High performance strontium-calcium permanent magnetic ferrite magnet and preparation method thereof

A ferrite and strontium-calcium permanent magnet technology is applied in the field of high-performance strontium-calcium permanent magnet ferrite magnet and its preparation, which can solve the problems of reducing production cost, unable to further improve production efficiency, etc., so as to reduce production cost and prevent crystal grains. The effect of growing up and improving the eigenparameters

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

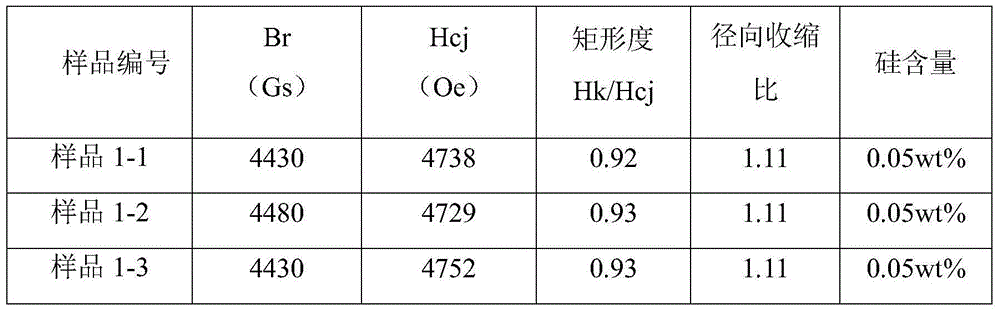

Embodiment 1

[0034] The requirements and corresponding weights of raw materials selected in a batching process are as follows:

[0035] ①Iron oxide (Fe 2 o 3 ) powder (purity ≥ 99.0wt%, original average particle size of particles: 0.9μm), weight 1271.0Kg;

[0036] ②Calcium carbonate (CaCO 3 ) powder (purity ≥ 98.5wt%, original average particle size of particles: 1.0 μm), weight 60.7Kg;

[0037] ③ strontium carbonate (SrCO 3 ) powder (purity ≥ 98.5wt%, original average particle size of particles: 1.0 μm), weight 44.3Kg;

[0038] ④ Lanthanum oxide (La 2 o 3 ) powder (purity ≥ 99.0wt%, original average particle size of particles: 1.0 μm), weight 99.8Kg;

[0039] ⑤ cobalt oxide (Co 3 o 4 ) powder (purity calculated based on cobalt content ≥ 72.0%, original average particle size of particles: 1.0 μm), weight 25.1Kg. (The particle size of raw material is too small, will cause the generation of fine particle after calcining and ball milling, is unfavorable for forming; The particle size...

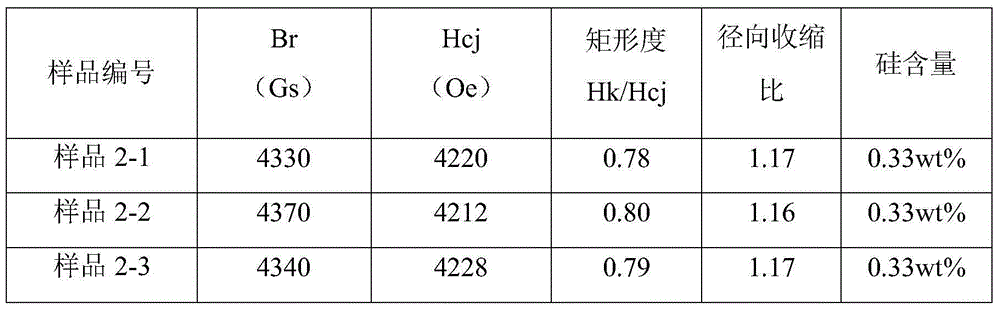

Embodiment 2

[0064] The requirements and corresponding weights of raw materials selected in a batching process are as follows:

[0065] ①Iron oxide (Fe 2 o 3 ) powder (purity ≥ 99.0wt%, original average particle size of particles: 1.1 μm), weight 1264.0Kg;

[0066] ②Calcium carbonate (CaCO 3 ) powder (purity ≥ 98.5wt%, original average particle size of particles: 2.0 μm), weight 45.1Kg;

[0067] ③ strontium carbonate (SrCO 3 ) powder (purity ≥ 98.5wt%, original average particle size of particles: 2.0 μm), weight 66.8Kg;

[0068] ④ Lanthanum oxide (La 2 o 3 ) powder (purity ≥ 99.0wt%, original average particle size of particles: 2.0 μm), weight 99.5Kg;

[0069] ⑤ cobalt oxide (Co 3 o 4 ) powder (purity calculated based on cobalt content ≥ 72.0%, original average particle size of particles: 2.0 μm), weight 25.1Kg.

[0070] Add the above-mentioned weighed raw materials into a 1.5T ball mill without adding any additives, add 1.5 tons of water, and ball mill for 5 hours, then the mixe...

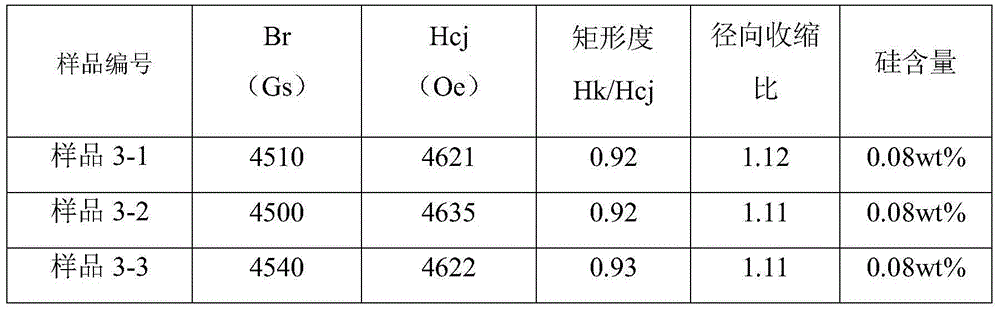

Embodiment 3

[0079] The requirements and corresponding weights of raw materials selected in a batching process are as follows:

[0080] ①Iron oxide (Fe 2 o 3 ) powder (purity ≥ 99.0wt%, original average particle size of particles: 1.5μm), weight 1271.0Kg;

[0081] ②Calcium carbonate (CaCO 3 ) powder (purity ≥ 98.5wt%, original average particle size of particles: 1.4 μm), weight 60.7Kg;

[0082] ③ strontium carbonate (SrCO 3 ) powder (purity ≥ 98.5wt%, original average particle size of particles: 1.6 μm), weight 44.3Kg;

[0083] ④ Lanthanum oxide (La 2 o 3 ) powder (purity ≥ 99.0wt%, original average particle size of particles: 1.3 μm), weight 99.8Kg;

[0084] ⑤ cobalt oxide (Co 3 o 4 ) powder (purity calculated based on cobalt content ≥ 72.0%, original average particle size of particles: 1.7 μm), weight 25.1Kg.

[0085] Add the above-mentioned weighed raw materials into a 1.5T ball mill without adding any additives, add 1.5 tons of water, and ball mill for 5 hours, then the mixed...

PUM

| Property | Measurement | Unit |

|---|---|---|

| strength | aaaaa | aaaaa |

| height | aaaaa | aaaaa |

| magnetic flux density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com