Semi-steel making method

A slag and oxygen lance technology, applied in the field of iron and steel metallurgy, can solve the problems of serious phosphorus reversion in molten steel, difficult to control the amount of slag, slow down the production rhythm, etc. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

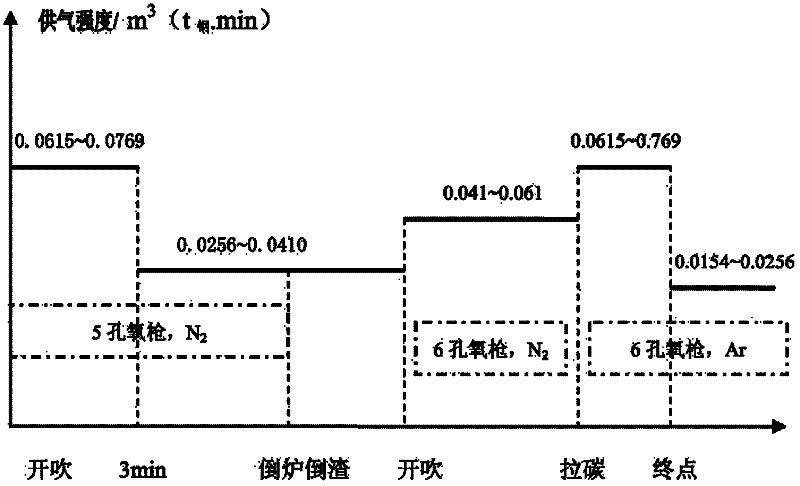

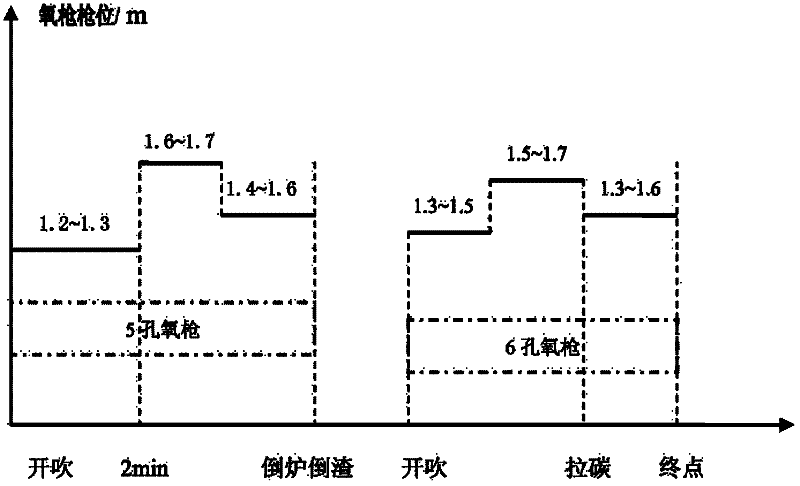

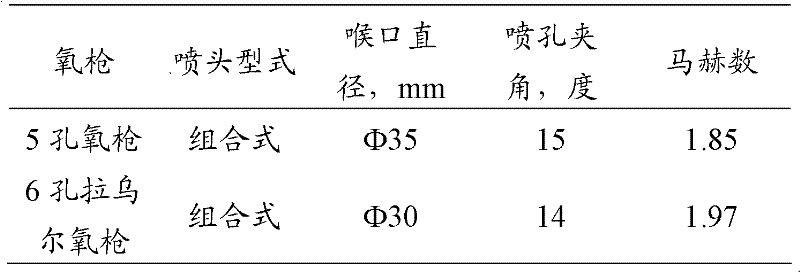

[0022] A steel plant uses 5-hole oxygen lance and 6-hole Raoult oxygen lance for semi-steel smelting. The nozzle parameters of 5-hole oxygen lance and 6-hole Raoult oxygen lance are shown in Table 1.

[0023] Table 1 Oxygen lance nozzle parameters

[0024]

[0025] When a 120-ton converter in a steel plant is smelted with a 5-hole oxygen lance, the working pressure of the oxygen supply is 0.75MPa, and the oxygen supply intensity is 2.2m 3 / t 半钢 . The amount of the first batch of slagging materials added is: active lime 10kg / t 半钢 ;The amount of high magnesium lime added is 20kg / t 半钢 ; The amount of compound slagging agent added is 22kg / t 半钢 . After the start of oxygen blowing, nitrogen is blown at the bottom, and the gas supply intensity of nitrogen within 3 minutes after adding the slagging material is 0.0615m 3 / (min t 半钢 ), after 3min the gas supply intensity of bottom blowing nitrogen is 0.0256m 3 / (min t 半钢 ), the amount of slagging agent (sludge ball) added in...

example 2

[0035] A steel plant uses 5-hole oxygen lance and 6-hole Raoult oxygen lance for semi-steel smelting. The nozzle parameters of 5-hole oxygen lance and 6-hole Raoult oxygen lance are shown in Table 4.

[0036] Table 4 Oxygen lance nozzle parameters

[0037]

[0038] When a 120-ton converter in a steel plant is smelted with a 5-hole oxygen lance, the working pressure of the oxygen supply is 0.75MPa, and the oxygen supply intensity is 2.5m 3 / t 半钢 . The amount of the first batch of slagging materials added is: active lime 20kg / t 半钢 ;The amount of high magnesium lime added is 10kg / t 半钢 ; The amount of compound slagging agent added is 10kg / t 半钢 ; After oxygen blowing starts, nitrogen is blown at the bottom, and the nitrogen gas supply intensity within 3 minutes after adding the slagging material is 0.0769m 3 / (min t 半钢 ), after 3 minutes, the gas supply intensity of bottom blowing nitrogen is 0.0410m 3 / (min t 半钢 ), the amount of slag adjusting agent (composite slag) add...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com