Method for improving stability of perovskite film through sulphuring treatment

A film stability, perovskite technology, applied in photovoltaic power generation, electrical components, electric solid devices, etc., can solve the problems of water vapor sensitivity, limited large-scale application, poor stability, etc., to achieve smooth surface, fast response, and stability. improved effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0029] This example involves Na 2 S is dissolved in isopropanol, and then the method for obtaining the sulfur-treated perovskite film by spin-coating the perovskite film, the method includes the following steps:

[0030] 1) Add 0.0109g Na 2 S was dissolved in 1 mL of isopropanol to obtain solution A;

[0031] above Na 2 The molar concentration of S is 0.2M.

[0032] 2) Spin-coat solution A obtained in step 1) onto CH at 4000rpm for 20s 3 NH 3 PB 3 The perovskite film substrate was then annealed on a 100°C hot stage for 5 minutes.

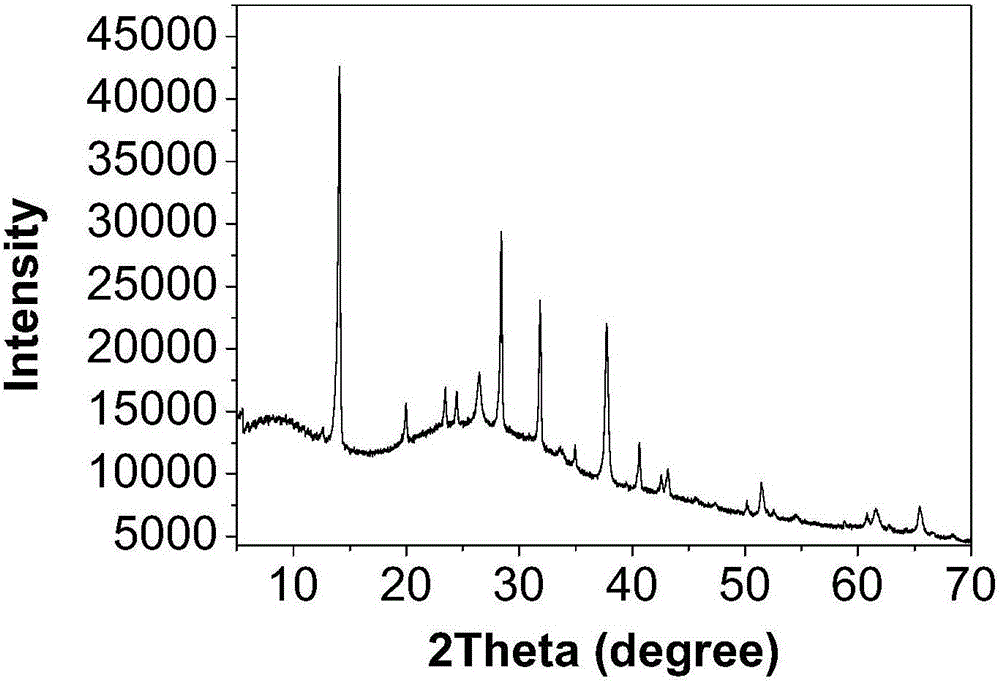

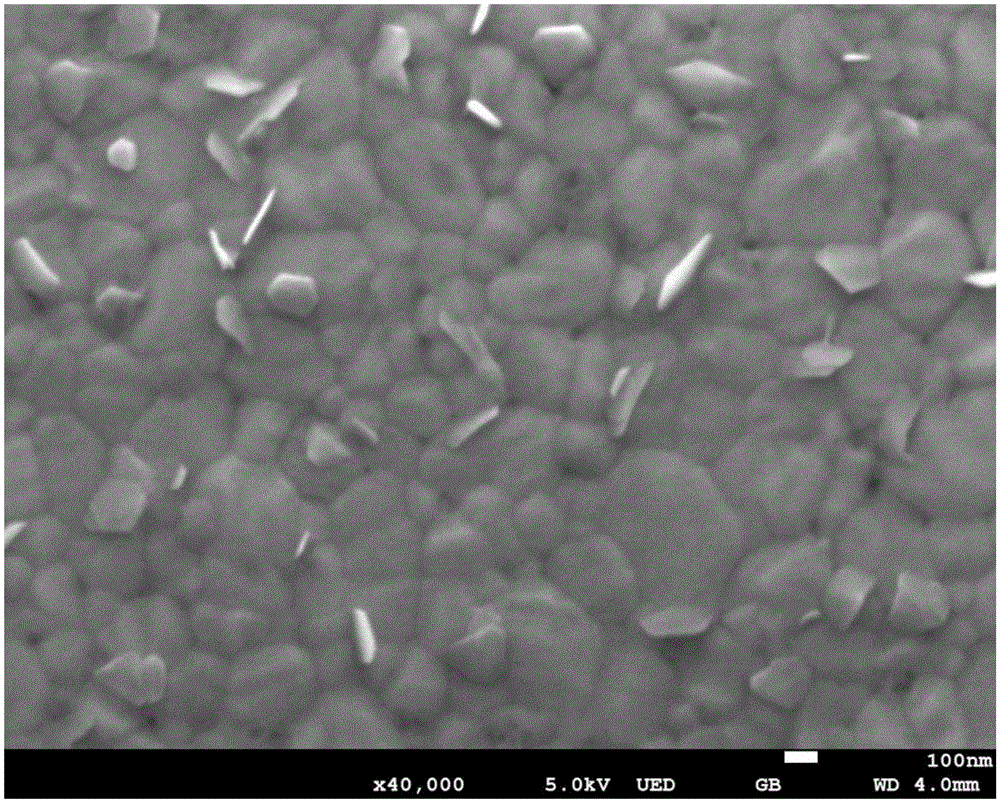

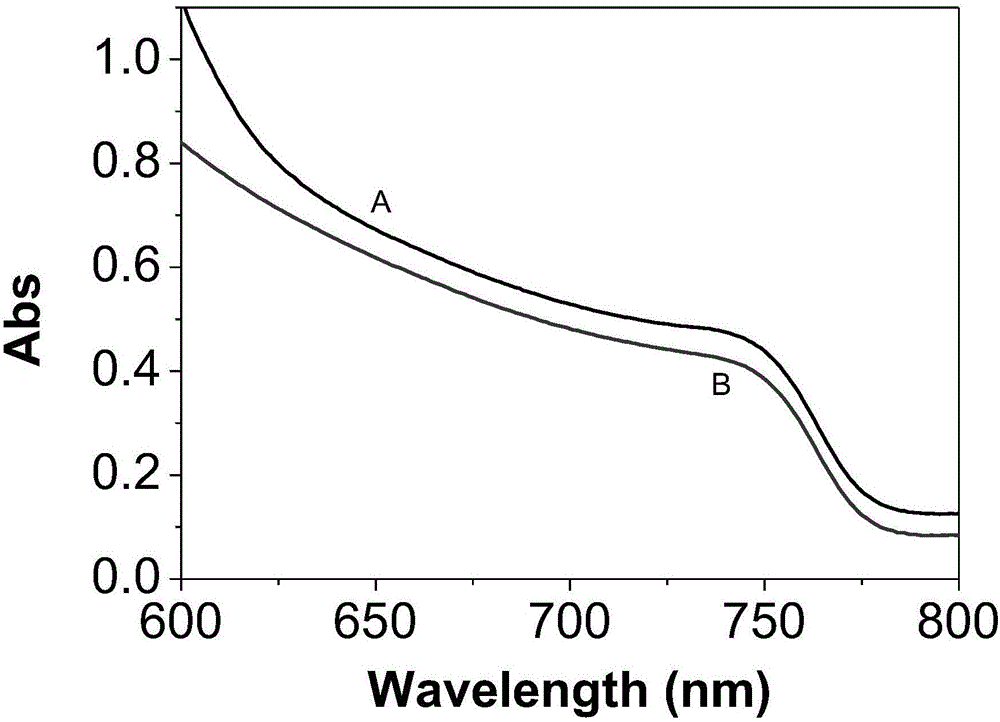

[0033] figure 1 It is the X-ray diffraction spectrum of Example 1, from which it can be concluded that the crystal form of the sulfur-treated perovskite film obtained in Example 1 is still perovskite, and has good crystallinity; figure 2 It is a scanning electron microscope photo of Example 1, and the photo shows that the surface of the perovskite film is dense after sulfur treatment. image 3 It is the ultraviolet-visible spectrogram of t...

Embodiment 2

[0037] This embodiment relates to (NH 4 ) 2 The S solution is added in isopropanol, and then the method for obtaining the sulfur-treated perovskite film by spin-coating the perovskite film, the method comprises the following steps:

[0038] 1) Add 0.047mL (NH 4 ) 2 Solution S (concentration 2.93M) was dissolved in 1 mL of isopropanol to obtain solution A;

[0039] In the above solution A (NH 4 ) 2 The molar concentration of S is 0.14M.

[0040] 2) Spin-coat solution A obtained in step 1) onto CH at 4000rpm for 20s 3 NH 3 The PbB perovskite thin film substrate was then annealed on a 100°C hot stage for 5 min.

[0041] The fluorescence properties of the films obtained in this implementation case were placed under 60% humidity for 15 days, and the fluorescence properties of the films after sulfur treatment were far stronger than those of the sample without sulfur treatment in Comparative Example 1 ( Figure 5 ). It shows that the stability of the perovskite film after s...

Embodiment 3

[0043] This embodiment relates to (NH 4 ) 2 The S solution is added in isopropanol, and then the method for obtaining the sulfur-treated perovskite film by spin-coating the perovskite film, the method comprises the following steps:

[0044] 1) Add 0.047mL (NH 4 ) 2 Solution S (concentration 2.93M) was dissolved in 1 mL of isopropanol to obtain solution A;

[0045] In the above solution A (NH 4 ) 2 The molar concentration of S is 0.18M.

[0046] 2) Spin-coat the solution A obtained in step 1) onto CH at 3000rpm for 30s 3 NH 3 The PbB perovskite thin film substrate was then annealed on a 90°C hot stage for 10 min.

[0047] The fluorescent performance of the film obtained in this embodiment case is consistent with that of Example 1 after being placed at 60% humidity for 15 days, and the prepared perovskite film has high stability.

[0048] In summary, the present invention uses sulfur-containing inorganic salts to treat the perovskite film, so that the stability of the p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com