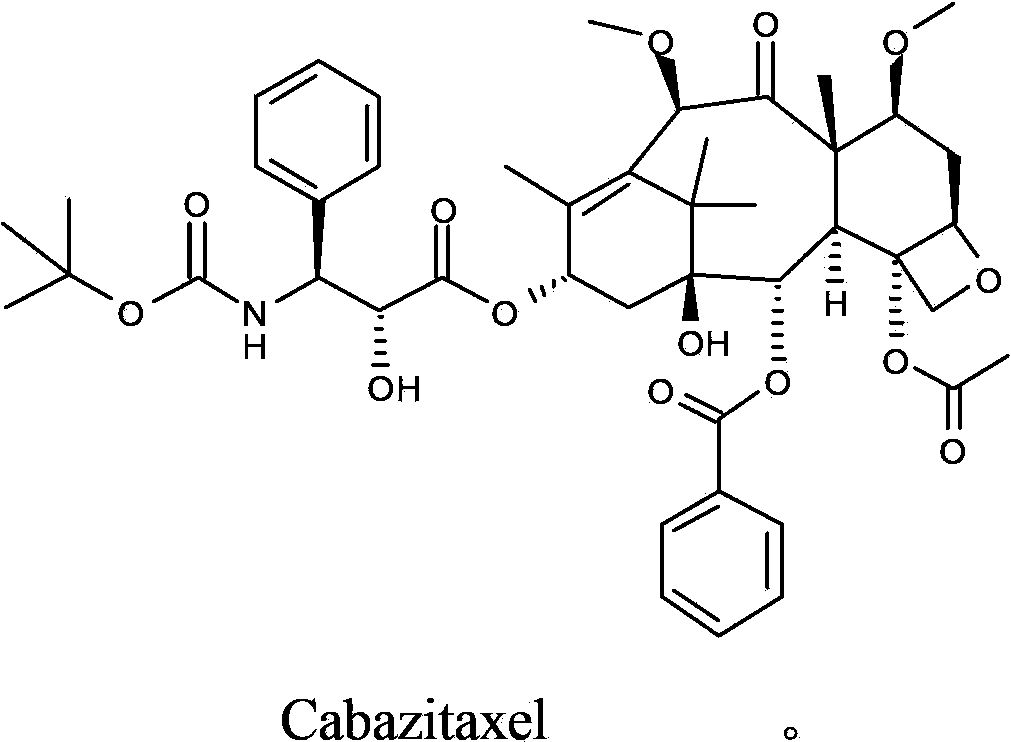

Cabazitaxel intermediate as well as preparation method and application thereof

A cabazitaxel and intermediate technology, which is applied in the field of pharmaceutical synthesis, can solve the problems of harsh three-step synthesis reaction conditions, unsuitable for industrial production requirements, and low purity of the final product, and achieves simple preparation method, mild reaction conditions, and yield. high effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

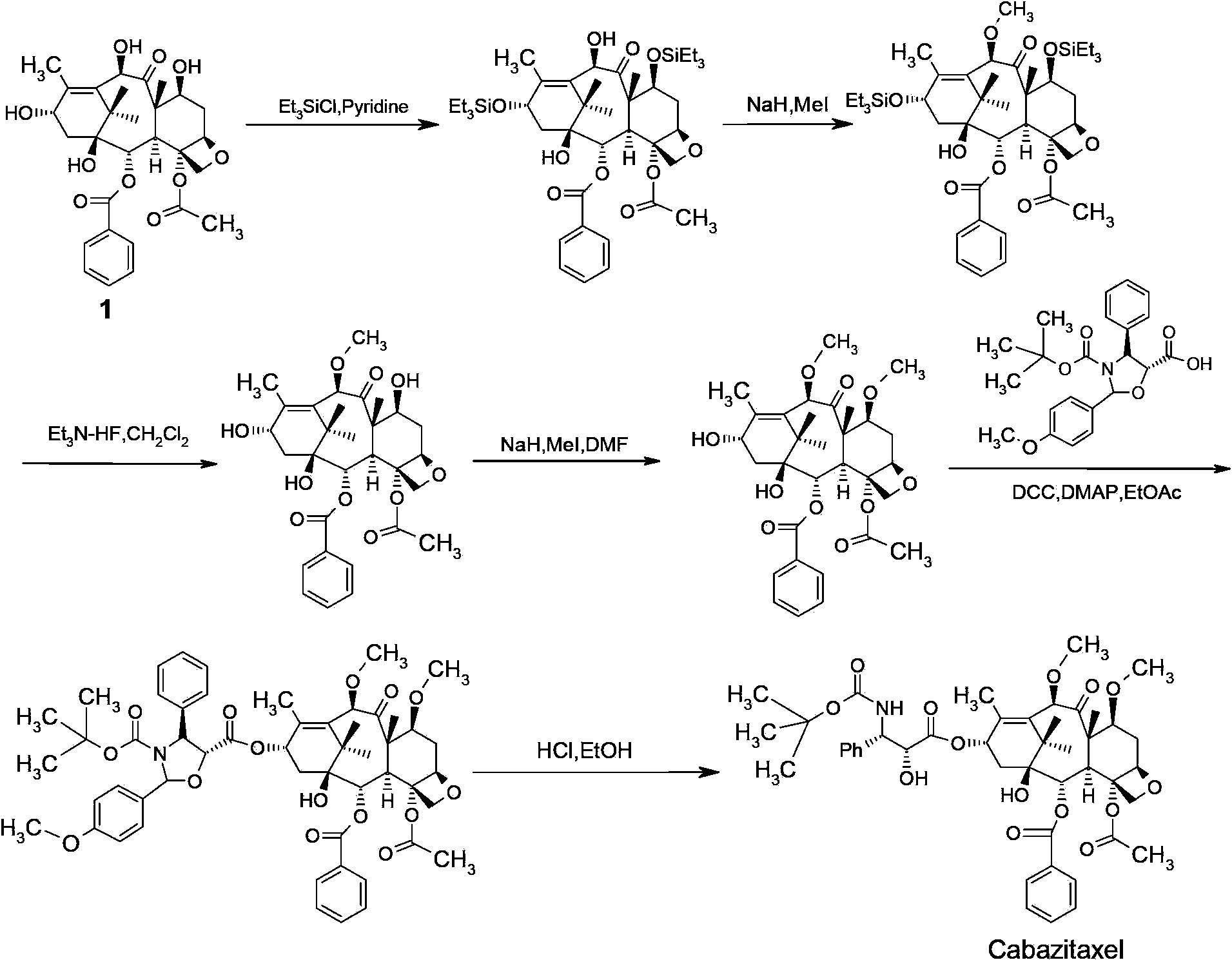

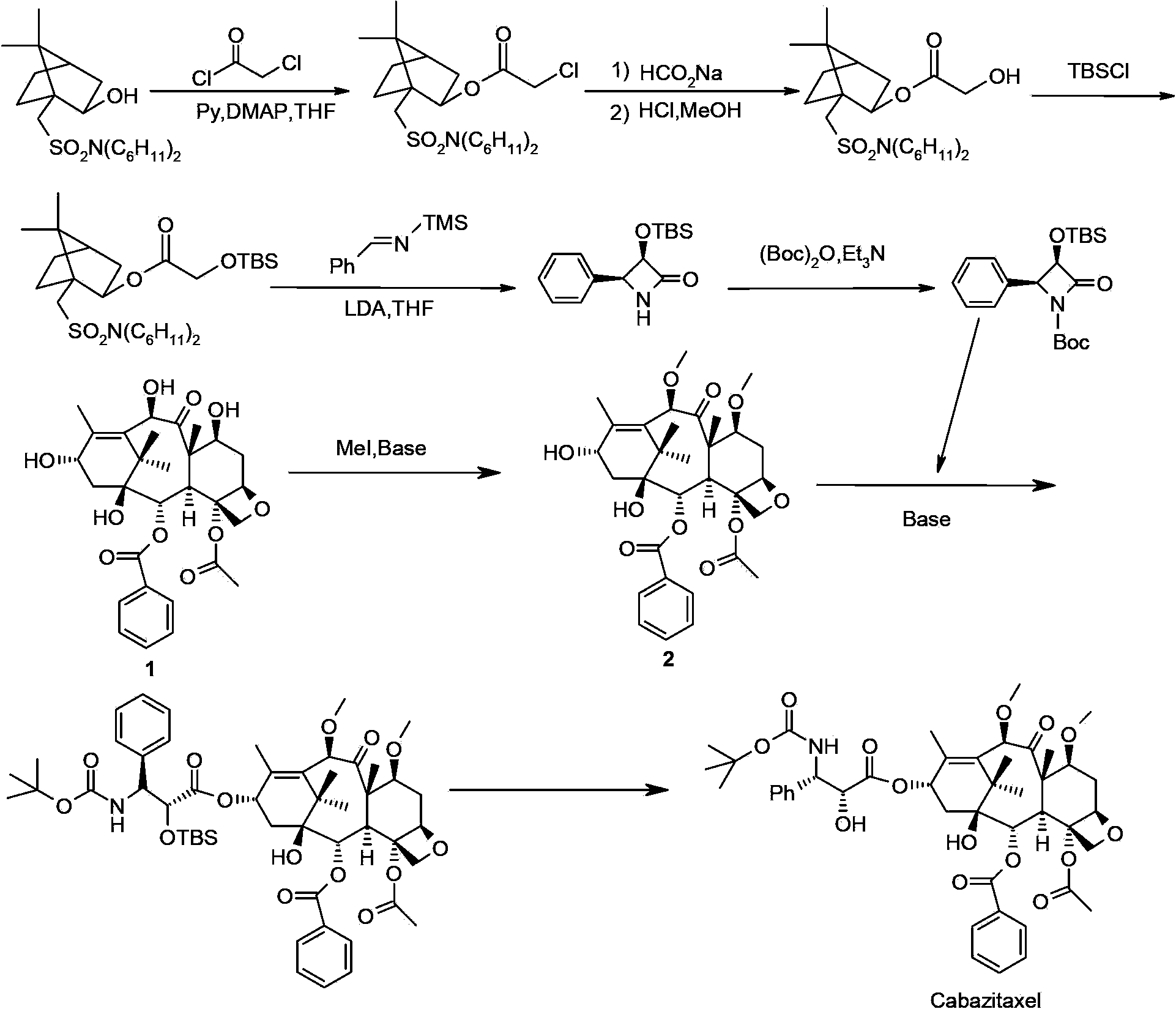

Method used

Image

Examples

Embodiment 1

[0049] Embodiment 1: preparation intermediate of the present invention

[0050]

[0051] Step A:

[0052] Under the protection of argon, 10.9 g (20 mmol, commercially available) of 10-deacetylbaccatin III (compound of formula 1) was dissolved in 100 mL of N-methylpyrrolidone (NMP); cooled to -30 ° C, and 1.68 g of sodium hydride was added (70mmol), insulated and stirred for 10 to 20 minutes; 11.36g (80mmol) of methyl iodide was added dropwise, and the insulated and stirred for 3 hours after dropping; naturally warming up to room temperature, stirring and reacting for 6 to 8 hours, TLC detection (developing agent is dichloromethane / Methanol=25 / 1, V / V) After the reaction of the raw materials is completed, the reaction solution is cooled to 0°C, and then 50mL of saturated ammonium chloride aqueous solution is added dropwise; Continue to stir for 1 hour, filter to obtain a light yellow solid; beat with 30% methanol aqueous solution; filter; vacuum-dry at 50°C for 8 hours; the...

Embodiment 2

[0059] Embodiment 2: preparation intermediate of the present invention

[0060] Step A:

[0061] Under argon protection, 10.9 g (20 mmol, commercially available) of 10-deacetylbaccatin III (compound of formula 1) was dissolved in 60 mL of N-ethylpyrrolidone (NEP) and 30 mL of tetrahydrofuran; cooled to -30 ° C, added tert Potassium butoxide 4.5g (40mmol), keep stirring for 10-20 minutes; add 4.24g (40mmol) of trimethyl orthoformate dropwise, keep stirring for 3 hours after dropping; naturally warm to room temperature, stir for 8-10 hours, TLC detection (The developer is dichloromethane / methanol=25 / 1, V / V) After the reaction of the raw materials is completed, the reaction solution is cooled to 0°C, and then 50mL of saturated ammonium chloride aqueous solution is added dropwise; Butyl ether, the solid slowly precipitated, and continued to stir for 1 hour after adding, and filtered to obtain a light yellow solid; slurred with 30% methanol aqueous solution; filtered; vacuum dried...

Embodiment 3

[0064] Embodiment 3: preparation intermediate of the present invention

[0065] Step A:

[0066] Dissolve 5.5g (10mmol) of 10-deacetylbaccatin III (compound of formula 1) in 60mL of pyridine and 40mL of toluene under the protection of argon; cool to -30°C, add 1.0g (41.7mmol) of sodium hydride, and keep stirring 10 to 20 minutes; add 3.8 g (40 mmol) of methyl bromide dropwise, and keep stirring for 3 hours after dropping; naturally warm up to room temperature, stir and react for 6 to 8 hours, and detect by TLC (developing agent is dichloromethane / methanol=25 / 1, V / V) After the reaction of the raw materials is completed, the reaction solution is cooled to 0° C., and then 50 mL of saturated ammonium chloride aqueous solution is added dropwise; after the drop is completed, 300 mL of isopropyl ether is added under stirring, and the solid is slowly precipitated out. After the addition, continue to stir for 1 hour, and filter. A small amount of toluene was rinsed to obtain a light ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com