Method for preparing high-luminous-efficiency inorganic perovskite thin film on basis of one-step method

A high luminous efficiency, inorganic calcium technology, applied in the direction of luminescent materials, chemical instruments and methods, electrical components, etc., can solve the problems of easy formation of heterogeneous phases, high requirements for preparation operations, and difficult diffusion, so as to promote thorough reaction and process The effect of low cost and high quantum yield

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

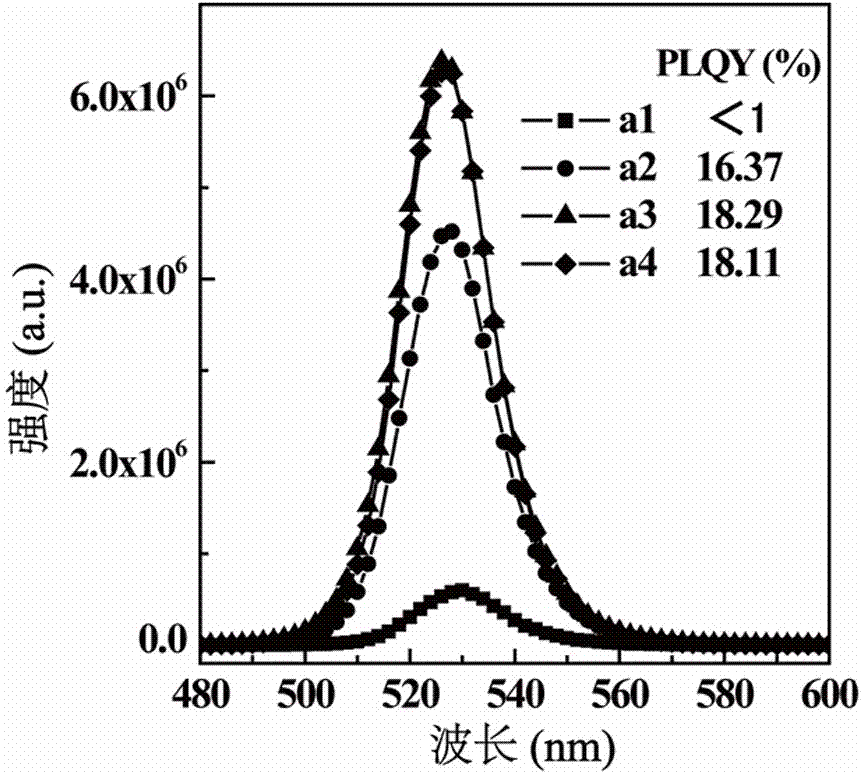

Embodiment 1

[0031] Weigh 0.0614g of PbBr 2 Add 0.0356g of CsBr into 0.5ml of DMSO, stir at room temperature until completely dissolved, and form PbBr 2 A perovskite precursor solution with a molar ratio of 1:1 to CsBr and a solution concentration of 15wt%.

[0032] Use a pipette gun to pipette 25 μl of the perovskite precursor solution, drop it slowly on the glass substrate, and spin-coat at 3000 rpm for 60 s to form a thin film.

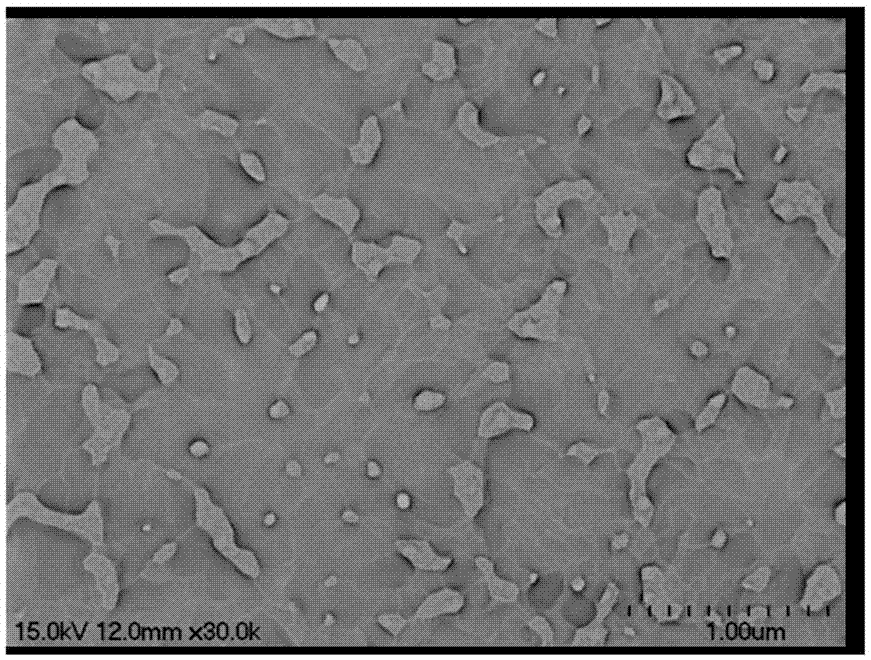

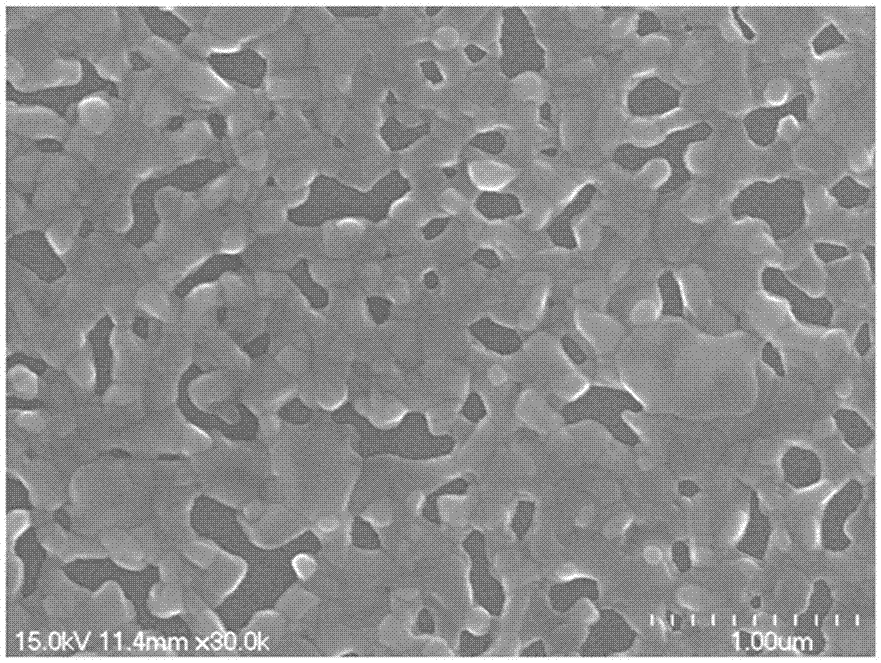

[0033] The film was placed on a heating platform, and the inorganic perovskite film was prepared by heat treatment at 70°C for 15 minutes, and the sample was marked as a1.

Embodiment 2

[0035] Using the same process as in Example 1, the difference is that the PbBr of Example 1 2 The molar ratio of CsBr and CsBr was changed to 1:1.1, and other conditions remained the same, and the sample was marked as a2.

Embodiment 3

[0037] Using the same process as in Example 1, the difference is that the PbBr of Example 1 2 The molar ratio of CsBr and CsBr was changed to 1:1.2, and other conditions remained the same, and the sample was marked as a3.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com