Adsorption method for preparing soybean lecithin

A technology for soybean lecithin and soybean lecithin, which is applied in the field of preparation of high-purity soybean lecithin, can solve the problems of harsh operation conditions of supercritical fluid extraction, large-scale promotion of equipment costs, unfavorable separation of phospholipids, etc., and can meet the requirements of large-scale industrial production. , The effect of high production efficiency and high recovery rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

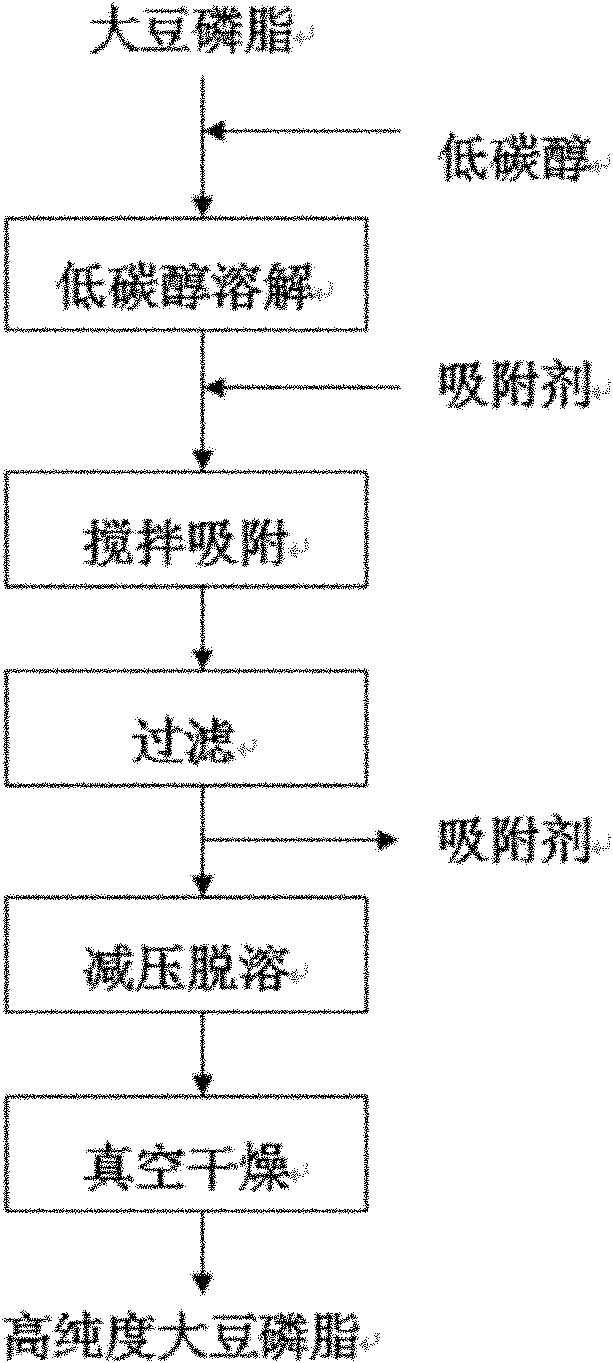

Image

Examples

Embodiment 1

[0022] Get soybean powder phospholipid 80g (phosphatidylcholine mass percentage content 45wt%), dissolve completely with 8L of absolute ethanol, add 240g activated alumina (100 mesh, Sinopharm Chemical Reagent Co., Ltd.), stir under 25 ℃ condition Adsorption for 120min. Filtrate to remove activated alumina. The filtrate was desolvated under reduced pressure at 0.015 MPa, then concentrated and dried in vacuum at 0.008 MPa and 55°C for 5 hours to obtain 36.2 g of solid lecithin product. The purity of phosphatidylcholine in the phospholipid sample determined by HPLC-UV method was 89.6%, and the recovery rate of phosphatidylcholine was 86.94%.

Embodiment 2

[0024] Get soybean lecithin 50g (phosphatidylcholine mass percentage content 47wt%), dissolve completely with 3.5L isopropanol, add 200g neutral alumina (300 mesh, Shanghai Ludu Chemical Reagent Factory), at 35 DEG C Stir and adsorb for 80min. Filter to remove the neutral alumina, and the filtrate is desolvated under reduced pressure at 0.02MPa, then concentrated and dried in vacuum at a pressure of 0.015MPa and a temperature of 45°C for 4.5h to obtain 23.57g of solid lecithin product. The purity of phosphatidylcholine in the phospholipid sample determined by HPLC-UV method was 85.3%, and the recovery rate of phosphatidylcholine was 85.83%.

Embodiment 3

[0026] Take 100g of soybean lecithin (phosphatidylcholine mass percentage 40wt%), dissolve it completely with 5L of methanol, add 300g of silica gel (200 mesh, Qingdao Ocean Chemical Co., Ltd.), and stir and adsorb at 30°C for 30min. Filtrate to remove the silica gel. The filtrate was first desolvated under reduced pressure at 0.025 MPa, and then concentrated and dried in vacuo at a pressure of 0.012 MPa and a temperature of 35° C. for 3.5 hours to obtain 46.70 g of solid lecithin product. The purity of phosphatidylcholine in the phospholipid sample determined by HPLC-UV method was 80.8%, and the recovery rate of phosphatidylcholine was 89.05%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com