Patents

Literature

260results about How to "Improve slag removal effect" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

De-oxidation modifying agent for steel ladle top slag

ActiveCN103374642AThe modifier has good reducibility and continuous stabilityImprove reducibilityProcess efficiency improvementLadle furnace slagSlag

The invention relates to steel ladle furnace slag modifying agent in a converter steel tapping process. The de-oxidation modifying agent for the steel ladle top slag comprises the following main components in percentage by weight: 30%-50% of Al, 50%-30% of CaO, 5.0%-8.0% of Al2O3, not more than 3.0% of SiO2, not more than 0.07% of S+P, 0.7%-1.4% of C, 3.0%-8.0% of CaFe2 and not more than 0.2% of H2O. The modifying agent disclosed by the invention is a reductive modifying agent which can be used for solving an oxidation problem of the steel ladle top slag in a low-carbon pipeline steel production process, so that guarantee is provided for vacuum desulfurization and pure production of the pipeline steel.

Owner:BAOSHAN IRON & STEEL CO LTD

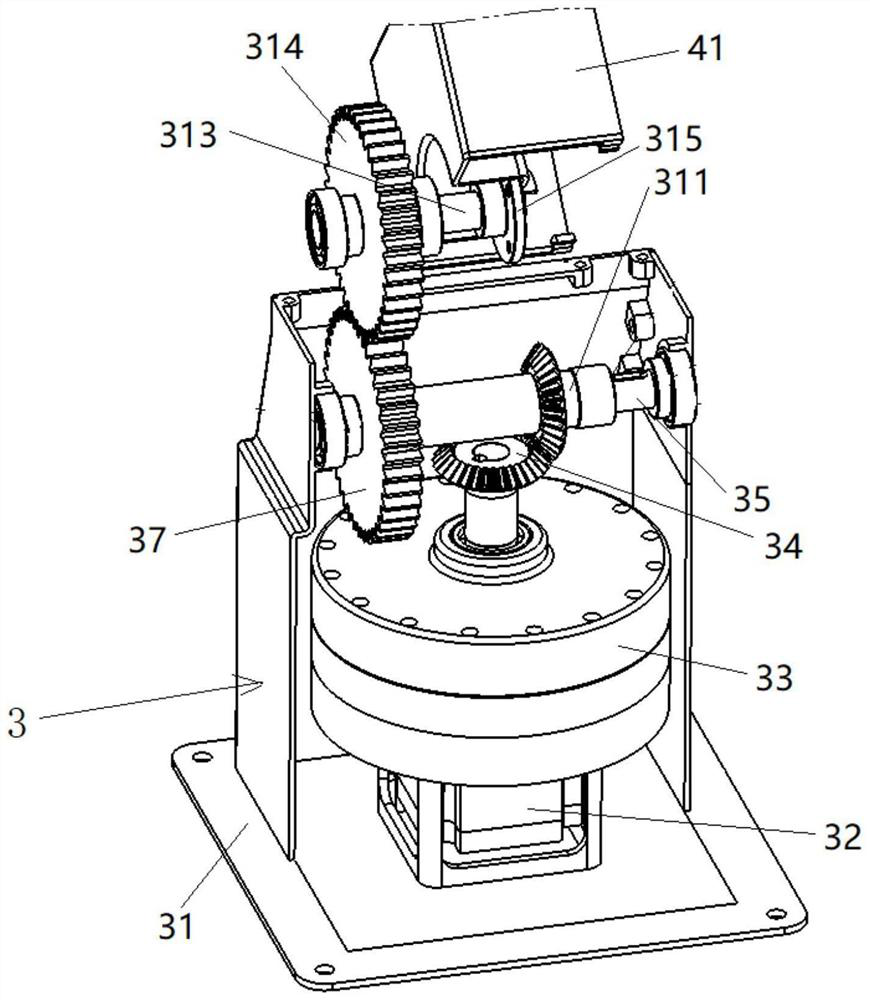

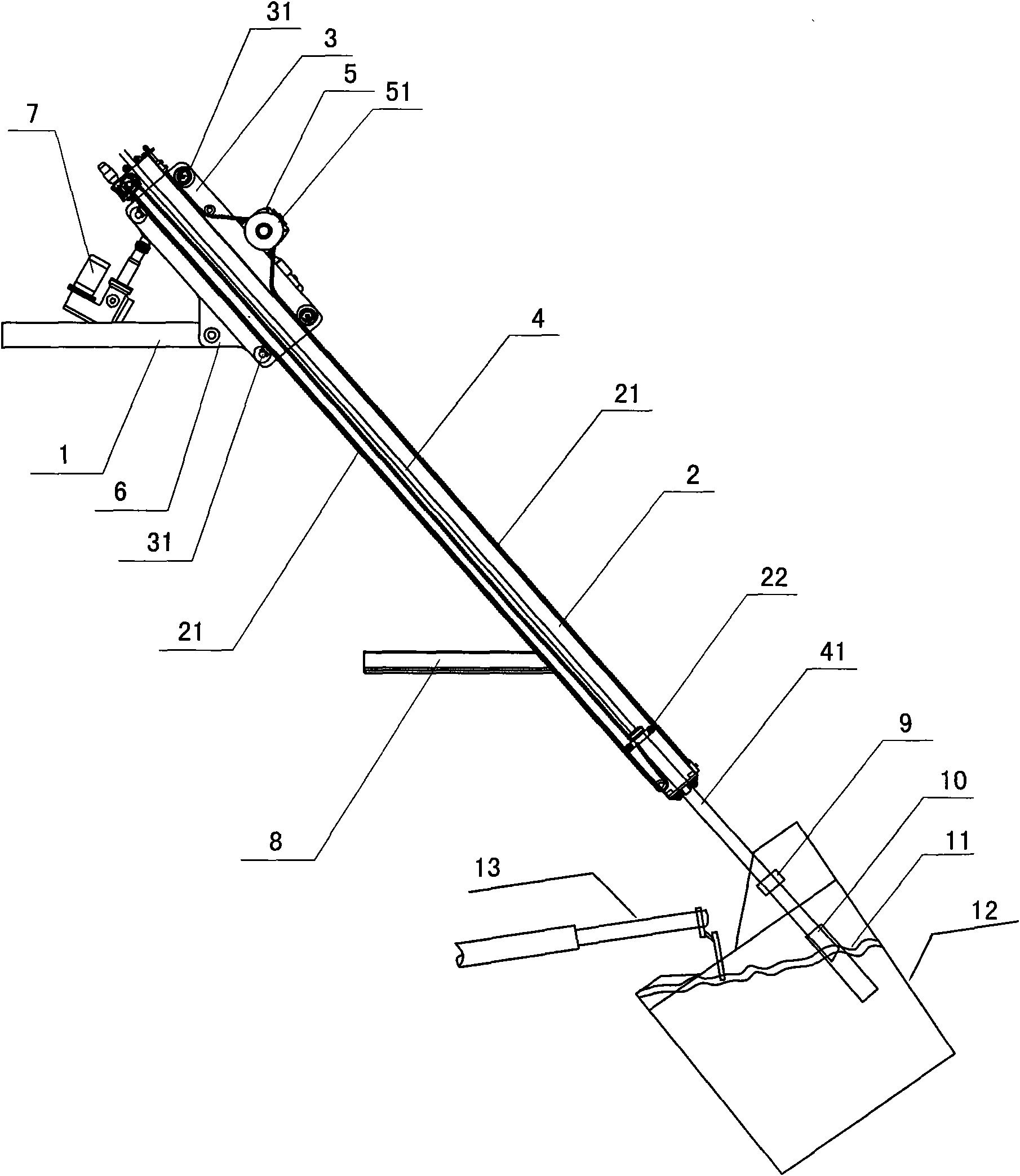

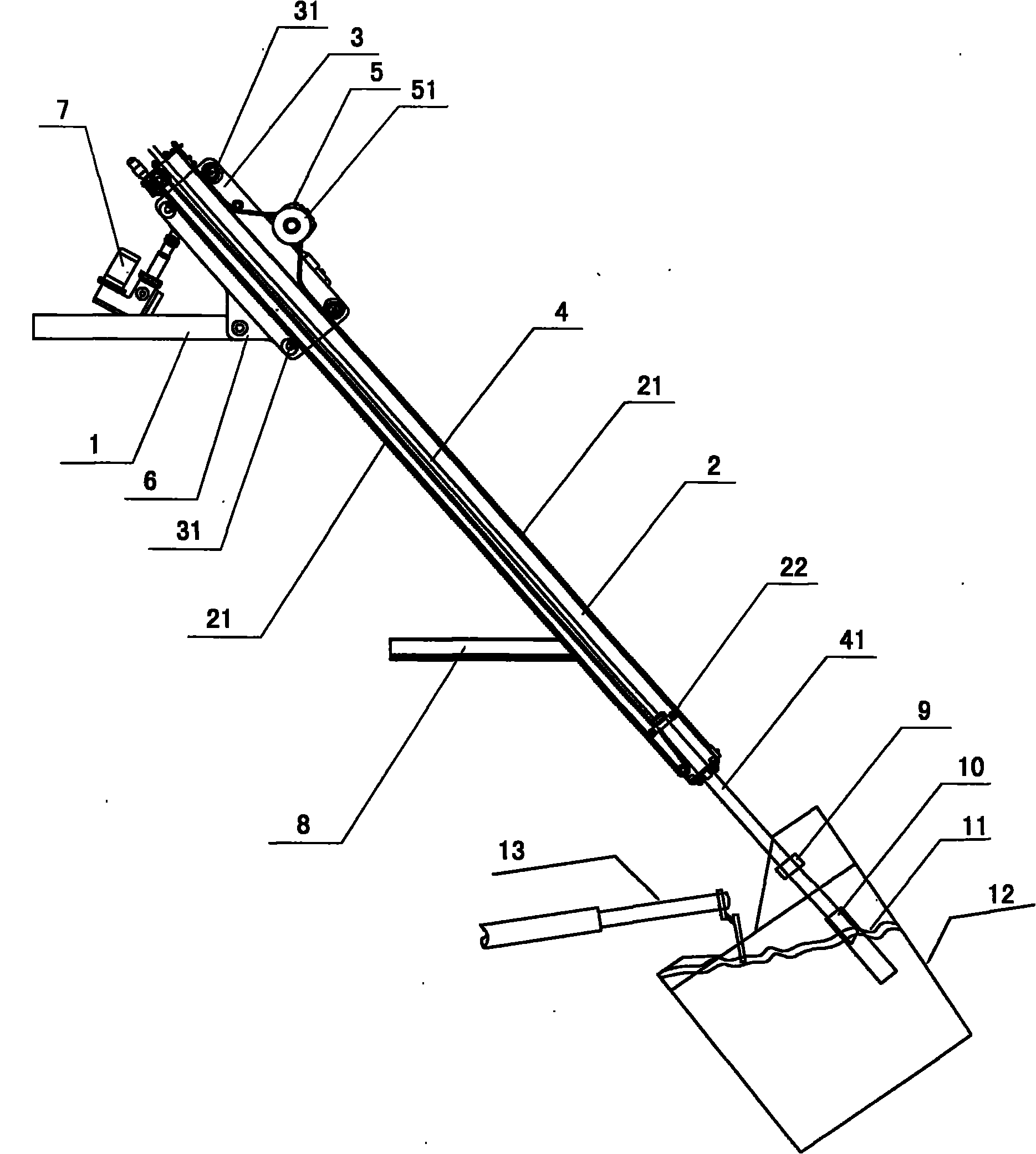

Gas-blowing and slag-removing device and slag-removing method

The invention relates to a gas-blowing and slag-removing device and a process, mainly solving the technical problems that the slag removing is difficult to realize and the slag-removing effect is poor in the existing slag-removing device. The technical scheme of the invention is as follows: the gas-blowing and slag-removing device comprises a gas-blowing mechanism, a hot-iron ladle and a slag-skimming machine, and is characterized in that the gas-blowing mechanism is fixed at one side of a supporting platform by a hinge base and comprises an oblique rail frame which is provided with a rail chain; the gas-blowing and slag-removing device also comprises a bracket which is level to the upper surface of the rail frame and is provided with a speed-changing machine; an output shaft of the speed-changing machine is provided with a first chain wheel matched with the rail chain; the rail frame is also provided with a clamping trolley which forms a moving pair with the rail frame; the clamping trolley is provided with a second chain wheel which is fixed together with the rail chain; a connecting rod positioned in the middle of the rail frame is clamped and fixed in the middle of the clamping trolley, and is equidirectional with the rail frame; and the lower end of the connecting rod is provided with a connector and is connected with a gas-blowing and slag-removing gun by a connecting flange. The invention is mainly used for removing the slag on the surface of hot iron in the hot-iron ladle.

Owner:SHANGHAI MEISHAN IRON & STEEL CO LTD +1

Flux used in aluminum and alloy melt processing, and preparation method thereof

InactiveCN103088232AGood for alkali removalGood ability to remove oxide inclusionsPotassiumAlkali metal

The invention provides a flux used in aluminum and alloy melt processing, and a preparation method thereof. The flux is mainly composed of potassium chloride, magnesium chloride and fluoride salt, wherein potassium chloride accounts for 25-65%, magnesium chloride accounts for 30-70%, fluoride salt accounts for 2.5-25%, and the total amount of the components is 100%. The preparation method comprises the steps that: the components are placed in a crucible, and are molten under high temperature; the materials are uniformly mixed; the obtained mixture is poured out, cooled, and solidified; the obtained material is crushed and sieved, and is sealed by using packages. The flux is a refining agent needed in an aluminum alloy smelting process, and has a good refining effect. With the flux, impurities such as alkali metal elements of sodium, calcium, and lithium, and oxides can be effectively removed, and a good slag removing effect is provided.

Owner:江西永特合金有限公司

Semi-steel making method

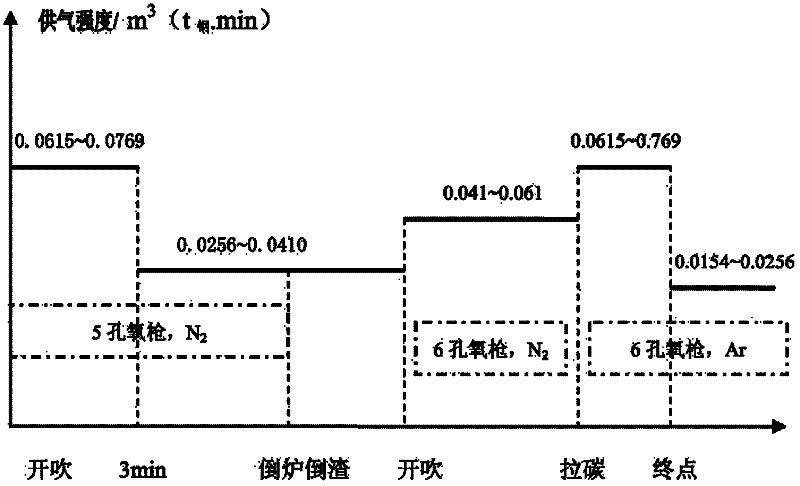

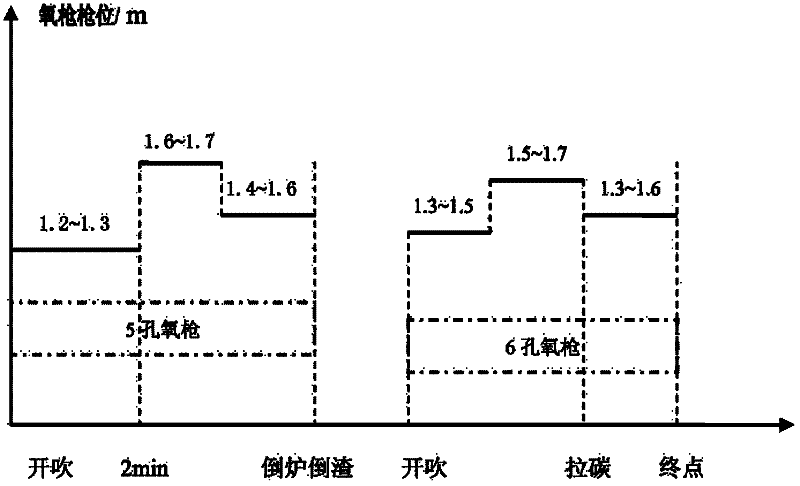

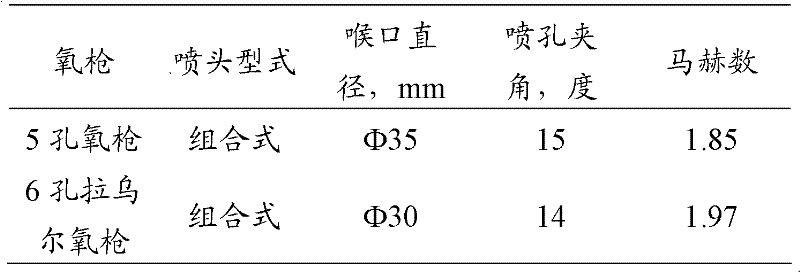

The invention provides a semi-steel making method. The method comprises the following steps of: a, adding a slag forming material into a molten pool of a converter, performing blowing slag formation by a 5-hole oxygen lance oxygen-blowing process at the top of the converter and an inert gas bottom blowing process at the bottom of the converter to remove phosphorus in the molten steel, and discharging slag when the molten pool temperature in the converter is 1,410 to 1,460 DEG C, the alkalinity of the slag is 2.0 to 2.5 and the full iron content of the slag is 10 to 15 weight percent; and b, adding the slag forming material into the molten pool of the converter again, performing blowing slag formation again by a 6-hole Raoult oxygen lance oxygen-blowing process at the top of the converter and the inert gas bottom blowing process at the bottom of the converter to further remove the phosphorus in the molten steel, blocking slag and discharging steel when the molten pool temperature in the converter is 1,670 to 1,700 DEG C, the alkalinity of the slag is 3 to 4.5 and the full iron content of the slag is 17 to 20 weight percent, and thus obtaining molten steel, the phosphorus element content of which is not more than 0.006 weight percent. The method has the advantages of good slag formation effect, short slag formation time, high phosphorus removal efficiency and capabilities of remarkably reducing the full iron content of the final point slag and keeping the phosphorus content of the steel less than 0.006 percent.

Owner:PANZHIHUA IRON & STEEL RES INST OF PANGANG GROUP

Method for producing high carbon steel by high-catching carbon method

ActiveCN101333578AReduce oxidationReduce erosionManufacturing convertersProcess efficiency improvementHigh carbonSmelting process

The invention provides a method for producing high-carbon steel by a high-carbon-withdrawal method, in particular to a smelting process of high-carbon-withdrawal tapping when a converter adopts a single slag process to produce high-carbon steel. The process comprises the following steps of: (1) putting molten iron and scrap steel into the converter according to the requirements on tapping temperature and a certain hot metal ratio; (2) air refining with the oxygen supply strength of 3.1 to 3.4Nm<3> / min / t in the converter; (3) adding active lime and an ore slagging element into the converter; (4) adopting an oxygen supply system of different lance positions under constant flow, adopting rather high lance positions in the whole course of air refining of the converter, and adopting a lance position system in which lance positions get lower piecewise from the beginning to the end of air refining; (5) adding ore and fluorite in small amount by a plurality of batches when the total air refining oxygen consumption is within 70 percent to 85 percent; (6) finishing the air refining of the converter, deslagging by turning down the converter, temperature measurement and sampling; and (7) converter tapping. The smelting process has advantages of short time of air refining of the converter and active slag, and can meet the dephosphorization effect under the high-carbon-withdrawal condition of molten steel, and realize the high-carbon-withdrawal tapping.

Owner:SHOUGANG CORPORATION

Method for controlling nitrogen content in process of producing aluminium deoxidation high-carbon steel

ActiveCN104004881AImprove slag removal effectImprove efficiencyElectric furnaceProcess efficiency improvementCarbon steelAluminium

The invention relates to a method for controlling the nitrogen content in the process of producing aluminium deoxidation high-carbon steel. The outlet steel temperature and the end point carbon content are controlled in the steel outlet process of an electric converter, deoxidizing agents are added in a step-by-step measurement mode in the steel outlet process, the slugging effect is improved, the outlet steel argon blowing pressure is controlled, foaming slag is manufactured in the refining process, the refining electricity conduction time, the outlet sulfur content and the aluminum content are controlled strictly, the vacuum nitrogen removal efficiency is improved, continuous casting protective casting is reinforced, and molten steel is prevented from absorbing massive nitrogen. The method effectively and quantitatively uses the double functions of nitrogen absorption and denitrification of surface-active elements in the molten steel, lays emphasis on nitrogen control in the key links of the whole smelting process, a single nitrogen control operating parameter takes the other links or other process indicators into consideration, and effectively reduces the nitrogen content of aluminium deoxidation high-carbon steel smelted by the electric converter to be below 40*10-6.

Owner:ZENITH STEEL GROUP CORP +1

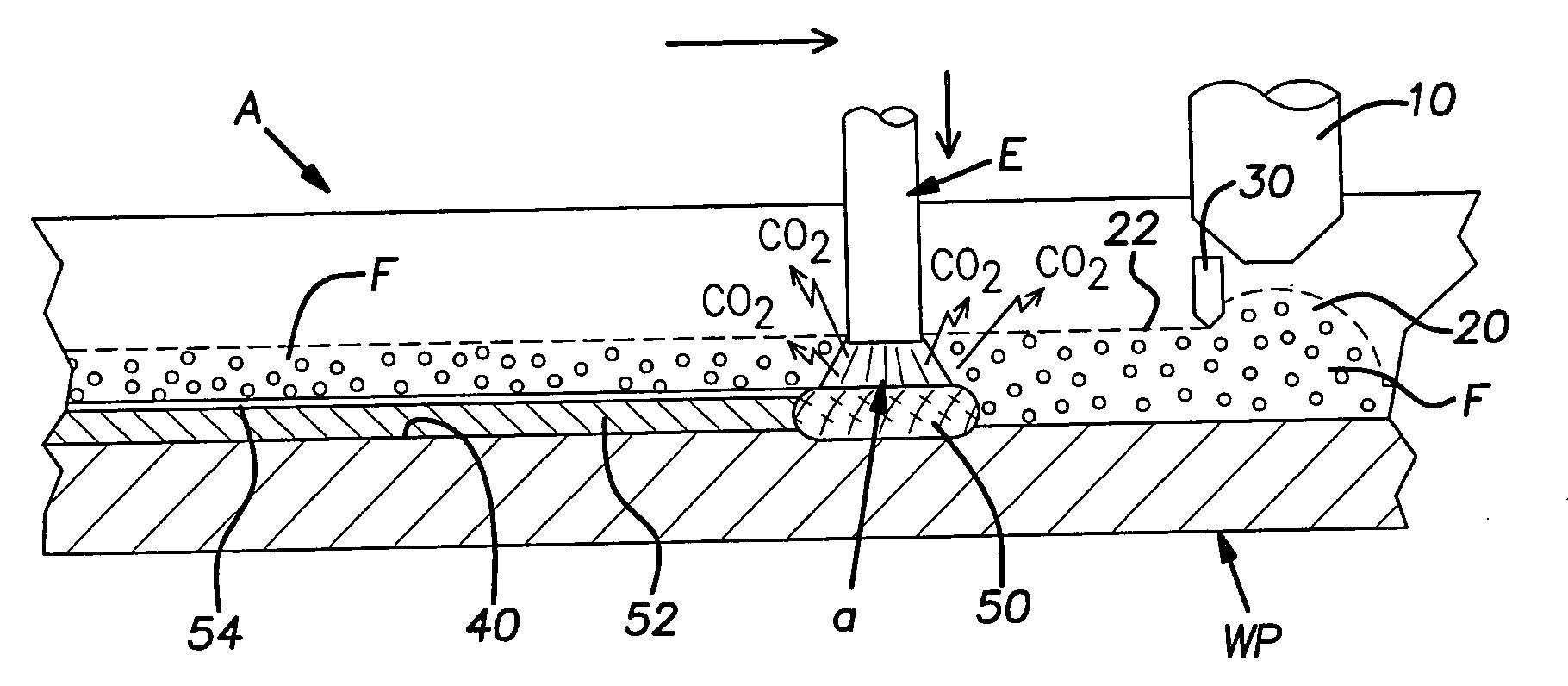

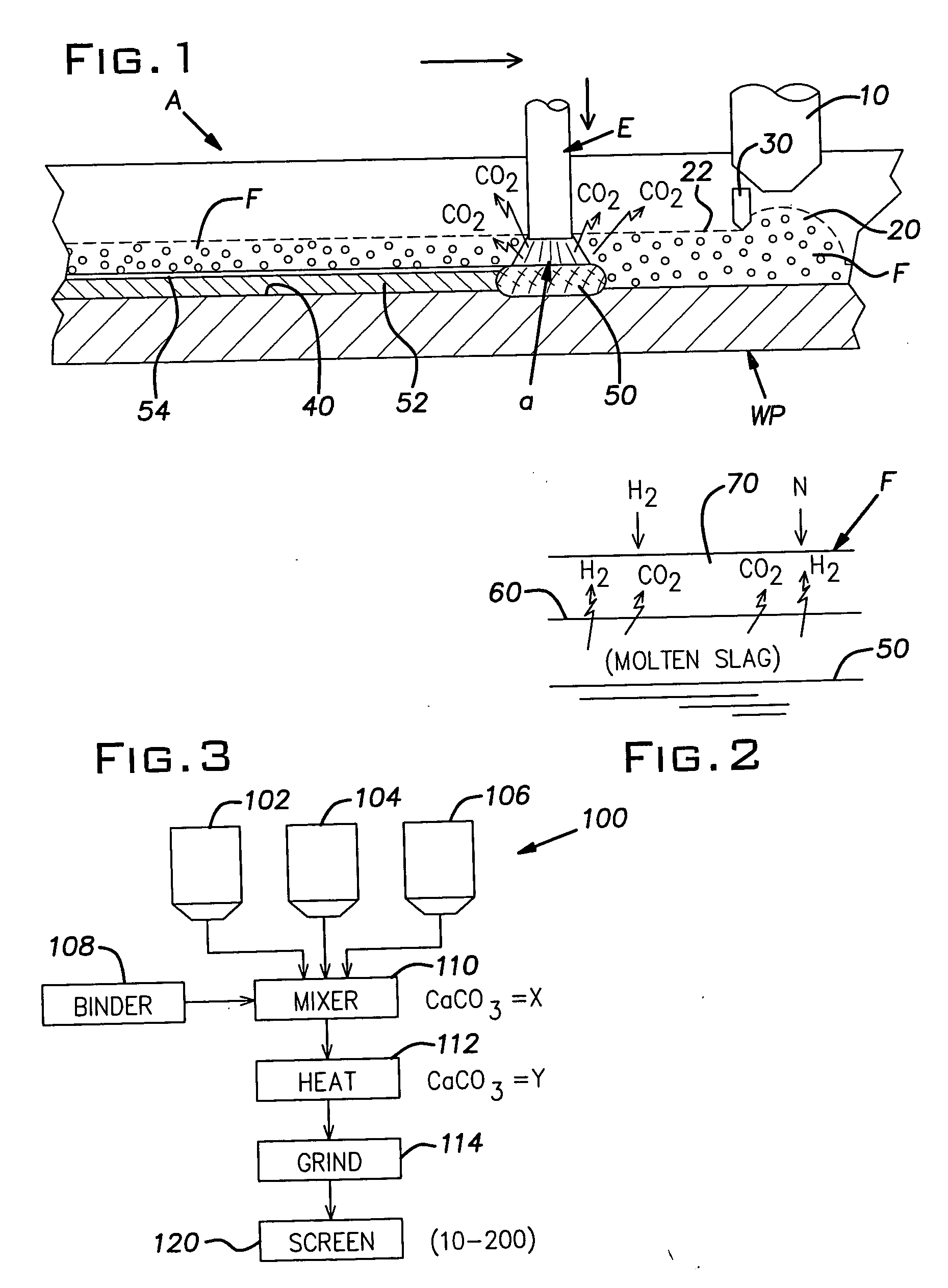

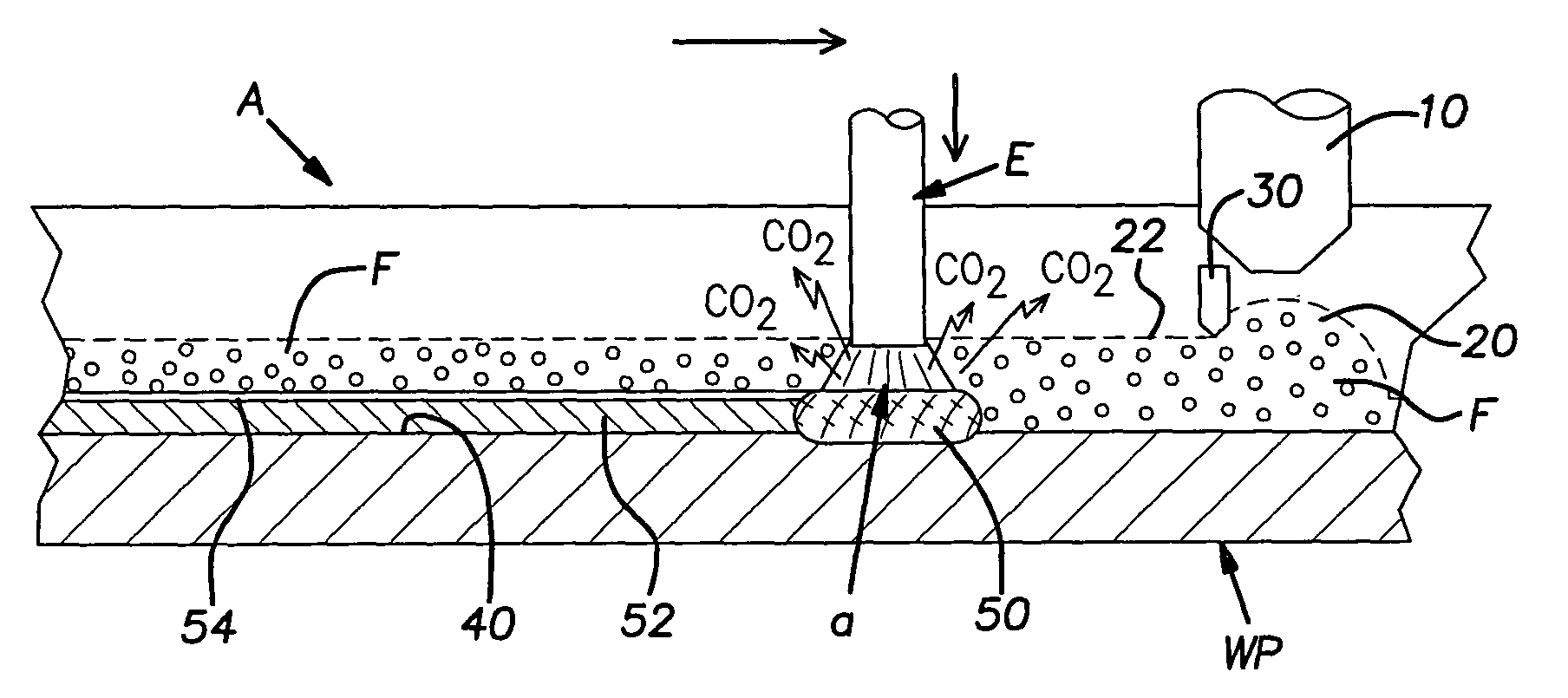

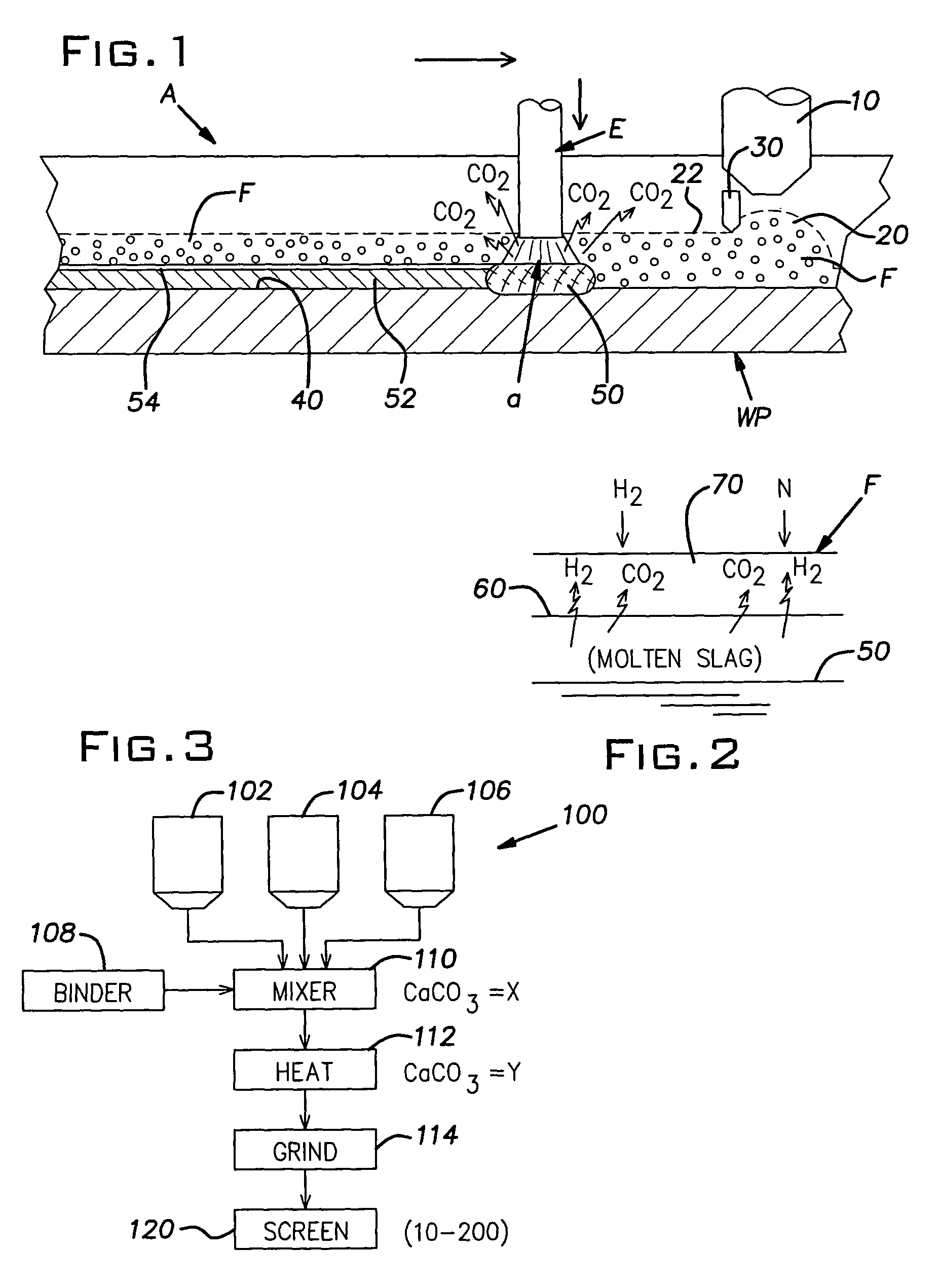

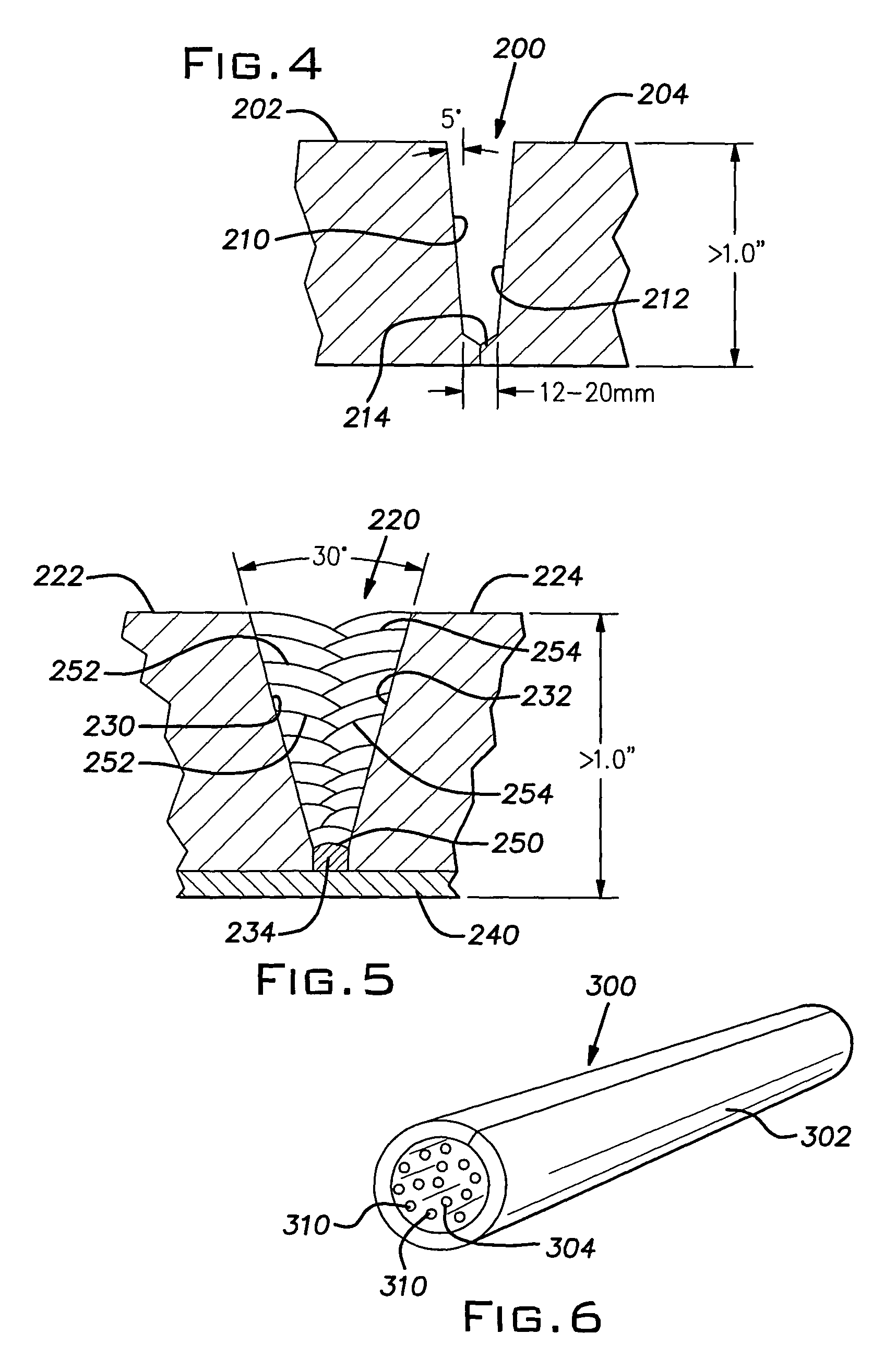

Submerged arc flux

ActiveUS20060272746A1Low costImprove slag removal effectWelding/cutting media/materialsSoldering mediaHydrogenParticle flux

A highly basic particle flux for submerged arc welding that produces less than 7 ml / 100 gr of diffusible hydrogen in the weld metal, which flux comprises a carbon dioxide containing compound with an effective amount of heat releasable carbon dioxide in the range of 0.5-3.5% by weight of the flux over 10% by weight of a low melting point compound and a binder.

Owner:LINCOLN GLOBAL INC

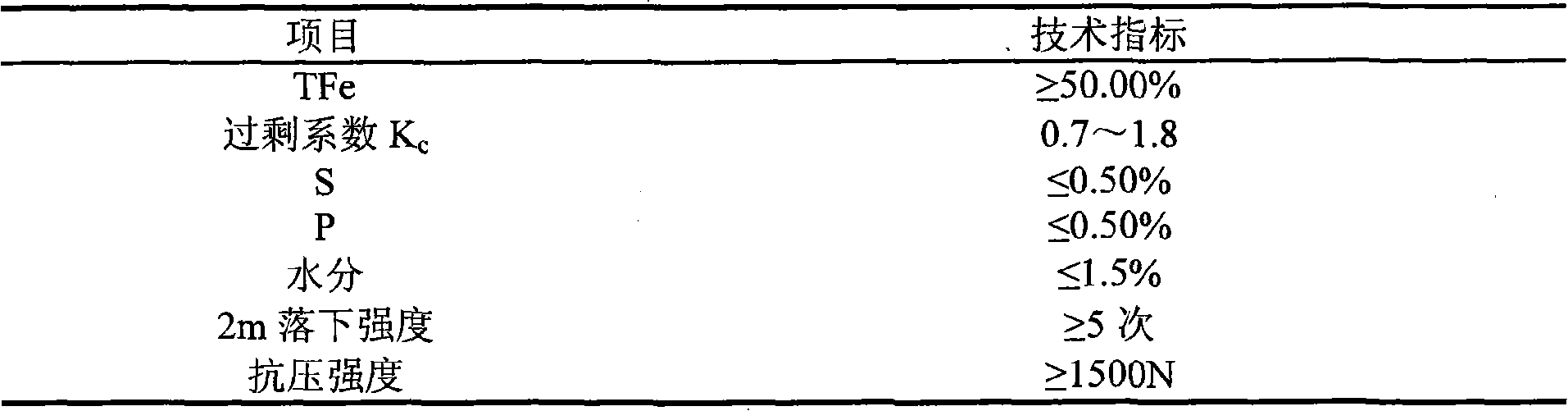

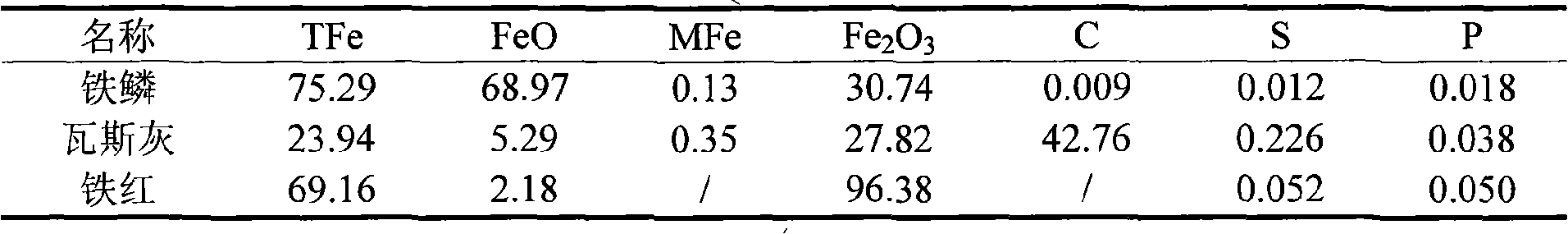

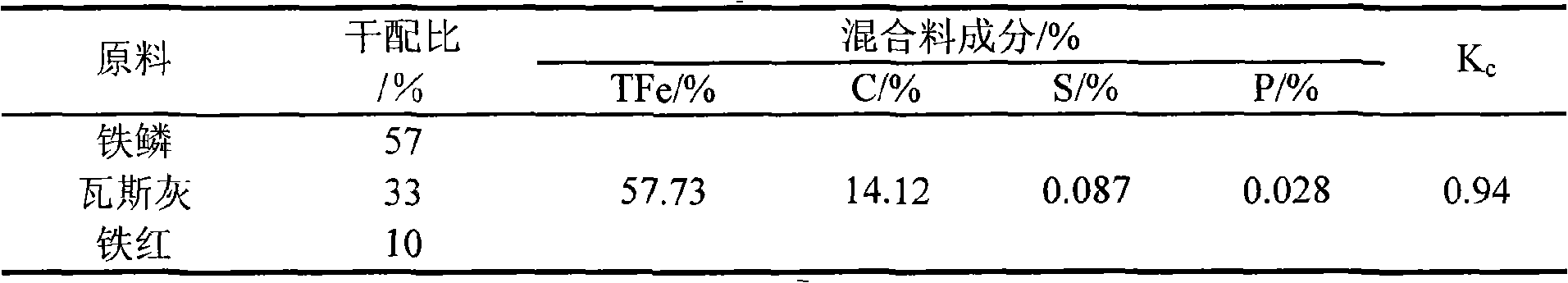

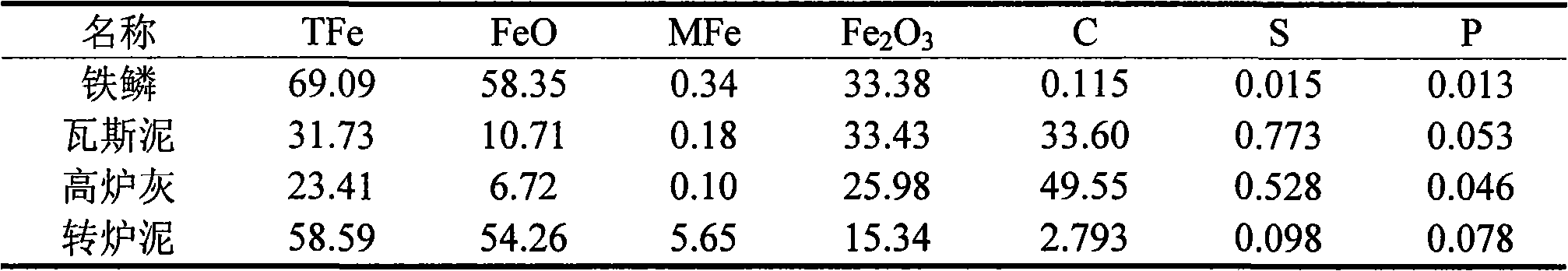

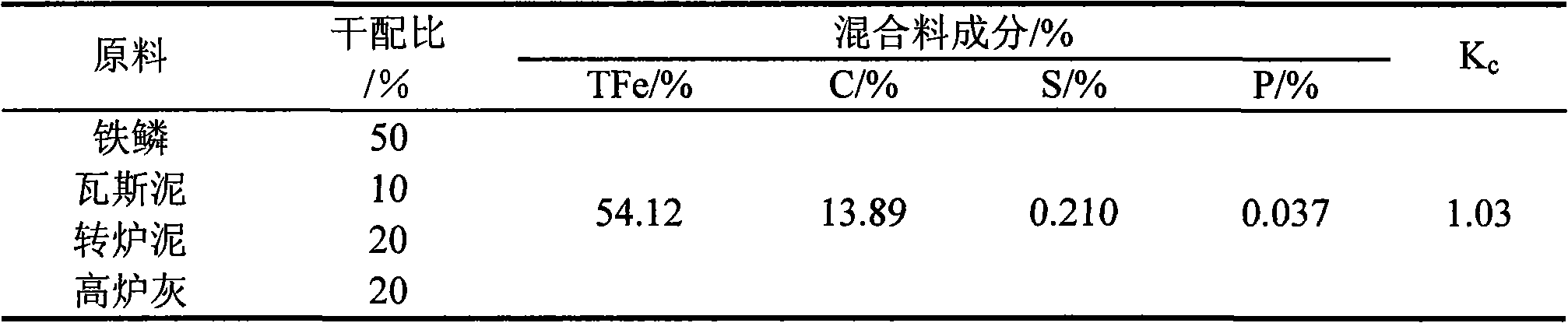

Rotary furnace cooling agent made of metallurgical waste material product and using method thereof

ActiveCN101560583AImprove slag removal effectEmission reductionManufacturing convertersProcess efficiency improvementChemical compositionEconomic benefits

The invention provides a rotary furnace cooling agent and a manufacturing method thereof. The cooling agent is a carbonic and ferreous conglomeration which mainly takes iron scale, carbonic waste material and ferreous waste material as raw materials, and prepared by additionally adding caking agent into the raw materials. The weight percentage of the main chemical compositions of the cooling agent meets the following condition: the carbon content is 5-25%, the content of TFe is more than or equal to 50%, the content of S is less than or equal to 0.50% and the content of P is less than or equal to 0.50%. The manufacturing method comprises: the wet materials in the carbonic waste material and the ferreous waste material are firstly dried and crushed by a crusher, and then enters a blending machine to be mixed together with the dry materials such as the iron scale and the like; the mixture is added with the caking agent to be evenly mixed, and the mixed material is sent into a mixing mill and then into a twin-roller ball press machine to be pressed into conglomeration; the pressed conglomeration is screened by a sieving machine, and the qualified screened conglomeration can be sent into a dry furnace to be dried, so that the finished product conglomeration can be obtained. The rotary furnace cooling agent completely uses the waste materials generated in the steel production, and can be used for replacing the common waste steel to be applied in smelting of a rotary furnace, so that no special reduction plant is needed for use, the process flow is short, the cost is low, the using method is flexible, the adding quantity is large, the recovery rate is high, the field operation is seldom affected, the economic benefit and the environmental protection benefit are remarkable, and the promotion and application values are excellent.

Owner:ANGANG STEEL CO LTD

Exothermic agent for converter molten iron with low heating value

InactiveCN101988137AAdjust alkalinityPlay the role of supplementing molten iron [Si]Manufacturing convertersSlagSilicon

The invention discloses an exothermic agent for converter molten iron with a low heating value, which comprises the following components in percentage by weight: 31-44 percent of carbonaceous material, 35-48 percent of siliceous material, 6-14 percent of bauxite, 4-10 percent of iron granules or scrap iron and 4-8 percent of binder, and the bulk specific weight of the exothermic agent is 2.2-3.5ton / m<3>. The exothermic agent for the converter molten iron with the low heating value has the characteristic of raising the temperature obviously and promoting slagging for low-silicon and low-temperature molten iron, and can improve the dephosphorizing capability of converter slag.

Owner:BAOSHAN IRON & STEEL CO LTD

Submerged arc flux

ActiveUS7727339B2Low costImprove slag removal effectWelding/cutting media/materialsSoldering mediaHydrogenParticle flux

Owner:LINCOLN GLOBAL INC

Process-controlled rapid fermentation processing method of pure strains of Liuyang salt black beans

ActiveCN103932077AEasy to operateReduce dependenceFood dryingFood preparationBiotechnologyNeutral protease

The invention discloses a process-controlled rapid fermentation processing method of pure strains of Liuyang salt black beans. The method comprises the following steps: removing impurities of fresh black beans; soaking; steaming at high pressure to ensure that proteins are denatured properly and cooling; inoculating aspergillus oryzae for enlarge cultivation and uniformly stirring for fermentation starter propagation; naturally cooling prepared cooked yeast, wherein protease activity is 800-1,200 unit / g dry basis (based on neutral protease); adding hot water and stirring; rapidly draining and adding small amount of salt or white spirit; uniformly stirring and compacting and putting into a sealing interlayer tank for heat-preservation fermentation so that fermented amino acid nitrogen is up to more than 0.55 percent; finally, dehydrating and drying by using continuous flow belt type drying equipment so that the water content of the product is less than 15 percent, the amino acid nitrogen is more than 0.85 percent, and the bacterial quantity is less than 103 cfu / g. The quality of the product is stable, the key procedures of each process are controlled in an interlocking mode and have synergistic effects, and the process from material input to acquisition of finished product only needs 15-25 days. The method is short in process period and stable in quality, and a production method and a production process with high efficiency, standardization, large scale, continuity and feasibility are provided for safe and convenient low-salt or salt-free Liuyang salt black bean products.

Owner:HUNAN AGRICULTURAL UNIV

Fluoride-free slagging medium for use in converter and preparation method thereof

InactiveCN102827990AReduce ton consumption costIncreased Metal YieldManufacturing convertersProcess efficiency improvementSteelmakingMetallic aluminum

The invention relates to a fluoride-free slagging medium for use in a converter and a preparation method thereof. The fluoride-free slagging medium comprises metal aluminum, aluminum sesquioxide, iron and oxides thereof, silicon dioxide, calcium oxide, magnesium oxide and other inevitable impurities, and is suitable for slagging during steelmaking in the converter. Used raw materials are ordinary, a pelletizing process is advanced and reliable, and the fluoride-free slagging medium is convenient to use. The fluoride-free slagging medium has the advantages that: the reaction dynamics condition of a melting bath can be improved remarkably, a good slagging effect is achieved, and the problems of steel adhesion to an oxygen lance, melting spraying and poor capability of removing S and P from slag caused by 'return to dryness' of slag are solved; the TFe content of slag is lowered, the metal yield of molten steel is increased, and the tonnage consumption cost of molten steel is lowered; furnace lining erosion is reduced, and a good slag splashing effect is achieved; and F<-> is not contained, so that environmental protection is facilitated, fluoride-free steelmaking is realized, and the slagging medium is suitable for the requirement of cleanliness in a steelmaking production process of the converter.

Owner:西峡县恒基冶材有限公司

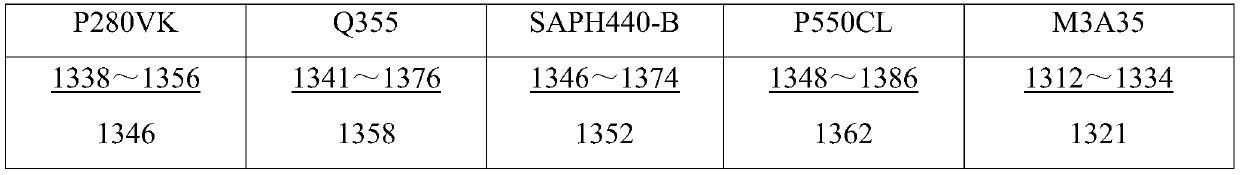

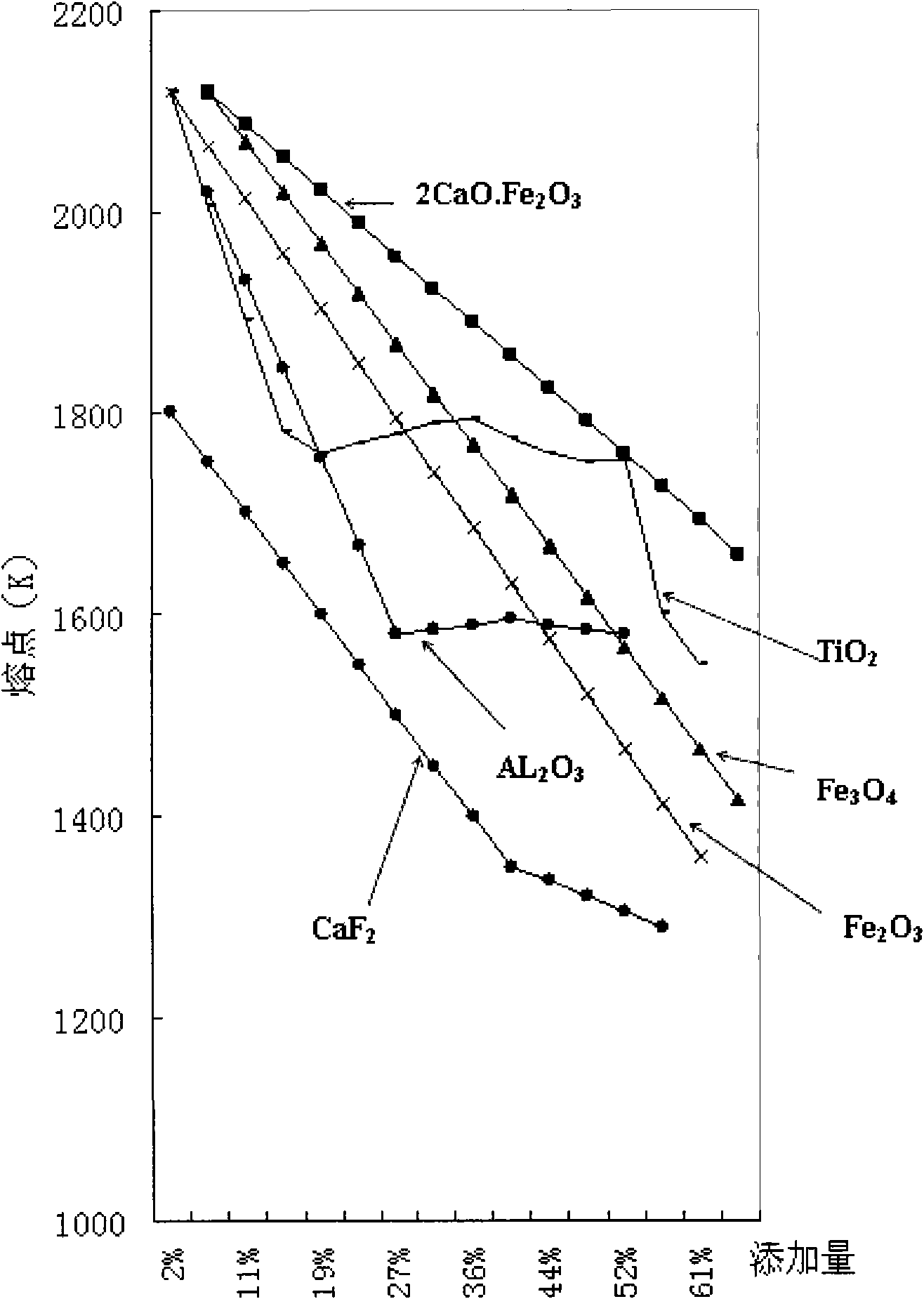

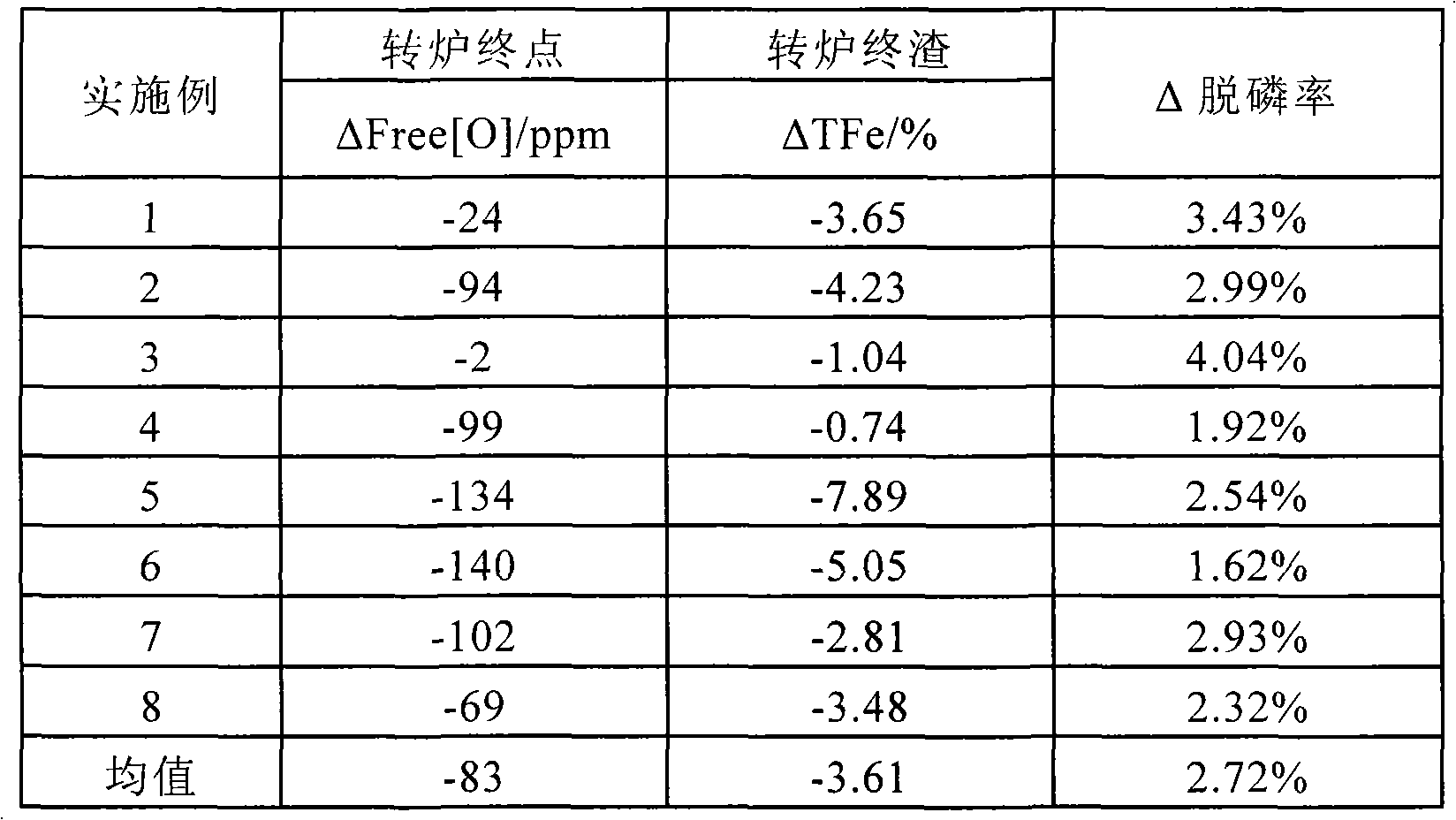

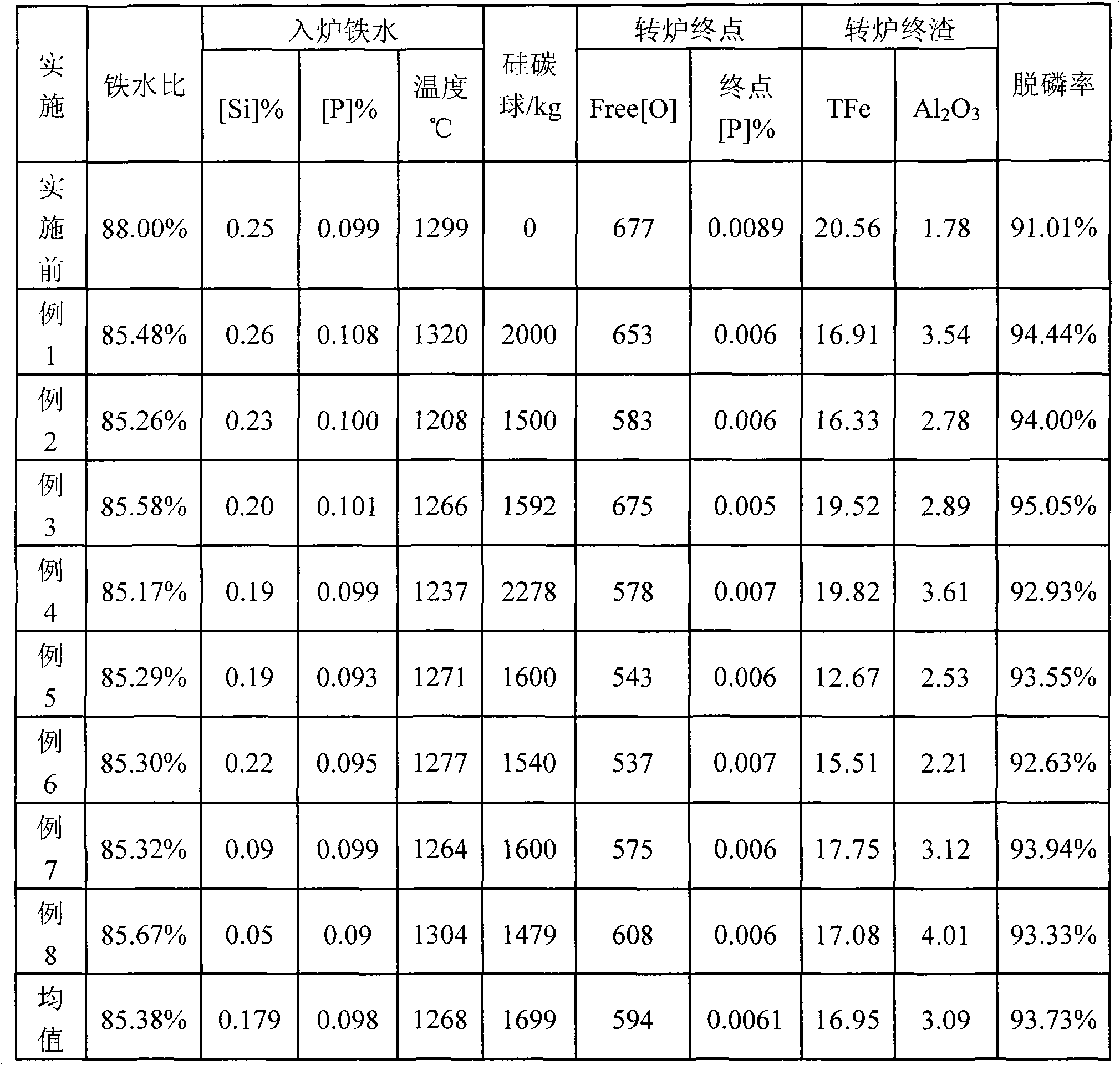

Converter steelmaking method for molten iron [Si] (0.50%)

InactiveCN108893574ANo splashingThe smelting process is stableManufacturing convertersLime productionSteelmakingPhosphor

The invention discloses a converter steelmaking method for molten iron [Si] (0.50%). The converter steelmaking method comprises the following steps: confirming objective temperature, objective carbon,final phosphor, dephosphorizing rate and alkalinity of final residue according to different types of steel; calculating lime addition amount, dolomite addition amount, sinter addition amount and oxygen addition amount during a blowing process according to oxygen balance and heat balance; performing circular smelting in the smelting sequence of leaving residue in the converter, protecting the converter by splashing residue, adding waste steel and mixing with iron, blowing and then tapping. According to the invention, the slag amount and the process splashing phenomenon can be reduced and the consumption of lime and dolomite can be reduced without influence on the dephosphorizing rate.

Owner:SHANDONG IRON & STEEL CO LTD

Method for producing converter slugging agent through electrolytic aluminum overhaul slag

InactiveCN109735678ASpeed up meltingImprove liquidityManufacturing convertersProcess efficiency improvementProduction lineSlag

The invention discloses a method for producing a converter slugging agent through electrolytic aluminum overhaul slag. The method comprises the steps that firstly, the electrolytic aluminum overhaul slag is classified, electrolyte left after picking out carbon blocks is processed through a ball mill until the particle sizes are 1 mm-5 mm; secondly, vermiculite raw materials are purchased, the vermiculite raw materials comprise, by weight percent, 30%-45% of SiO2, 5%-35% of Fe2O3, less of 20% of Al2O3, 15%-26% of MgO, less of 1% of CaO, a jaw crusher is used for crushing the raw materials into3 mm-5 mm to serve as aggregate during pelletizing; thirdly, the materials are mixed according to the mass percent of 80: 17 to be uniform, and 3% of heavy oil is added to serve as a binding agent; fourthly, the materials are pressed into the 30 mm-50 mm spherical slugging agent through a dry powder ball press machine, and the spherical slugging agent comprises components including, by weight percent, 2%-10% of Fe2O3, less of 35% of F, less of 5% of MgO, and less or 20% of Na; fifthly, the slugging agent spheres are transported to a converter production line to be used; sixthly, the slugging agent spheres are normally used according to an application method of the slugging agent; and seventhly, the application amount of the slugging agent is 0.8 kg / ton of steel-3 kg / ton of steel.

Owner:新疆中合大正冶金科技有限公司

Method for removing ladle dross

ActiveCN1806964AFast slag removalEfficient slag removalCasting cleaning apparatusLiquid slagMolten steel

The invention provides the method of removing liquid steel scum, comprising the following steps: dragging the scum from liquid steel liquid level with harrow rotary dragging method, at the same time, adding the anti-oxidization agent on the clean liquid steel surface. Because of adopting the harrow rotary dragging method, the invention solves the problems of big loss of scarfing cinder, hard operation and heavy labor strength. Adding the anti-oxidization agent avoids the secondary oxidization of liquid steel. The method uses the freezing slag agent to solidify the liquid slag. It strengthens the effect of removing slag.

Owner:YANTAI SHENGLIDA ENG TECH

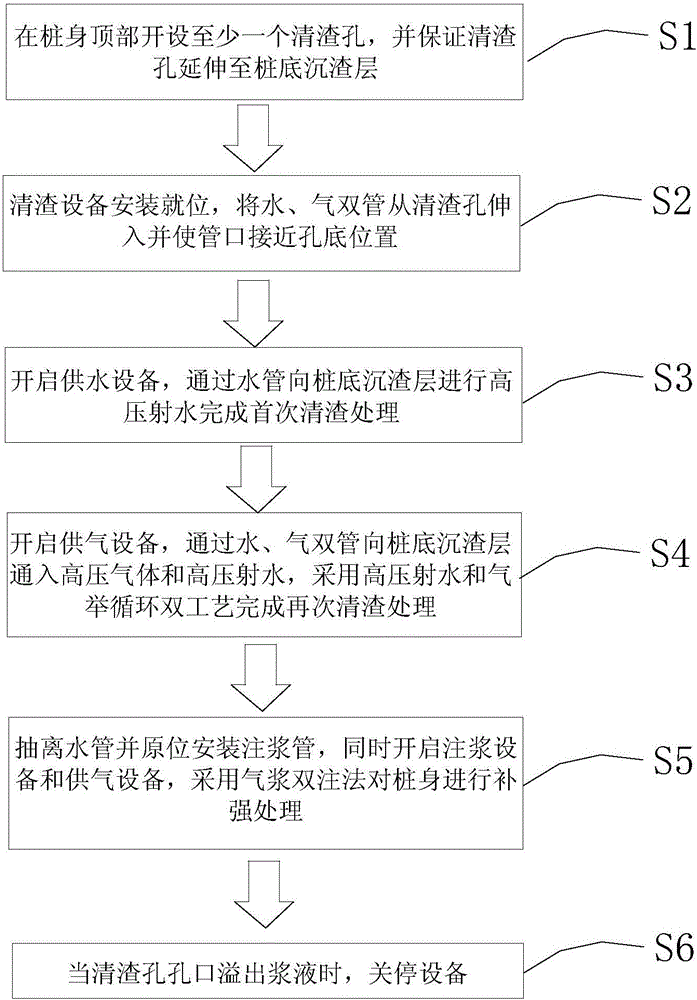

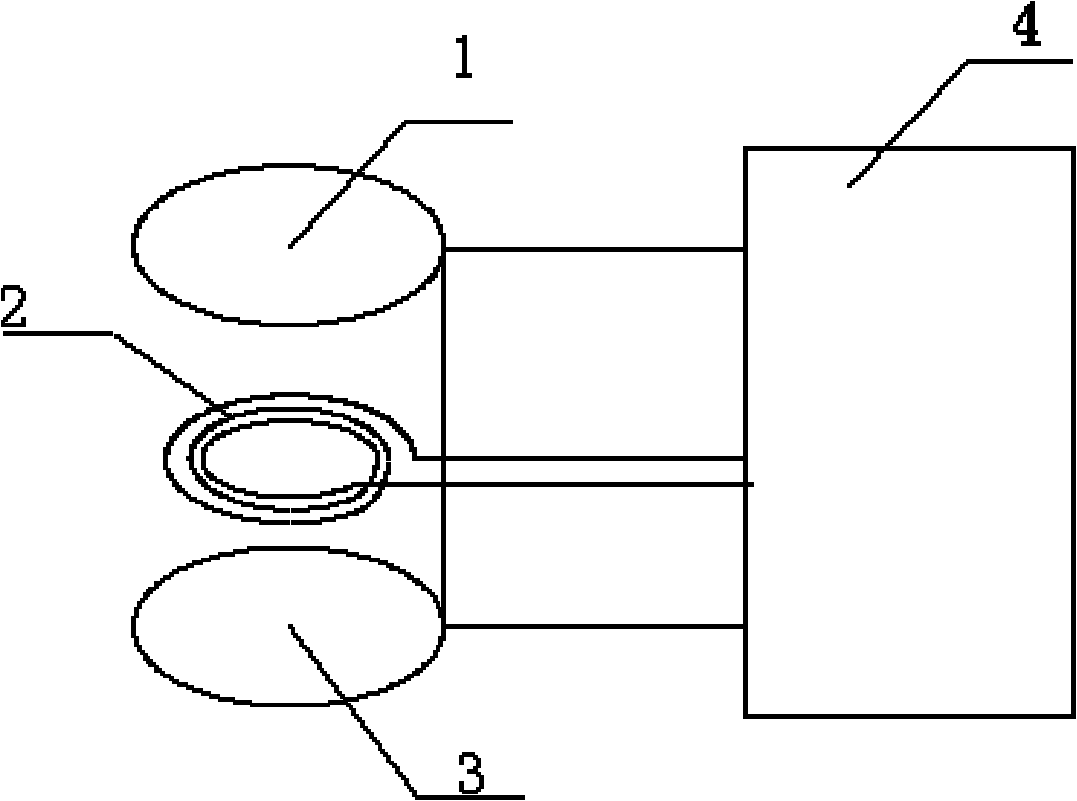

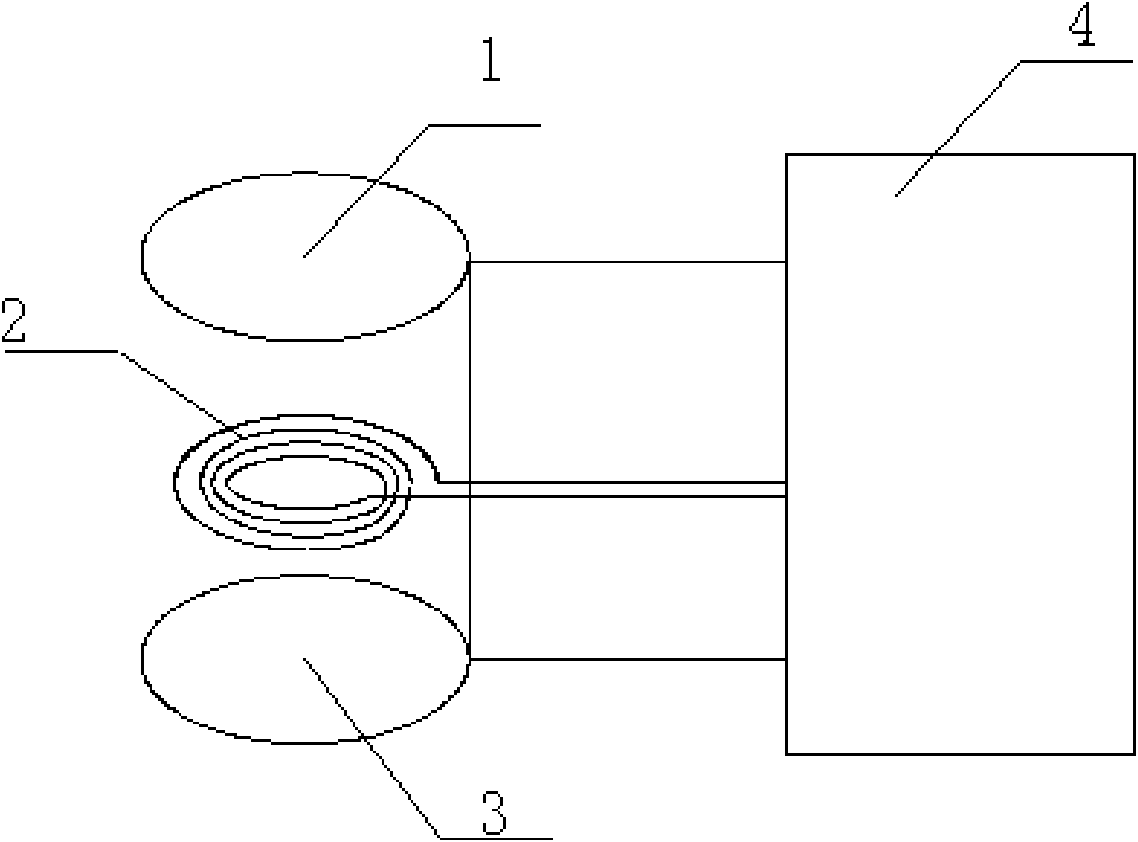

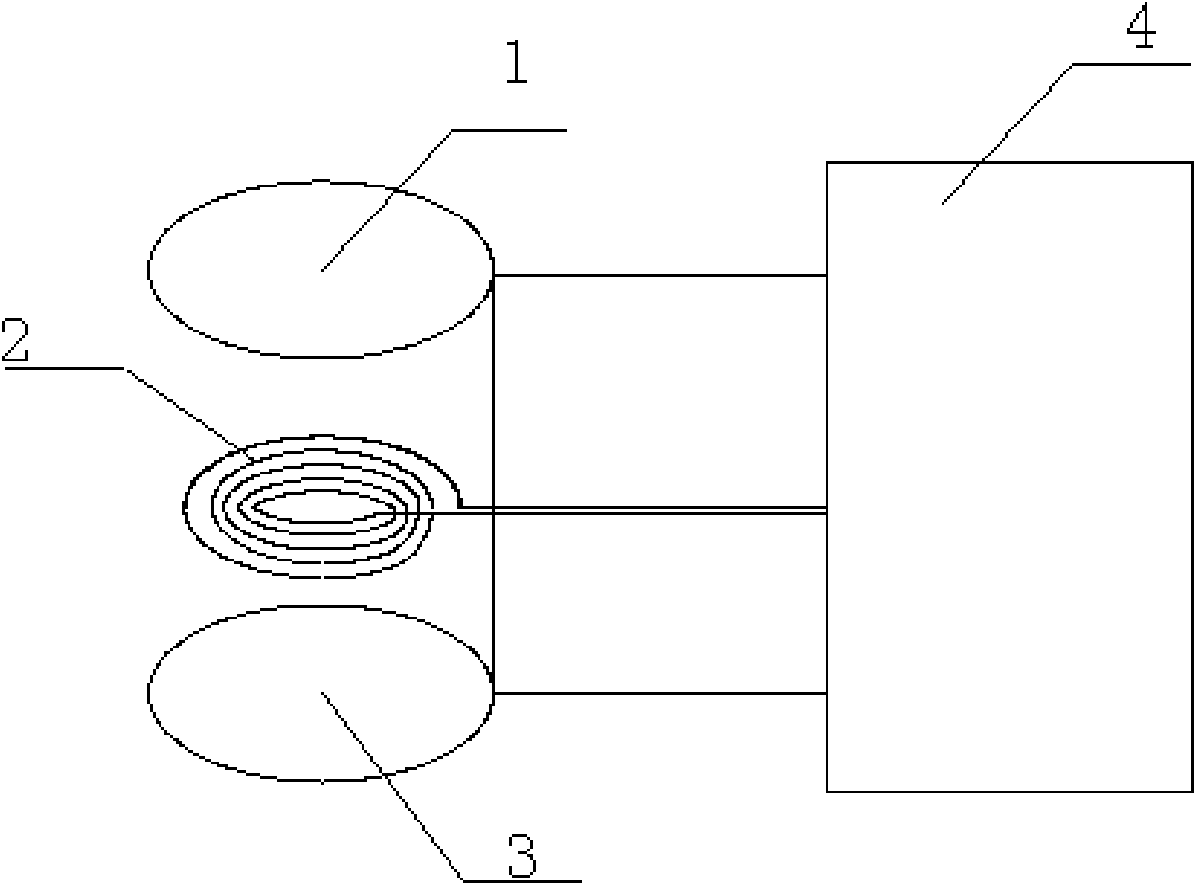

Reinforcement process method for pile bottom sediment removal of pouring pile

ActiveCN106120783AImprove structural strengthEfficient slag removalBulkheads/pilesEngineeringGas supply equipment

The invention discloses a reinforcement process method for pile bottom sediment removal of a pouring pile. The reinforcement process method comprises the following steps: forming at least one sediment removal hole in the top of a pile body, and ensuring that the sediment removal hole extends to a pile bottom sediment layer; installing sediment removal equipment in place, stretching a water tube and a gas tube from the sediment removal hole and enabling tube orifices to approach to a hole bottom position; starting water supply equipment, and carrying out high-pressure water jetting on the pile bottom sediment layer through the water tube to complete primary sediment removal treatment; starting gas supply equipment, charging a high-pressure gas in the pile bottom sediment layer and carrying out the high-pressure water jetting on the pile bottom sediment layer through the water tube and the gas tube, and completing secondary sediment removal treatment through the double processes of high-pressure water jetting and gas lift circulation; pulling away the water tube and installing a grouting tube in situ, starting grouting equipment and the gas supply equipment simultaneously, and carrying out reinforcement treatment on the pile body through a gas-injecting and grouting method; and stopping the equipment when a grout overflows from the orifice of the sediment removal hole. The reinforcement process method disclosed by the invention is capable of realizing efficient and thorough elimination for pile bottom sediments, good in sediment removal effect, and capable of increasing the structural strength of the pile body, meeting safety indexes, and meeting the requirements of construction technical indexes.

Owner:GUANGZHOU CITY LUBAN CONSTR

Heater coil device for preparing high resistance zone-melting monocrystalline silicon in vacuum condition

ActiveCN101787559APrevent collapseWalking smoothlyPolycrystalline material growthBy zone-melting liquidsHigh resistanceZone melting

The invention discloses a heater coil device and an ancillary device for preparing high resistance zone-melting monocrystalline silicon with more than 40 mm of diameter in vacuum condition; wherein, a first type of multi-turn coil device is used for vacuum purification, and a second type of single-turn coil device is used for vacuum crystallization, and the two types of coil devices are coordinated with each other; the multi-turn coil device comprises an upper short circuit ring, a multi-turn heater coil and a lower short circuit ring, and the single-turn coil device comprises a single-turn flat heater coil; the invention designs special size specifications and contours for the two coils and additionally adopts effective auxiliary ancillary parts for solving the two technical problems of vacuum environment and large diameter; as a result, the coils and the ancillary device can be adopted to continuously purify larger-diameter raw material in vacuum condition and draw the purified raw material into large-diameter high resistance zone-melting monocrystalline silicon with quality reaching detector-level standards.

Owner:峨嵋半导体材料研究所

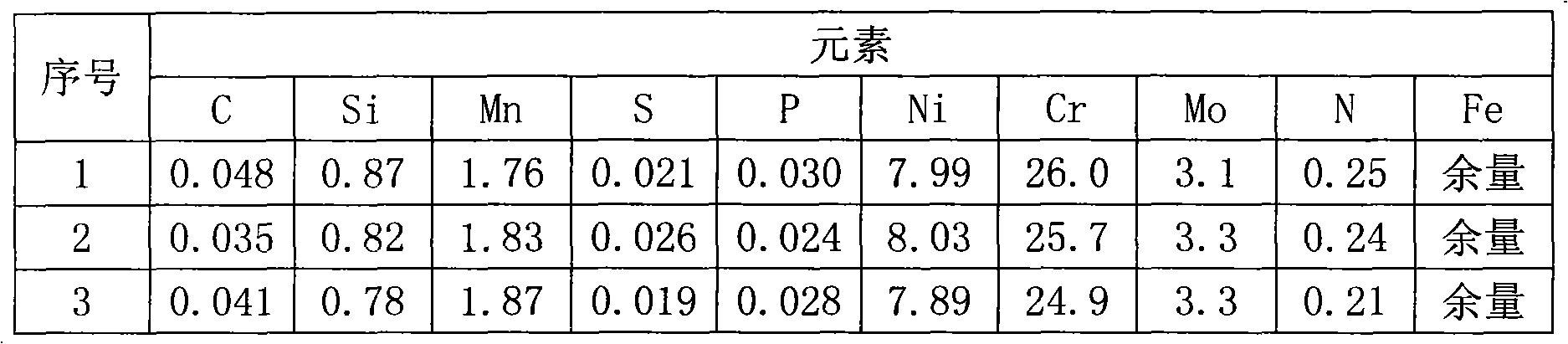

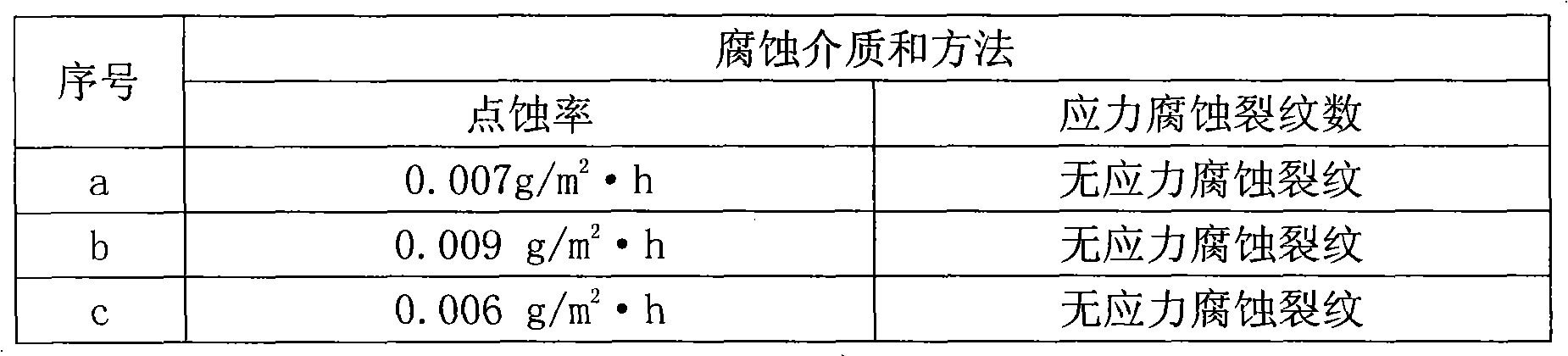

Two phase stainless steel welding rod

InactiveCN102019518AImprove mechanical propertiesImprove pitting resistanceWelding/cutting media/materialsSoldering mediaChromium nitrideMechanical property

The invention discloses a two phase stainless steel welding rod which comprises a solder wire and a coating, wherein the coating comprises the following components in percentage by weight: 35-45 percent of calcium oxide, 16-25 percent of calcium fluoride, 5-10 percent of titanium white, 5-10 percent of silica, 4-8 percent of silicon iron, 3-5 percent of medium carbon ferromanganese, 2-4 percent of ferro-molybdenum, 3-5 percent of chromium nitride iron, 3-5 percent of potassium oxide, 4-6 percent of sodium oxide and 1-3 percent of nickel. The metal clad with the corrosion-resisting high-strength two phase stainless steel welding rod has excellent mechanical property, welding performance and pitting and stress corrosion resistance.

Owner:上海狮百盛焊材科技有限公司 +1

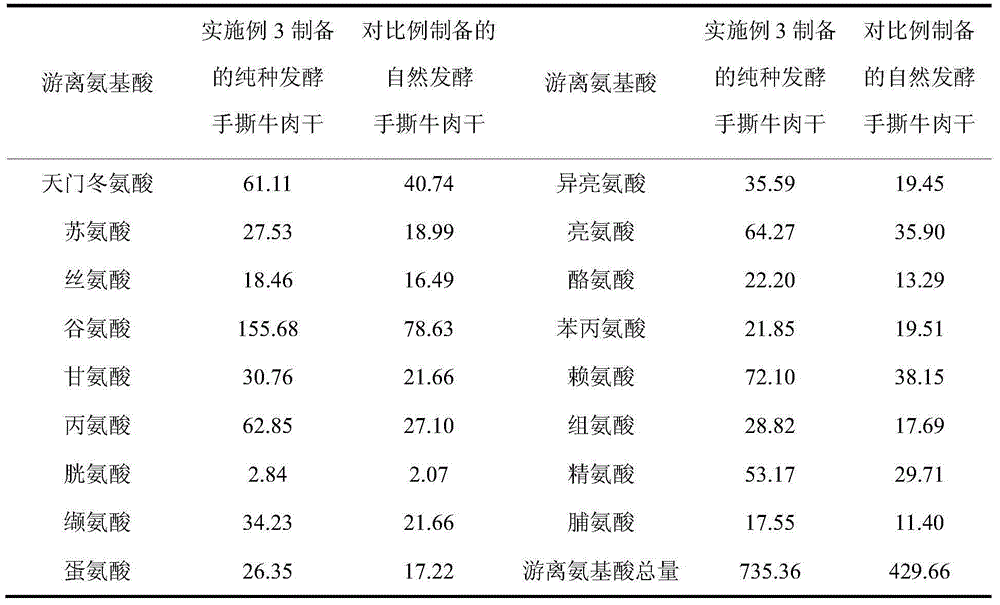

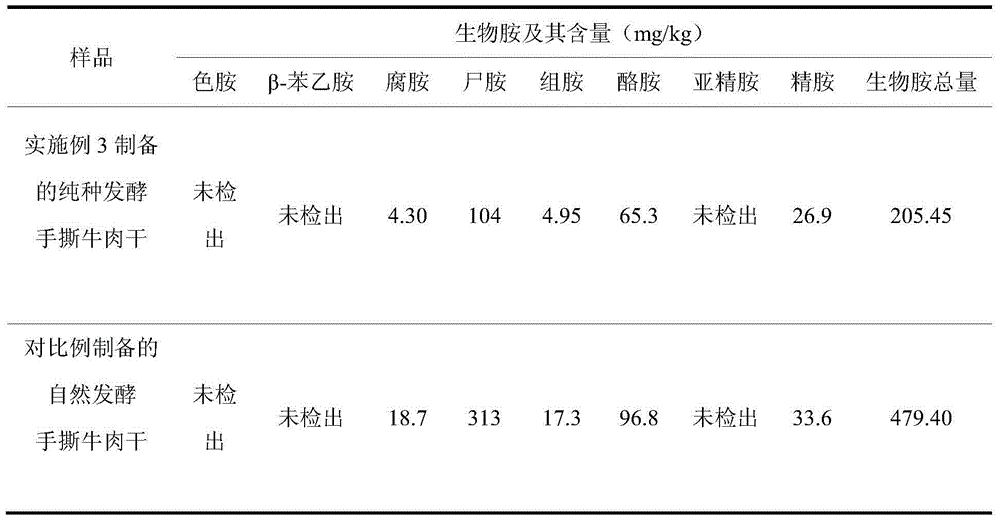

Purely-fermented shredded beef jerk and preparation method thereof

ActiveCN104643113AReduce in quantityPromote growthClimate change adaptationFood preparationSterile waterFermentation

The invention discloses a preparation method of purely-fermented shredded beef jerks, which comprises the following steps: (1) bacteria-reducing treatment: uniformly coating table salt with a mass accounting for 10-12% of that of a beef on the surface of the beef which is subjected to fascia and fat eliminating and cleaned, kneading for 8.0-10 min, washing off the table salt on the surface of the beef by using sterile water, putting the cleaned beef into a lactic acid solution with a mass concentration of 2.5-3.5% to soak for 8.0-10 min, wherein the ratio of the volume of the lactic acid solution to the mass of the cleaned beef is (1.5-2.5) : 1, the volume unit is mL, and the mass unit is g; and after soaking is completed, washing off a lactic acid on the surface of the beef by using sterile water, so that a beef subjected to bacteria-reducing treatment is obtained; (2) inoculated fermentation; (3) salting; (4) drying; (5) boiling; and (6) molding, flavoring, packaging and sterilizing. The method disclosed by the invention can shorten the fermentation time, and improve the safety of products.

Owner:成都生禾田文化传播有限责任公司

Composition for fabricating pellets

The invention relates to a composition for fabricating pellets, which comprises boric sludge and cement. The composition can be fabricated by directly adopting boron or ferroboron tailing powder, namely the boric sludge; the pellets fabricated from wastes not only have low cost, the bonding performance of the pellets is improved simultaneously, and the stability and fluidity of slag are improved; especially in the process of smelting the pellets, no or a little magnesium powder and boron powder both with high price are necessary to prepare, therefore the smelting cost is further reduced.

Owner:王铮

Magnesium alloy desilicon flux and production method

Besides magnesium chloride 15-30%, potassium chloride 15-30%, calcium fluoride 10-20%, barium chloride 8-12% and magnesium fluoride 10-25% etc. the chemical constituent of fusing agent has titanium compound 10-20% and carbonate 1-10% being added. Magnesium chloride and potassium chloride etc. is added into the warmed up crucible. With the magnesium chloride etc. being melted, calcium fluoride andmagnesium fluoride is added to the crucible. The fusing agent is made through procedures of heating up, stirring and pouring in bulk, then the procedures of crushing, milling and sifting out as well as with titanium compound and carbonate being added. The invented magnesium alloy provides the advantages of remarkable effect of removal of silica and excellent deslagging performance as well as improving mechanical property and corrosion-resisting properties.

Owner:SHANGHAI JIAO TONG UNIV

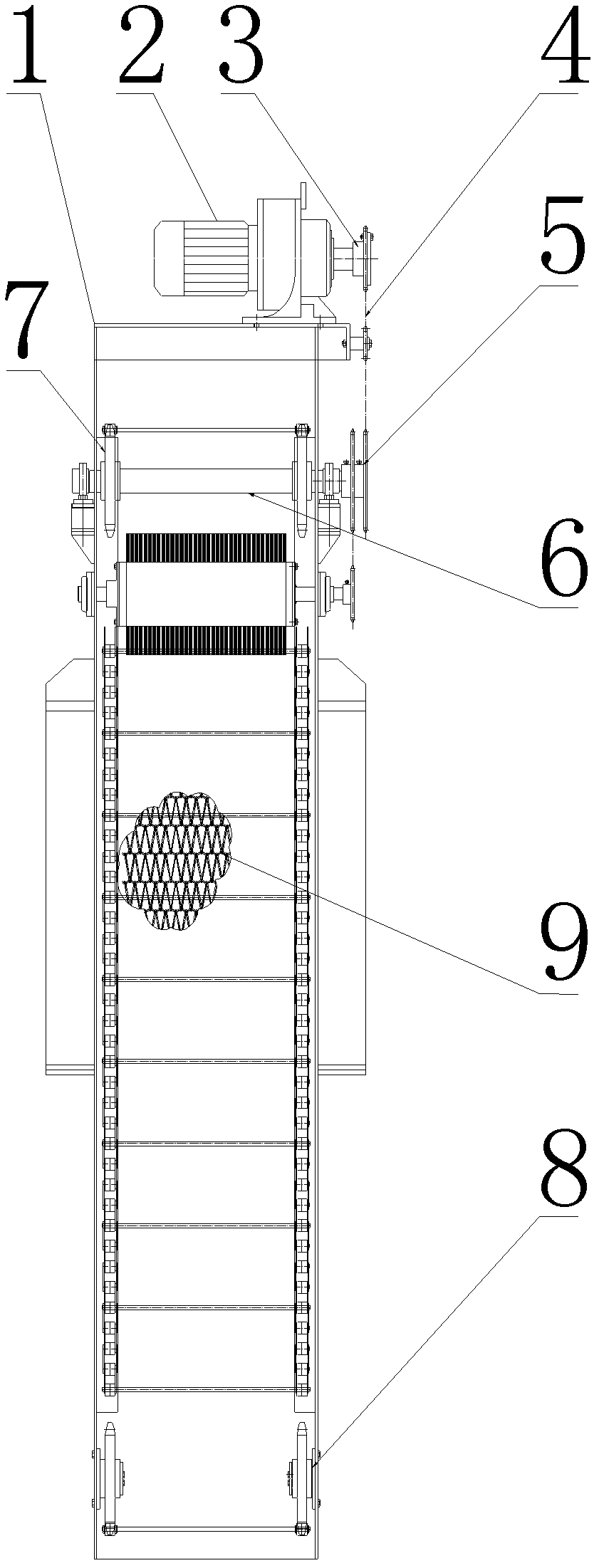

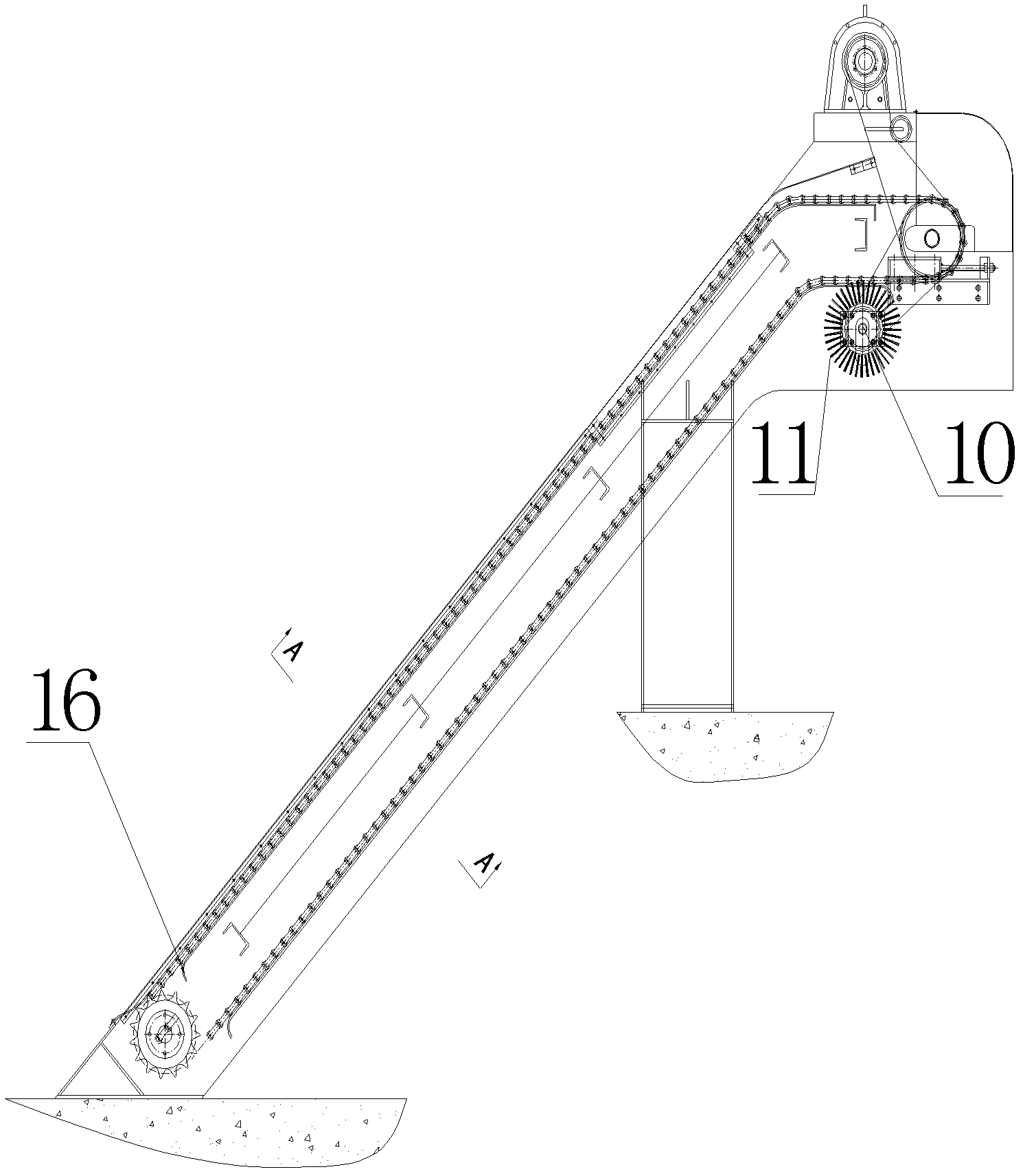

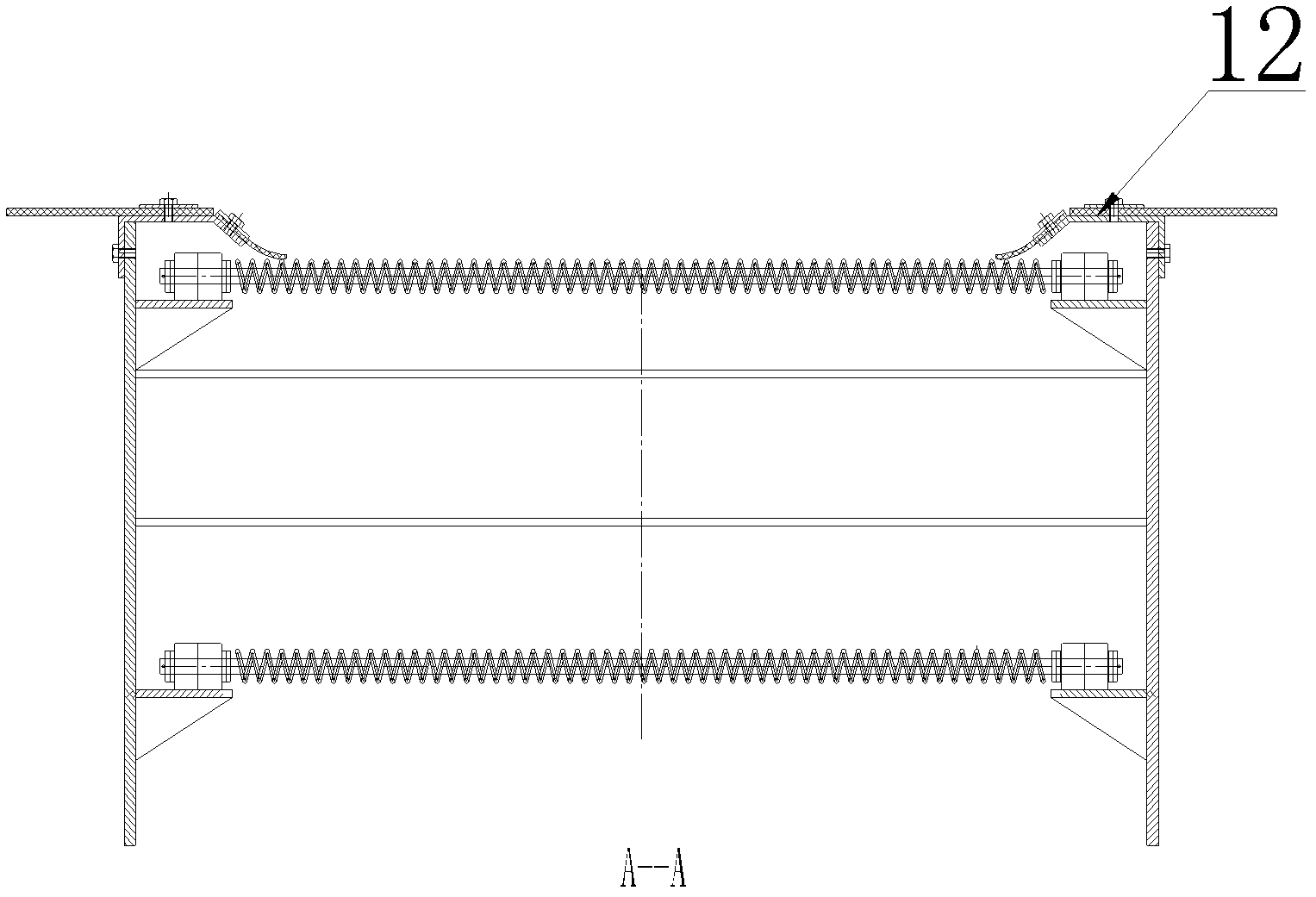

Rotary network chain type grid cleaner

InactiveCN102600655AImprove slag removal effectSimple structureMoving filtering element filtersSlagAgricultural engineering

The invention relates to a rotary network chain type grid cleaner, comprising a rack and a speed-reducing motor arranged at the top part of the rack, wherein the output end of the speed-reducing motor is connected with a drive chain wheel group which is connected with a driving chain wheel group through a chain; a main shaft is arranged in the middle of the driving chain wheel group and two ends of the main shaft are provided with main shaft guide wheels; an underwater guide wheel is arranged at the tail part of the rack and a chain network is arranged between the main shaft guide wheels and the underwater guide wheel; a slag brushing chain wheel group is arranged below the main shaft guide wheels and the chain network comprises two main chains and a steel wire gridding; the steel wire gridding is formed by annularly connecting steel wires; and a gap reserved between the steel wires is more than 1 mm and a roller chain supporting plate is arranged below the chain network. The rotary network chain type grid cleaner has the advantages of simple structure, high slag unloading efficiency, wide grid gap size and fewer structural parts.

Owner:UNIVERSAL ENVIROMENTAL PROTECTION EQUIP YIXING CITY

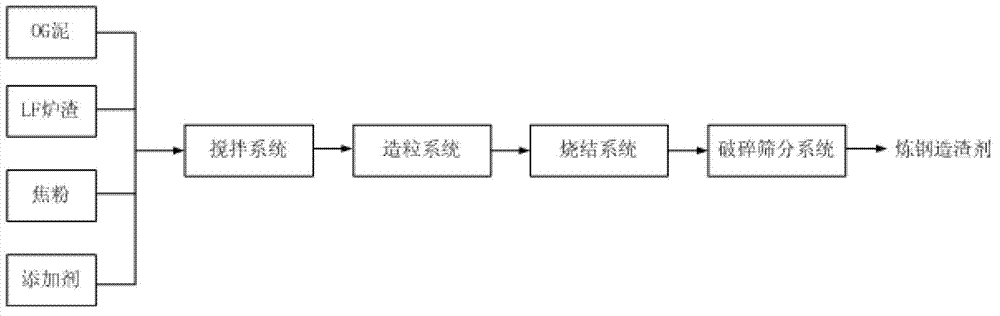

Steelmaking slag former and preparation method thereof

InactiveCN102808081AFast meltingImprove slag removal effectProcess efficiency improvementSteelmakingSludge

The invention discloses steelmaking slag former and a preparation method thereof and belongs to the technical field of ferrous metallurgy and solid waste recycling. The steelmaking slag former comprises the following components in percentage by weight: 60 to 70 percent of oxygen converter gas recovery sludge (OG), 20 to 30 percent of steelmaking low furnace (LF) slag, 5 to 10 percent of coke powder and 1 to 2 percent of bonder. The method comprises the following steps of: premixing raw materials by using a stirring system, pelletizing the raw materials by using a pelletizing system, partially premelting small balls and bonding the small balls into blocks by using a sintering system, and treating by using a crushing and screening system to finally obtain the steelmaking slag former of which the particle size is 10 to 50mm. The method has the advantages that the powdery wastes produced in a steelmaking process can be fully utilized and are also efficiently recycled, a high melting speed is achieved, and the steelmaking slag former is good in slagging effect.

Owner:SHOUGANG CORPORATION

Rotary furnace cooling agent and manufacturing method thereof

ActiveCN101560581AEmission reductionHigh yieldManufacturing convertersProcess efficiency improvementChemical compositionEconomic benefits

The invention provides a rotary furnace cooling agent and a manufacturing method thereof. The cooling agent is a carbonic and ferreous conglomeration which mainly takes iron scale, carbonic dry ash and ferreous dry waste material as raw materials, and prepared by additionally adding caking agent into the raw materials. The weight percentage of the main chemical compositions of the cooling agent meets the following condition: the carbon content is 5-25%, the content of TFe is more than or equal to 50%, the content of S is less than or equal to 0.50% and the content of P is less than or equal to 0.50%. The manufacturing method comprises: the iron scale, the carbonic dry ash and the ferreous dry waste material are firstly sent into a blending machine to be mixed together and evenly mixed with the caking agent; after being evenly mixed, the materials are sent into a mixing mill and then into a twin-roller ball press machine to be pressed into conglomeration; the pressed conglomeration is screened by a sieving machine, and the qualified screened conglomeration can be sent into a dry furnace to be dried, so that the finished product conglomeration can be obtained. The rotary furnace cooling agent can be used for replacing the common waste steel to be applied in smelting of a rotary furnace; compared with the prior art, the cooling agent completely uses the waste materials generated in the steel production, so that the process flow is short, the cost is low, the using method is flexible, the adding quantity is large, the recovery rate is high, the field operation is seldom affected, the economic benefit and the environmental protection benefit are remarkable, and the promotion and application values are excellent.

Owner:ANGANG STEEL CO LTD

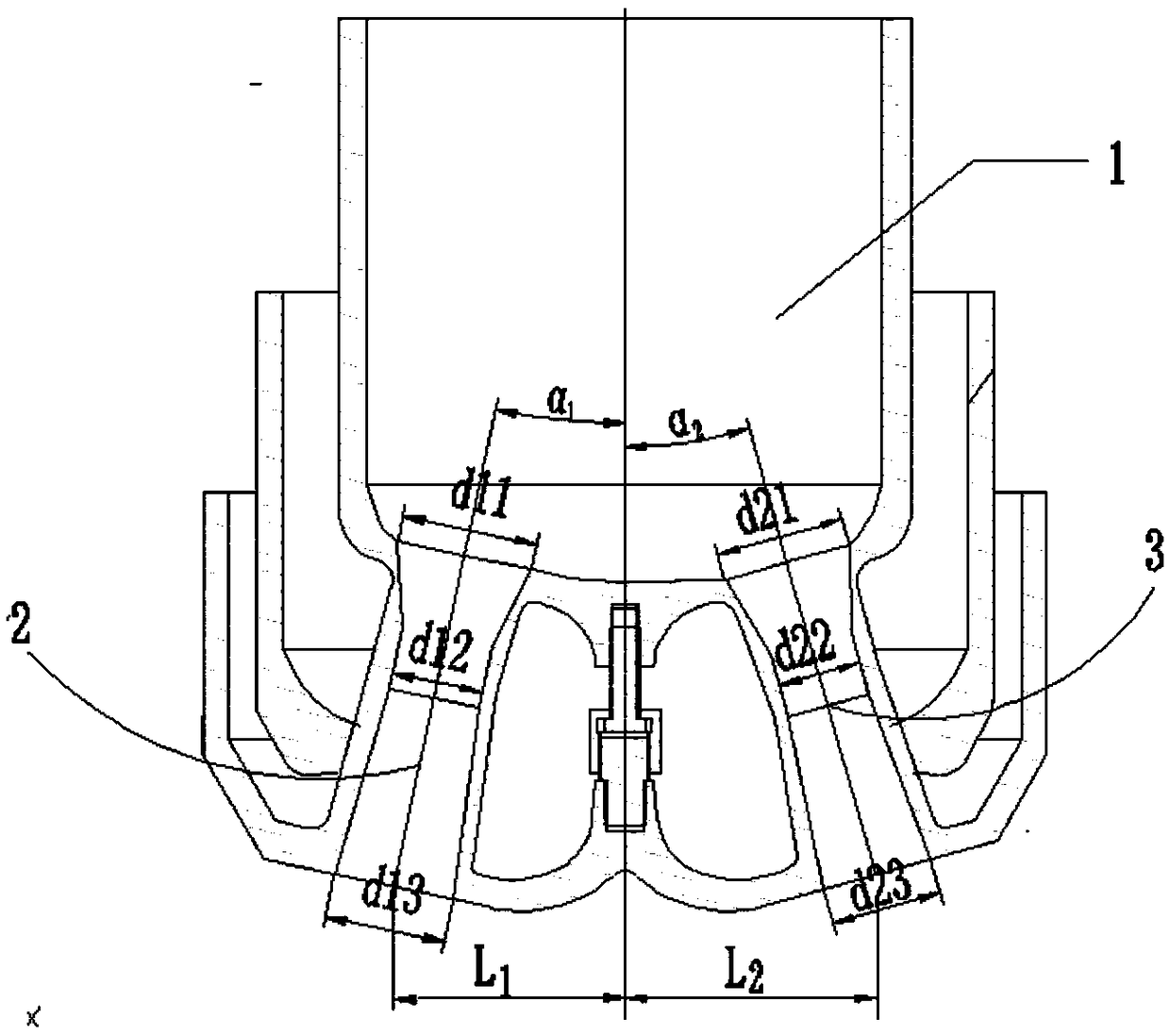

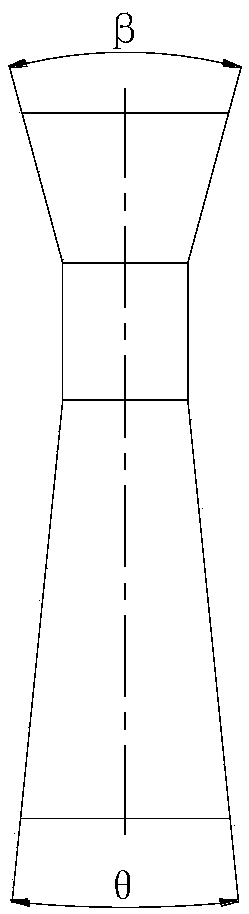

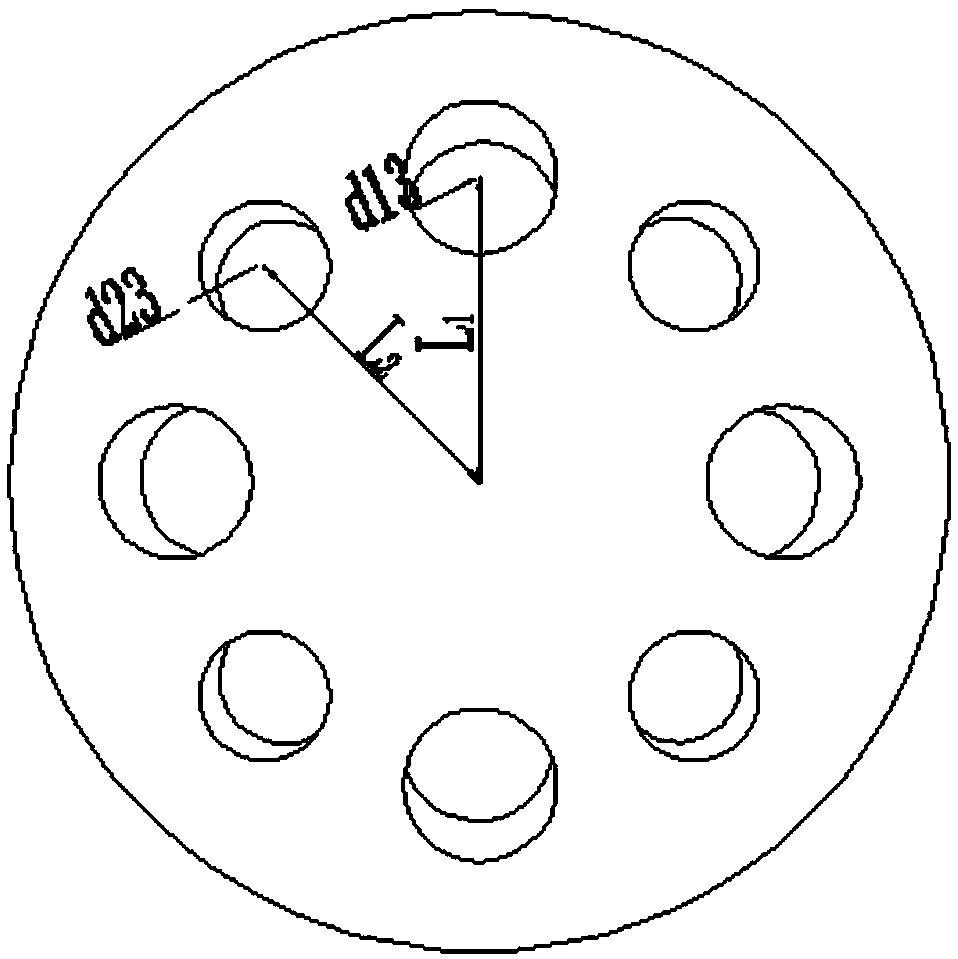

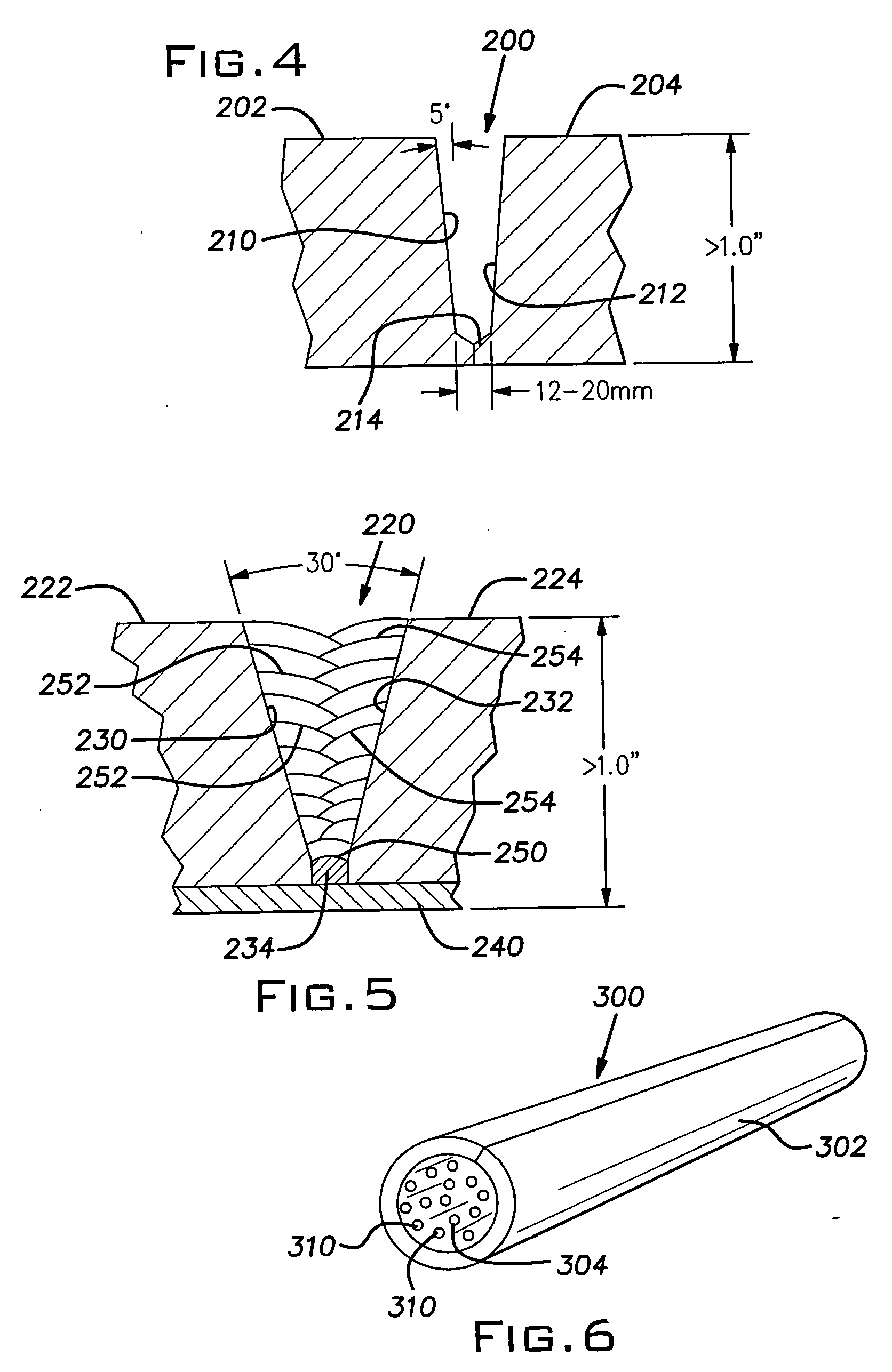

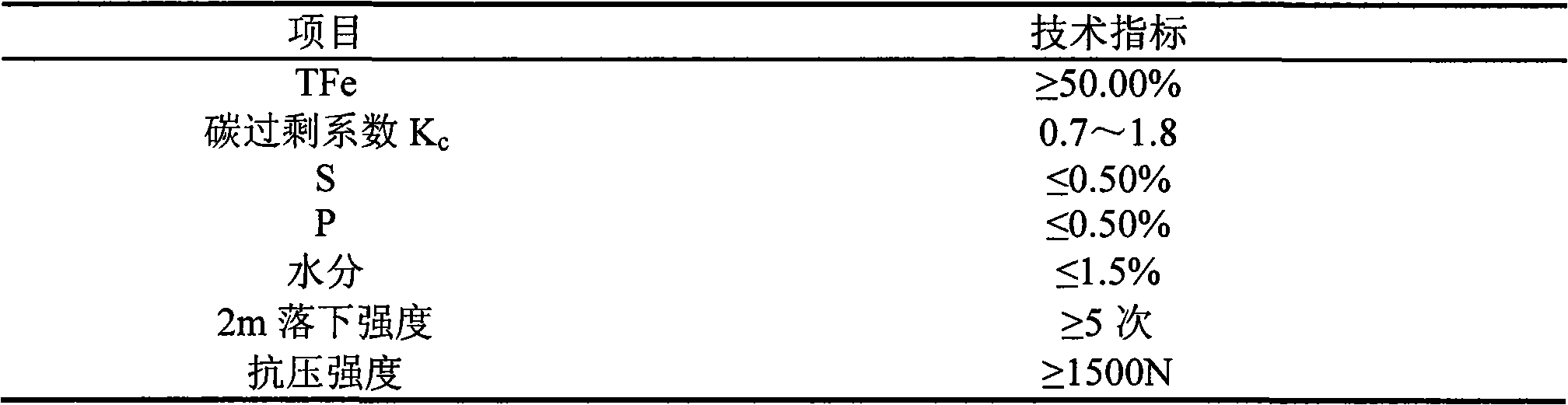

Single-runner dual-structure oxygen lance spraying head and blowing technology

PendingCN108642234AHigh strengthImprove the impact effectManufacturing convertersHead coolingEngineering

The invention relates to a single-runner dual-structure oxygen lance spraying head which comprises an oxygen inlet, laval pipe main holes and laval pipe auxiliary holes. The laval pipe main holes andthe laval pipe auxiliary holes are arranged alternatively; and the single-runner dual-structure oxygen lance spraying head is characterized in that the laval pipe main holes are small in flare angle and large in hole diameter, and the laval pipe auxiliary holes are large in flare angle and small in hole diameter. In the blowing process, the main hole jet flow strength is improved, the impact effect and the stirring strength of spraying head jet flows to a molten bath are strengthened, and the main hole spraying head jet flow core zone distance is lengthened. Auxiliary hole jet flows effectively buffer the main hole jet flow damping, the molten bath area is obviously increased, and the slugging effect is obvious; and the fusion distance of all jet flows in the furnace is obviously increased, the coverage possibility is greatly reduced, the splash rate is obviously reduced under the main and auxiliary hole coordinated work, gaps between columns are increased, the cooling water flow is better increased, the spraying head cooling effect is obvious, and the service life of the spraying head is prolonged.

Owner:UNIV OF SCI & TECH LIAONING

Fluoride-free refined flux slagging agent and preparation method and application method thereof

InactiveCN111334644AImprove slag removal effectReduce manufacturing costProcess efficiency improvementFluorine freeSlag

The invention belongs to the technical field of iron and steel metallurgy, and particularly relates to a fluoride-free refined flux slagging agent and a preparation method and application method thereof. Aiming at the problems that an existing fluoride-free slagging agent is high in production cost and complex in preparation process, the invention provides the fluoride-free refined flux slagging agent, which comprises the components in percentages by weight: main raw materials including 40-60% of continuous casting slag tailings, 20-40% of ferrovanadium smelting corundum slag and 8-20% of industrial barium carbonate, and an auxiliary material forming binder accounting for 3-4% of total mass of the main raw materials. The invention further provides the preparation method and application method of the slagging agent. The slagging agent is good in slagging effect and can effectively replace fluorite, and the production cost is reduced. By adopting a dry ball pressing mode, appropriate ball pressing parameters are determined through tests, and the preparation method and the application method are simple in production process, high in efficiency, low in cost and suitable for industrialapplication.

Owner:PANZHIHUA IRON & STEEL RES INST OF PANGANG GROUP

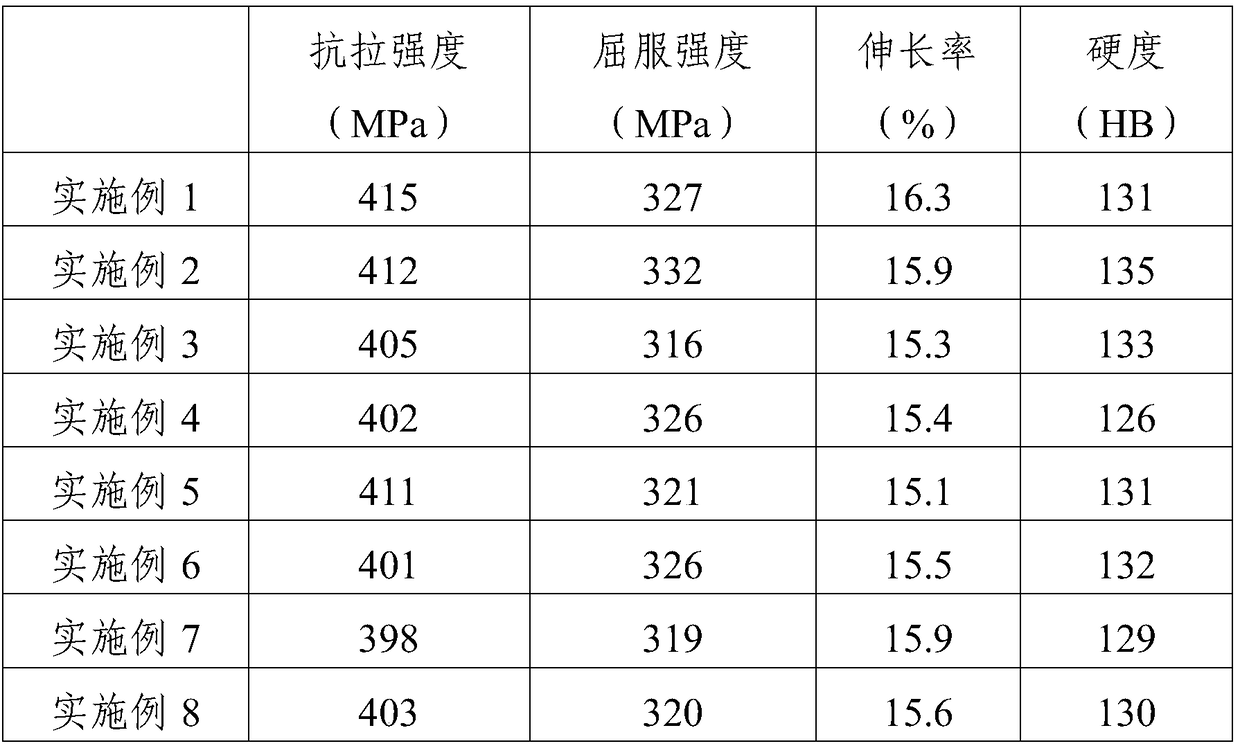

High-toughness and high-strength aluminum alloy hub for automobile and manufacturing method of high-toughness and high-strength aluminum alloy hub

ActiveCN109252074ARefined recrystallized grainsRaise the recrystallization temperatureHubsMass ratioHigh intensity

The invention provides a high-toughness and high-strength aluminum alloy hub for an automobile and a manufacturing method thereof, and relates to the technical field of automobile hub manufacturing. The aluminum alloy hub is prepared from the following components in percentage by mass: 3.3-4.8% of Si, 1.2-1.7% of Mg, 0.45-0.7% of Mn, 0.2-0.6% of V, 0.35-0.7% of Ti, 0.05-0.13% of Zr, 0.05-0.12% ofRE, and the balance of Al; RE is composed of Yb, Pr, Nd and Sc with the mass ratio being 1:(0.2 to 0.6):(0.3 to 0.8):(0.6 to 1.2). The manufacturing method comprises the steps of smelting, refining, casting, solid solution treatment, deep cold treatment, aging treatment and the like. The manufactured aluminum alloy hub is uniform and dense in structure, high in toughness, high in strength, good incorrosion resistance, high in dimensional stability, excellent in comprehensive performance and long in service life, and has great using prospects.

Owner:江苏创斯达科技有限公司

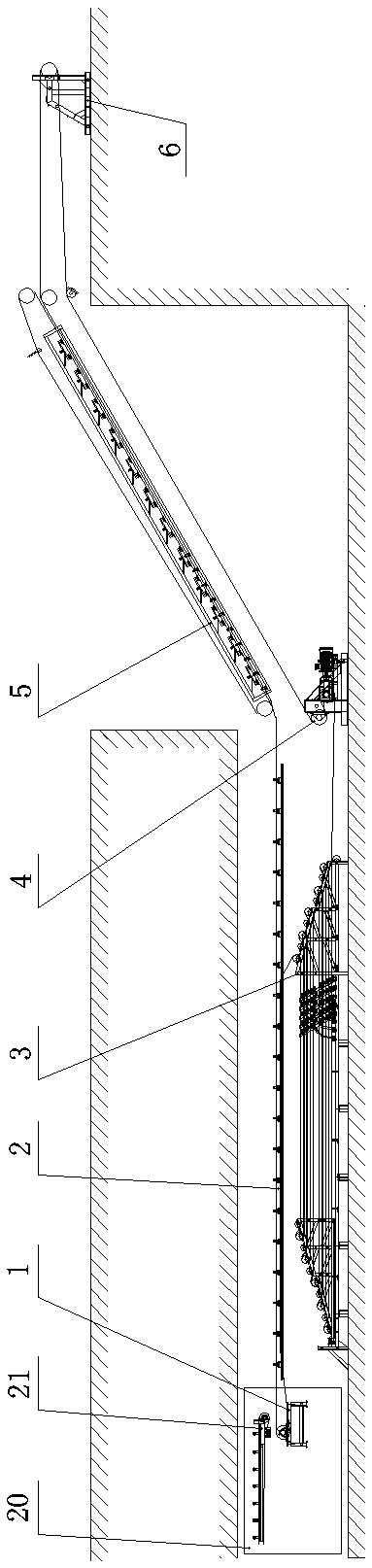

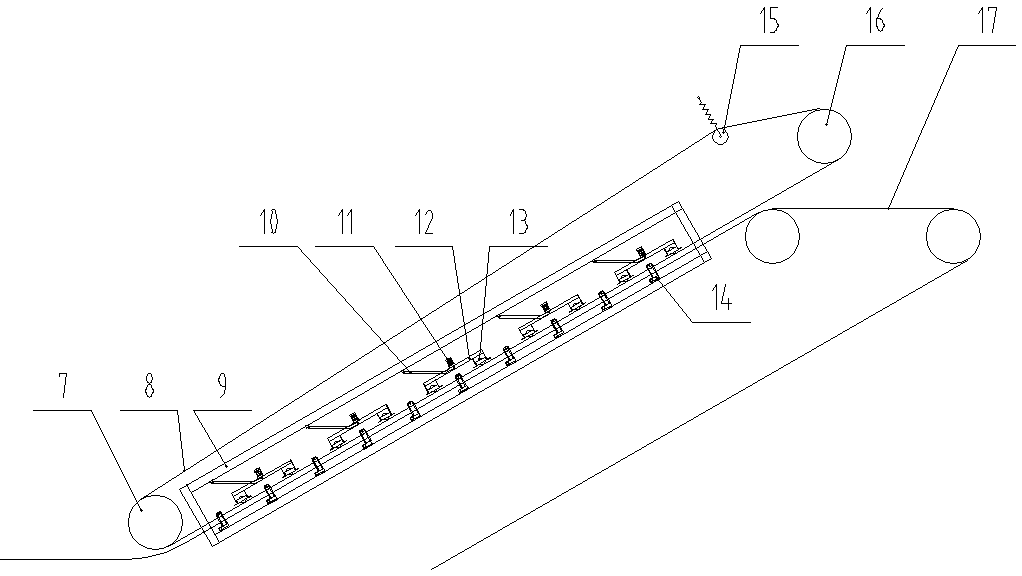

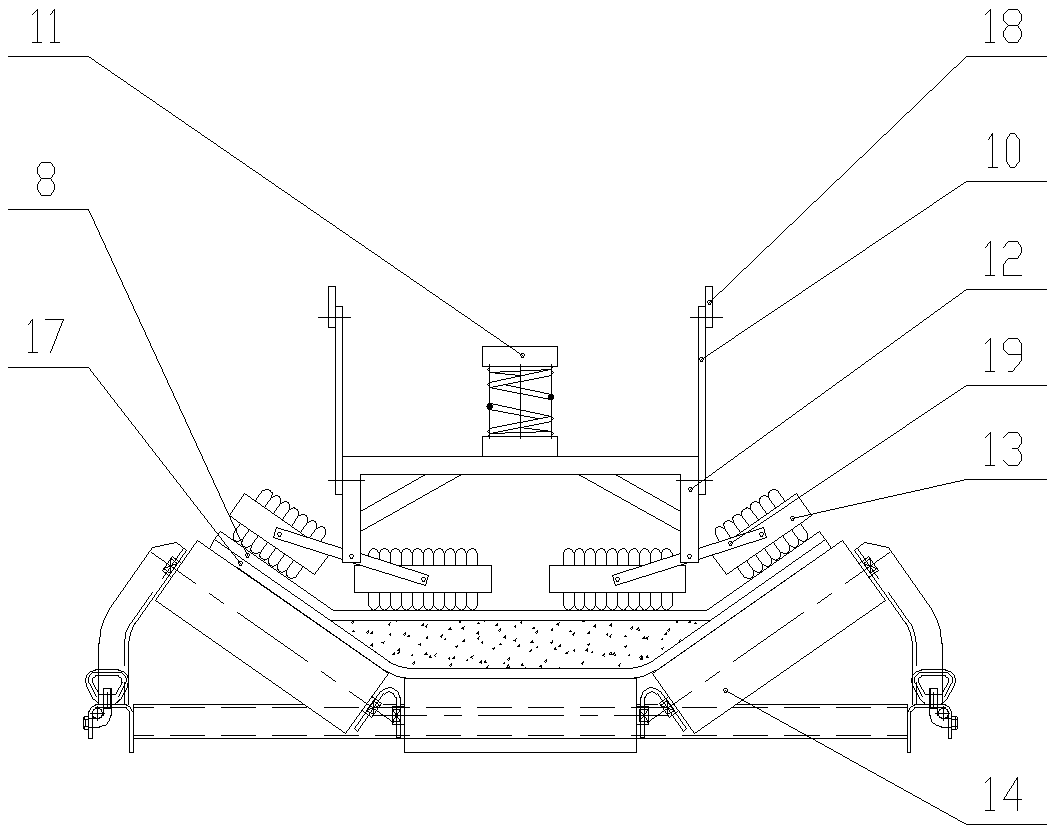

Large-inclination-angle continuous muck discharge method used for subway tunnel construction

InactiveCN108979710AThe overall structure of the equipment is simpleImprove efficiencyEarth drilling and miningUnderground transportTunnel constructionShield machine

The invention provides a large-inclination-angle continuous muck discharge method used for subway tunnel construction. The method includes the following steps that 1, when a shield machine moves forward for tunneling, a main machine belt conveyor is adopted for discharging muck which is dug out during tunneling; 2, the muck on the main machine belt conveyor is transferred to the tail part of a continuous belt conveyor; 3, the muck on the continuous belt conveyor is conveyed to the bottom of a shaft segment; 4, at the shaft segment, under the combined action of the continuous belt conveyor anda pressing belt part, the muck is conveyed to the ground surface at a large inclination angle; 5, on the ground surface, the continuous belt conveyor continues to extend to convey the muck to a machine head of the continuous belt conveyor for discharging. The method has the advantages that the continuous belt conveyor with a pressing belt can directly conduct conveying at a large inclination angle, there is no need to transfer the muck, the overall structure of equipment is simplified, and the efficiency is improved. By adopting two reels of adhesive tape for clamping materials, it is ensuredthat the materials cannot be leaked during conveying at the large inclination angle. Compared with a corrugated flange vertical-lifting belt conveyor, the method has the advantages that the cost is low, the reliability is high, and the effect of removing the muck on the adhesive tape is great.

Owner:CHINA RAILWAY ENGINEERING EQUIPMENT GROUP CO LTD

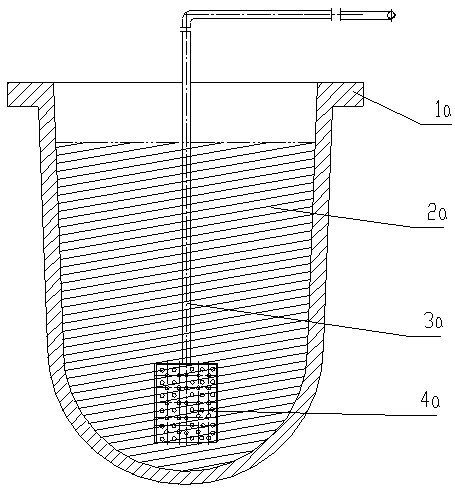

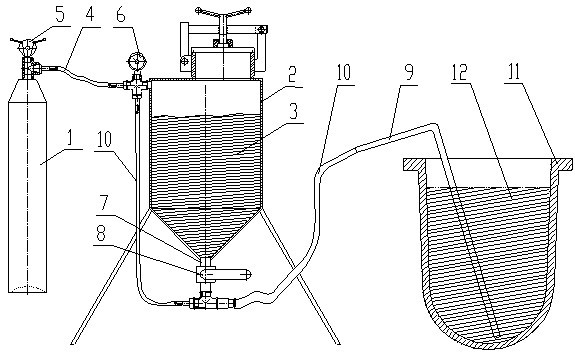

Degassing and deslagging device for aluminum liquid

The invention provides a degassing and deslagging device for aluminum liquid. The degassing and deslagging device comprises a gas storage bottle and a storage tank, wherein gas for the degassing and deslagging of the aluminum liquid is stored in the gas storage bottle. The degassing and deslagging device is characterized in that: a deslagging agent is sealed in the storage tank; a gas pipeline is arranged between the gas storage bottle and the storage tank, the gas in the gas storage bottle is introduced into the storage tank by the gas pipeline in the controlled state; a discharging pipe is arranged at the lower end of the storage tank; a heat-resisting pipe is connected to the back of the discharging pipe; a branch pipeline is arranged on the gas pipeline; and the other end of the branch pipeline is connected to the discharging pipe or is connected to the heat-resisting pipe. According to the degassing and deslagging device, the deslagging agent is blown into the bottom of the aluminum liquid by nitrogen, inertia nitrogen and the deslagging agent of which the specific gravity is smaller than that of the aluminum liquid are floated upwards automatically to carry away hydrogen and impurities in the aluminum liquid, so that gas content in the aluminum liquid is reduced effectively and the impurities in the aluminum liquid are removed effectively, and the quality conformance of the aluminum liquid is ensured; and the deslagging agent is driven by the gas to be diffused in the aluminum liquid, so that the deslagging agent can be distributed at the bottom of the aluminum liquid uniformly, and the integral degassing and deslagging effect is good.

Owner:CHONGQING DAJIANG MILLISON DIE CASTING

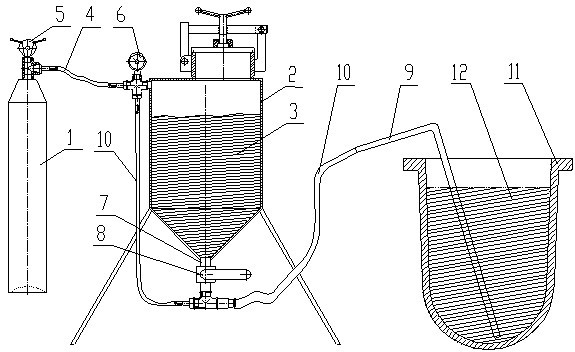

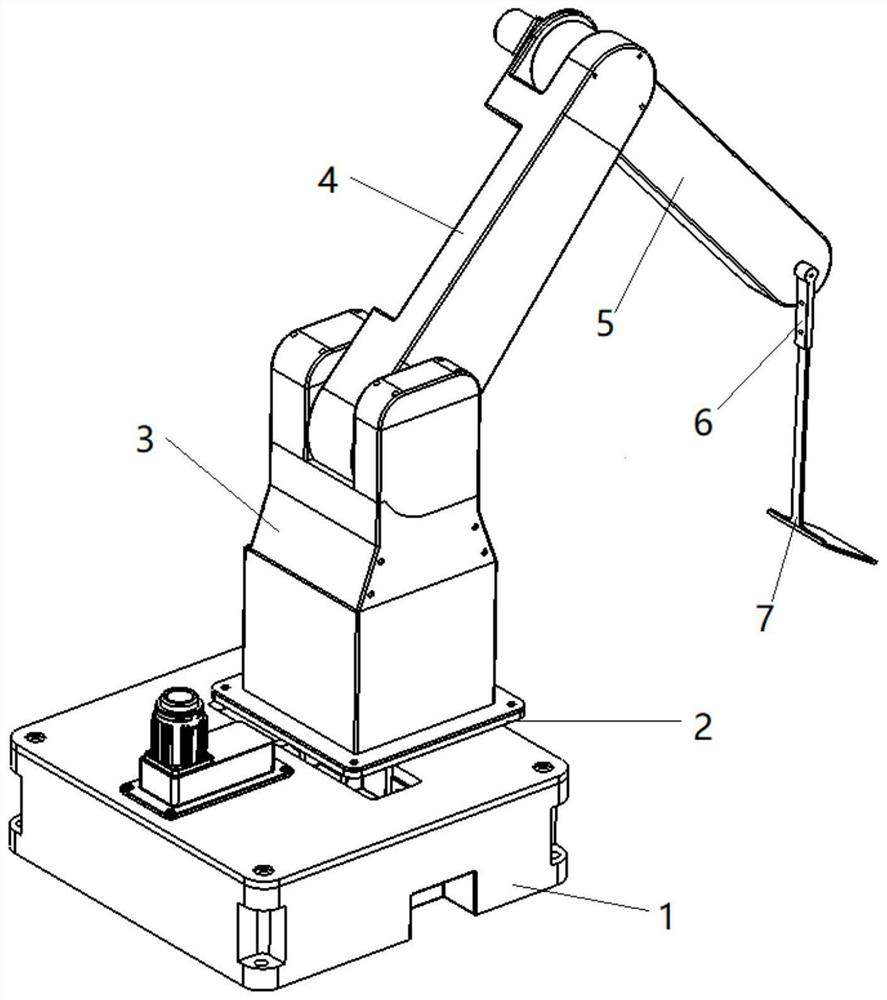

Zinc alloy slagging robot and working method

ActiveCN111923063AGuaranteed stabilityReduce volumeProgramme-controlled manipulatorJointsEngineeringZinc alloys

The invention discloses a zinc alloy slagging robot and a working method thereof. The robot comprises a synchronous moving device (1), wherein the top of the synchronous moving device (1) is connectedwith a mechanical arm base (3) through a mechanical arm bracket (2), a mechanical arm big arm device (4) is installed on the mechanical arm base (3), the top end of the mechanical arm big arm device(4) is connected with a mechanical arm small arm device (5), a mechanical arm wrist part (6) is installed at the top end of the mechanical arm small arm device (5), and a slagging plate (7) is arranged at the front end of the mechanical arm wrist part (6). According to the robot, automatic slagging can be performed, labor is released, the cost is saved, and the robot has the characteristics of good slagging effect.

Owner:WENZHOU UNIVERSITY

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com

![Converter steelmaking method for molten iron [Si] (0.50%) Converter steelmaking method for molten iron [Si] (0.50%)](https://images-eureka.patsnap.com/patent_img/b91bb63e-6f3d-4dcb-be2c-2c0d3c4466dc/BDA0001701172290000041.png)

![Converter steelmaking method for molten iron [Si] (0.50%) Converter steelmaking method for molten iron [Si] (0.50%)](https://images-eureka.patsnap.com/patent_img/b91bb63e-6f3d-4dcb-be2c-2c0d3c4466dc/BDA0001701172290000042.png)

![Converter steelmaking method for molten iron [Si] (0.50%) Converter steelmaking method for molten iron [Si] (0.50%)](https://images-eureka.patsnap.com/patent_img/b91bb63e-6f3d-4dcb-be2c-2c0d3c4466dc/BDA0001701172290000051.png)