Cyclone-shaped mass transfer component and static supergravity mass transfer separation device

A cyclone and component technology, applied in the field of static supergravity mass transfer separation equipment, can solve the problems of small processing capacity, high operating costs and maintenance costs, and achieve the effects of improving processing capacity, meeting large-scale industrial production, and reducing manufacturing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

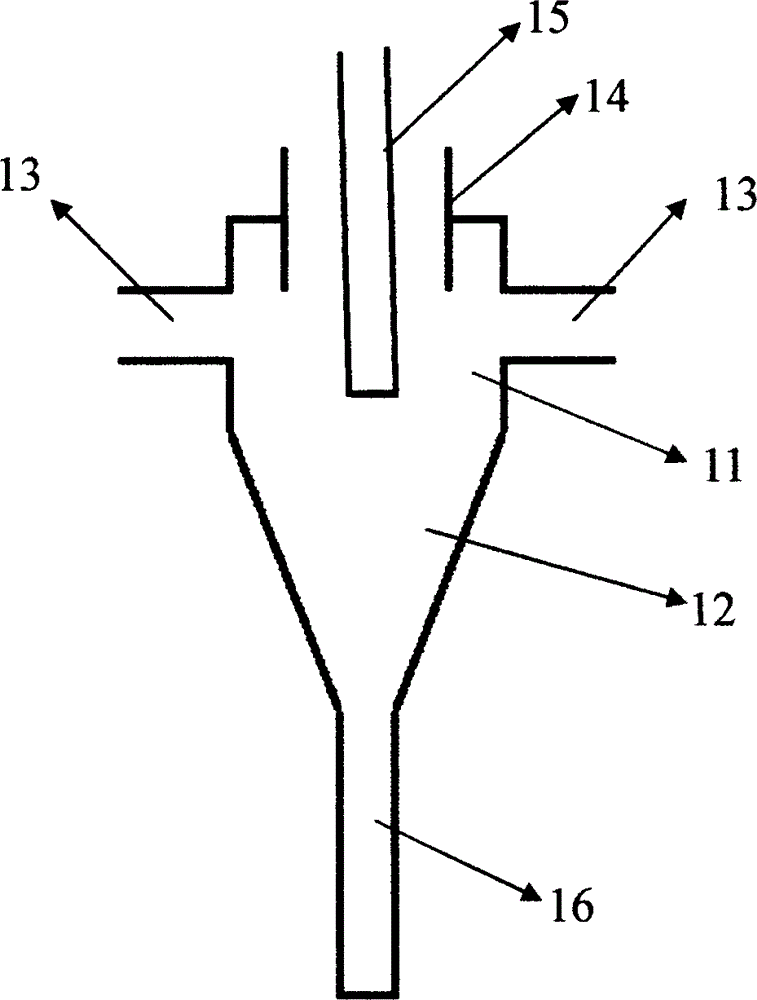

[0020] Such as figure 1 As shown, a cyclone-shaped mass transfer element 1 includes a cavity, and the cavity includes a cylindrical first cavity 11 and a conical second cavity 12 connected together. The second cavity can also be It is a biconical or other existing cyclone structure. The first cavity 11 is provided with two light-phase feed pipes 13 along the tangential direction, the upper center of the first cavity is provided with a light-phase overflow pipe 14, and the center of the light-phase overflow pipe 14 is provided with a heavy-phase feed pipe 15 , the heavy phase feeding pipe 15 is inserted into the first cavity along the light phase overflow pipe 14 or extends to the second cavity; the center of the lower end of the second cavity is the tail pipe 16 .

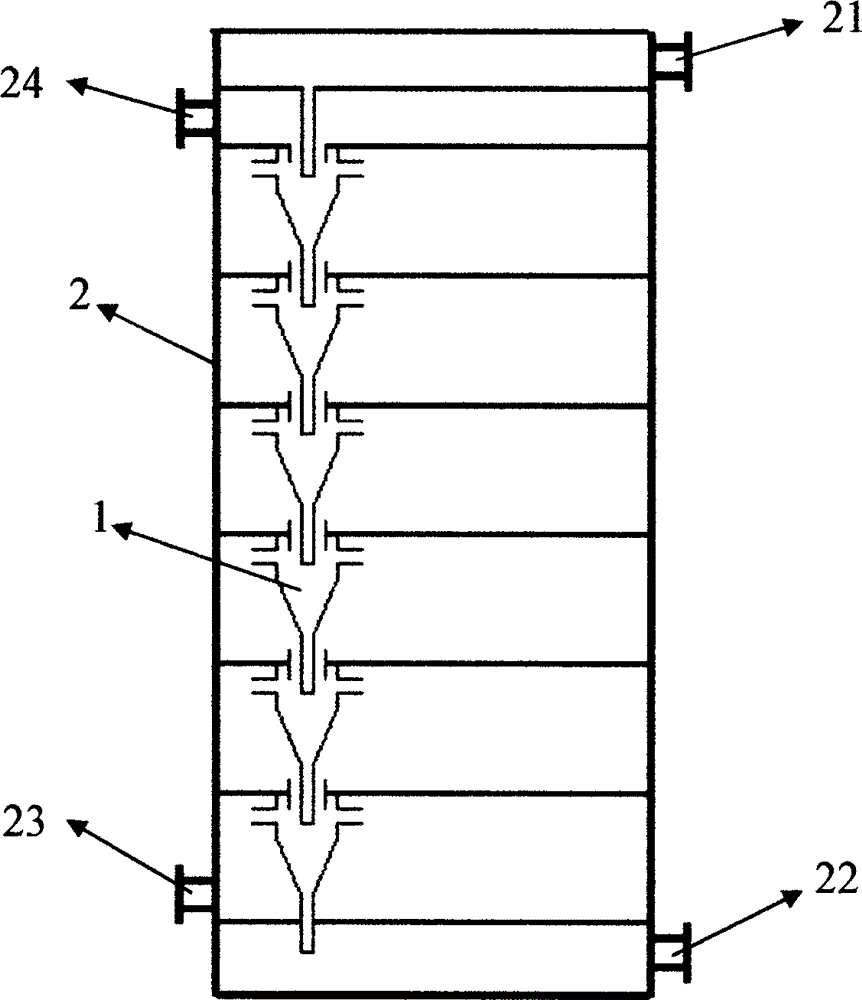

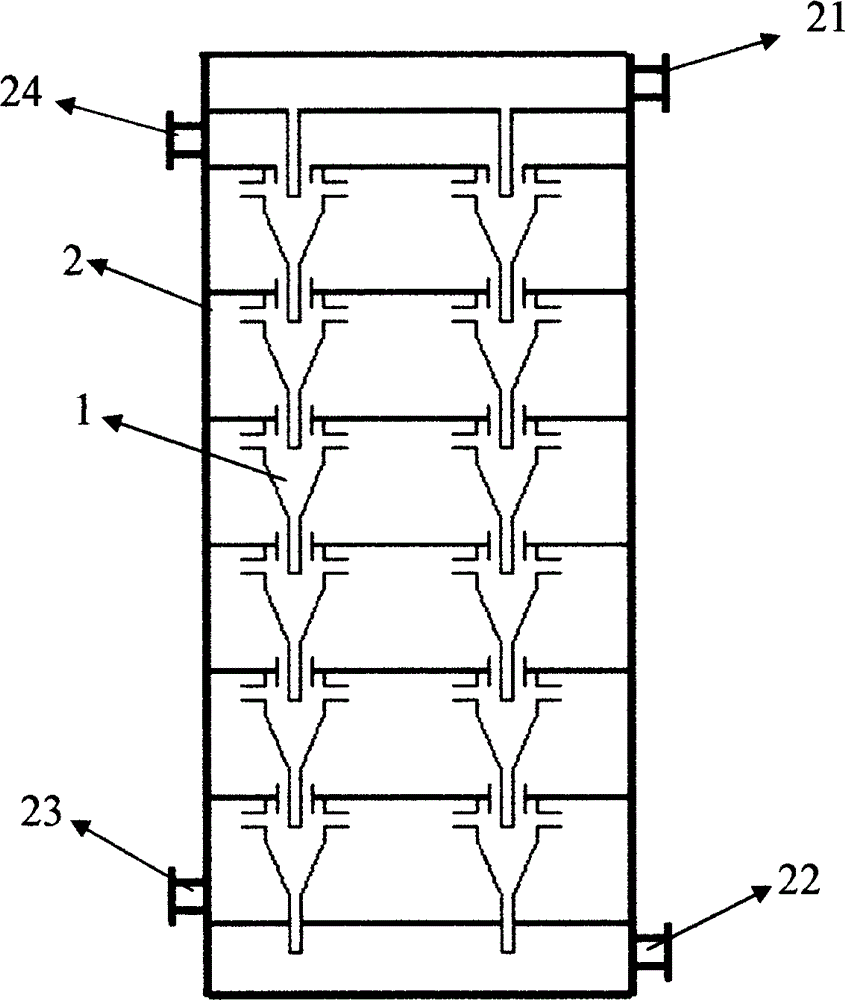

[0021] Such as figure 2 Shown is a static supergravity mass transfer separation device, including a plurality of mass transfer elements 1 connected in series, and the tailpipe of the N+1th stage mass transfer el...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com