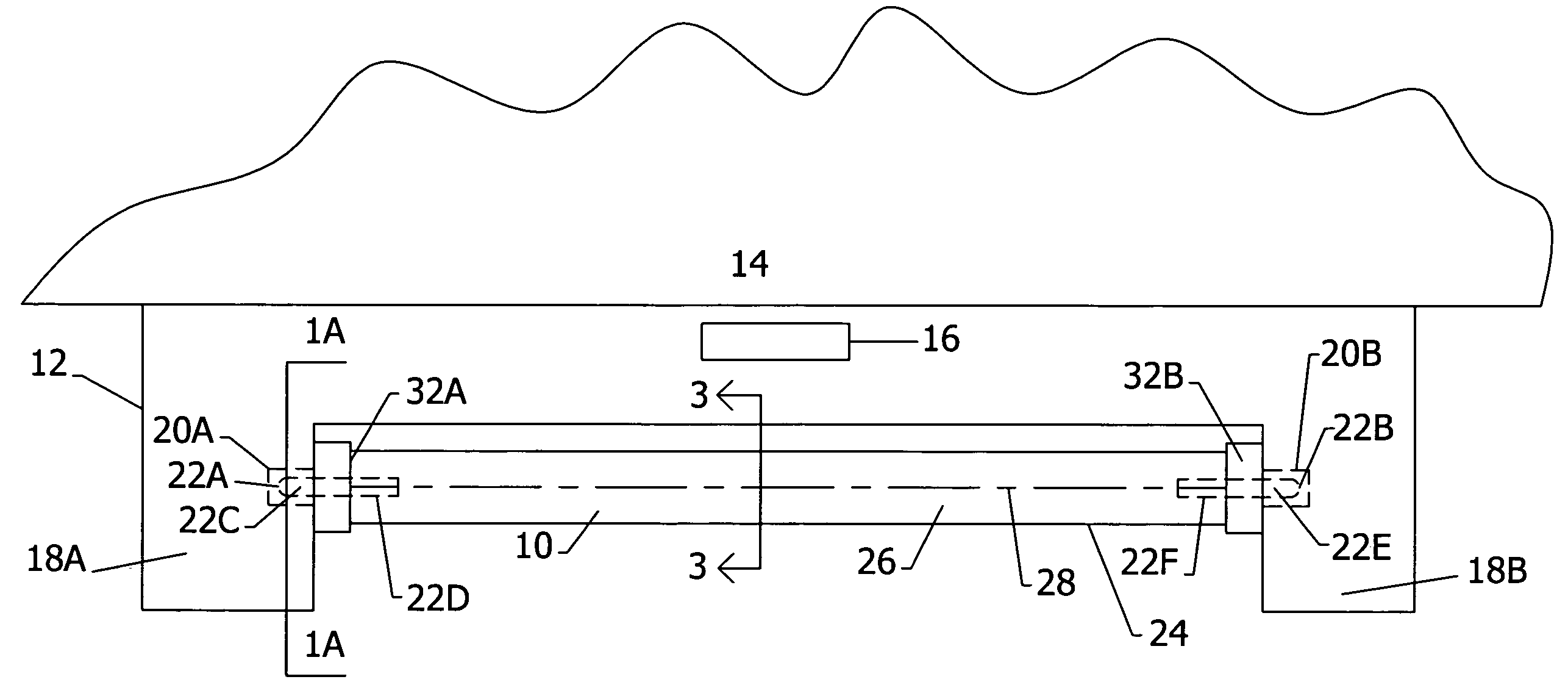

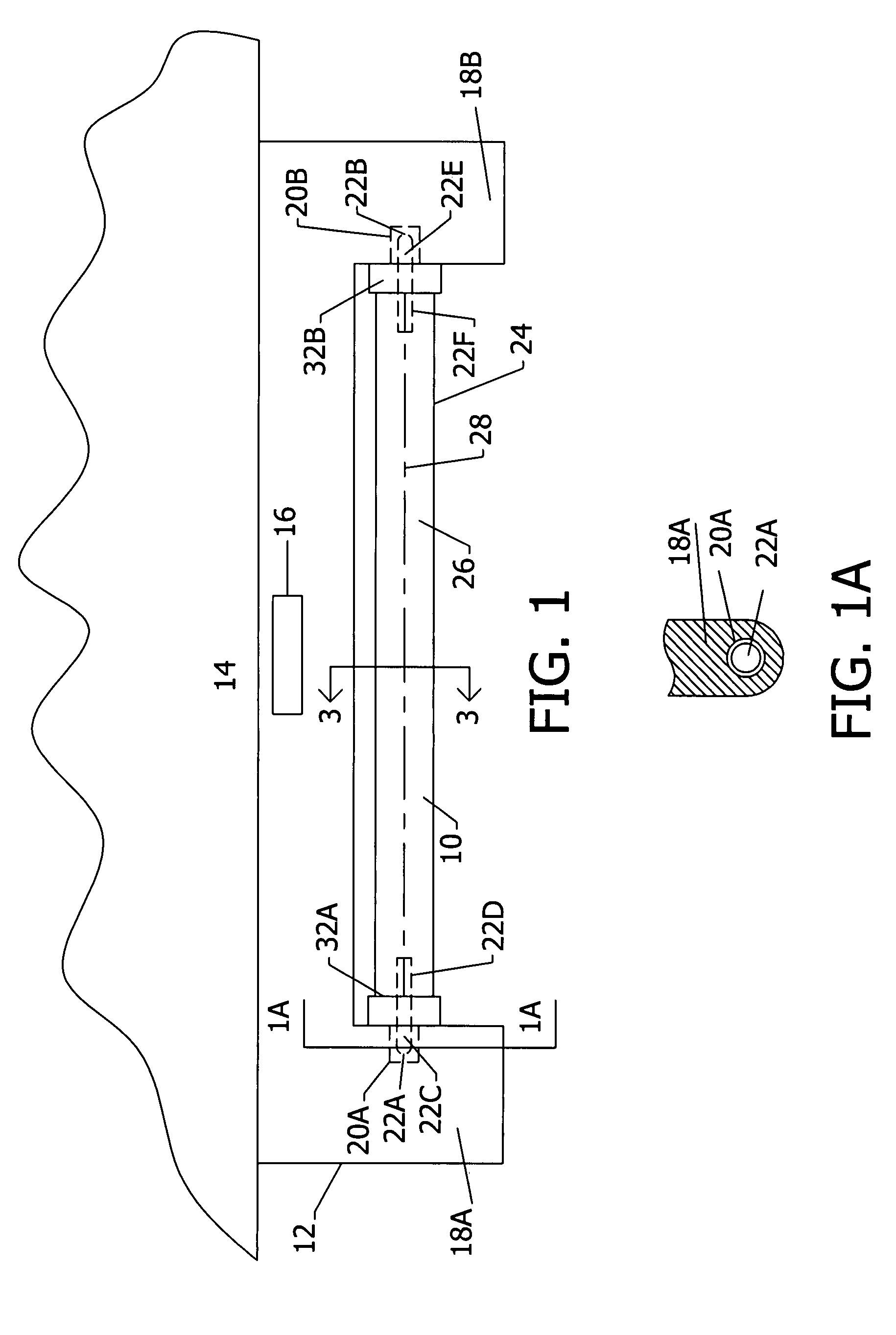

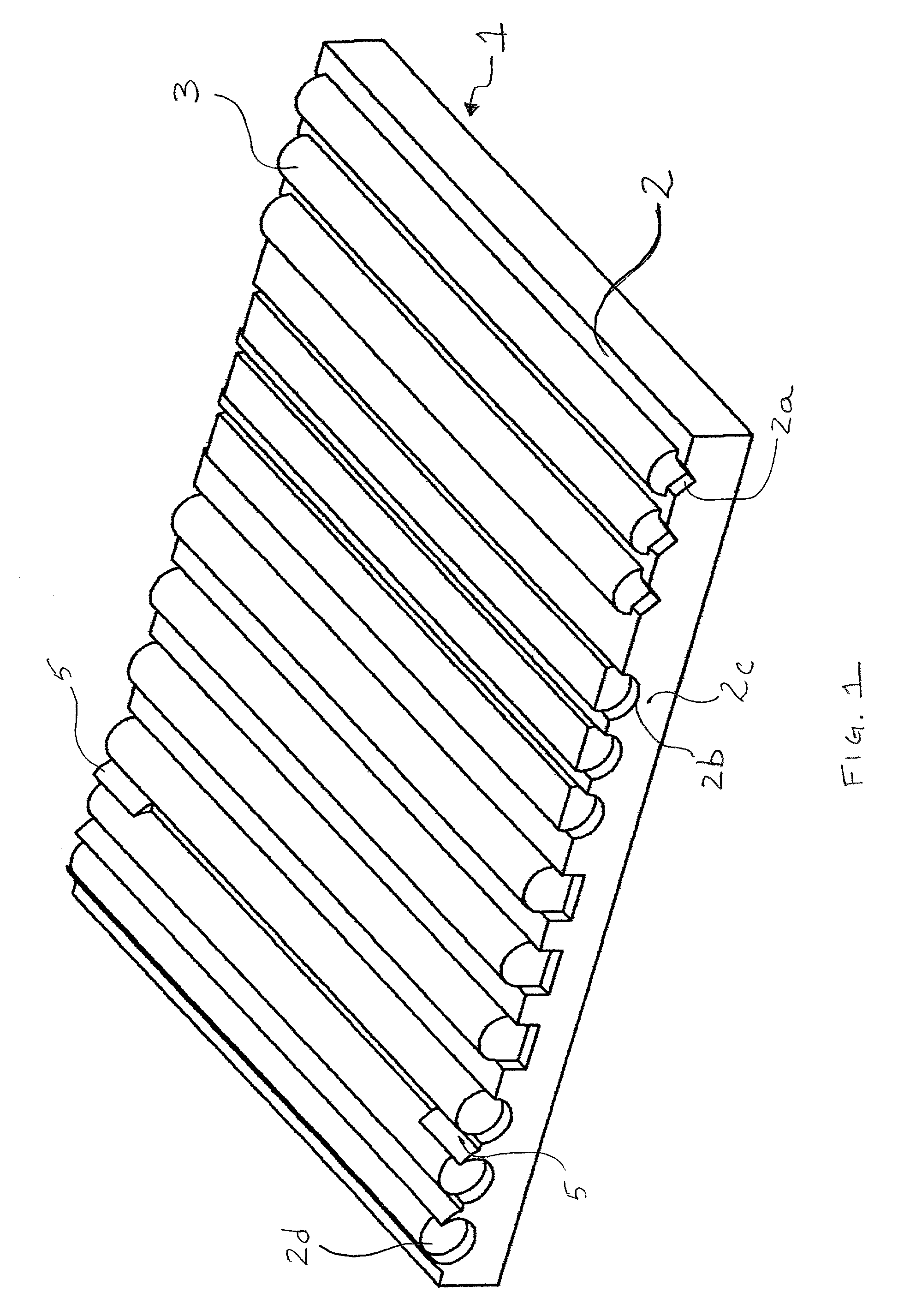

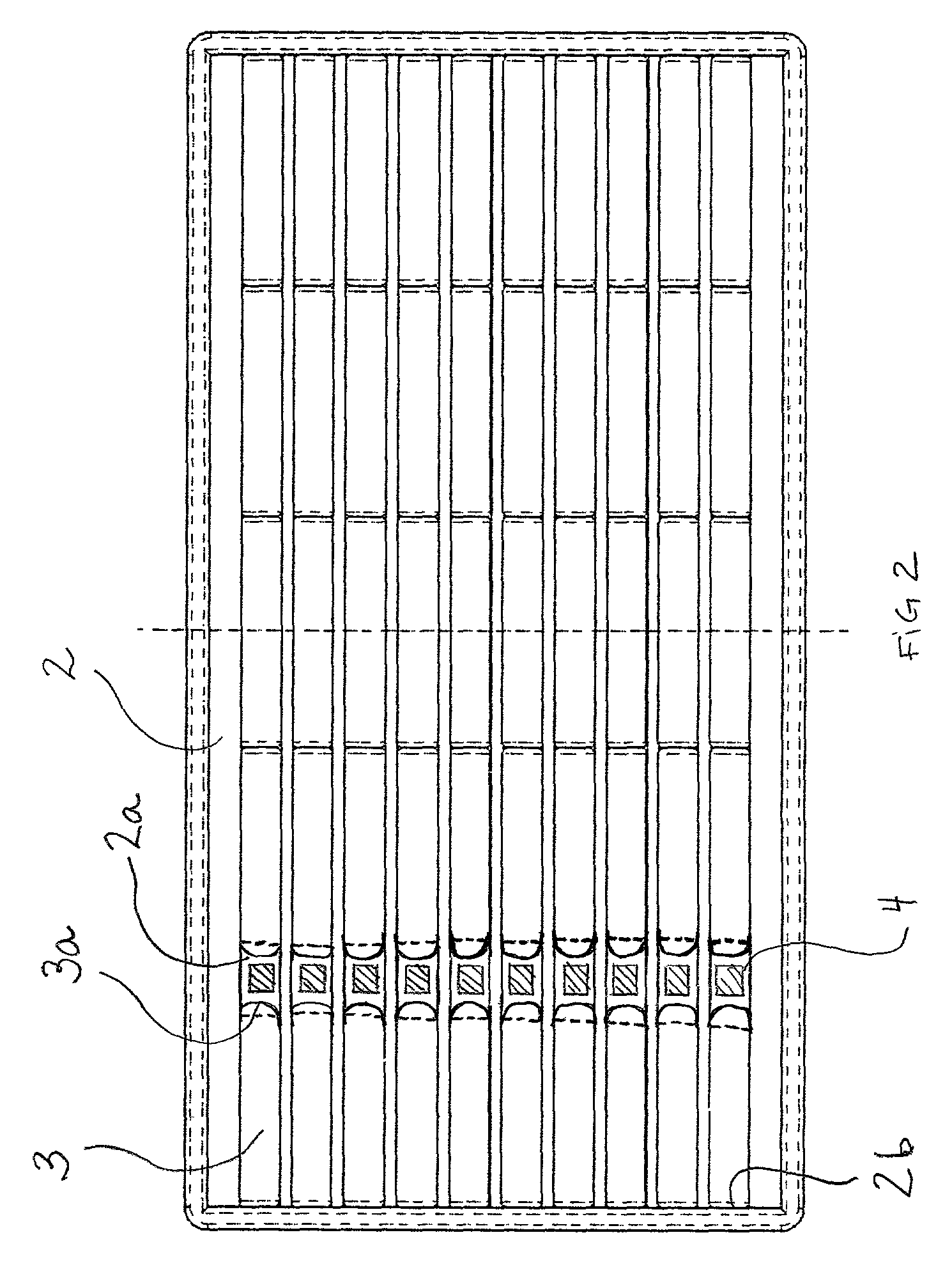

Retrofit LED lamp for fluorescent fixtures without ballast

ActiveUS7507001B2Reduce flickerReduce usageLighting support devicesPoint-like light sourceFluorescenceNetwork communication

An energy saving device for an LED lamp mounted to an existing fixture for a fluorescent lamp where the ballast is removed or bypassed. The LEDs are positioned within a tube and electrical power is delivered from a power source to the LEDs. The LED lamp includes means for controlling the delivery of the electrical power from the power source to the LEDs, wherein the use of electrical power can be reduced or eliminated automatically during periods of non-use. Such means for controlling includes means for detecting the level of daylight in the illumination area of said least one LED, in particular a light level photosensor, and means for transmitting to the means for controlling relating to the detected level of daylight from the photosensor. The photosensor can be used in operative association with an on-off switch in power connection to the LEDs, a timer, or with a computer or logic gate array in operative association with a switch, timer, or dimmer that regulates the power to the LEDs. An occupancy sensor that detects motion or a person in the illumination area of the LEDs can be also be used in association with the photosensor and the computer, switch, timer, or dimmer, or in solo operation by itself. Two or more such LED lamps with a computer or logic gate array used with at least one of the lamps can be in network communication with at least one photosensor and / or at least one occupancy sensor to control the power to all the LEDs.

Owner:SIGNIFY HLDG BV

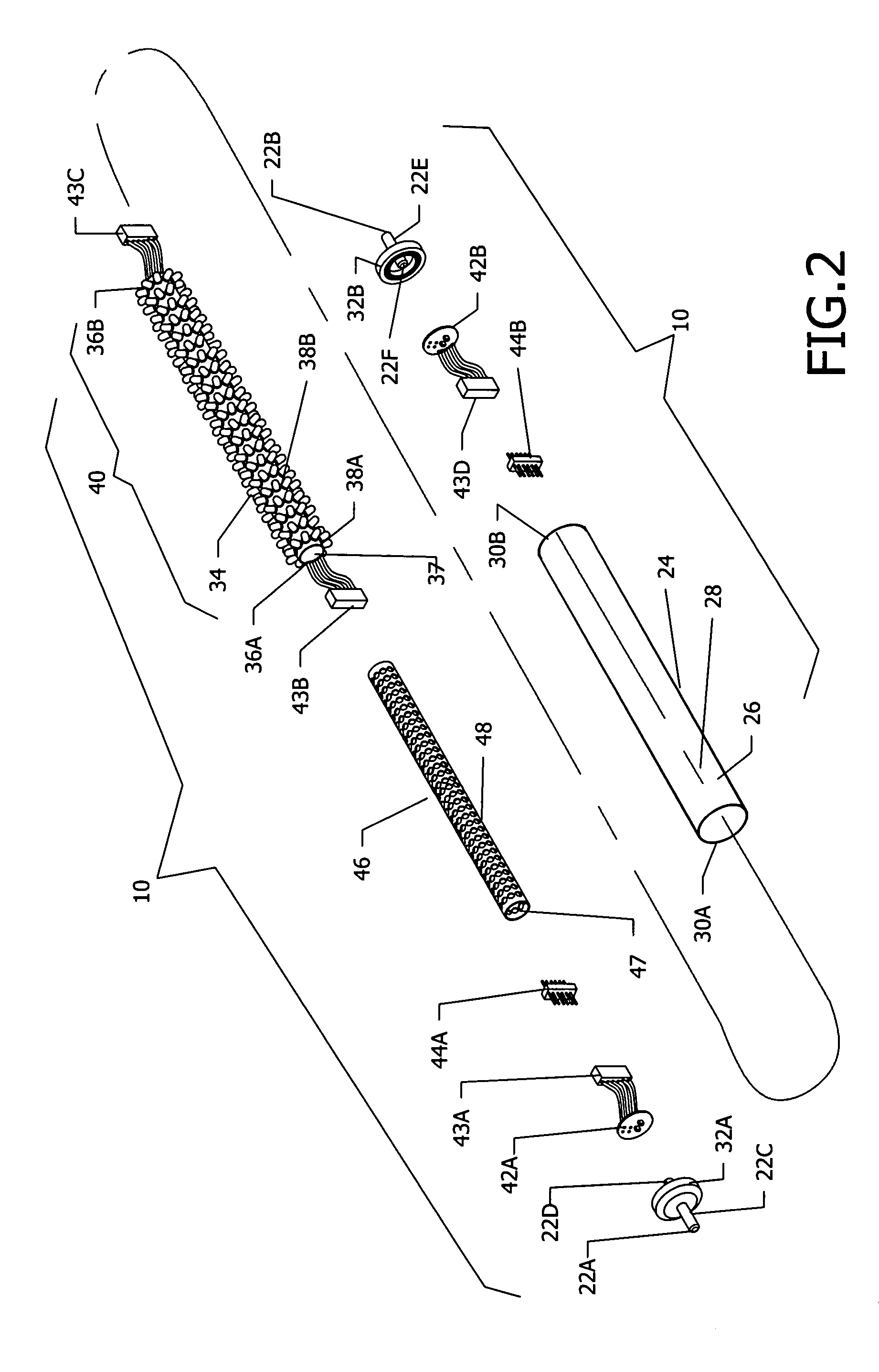

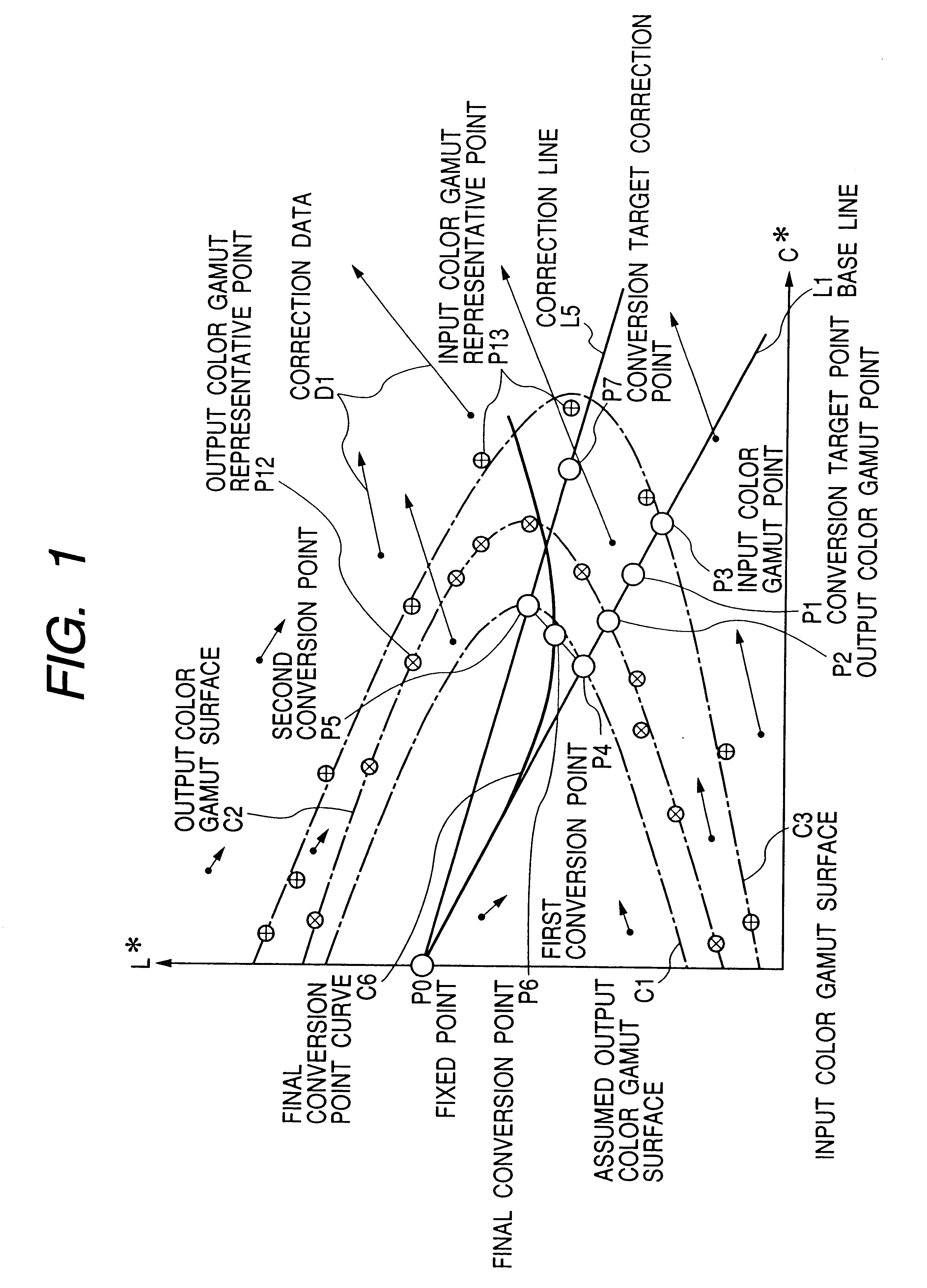

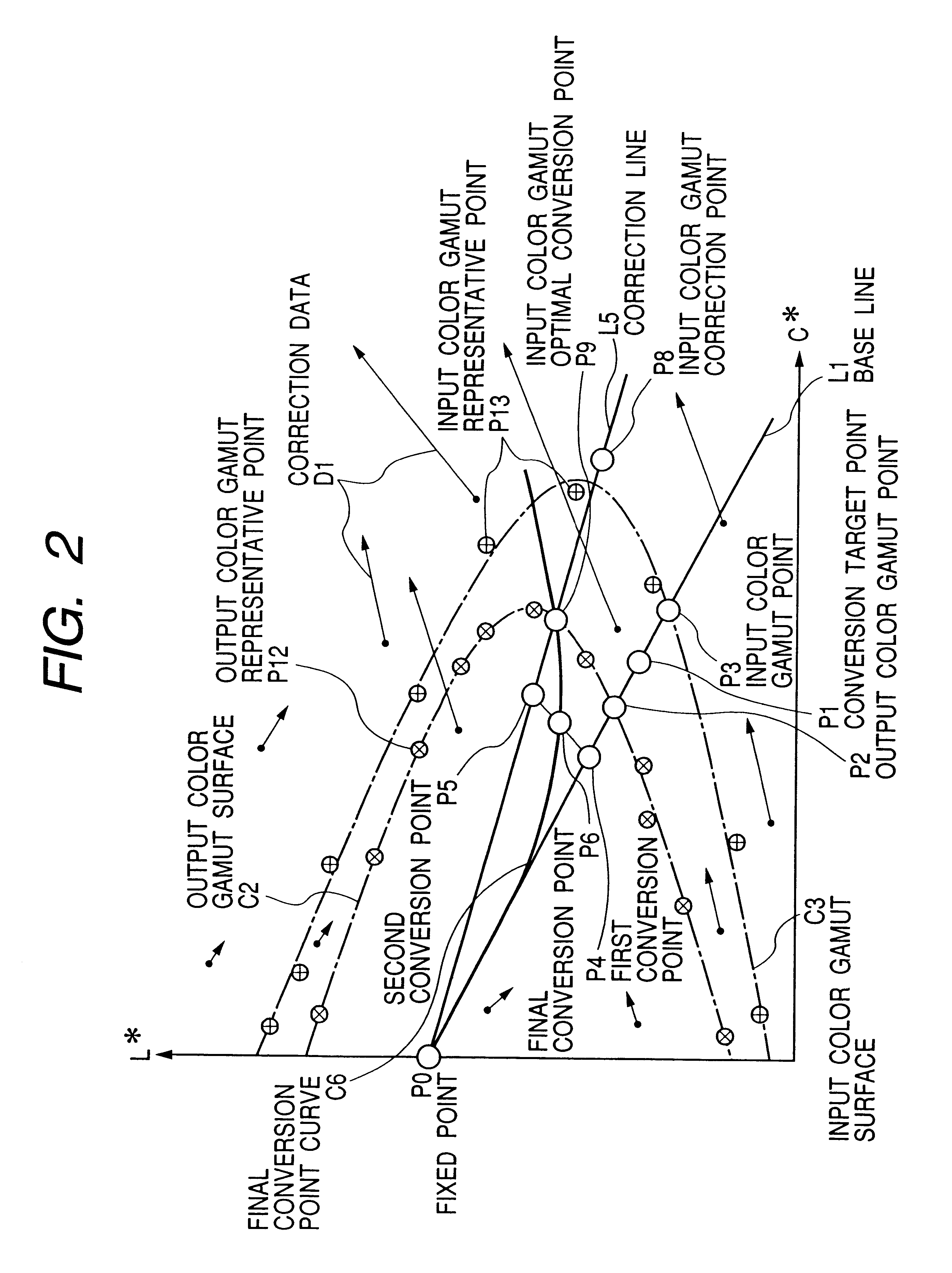

Image processing method and image processing apparatus

InactiveUS6724507B1More colorColour-separation/tonal-correctionPictoral communicationColor imageColor transformation

Provided is an image processing method and a apparatus of converting a color input image or a partial region thereof in accordance with a color gamut of a color image output apparatus is provided. The method and apparatus is characterized in that only the region requiring color gamut compression can be put to color gamut compression depending on the distribution of an input image, that the direction of the color gamut compression can be controlled continuously for each of the regions; the amount of the color gamut compression can be controlled continuously including clipping, that when color gamut compression is conducted by a color converter of a multi-dimensional DLUT interpolating calculation type, an excessively unnecessary color gamut compression can be avoided particularly upon clipping, and that there is enabled correction for visual bending in iso-hue lines caused by distortion of a color space in each of the regions of the color space.

Owner:FUJIFILM BUSINESS INNOVATION CORP

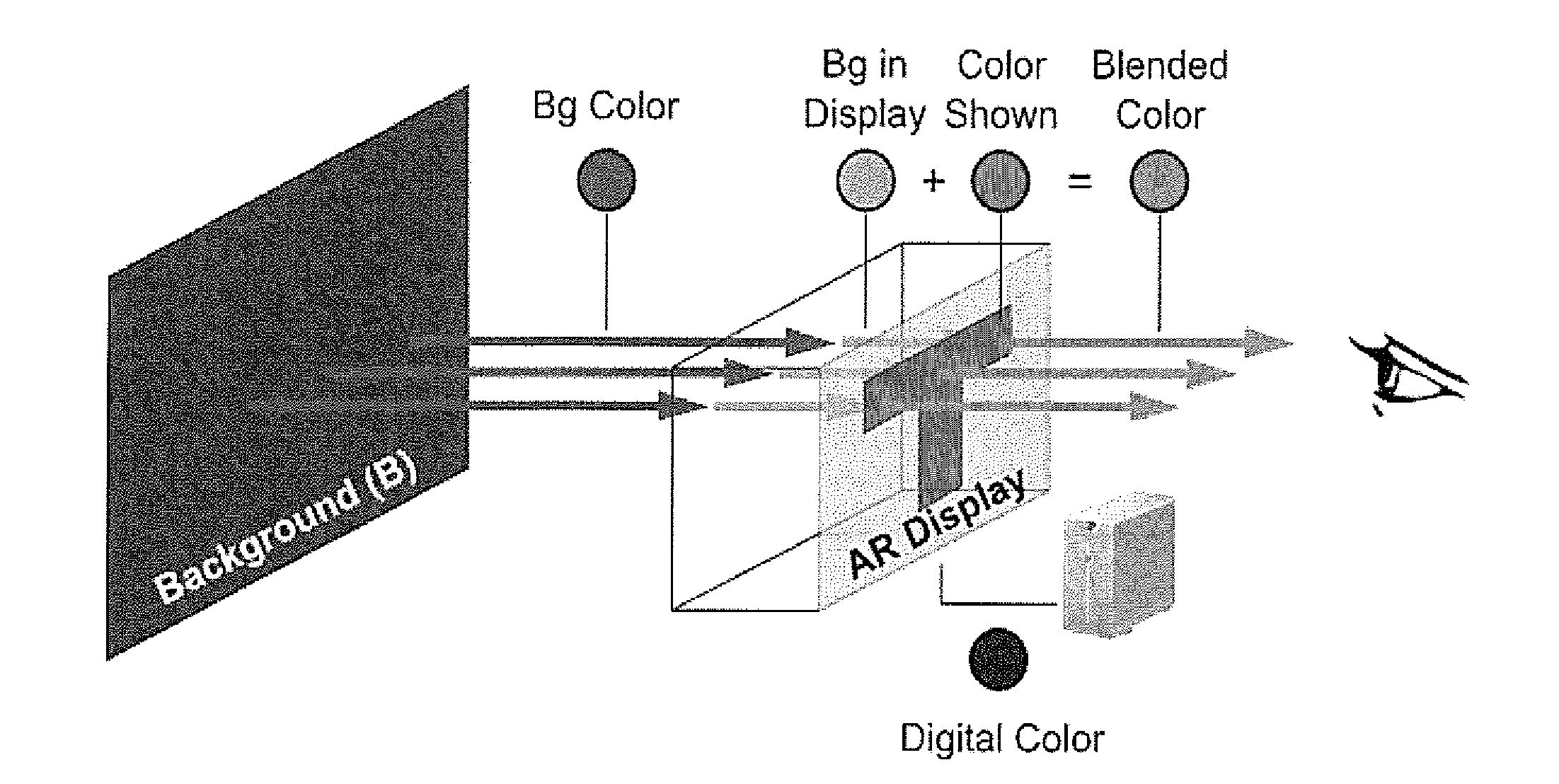

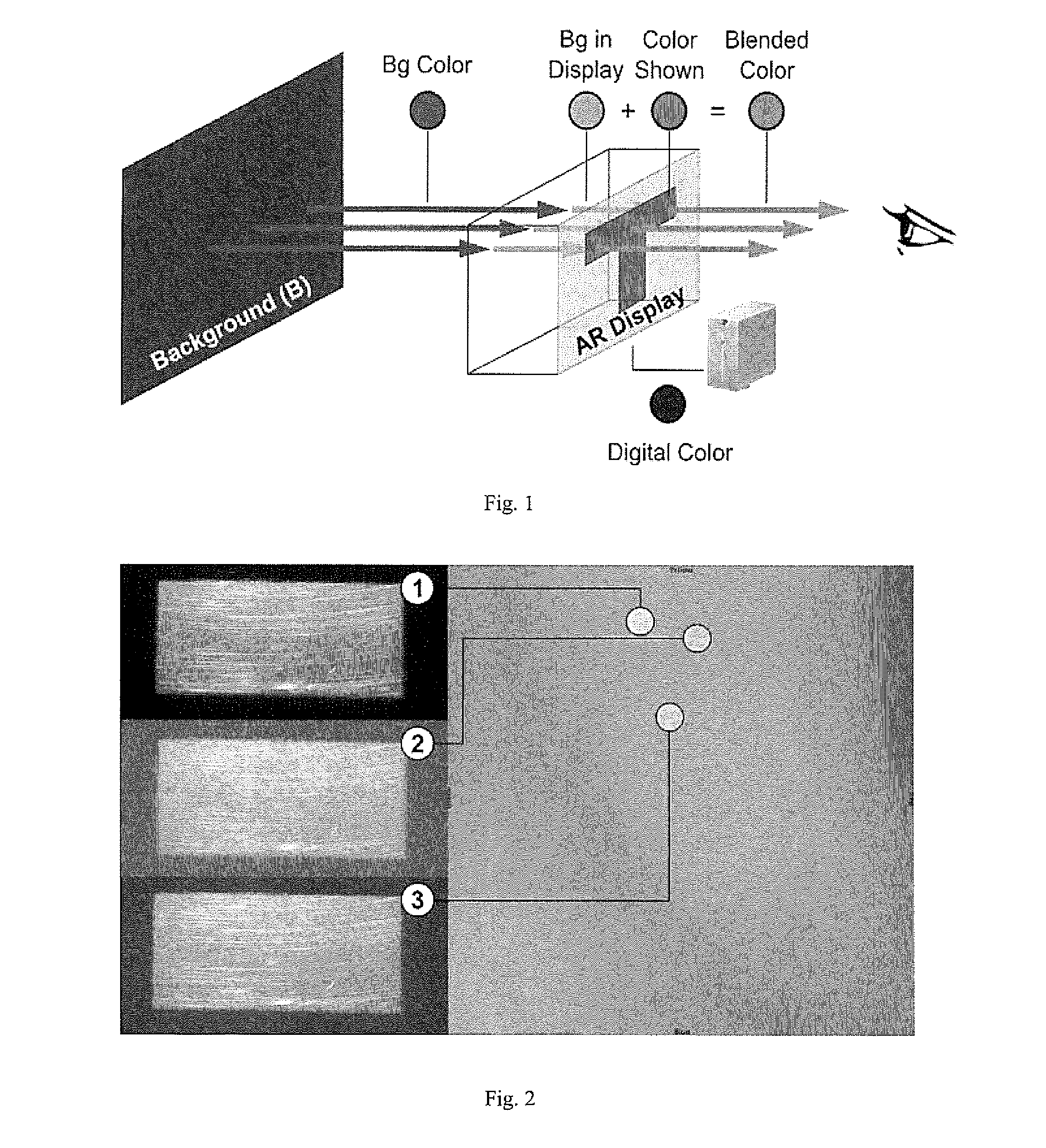

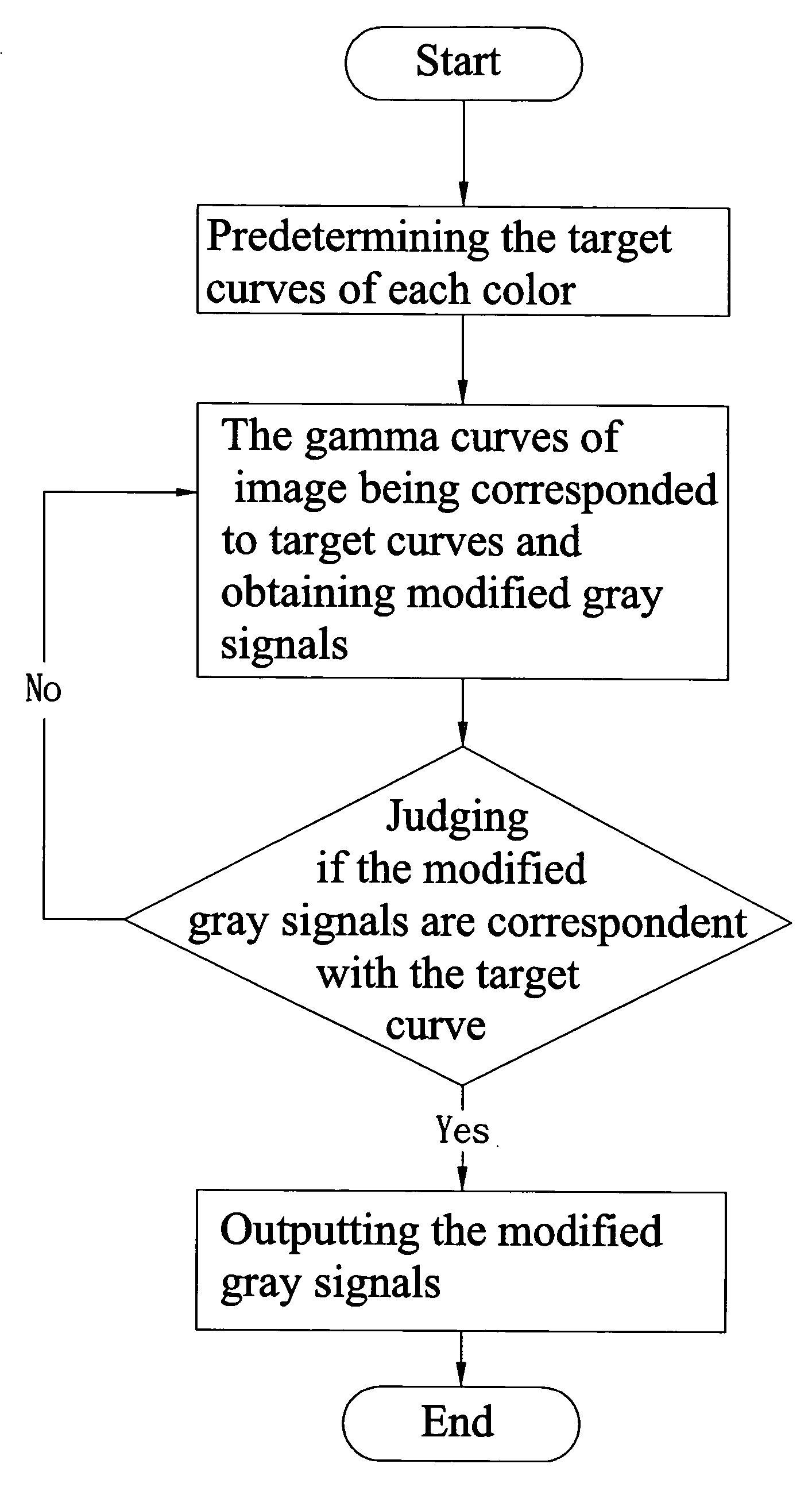

Color Correction Method for Optical See-Through Displays

InactiveUS20160240125A1Effective coloringMore colorCathode-ray tube indicatorsOptical elementsGraphicsGraphical content

In a method of correcting a desired color of a pixel to be displayed in an optical see-through display, a binned-display profile of prescribed colors arranged to be rendered by the display include background colors added to it so that the desired color can be matched to a closest one of the resulting predicted color profile of colors which are predicted to be perceived by a user. The display is then instructed to display the prescribed color which corresponds with the closest matching predicted color such that an observer substantially perceives the desired color. Typically the desired color is only compared to a subset of the predicted colors for efficiency. Additional corrections may take place to improve contrast of graphical content compared to the background in some instance.

Owner:UNIVERSITY OF MANITOBA

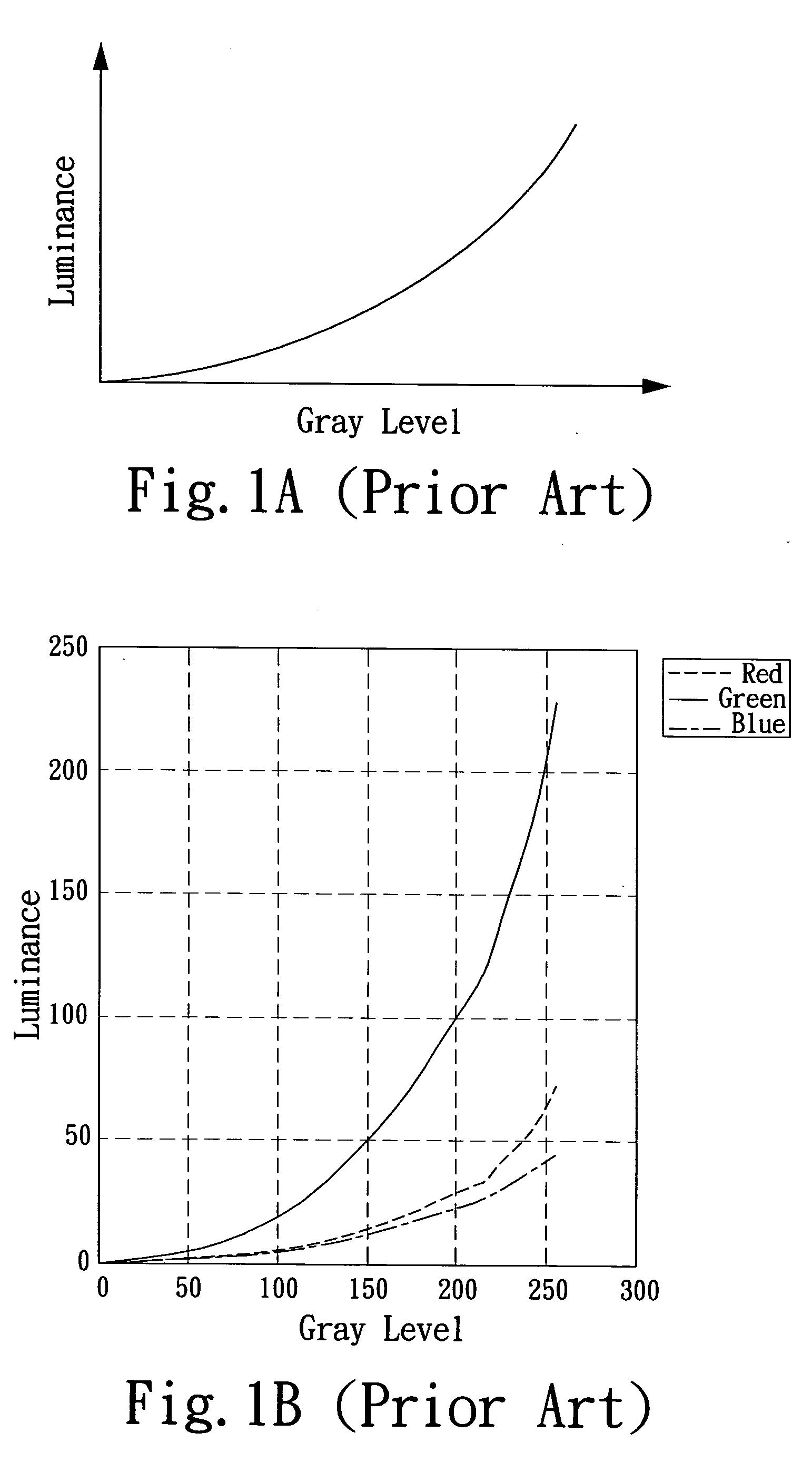

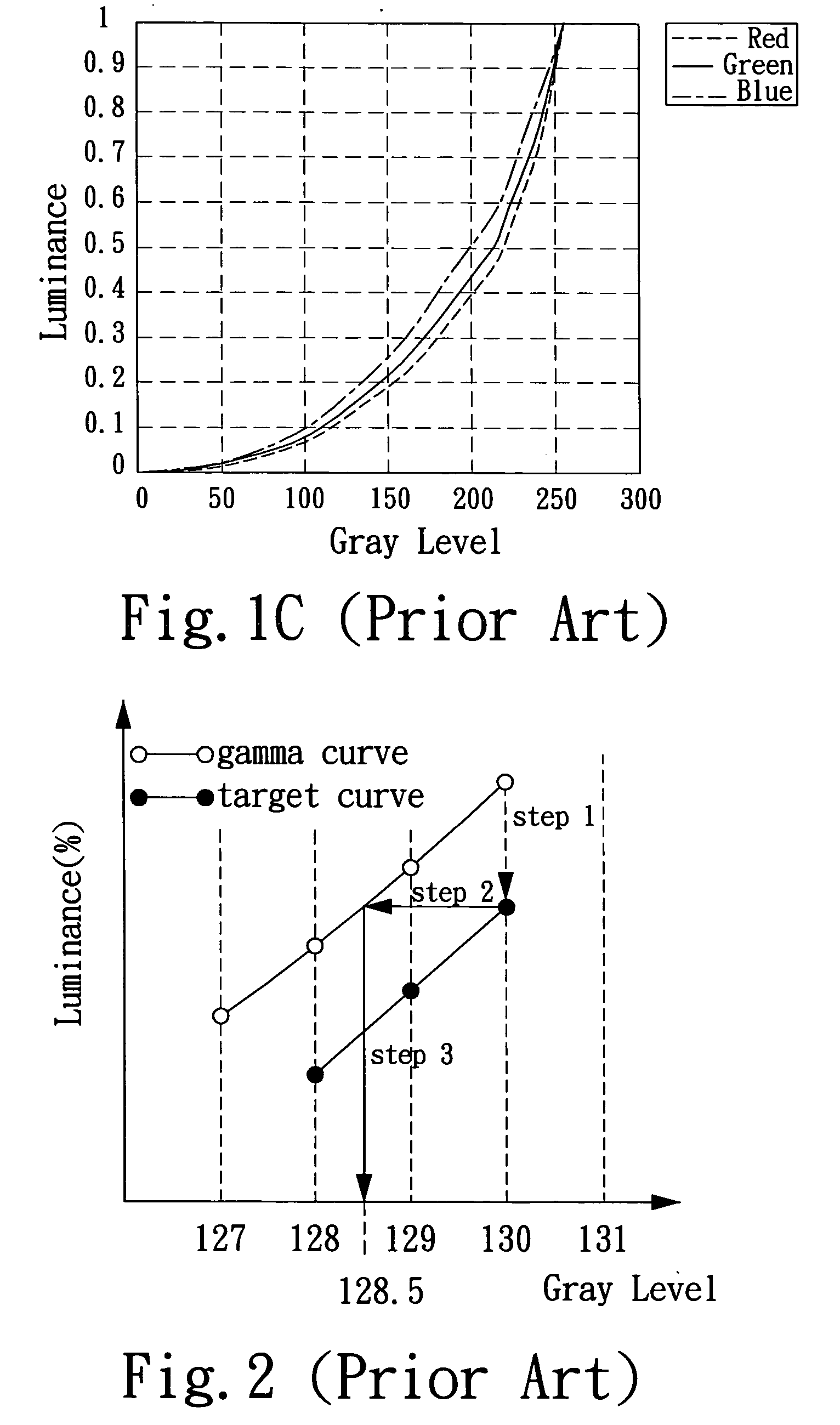

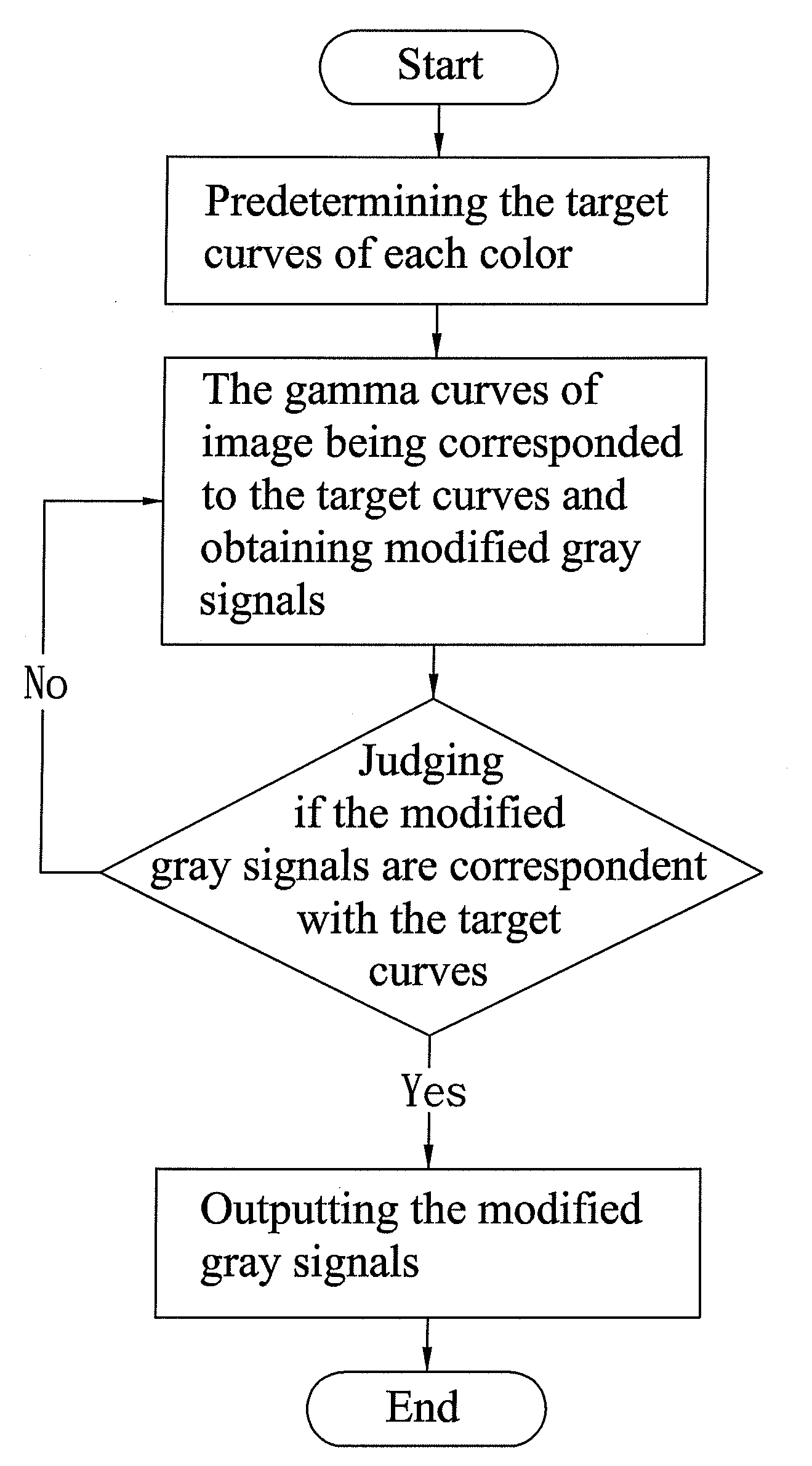

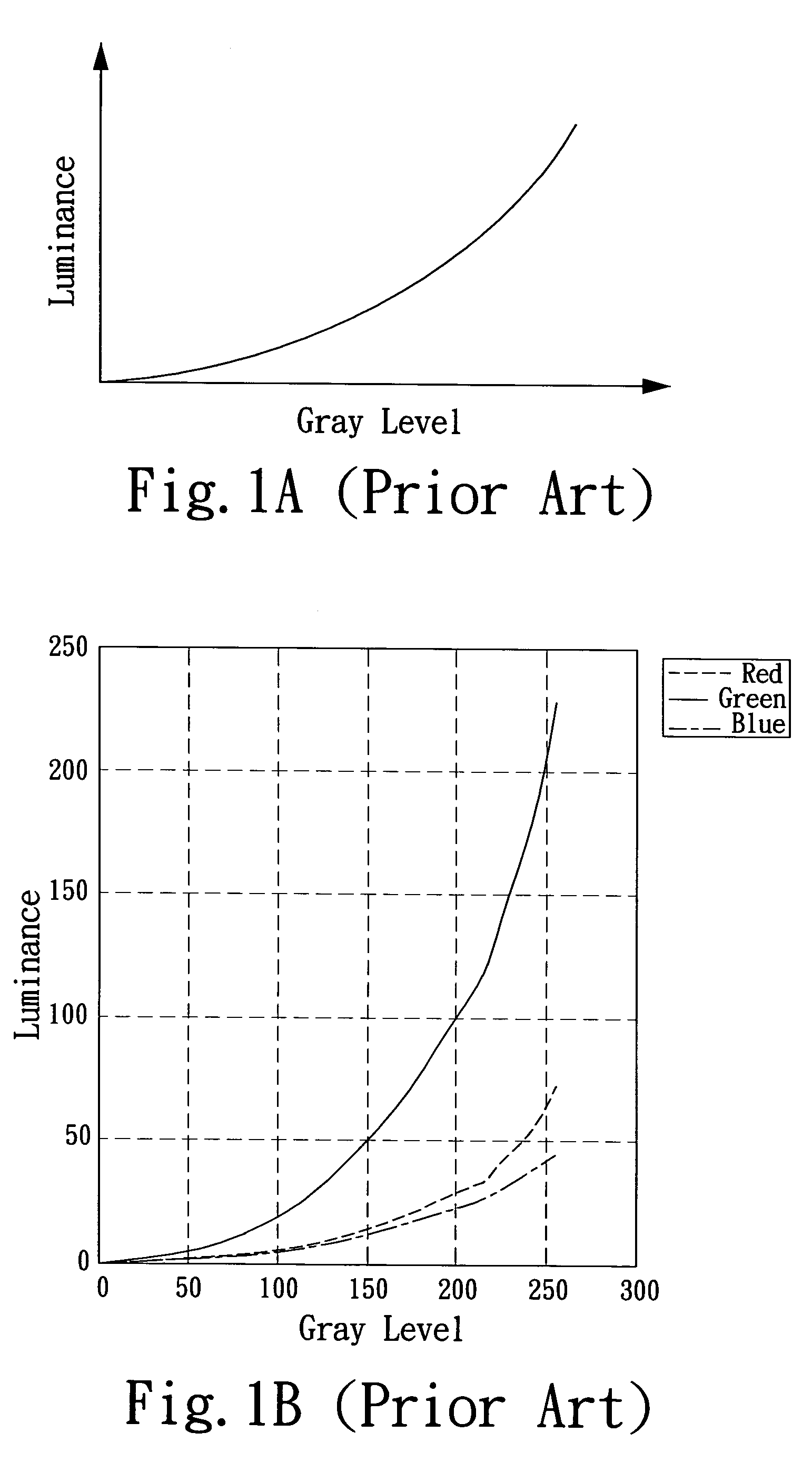

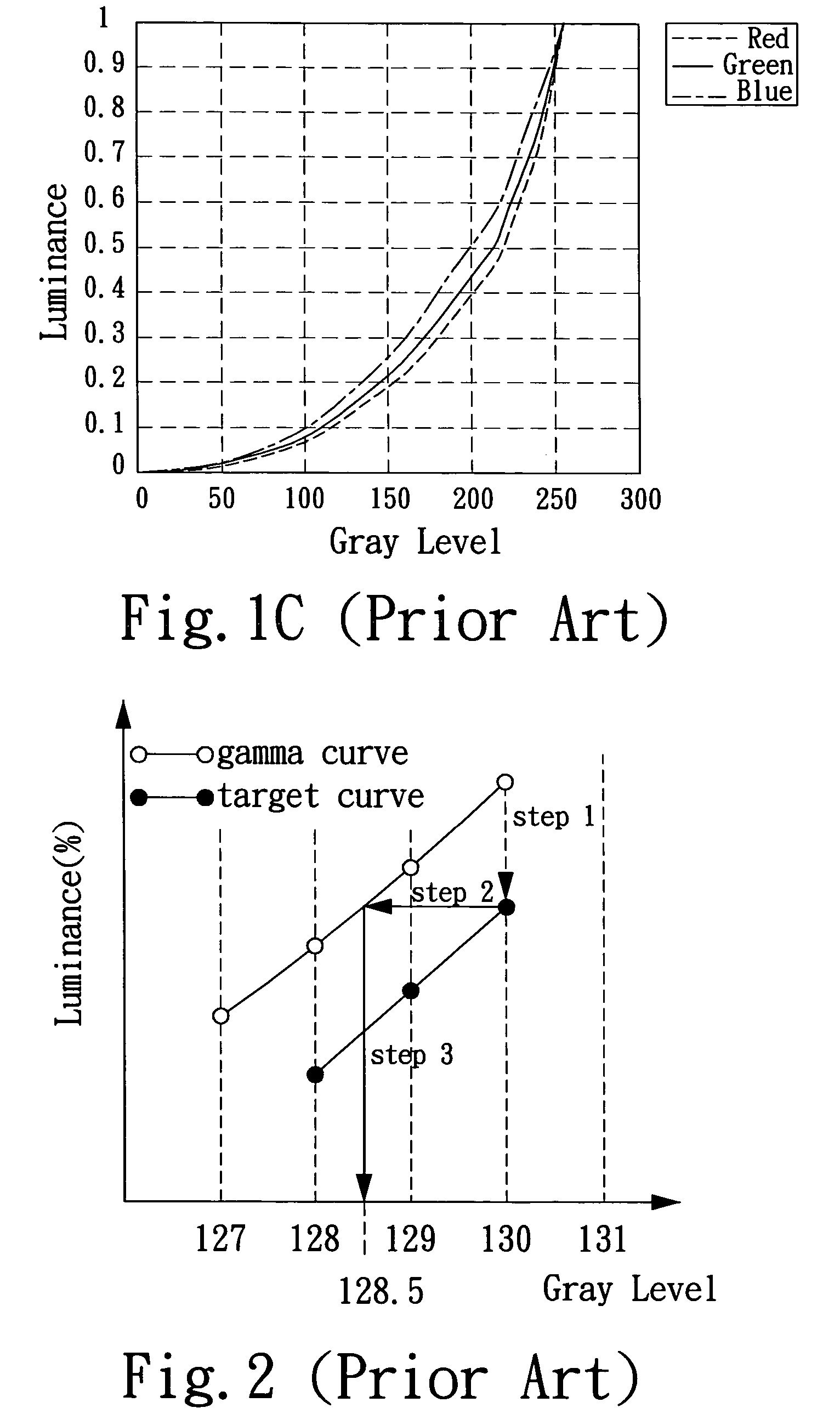

Method for color correction

InactiveUS20050201615A1Quickly luminanceShorten the timeTelevision system detailsDigitally marking record carriersLiquid-crystal displayGray level

A method for color correction is provided. In this method, a plurality of groups of gray levels and luminance of light source of display device are respectively selected by color measurement system. The selected data of each color light are respectively calculated to obtain fitting functions which can fit the gray level data of each interval. The fitting luminance of the gray levels in interval is obtained by the fitting function and formed into a lookup table. Then in order to correspond a gamma curve of normalized gray data of image to a predetermined target curve, the two gamma curves are first taken to logarithmic calculation and the modified gray signals are obtained from the lookup table, then the modified gray signals are transmitted out for providing the display device to express the gray distribution state. The method for color correction is applicable to various display devices, especially liquid crystal display device.

Owner:VASTVIEW TECH

Coloured cementing material for paving road surface and its preparation method

InactiveCN1478955ASimple preparation processSave energyIn situ pavingsEpoxy resin adhesivesEpoxyDiluent

A color cementing material for paving is prepared from epoxy resin, diluent, toughening agent, inorganic pigment and solidifying agent through stirring. Its advantages are ordinary-temp application, high adhesion and resistance to high temp, low temp and abrasion, and long service life.

Owner:CHONGQING POFUN TRAFFIC TECH

Method for color correction

InactiveUS7375854B2Quickly luminanceShorten the timeTelevision system detailsDigitally marking record carriersLiquid-crystal displayGray level

A method for color correction is provided. In this method, a plurality of groups of gray levels and luminance of light source of display device are respectively selected by color measurement system. The selected data of each color light are respectively calculated to obtain fitting functions which can fit the gray level data of each interval. The fitting luminance of the gray levels in interval is obtained by the fitting function and formed into a lookup table. Then in order to correspond a gamma curve of normalized gray data of image to a predetermined target curve, the two gamma curves are first taken to logarithmic calculation and the modified gray signals are obtained from the lookup table, then the modified gray signals are transmitted out for providing the display device to express the gray distribution state. The method for color correction is applicable to various display devices, especially liquid crystal display device.

Owner:VASTVIEW TECH

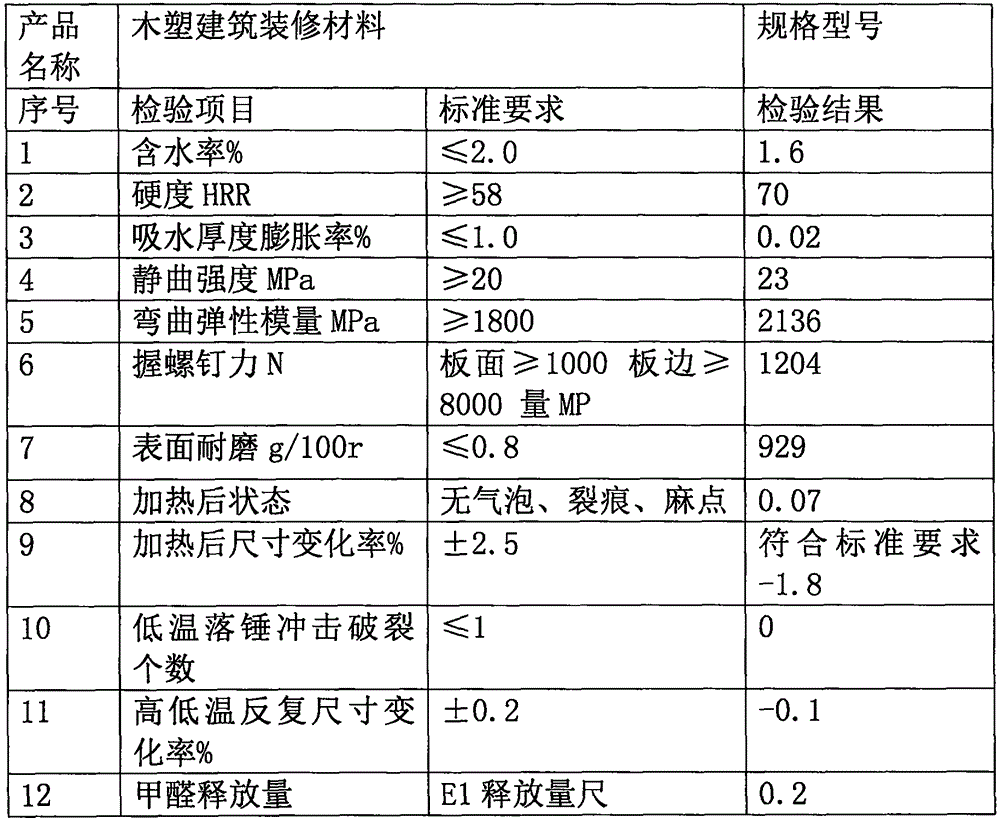

Composite ecological wood

The invention provides composite ecological wood. The wood comprises the following compositions in percentage by weight: 35 to 40 percent of wood meal, 40 to 49 percent of PVC, 2 to 3 percent of calcium carbonate, 4 to 6 percent of a foaming regulator, 4 to 6 percent of a stabilizing agent, 4 to 6 percent of impact-resistant ACR, 0.5 to 1.5 percent of a processing additive ACR, 0.2 to 0.4 percent of toner, an internal lubricant and an external lubricant, a foaming agent accounting for 0.1 to 1 percent of the PVC and a coupling agent accounting for 3 to 5 percent of the wood meal; and when a product is used outdoors, the product also comprises an antioxidant, an ultraviolet absorbent and a light stabilizing agent which have 0.1 to 0.5 percent of weight portions respectively. Compared with the prior art, the composite ecological wood thoroughly overcomes the disadvantages of raw wood, improves the shortage of the raw wood and keeps the particular wooden texture of the raw wood; simultaneously, for the addition of the antioxidant, the ultraviolet absorbent and the light stabilizing agent, the composite ecological wood also prevents photooxidation, fading, cracking and the like caused by ultraviolet irradiation, increases the weather resistance and prolongs the service life.

Owner:孙玉武

Case for presenting and using cosmetic powders

InactiveUS7117874B2The implementation process is simpleEasy to manufacturePackaging toiletriesPackaging cosmeticsComing outMaterials science

A case for extruded powders comprising a surface having at least one groove with extruded powders disposed therein. The powders are preferably not all the same color. Preferably, forty percent or more of each extruded powder rises above the surface and preferably, the cross sectional shape of each groove matches the cross sectional shape of that part of the extruded powder that is disposed in the groove. Optional dividers separate the extruded powders so that they do not contact each other. Optional restraints inhibit the powders from coming out of the grooves. Also optional are an outer container into which the surface is disposed and cover to protect the powders when not in use. The case may comprise other cosmetic elements such as an applicator, a mirror or a pan or pressed powder.

Owner:E L MANAGEMENT

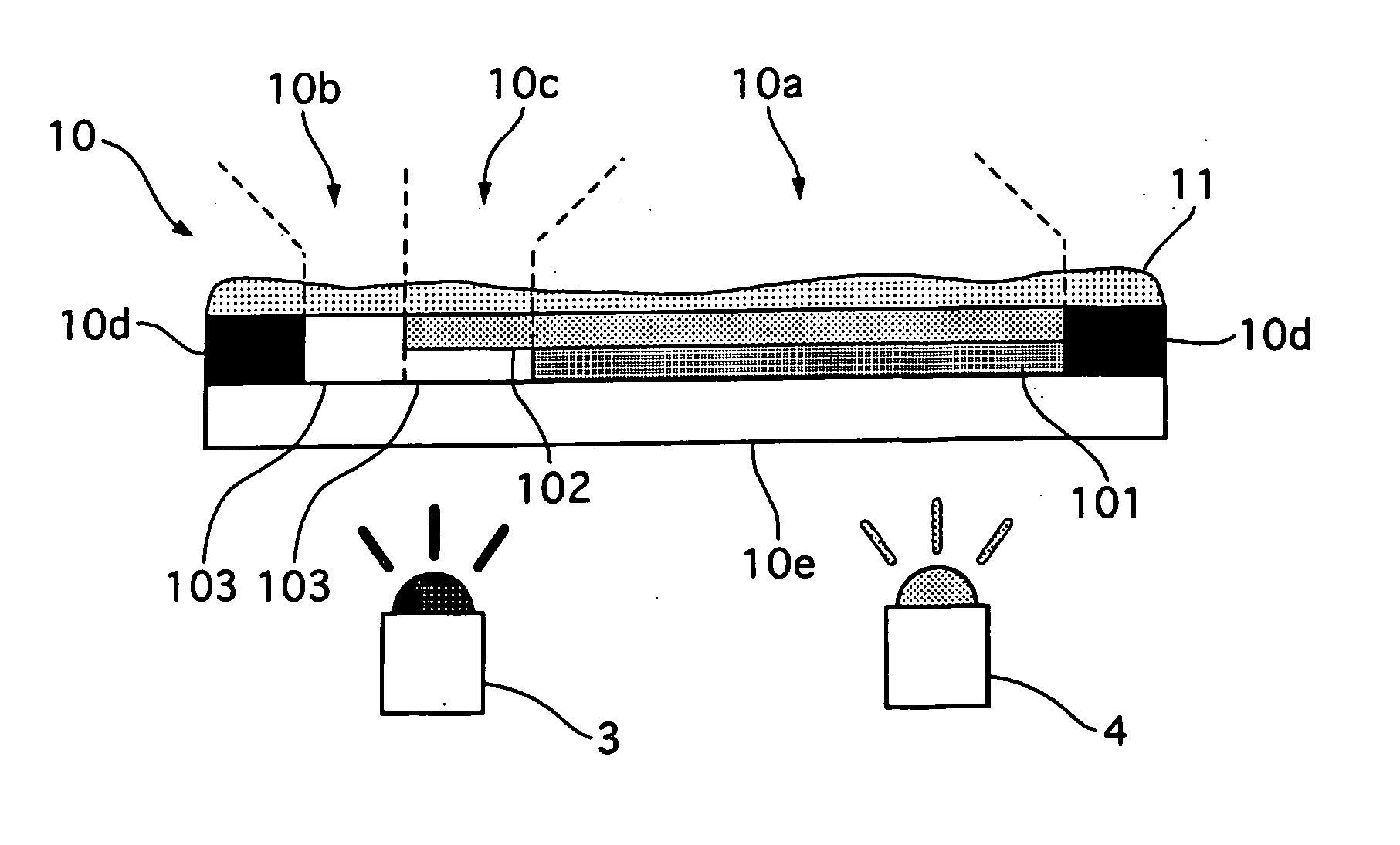

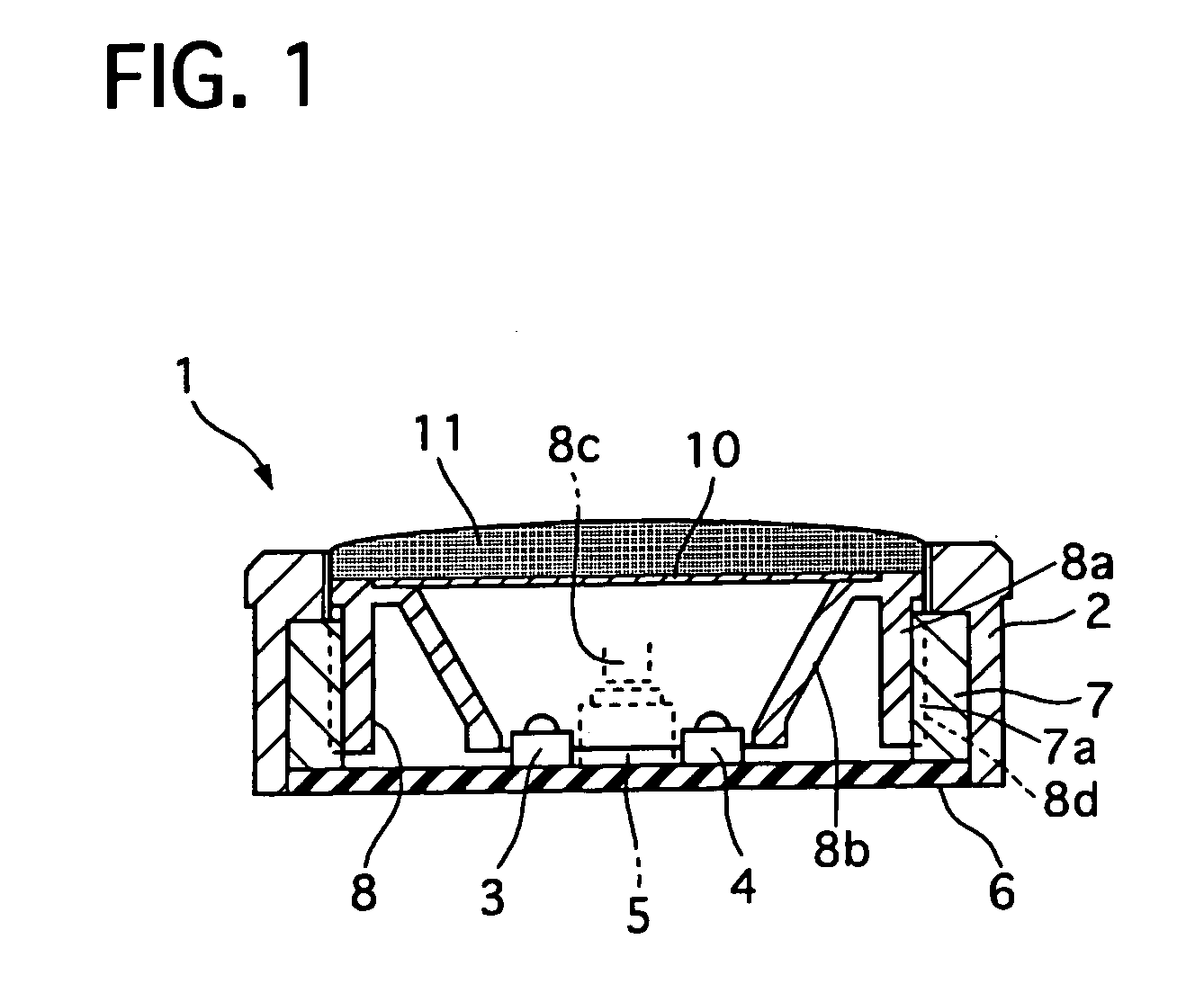

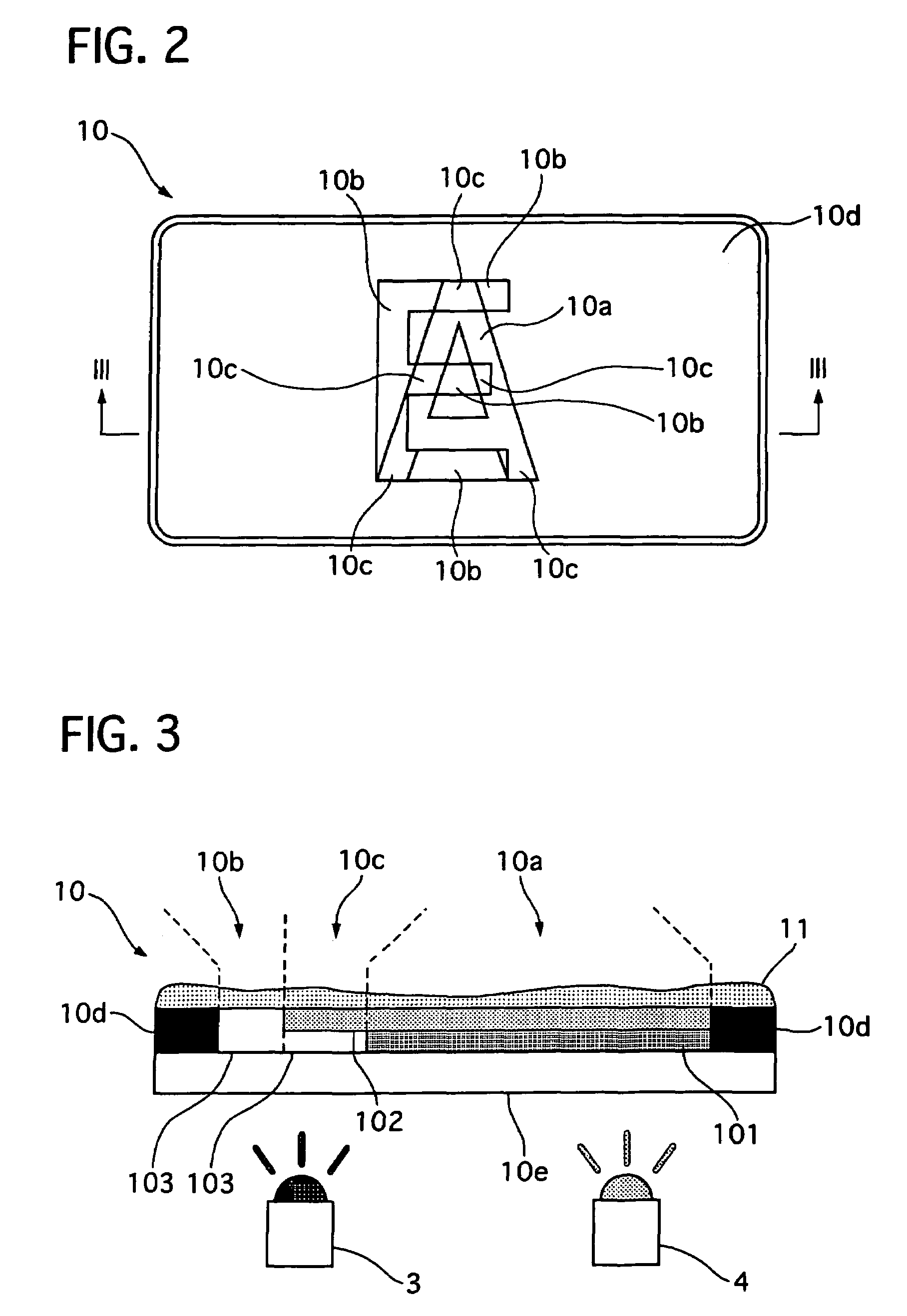

Display device

InactiveUS20070047215A1Reduce manufacturing costEasy to limitMeasurement apparatus componentsPoint-like light sourceDisplay deviceUltraviolet lights

A display device includes an ultraviolet light source, a color light source, and a filter selectively hit by their lights. The filter has a first area part for displaying the first display contents excluding an overlapped parts when the ultraviolet light is emitted, a second area part for the second display contents excluding the overlapped parts when the color light is emitted, and a third display part for displaying the overlapped parts when one of the ultraviolet and color light is emitted. The first area part blocks the color light and produces visible light when the ultraviolet light hits the first area part, the second area part allows the ultraviolet and color lights to pass therethrough, and the third area part allows the ultraviolet and color lights to pass therethrough and produces the visible light when the ultraviolet light hits the third area part.

Owner:CALSONIC KANSEI CORP

Water colour transparent glass paint and its preparation method and application

The present invention discloses a water-soluble colored transparent glass paint, its preparation method and application. Said glass paint composition includes (by weight portion) 50-60 portions of water-soluble silicon-acrylic resin, 14-20 portions of amino resin, 17.8-21.7 portions of deionized water, 3-5 portions of n-butyl alcohol, 2-4 portions of silane compling agent and 3-5 portions of water-soluble metal complex dyestuff. Its preparation method includes the following steps: firstly, adding water-soluble silicon-acrylic resin, n-butyl alcohol and deionized water into stirring still successively, stirring, adding water-soluble amino resin, then adding water-soluble metal complex dyestuff, finally adding silane coupling agent, defoaming agent and leveling agent and stirring them so as to obtain the invented product. After the glass surface is coated with said paint, under the condition of 120-150 deg.C it baked for 3-5 min and can be solidified and formed into film.

Owner:SOUTH CHINA UNIV OF TECH

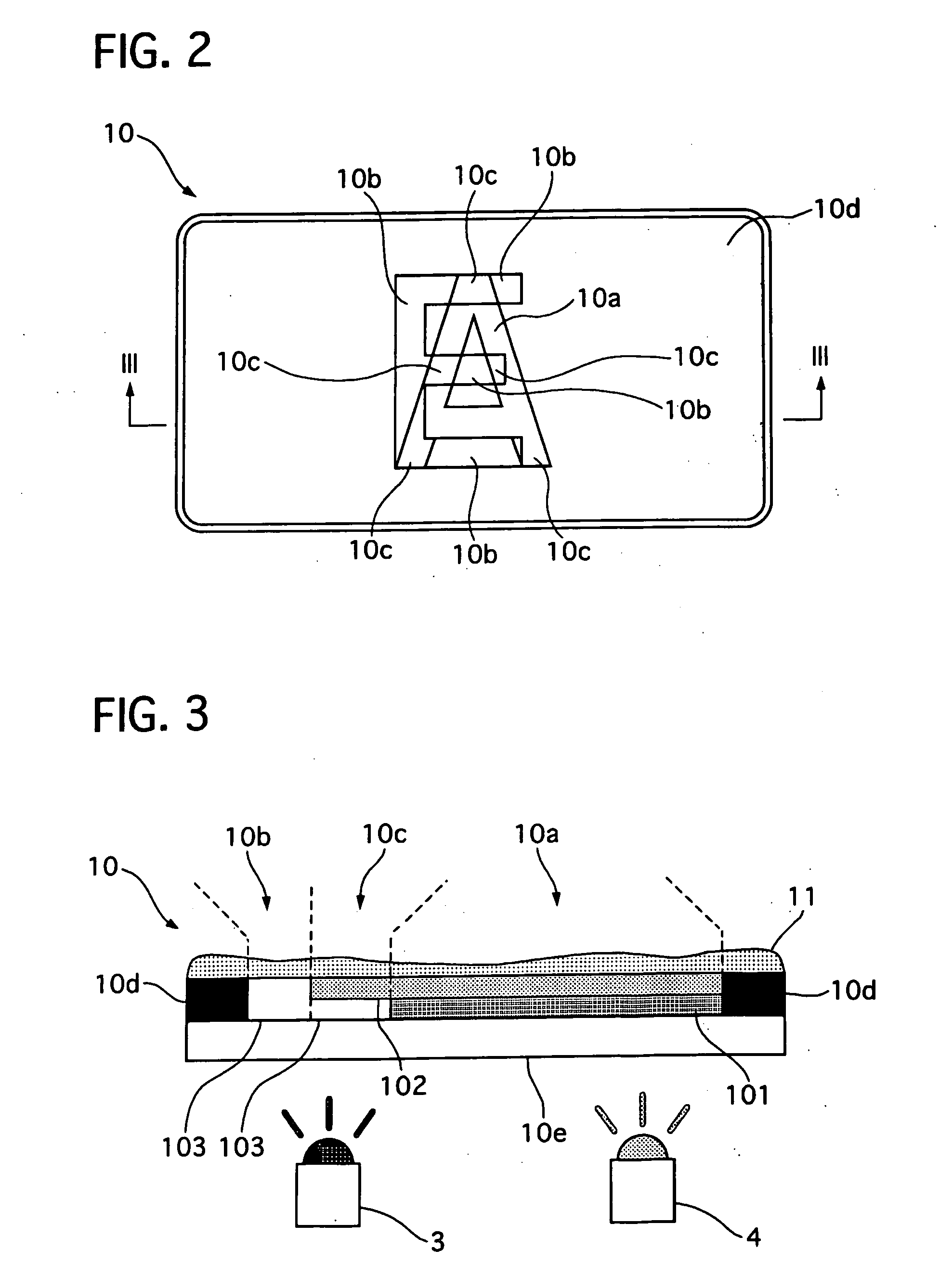

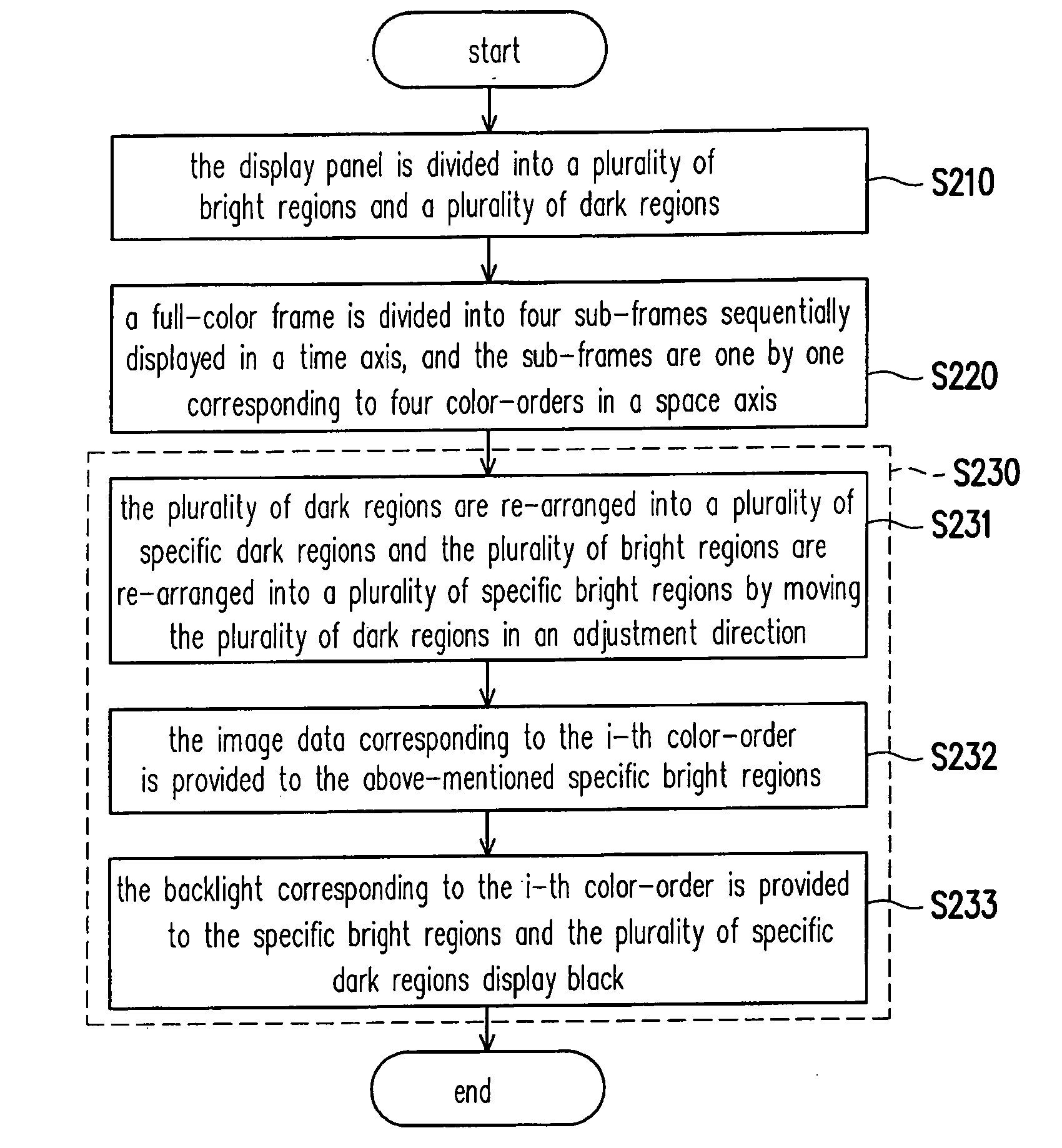

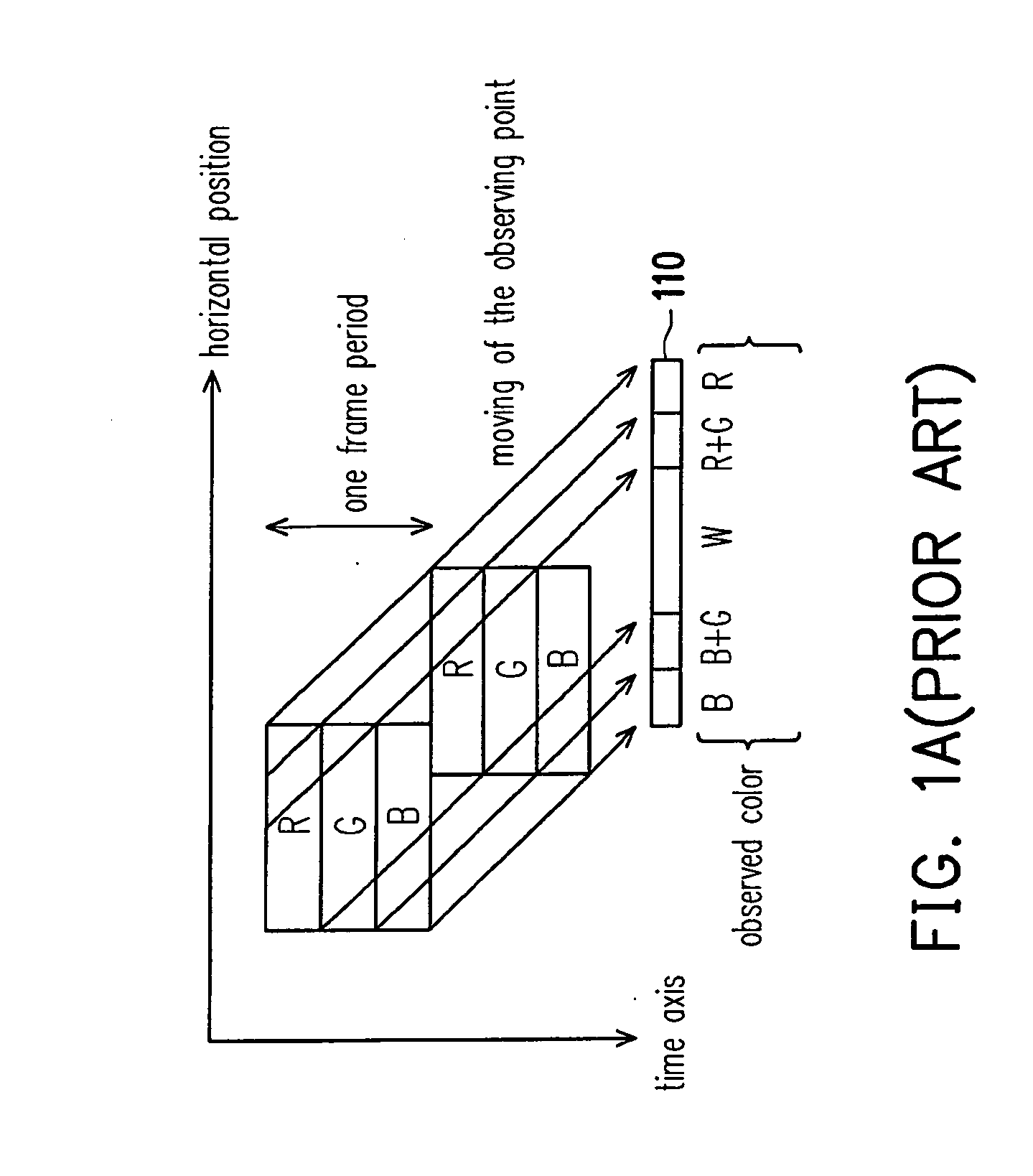

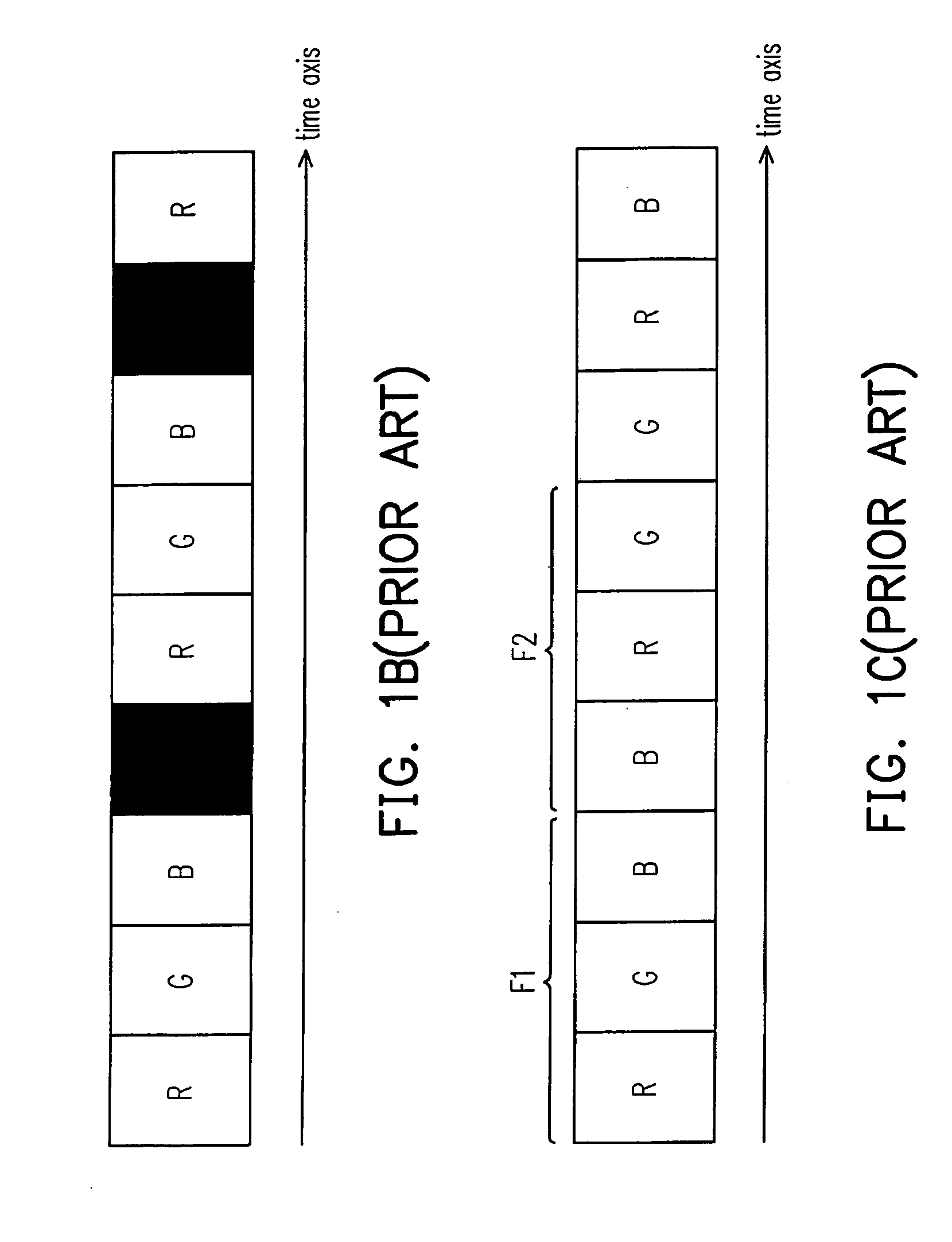

Method for driving a display

ActiveUS20080266312A1Improve influenceHigh light transmittanceTelevision system detailsCharacter and pattern recognitionDisplay deviceComputer science

Owner:CHUNGHWA PICTURE TUBES LTD

Colored optical filter

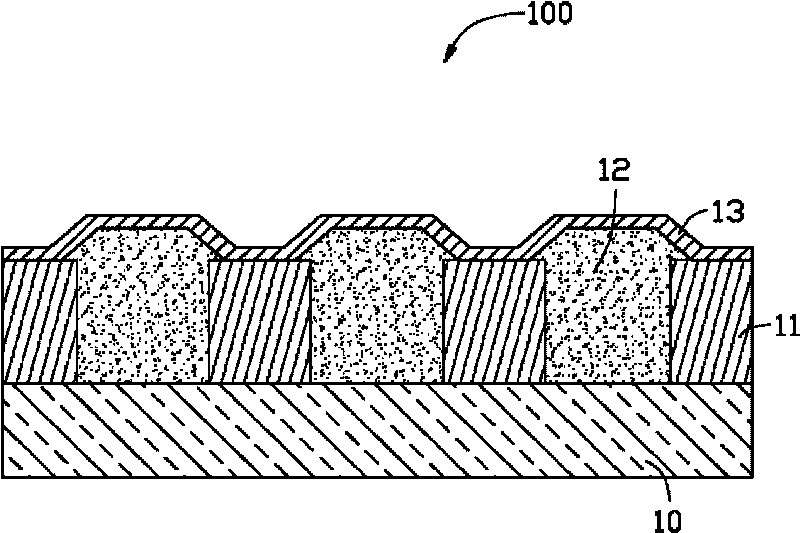

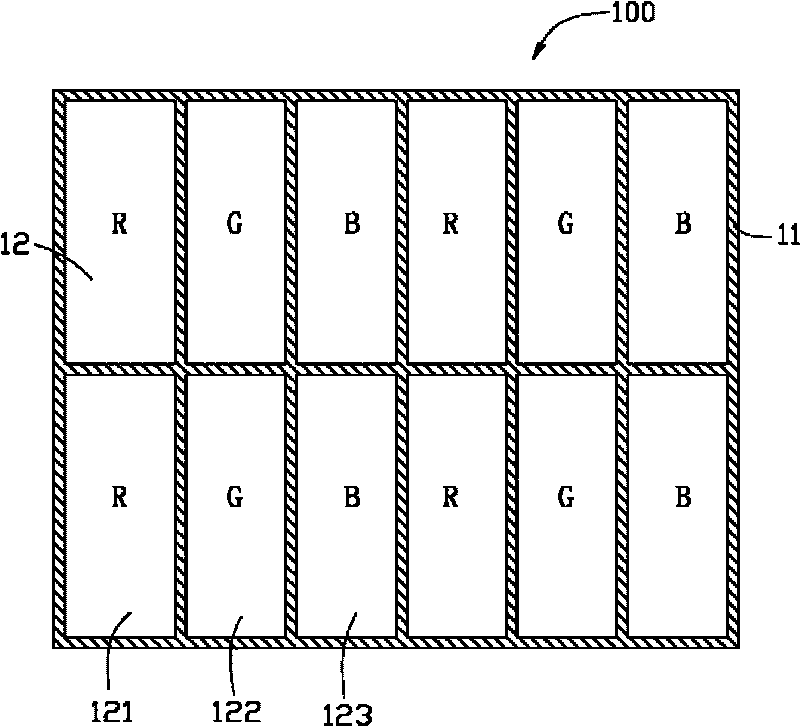

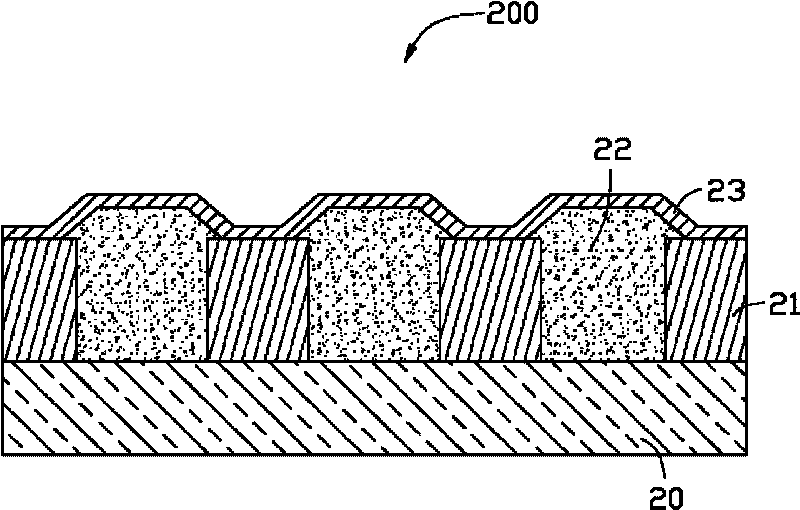

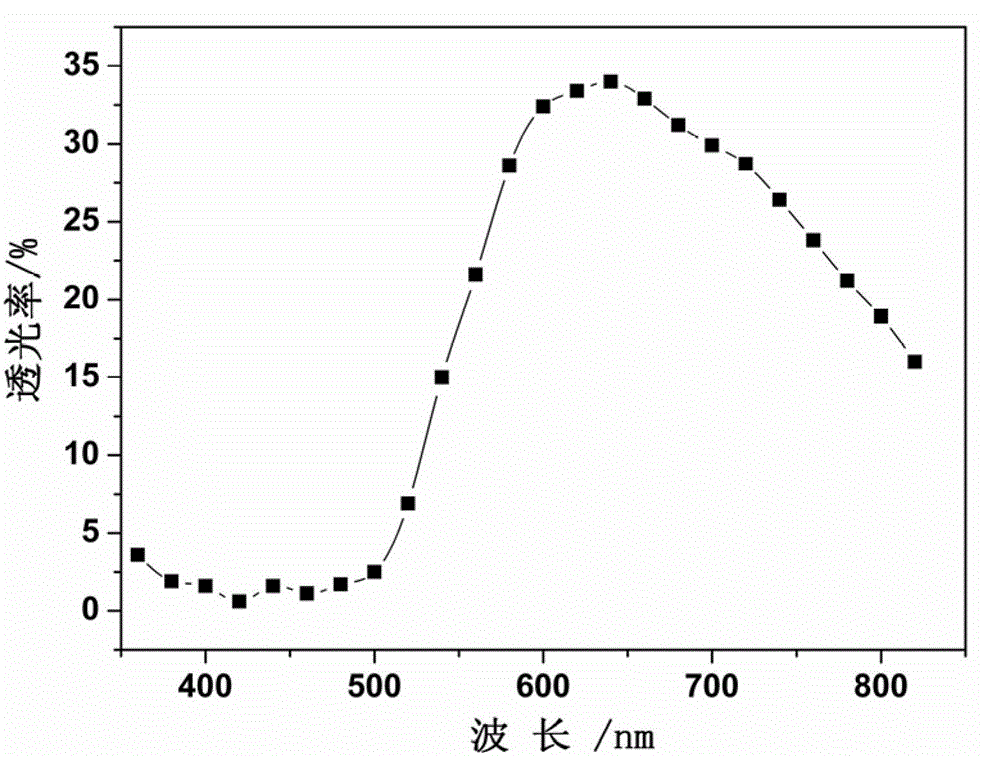

InactiveCN101750791AImprove energy utilizationMore colorNon-linear opticsOptical elementsColor gelLight filter

The invention discloses a colored optical filter comprising a substrate and a filter part formed on the substrate. The filter part comprises a plurality of composite pixels for displaying the colors, wherein each compound pixel comprises six basic pixels in different colors; and colored emitting light rays can be formed by mixing the emitting light rays in six colors formed through the six basic pixels.

Owner:SHENZHEN FUTAIHONG PRECISION IND CO LTD +1

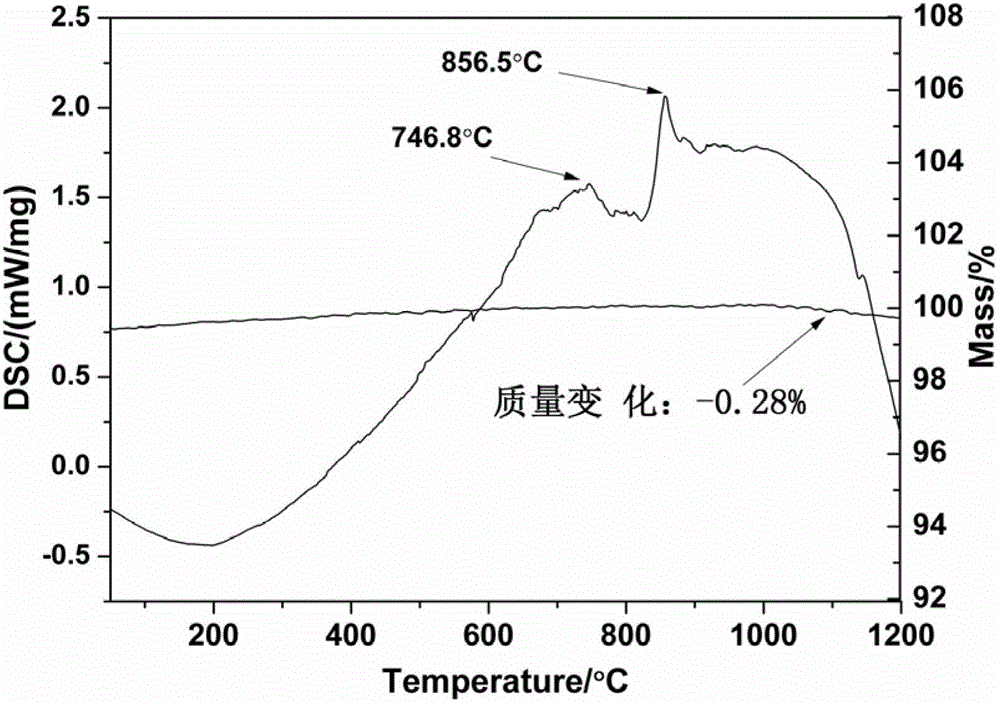

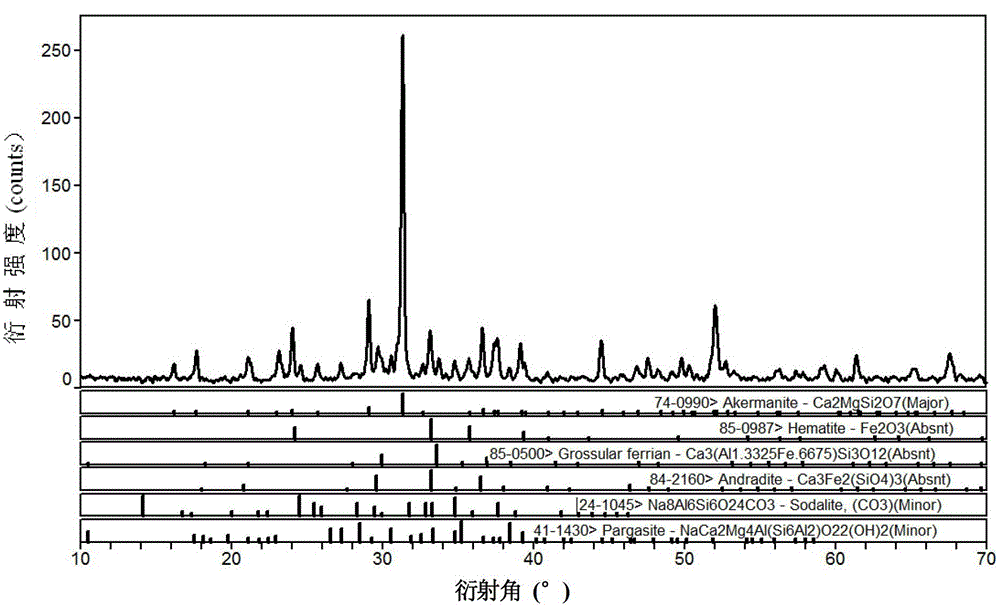

Method for preparing microcrystalline glass by utilizing blast furnace steel slag

The invention relates to a method for preparing a microcrystalline glass by utilizing steel slag. The method comprises the following steps of: firstly, carrying out drying and ball milling on the steel slag and removing iron contained in the steel slag to prepare powder of 100 meshes; then mixing the steel slag powder, quartz sand, sodium nitrate, barium nitrate, zinc oxide and cerium dioxide into a compound material; placing the mixture obtained from the former step into a crucible, and smelting at 1250-1380 DEG C to form a transparent steel slag glass; and finally, crystallizing the transparent steel slag glass to form the steel slag microcrystalline glass containing calcium akermanite as a main crystal phase. The method disclosed by the invention utilizes the blast furnace steel slag as a main raw material and achieves the utilization amount of the steel slag at 96%; and the microcrystalline glass prepared according to the method has the advantages of high structural strength, low water absorption, high crystalline degree and various color. The preparation process disclosed by the invention is simple in operation process and low in cost, can effectively reduce the production cost of the microcrystalline glass, protects the environment and changes the wastes into valuables, is suitable for industrialized large-scale production and has obvious economic benefit and environmental benefit.

Owner:承德远通钢铁设备制造有限公司

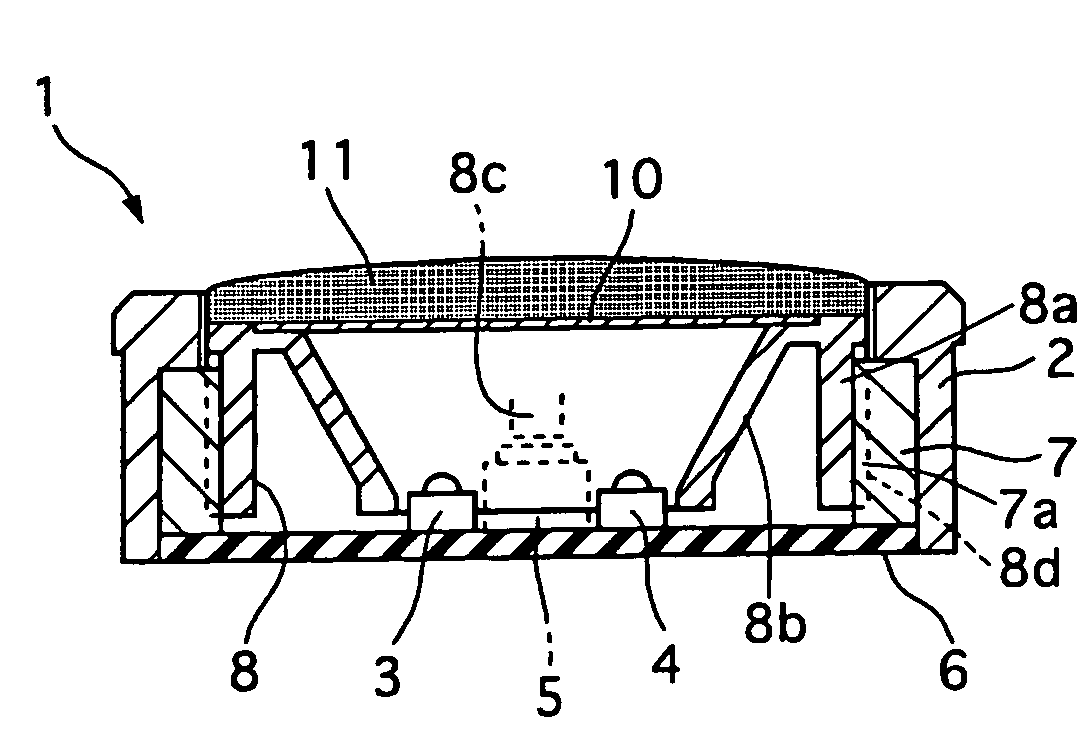

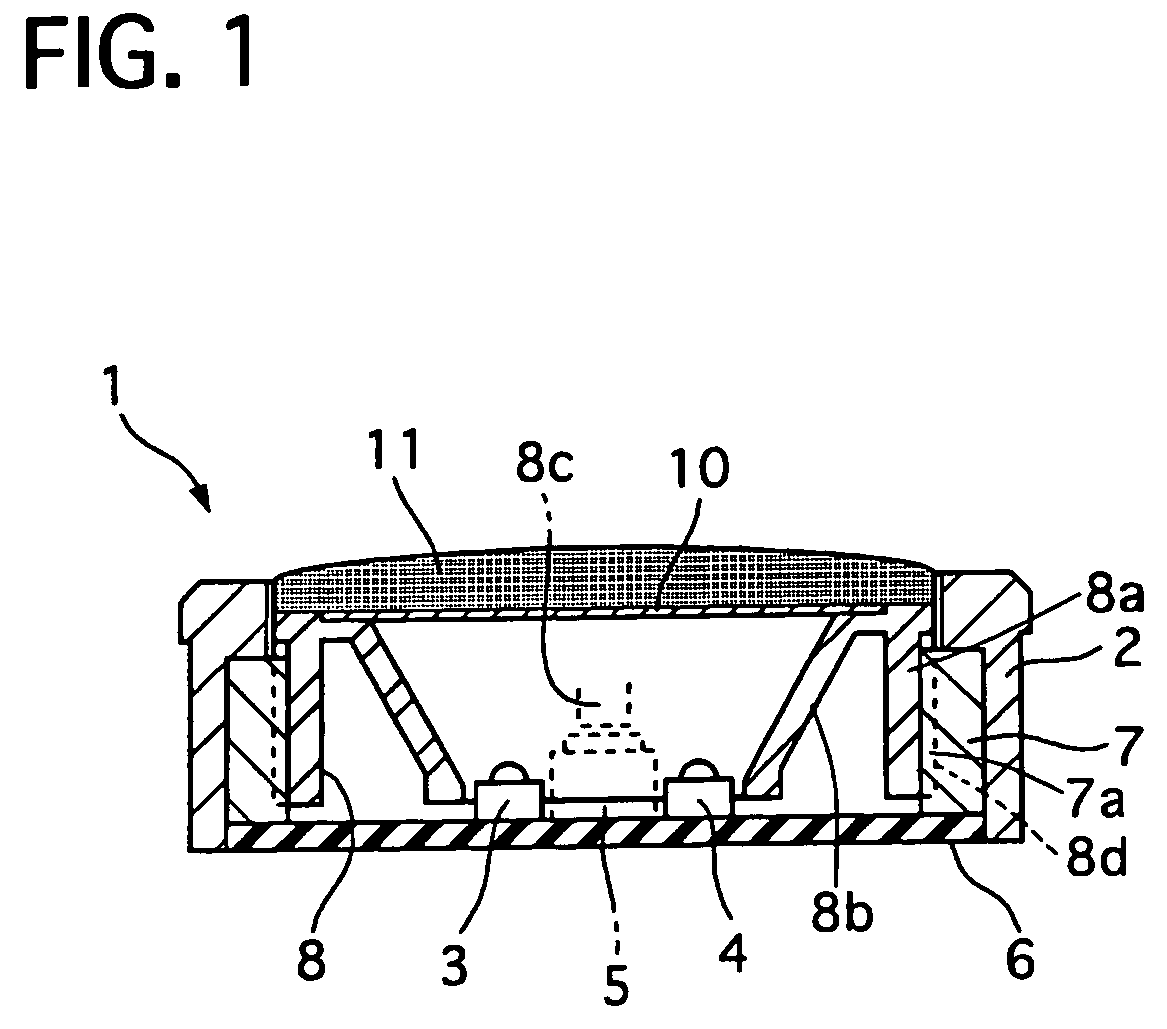

Display device

InactiveUS7581342B2Easy to limitMore colorNon-electric lightingMeasurement apparatus componentsUltraviolet lightsDisplay device

A display device includes an ultraviolet light source, a color light source, and a filter selectively hit by their lights. The filter has a first area part for displaying the first display contents excluding an overlapped parts when the ultraviolet light is emitted, a second area part for the second display contents excluding the overlapped parts when the color light is emitted, and a third display part for displaying the overlapped parts when one of the ultraviolet and color light is emitted. The first area part blocks the color light and produces visible light when the ultraviolet light hits the first area part, the second area part allows the ultraviolet and color lights to pass therethrough, and the third area part allows the ultraviolet and color lights to pass therethrough and produces the visible light when the ultraviolet light hits the third area part.

Owner:CALSONIC KANSEI CORP

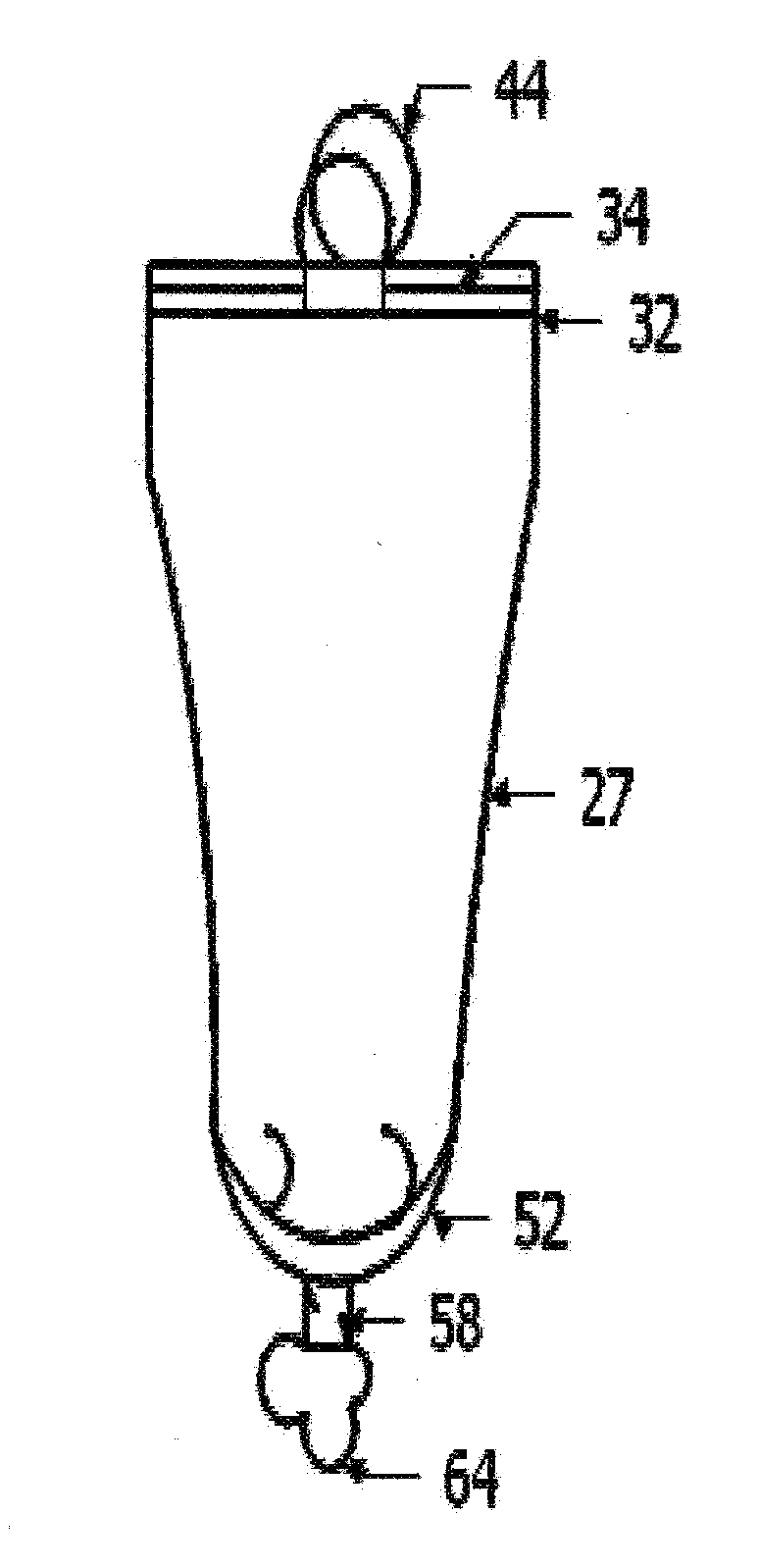

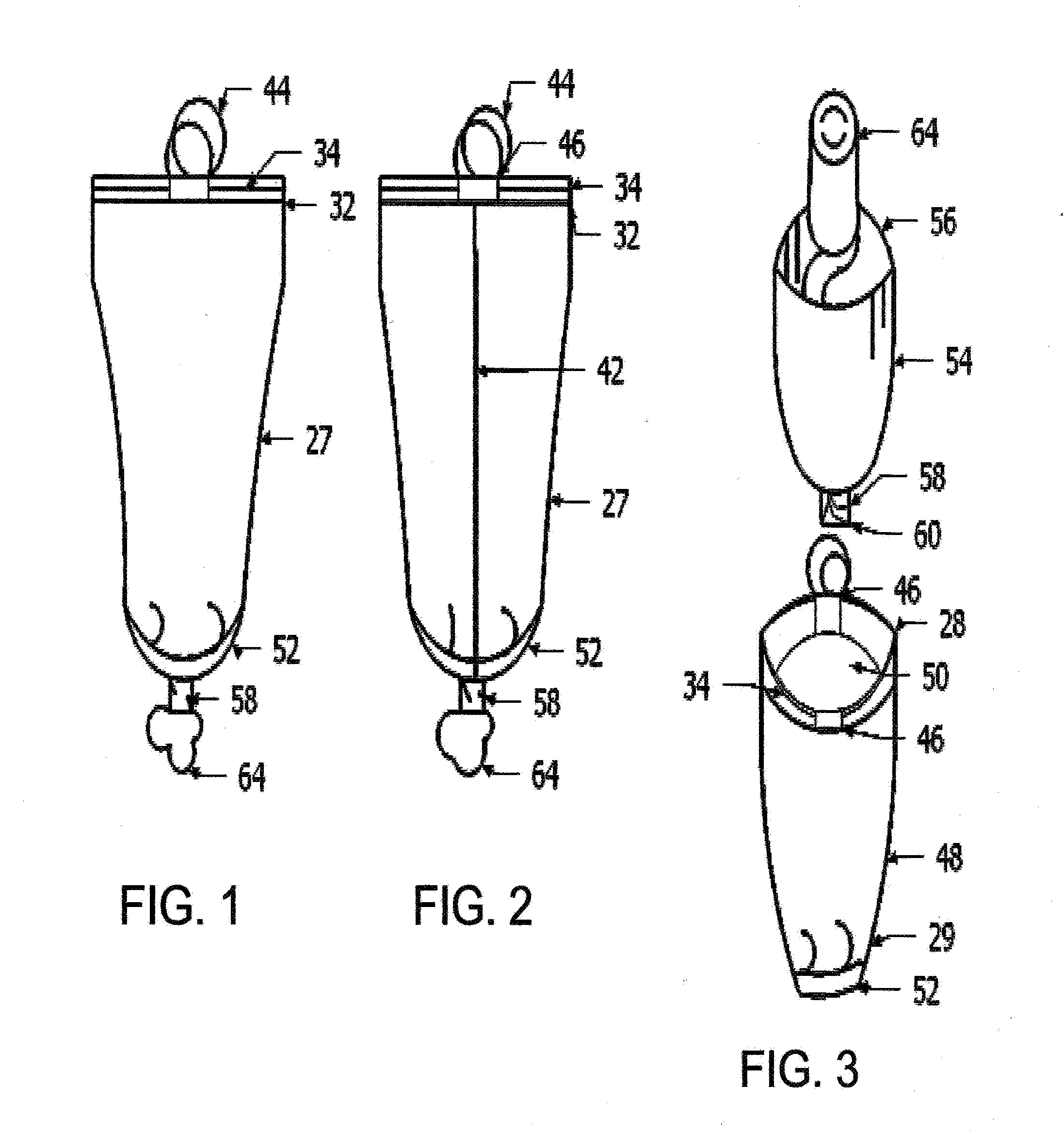

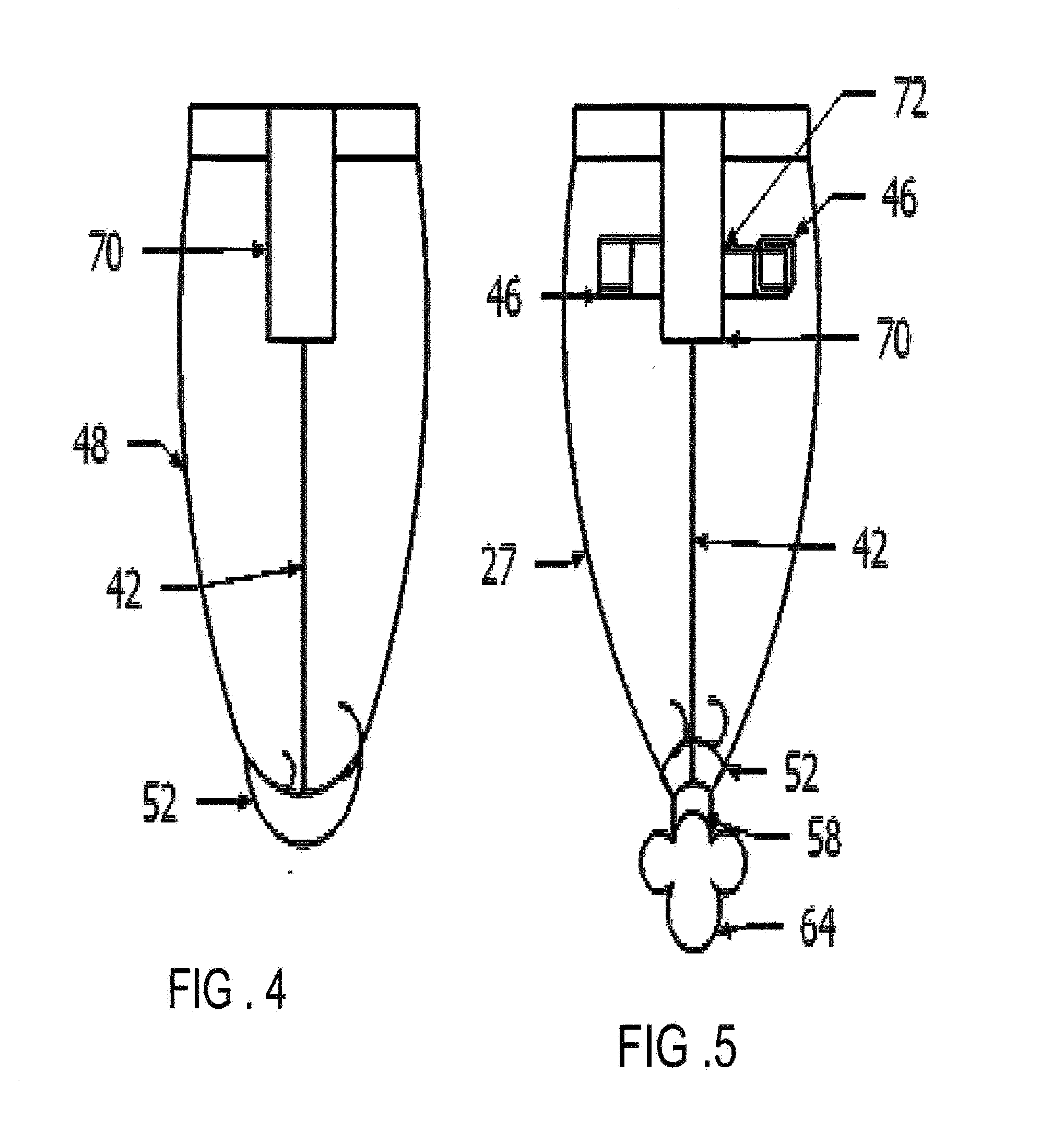

Decorative Trash Bag Dispenser/Organizer

InactiveUS20130248554A1Faster more organizedMore colorContainers for annular articlesRefuse receptaclesWheelchairSmall neck

A dispenser and organizer for dispensing trash bags, generally made of a flexible fabric in a tubular shape having a hollow body with a large closable entry opening at the top and a smaller elasticized dispensing opening at the bottom. The body therein holds a container, the container having a large entry opening and a smaller dispensing opening with a neck, the container defining a roll of plurality of trash bags. Whereby the body when coupled with a container with small neck can be that of an organizer, for example a hand sanitizer bottle. Whereby two different sizes can be made as one unit to accommodate two sizes in one location. Other advantages is its ability to be utilized at a preferred height by individuals confined to a wheelchair and to carry along hands free.

Owner:ROBIN LINDA S

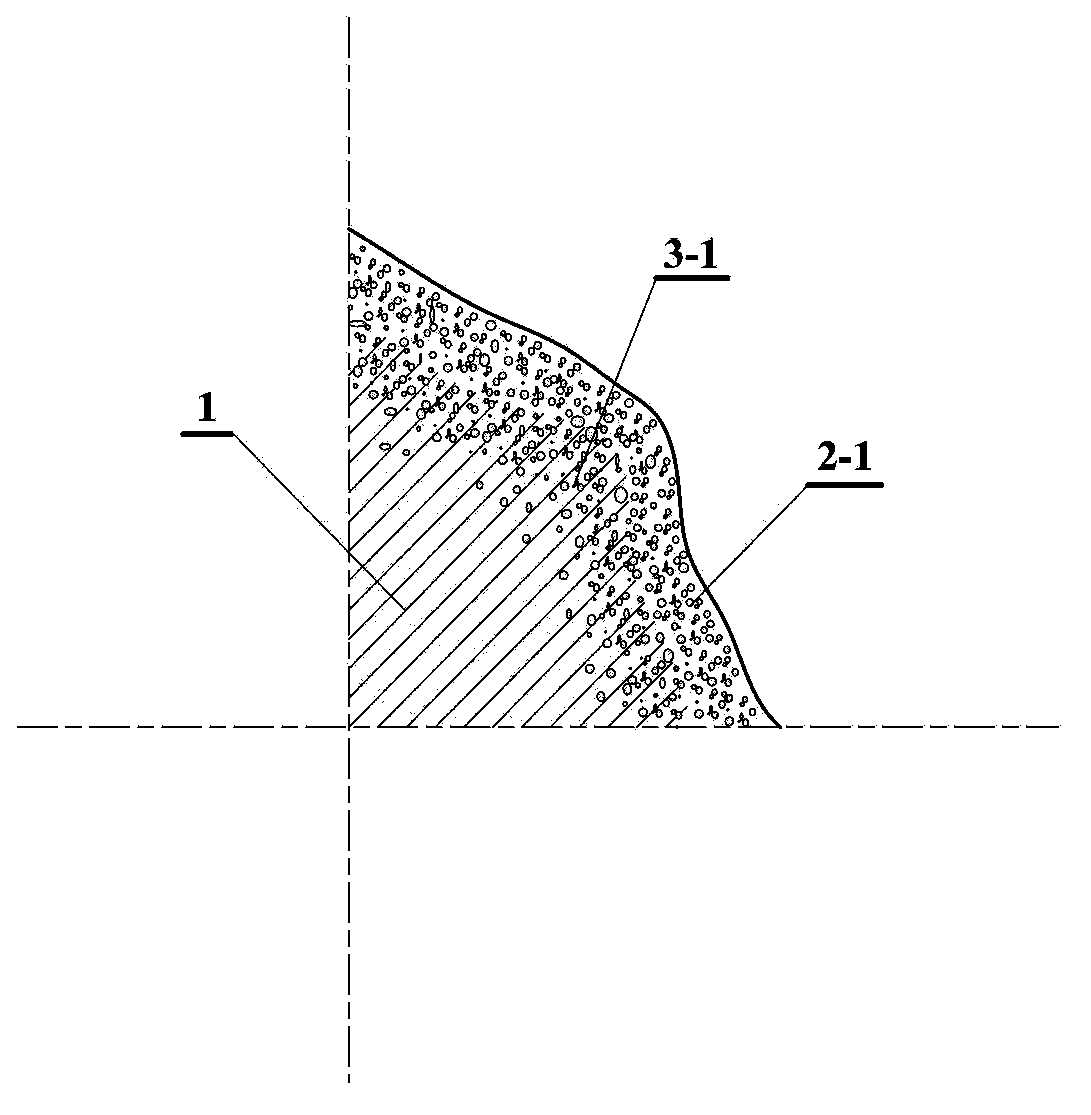

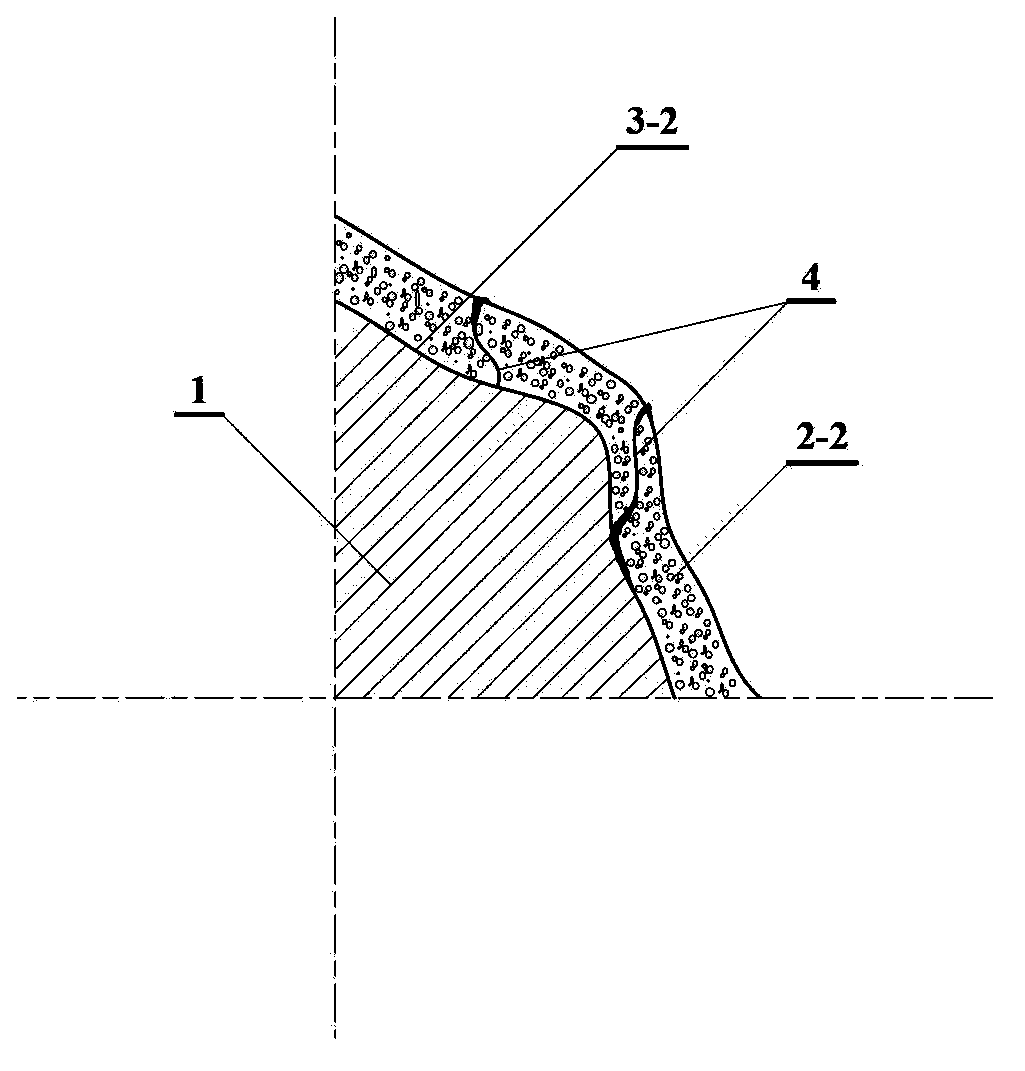

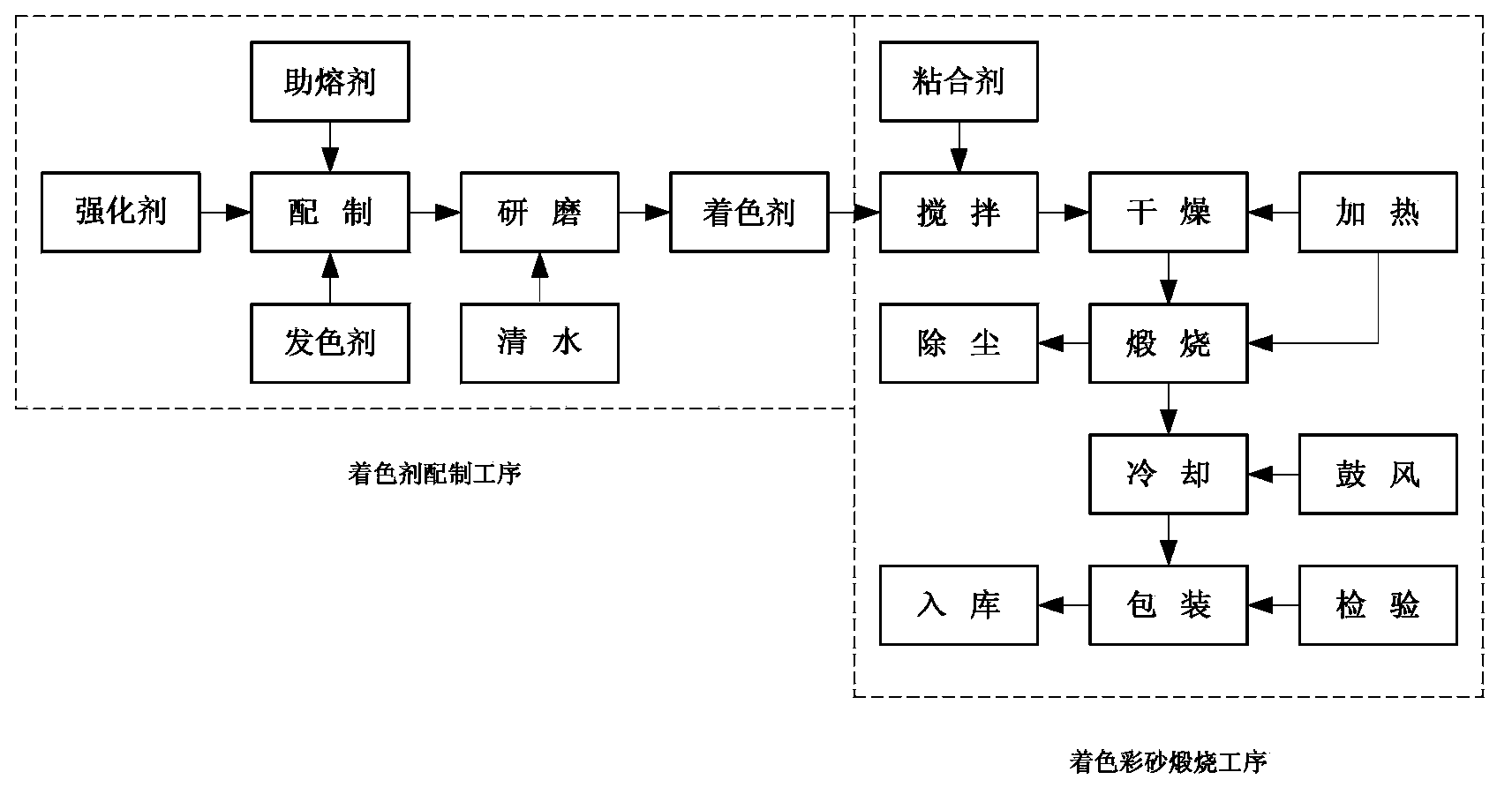

Colored sand capable of coloring by reaction and its preparation method

The invention relates to colored sand capable of coloring by reaction and its preparation method, the colored sand is prepared by the following components: 100wt parts of aggregate, 1.0-5.0wt parts of adhesive and 0.2-3.5wt parts of colouring agent; wherein the aggregate is other sandstone such as basalt sand, quartz sand, yellow sand or sea sand; and the colouring agent is composed 30.0-45.0wt parts of intensifying agent, 50.0-65.0wt parts of fluxing agent, 2.5-7.0wt parts of colour former and 50.0-80.0 wt parts of clear water according to a mechanism of ceramic colored glaze. The preparation method is characterized in that the colouring agent and the adhesive through grinding are coated on the surface of the aggregate together, then dried and calcined under the temperature of 700-950 DEG C to obtain the reaction-type colored sand. The colored sand has the advantages of uniform coloring, bright color and various types; a color layer is combined with the aggregate through reaction, and has the advantages of fastness and stabilization, no fading, strong corrosivity resistance, good weatherability and long usage life.

Owner:WEIFANG LONGCHENG BUILDING MATERIAL

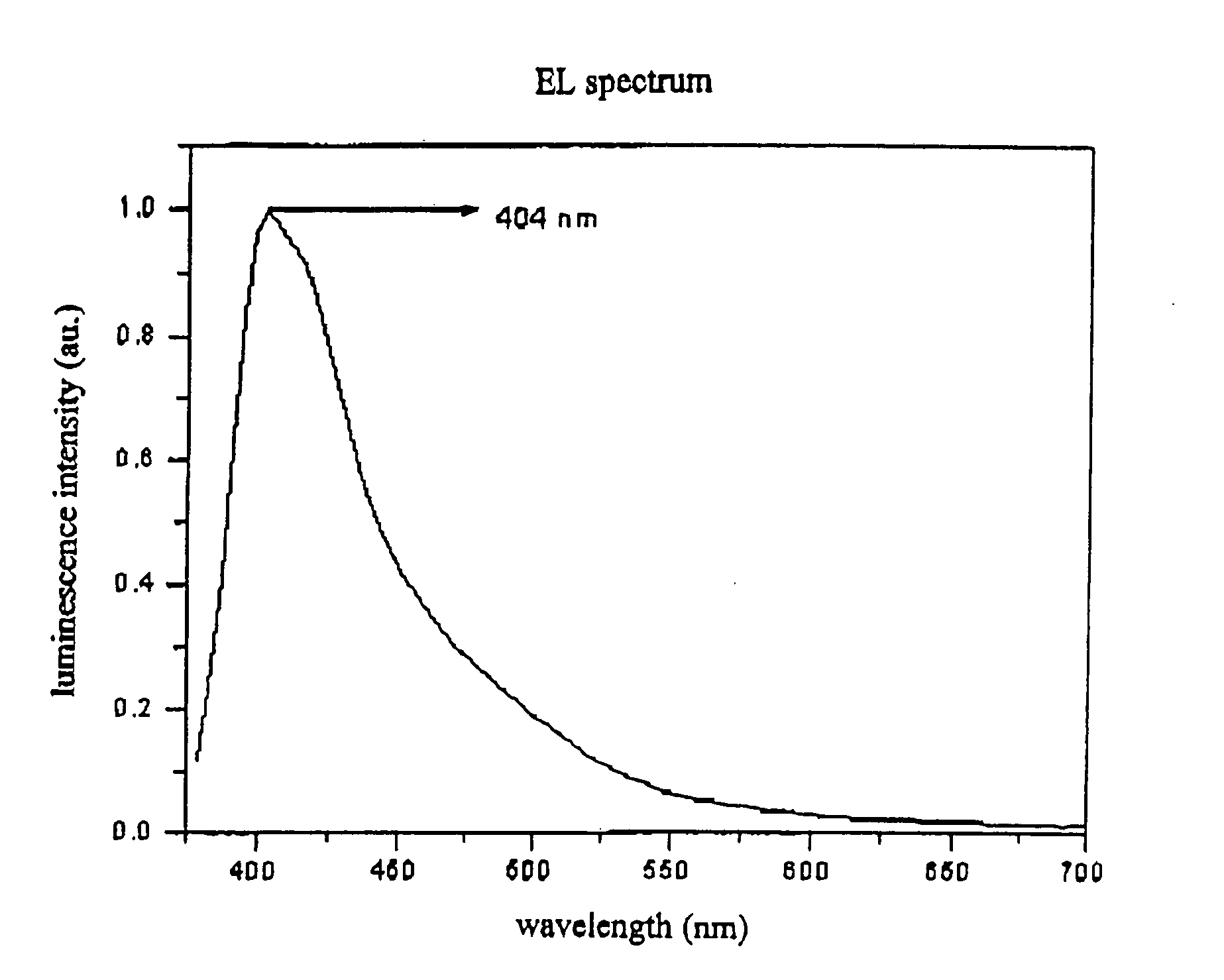

Organic light emitting materials and use thereof

InactiveUS20060270827A1Improve luminous efficiencyMore colorDischarge tube luminescnet screensElectroluminescent light sourcesLight-emitting diodeOLED

Owner:ETERNAL MATERIALS CO LTD

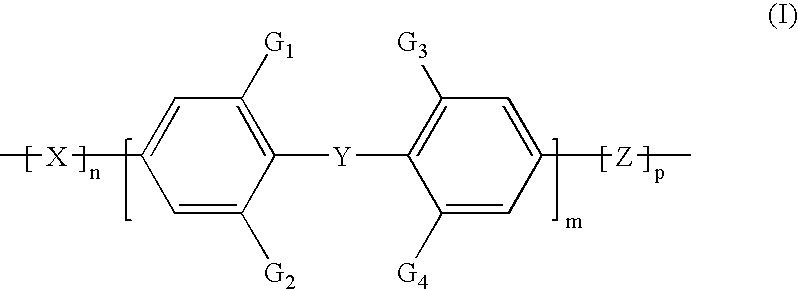

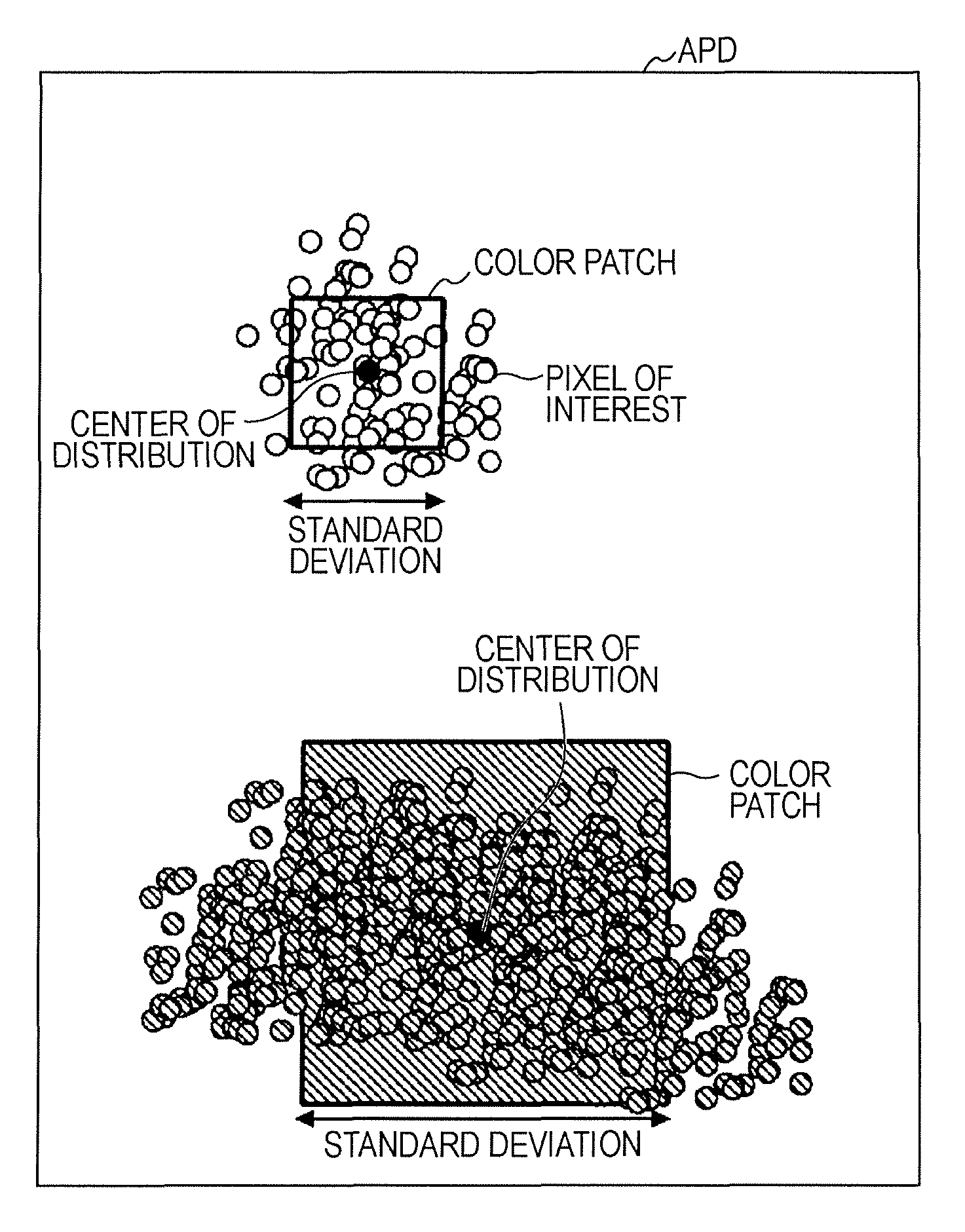

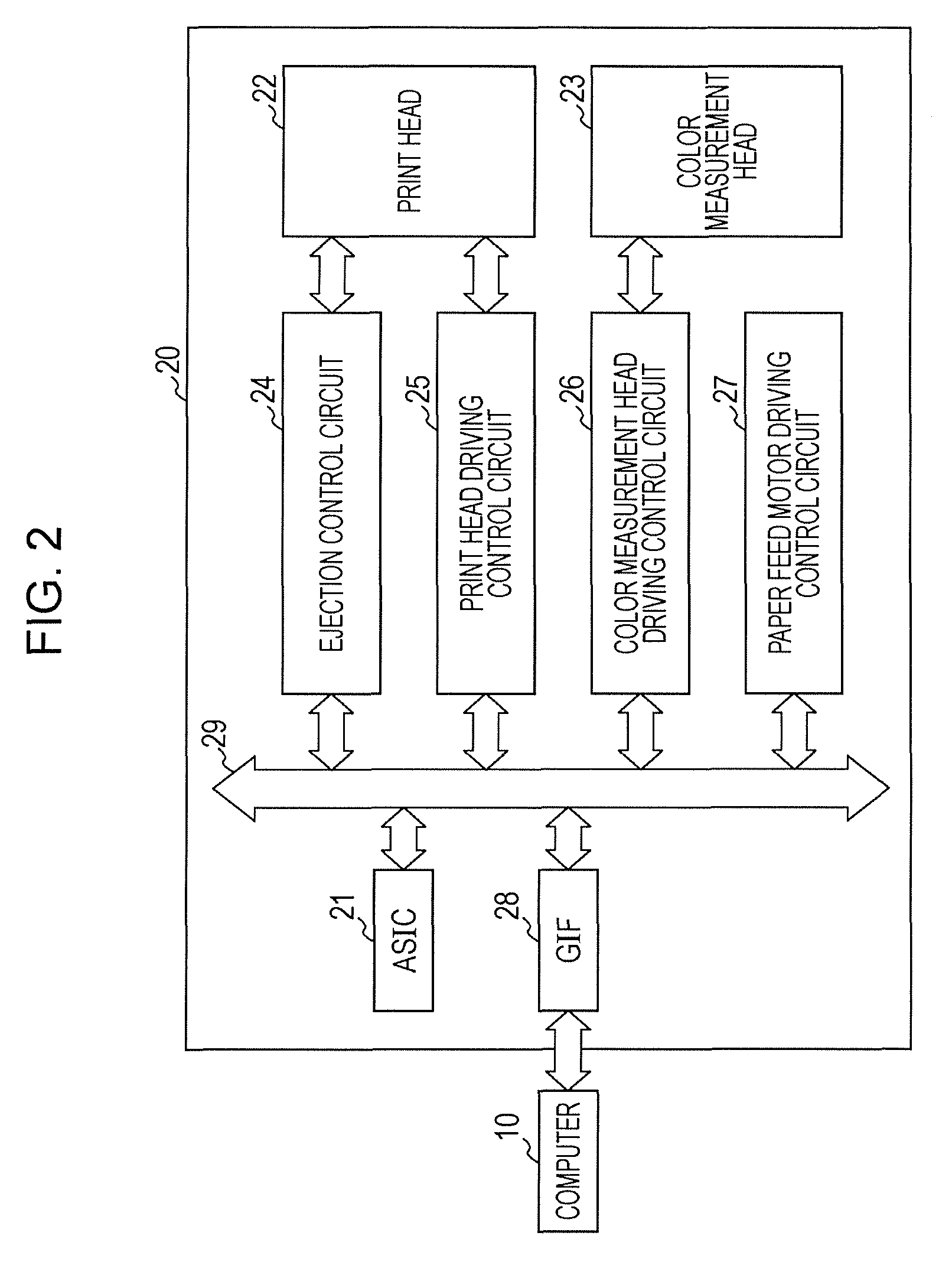

Printing apparatus and calibration method

InactiveUS20110075171A1Efficient calibrationEfficient executionDigitally marking record carriersDigital computer detailsColor measurementImaging data

A printing apparatus is adapted to form a printed image by forming ink dots based on an ink amount specified for each of a plurality of pixels forming image data. The determination unit is configured to analyze the image data and to determine at least one color patch to be printed based on a result of the analysis. The patch printing unit is configured to print the color patch. The color measurement unit is configured to perform color measurement on the color patch to obtain a color value indicated in the color patch. The correction data creation unit is configured to create correction data using the color value obtained by the color measurement unit. The printing unit is configured to form the ink dots based on the ink amount that has been corrected based on the correction data.

Owner:SEIKO EPSON CORP

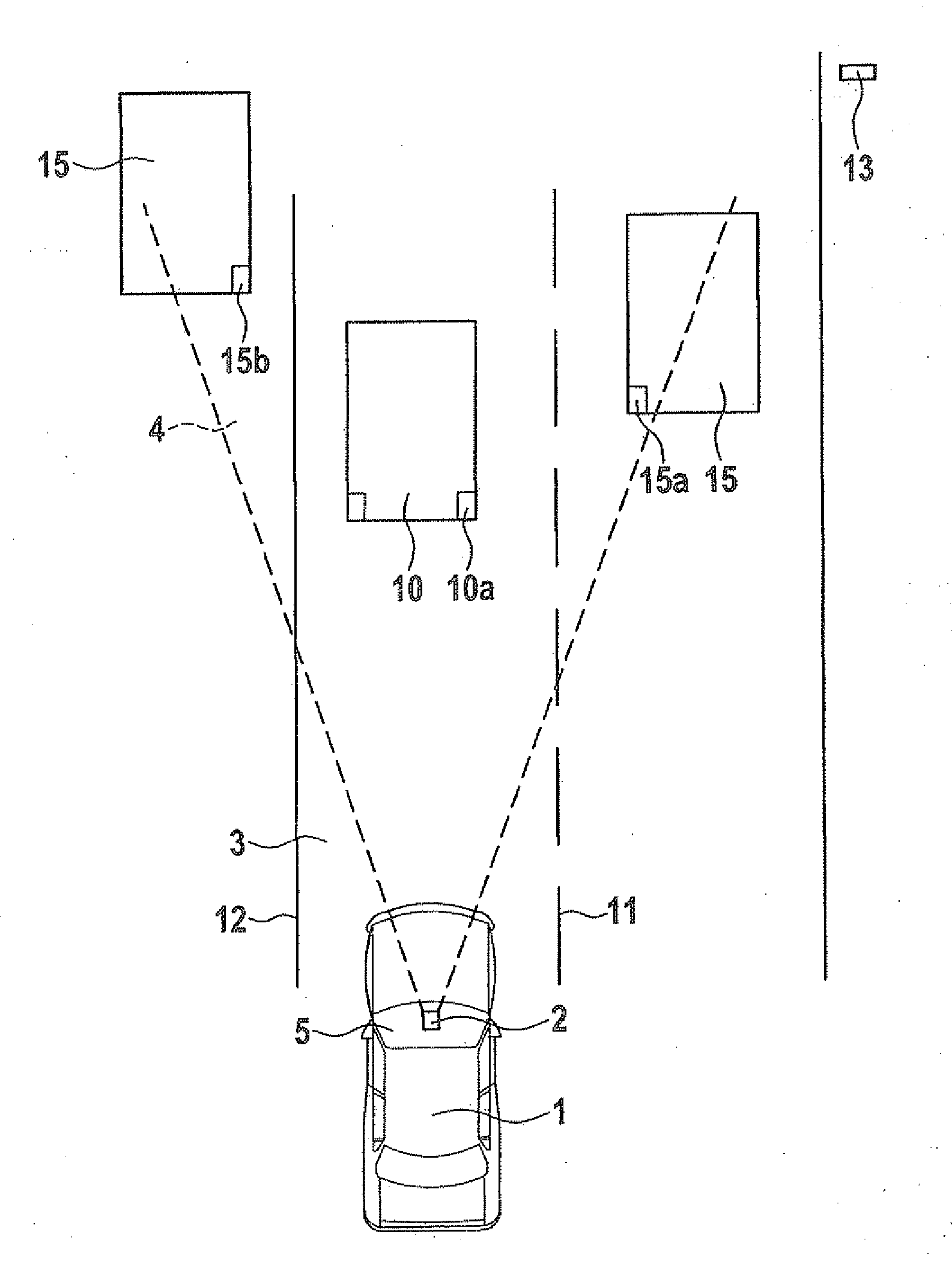

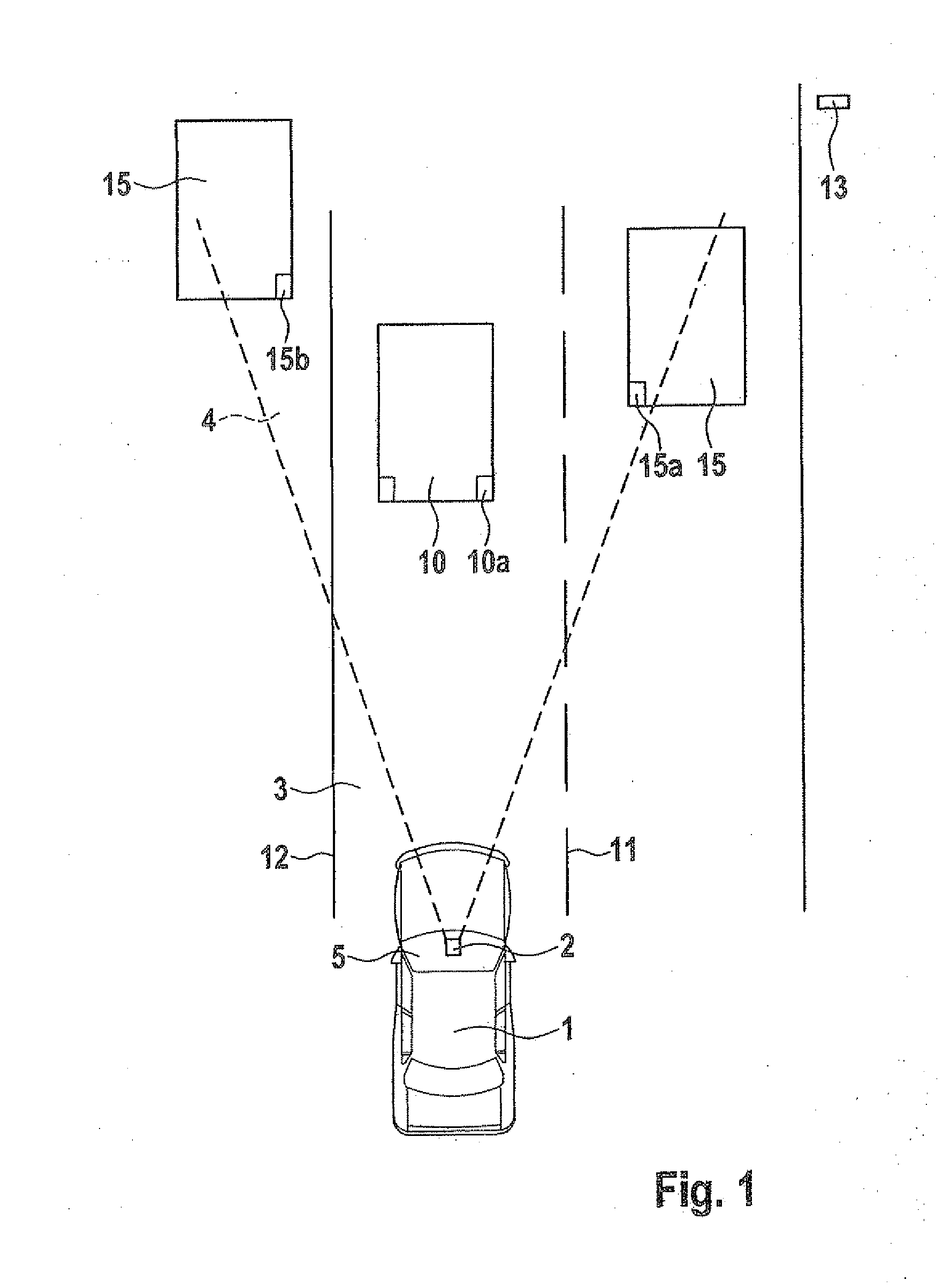

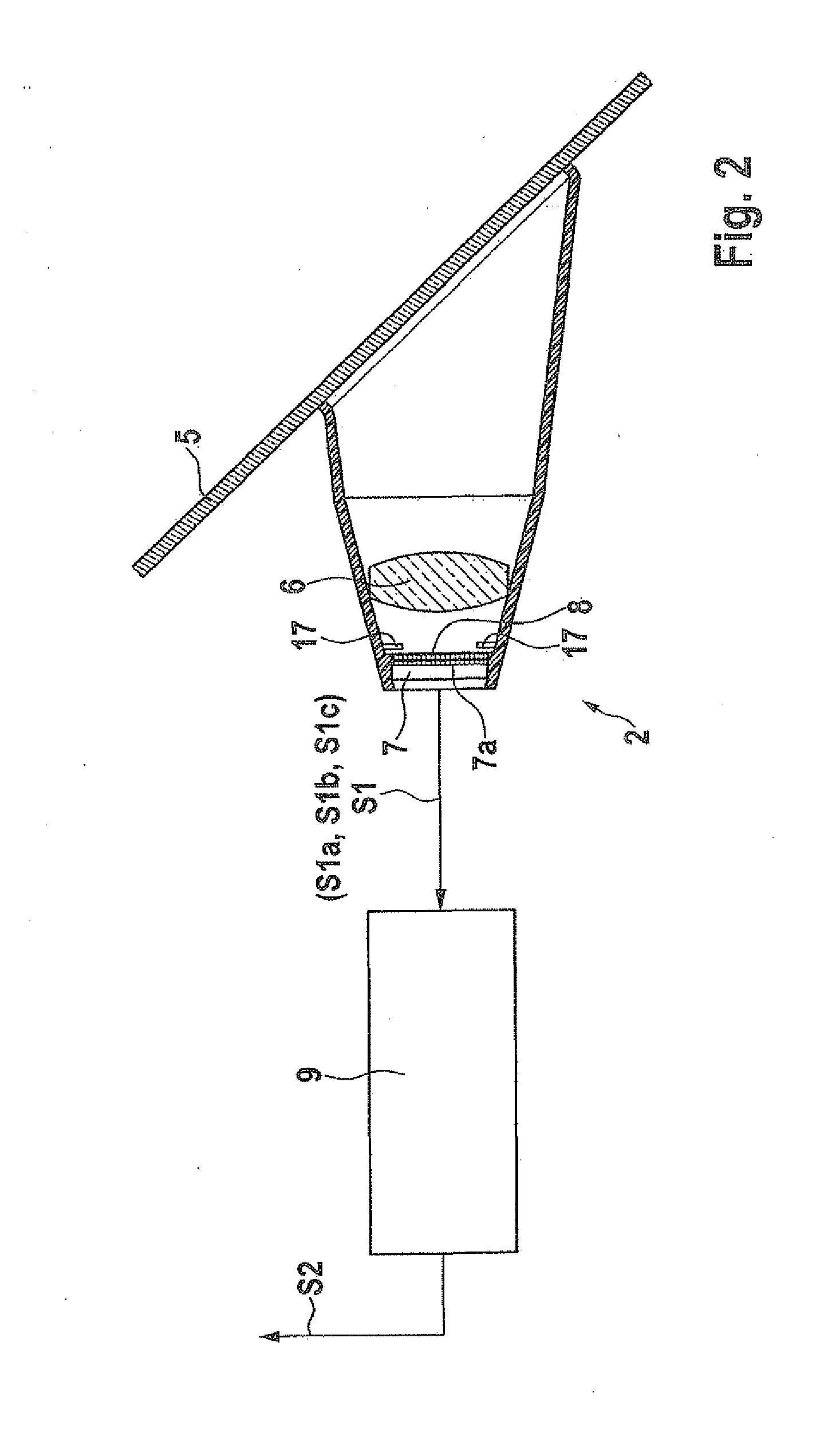

Color mask for an image sensor of a vehicle camera

InactiveUS20130027560A1Fast data processingMore colorTelevision system detailsTelevision system scanning detailsSpectral transmissionLength wave

A color mask for an image sensor of a vehicle camera, the color mask having a matrix configuration of filter pixels having different spectral transmission behaviors, some filter pixels being transparent filter pixels, which are at least essentially uniformly transparent for optical light, and additional filter pixels being color pixels having a wavelength-selective transmission behavior, the color mask having a color pattern as a repeating configuration of filter pixels having a specific transmission behavior. The color mask has a central area having a first color pattern and a lower area and / or an upper area having a second color pattern, the first color pattern and the second color pattern being different, and the first color pattern containing transparent filter pixels.

Owner:ROBERT BOSCH GMBH

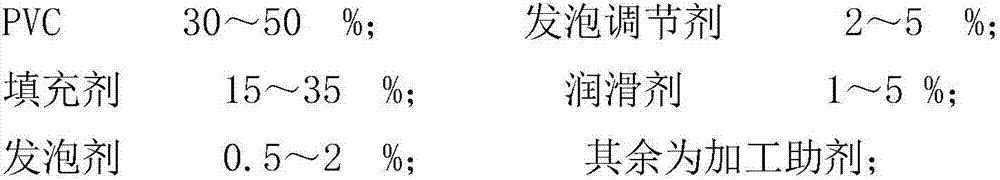

Energy-saving and environment-friendly wood plastic material

The invention discloses an energy-saving and environment-friendly wood plastic material, which consists of the following raw materials by mass: 40-60 parts of polyvinyl chloride resin powder, 30-40 parts of wood powder, 20-30 parts of calcium carbonate powder, 2-3 parts of a modifier, 3-5 parts of a processing aid, 2-3 parts of a foaming agent, 1-2 parts of a stable solvent, 1-2 parts of a foaming aid, 1-1.5 parts of a lubricant, and 0.5-1 part of a colorant. The wood plastic material has the characteristics of moisture protection, waterproofness, insect prevention, termite prevention, low carbon and energy saving, the product does not contain benzene, has a formaldehyde content of 0.2, which is lower than the EO level standard and meets the European grading standard, can realize recycling, greatly saves wood usage, is suitable for the national policy of sustainable development, and benefits the society. The whole production process does not generate industrial waste gas and waste water, is low in noise, and is in line with various national industrial production environmental protection requirements, thus being suitable for large-scale promotion and application.

Owner:高智慧

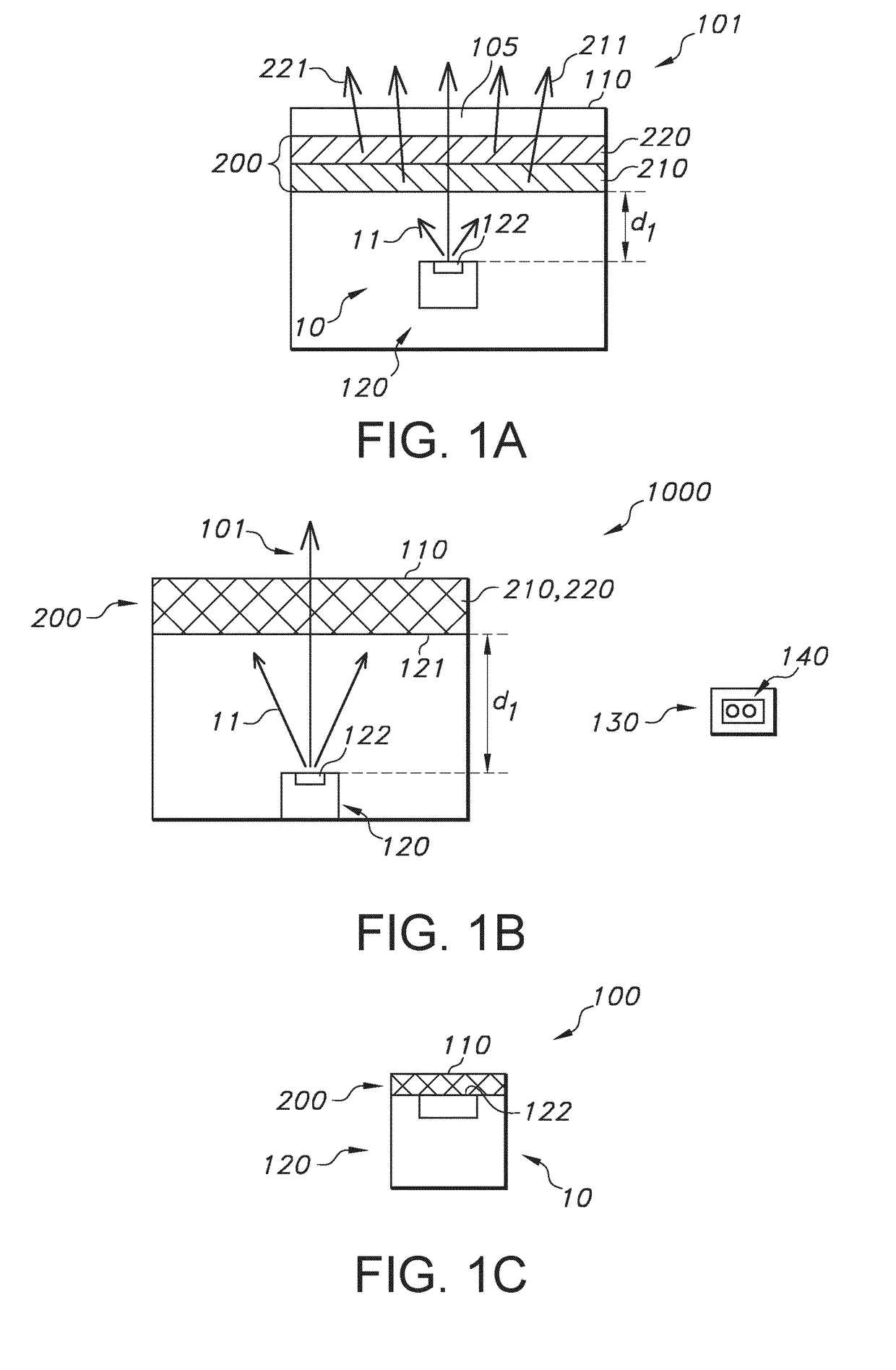

Improved white lighting device for retail illumination

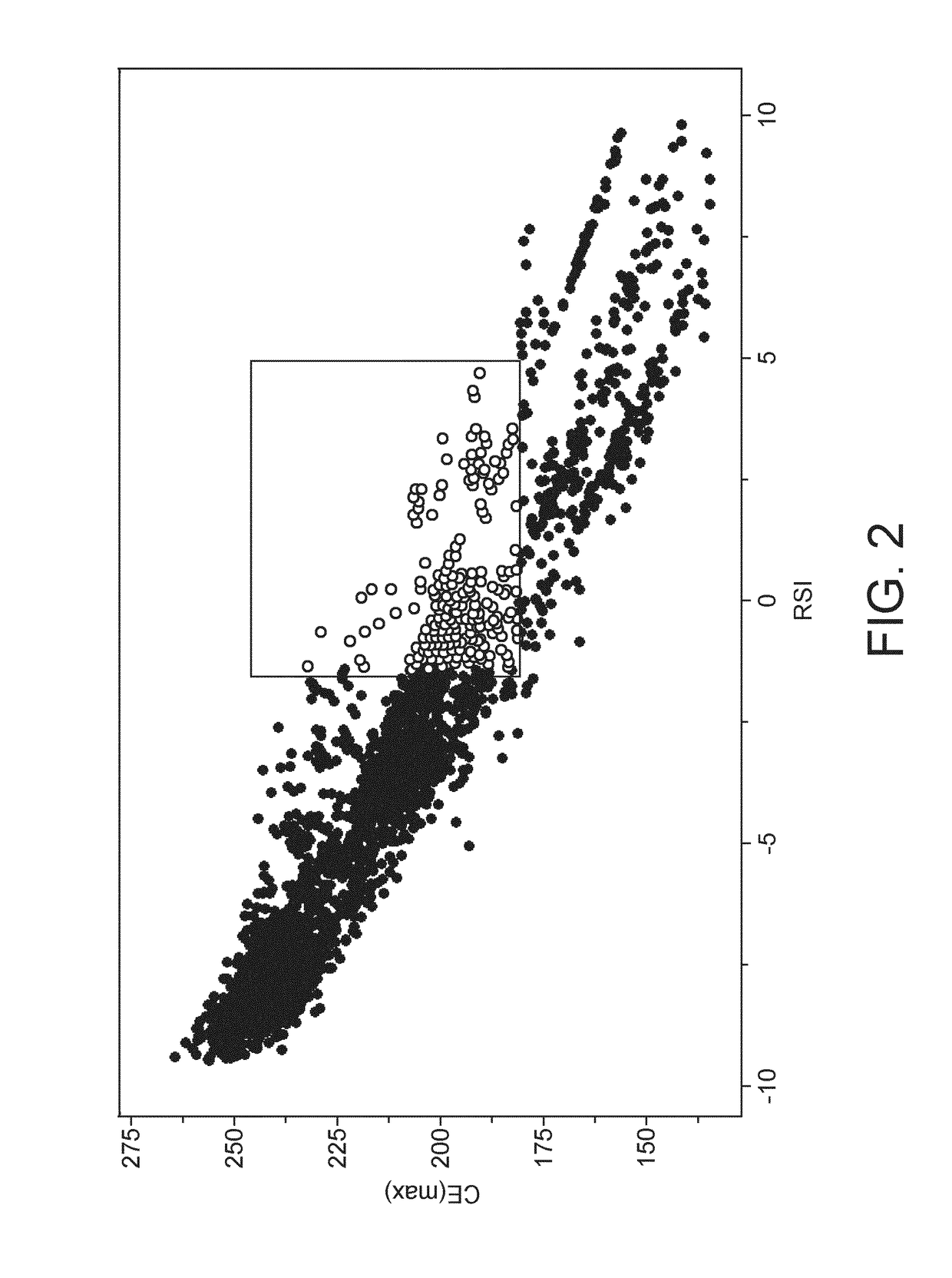

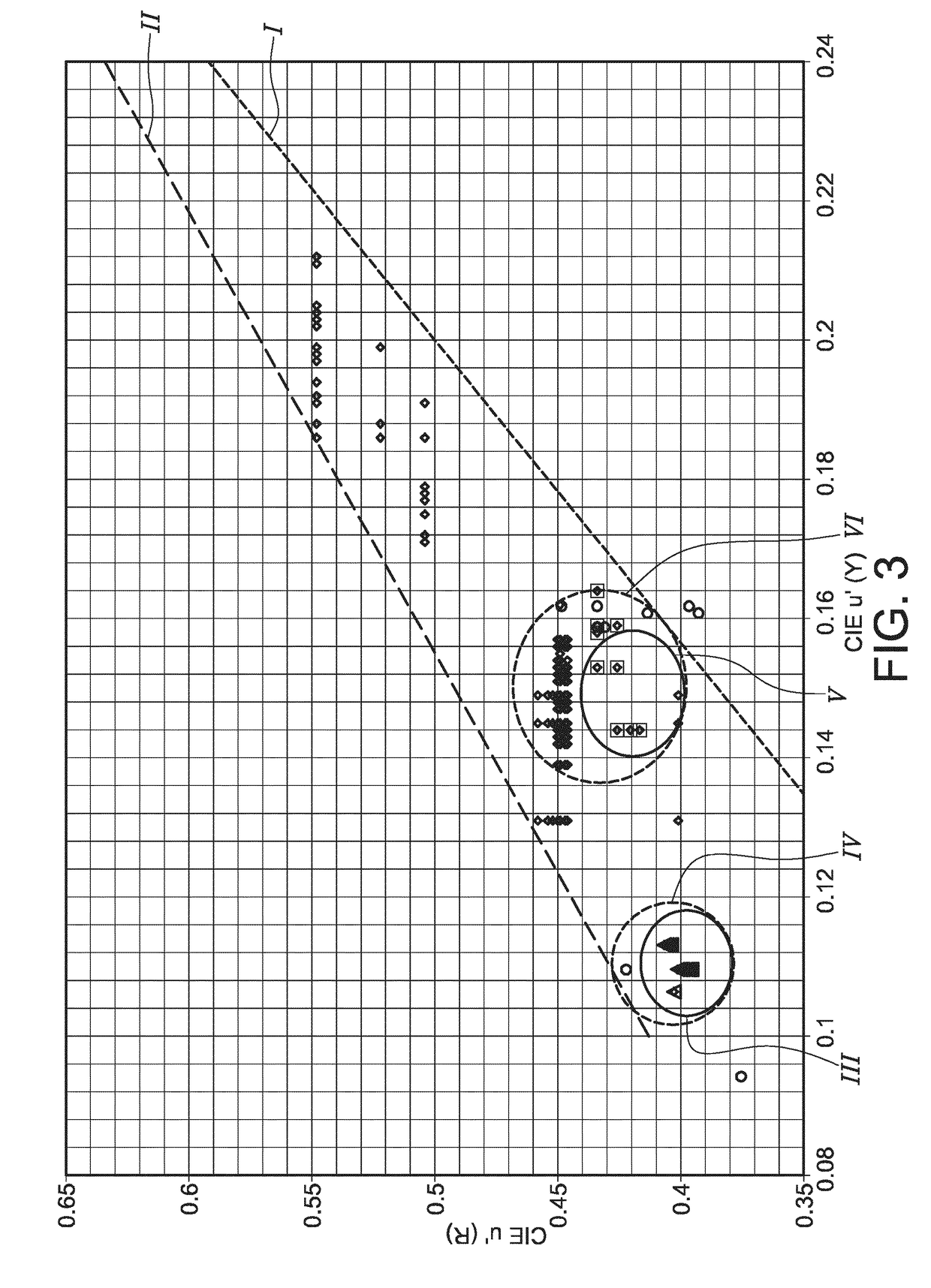

ActiveUS20190055468A1Improve efficiencyGood colorLuminescent compositionsSpectral modifiersEffect lightLuminescent material

The invention provides a lighting device (100) comprising a solid state light source (10) configured to provide blue light (11) having a dominant wavelength selected from the range of 440-490 nm, a first luminescent material (210) configured to convert part of the blue light (11) into first luminescent material light (211) having intensity in one or more of the green and yellow having a CIE u′ (211), and a second luminescent material (220) configured to convert part of one or more of the blue light (11) and the first luminescent material light (211) into second luminescent material light (221) having intensity in one or more of the orange and red having a CIE u′ (221), wherein the first luminescent material (210) and the second luminescent material (220) are selected to provide said first luminescent material light (211) and said second luminescent material light (221) defined by a maximum ratio of CIE u′ (211) and CIE u′ (221) being CIE u′(221)=1.58*CIE u′(211)+0.255, and a minimum ratio of CIE u′ (211) and CIE u′ (221) being CIE u′(221)=2.3*CIE u′(211)+0.04.

Owner:SIGNIFY HLDG BV

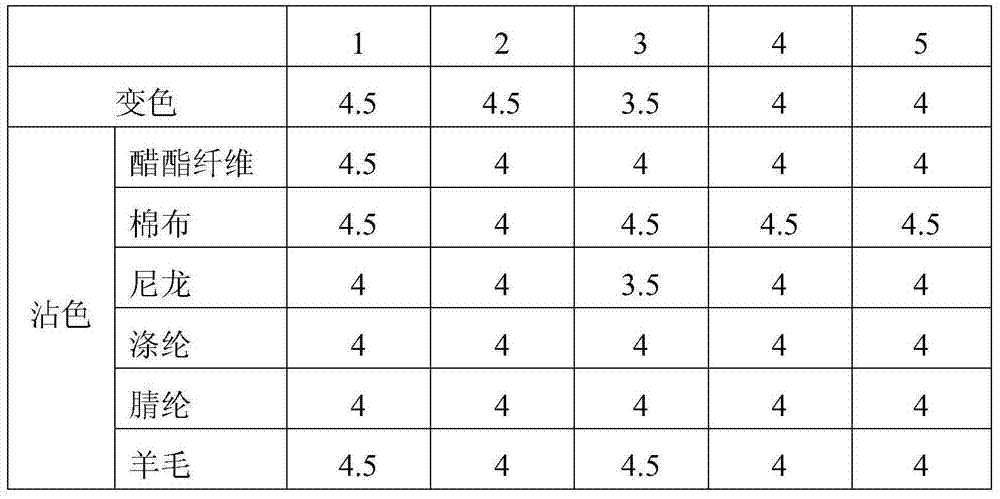

Method for dyeing original ecological cashmere by using plant dye

ActiveCN104711869ADoes not contain hazardous substancesLower dyeing temperatureDyeing processEngineeringEnergy conservation

The invention discloses a dyeing method of cashmere. The dyeing method comprises the following steps:(a) moistening and modifying a cashmere fabric; (b) dyeing the cashmere fabric obtained in the step (a) by using a dyeing solution containing tobacco leaves and stem extracts under the temperature condition of 30-45 DEG C for a time long enough to enable the dyeing solution to be adsorbed on the surface of the cashmere fabric and penetrated in the cashmere fabric, subsequently raising temperature to 65-75 DEG C, and performing heat preservation for a time long enough to enable color to be fixed on the cashmere fabric so that the color of the cashmere fabric is further fixed; (c) washing the cashmere fabric obtained through treatment in the step (b). The dyeing method of the cashmere, disclosed by the invention, has the advantages of environmental protection, energy conservation, good dyeing effect and the like.

Owner:广东印象派服装有限公司

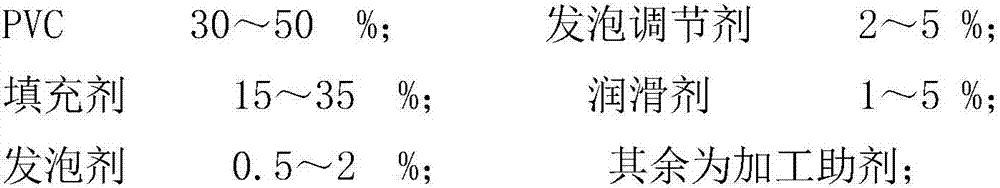

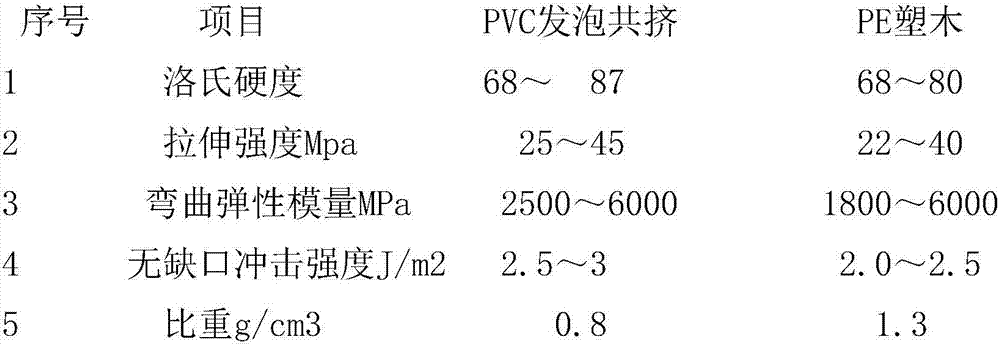

PVC foamed co-extruded floor preparation process

The invention provides a PVC foamed co-extruded floor preparation process, and relates to the technical field of production of plastics-wood materials. The floor preparation process mainly comprises the following steps: material mixing, extrusion foaming, co-extrusion and cooling and shaping production. In the material mixing process, 30-50% of PVC, 2-5% of foaming modifiers, 15-35% of filling agents, 1-5% of lubricating agents, 0.5-2% of foaming agents and processing agents are needed, wherein the percentage sum of all the components is 100%. In the material foaming process, high polymer materials cover foamed base materials through a co-extruder. The floor preparation process has the advantages that the water resistance and moisture resistance are achieved, the problem that the wood product is easy to rot and expand after absorbing water and being affected with the damp in a humid and moist environment is fundamentally solved, the plasticity is high, the personalized modeling can be realized very easily, the individual style is fully embodied, cracking is avoided, expansion is avoided, deformation is avoided, repair and maintenance are not needed, cleaning is facilitated, and later repair and maintenance cost is saved.

Owner:ANHUI SENTAI WPC GRP CO LTD

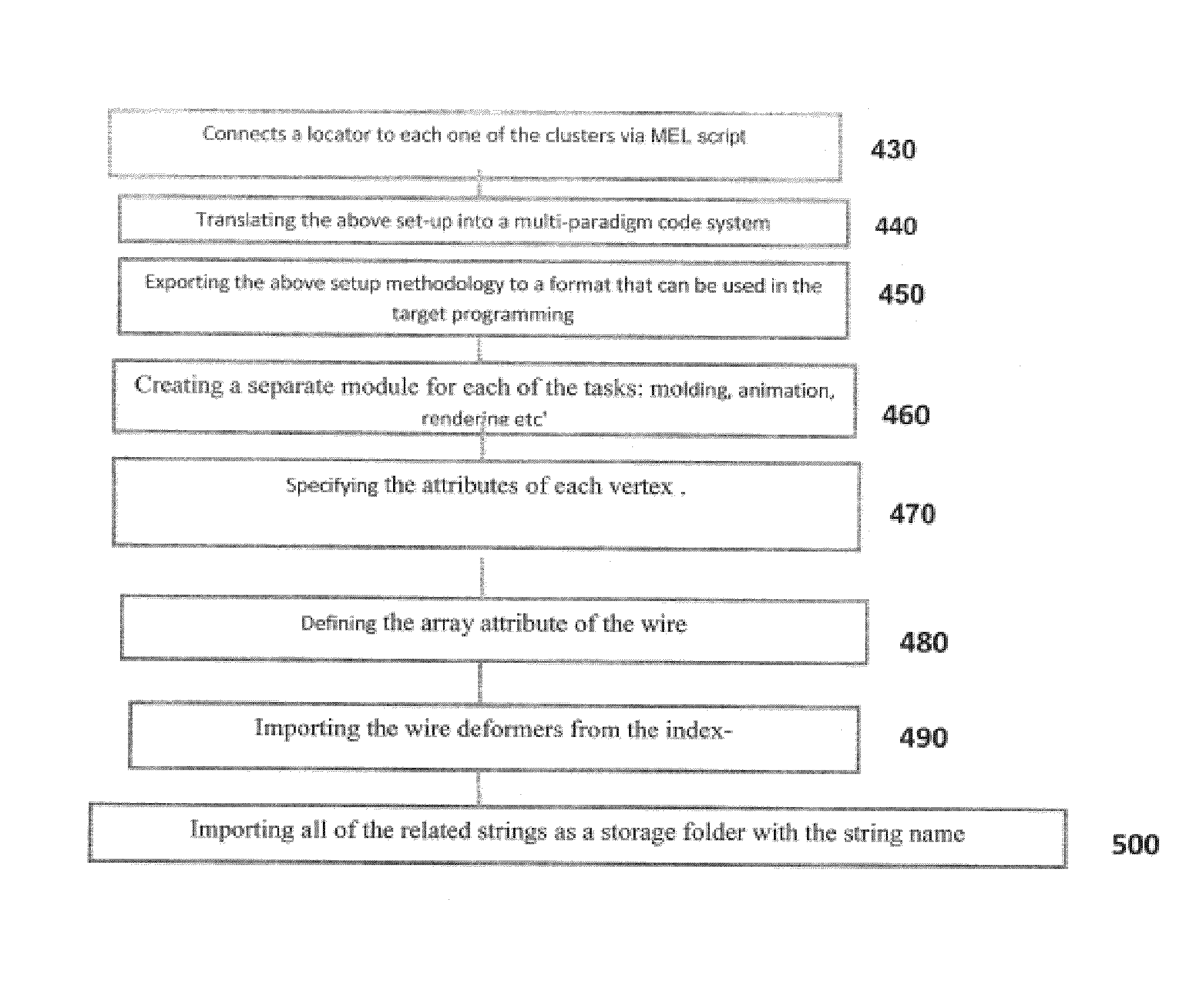

Adding objects to digital photographs

ActiveUS20150221074A1More colorEasy to shareImage enhancementTelevision system detailsComputer graphics (images)Engineering

A system and method for enhancing digital photographs by enabling end-users to add 3D objects to digital photographs. The end-user can select a 3D object from a library, place the 3D object on the digital photograph and then manipulate the 3D object to customize it to its taste. The 3D object can be directly manipulated by the end-user and the end-user can create an infinite number of object variations, in contrast to systems of the art where an end-user can only select object variations from a given number of preloaded object variations. The modified digital photograph can then be shared by the user in one or more social networks.

Owner:SEEMSOME EVERYONE

Wet spinning method for multi-color conductive polymer-based composite conductive fiber

InactiveCN102677223AOvercome the disadvantages of monotonous colorsMore colorArtificial filament heat treatmentWet spinning methodsEmulsionWater soluble

The invention relates to a wet spinning method for multi-color conductive polymer-based composite conductive fiber. The wet spinning method for the multi-color conductive polymer-based composite conductive fiber comprises the following steps: by taking a water-soluble sulfonated polymer as a main dopant, acidic dye or acidic fluorescent dye as a secondary dopant and a polyoxyethylene-containing ester or ether material as an emulsifier, preparing a conductive polymer emulsion through chemical oxidative polymerization reaction with a conductive polymer monomer, blending the conductive polymer emulsion with polyvinyl alcohol, standing and defoaming to obtain a raw spinning solution, and performing wet spinning on the raw spinning solution. The prepared multi-color conductive polymer-based composite conductive fiber has the characteristics of high conductivity, color diversity and good mechanical properties and the like and has a certain electrochromic property; and the wet spinning method for the multi-color conductive polymer-based composite conductive fiber is simple in operating process and easy to realize industrial production, can be used for producing conductive and antistatic fiber and fabric with high added value and the like, and has a wide application prospect.

Owner:BEIJING INSTITUTE OF CLOTHING TECHNOLOGY

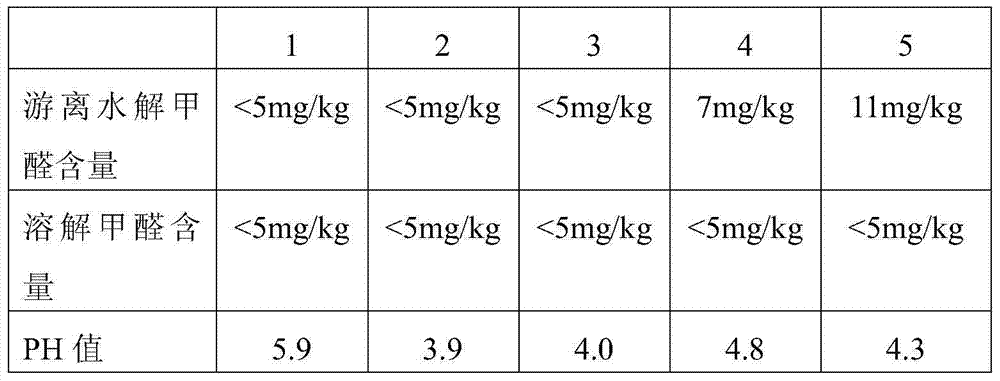

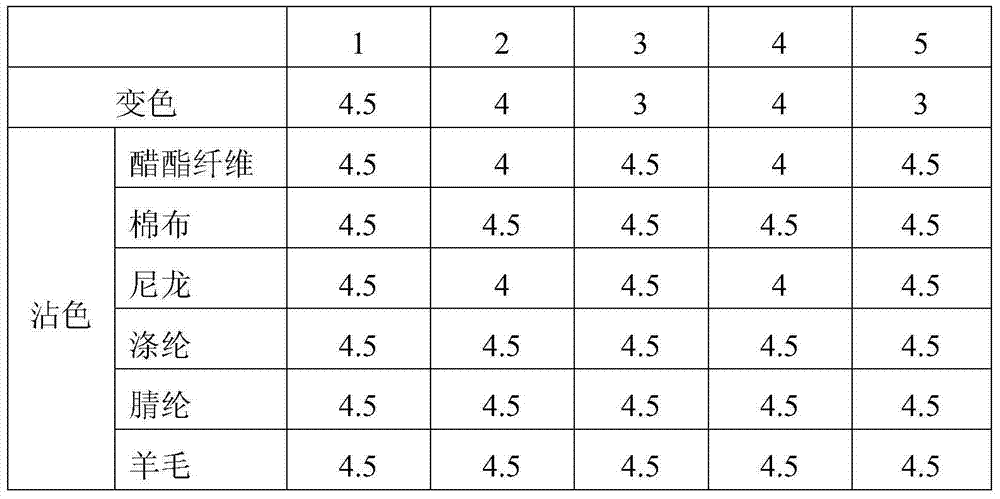

Impregnated film paper veneer blockboard free from formaldehyde release as well as production process thereof

InactiveCN110341009AEasy to cleanEasy to useWood veneer joiningAdhesive application devicesHot pressingPollution

The invention discloses an impregnated film paper veneer blockboard free from formaldehyde release as well as a production process thereof. The blockboard comprises a board core, a middle board, a surface board and impregnated film paper; and the middle board, the surface board and the impregnated film paper adhere to the two surfaces of the board core sequentially and symmetrically. The production process comprises board core production and blockboard production, wherein the blockboard production comprises the processes of gluing, assembling, performing cold-press molding, hot-pressing, reliving pressure, performing putty filling maintenance, determining thickness and sanding, gluing and sticking the surface board, performing cold-press molding, hot-pressing, sanding, performing edge sawing and pressing to stick decorative film paper. The problem of formaldehyde pollution of the blockboard can be solved, and people's high demand on environmental protection life can be met.

Owner:NANNING KETIAN SHUIXING TECH LTD CO

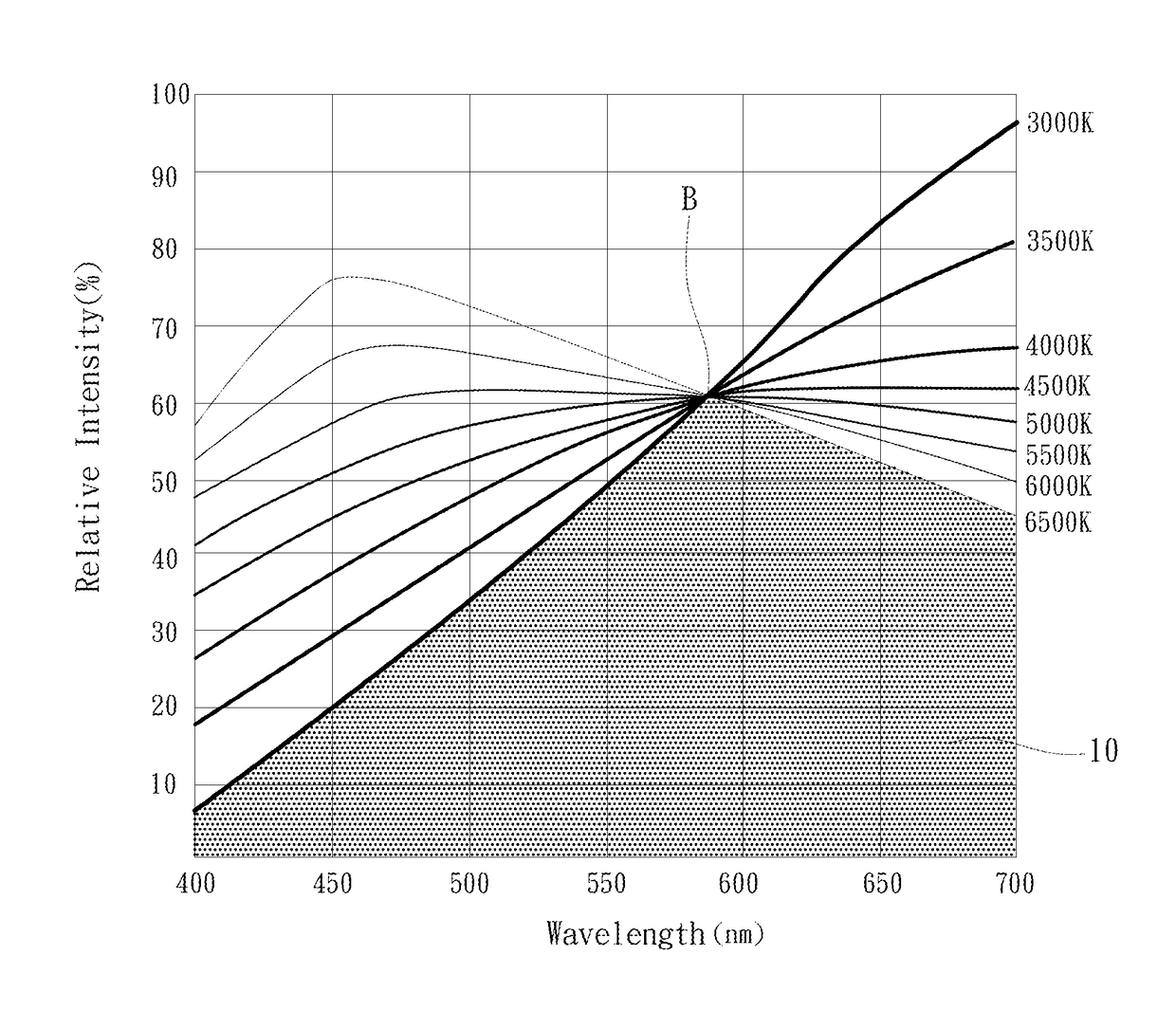

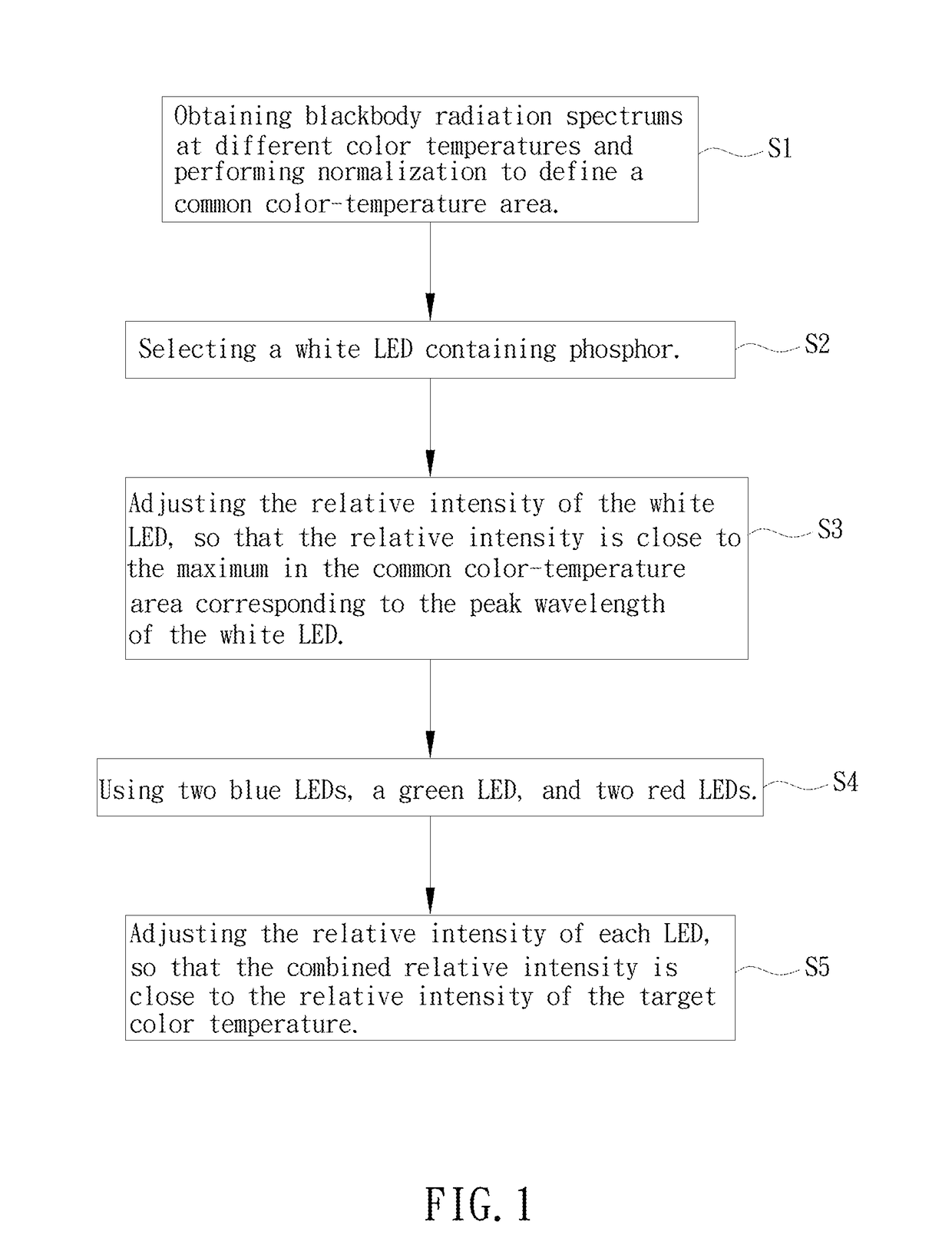

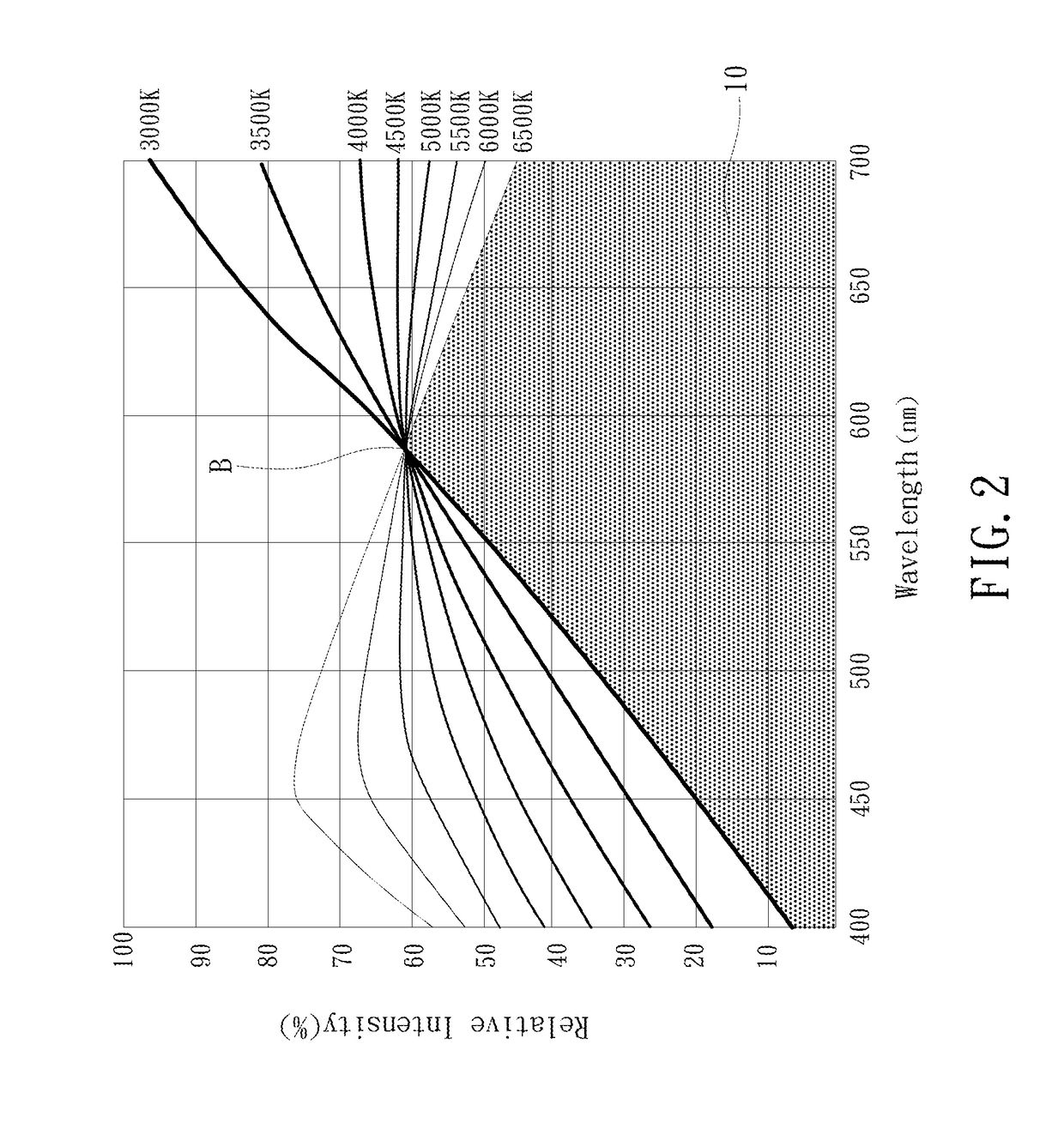

Method for modulating color temperature in visible band

InactiveUS9596731B1More colorModulate a light source to a target color temperature more accuratelyElectrical apparatusElectroluminescent light sourcesPhosphorRelative intensity

A color temperature modulating method involves: computing blackbody spectrums including a target color temperature, and performing normalization at a benchmark wavelength to define a common color-temperature area; selecting a white LED containing phosphor; adjusting the white LED's intensity such that the primary-peak wavelength is close to a maximum relative intensity in the common color-temperature area accordingly; using a blue LED, a green LED, and at least two red LEDs, wherein peak wavelengths of the blue and green LEDs are located between the primary and the secondary wavelength of the white LED, and peak wavelengths of the red LEDs are greater than the primary-peak wavelength; and adjusting relative intensities of the blue, green, and red LEDs to make a relative intensity of a combination of these LEDs and the white LED close to the target color temperature.

Owner:HM ELECTRONICS CO LTD

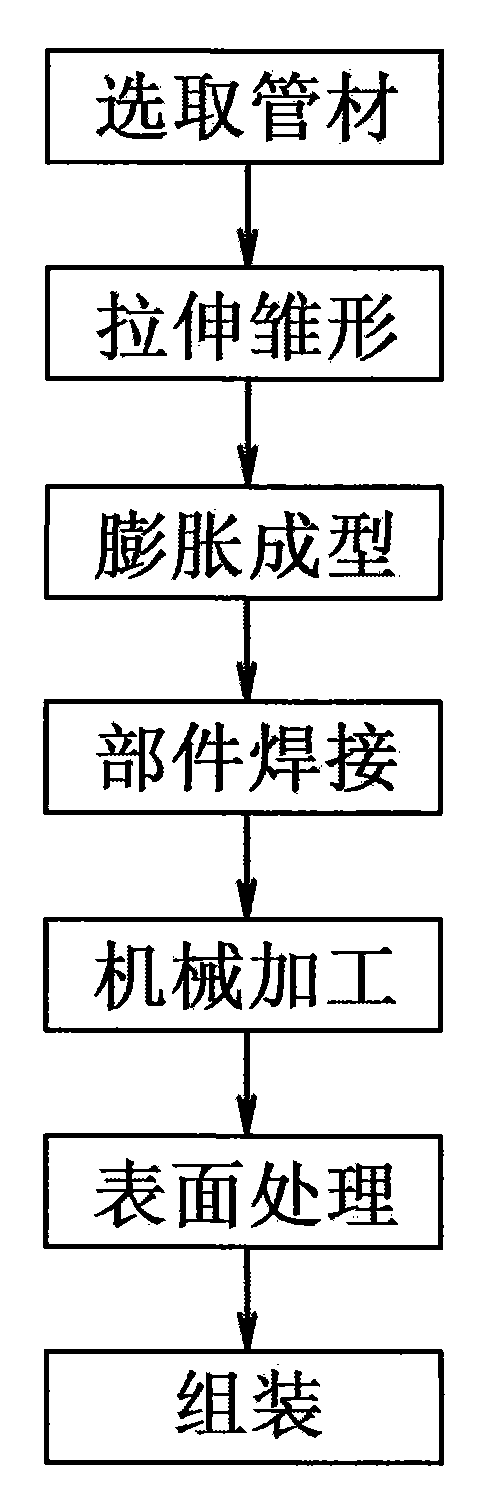

Water or oil expansion or extension type faucet manufacturing technology

The invention discloses a water or oil expansion or extension type faucet manufacturing technology. The technology is characterized by comprising the steps of (1) pipe selection, (2) prototype extension, (3) expansion forming, (4) part welding, (5) machining, (6) surface treatment and (7) assembly. Compared with the prior art, the technology has the advantages that a faucet manufactured with the technology is low in cost, available in multiple styles and colors, and capable of being formed into any shapes in an expansion mode, the yield is high, the faucet can be directly polished into a mirror surface, electroplating is not needed, durability is higher than that of copper alloy products or zinc alloy products, and the technology can replace the faucet body precision casting or welding technology.

Owner:邝振华

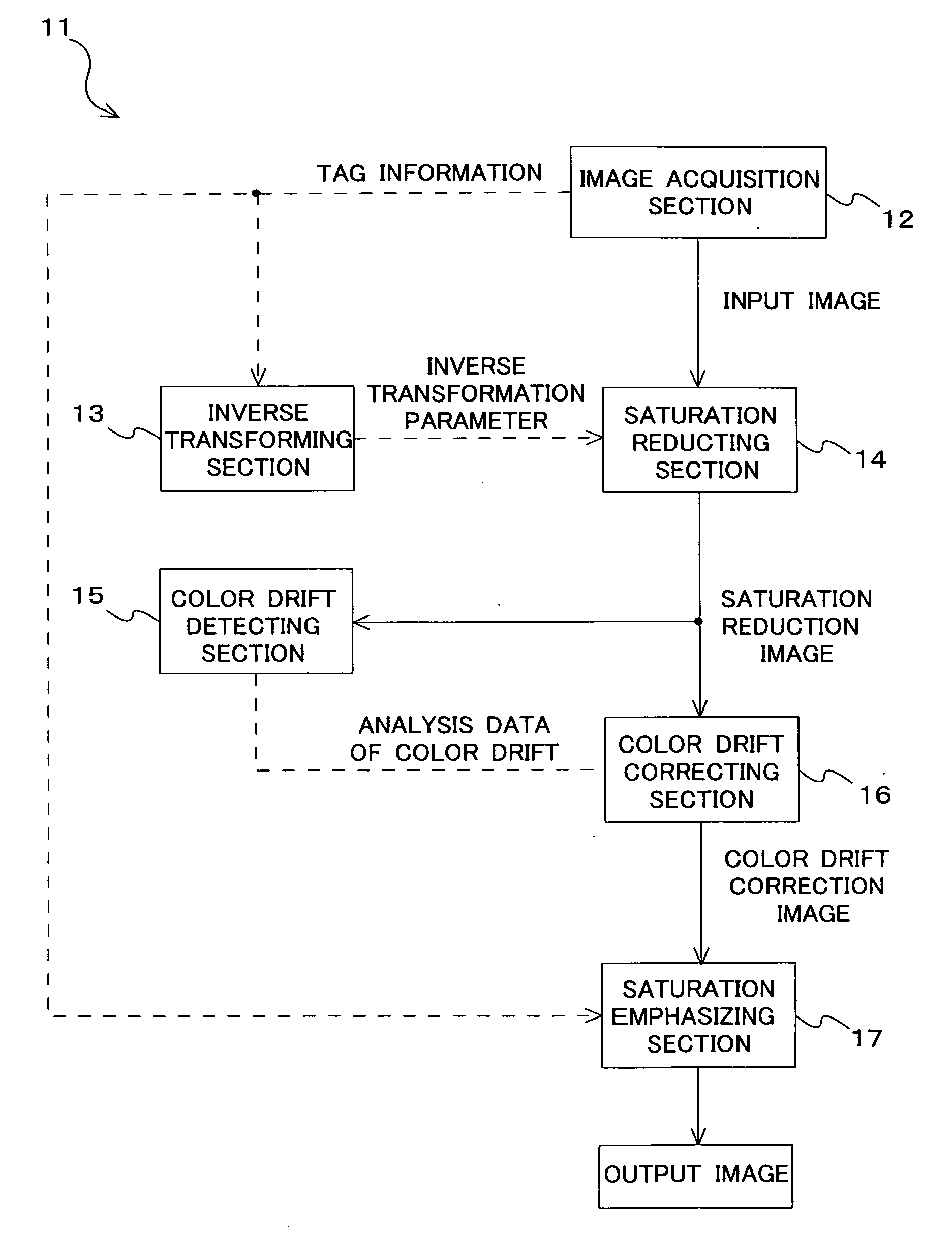

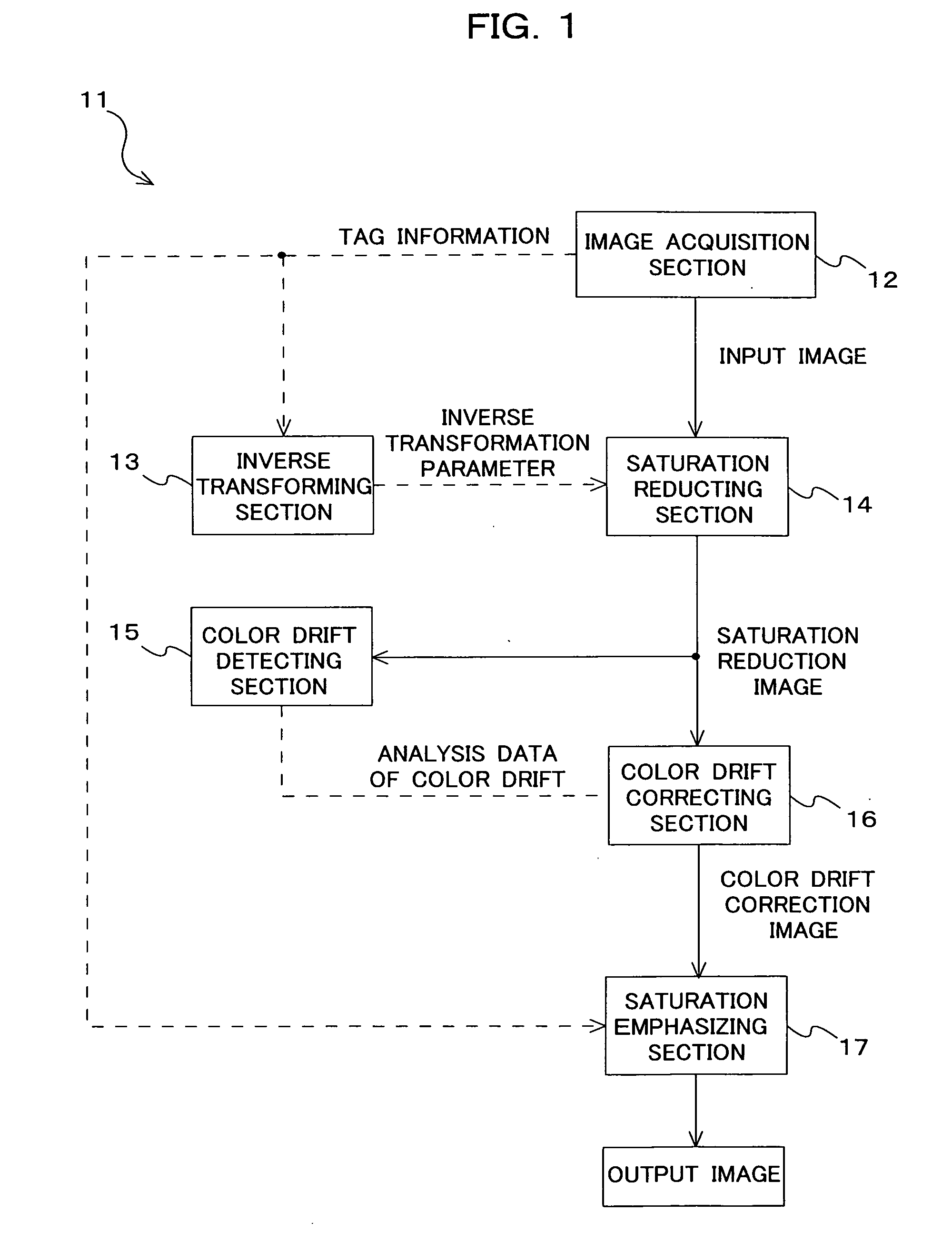

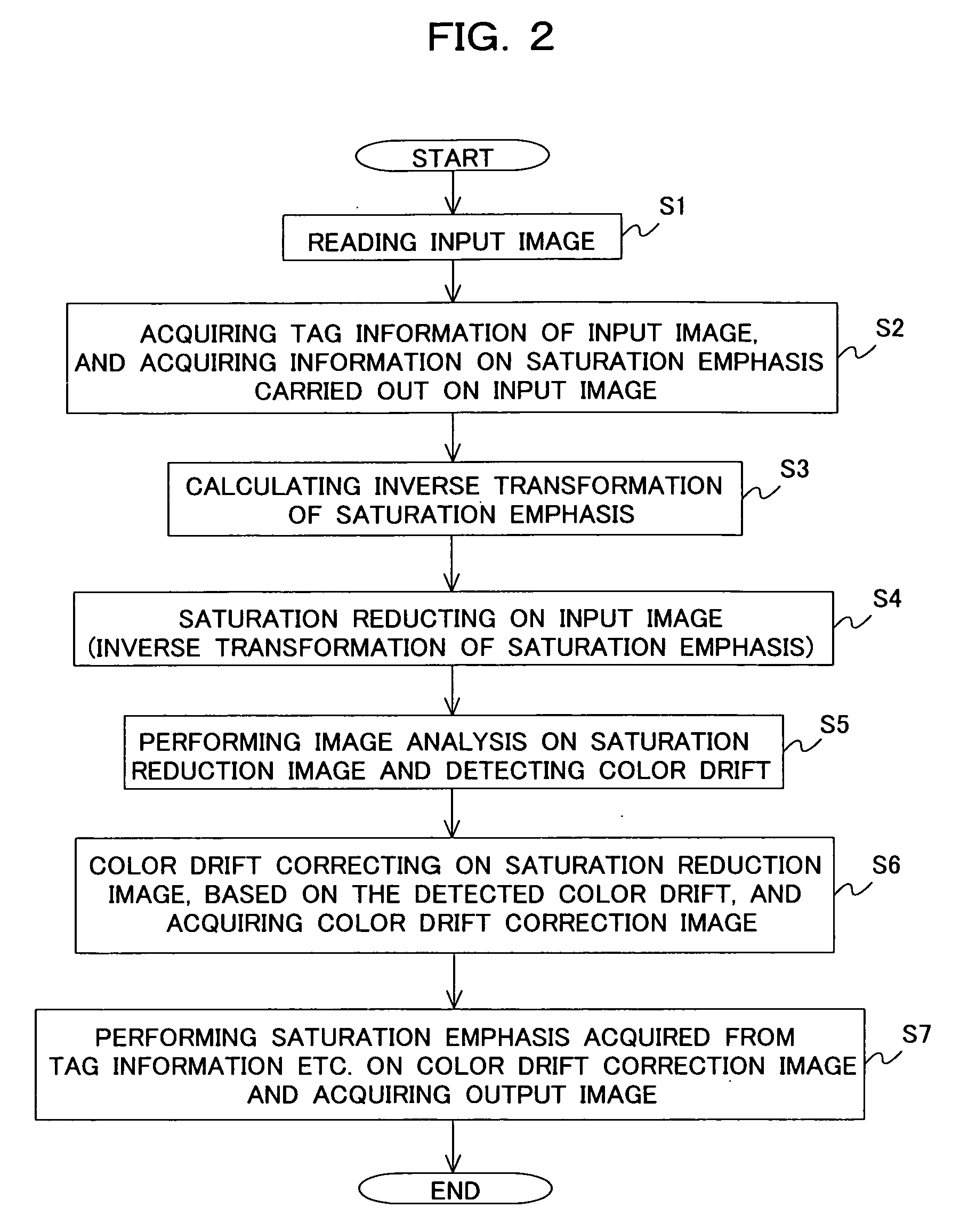

Image processing device for correcting image colors and image processing program

ActiveUS20100073523A1Reduce saturationMore colorTelevision system detailsColor signal processing circuitsImaging processing

An image processing device of the present application detects a color drift of an input image, and includes a saturation reducing section and a color drift detecting section. The saturation reducing section reduces a saturation of the input image and generates a saturation reduction image. The color drift detecting section detects a color drift of the saturation reduction image.

Owner:NIKON CORP

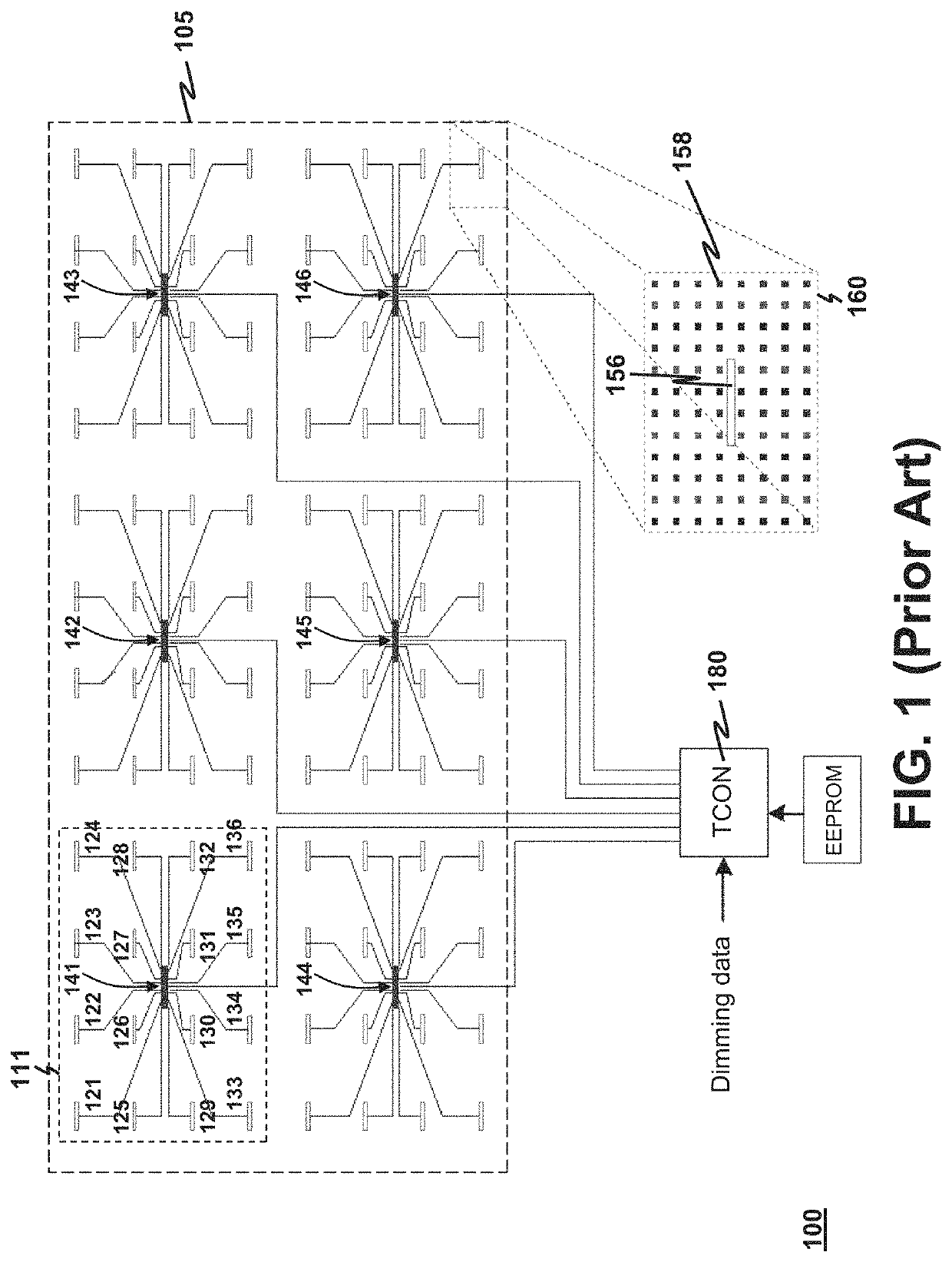

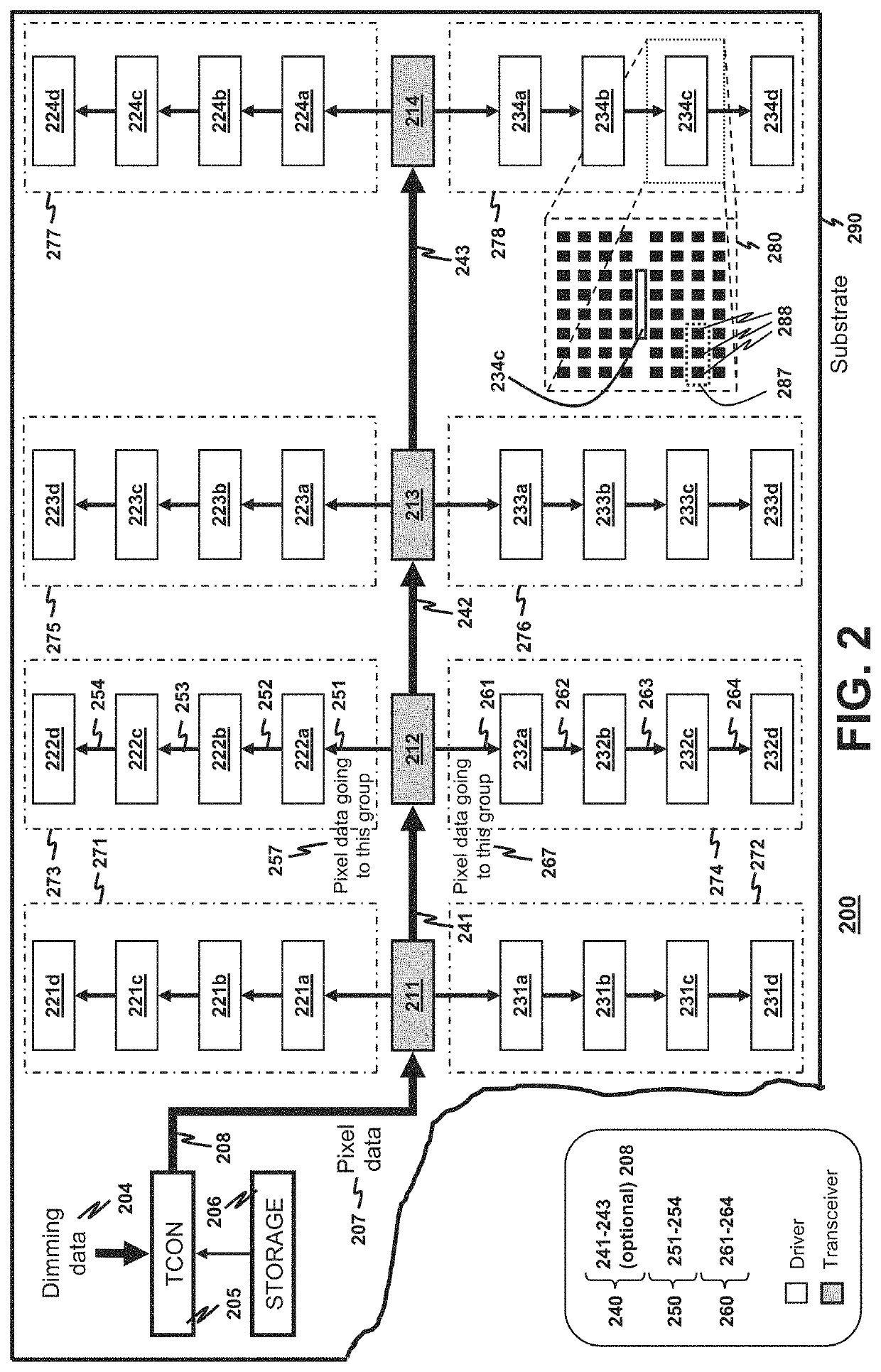

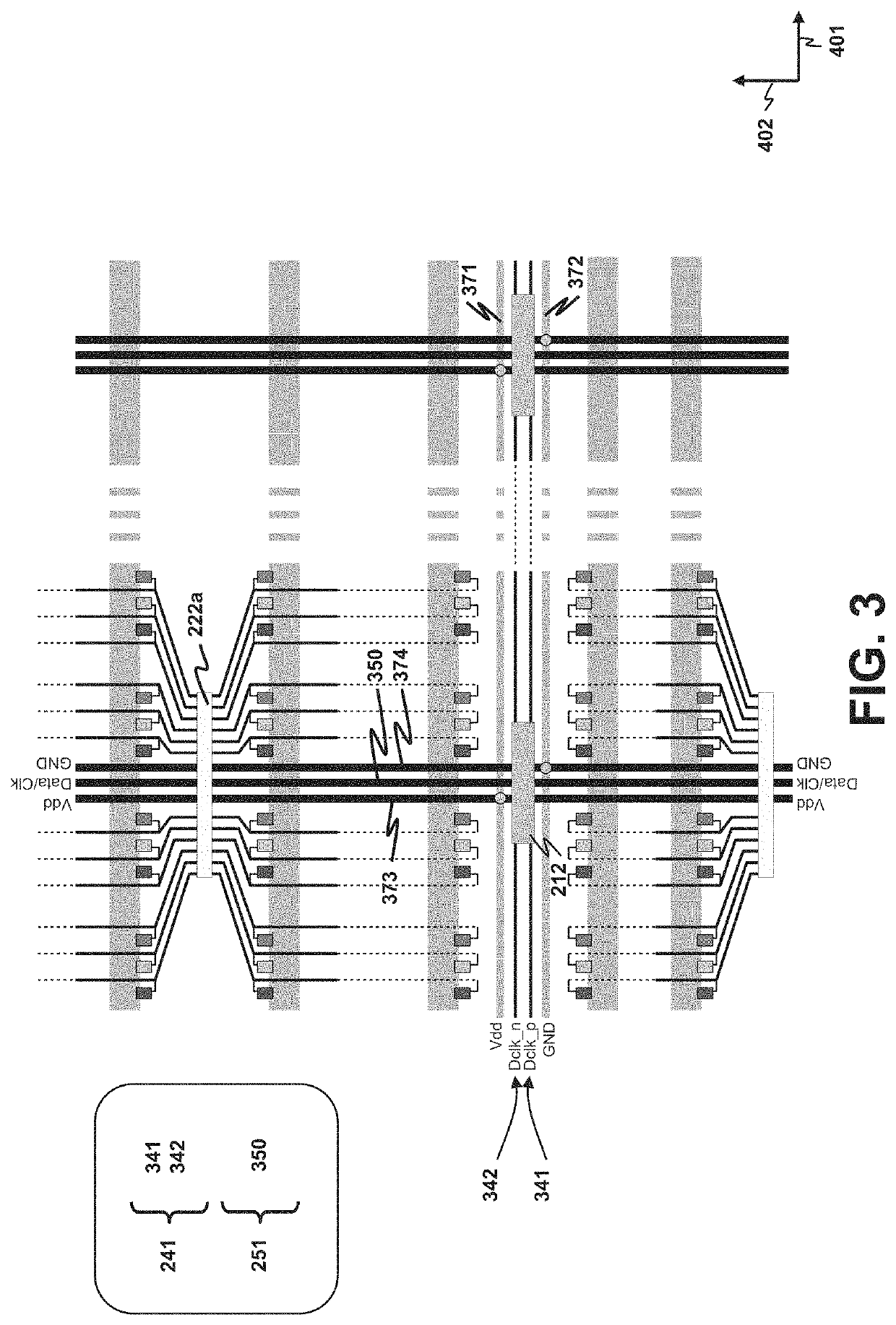

Display panel with distributed driver network

ActiveUS10950194B1Extended lighting rangeMore colorCathode-ray tube indicatorsInput/output processes for data processingEmbedded systemData transmission

In a display panel, drivers for driving LEDs of pixels are distributed over a substrate, and transceivers relay pixel data from a timing controller to the drivers. The drivers are divided into groups. Respective drivers in a group receive corresponding pixel data addressed thereto solely from one corresponding transceiver. The corresponding transceiver and the respective drivers are daisy-chained to form one first linear daisy chain, where each pair of immediately-adjacent first drivers are connected. Plural first linear daisy chains are formed for all groups. The transceivers are daisy-chained to form a second linear daisy chain by connecting each pair of immediately-adjacent transceivers. The first and second linear daisy chains form a fishbone topology network to enable transmission of pixel data from the timing controller to the drivers while reducing a data-line footprint on the substrate that mounts the pixels, driver and transceivers in comparison to a conventional star-topology network.

Owner:SOLOMON SYSTECH SHENZHEN LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com