Sealing device for sintering machine trolley and air box

A technology of sealing device and machine trolley, which is applied in the direction of engine sealing, mechanical equipment, engine components, etc., can solve the problems of air leakage from the bellows and the bench workshop, inability to reduce costs, and increase processing capacity, and achieve sintering. Low investment, low production cost, overcoming the effect of easy wear and tear

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

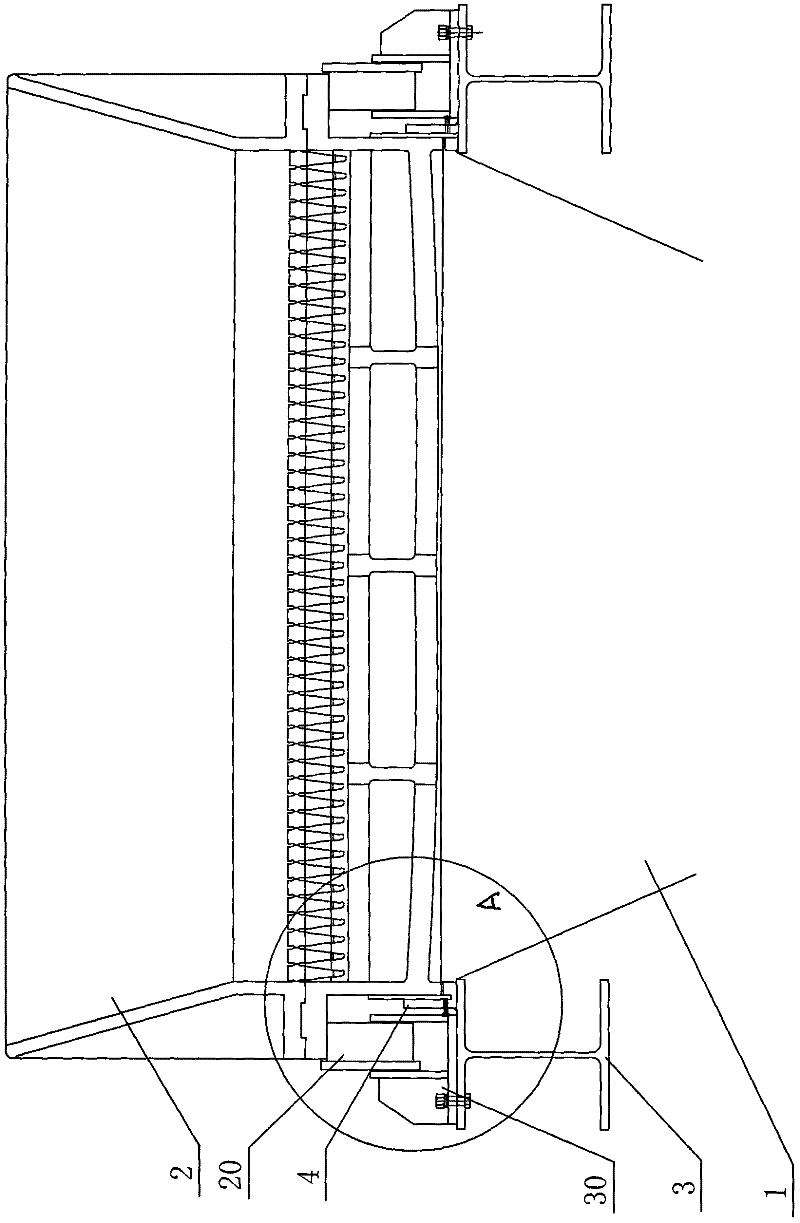

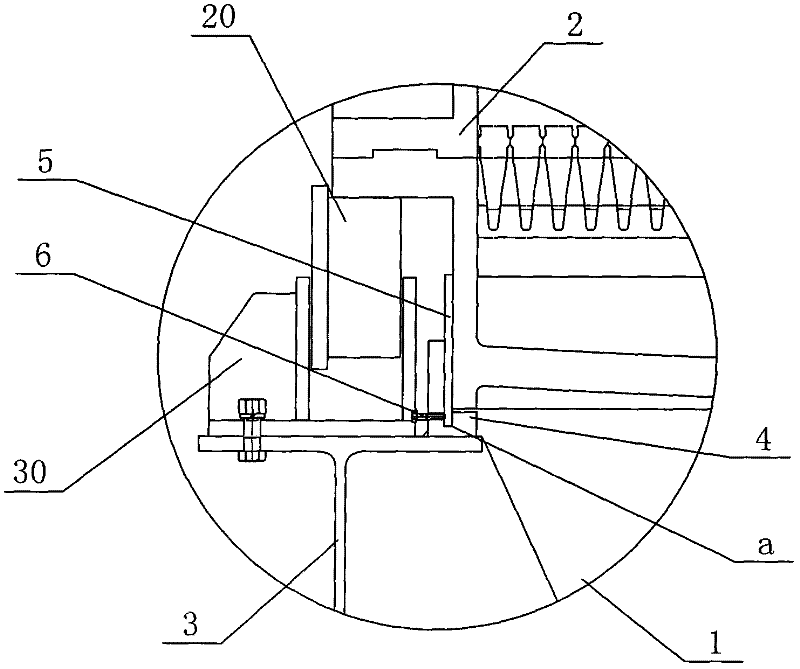

[0031] like figure 1 and figure 2 As shown, a sintering machine trolley 2 is arranged above the bellows 1 in the sintering system. During the sintering process, the sintering machine trolley 2 moves forward along the track above the bellows 1. For the convenience of description, the traveling of the sintering machine trolley 2 The direction is defined as the longitudinal direction, and the direction of the width direction of the sintering machine trolley 2 is defined as the transverse direction.

[0032] Trolley wheels 20 are arranged under the left and right outer sides of the sintering machine trolley 2, and the sintering machine trolley 2 is supported on the bellows 1 through the trolley wheels 20, and longitudinally extending mounting brackets 3 are respectively installed on the two outer sides of the top of the bellows 1 , the mounting bracket 3 is mounted with a wheel fixing frame 30 through a threaded fastening connector, the trolley wheel 20 of the present embodiment...

Embodiment 2

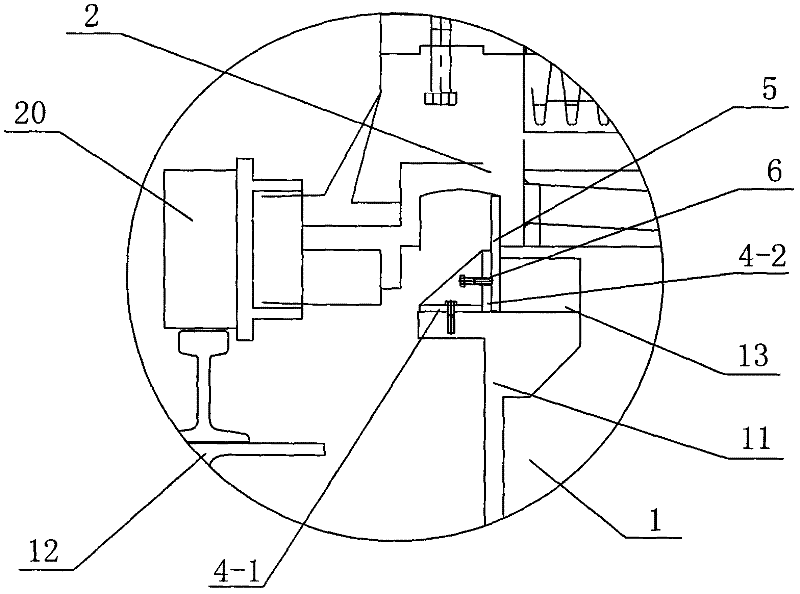

[0035] like image 3 and Figure 4As shown, the difference between this embodiment and Embodiment 1 is that the two outer sides of the top of the bellows 1 are installed with a longitudinally extending slide rail mounting bracket 11 and a wheel track bracket 12 through a threaded fastening connector, and the slide rail mounting bracket 11 is located on the wheel. The inner side of the track support 12 is the same as the existing sintering machine, and trolley wheels 20 are installed on the bottom two outer sides of the sintering machine trolley 2. The trolley wheels 20 are arranged on the track installed on the wheel track support 12, and the sintering machine trolley 2 The trolley wheel 20 is supported on the bellows 1 , and the trolley wheel 20 moves along the track to drive the sintering machine trolley 2 to travel. The slide rail mounting bracket 11 is located below the outside of the bottom of the bellows 1, and a slide rail 13 is installed on the slide rail mounting bra...

Embodiment 3

[0037] Such as Figure 5 As shown, the difference between this embodiment and Embodiment 2 is that the sealing mounting base 4 is integrally formed with a compression back plate 4-3, and the compression back plate 4-3 is located on the vertical side of the horizontal bottom plate 4-1. The inner side of the plate 4-2, the lower part of the sealing plate 5 is fixedly installed in the groove formed between the vertical side plate 4-2 and the compression back plate 4-3, and the compression back plate 4-3 is used for sealing the sealing plate 5. A pressing plane is provided to realize the functions of fixing the sealing plate 5 and completing the sealing. The top bolt 6 passes through the end of the vertical side plate 4-2 of the sealing mounting seat 4 and pushes against the bottom of the sealing plate 5. When the top bolt 6 is tightened, the sealing plate 5 can be tightly pressed against the side of the back plate 4-3. In contact, the top of the sealing plate 5 is attached to th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com