Production method of amino acid plant nutrient solution

A plant nutrient solution and production method technology, applied to fertilizers made from biological waste, ammonium sulfate, organic fertilizers, etc., to achieve the effects of improving the level of comprehensive utilization, high economic benefits, and solving worries

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

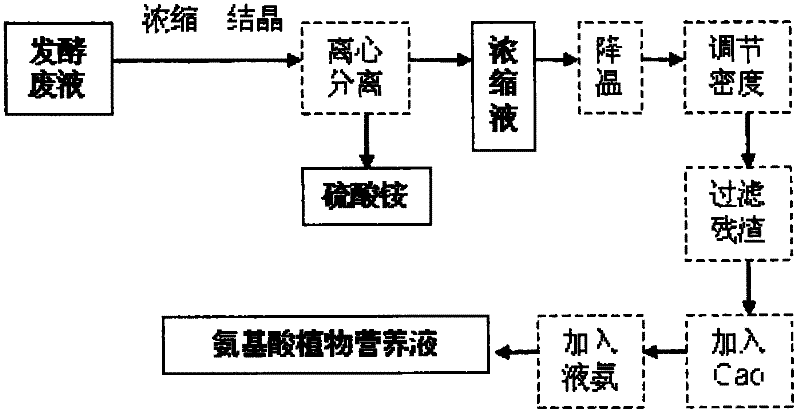

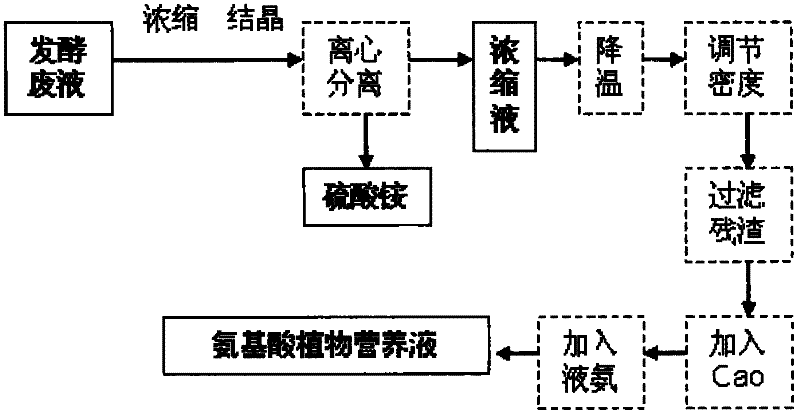

Image

Examples

Embodiment 1

[0022] Embodiment 1: the production method of amino acid plant nutrient solution, specifically comprises steps as follows:

[0023] (1) waste liquid after monosodium glutamate fermentation, after extracting thallus, evaporate and concentrate, obtain ammonium sulfate and concentrate after crystallization and separation;

[0024] (2) First lower the temperature of the concentrate to 52°C, add water to adjust the density to 1500kg / m 3 , filter the residue after dropping to normal temperature;

[0025] (3) First adjust the pH value to 4.7 with CaO to fix most of the sulfate groups, and then adjust the pH value to 5.8 with liquid ammonia. The amino acid plant nutrient solution is obtained.

Embodiment 2

[0026] Embodiment 2: the production method of amino acid plant nutrient solution, specifically comprises steps as follows:

[0027] (1) waste liquid after monosodium glutamate fermentation, after extracting thallus, evaporate and concentrate, obtain ammonium sulfate and concentrate after crystallization and separation;

[0028] (2) First lower the temperature of the concentrate to 46°C, add water to adjust the density to 1000kg / m 3 , filter the residue after dropping to normal temperature;

[0029] (3) First adjust the pH value to 4.2 with CaO to fix most of the sulfate radicals, then adjust the pH value to 5.2 with liquid ammonia to obtain amino acid plant nutrient solution.

Embodiment 3

[0030] Embodiment 3: the production method of amino acid plant nutrient solution, specifically comprise steps as follows:

[0031] (1) waste liquid after monosodium glutamate fermentation, after extracting thallus, evaporate and concentrate, obtain ammonium sulfate and concentrate after crystallization and separation;

[0032] (2) First lower the temperature of the concentrate to 50°C, add water to adjust the density to 1300kg / m 3 , and then filter the residue;

[0033] (3) First use CaO (consumed CaO is about 45.5kg / m 3 fertilizer) to adjust the pH value to 4.5, fix most of the sulfate radicals, and then use liquid ammonia (the amount of liquid ammonia consumed is about 29.4kg / m 3 fertilizer) to adjust the pH value to 5.5 to obtain amino acid plant nutrient solution.

[0034] In order to verify the quality of the amino acid plant nutrient solution, the conclusion that the applicant sent the amino acid plant nutrient solution gained in Example 3 to the Food Quality Supervis...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com