Manufacturing method of alloy steel section tubes

A manufacturing method and a special-shaped tube technology, which are applied in the field of manufacturing alloy steel special-shaped tubes by hot extrusion, to achieve the effects of good product quality, reduction of production costs, and satisfaction of large-scale industrial production.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0035] Follow the steps below to manufacture Q345B special-shaped pipes.

[0036] (1) Rod preparation: smelt the metal into an alloy steel whose chemical composition and weight percentage are 0.14% carbon, 1.2% manganese, 0.38% silicon, 0.019% sulfur, 0.015% phosphorus, 0.06% copper, and the balance is iron. into steel ingots, steel ingots are forged or rolled into bars, and the diameter of the bars is .

[0037] (2) Bar machining: Use a long stripping machine to strip the surface defects of the bar, and then saw the bar into blanks with a length of 400-500mm.

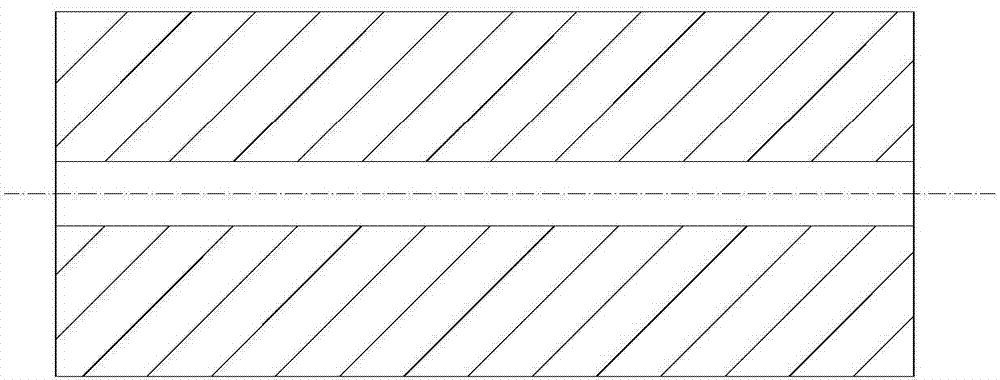

[0038] (3) Drilling: Then use a deep hole drilling machine to drill the blank with a diameter of 45mm; then process the end face (to make the end face flat), chamfer one end, and make it as figure 1 The tube blank 1 shown.

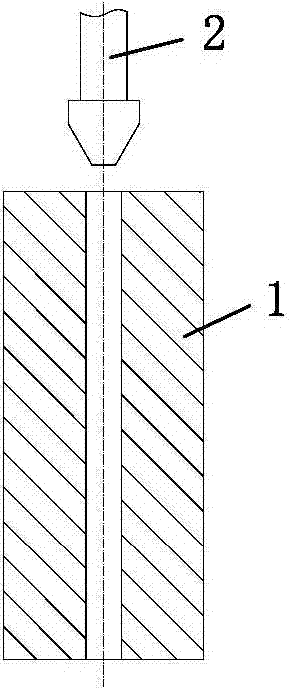

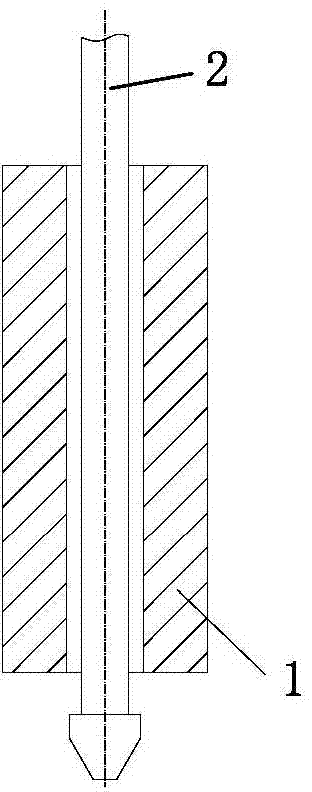

[0039] (4) Reaming: such as Figure 2A and Figure 2B As shown, the tube blank 1 is preheated to 700-750°C with a ring furnace first, and then the tube blank 1 is heated to 1100-1200°C with a...

Embodiment 2

[0045] Follow the steps below to manufacture Q345B special-shaped pipes.

[0046] (1) Bar preparation: metal smelting into alloy steel with chemical composition and weight percentage of 0.16% carbon, 1.4% manganese, 0.20% silicon, 0.015% sulfur, 0.010% phosphorus, 0.14% copper, and iron as the balance, casting into steel ingots, steel ingots are forged or rolled into bars, and the diameter of the bars is .

[0047](2) Bar machining: Use a long stripping machine to strip the surface defects of the bar, and then saw the bar into blanks with a length of 500-600mm.

[0048] (3) Drilling: Then use a deep-hole drilling machine to drill the blank with a diameter of 45 mm; then process the end face (to make the end face flat), and chamfer one end to obtain the tube blank 1 .

[0049] (4) Hole expansion: Preheat the tube blank 1 to 800-900°C with a ring furnace first, then heat the tube blank 1 to 1100-1200°C with an induction heating furnace, and use a hole reamer 2 to expand the t...

Embodiment 3

[0054] Follow the steps below to manufacture Q345B special-shaped pipes.

[0055] (1) Rod preparation: smelt the metal into an alloy steel whose chemical composition and weight percentage are 0.20% carbon, 1.6% manganese, 0.45% silicon, 0.020% sulfur, 0.020% phosphorus, 0.40% copper, and the balance is iron. into steel ingots, steel ingots are forged or rolled into bars, and the diameter of the bars is .

[0056] (2) Machining of rods: Use a long material peeling machine to strip the surface defects of the rods, and then saw the rods into blanks with a length of 400-450 mm.

[0057] (3) Drilling: Then drill the blank with a deep hole drilling machine, the diameter of the drilled hole is Ф44.8mm; then process the end face (make the end face flat), and chamfer one end to obtain the tube blank 1.

[0058] (4) Hole expansion: Preheat the tube blank 1 to 800-900°C with a ring furnace, then heat the tube blank 1 to 1150-1200°C with an induction heating furnace, and use a hole rea...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com