Colored sand capable of coloring by reaction and its preparation method

A colored sand and colored technology, applied in the field of colored sand, can solve the problems of reducing the hydrophobicity of the sand surface, rough surface coloring layer, exposing the color and texture of the original aggregate sand, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

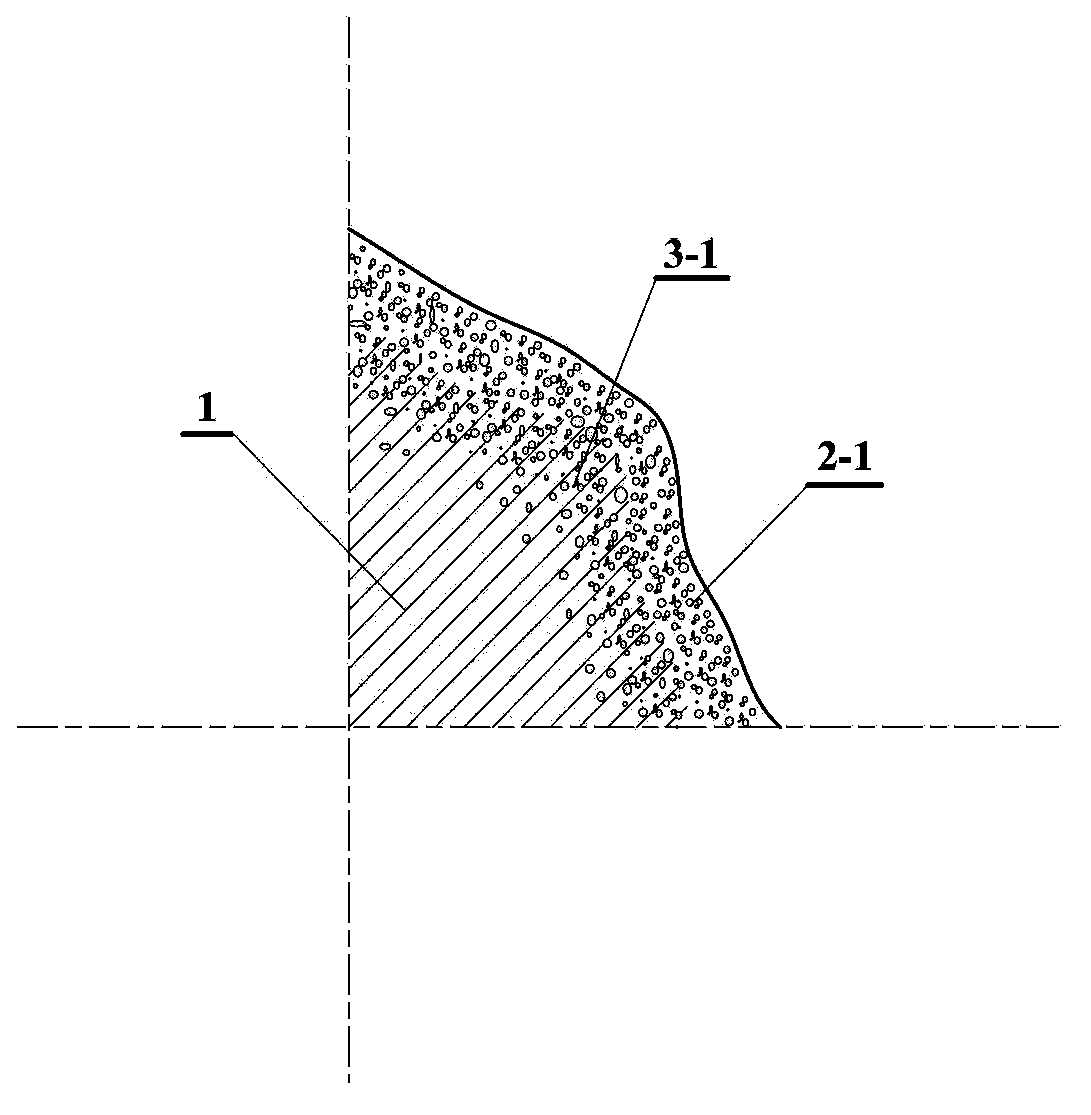

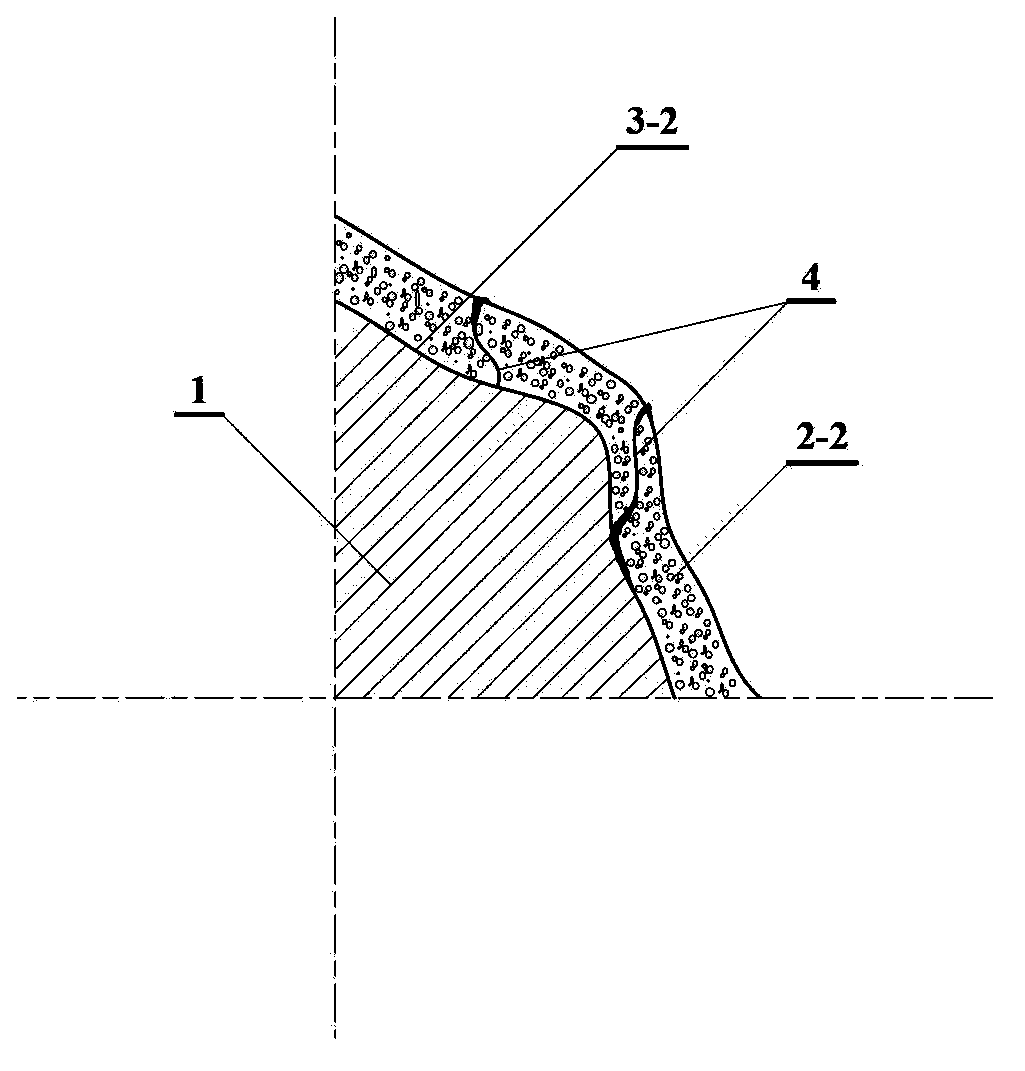

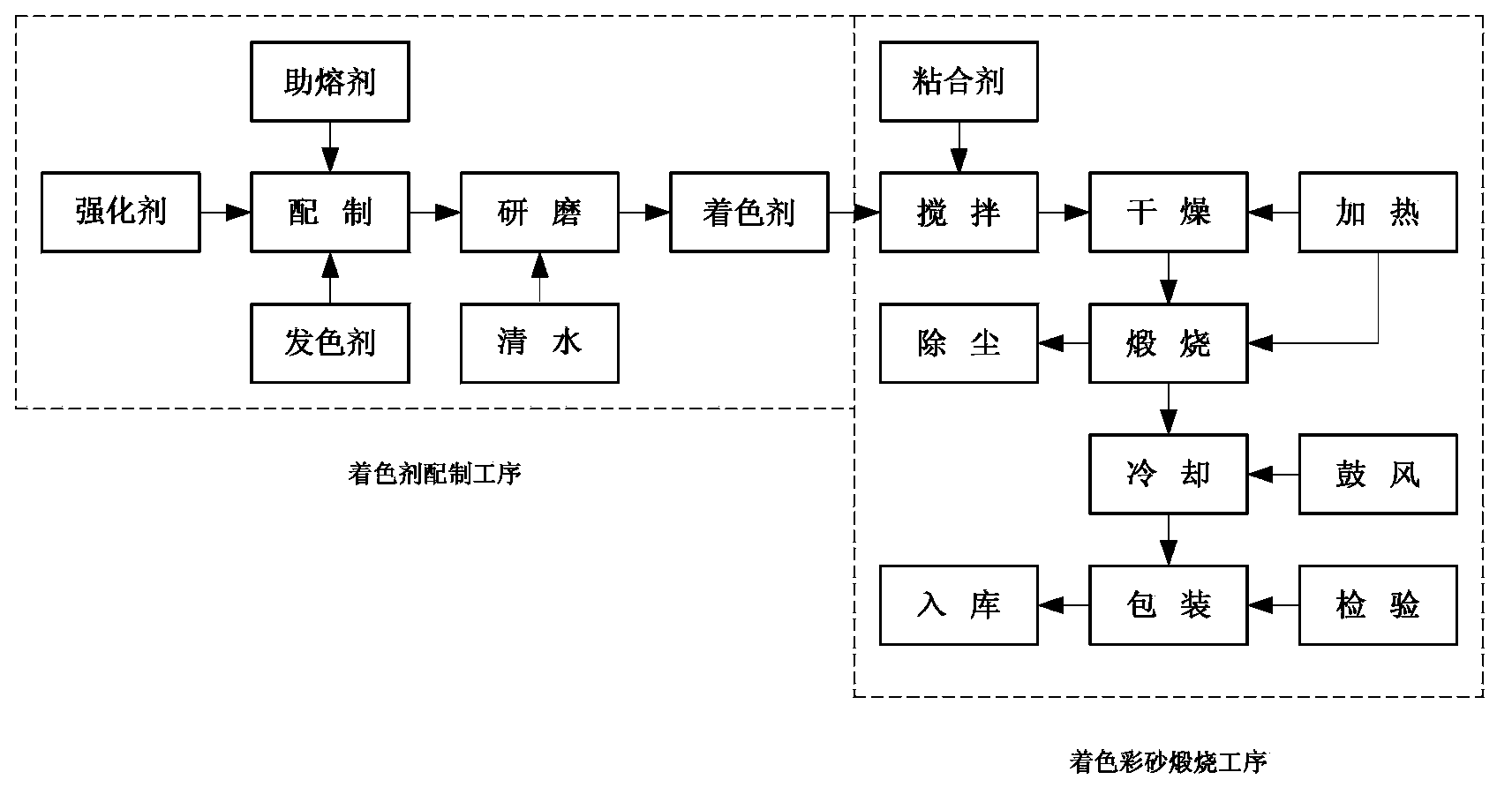

[0095] according to figure 1 and image 3 The production process and product requirements of a colored sand that adopts reaction coloring and its preparation method are shown, and a kind of colored sand that adopts reaction coloring of the present invention is prepared. The specific steps are as follows:

[0096] 1) Preparation of colorant paste:

[0097]Add the raw materials of 15.3 parts by weight of quartz powder, 20.5 parts by weight of kaolin, 23.9 parts by weight of lead carbonate, 36.8 parts by weight of borax, 3.2 parts by weight of ferric oxide, 0.3 parts by weight of potassium dichromate and 66.0 parts by weight of clear water into the grinding machine. Grinding in the grinding bucket, when the particle size of solid objects in the colorant slurry reaches below 5 μm, take out the colorant slurry in the grinding bucket, put it into a container and tightly cover it for later use;

[0098] 2) Preparation of colored sand raw materials:

[0099] 2.1) Put 100.0 parts b...

Embodiment 2

[0107] according to figure 1 and image 3 The production process and product requirements of a colored sand that adopts reaction coloring and its preparation method are shown, and a kind of colored sand that adopts reaction coloring of the present invention is prepared. The specific steps are as follows:

[0108] 1) Preparation of colorant paste:

[0109] 13.5 parts by weight of quartz powder, 5.0 parts by weight of heavy calcium powder, 17.2 parts by weight of aluminum sesquioxide, 25.9 parts by weight of sodium carbonate, 15.8 parts by weight of boric acid, 19.6 parts by weight of zinc oxide, 3.0 parts by weight of potassium dichromate and 60.0 parts by weight of clear water Parts of raw materials are added to the grinding barrel of the grinder for grinding in turn, and when the particle size of the solid object in the colorant slurry reaches below 5 μm, take out the colorant slurry in the grinding barrel, put it into a container and tightly cover it for later use;

[011...

Embodiment 3

[0118] according to figure 1 and image 3 The production process and product requirements of a colored sand that adopts reaction coloring and its preparation method are shown, and a kind of colored sand that adopts reaction coloring of the present invention is prepared. The specific steps are as follows:

[0119] 1) Preparation of colorant paste:

[0120] Add 18.1 parts by weight of kaolin, 6.7 parts by weight of magnesium oxide, 12.8 parts by weight of quartz powder, 16.7 parts by weight of zinc oxide, 24.6 parts by weight of potassium carbonate, 18.2 parts by weight of borax, 2.9 parts by weight of cobalt oxide and 62.0 parts by weight of clear water into the grinding Grinding in the grinding bucket of the machine, when the particle size of the solid object in the colorant slurry reaches below 5 μm, take out the colorant slurry in the grinding bucket, put it into a container and tightly cover it for later use;

[0121] 2) Preparation of colored sand raw materials:

[012...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com