Side sealing device, sintering pallet and sintering machine

A technology of side seals and locomotives, which is applied in the direction of engine seals, mechanical equipment, engine components, etc., can solve problems such as heavy workload, affecting production progress, and time-consuming, so as to overcome the easy wear of seals and reduce production and maintenance. The effect of cost and easy maintenance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

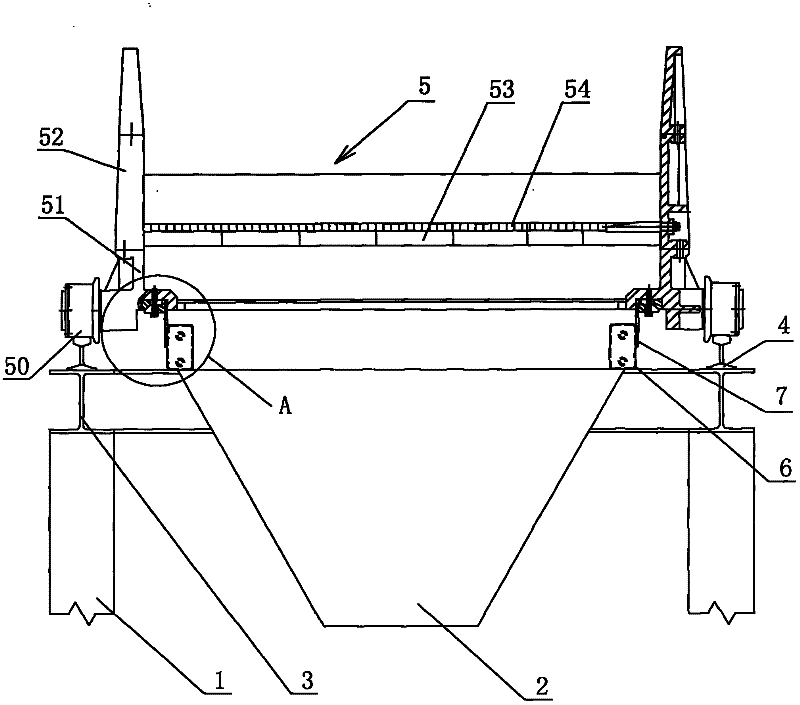

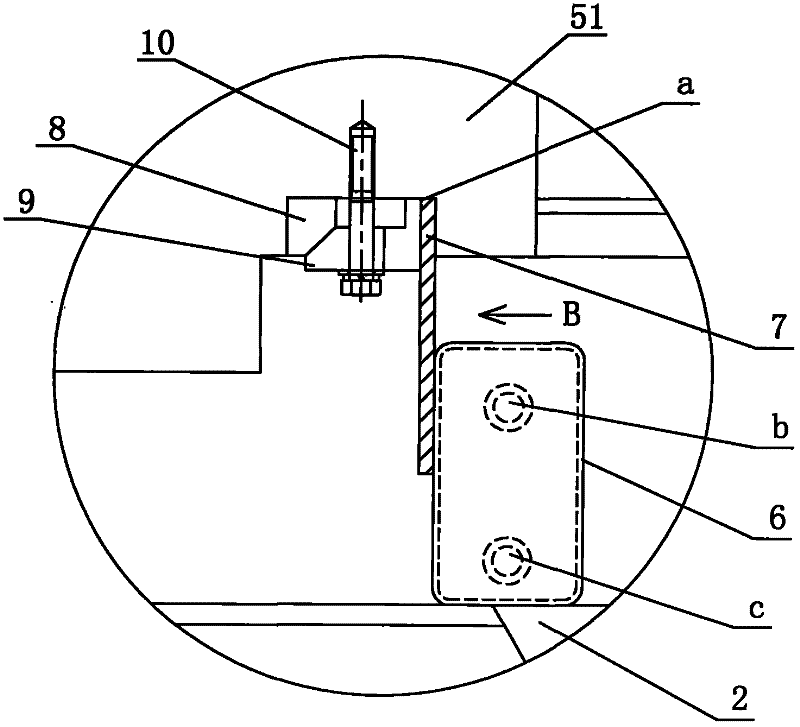

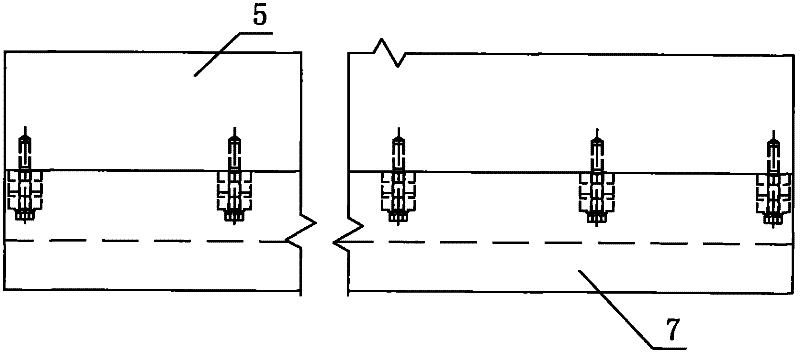

[0030] Such as figure 1 , figure 2 and image 3 As shown, in the sintering equipment, the sintering machine trolley 5 is set above the bellows 2. During the sintering process, the sintering machine trolley 5 moves above the bellows 2 along the track 4, and completes sintering after material distribution, ignition, sintering, and cooling to the tail of the machine. After the whole process, the sintering machine trolley 5 turns the sintered ore in it into the sintering ore trough, and then the sintering machine trolley 5 returns to the starting position through the empty lane, and repeats the above-mentioned cyclic sintering process. The sintering machine trolley 5 includes trolley wheels 50, a trolley body 51, a trolley fence 52 arranged on the trolley body 51, a heat insulating element 53 installed in the trolley body 51, and a heat insulating element 53 arranged on the top of the heat insulating element 53. The castor bar 54. For the convenience of the following descripti...

Embodiment 2

[0036] Such as Figure 8 As shown, the difference between this embodiment and Embodiment 1 is that the trolley wheel 50 is installed on the mounting frames 3 on both sides of the bellows 2 through the wheel mounting frame 55, forming a roller track on which the sintering machine trolley 5 runs, The left and right outer sides of the lower part of the trolley body 51 are processed with trolley support wheel limit guide grooves d extending from front to rear. The sintering machine trolley 5 is supported above the bellows 2 by the trolley wheels 50. The sintering machine trolley of this embodiment And the structure of the sintering machine and the applicant's patent application number are 201120028769.6, the name of invention is the same as the sintering machine trolley and the sintering machine structure of the roller support type sintering trolley and sintering machine. A sealing plate 7 is arranged in the limit guide groove d of the supporting wheel of the trolley. The sealing ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| height | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com