Method for preparing organic-inorganic hybrid perovskite material through gas-liquid or gas-solid two phase in-situ reaction

A perovskite material and in-situ reaction technology, applied in organic chemistry, organic chemical methods, amino compound preparation, etc., can solve the problems of high energy consumption, inability to completely convert lead halide PbX, cumbersome process, etc., and achieve film-forming properties Good, reduce the pre-preparation process, the effect of convenient operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0037] This embodiment relates to a method in which hydroiodic acid (HI) and lead iodide are dissolved in DMF and then spin-coated and reacted with methylamine vapor in situ to prepare a perovskite film under a methylamine atmosphere. The method includes the following steps:

[0038] 1) Dissolve 0.461g of lead iodide and 0.132mL of hydroiodic acid solution in 1mL of DMF to obtain precursor solution A; the molar ratio of the above-mentioned lead iodide and hydroiodic acid is calculated as 1:1.

[0039] 2) The solution A obtained in step 1) was spin-coated onto the FTO substrate at 3500 rpm for 30 s, and the spin-coating was performed under a methylamine gas atmosphere, and dried at room temperature.

[0040] 3) The perovskite film can be obtained by annealing the substrate obtained in step 2) at 100°C for 5 minutes.

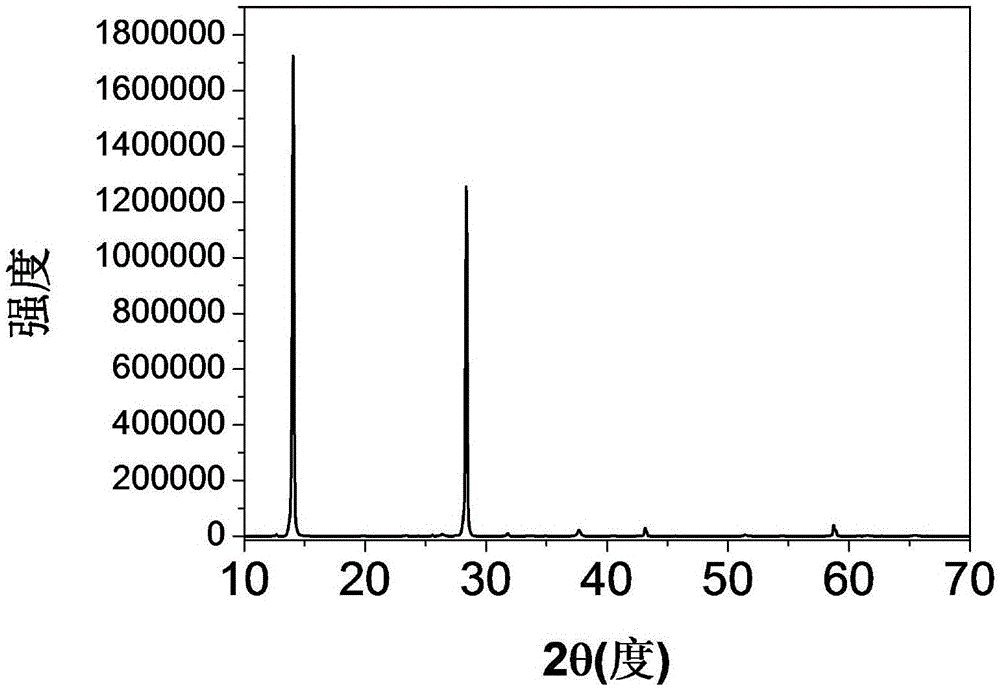

[0041] figure 1 It is the X-ray diffraction spectrum of Example 1, from which it can be drawn that the crystal form of the perovskite film obtained in Example 1 ...

Embodiment 2

[0045] This embodiment relates to a method for preparing a perovskite film by dissolving hydrobromic acid (HBr) and lead bromide in GBL and then reacting in situ with methylamine vapor in an atmosphere of methylamine. The method includes the following steps:

[0046] 1) Dissolve 0.369g of lead bromide and 0.121mL of HBr solution (molar concentration 8.65M) in 1mL of DMF to obtain precursor solution A; the molar ratio of lead bromide and hydrobromic acid is calculated as 1:1.05.

[0047] 2) The solution A obtained in step 1) was spin-coated onto the FTO substrate at 3500 rpm for 20 s, and the spin-coating was performed under a methylamine gas atmosphere, and dried at room temperature.

[0048] 3) The perovskite film can be obtained by annealing the substrate obtained in step 2) at 100°C for 5 minutes.

[0049] The XRD spectrum of perovskite obtained in this embodiment is shown in Figure 5 , indicating that a phase-pure, highly crystalline methylamine lead bromide perovskite t...

Embodiment 3

[0051] This embodiment relates to a kind of concentrated hydrochloric acid (HCl), lead chloride (PbCl 2 ) is dissolved in DMF and then spin-coated under a methylamine atmosphere and reacts with methylamine vapor in-situ to prepare a method for a perovskite film, the method comprising the steps of:

[0052] 1) Dissolve 0.222g of lead chloride and 0.082mL of HCl solution (molar concentration 12M) in 1mL of GBL to obtain precursor solution A; the molar ratio of the above lead chloride and concentrated hydrochloric acid is calculated as 1:0.95.

[0053]2) The solution A obtained in step 1) was spin-coated onto the FTO substrate at 3500 rpm for 10 s, and the spin-coating was performed under a methylamine gas atmosphere, and dried at room temperature.

[0054] 3) The perovskite film can be obtained by annealing the substrate obtained in step 2) at 100°C for 5 minutes.

[0055] The XRD spectrum of perovskite obtained in this embodiment is shown in Image 6 , indicating that a phase...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com