Patents

Literature

116results about How to "Obvious economy" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

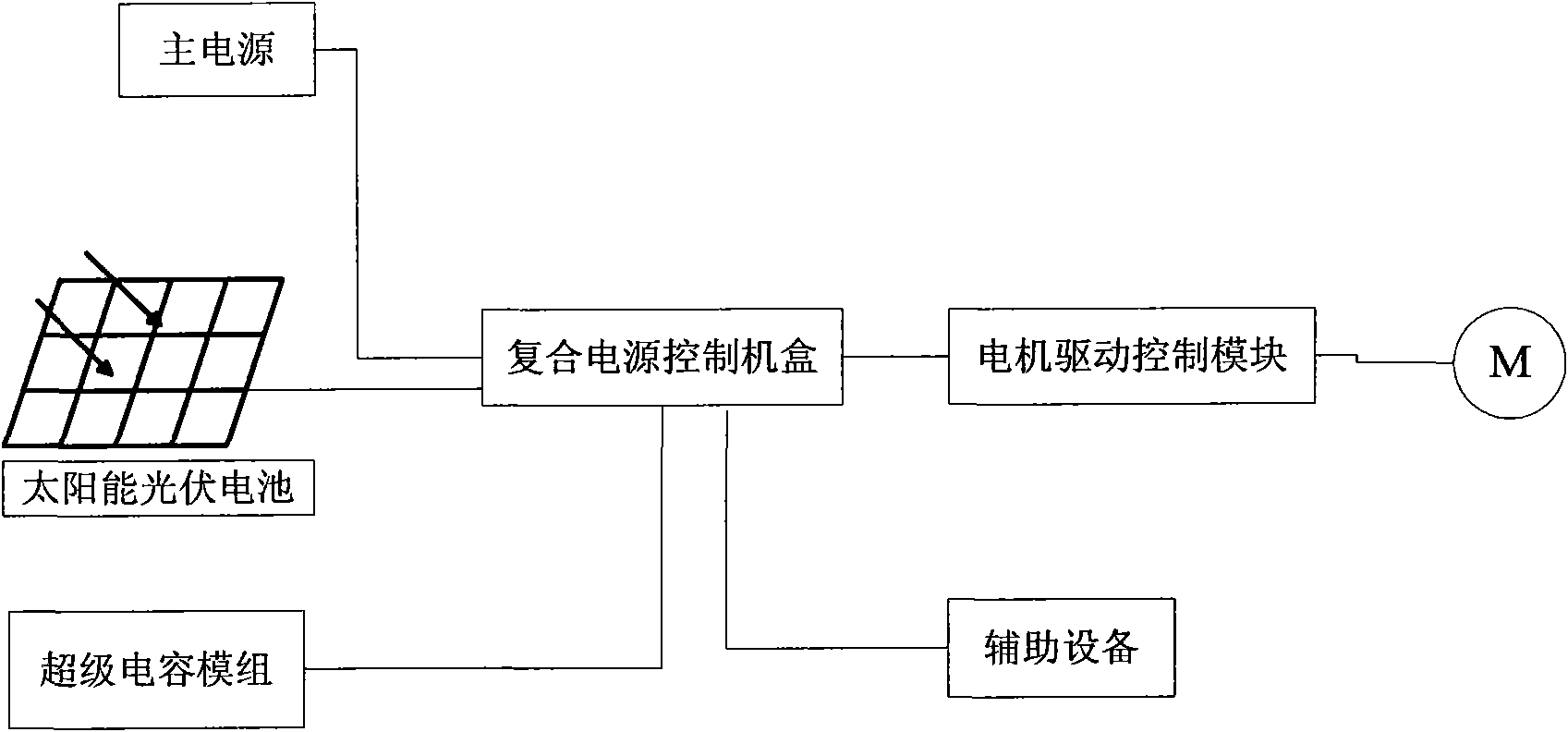

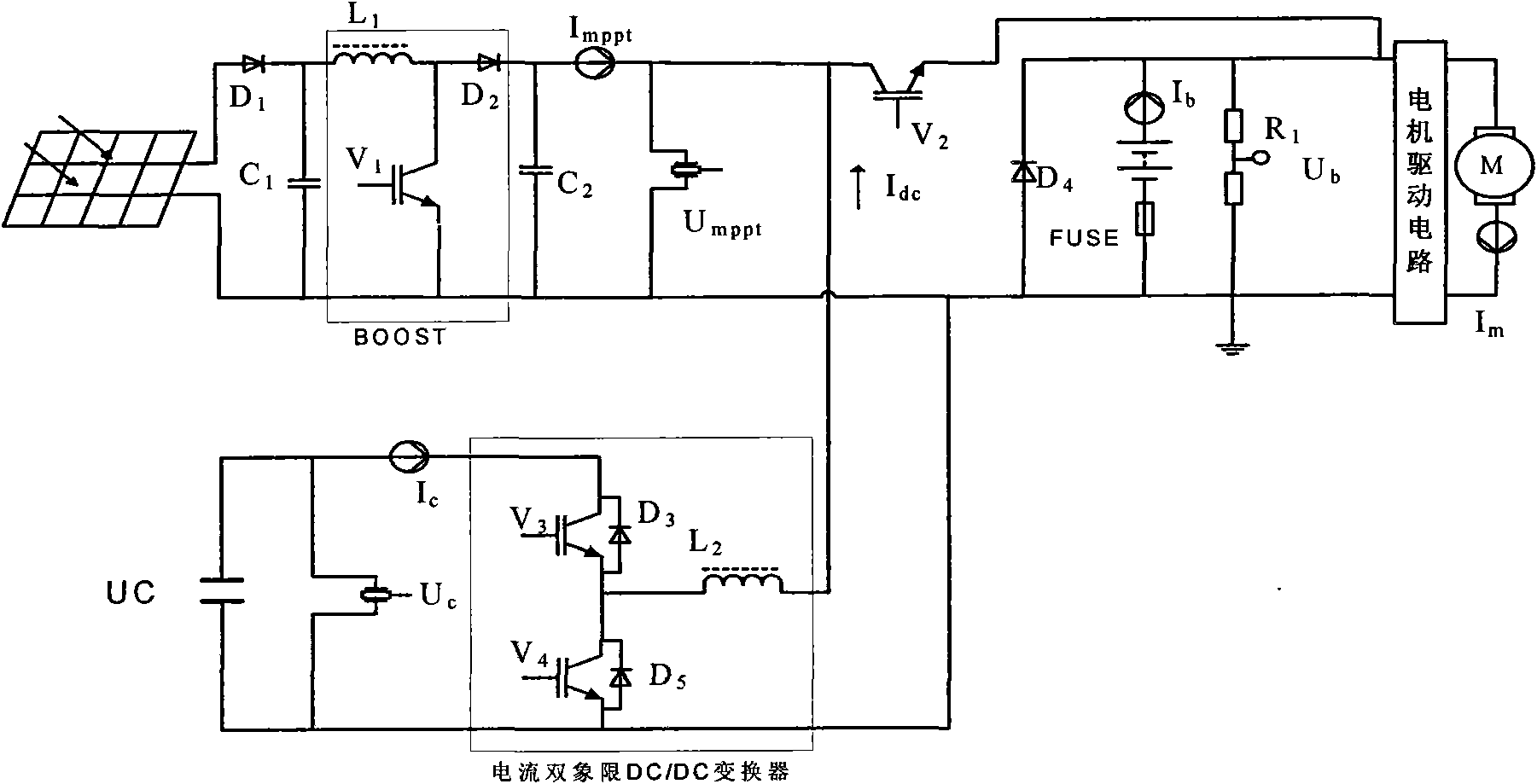

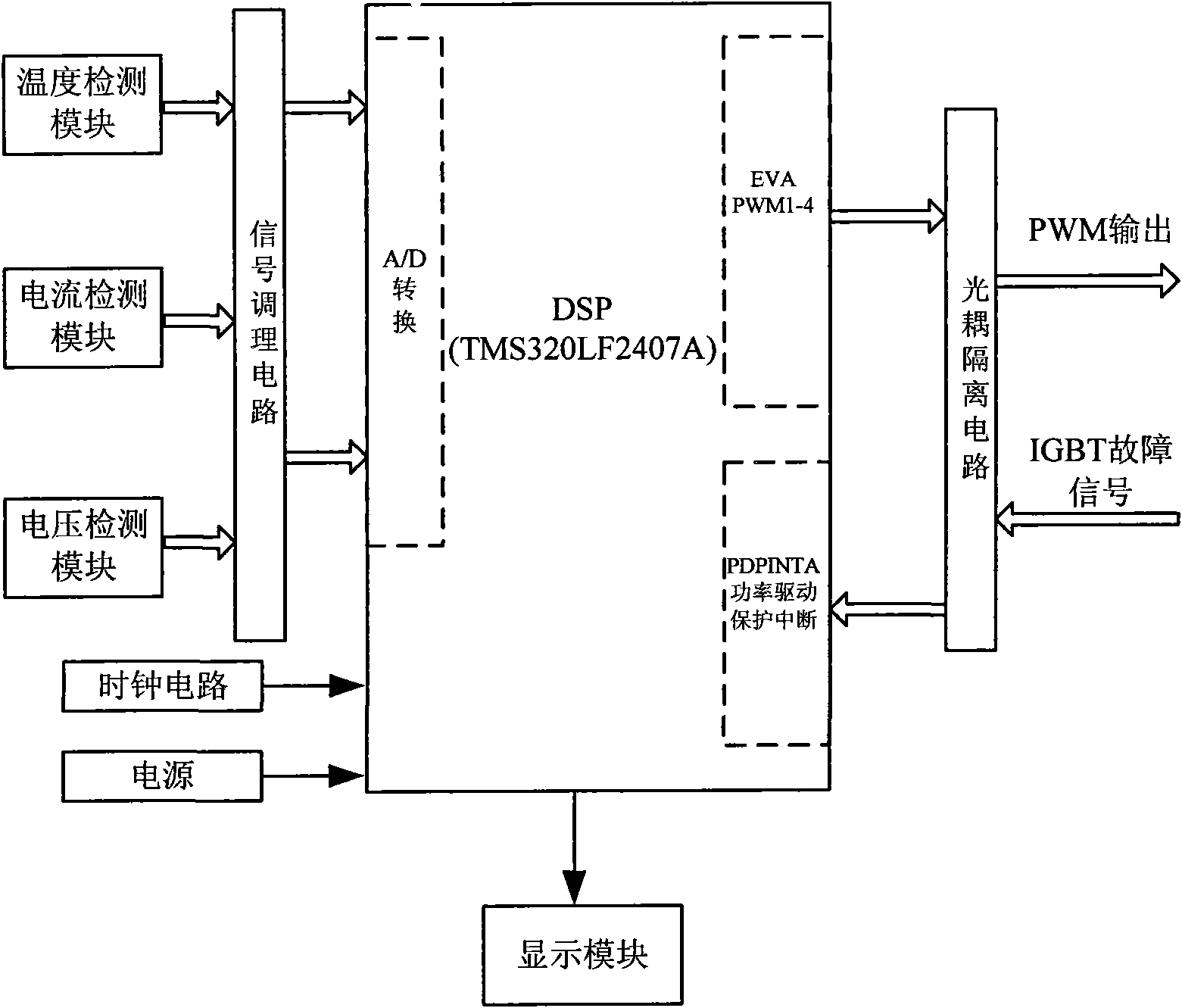

Power system of compound energy electro-vehicle

InactiveCN101630862AMaximize utilizationIncrease mileageElectrical storage systemBatteries circuit arrangementsCapacitanceEngineering

The invention provides a power system of a compound energy electro-vehicle, comprising a compound power supply controlling machine box, a main power supply connected with the power supply controlling machine box, a solar energy photovoltaic cell and a super capacitor module set, wherein, the output end of the compound power supply controlling machine box is connected with a motor driving controlling module and an assistant device, and the other end of the motor driving controlling module is connected with a motor; a hardware main circuit and a control circuit which are mutually connected are arranged in the compound power supply controlling machine box; the hardware main circuit is connected with the solar energy photovoltaic cell via an unidirectional DC / DC converter and is connected with the super capacitor module set via a bidirectional DC / DC converter; the input end of a microprocessor in the control circuit is connected with a temperature detecting module, a current detecting module and a pressure detecting module via a signal conditioning circuit, and the output end is connected with the motor driving circuit and an assistant device potentiometer via an optocoupler isolation circuit. The invention can better improve the acceleration performance and climbing performance of a vehicle, reduce heavy current discharging time of the main power supply and avoid the main power supply from damage and reduction of volume.

Owner:SOUTH CHINA UNIV OF TECH

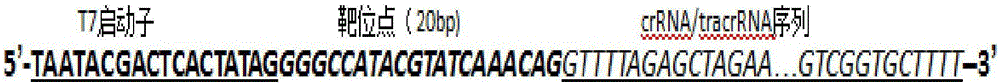

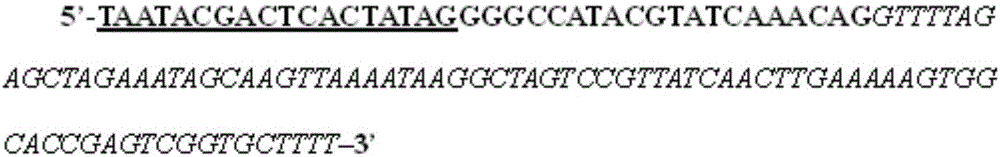

Bombyx mori silk fibroin heavy chain gene mutant obtained by utilizing CRISPR/Cas technology and mutation method and application

InactiveCN106222203AObvious economyObvious research valueMicroinjection basedAnimals/human peptidesMutantHeavy chain gene

The invention discloses a bombyx mori silk fibroin heavy chain gene mutant obtained by utilizing CRISPR / Cas technology and a mutation method and application. The mutation method includes: mixing cas9mRNA with sgRNA, micro-injecting a mixture into a bombyx mori egg, identifying genotype through PCR (polymerase chain reaction), screening out heterozygotes, and mutually mating the heterozygotes to obtain F1 generation in which pure heterozygotes appear; performing genotype detection on bombyx mori with phenotype, mating the bombyx mori with same genotype, screening out homozygotes which can be stably inherited to next generation, and then screening out the bombyx mori silk fibroin heavy chain gene mutant, wherein a core sequence of sgRNA is designed aiming at 1213-1236, 1274-1297 or 1349-1372 loci of bombyx mori silk fibroin heavy chain gene. By the method, an experiment material having economic value and scientific value is obtained quickly and efficiently, and a new material is provided for large-scale production of bombyx mori sericine cocoon and enabling the bombyx mori to serve as a bioreactor to express foreign protein.

Owner:云南纳博生物科技有限公司

Quick regenerating method for vegetation of returning farmland to grassland zone in extremely cold areas

The invention relates to a quick regenerating method for vegetation of returning farmland to grassland zone in extremely cold areas, which comprises the following steps of: (1) mixing and seeding annual pasture oat and perennial pasture on the farmland returning to grassland zone, and building an artificial pasture integrating mowing and grass seed harvesting functions; (2) ploughing and raking the artificial pasture; (3) sowing the seeds and applying base fertilizer; and (4) mowing the oat forage grass in the first year and harvesting the grass seeds and mowing the perennial pasture in the second year or later after covering and compacting the grass seeds in the step (3). The method utilizes the annual oat and perennial pasture to form different biotypes of pasture mixing and seeding community, so that the weed spreading can be obviously suppressed, the soil humidity and air humidity are obviously improved, the evaporation capacity and water loss and soil erosion intensity are reduced, therefore, the soil exposure time is short after regeneration of the grassland zone, the vegetation covering is quick, the water retention and preservation of soil moisture effect is obvious, and the ecological and economic benefits are remarkable.

Owner:CHINA ACAD OF SCI NORTHWEST HIGHLAND BIOLOGY INST +1

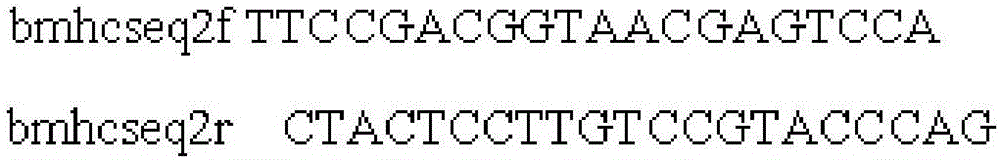

Asphalt recycling agent for hot recycling of asphalt on asphalt road surface

The invention discloses an asphalt recycling agent for hot recycling of asphalt on an asphalt road surface. The recycling agent comprises the following components by weight: 19-70% of an aromatic oil, 20-60% of heavy oil, 5-30% of liquid petroleum resin and 0.2-1% of a stabilizer. The invention also provides a preparation process of the asphalt recycling agent and a method for preparing recycled asphalt by use of the asphalt recycling agent. The recycling agent disclosed by the invention is good in recycling effect, easy for raw materials purchase, stable in quality, low in equipment investment, simple in processing steps, short in processing time of finished products, good in storage stability, stable in physicochemical property, and convenient for on-site operation, and is suitable for on-site hot recycling construction as a special recycling agent.

Owner:YINGDA HEAT REGENERATION

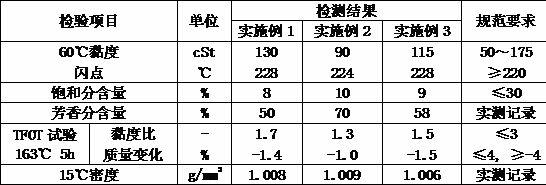

Stalk light body energy-saving heat preserving building blocks and manufacturing method thereof

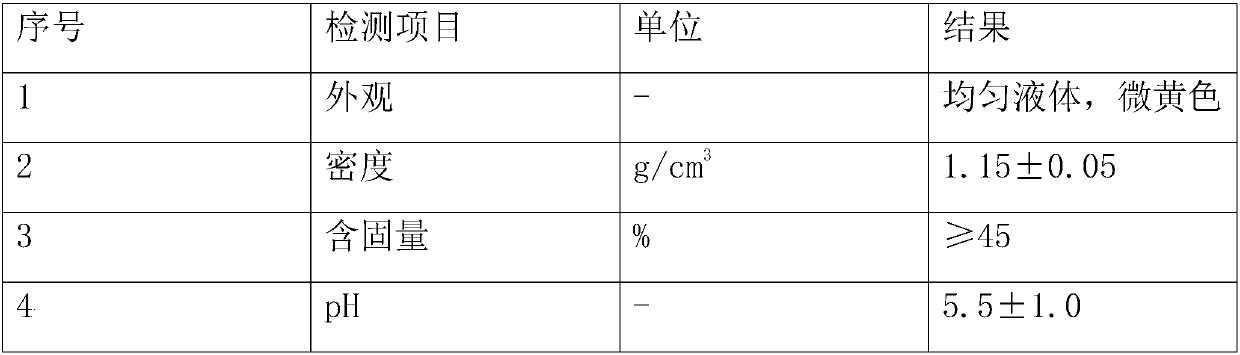

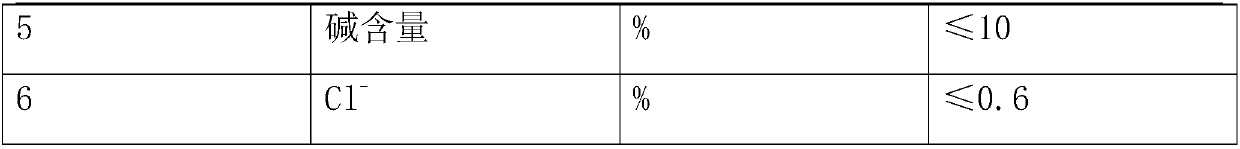

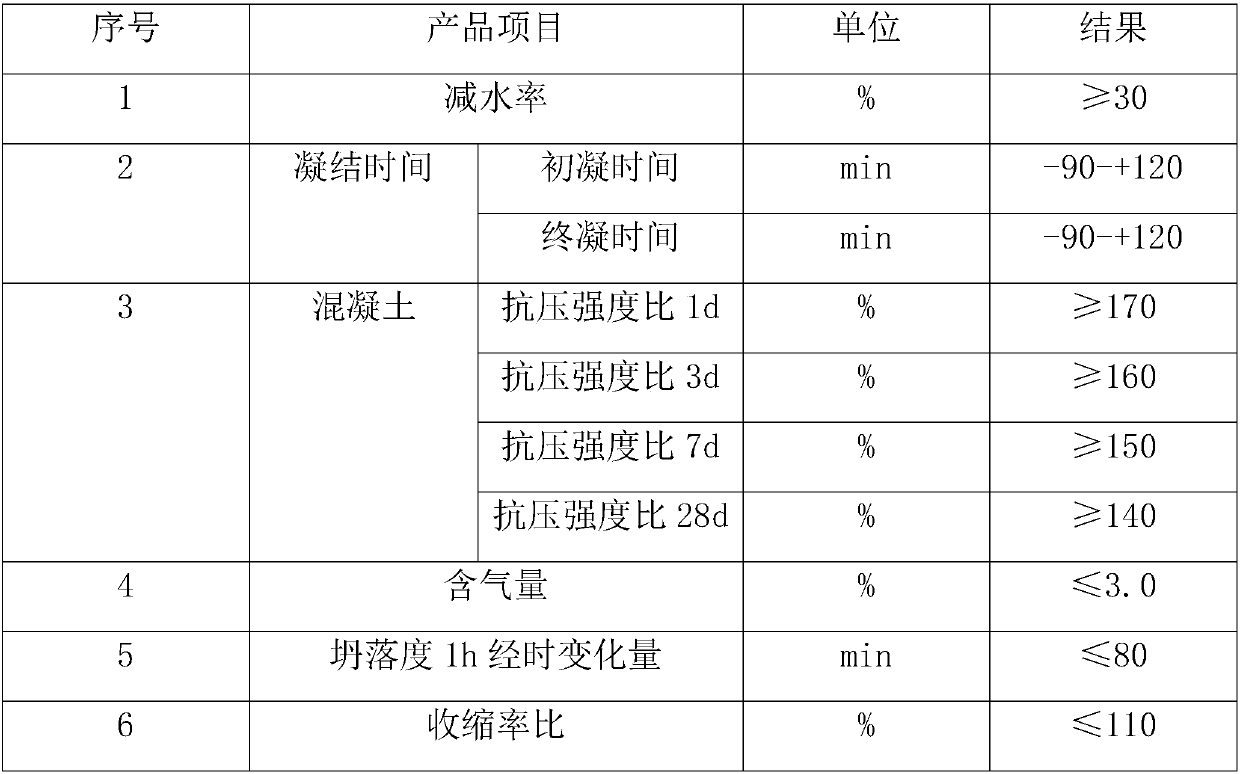

InactiveCN101476365AImprove insulation effectLow water absorptionBuilding componentsPolymer scienceThermal insulation

The invention discloses a straw light-weight energy-saving insulated building block and a method for producing the same. The method comprises the following steps: using broken straw segments processed by a surface modifier, high strength low-alkali cement, fly ash, superfine active mixed materials and the like as main raw materials; adding various additives such as a waterproof impermeable agent, a preservative, a high-efficiency water reducing agent, an excitant and the like and modified materials to the main raw materials, mixing all the materials evenly, and adding water to the mixture and blending the mixture evenly; molding, demolding and maintaining the mixture to mold the building block (a reinforcing rib of which the surface is provided with a plurality of transverse lug bosses), and coating cement waterproof fluid on the outside; and making protection layers on two sides of the building block with ordinary Portland cement, sand, slag, additives and water so as to obtain the straw light-weight energy-saving insulated building block. The straw light-weight energy-saving insulated building block has the characteristics of light weight, high strength, good thermal insulation property, low water absorption rate, high freeze-melt resistance, fire prevention, water prevention, seepage prevention, insect and mouse damage prevention and the like, and saves 50 percent of energy for a single wall body material in the northern cold areas. Besides, the straw light-weight energy-saving insulated building block can be widely popularized and applied to the field of construction, in particular to the village and small town dwelling constructions in the northern cold areas.

Owner:肖力光

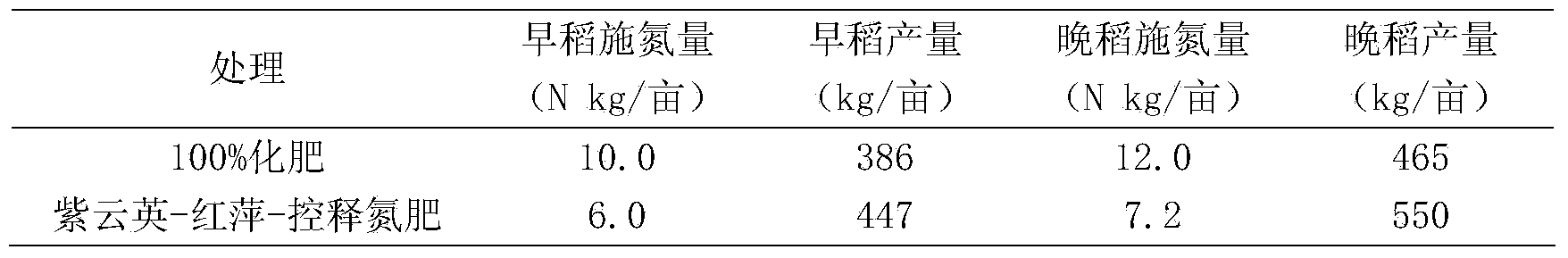

Double cropping rice nitrogen-saving high-yield production method

InactiveCN103858720AGrowth inhibitionDrain controlFertilising methodsCultivating equipmentsCrop cultivationGreen manure

The invention relates to a double cropping rice nitrogen-saving high-yield production method. A double cropping rice planting region is selected; 15 to 30 days before late rice is harvested, astragalus sinicus planting is carried out; after the late rice is harvested, ditching is carried out according to an astragalus sinicus planting technology; 30 to 50kg of calcium magnesium phosphate fertilizer is applied per mu; 1 to 2kg of potassium chloride used as a base fertilizer is applied per mu; 10 to 15 days before early rice is transplanted, dry tillage and plowing pressing are carried out; land preparation is carried out according to the early rice planting requirements; azolla is bred; and after shoal water of field water, which has a height of 1.5 to 3.5cm, is kept for 8 to 10 days, the base fertilizer is applied to carry out early rice transplanting. During growth of the early rice and the late rice, duckweed utilization is naturally carried out; before the late rice is transplanted, a sustained-release nitrogen fertilizer is applied in one step as the base fertilizer; and on mid-to-late September in the next year, circulation operation of farming of planting astragalus sinicus green manure crops and the like is carried out. According to the invention, astragalus sinicus green manure is planted during the slack winter season of double cropping rice planting, the azolla is bred during growth of rice, the rice special sustained-release nitrogen fertilizer is applied to the late rice in a decreasing manner, the astragalus sinicus and the azolla are utilized to fix nitrogen and adsorb carbon, the land is maintained by the land, organic materials and an organic nitrogen source are provided for rice, nutritive substances in the double cropping rice field, which are easy to loss, are adsorbed, non-point source pollution is reduced and fertilizer supply and the fertilizer requirement of rice are coordinated and consistent.

Owner:CHANGSHA ENVIRONMENTAL PROTECTION COLLEGE +2

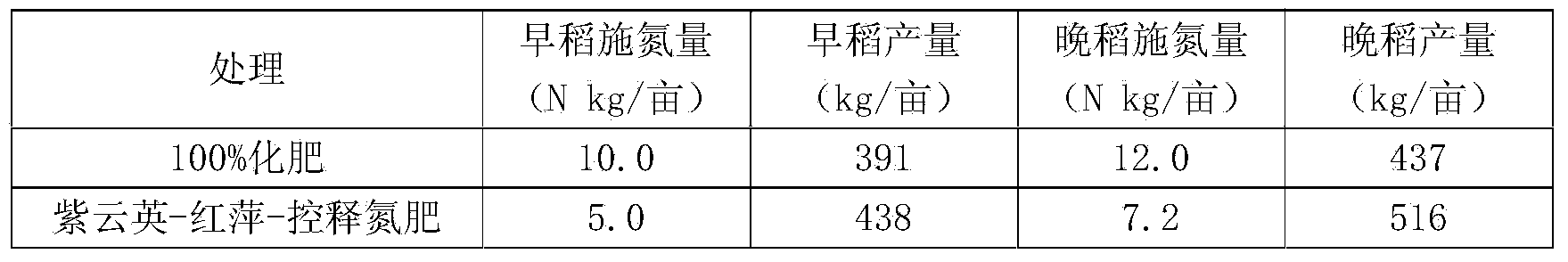

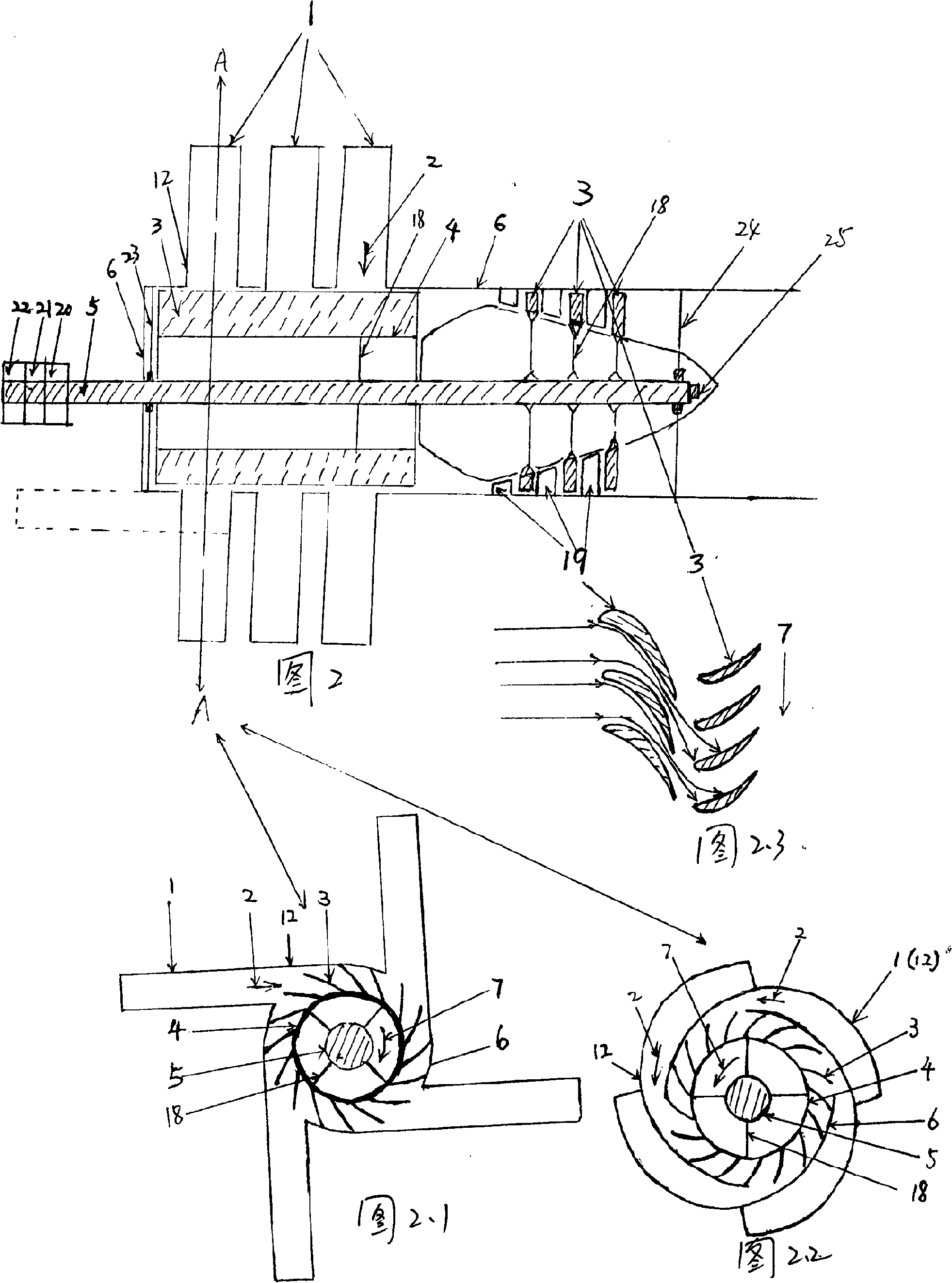

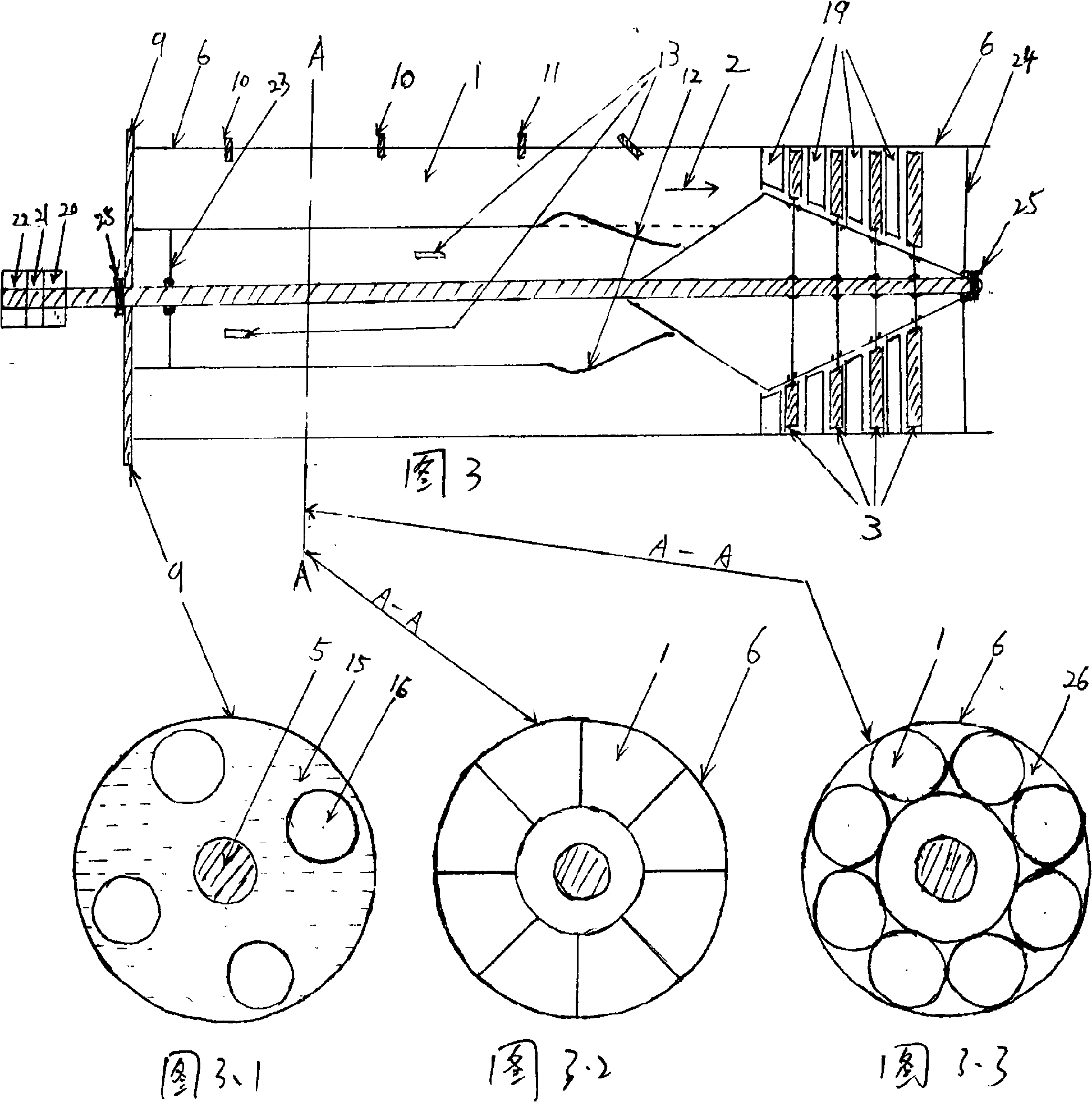

Pulse knock rotor spindle engine

InactiveCN101338702AIncrease useSingle purposeTurbine/propulsion engine coolingGas turbine plantsHigh pressureSubmarine

The present invention relates to a pulse detonation rotor shaft engine. In the technical proposal, the pulse detonation rotor shaft engine mainly consists of a pulse detonation engine, a rotor and an output shaft; propulsive gas with the high temperature and high pressure expansion of pulse which is ejected when the pulse detonation engine works is used as a power source to push the rotor to rotate; the rotor drives the output shaft to rotate; a pulse detonation rotor shaft engine uses the output shaft to output most energy produced by the pulse detonation engine by outputting torsion continuously; the output shaft drives various kinds of loads to work. The pulse detonation rotor shaft engine has the beneficial effects as follows: firstly, the pulse detonation rotor shaft engine can be used as a shaft engine to be widely applied in various kinds of dynamic systems, such as ship, submarine, tank, tractor, automobile, train, and the like and has wide purposes; secondly, the pulse detonation rotor shaft engine overcomes the disadvantage of the large noise of the prior pulse detonation engine; thirdly, compared with a piston type engine, the pulse detonation rotor shaft engine has the obvious advantages of simple structure, low cost, high reliability, long service life, light weight, less fraction resistance loss, etc.

Owner:RUGAO HUAYANG ALUMINUM PROD

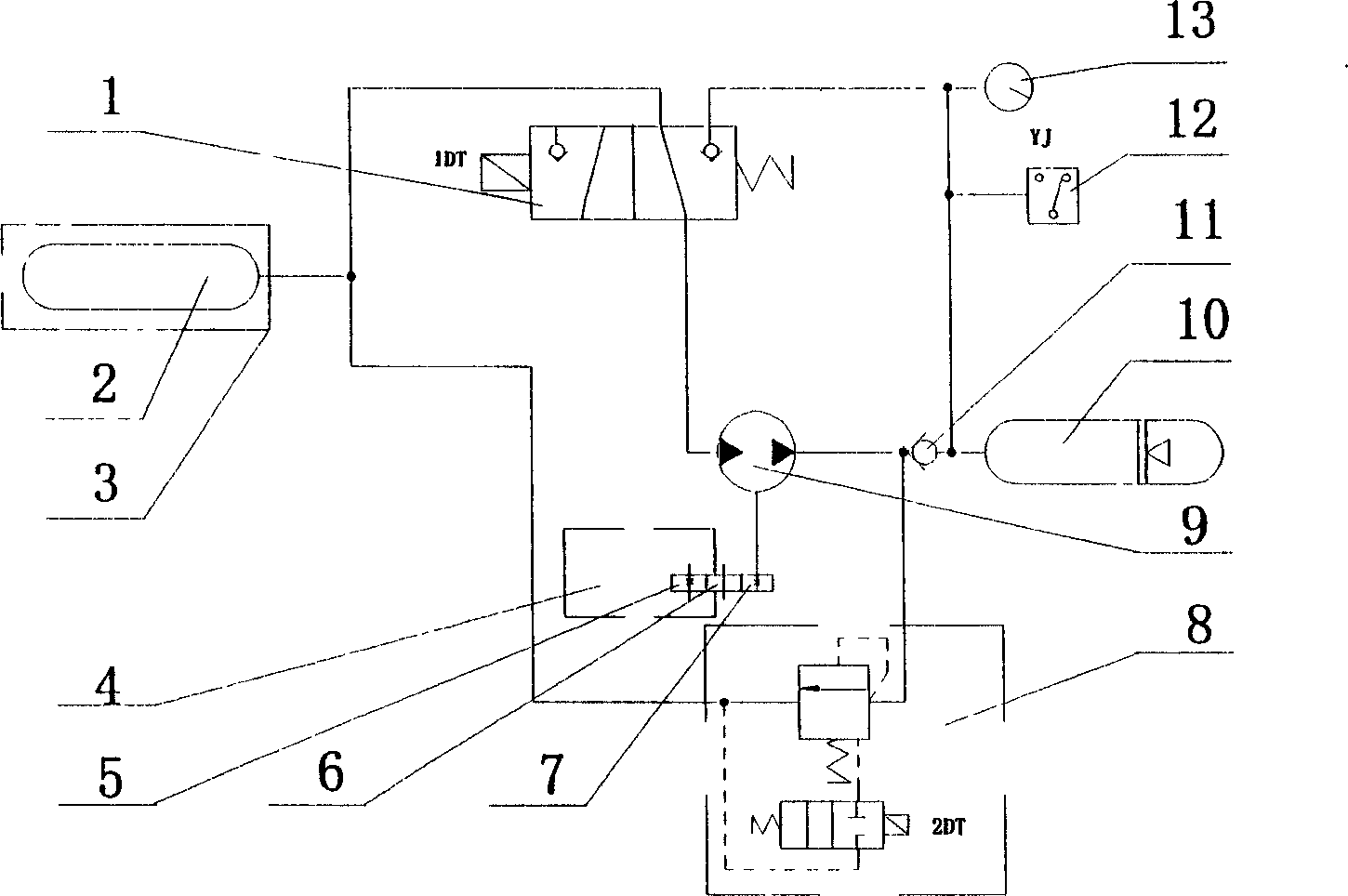

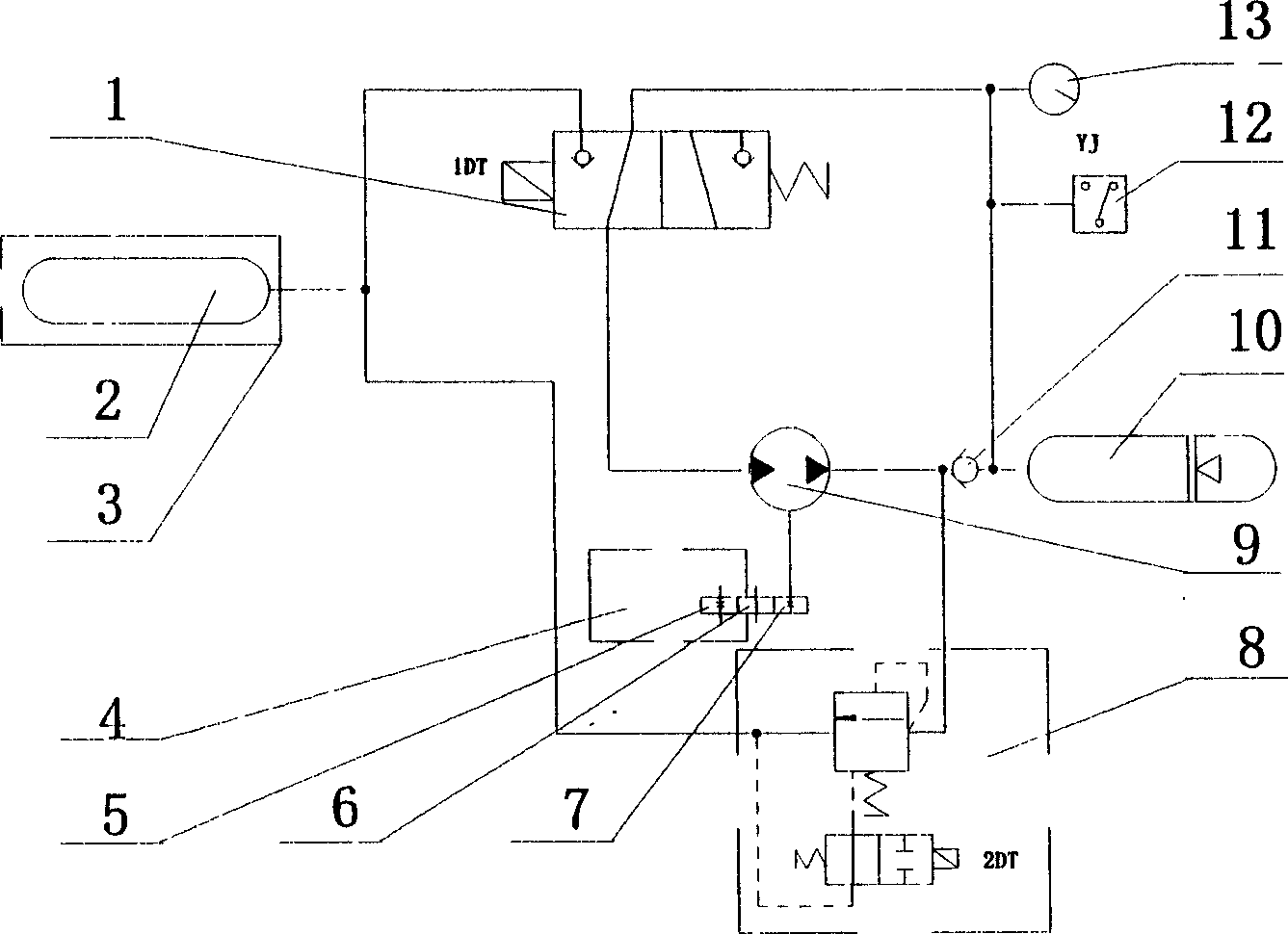

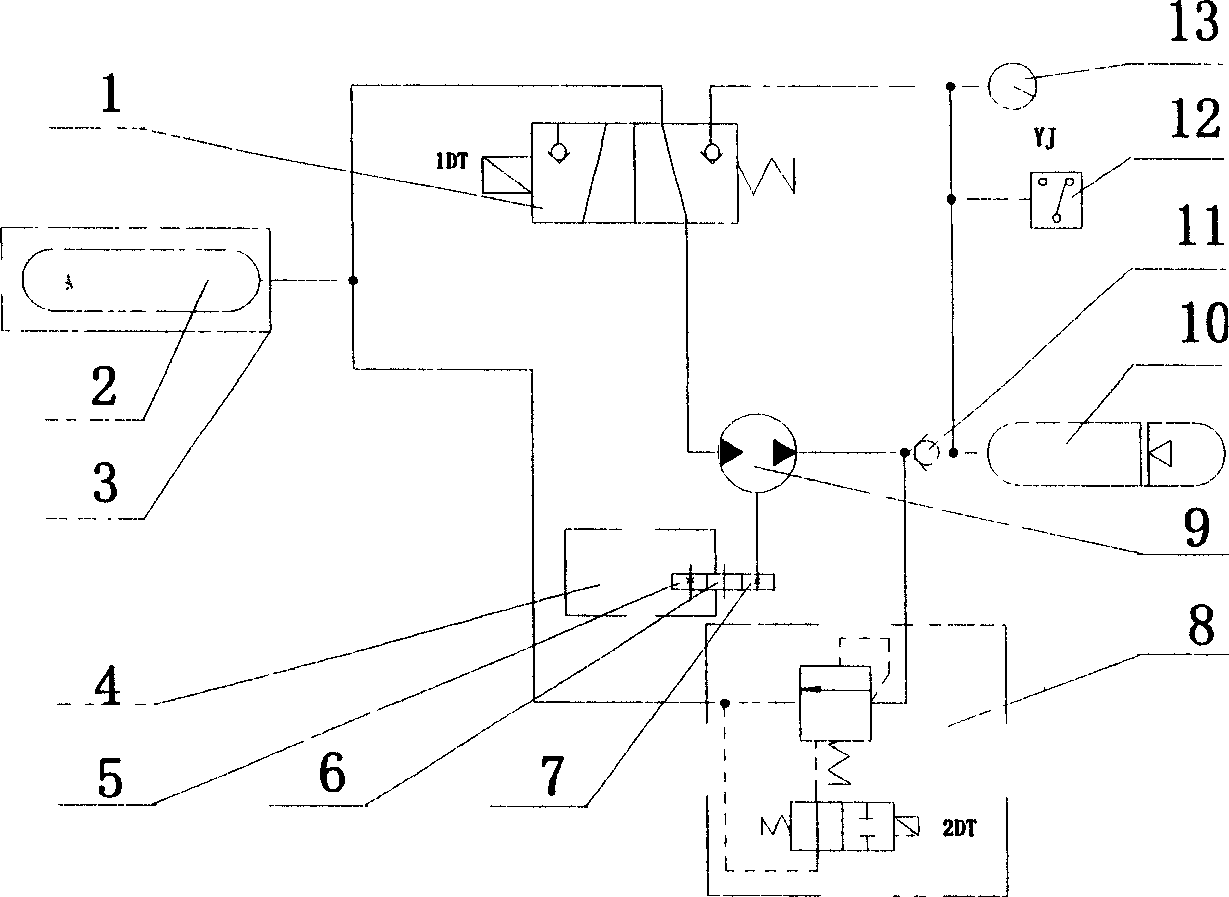

Automotive braking force reclaiming economizing and accelerating unit

InactiveCN1833901AImprove economyExtend your lifeGas pressure propulsion mountingPlural diverse prime-mover propulsion mountingFuel tankAutomotive transmission

An oil-saving boosting unit able to recover the braked kinetic energy for car features that the additional mechanical structure and simple hydraulic system are additionally installed to the output axle of speed variator or drive axle. When the car is braking, its inertia can drive oil pump to become the pressure energy of fluid and store it in energy accumulator. When the car is driven or accelerated, the energy is released via the same mechanism. An enclosed leather bag type oil tank and a simple hydraulic system are used.

Owner:SHANGHAI SHENZHOU VEHICLE RES & DEV

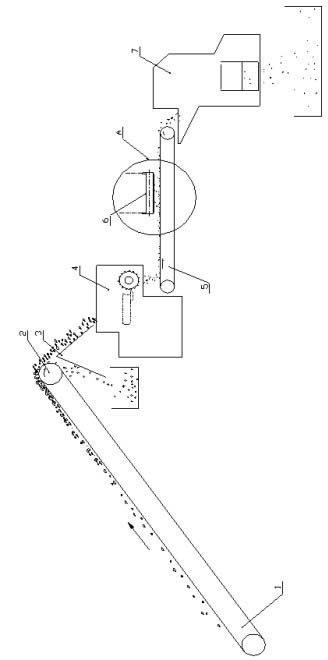

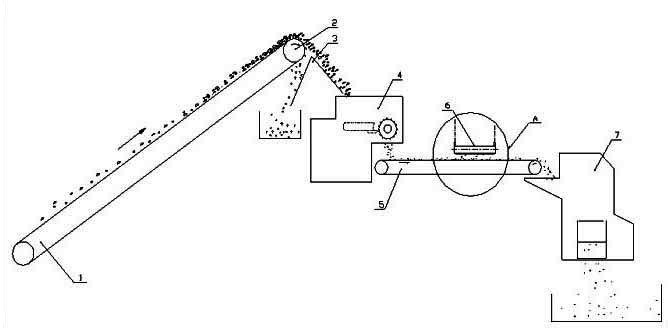

Preparation method for high-quality recycled concrete aggregates

InactiveCN103332881AEasy to shapeImprove stripping rateSolid waste managementResource utilizationArchitectural engineering

Provided is a preparation method for high-quality recycled concrete aggregates. The preparation method comprises steps of sorting of waste concrete, primary crushing, primary screening, rod milling, secondary screening and cleaning, and then the graded aggregates are mixed according to required gradations to obtain recycled coarse aggregates with different particle sizes. According to the preparation method, the cyclic utilization rate of waste concrete can be close to 80%, the resource utilization of construction waste in cities can be realized, the secondary pollution of construction waste to the environment can be reduced, the land occupation account for landfilling of construction waste can be saved, and the industrialization development of comprehensive utilization of construction waste can be promoted to some extent.

Owner:GUANGXI UNIV +1

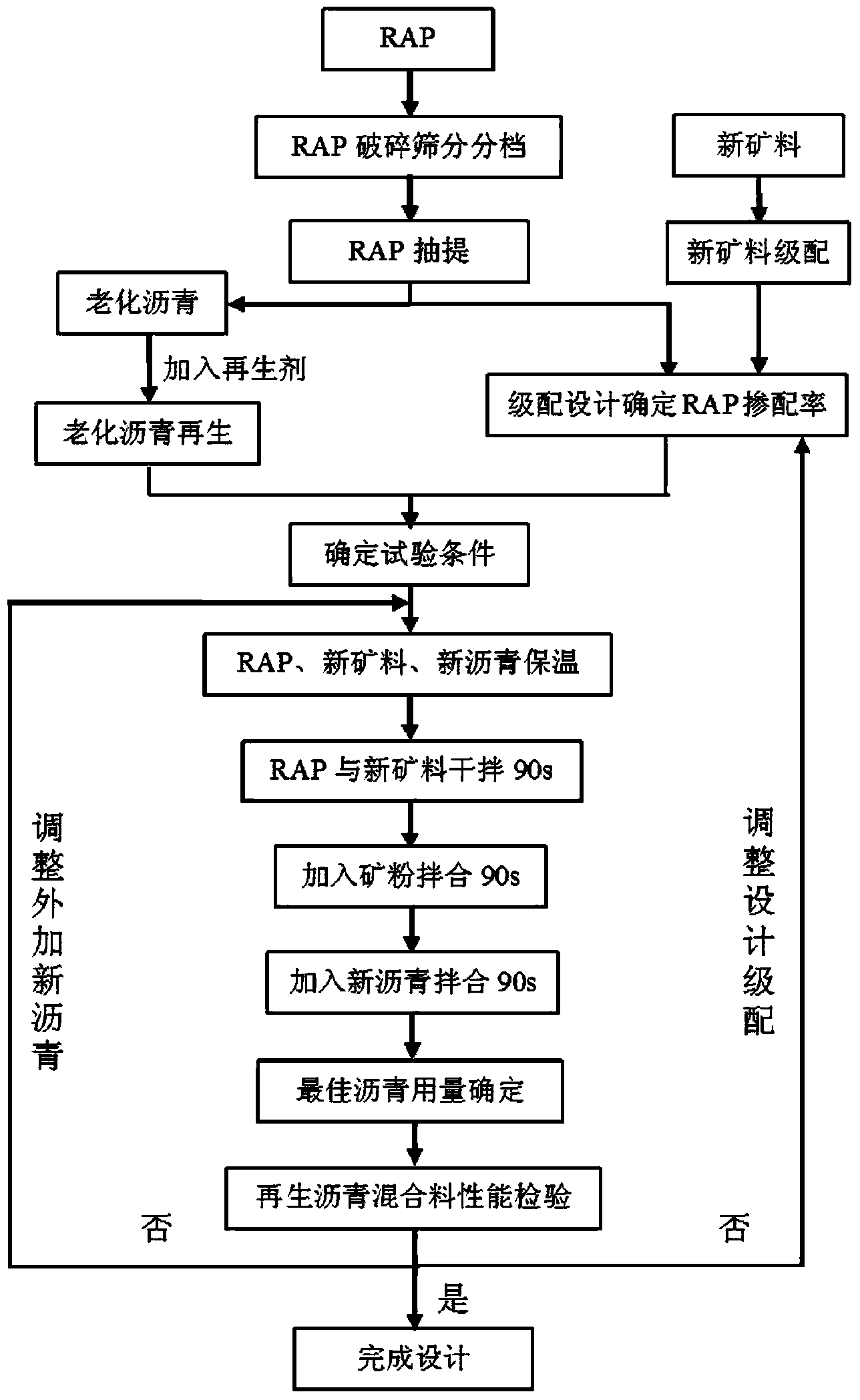

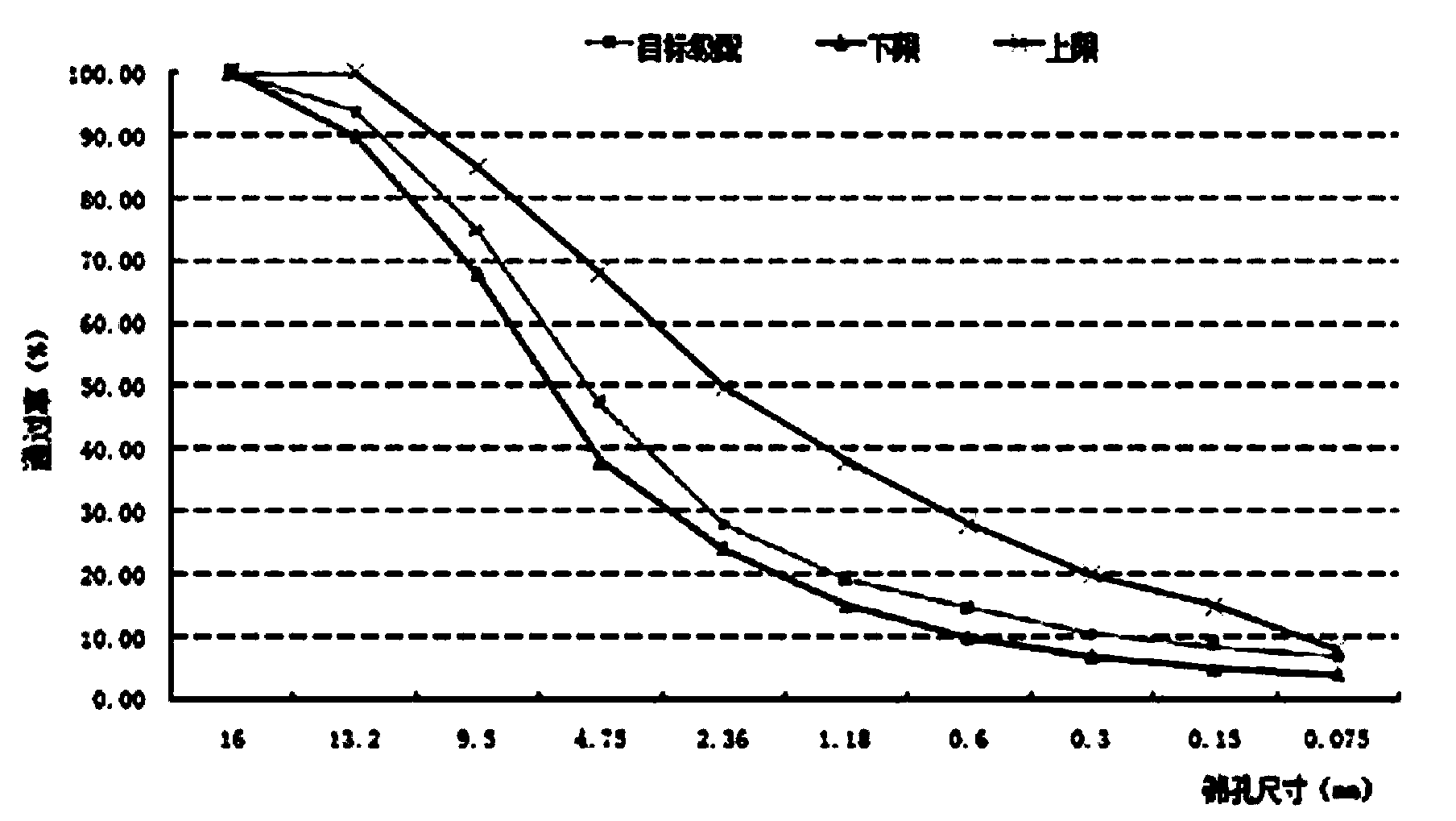

Design method of hot recycled asphalt mixture with high RAP proportion

The invention belongs to the technical field of road engineering, and particularly relates to a design method of a hot recycled asphalt mixture with a high RAP proportion. The method comprises the steps of controlling the variability of an RAP material, improving the recycling effect of a recycling agent and determining appropriate test conditions. The design method can effectively increase the blending rate of the RAP, the performance of the recycled asphalt mixture meets the relevant provisions, and the blending ratio of the RAP can reach 36%. According to the design method provided by the invention, the RAP material is well utilized, resources are saved, the waste of materials is avoided, the material cost of highway construction can be effectively reduced, and the damage of resource mining to the environment also can be reduced simultaneously. The economic and environmental advantages of a technology are very obvious.

Owner:BEIJING UNIV OF CIVIL ENG & ARCHITECTURE +1

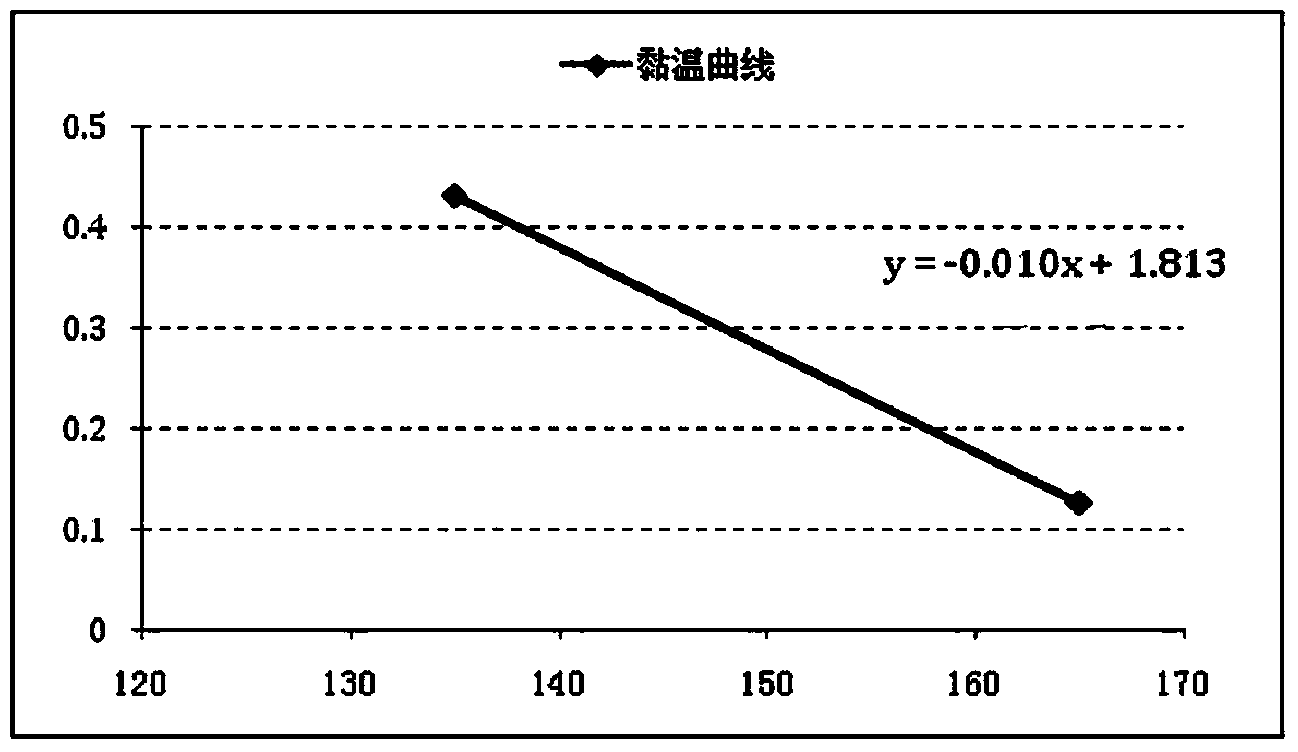

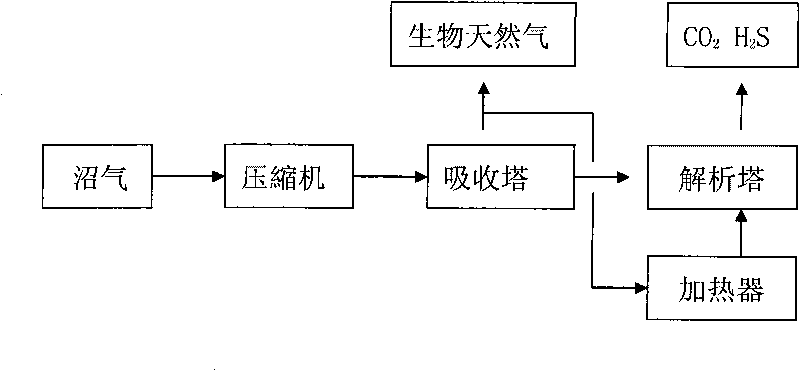

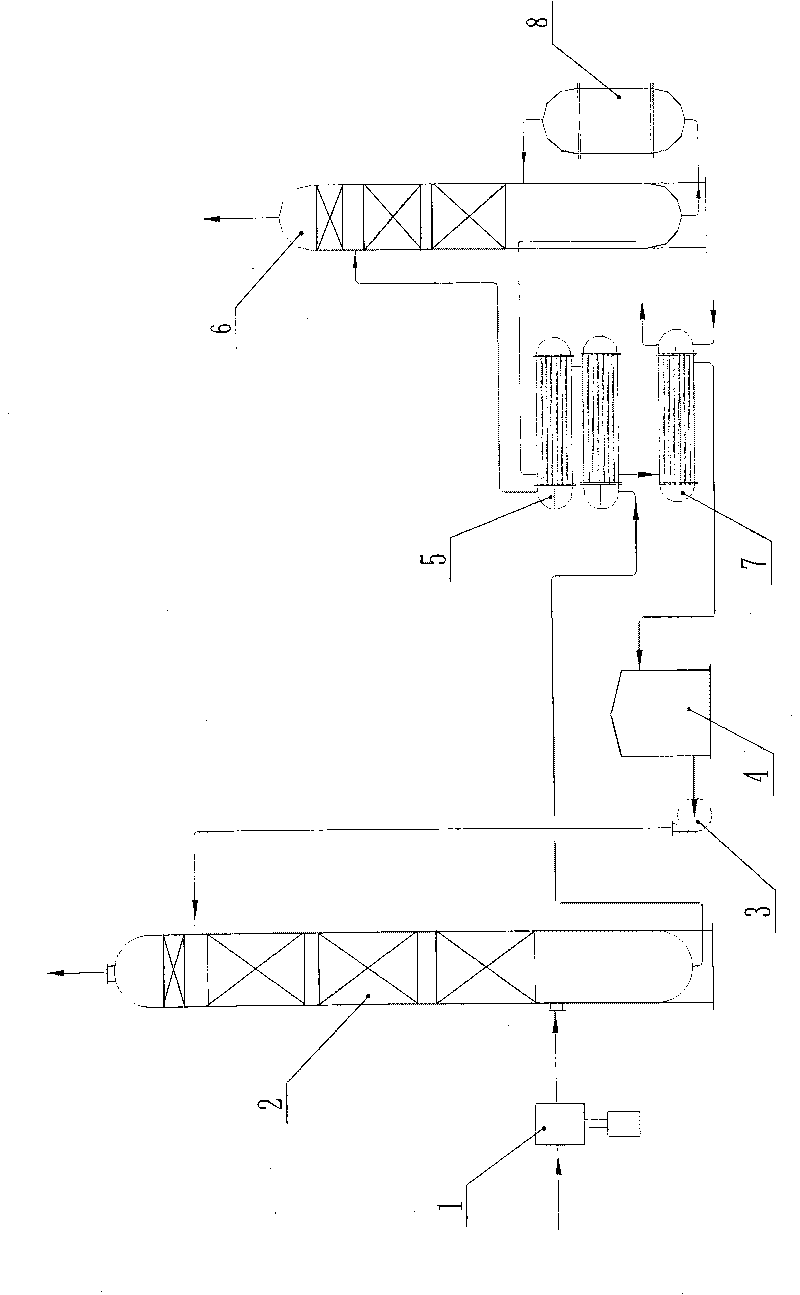

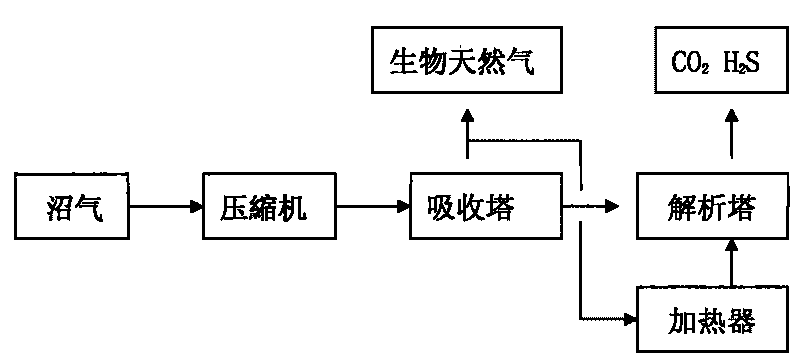

Method for preparing biological natural gas from marsh gas

The invention relates to a method for preparing biological natural gas from marsh gas. The method is characterized in that marsh gas is compressed to 0.35-0.7MPa and then enters an absorption tower; in the absorption tower, the marsh gas from bottom to top has a countercurrent contact with a monoethanolamine solution used as an absorbent from top to bottom to absorb CO2 and H2S; gas coming out of the top of the absorption tower is purified biological natural gas; and rich liquor coming out of the absorption tower is heated to 11-125 DEG C through a heater and then decomposed in a decomposing tower to release the CO2 and the H2S, wherein the pressure of the absorption tower is 0.35-0.7MPa, the temperature is normal temperature, and the temperature of the decomposing tower is 105-110 DEG C. The method utilizes the excellent absorbent (monoethanolamine) with a large solubility to absorb the carbon dioxide and the sulfide in the marsh gas so as to remove the carbon dioxide and impurities in the marsh gas, ensures that the content of methane is improved to be higher than 95 percent, and meets the requirement on components of the natural gas, thus the obtained natural gas prepared by the method is called biological natural gas. The method enlarges the application of the marsh gas, improves the use value of the marsh gas, and has obvious economic, social and environmental benefits.

Owner:KUNMING UNIV OF SCI & TECH

Biological control method for orchard ecology

Disclosed is the biological control method for orchard ecology, which integrates the techniques of utilizing natural enemy insects and biological pesticides, the insect hazard to the plants in the orchard can be controlled, the application of pesticide can be reduced substantially, the ecological environmental contamination to the orchard can be minimized.

Owner:BEIJING ACADEMY OF AGRICULTURE & FORESTRY SCIENCES

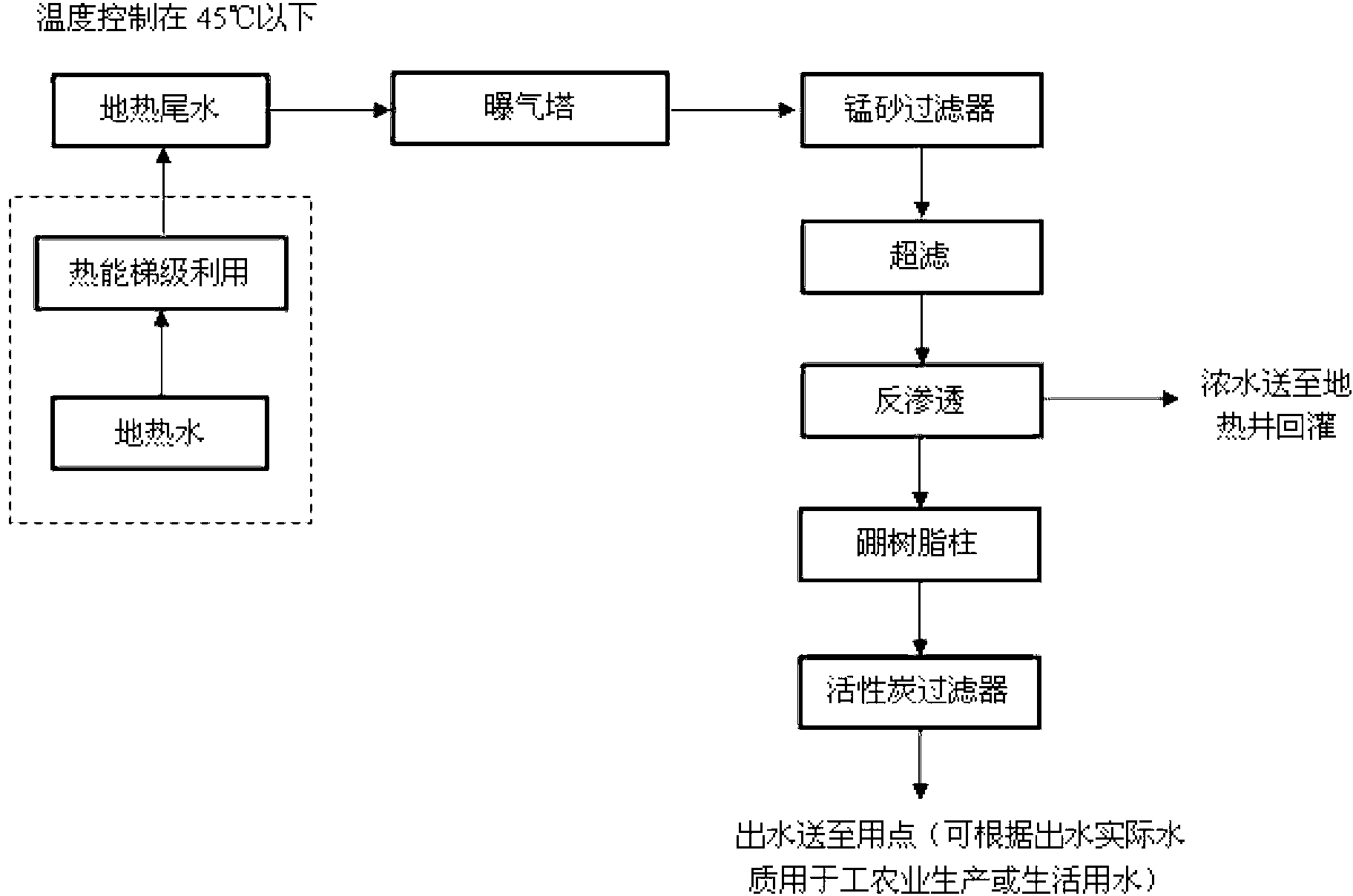

Terrestrial heat tail water treating process

InactiveCN103011454AWide range of water qualityAchieve integrationWater/sewage treatment bu osmosis/dialysisMultistage water/sewage treatmentActivated carbon filtrationReverse osmosis

The invention provides a terrestrial heat tail water treating process which comprises the following steps: (1) controlling the tail water temperature after the terrestrial heat water is subjected to heat energy gradient utilization to be less than 45 DEG C; (2) aerating the terrestrial heat tail water by using an aeration tower; (3) flowing the aerated terrestrial heat tail water through a manganese sand filter to be filtered; (4) carrying out membrane integrated treatment on the filtered terrestrial heat tail water by using a double-membrane method process; (5) carrying out boron selective resin absorption treatment on the reverse osmosis water; and (6) filtering the effluent subjected to boron removal by using an active carbon filter and conveying to a use point. Aiming at the harmful ingredients and pollutant types in terrestrial heat tail water, the invention integrates a plurality of water treatment unit techniques, realizes integration and optimization of process systems, is wide in water quality application range of the terrestrial heat tail water, advanced in process and reliable in technique, and has practical popularization and application values in development and utilization in terrestrial heat tail water, and as a result, significant social, economic and environmental benefits are achieved.

Owner:CHINA UNIV OF GEOSCIENCES (WUHAN)

Regenerative bone material by concrete and preparing method thereof

InactiveCN1559956AHigh strengthHave physicalSolid waste managementRoad engineeringUltimate tensile strength

The invention is a concrete regenerative aggregate obtained by crushing discarded concrete and its preparing method, using the discarded concrete as raw material, and making special processes of crushing, dry-blending, screening and washing to obtain it. It has physical and mechanical properties approaching those of natural stones, a relatively ideal material for preparing regenerative concretes with low strength, medium strength, etc, able to be widely applied to road engineering, municipal engineering and houses and buildings engineering.

Owner:TONGJI UNIV

Inorganic regenerated concrete mixture and its preparing method

InactiveCN1473787AQuality improvementExtend your lifeSolid waste managementSlagUltimate tensile strength

The present invention relates to a kind of inorganic regenerated concrete mixture and its preparation process. The inorganic regenerated concrete mixture is prepared with waste concrete regenerated aggregate and industrial waste slag as main material and through adding activating agent and water and through stirring. The mixture has the features of high strength, good hydraulicity and powerful deformation resistance. It is one ideal road base material and may be used widely in the road construction in soft soil foundation area.

Owner:TONGJI UNIV

Premixing environmental protection energy-saving concrete and preparation method thereof

The invention relates to premixing environmental protection energy-saving concrete and a process for preparation, which employs regenerating coarse aggregate formed by slacking waste concrete and mineral admixture processed by waste slag as main materials and adds natural carpolite, sand, cement, additive and water and stir to form. The concrete has good working property and durability, high strength and is adapted for being transported by mixer truck or pump, which can be widely used in road engineering and constructional engineering and the like.

Owner:TONGJI UNIV +1

Preparation method for (PVC) nontoxic calcium zinc heat stabilizer and uses thereof

The invention discloses a manufacturing method of composite intoxic Ca-Zn heat stabilizer, which is characterized by the following: fusing high-level aliphatic acid and Ca-Zn oxide or hydroxide without solvent directly to synthesize integral stabilizer; complexing with sodium biphosphate, beta-diketone and bisphenol A; shortening manufacturing period from 15h to 6h; saving cost obviously.

Owner:GUANGDONG GAOKEDA TECH IND +1

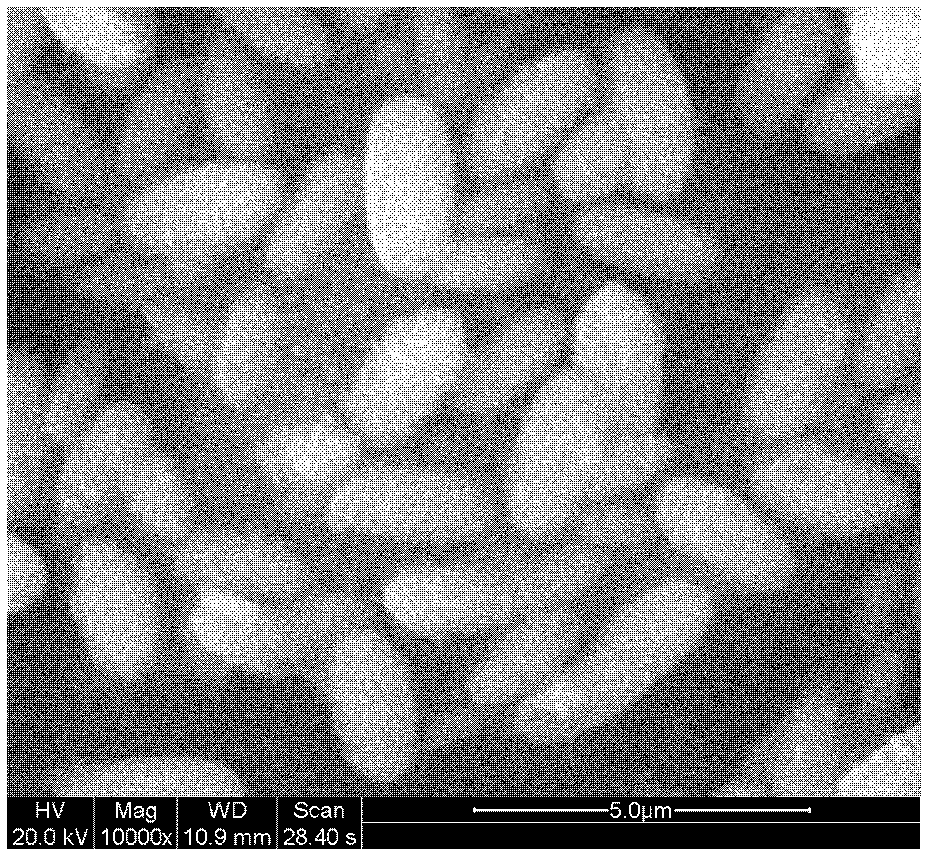

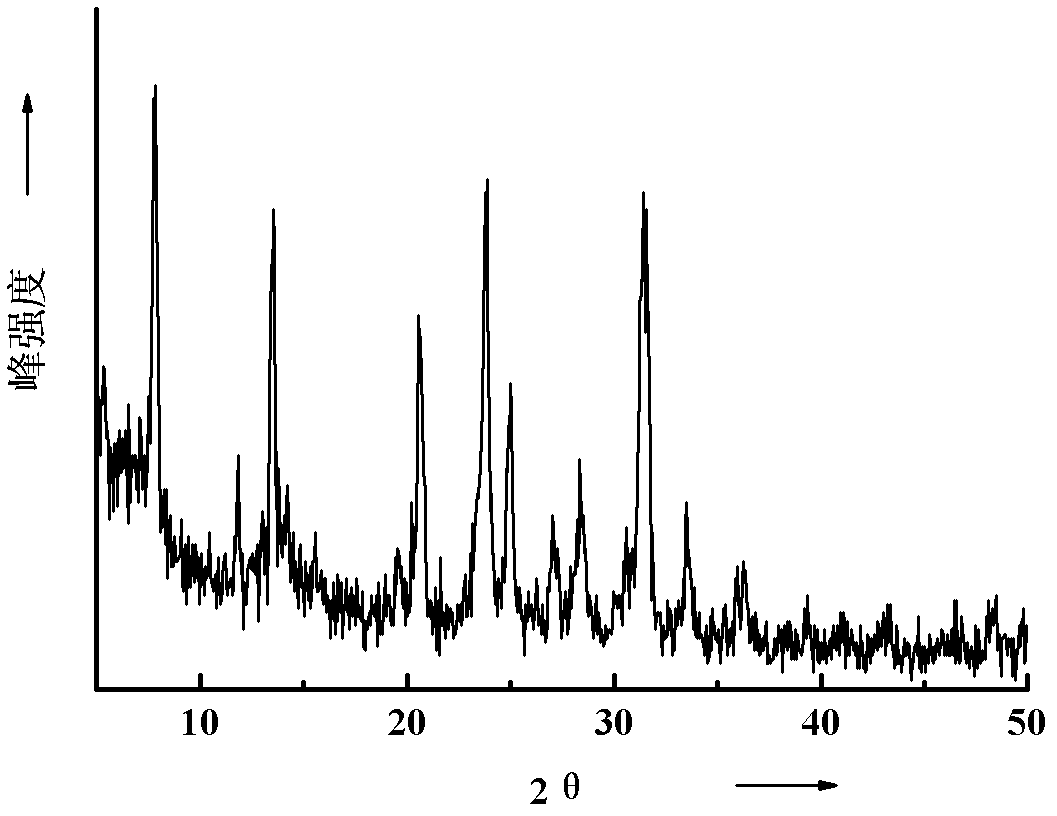

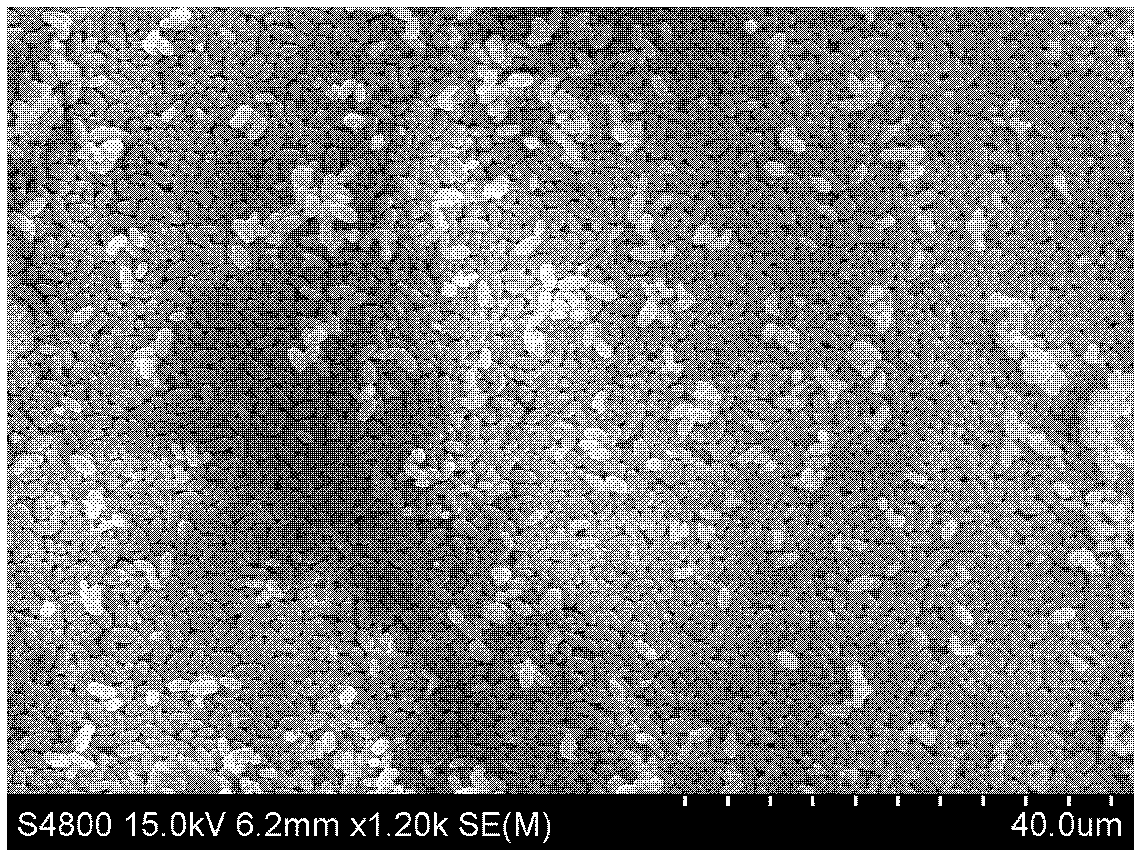

Hollow fiber acidproof and permeable molecular sieve membrane and its preparation method

InactiveCN102397757AObvious technical advantageObvious economySemi-permeable membranesFiberHollow fibre

The invention relates to a hollow fiber acidproof and permeable molecular sieve membrane and its preparation method. The hollow fiber acidproof and permeable molecular sieve membrane is characterized by taking hollow fiber porous ceramic as the support body and a T-type molecular sieve membrane as the membrane layer. The method comprises the steps of: mixing a silicon source, an aluminum source, sodium hydroxide, potassium hydroxide and water uniformly in proportion, conducting stirring for aging so as to obtain a reaction solution; putting a hollow fiber porous ceramic support body with a precoated T-type molecular sieve crystal seed into a reaction vessel, adding the reaction solution for hydrothermal synthesis; after the reaction, taking out the membrane and washing it to pH of 7-10, and drying it, thus obtaining a hollow fiber acidproof and permeable molecular sieve membrane. The T-type molecular sieve membrane of the invention is in a hollow fiber shape, and has a filling area over 1000m<2>.m<-3>, which is far higher than the filling area (30-250m<2>.m<-3>) of a single-channel tubular membrane. Besides, the hollow fiber porous ceramic support body has a thin wall, thus being in favor of reducing the support body mass transfer resistance and improving the pervaporation flux.

Owner:NANJING UNIV OF TECH

Room temperature synthetic polyester polyether polycarboxylic acid water-reducing agent and preparation method thereof

The invention discloses a normal temperature synthetic polyester polyether polycarboxylic acid water-reducing agent and a preparation method thereof, wherein the water reducing agent is prepared as follows: at normal temperature in a redox system, esters, ethers and unsaturated carboxylic acids and derivatives thereof are polymerized to form a polymer with the carboxylic acids and derivatives thereof as a backbone, and a chain transfer agent is used for control of the degree of polymerization. Concrete prepared by the water reducing agent has the advantages of good workability, good slump lossresistance, good workability and high strength, and the water-reducing agent is suitable for precast and cast-in-place concrete, reinforced concrete and prestressed concrete for high-speed railways,passenger dedicated lines, industrial and civil buildings, roads, bridges, ports, piers, airports and other engineering construction.

Owner:四川铁科新型建材有限公司

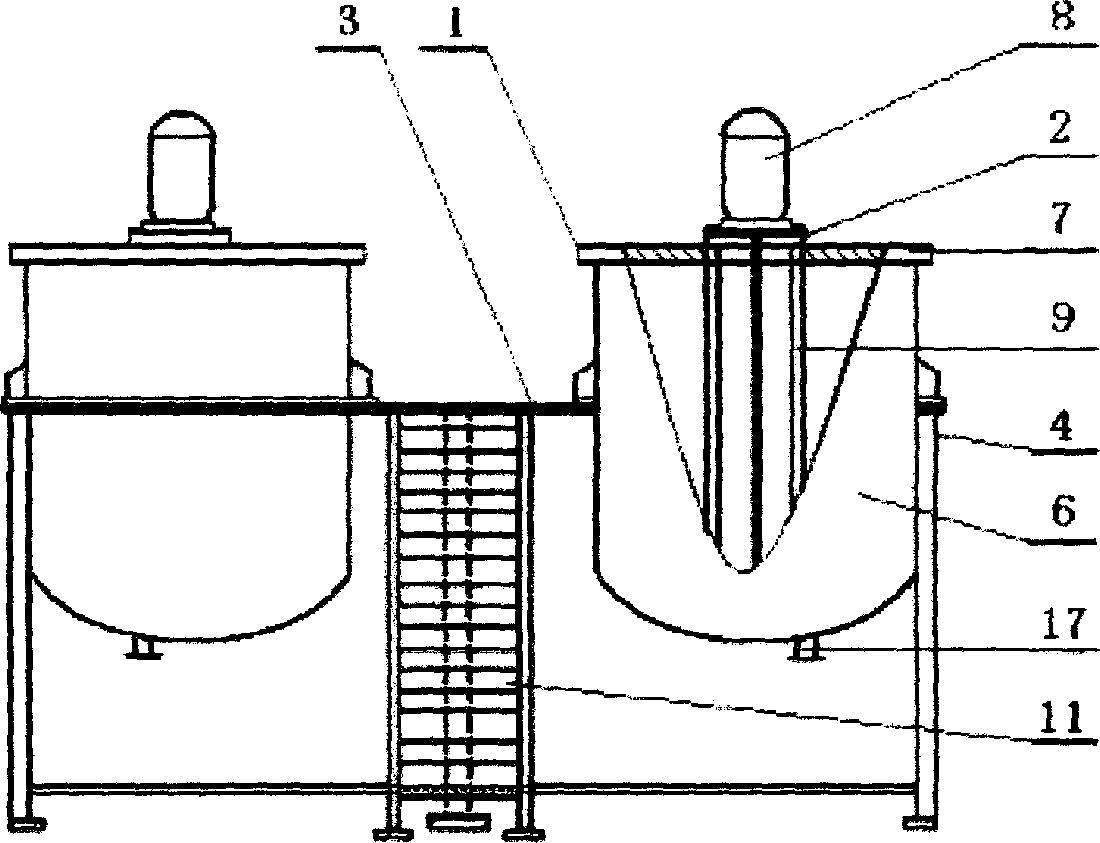

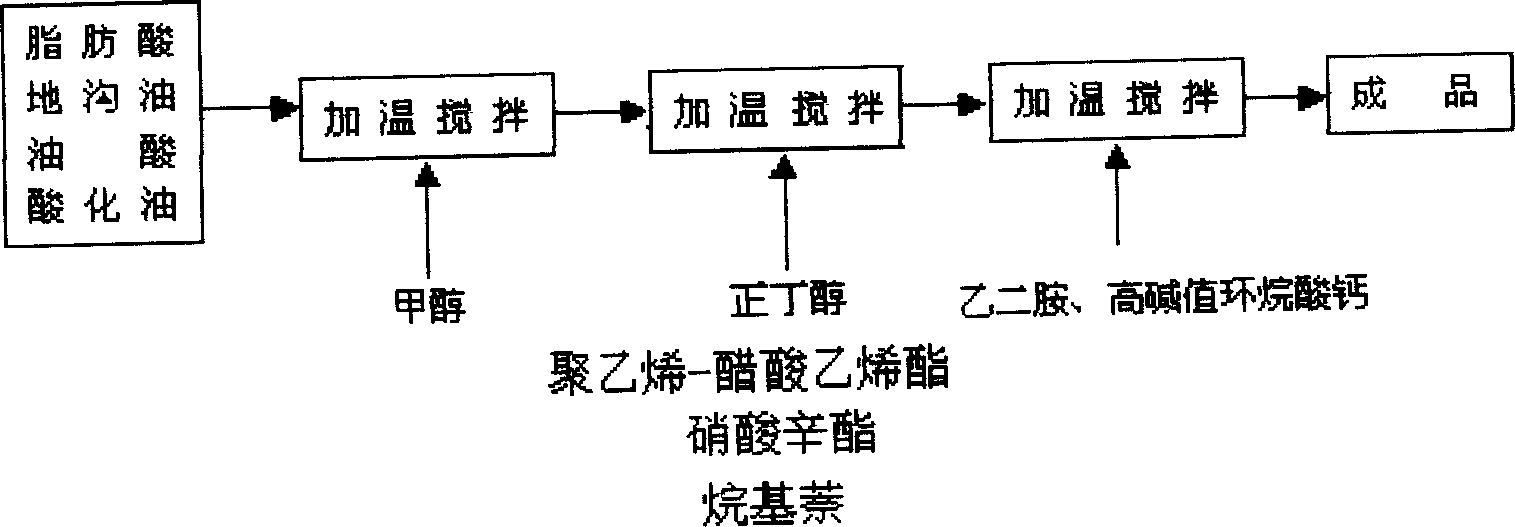

Method and device for producing biological diesel oil

InactiveCN1821348AReduce work intensitySimple processBiofuelsLiquid hydrocarbon mixture productionEthylenediamineBiodiesel

The biological diesel oil is produced with fatty acid, oleic acid, acidified oil and / or sewage oil as main material, and through adding methanol in 5-10 wt%, n-butanol in 5-10 wt%, ethylene-vinyl acetate copolymer in 0.1 wt%, octyl nitrate in 0.1 wt%, alkyl naphthalene in 0.05 wt%, and ethylenediamine and high base number calcium naphthenate successively white stirring in a reactor. The production apparatus consists of reacting tank, high speed stirrer, operating platform, rack and PLC control system. The present invention provides environment friendly biological diesel oil.

Owner:杨慈闵 +1

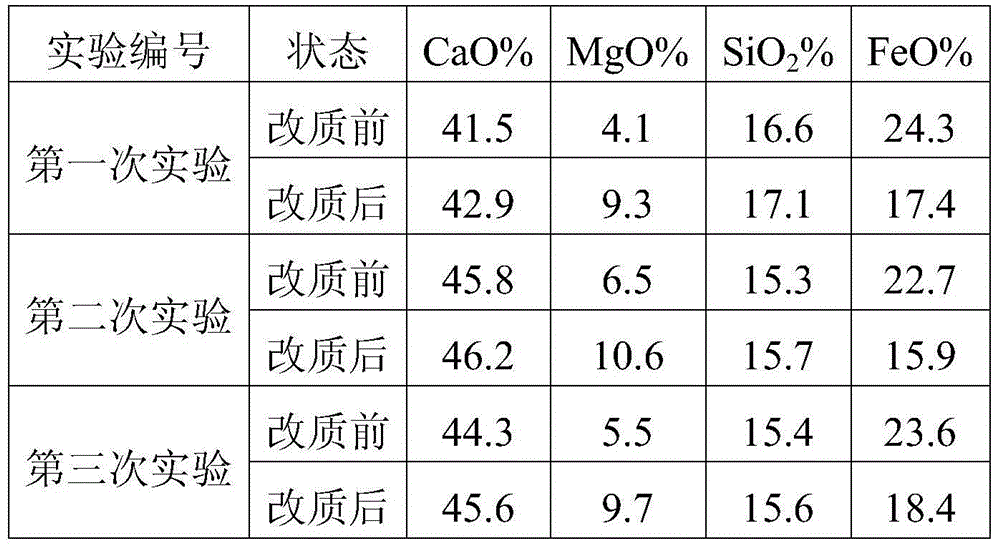

Resource utilization method of waste magnesia powder after treating oriented silicon steel

ActiveCN104099469AEfficient use ofHigh viscosityManufacturing convertersEnvironmental resistanceSlag

The invention discloses a resource utilization method of waste magnesia powder after treating oriented silicon steel. The resource utilization method comprises the following steps: (1) the waste magnesia powder after treating the oriented silicon steel is collected, and is evenly mixed with carbon powder and asphalt powder to obtain a mixed raw material by the following weight percentages: the waste magnesia powder is 60-95%, the carbon powder is 0-30%, and the asphalt powder is 5-10%; (2) the mixed raw material is prepared to green pellets with the diameter of 10-15 mm; and then the temperature of the green pellets is kept at 190-210 DEG C for 0.8-1.2 hours to prepare magnesium carbon pellets; and (3) the cooled magnesium carbon pellets are used as a slag splashing furnace protecting material. The resource utilization method uses the waste magnesia powder after treating the oriented silicon steel to replace the magnesium carbon pellets for the slag splashing furnace protection of a caustic-burned magnesia powder production converter; and the magnesium carbon pellets have high mechanical strength, can effectively enhance the viscosity of furnace slag, and can improve the slag splashing effect, so that the waste magnesia powder is effectively used, the stacking place is saved, the groundwater pollution is prevented, and the dual effects of environmental protection and economy are achieved.

Owner:武汉钢铁有限公司

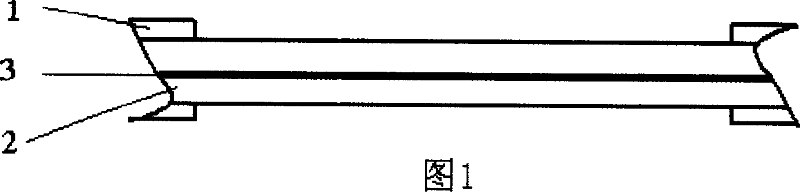

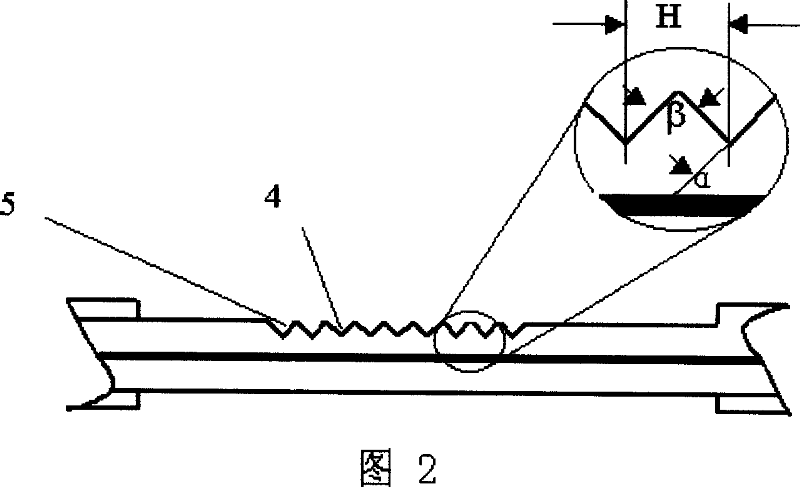

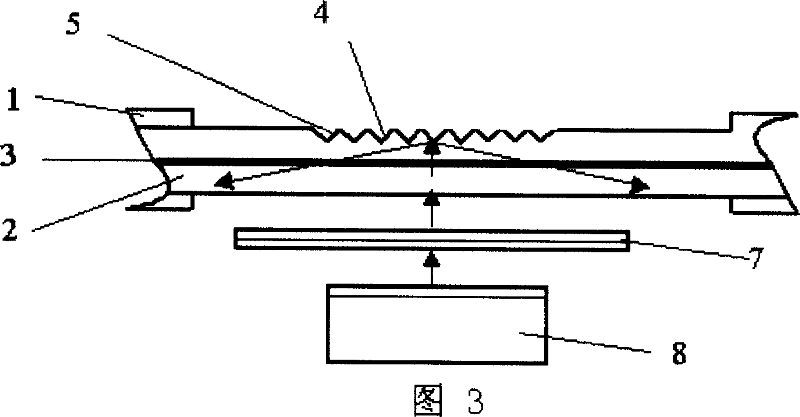

Double covered optical fiber side-pumping coupler grating and realization method thereof

InactiveCN101042514AGood effectObvious economyOptical fibre with multilayer core/claddingCoupling light guidesFiberGrating

This invention relates to one double coverage layer fiber side pump coupler grating, which comprises the following parts: inner package layer with one set of isosceles triangle level tanks with same structure parallel and tightly distributed with same length with LD array slow axis; the tank slope angle is more than sin-1n0 / n2 with width H equal to lambada / n2sin2alpha. The method comprises the following steps: removing outer package layer; etching the inner package layer as process type; polishing the tank and coating the medium film to form inner coverage coupler grating.

Owner:BEIJING JIAOTONG UNIV

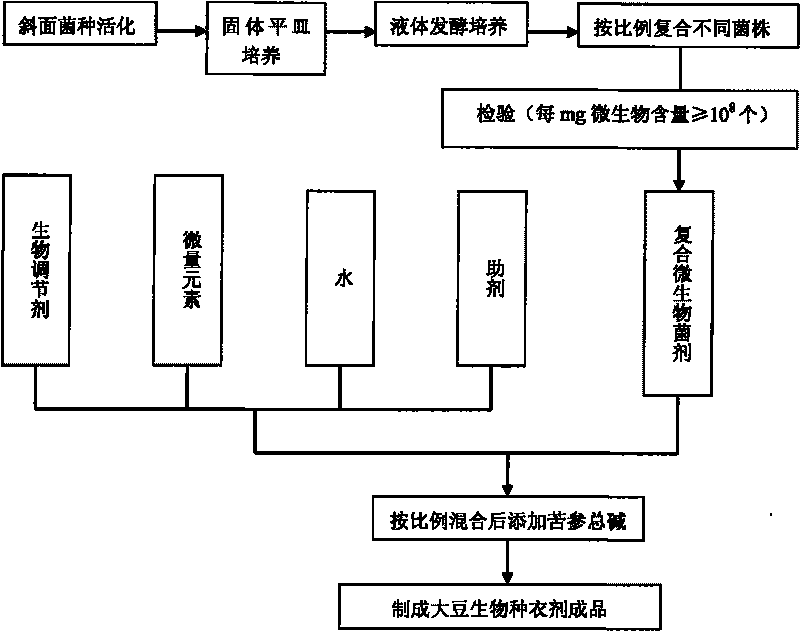

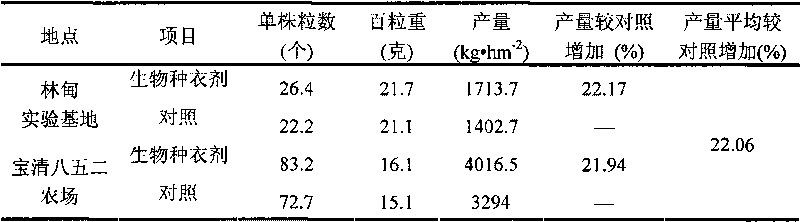

Soybean biological seed coating agent

InactiveCN101723763ALow toxicityOvercome the disadvantage of high residueBiocidePlant growth regulatorsMicroorganismMatrine

The invention discloses a soybean biological seed coating agent which is prepared from the following components in percentage by weight: 20 percent of complex microbial community, 5 percent of bio-regulator SODM, 10 percent of trace element, 10 percent of auxiliary agent, 0.4 percent of total matrines, and the balance of water. The invention has the advantages of environmental protection, enhancement of crop stress tolerance, strengthening of seedling, and improvement of yield and quality.

Owner:HEILONGJIANG BAYI AGRICULTURAL UNIVERSITY +1

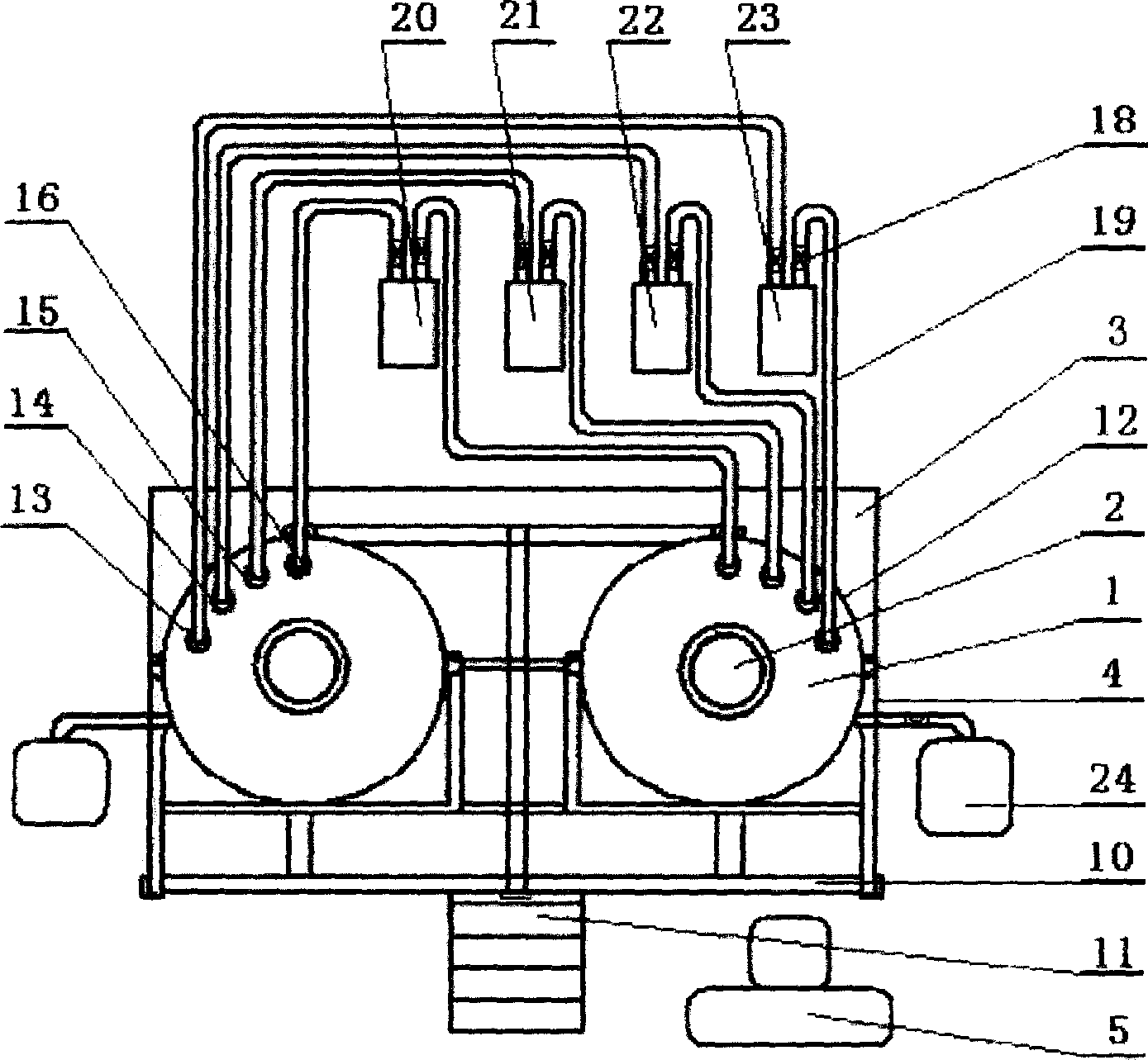

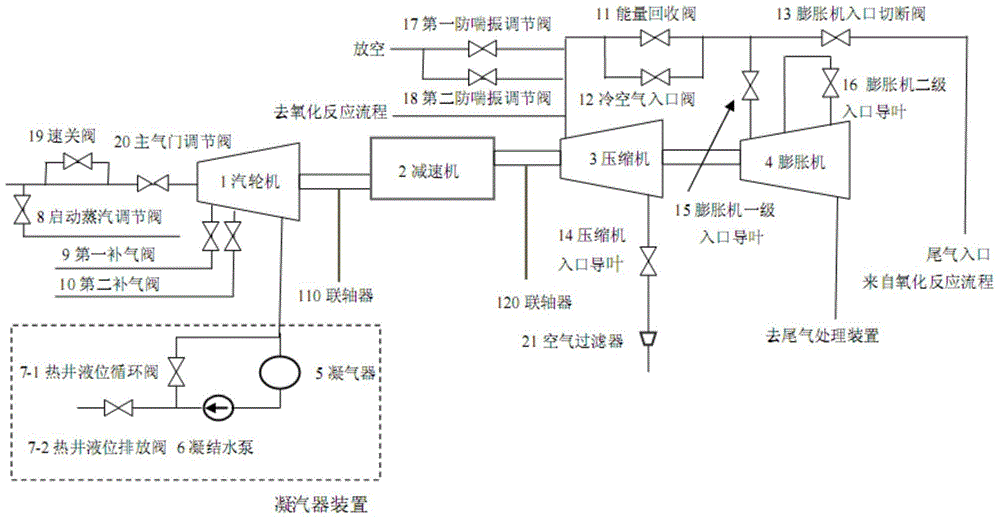

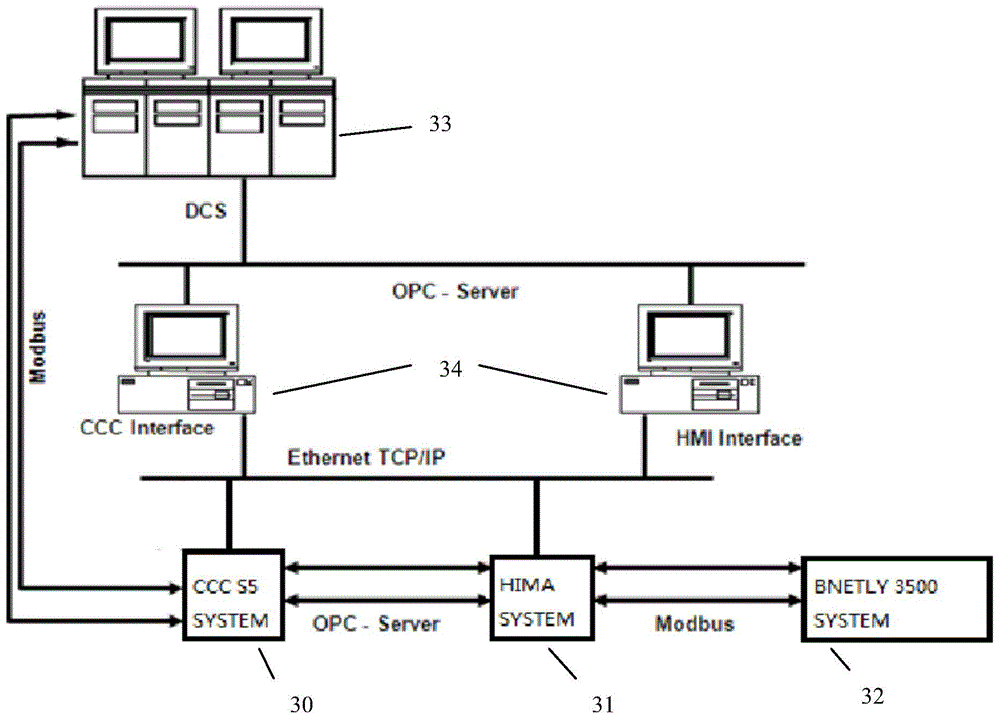

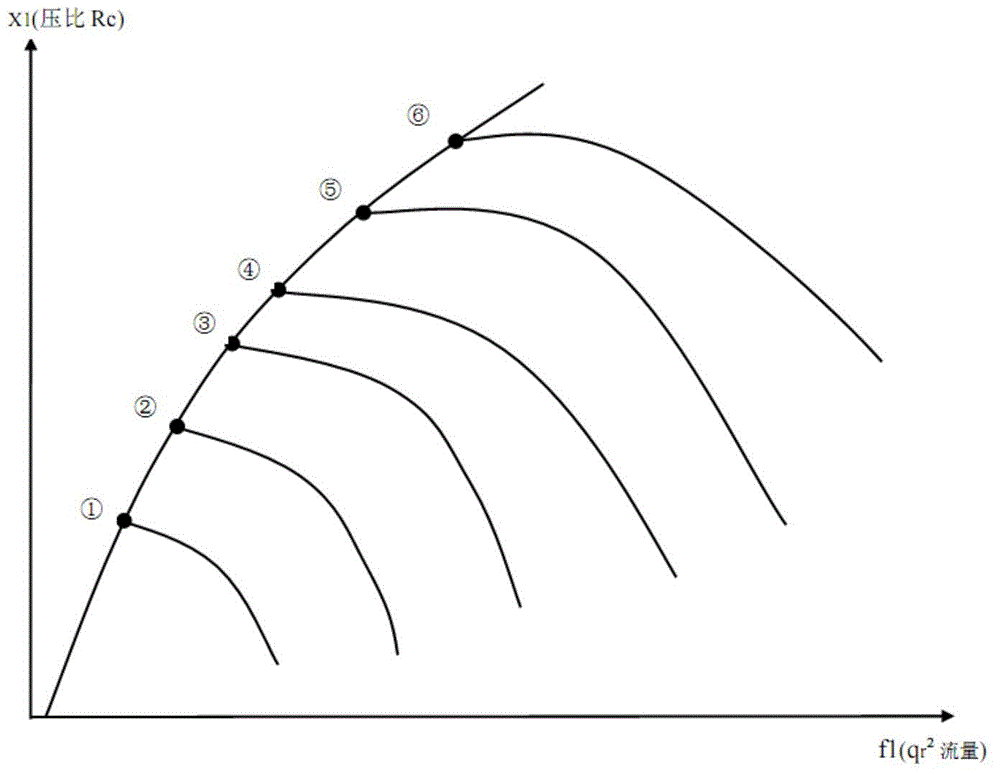

Unit control system and method for energy recovery of purified terephthalic acid (PTA) device

ActiveCN105443173AReduce operation and maintenance personnelReduce operational failure pointsSteam engine plantsControl systemEnergy recovery

The invention relates to a unit control system for energy recovery of a purified terephthalic acid (PTA) device. A turbine, a speed reducer, a compressor and an expansion machine are sequentially connected. A first auxiliary system is connected with the turbine, and a second auxiliary system is connected with the compressor and the expansion machine. A control device is connected with the turbine, the compressor, the first auxiliary system and the second auxiliary system. A control method includes the steps that all valves in the first auxiliary system and the second auxiliary system are controlled to be in initial states; the turbine is started to drive the compressor unit to carry out the first time of warming, and the second time of warming is carried out after the rotating speed of the turbine reaches a first set value and is kept for set time; after the rotating speed of the turbine reaches a second set value and is kept for set time, the rotating speed exceeds a critical rotating speed value and then reaches a rated rotating speed; and anti-surge control is carried out in a rated rotating speed stage, all the valves of the second auxiliary system are controlled to be opened or closed, and the turbine is driven to keep the set rotating speed. By means of the control system and the control method, the optimal load regulation and switching are achieved, efficient gradient utilization of energy is achieved, and capacity balance of the whole control system is achieved.

Owner:SHENYANG BLOWER WORKS GRP AUTOMATIC CONTROL SYST ENG

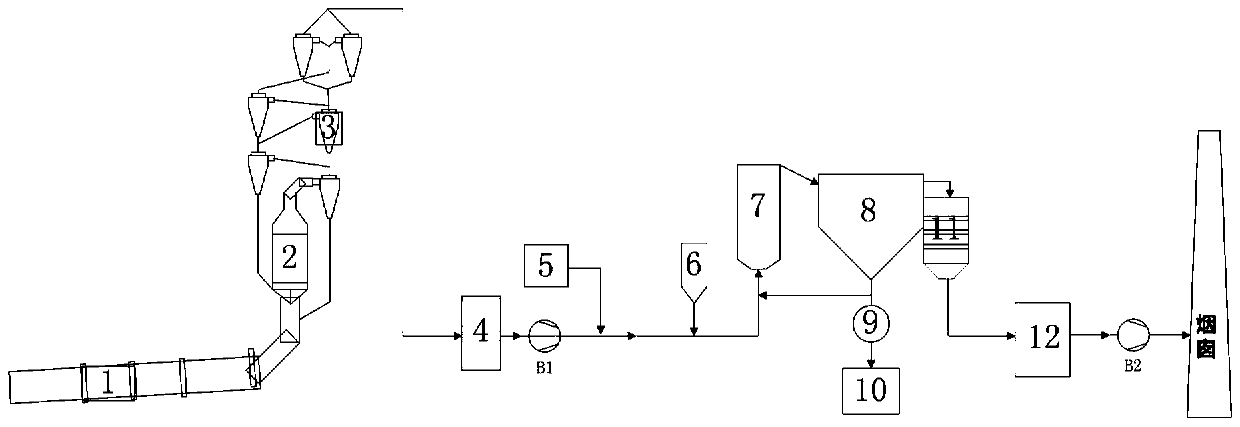

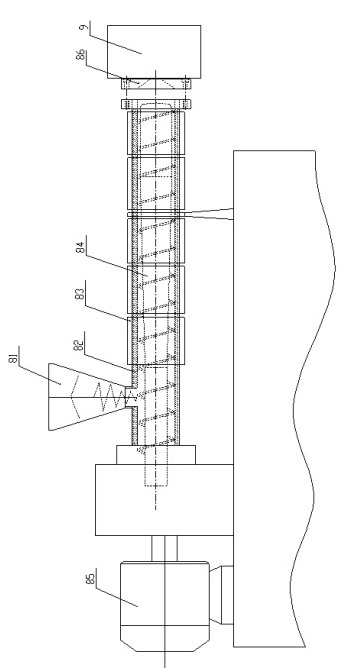

Dry desulfurization, denitration and dust removal device and method for low-sulfur flue gas in cement kiln tail

PendingCN110665352AReduce filter areaReduce resistanceGas treatmentDispersed particle filtrationDust controlCement kiln

The invention relates to a dry desulfurization, denitration and dust removal device for low-sulfur flue gas in cement kiln tail. The dry desulfurization, denitration and dust removal device includes acement kiln, a decomposing furnace, a suspension preheater, a cooling device, a desulfurization tower, a dust remover and a medium-temperature SCR denitration device, wherein the cement kiln, the decomposing furnace, the suspension preheater and the cooling device are successively connected, an air inlet pipeline of the desulfurization tower is connected with a flue gas outlet of the cooling device, and the desulfurization tower is a circulating fluidized bed dry desulfurization tower with the low density, a low bed and no water spraying; the air inlet pipeline is provided with a high-temperature fan, and connected with a raw mill, a desulfurizer bin and a smoke dust return device; a flue gas inlet of the dust remover is connected with a flue gas outlet of the desulfurization tower, and aby-product outlet of the dust remover communicates with the air inlet pipeline through the smoke dust return device, and is connected with a raw material warehouse through a by-product conveying device; and a flue gas inlet of the medium-temperature SCR denitration device is connected with a flue gas outlet of the dust remover, an air outlet pipeline of the medium-temperature SCR denitration device is successively provided with a waste heat boiler and an induced draft fan, and discharges purified gas through a chimney. According to the dry desulfurization, denitration and dust removal device,synergistic removal of multi-component contaminants can be achieved while high-efficiency desulfurization, denitration and dust removal are achieved, corrosion prevention is not needed, zero waste water discharge and transparent chimney discharge are achieved, and meanwhile long-term stable operation can be achieved.

Owner:FUJIAN LONGKING DSDN ENGINEERING CO LTD

Mixed treatment method of waste plastics

InactiveCN102423909AImprove recycling ratesSolve landfillPlastic recyclingLimited resourcesEnvironmental engineering

The invention provides a process method for recycling waste plastics. The treatment process of the waste plastics of the method is as follows: removing bulk metal, stone blocks and other substances which are difficult to crush, crushing, entering into a mixed treatment device and producing products. By adopting the technical scheme according to the invention, the various waste garbage plastics can be processed into various mixed plastic products by mixed treatment, thereby reducing the process steps of classifying of the plastics, cleaning and post-treatment in the original recycling treatment technology of the waste plastics and solving the original defects caused by landfill and burning of the garbage plastics; more important, the recycling rate of the waste plastics is improved, the circulating utilization is realized, the maximal utilization of limited resources is realized, the environmental damages caused by the waste plastics are effectively reduced and the environmental pollution caused by the original recycling technology is further solved.

Owner:银万平

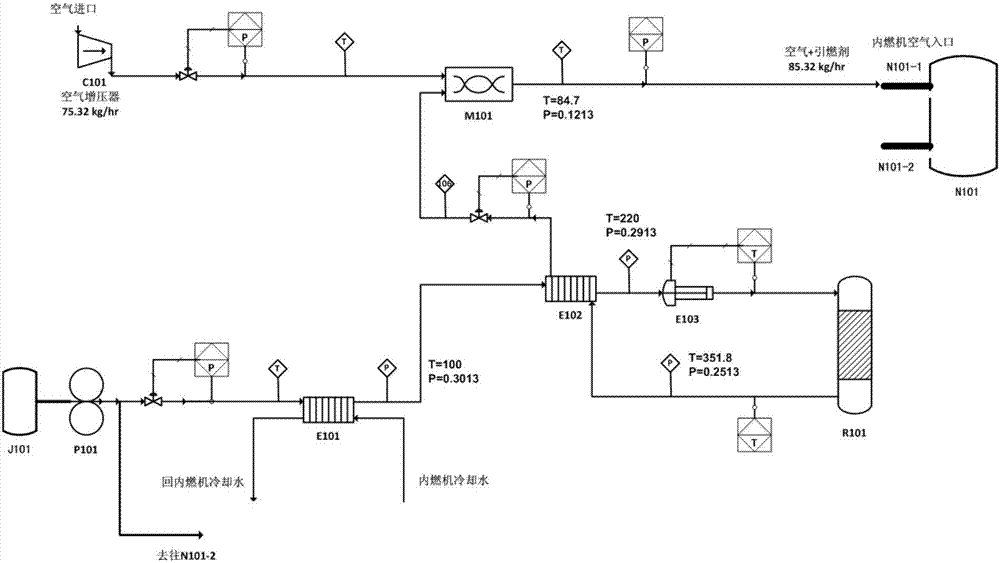

Compression ignition internal-combustion engine system adopting carbinol-group fuel and operation method thereof

InactiveCN107084045AComplete replacementImprove heat utilization efficiencyInternal combustion piston enginesChemical/physical processesFuel tankEngineering

The invention discloses a compression ignition internal-combustion engine system adopting carbinol-group fuel. The compression ignition internal-combustion engine system comprises a compression ignition type internal-combustion engine (N101), an air supply system, a fuel supply system and an ignition agent on-line preparation device (R101). The compression ignition type internal-combustion engine (N101) is provided with an air inlet (N101-1) and a fuel inlet (N101-2). The air supply system comprises an air supercharger (C101) and a mixer (M101), wherein the air supercharger (C101) and the mixer (M101) are in series connection, and an outlet of the mixer (M101) is connected to the air inlet (N101-1). The fuel supply system comprises a fuel tank (J101) and a fuel pump (P101), wherein the fuel tank (J101) and the fuel pump (P101) are in series connection, and the downstream of the fuel pump (P101) is connected to the fuel inlet (N101-2). The upstream of the ignition agent on-line preparation device (R101) is also connected to the fuel pump (P101), the downstream of the ignition agent on-line preparation device (R101) is connected to the mixer (M101), and the ignition agent on-line preparation device (R101) is internally provided with a catalyst bed layer. According to the compression ignition internal-combustion engine system, an ignition agent obtained through on-line preparation of the carbinol-group fuel is subjected to compression ignition in the compression ignition type internal-combustion engine, so that the carbinol-group fuel is ignited, and therefore under the circumstance that the structure of the existing compression ignition type internal-combustion engine does not need to be changed, diesel fuel can be completely replaced with the carbinol-group fuel.

Owner:SHENZHEN REVELATION TECH CO LTD

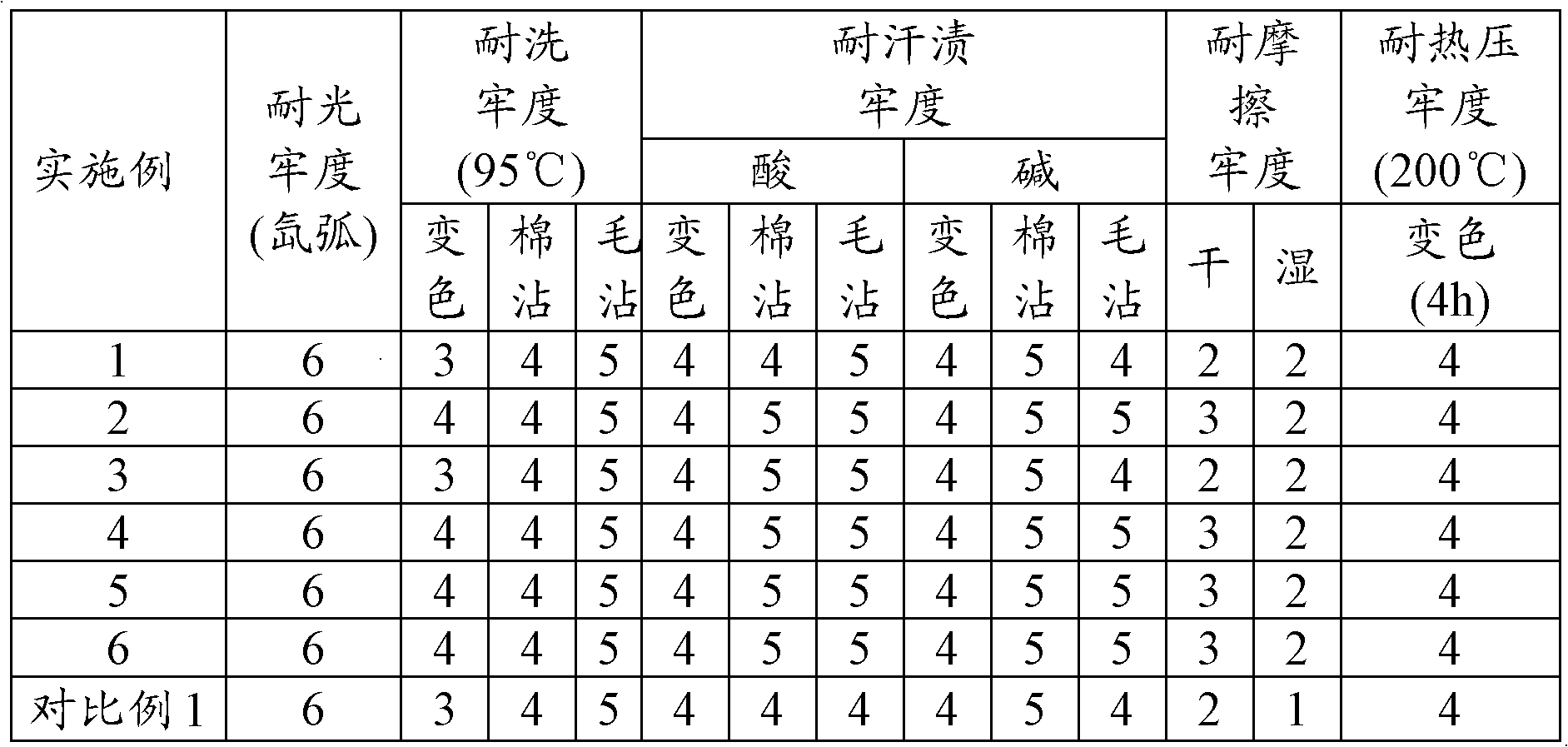

Preparation method and product of sulphur black dye

InactiveCN102174272AHigh coloring rateReduce dosageOrganic dyesDyeing processDyeing wastewaterFilter cake

The invention discloses a preparation method of a sulphur black dye. The method comprises the following steps: adding a sulphur black intermediate filter cake in water, heating to 90-100 DEG C while stirring, and adding the mixture in a sodium sulfide or sodium sulfide solution; then pulping for 30-60 minutes, adding a dispersant, and stirring for 5-30 minutes; and finally drying to obtain the sulphur black dye. The invention also discloses the sulphur black dye prepared by the method. By adding the dispersant in the dye, the strike rate of sulphur black on the cotton fabric and the cotton blended fabric can be increased, on the one hand, the dosage of the sulphur black can be reduced in the dyeing process, on the other hand, the amount of pollutants in printing and dyeing wastewater can be reduced, the treatment difficulty and environmental pollution of the printing and dyeing wastewater can be lowered, and the economic and environmental benefits are quite obvious.

Owner:浙江长征化工有限公司

Enzymatic packing for reactive distillation as well as coating method and application of enzymatic packing

InactiveCN107115889ANot easy to inactivateImprove stabilityOrganic-compounds/hydrides/coordination-complexes catalystsCatalyst activation/preparationCross-linkReactive distillation

An enzyme-catalyzed filler for reactive distillation and its coating method and application. The enzyme-catalyzed filler is prepared by the following method, including the following steps: immerse the filler in the sol containing biological enzyme for 20-30 seconds, take it out and dry it for 10-20 seconds; then immerse the filler in the sol again for 20-30 seconds, Take it out again and dry for 10 to 20 seconds; repeat the immersion-drying step 8 to 15 times; finally dry the filler until the weight remains unchanged, that is, obtain the enzyme-catalyzed filler with a biological enzyme coating attached; the composition of the sol is component A and component B; the A component includes an oxygen-containing silane mixture and a solvent; the B component includes a catalyst, a cross-linking agent, an enzyme solution and deionized water. The invention realizes the integration of biological enzyme immobilization technology and reactive distillation technology, and has novelty and economy.

Owner:HEBEI UNIV OF TECH

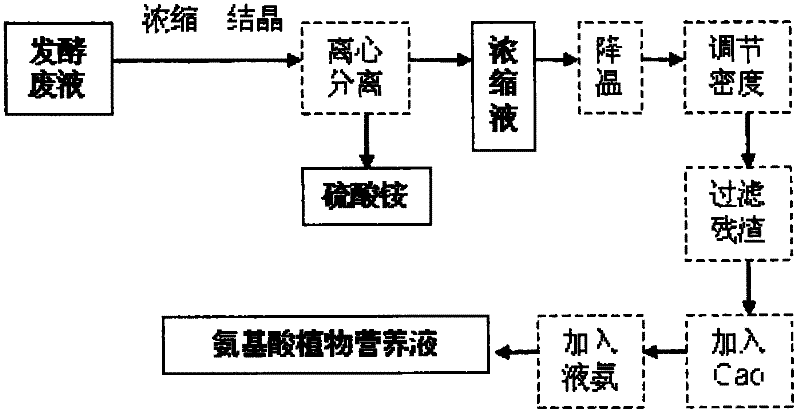

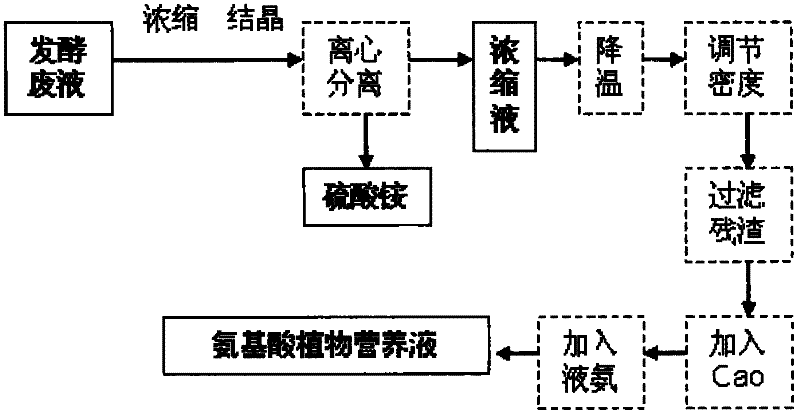

Production method of amino acid plant nutrient solution

InactiveCN102173881AImprove the level of comprehensive utilizationSolve the worries of developmentClimate change adaptationBioloigcal waste fertilisersMonosodium glutamateSulfate radicals

The invention discloses a production method of an amino acid plant nutrient solution. The method comprises the following steps: extracting thalli from the fermentation effluent of MSG (monosodium glutamate) to evaporate and concentrate, and crystallizing to separate and obtain ammonium sulfate and a concentrate; treating the concentrate with CaO and liquid ammonia, fixing sulfate radicals, and adjusting the pH value to obtain the amino acid plant nutrient solution. By adopting the production method, the wastewater treatment problem of the MSG fermentation industry can be solved fundamentally, the wastewater can be converted into the amino acid plant nutrient solution, and the environmental benefit, economic benefit and social benefit are significant.

Owner:LINGHUA GROUP INCORPORATED COMPANY

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com