Method for preparing simple and controllable nanoscale silver-loaded monox

A silver silicon oxide, nano-scale technology, applied in the fields of nanotechnology, nanotechnology, nanotechnology, etc. for materials and surface science, can solve the problems of uneven distribution and difficulty in further reducing the size of silver nanoparticles, and achieve distribution Uniform, to meet the needs of large-scale industrial production, the effect of strong operability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0038] a. Mix 160mL of absolute ethanol and 6mL of TEOS; mix 7mL of concentrated ammonia water, 40mL of water and 20mL of absolute ethanol, add to the above mixture, and stir at 25°C for 12 hours.

[0039] b. Centrifuge the solution obtained in step a. at room temperature, wash and dry to obtain monodisperse spherical SiO 2 particles.

[0040] c. 1g of SiO obtained in step b. 2 Disperse the particles and 8mL aminosilane coupling agent in 120mL toluene, and reflux at 80°C for 24 hours;

[0041] d. The mixture obtained in step c. was centrifuged and washed three times with absolute ethanol and water respectively, and then ultrasonically dispersed in 60 mL of water.

[0042] e. Take step d. Gained SiO 2 20mL of aqueous solution, add dropwise 20mL, 0.2M silver ammonia solution, and stir at 15°C for 24 hours;

[0043] f. Wash and centrifuge the mixed solution obtained in step e. for 3 times, and dry to obtain nano-scale silver-loaded SiO 2 particles.

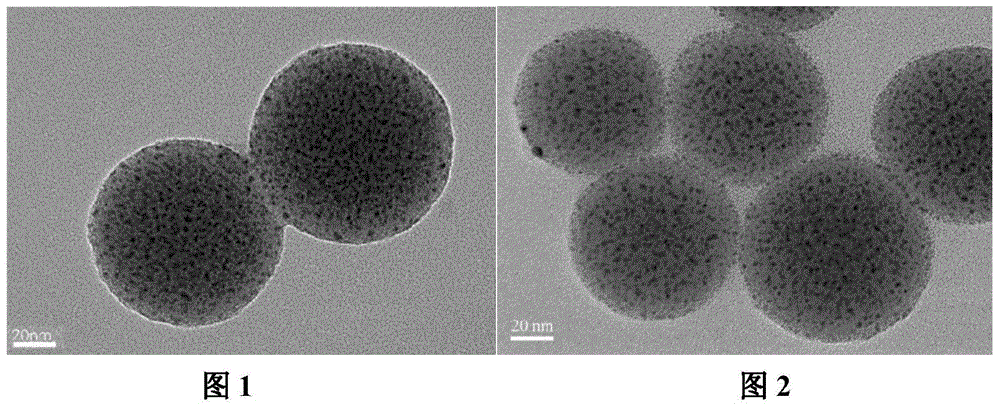

[0044] The test shows t...

Embodiment 2

[0046] a. Mix 160mL of absolute ethanol and 6mL of TEOS; mix 7mL of concentrated ammonia water, 40mL of water and 20mL of absolute ethanol, add to the above mixture, and stir at 25°C for 12 hours.

[0047] b. Centrifuge the solution obtained in step a. at room temperature, wash and dry to obtain monodisperse spherical SiO 2 particles.

[0048]c. 1g of SiO obtained in step b. 2 Disperse the particles and 4mL aminosilane coupling agent in 120mL toluene, and reflux at 80°C for 24 hours;

[0049] d. The mixture obtained in step c. was centrifuged and washed three times with absolute ethanol and water respectively, and then ultrasonically dispersed in 60 mL of water.

[0050] e. Take step d. Gained SiO 2 20mL of aqueous solution, add dropwise 20mL, 0.2M silver ammonia solution, and stir at 15°C for 24 hours;

[0051] f. Wash and centrifuge the mixed solution obtained in step e. for 3 times, and dry to obtain nano-scale silver-loaded SiO 2 particles.

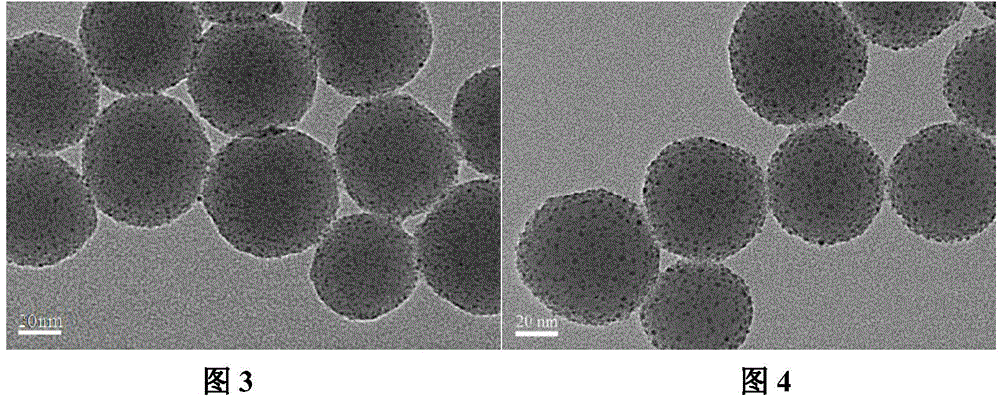

[0052] The test shows th...

Embodiment 3

[0054] a. Mix 160mL of absolute ethanol and 6mL of TEOS evenly, and heat up to 50°C; mix 7mL of concentrated ammonia water, 10mL of water and 20mL of absolute ethanol, add to the above mixture, and stir at 50°C for 8 hours.

[0055] b. Centrifuge the solution obtained in step a. at room temperature, wash and dry to obtain monodisperse spherical SiO 2 particles.

[0056] c. 1g of SiO obtained in step b. 2 Disperse the particles and 4mL aminosilane coupling agent in 120mL toluene, and reflux at 80°C for 24 hours;

[0057] d. The mixture obtained in step c. was centrifuged and washed three times with absolute ethanol and water respectively, and then ultrasonically dispersed in 60 mL of water.

[0058] e. Take step d. Gained SiO 2 20mL of aqueous solution, add dropwise 20mL, 0.05M silver ammonia solution, and stir at 15°C for 6 hours;

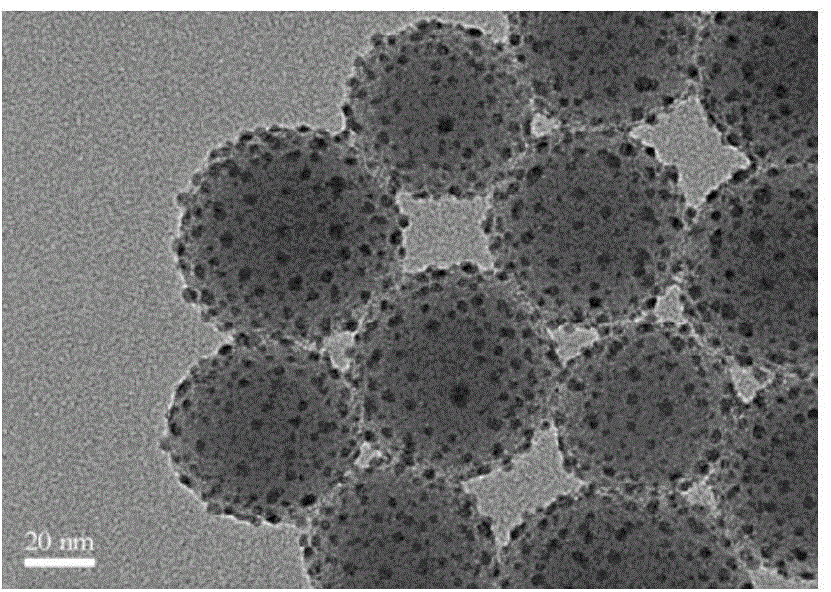

[0059] f. Wash and centrifuge the mixed solution obtained in step e. for 3 times, and dry to obtain nano-scale silver-loaded SiO 2 particles....

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com