Resource utilization method of waste magnesia powder after treating oriented silicon steel

A technology for discarding magnesia powder and oriented silicon steel is applied in the field of solid waste recycling, which can solve the problems of accumulation and occupation environment, pollution, etc., and achieve the effects of improving the viscosity of slag, a simple method of forming balls, obvious environmental protection and economic value.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

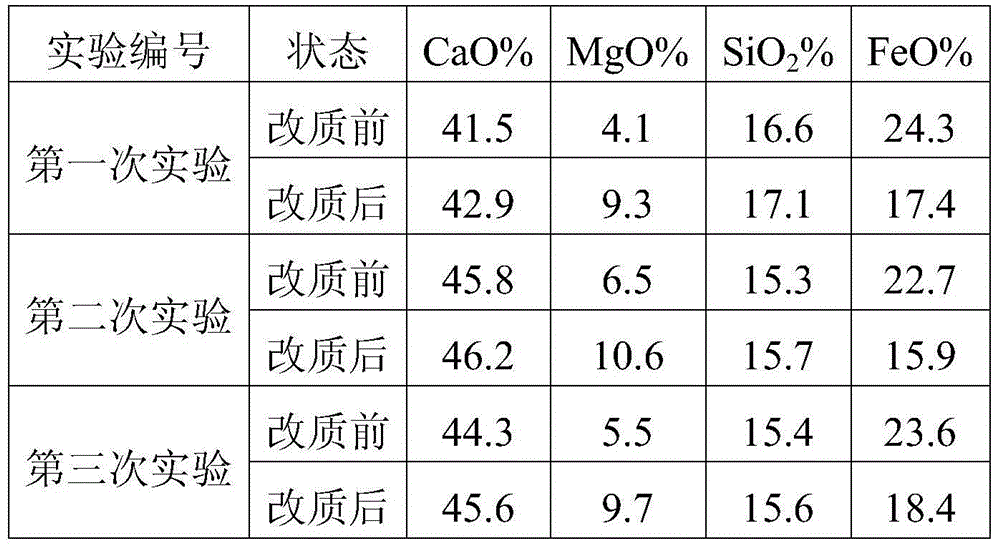

Examples

Embodiment 1

[0021] The discarded magnesia powder after heat treatment of oriented silicon steel was collected on site, and the chemical composition analysis showed that the composition and content (mass fraction) of the discarded magnesia powder were as follows: MgO, 92.3%; TiO 2 , 3.2%; SiO 2 , 1.6%; Al 2 o 3 , 1.5%; TFe0.3%, other impurities 0.8%, the particle size D50 of the waste magnesium oxide powder measured by a laser particle size analyzer is 18.6 μm; then the waste magnesium oxide powder, carbon powder, and asphalt powder are proportioned by weight 60-95%: 0-30%: 5-10%, the preferred weight ratio is 70%: 25%: 5%, add to the horizontal ribbon mixer and mix for 5-8 minutes, preferably 8 minutes, and discharge after mixing evenly , to obtain a mixed raw material, wherein the carbon powder in the raw material can be coke powder, coal powder, or a combination of one or more arbitrary ratios in graphite powder, and what selected in this example is coal powder;

[0022] Send the abo...

Embodiment 2

[0026] The discarded magnesia powder after heat treatment of oriented silicon steel was collected on site, and the chemical composition analysis showed that the composition and content (mass fraction) of the discarded magnesia powder were as follows: MgO, 94.3%; TiO 2 , 2.3%; SiO 2 , 1.2%; Al 2 o 3 , 0.9%; TFe0.3%, other impurities 0.7%, the particle size D50 of the waste magnesium oxide powder measured by a laser particle size analyzer is 17.4 μm; 60%: 30%: 10% is added to a horizontal ribbon mixer and mixed for 5-8 minutes, mixed evenly and discharged to obtain mixed raw materials;

[0027] Send the above mixed raw materials into a disc pelletizer and add water to form green pellets with a diameter of 10-15 mm. The amount of water added is 5% of the weight of the mixed raw materials; then send the green pellets into a baking oven at 200 ° C Keep warm for 1 hour to prepare magnesium carbon spheres, take them out and cool to room temperature naturally;

[0028] The cooled ...

Embodiment 3

[0031] The discarded magnesia powder after heat treatment of oriented silicon steel was collected on site, and the chemical composition analysis showed that the composition and content (mass fraction) of the discarded magnesia powder were as follows: MgO, 90.7%; TiO 2 , 5.1%; SiO 2 , 1.9%; Al 2 o 3 , 1.2%; TFe0.4%, other impurity 0.7%, measure the particle size D50 of this waste magnesium oxide powder by laser particle size analyzer to be 17.7 μ m; Then this waste magnesium oxide powder and graphite, and asphalt powder by weight ratio 80 %: 15%: 5% is added to a horizontal ribbon mixer and mixed for 5-8 minutes, mixed evenly and discharged to obtain mixed raw materials;

[0032] Send the above mixed raw materials into a disc pelletizer and add water to form green pellets with a diameter of 10-15mm. The amount of water added is 8% of the weight of the mixed raw materials; then send the green pellets into a baking oven at 200°C Keep warm for 1 hour to prepare magnesium carbon...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com