Purely-fermented shredded beef jerk and preparation method thereof

A hand-shredded beef, pure-bred fermentation technology, applied in the field of food processing, can solve the problems of protein corruption, too long fermentation time, affecting product quality and safety, etc., and achieve the goals of increasing content, low decarboxylase activity, and shortening the production cycle Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0034] The preparation process steps of purebred fermented shredded beef jerky in the present embodiment are as follows:

[0035] (1) Bacteria reduction treatment

[0036] Evenly smear 11% salt by mass on the surface of the cleaned beef after removing fascia and fat, and rub it repeatedly for 10 minutes, then wash off the surface salt with sterile water, put the cleaned beef into a lactic acid solution with a mass concentration of 3.0% Soak in medium for 8minmin, the mass ratio of the volume of described lactic acid solution and the beef after cleaning is 1.5:1, wash off surface lactic acid with aseptic water after soaking, obtain the beef that reduces bacteria;

[0037] (2) Inoculation fermentation

[0038] Cut the sterility-reduced beef obtained in step (1) into strips of 20 cm long, 3 cm wide and 0.8 cm thick along the meat fiber direction in a clean environment at 12°C to obtain beef strips, and add 0.5% glucose and beef D-sodium erythorbate with 0.2% of the mass of the ...

Embodiment 2

[0048] The preparation process steps of purebred fermented shredded beef jerky in the present embodiment are as follows:

[0049] (1) Bacteria reduction treatment

[0050] Evenly smear 12% salt by mass on the surface of the beef after the fascia and fat have been removed and washed, and rub it repeatedly for 9 minutes. Soak in medium for 9minmin, the mass ratio of the volume of described lactic acid solution and the beef after cleaning is 2.0:1, wash away surface lactic acid with aseptic water after soaking finishes, obtain the beef that reduces bacteria;

[0051] (2) Inoculation fermentation

[0052] The sterility-reduced beef obtained in step (1) is cut into strips of 22 cm in length, 3.5 cm in width and 1.0 cm in thickness along the meat fiber direction in a clean environment at 14° C. to obtain beef strips, and 0.6% of the quality of the beef strips is added with glucose and D-sodium erythorbate with 0.15% of the mass of beef strips was stirred evenly, then a compound fe...

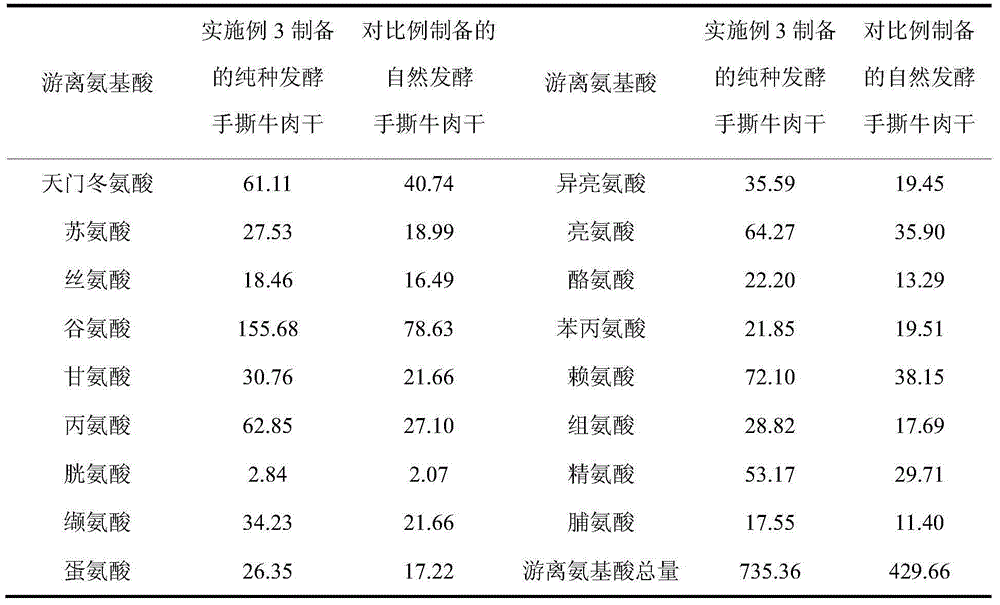

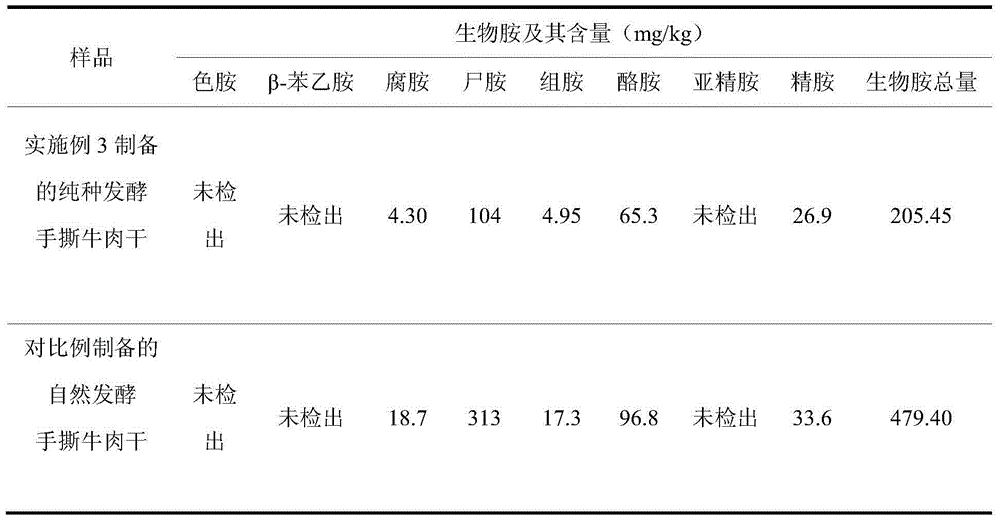

Embodiment 3

[0062] The preparation process steps of purebred fermented shredded beef jerky in the present embodiment are as follows:

[0063] (1) Bacteria reduction treatment

[0064] Evenly smear 10% of the mass of salt on the surface of the cleaned beef after fascia and fat have been removed, and rub it repeatedly for 8 minutes. Soak in medium for 10minmin, the mass ratio of the volume of described lactic acid solution and the beef after cleaning is 2.5:1, wash off surface lactic acid with aseptic water after soaking finishes, obtain the beef that reduces bacteria;

[0065] (2) Inoculation fermentation

[0066] Cut the sterility-reduced beef obtained in step (1) into strips of 24 cm in length, 4 cm in width and 1.2 cm in thickness along the meat fiber direction in a clean environment at 16° C. to obtain beef strips, and add 0.4% glucose and beef D-sodium erythorbate with 0.1% of the mass of the strips was stirred evenly, and then a compound fermentation broth with 2.0% of the mass of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com