Patents

Literature

30results about How to "Efficient slag removal" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

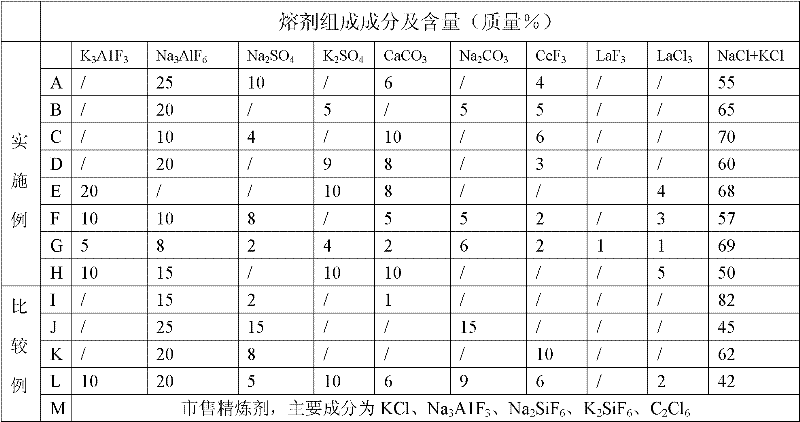

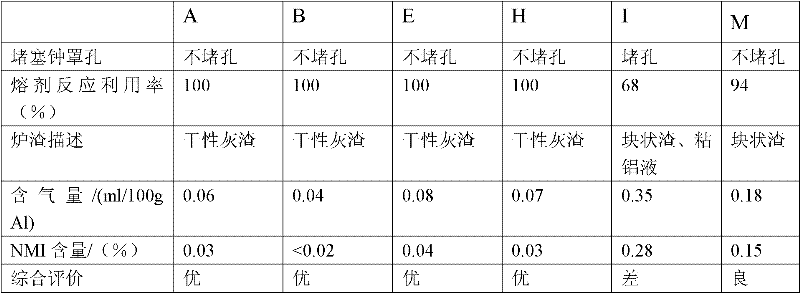

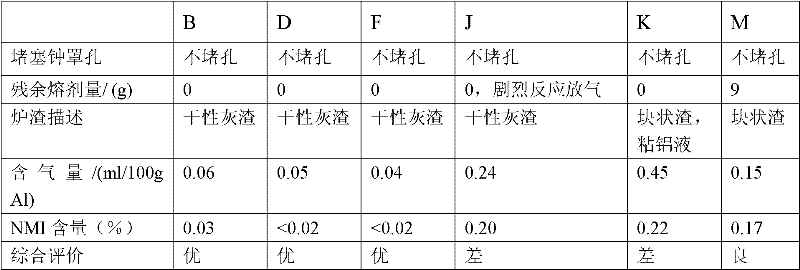

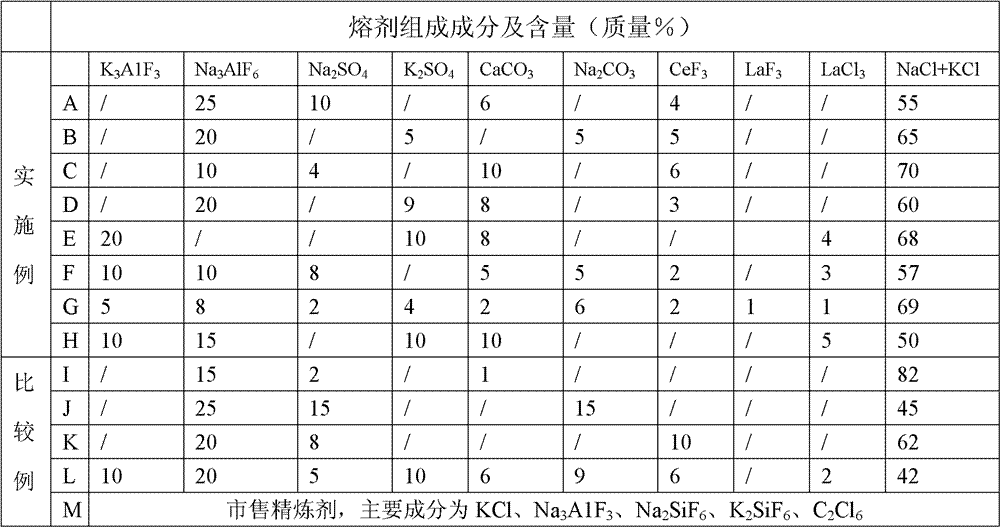

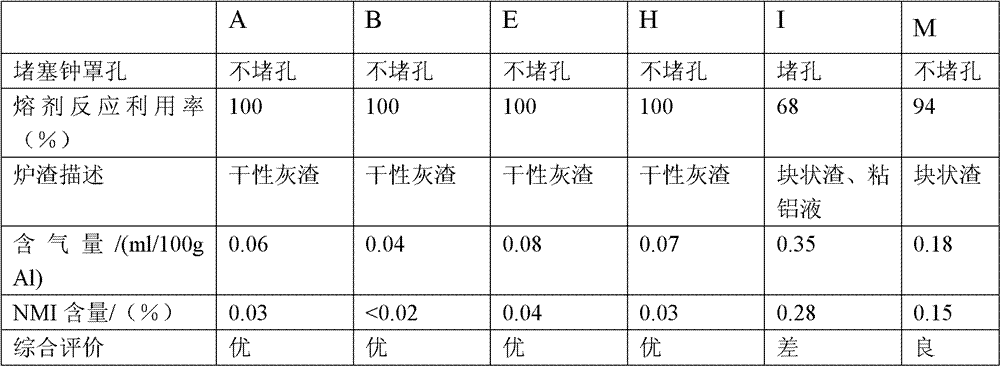

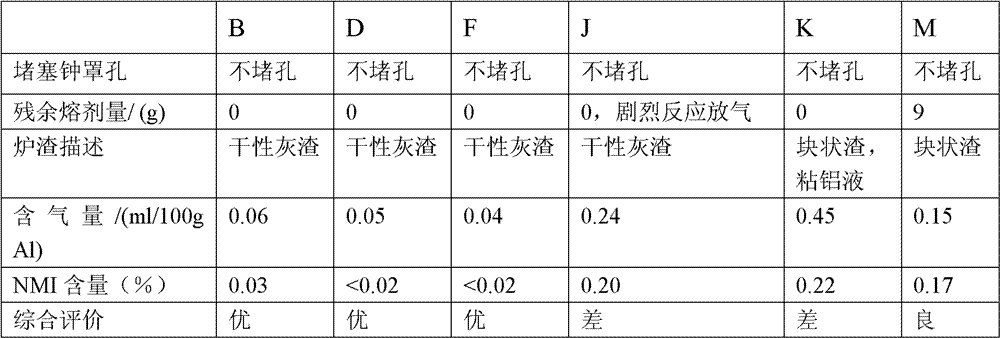

Refining flux used for purifying and processing aluminum or aluminum alloy melt, and its preparation method

The invention discloses a refining flux used for purifying and processing aluminum or aluminum alloy melt, and its preparation method. The invention is characterized in that the raw material formula of the refining flux is a powder mixture composed of the following components by mass: 25 to 35% of NaCl, 25 to 35% of KCl, 15 to 25% of Na3AlF6 and / or K3AlF6, 4 to 10% of Na2SO4 and / or K2SO4, 3 to 10% of CaCO3 and / or Na2CO3, 3 to 6% of REF3 and / or RECl3; wherein, a mass ratio of NaCl to KCl is 1:1; RE is Ce or La. The refining flux can be fully diffused after entering the melt without adsorption agglomeration and pore plugging; and has high efficient capability for producing dry slag without viscous aluminum melt; even the refining flux has a slight reaction with aluminum melt, the reaction products can be removed with slag; the refining flux provided in the invention has high efficiency of gas and slag removing.

Owner:SOUTH CHINA UNIV OF TECH +1

Method for removing ladle dross

ActiveCN1806964AFast slag removalEfficient slag removalCasting cleaning apparatusLiquid slagMolten steel

The invention provides the method of removing liquid steel scum, comprising the following steps: dragging the scum from liquid steel liquid level with harrow rotary dragging method, at the same time, adding the anti-oxidization agent on the clean liquid steel surface. Because of adopting the harrow rotary dragging method, the invention solves the problems of big loss of scarfing cinder, hard operation and heavy labor strength. Adding the anti-oxidization agent avoids the secondary oxidization of liquid steel. The method uses the freezing slag agent to solidify the liquid slag. It strengthens the effect of removing slag.

Owner:YANTAI SHENGLIDA ENG TECH

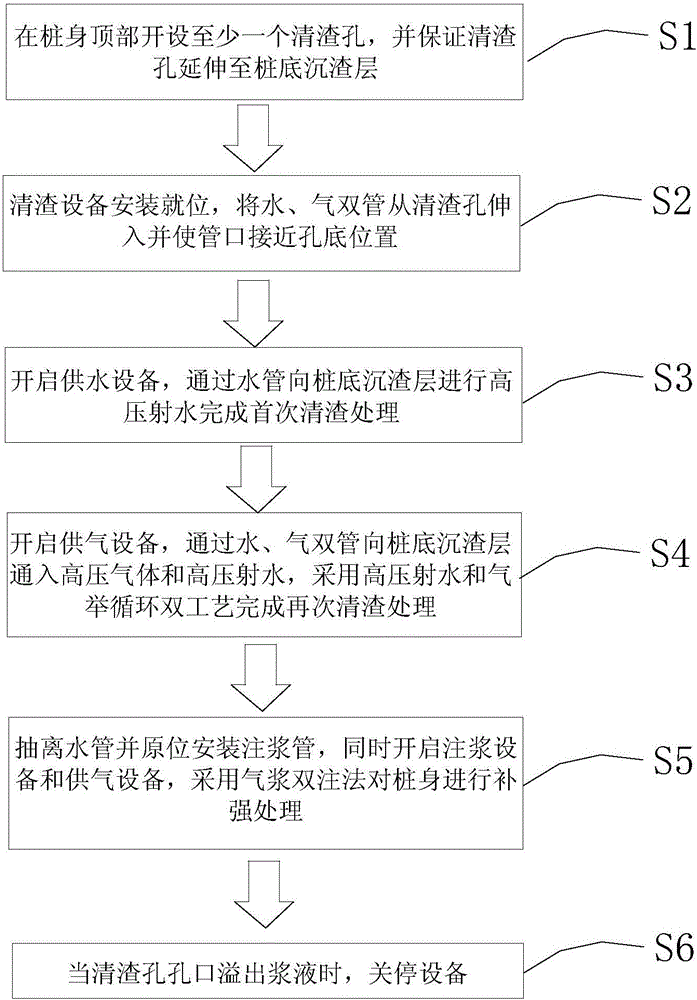

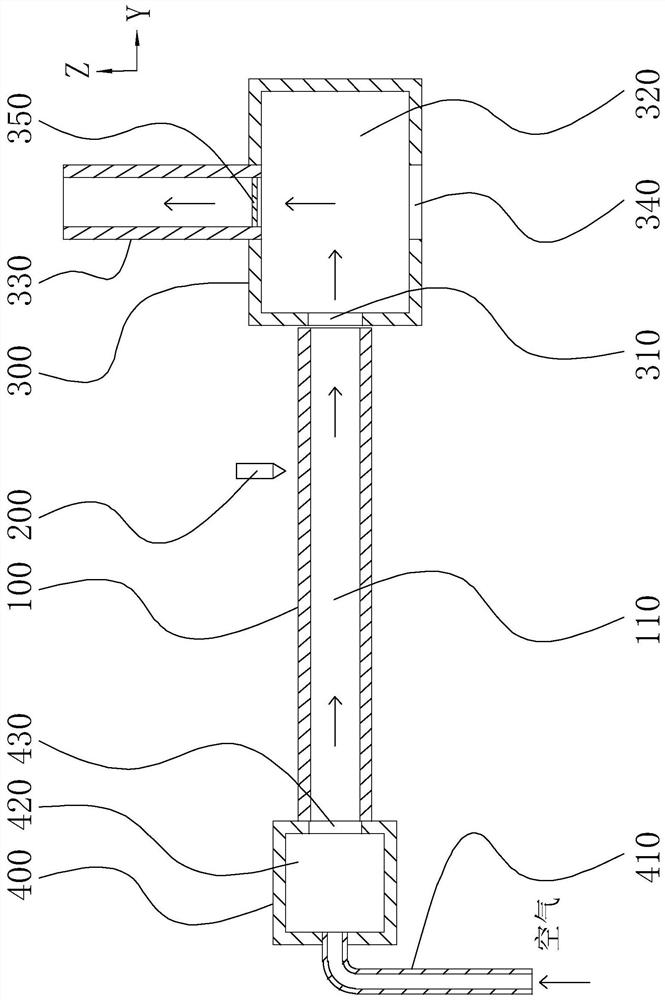

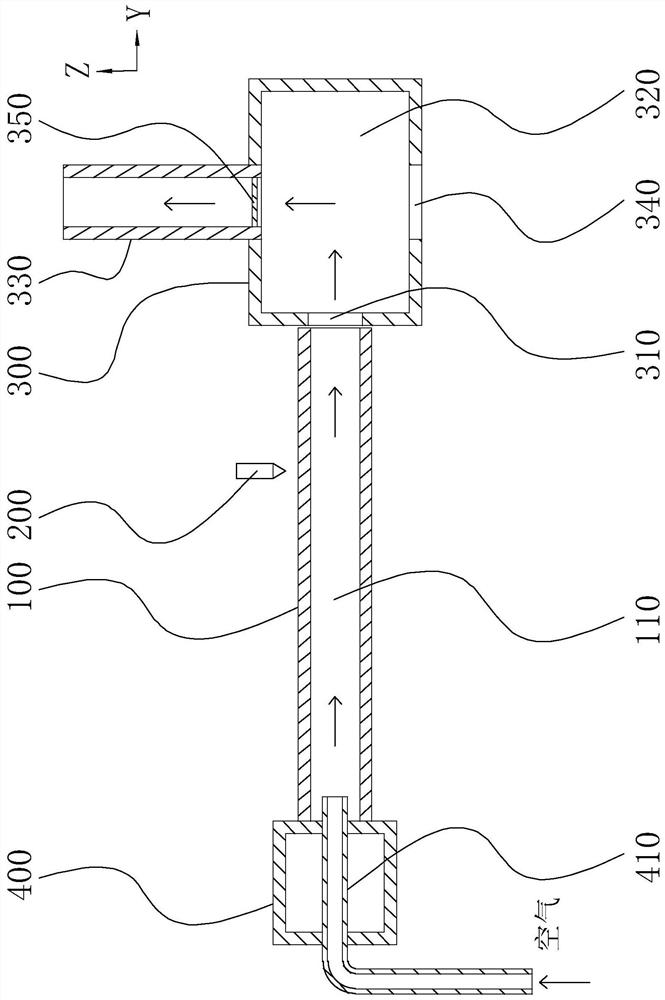

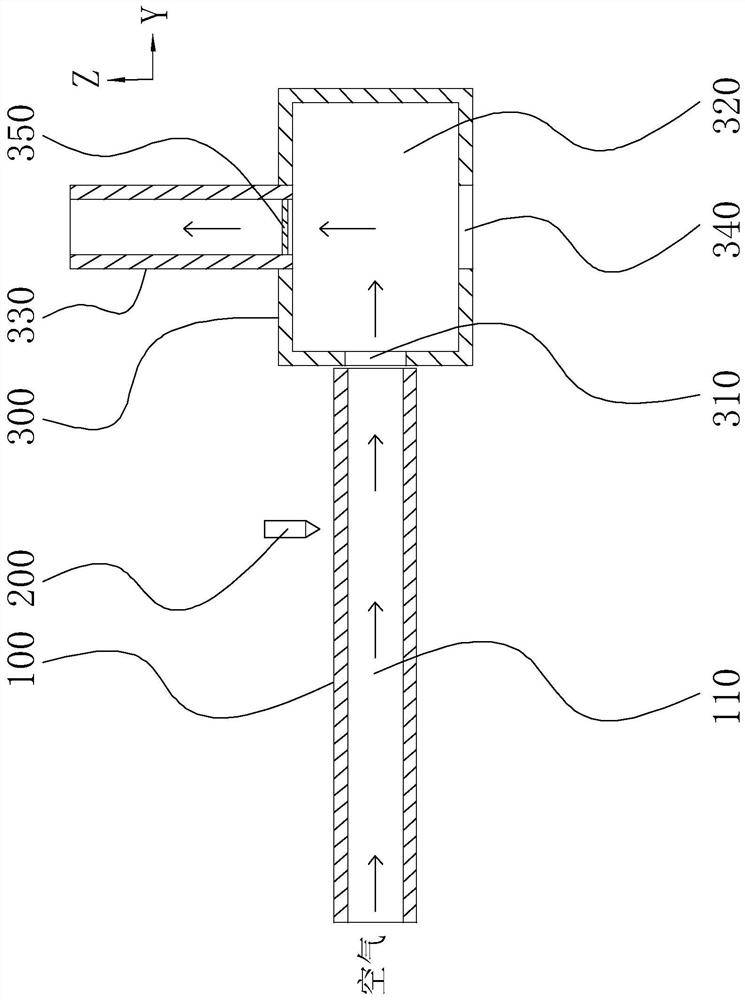

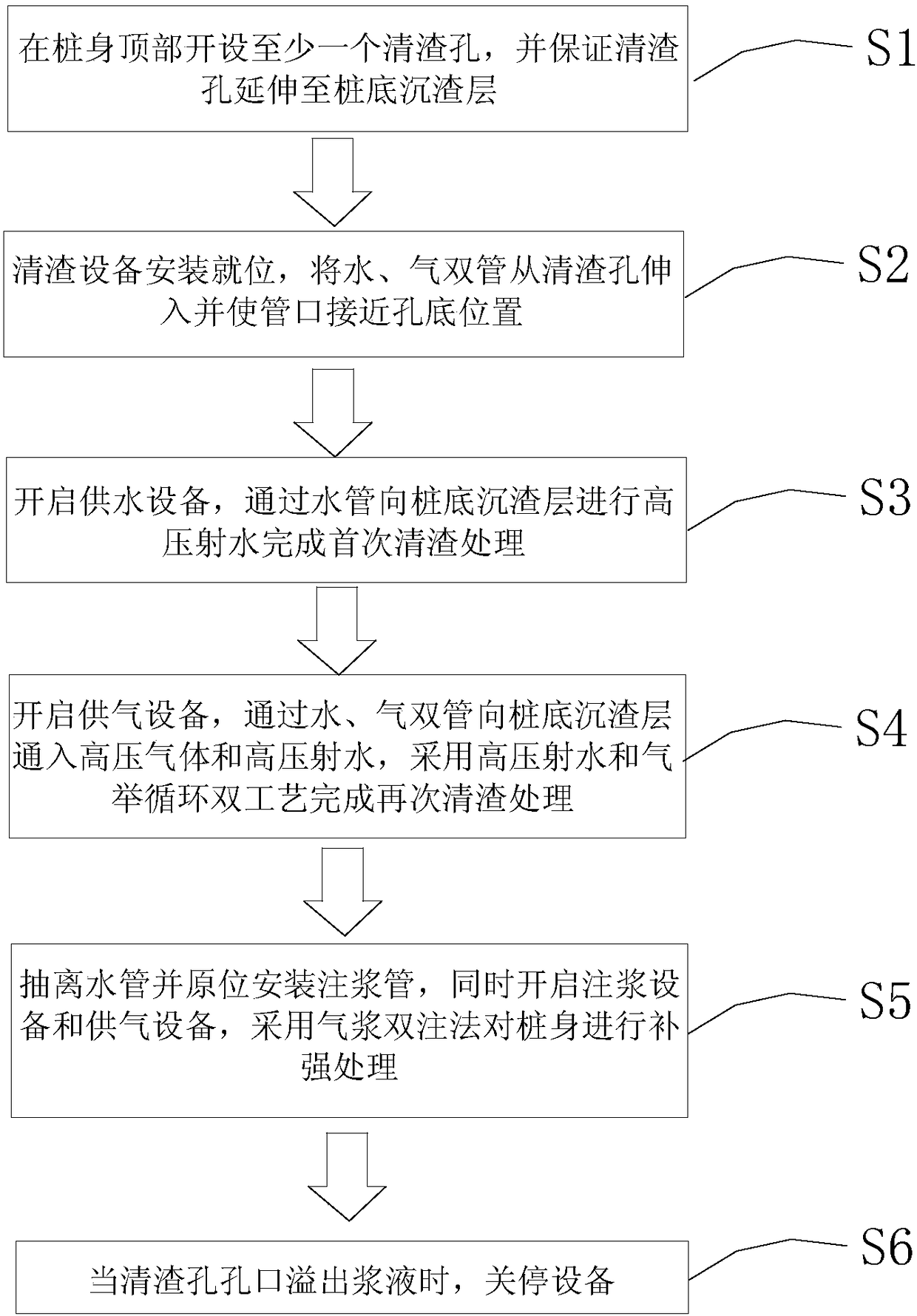

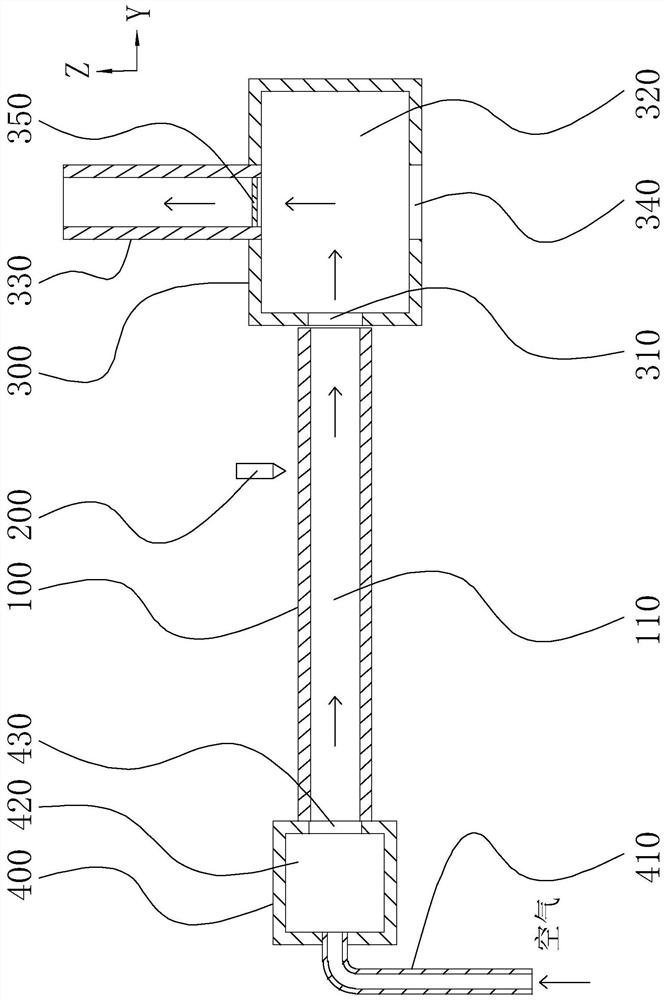

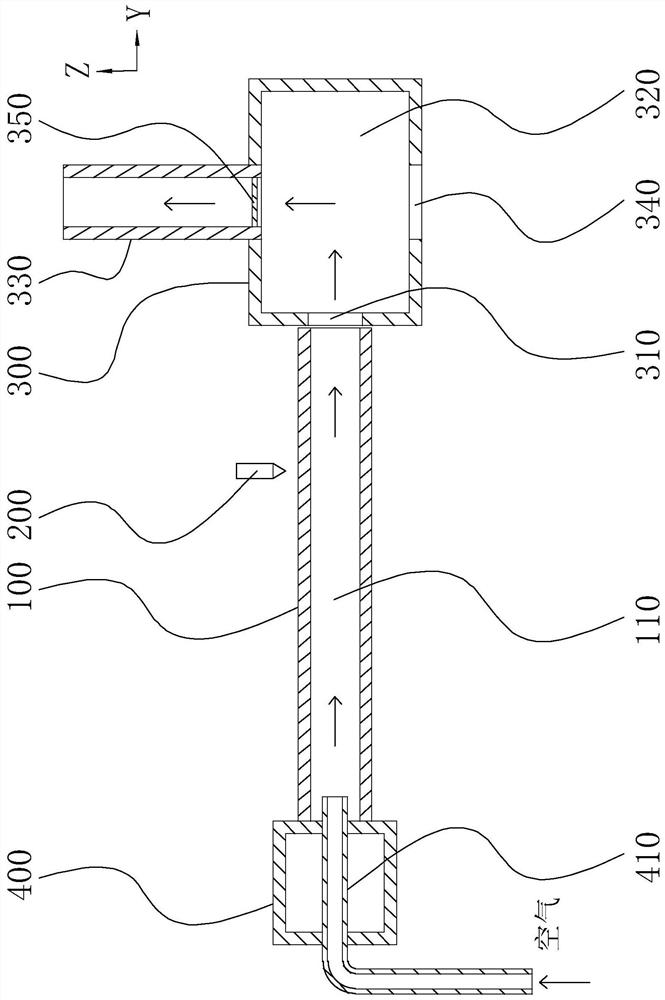

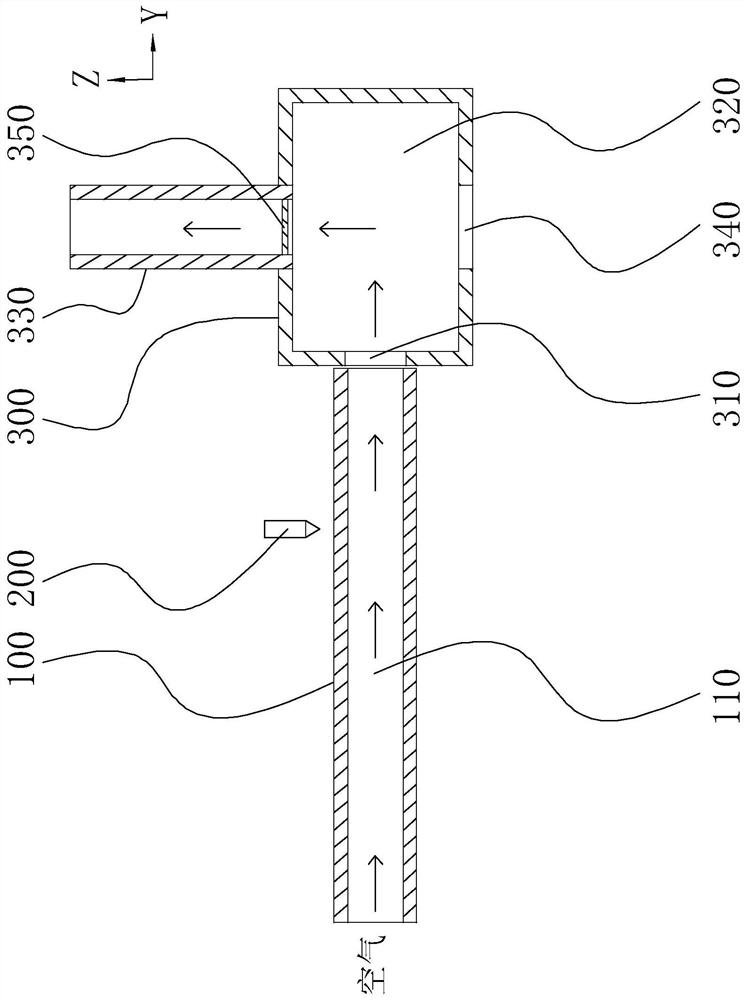

Reinforcement process method for pile bottom sediment removal of pouring pile

ActiveCN106120783AImprove structural strengthEfficient slag removalBulkheads/pilesEngineeringGas supply equipment

The invention discloses a reinforcement process method for pile bottom sediment removal of a pouring pile. The reinforcement process method comprises the following steps: forming at least one sediment removal hole in the top of a pile body, and ensuring that the sediment removal hole extends to a pile bottom sediment layer; installing sediment removal equipment in place, stretching a water tube and a gas tube from the sediment removal hole and enabling tube orifices to approach to a hole bottom position; starting water supply equipment, and carrying out high-pressure water jetting on the pile bottom sediment layer through the water tube to complete primary sediment removal treatment; starting gas supply equipment, charging a high-pressure gas in the pile bottom sediment layer and carrying out the high-pressure water jetting on the pile bottom sediment layer through the water tube and the gas tube, and completing secondary sediment removal treatment through the double processes of high-pressure water jetting and gas lift circulation; pulling away the water tube and installing a grouting tube in situ, starting grouting equipment and the gas supply equipment simultaneously, and carrying out reinforcement treatment on the pile body through a gas-injecting and grouting method; and stopping the equipment when a grout overflows from the orifice of the sediment removal hole. The reinforcement process method disclosed by the invention is capable of realizing efficient and thorough elimination for pile bottom sediments, good in sediment removal effect, and capable of increasing the structural strength of the pile body, meeting safety indexes, and meeting the requirements of construction technical indexes.

Owner:GUANGZHOU CITY LUBAN CONSTR

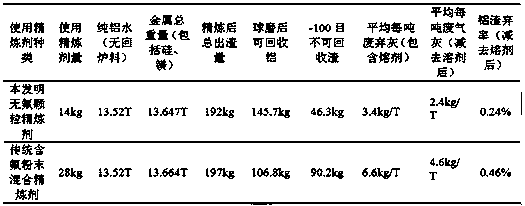

Fluoride-free particle refining agent for aluminum alloy, and preparation method of refining agent

The invention provides a fluoride-free particle refining agent for an aluminum alloy, and a preparation method of the refining agent. The refining agent is prepared from the following raw materials inpercentage by weight: 20-60% of MgCl<2> powder, 20-60% of KCl powder, 10-40% of CaCl<2> powder, and 10-40% of K<2>CO<3> powder. The aluminum loss is reduced, and the refining agent is a non-heating flux, so that aluminum oxidation can be reduced; the efficiency is high, and the reaction with molten aluminum is sufficient, so that the usage amount is greatly reduced; the refining agent is environment-friendly and free of smoke and dust in use, and does not contain harmful compounds, so that the emission level of particulate matters of a chimney can be guaranteed to reach the standard; the effect of removing alkali metals (Na, Ca and Li) and slags (oxide, boride and carbide) is obvious; and the impurity removal effect is good, and the cleanliness of the aluminum alloy produced with the method is higher.

Owner:HUNAN JINLIANXING SPECIAL MATERIALS CO LTD

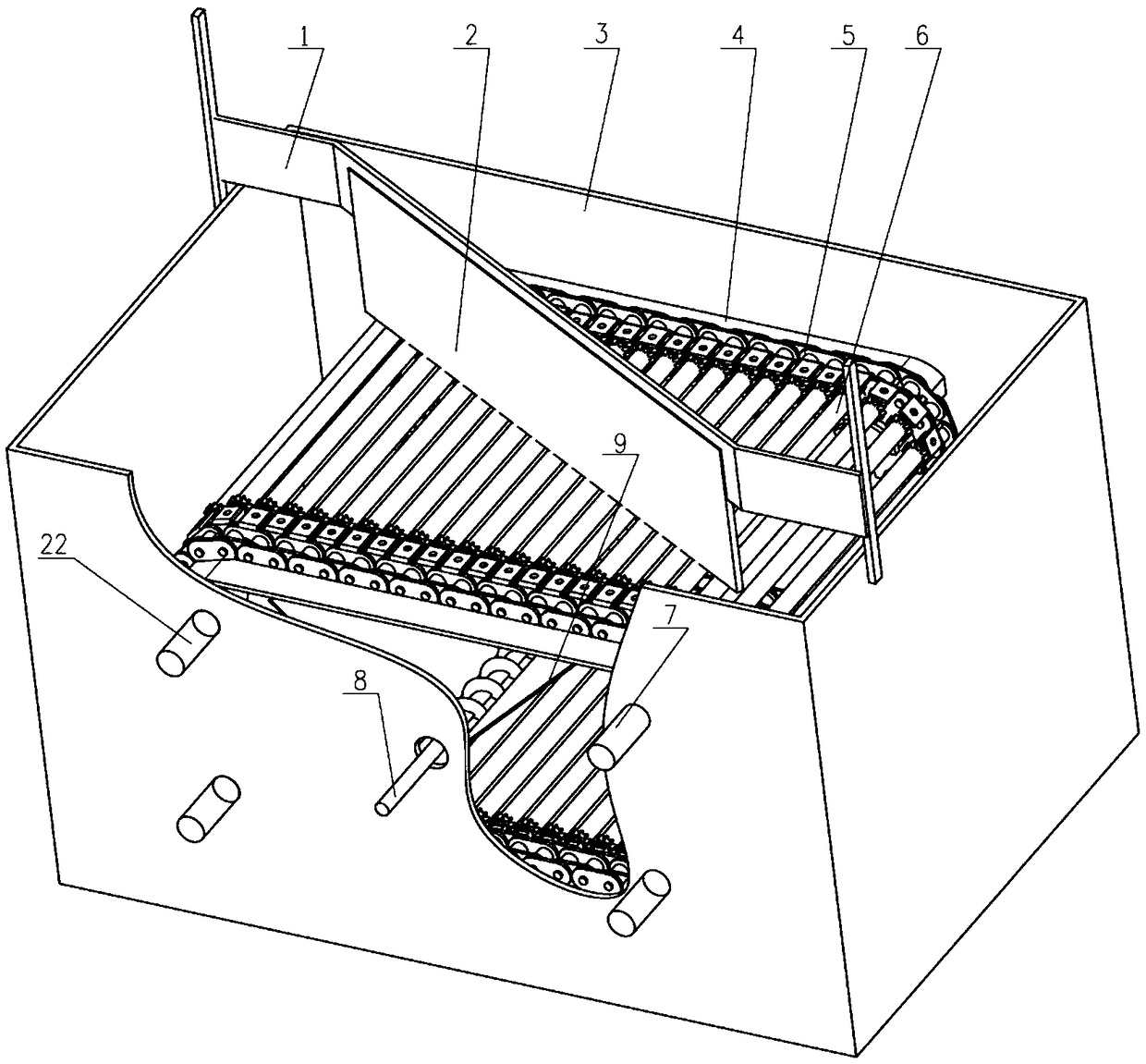

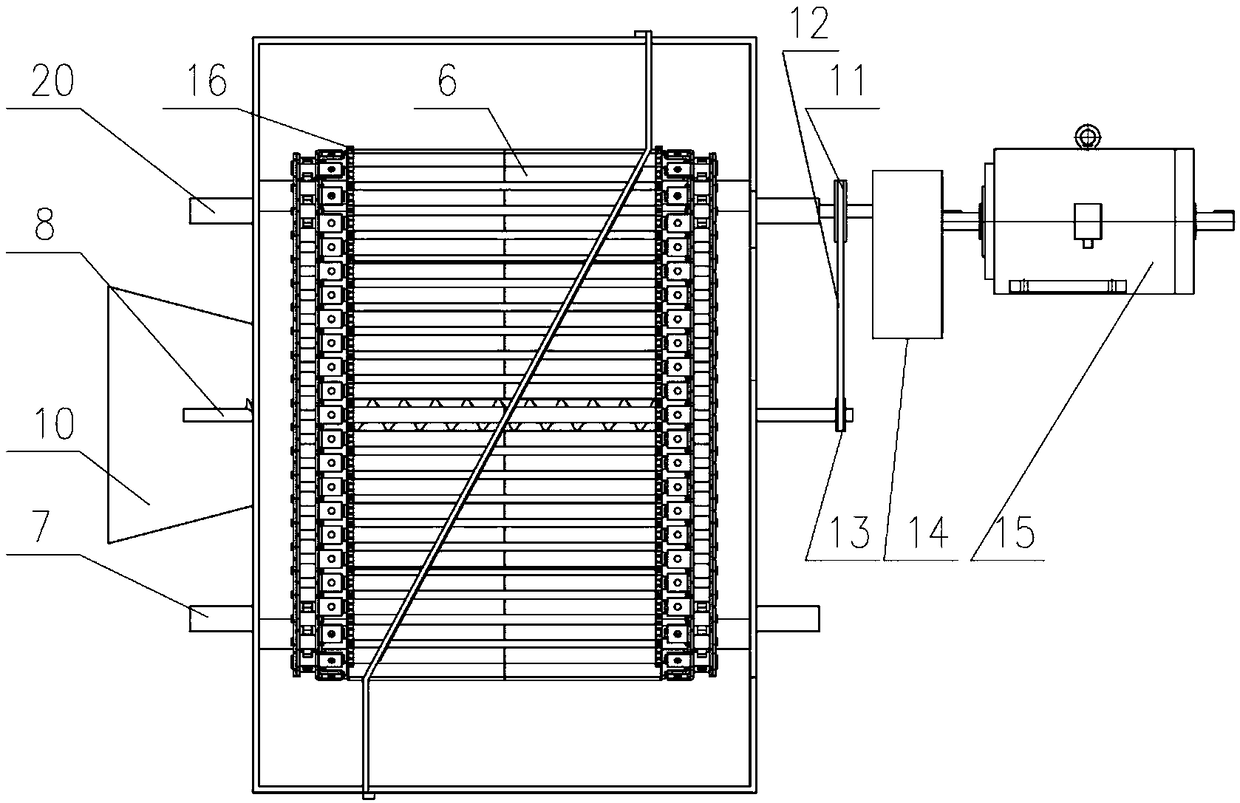

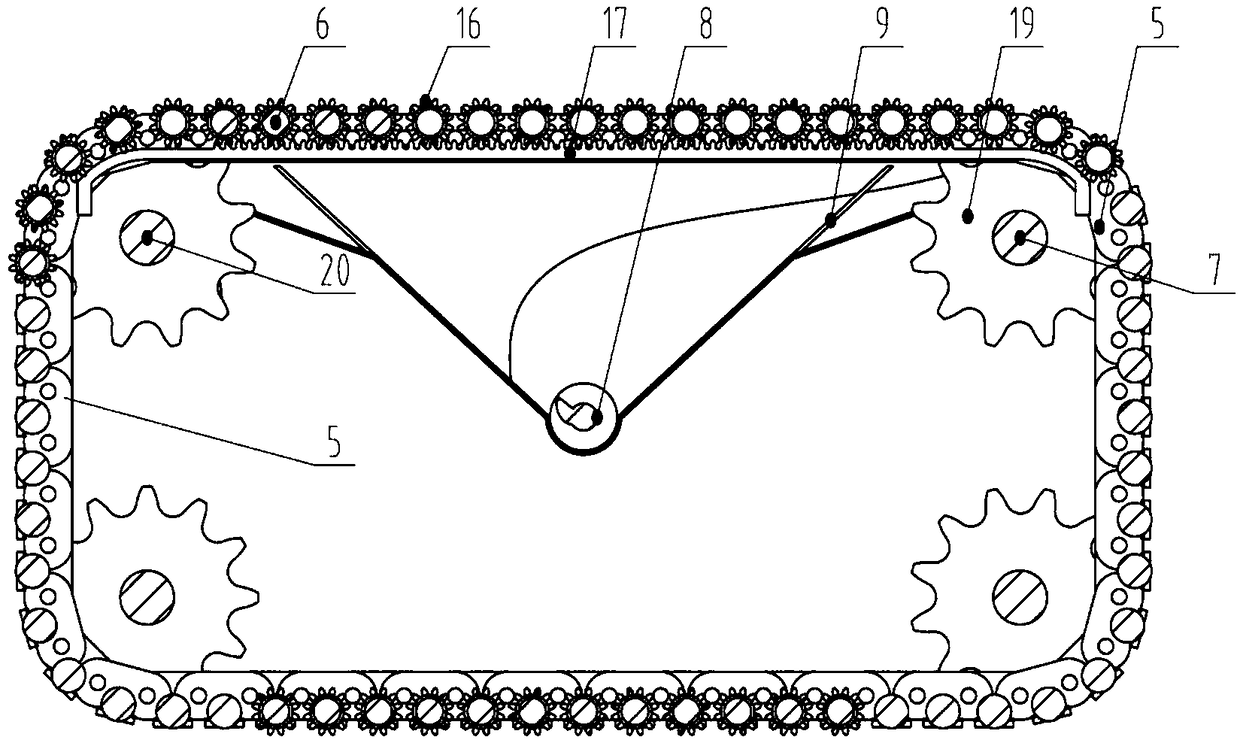

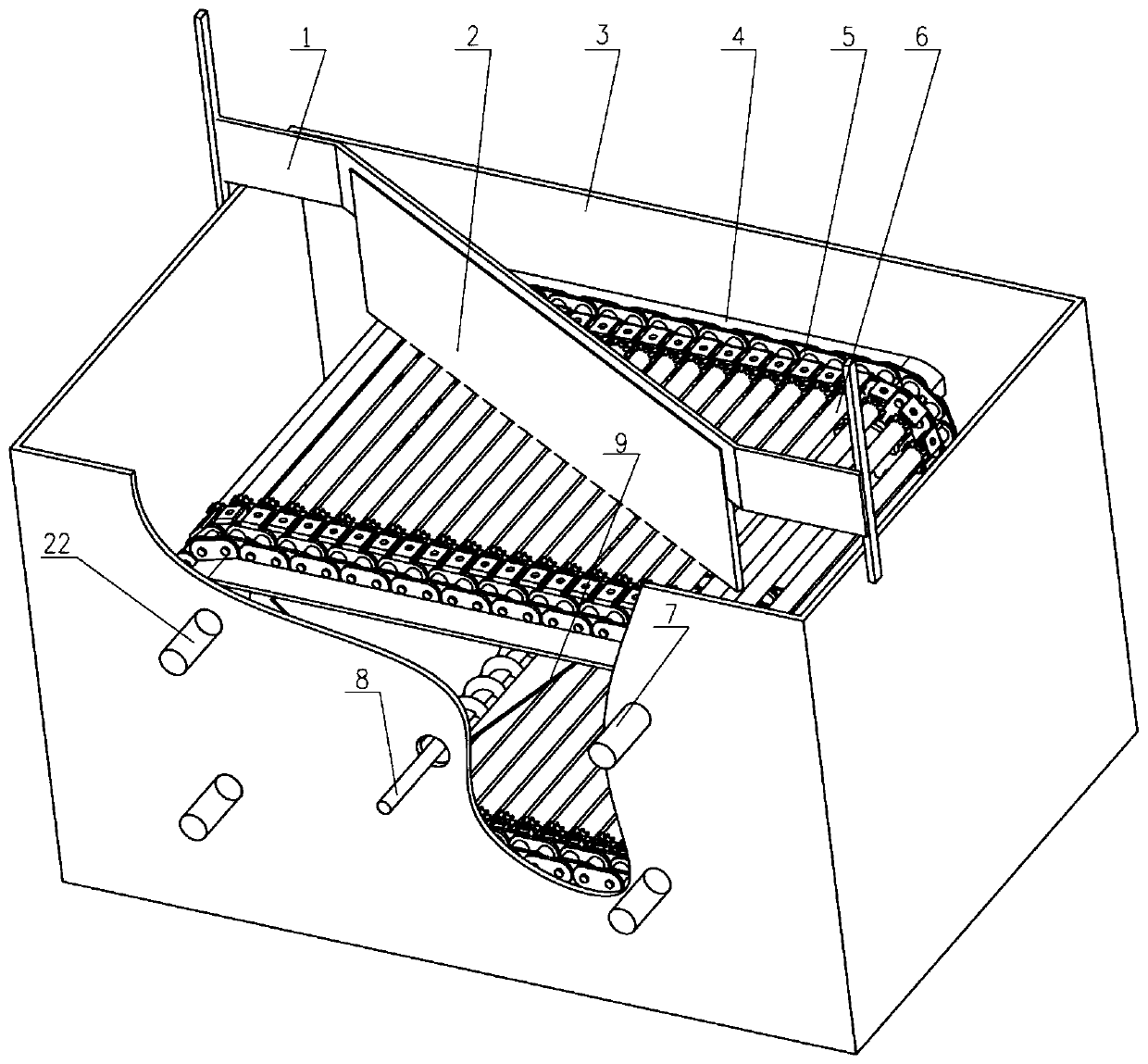

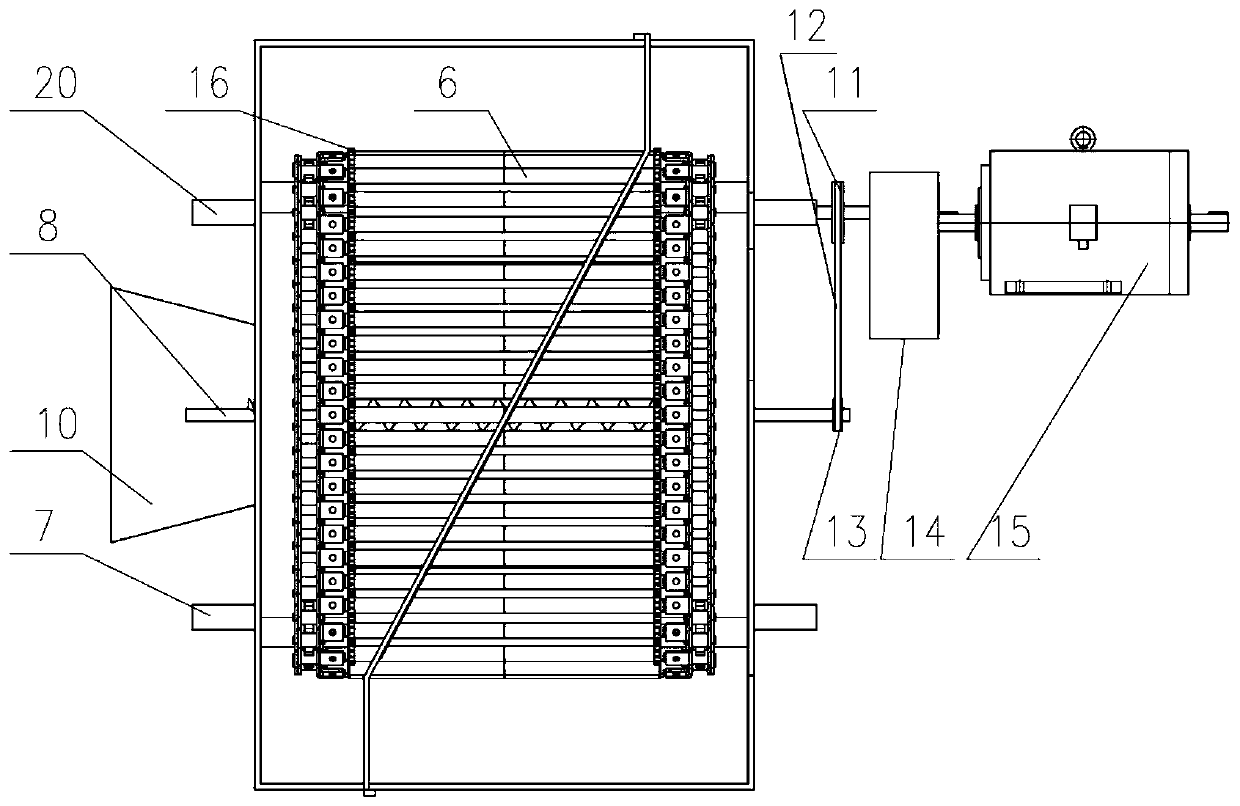

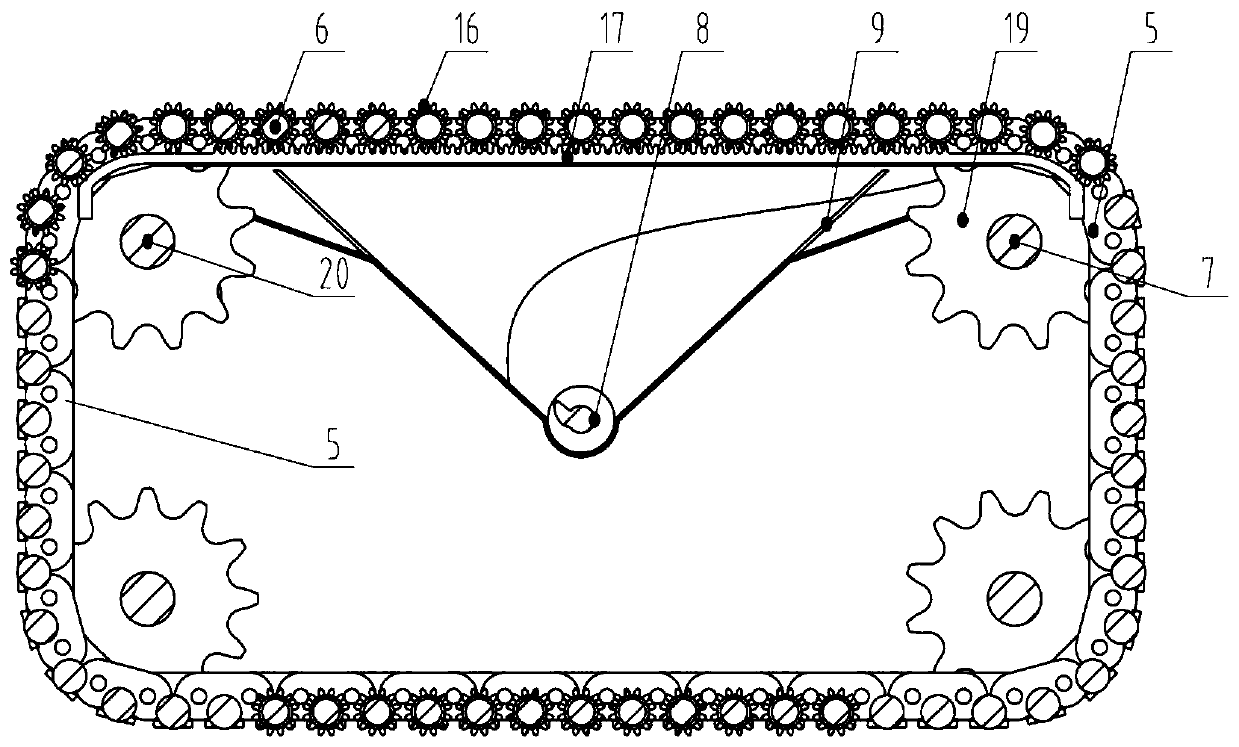

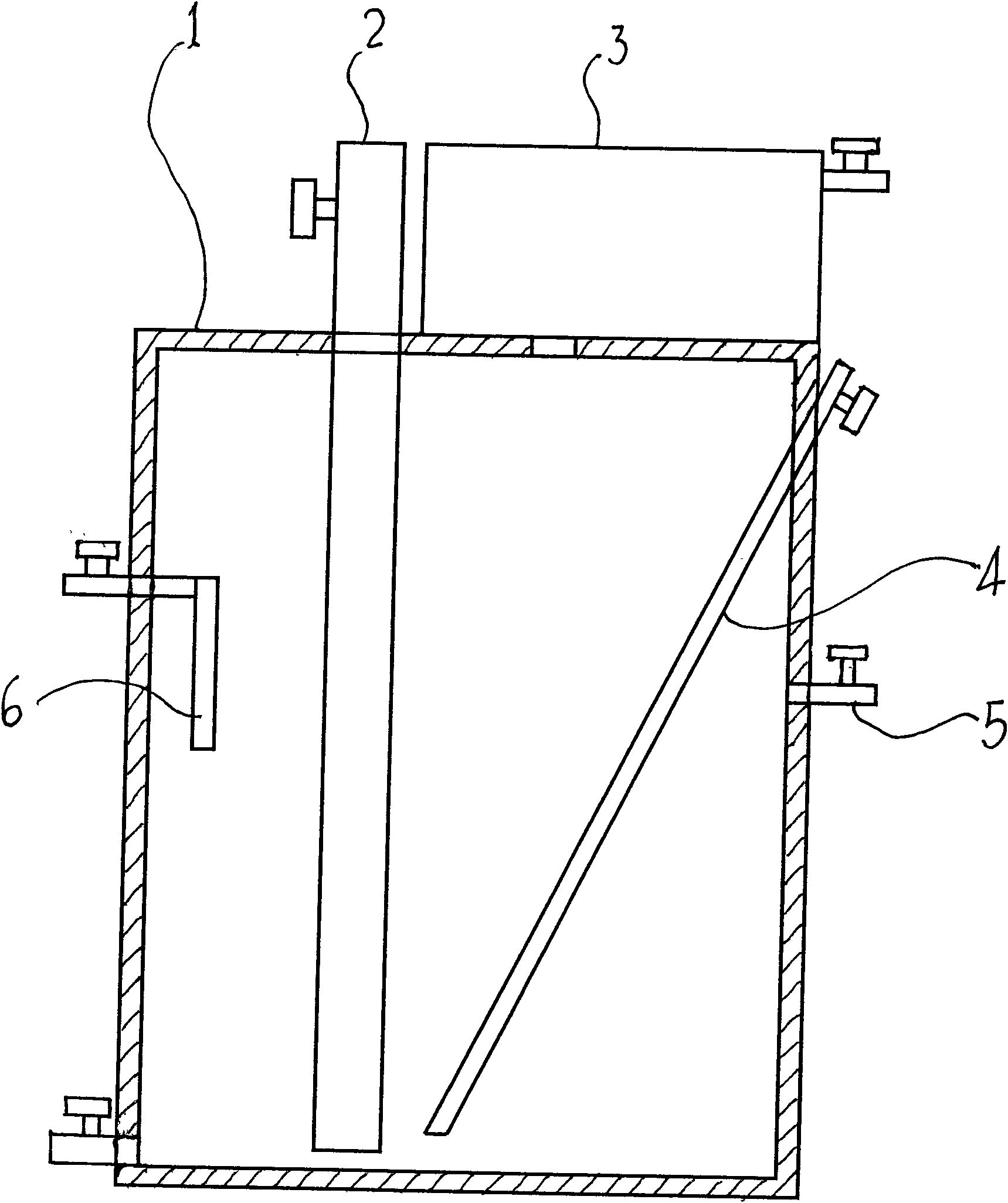

A magnetic bar self-rotation type permanent magnet filter

ActiveCN109201326ANot easy to wear and deformPrevent decontamination from being incompleteCleaning using toolsMagnetic separationMotor driveReciprocating motion

A magnetic bar self-rotation type permanent magnet filter is disclosed. A magnetic chain is driven by a motor drive mechanism to periodically reciprocate and to enter the liquid in a tank body used for storing cold rolling cooling liquid so that metal dust in the cooling liquid is adsorbed. A decontamination mechanism is disposed on the magnetic chain mechanism and is in contact with a decontamination segment, above the liquid level, of the reciprocating magnetic chain in a manner that the decontamination mechanism and the plane where the upper surface of the magnetic chain is are perpendicular to each other or arranged with a certain included angle, and in this process, each magnetic bar moves in a direction perpendicular to the length direction of the magnetic bar and rotates itself at the same time to scrape metal dust off the magnetic bar. Magnetic bar deformation or damage caused by rigid contact with the decontamination mechanism in a magnetic bar movement process, and device failure breakdown caused when the decontamination mechanism is stuck in the magnetic bar transmission chain can be prevented. In addition, the overall size of the device can be greatly reduced, the operation speed and follow-up effect of the magnetic chain mechanism are significantly improved, and the device has wider applicability.

Owner:WUHAN UNIV OF SCI & TECH

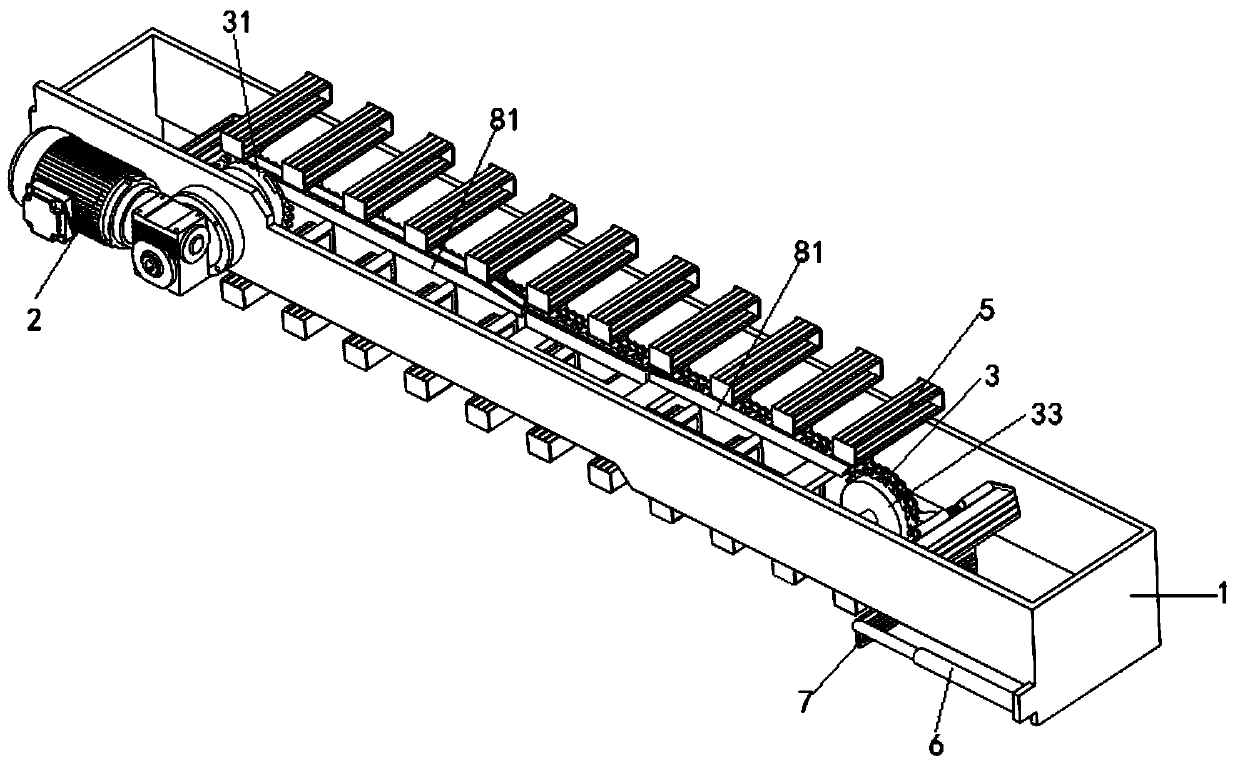

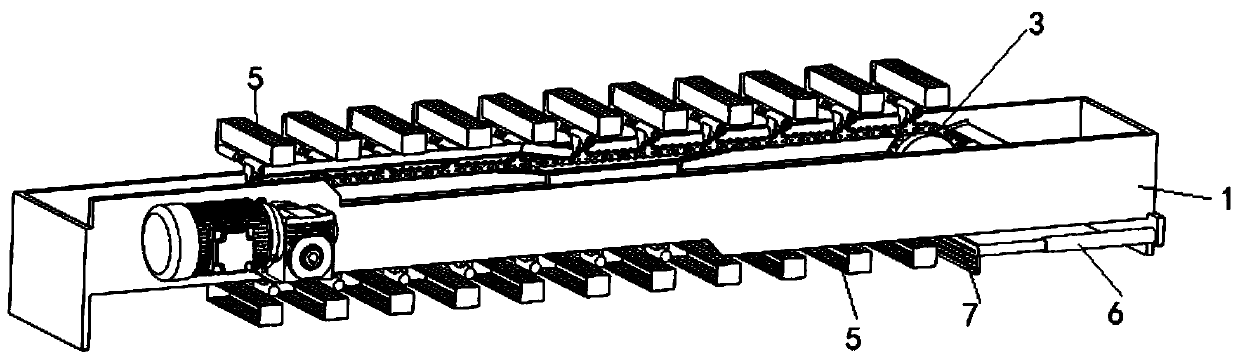

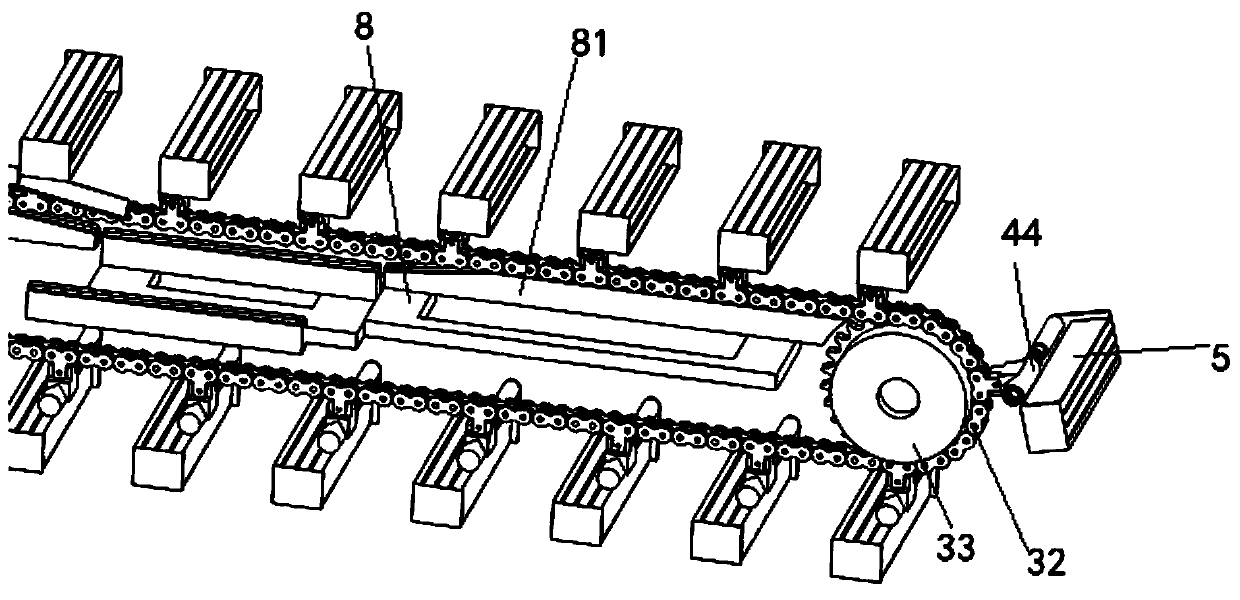

Waste slag fishing and conveying device for lead grid casting and use method thereof

InactiveCN110605381ARealize automatic fishingEfficient slag removalCasting cleaning apparatusProcess efficiency improvementHydraulic cylinderSlag

The invention discloses a waste slag fishing and conveying device for lead grid casting. The device is located in a lead grid casting device. The device comprises a base frame. A speed reduction motoris mounted on the outer surface of the rear side wall of the base frame. Meanwhile the speed reduction motor is connected with a chain transmission mechanism. A plurality of fixing seats are mountedon the chain transmission mechanism at equal intervals. A fishing seat is fixedly mounted on each fixing seat. Meanwhile a hydraulic cylinder is mounted on the left side wall of the base frame. A material pushing plate is fixedly mounted at the power output end of the hydraulic cylinder. According to the waste slag fishing and conveying device, the fishing seats are moved in the lead grid castingdevice through the chain transmission mechanism, so that automatic fishing of the waste residues is realized, the fished waste residues are directly and automatically dumped out and stacked on a discharge port and then can be pushed out through the material pushing plate, efficient slag fishing is achieved, and the working efficiency is improved.

Owner:ANHUI NARADA RENEWABLE RESOURCE TECH CO LTD

High-vanadium steel continuous casting flame cutting process

The invention discloses a high-vanadium steel continuous casting flame cutting process. The high-vanadium steel continuous casting flame cutting process includes the following steps of preheating, wherein preheating oxygen and fuel gas are conveyed to a cutting gun, the fuel gas is ignited to form preheating flames, and a casting blank is preheated; precutting, wherein combustion supporting oxygenand fuel gas are conveyed to the cutting gun, the preheating oxygen stops being conveyed, cutting flames are formed, and the lengths of the flames are adjusted until the flames penetrate through thecasting blank; and cutting, wherein when the flames penetrate through the casting blank and slag flows to a slag removal tank, the cutting gun is moved and a slag removal gun is started until cuttingoperation is completed, the lengths of the flames can be adjusted according to the thickness of the casting blank, the distances between the flames are matched with the thickness of the casting blank,and the cutting quality of the casting blank is guaranteed.

Owner:SICHUAN DESHENG GRP VANADIUM & TITANIUM CO LTD

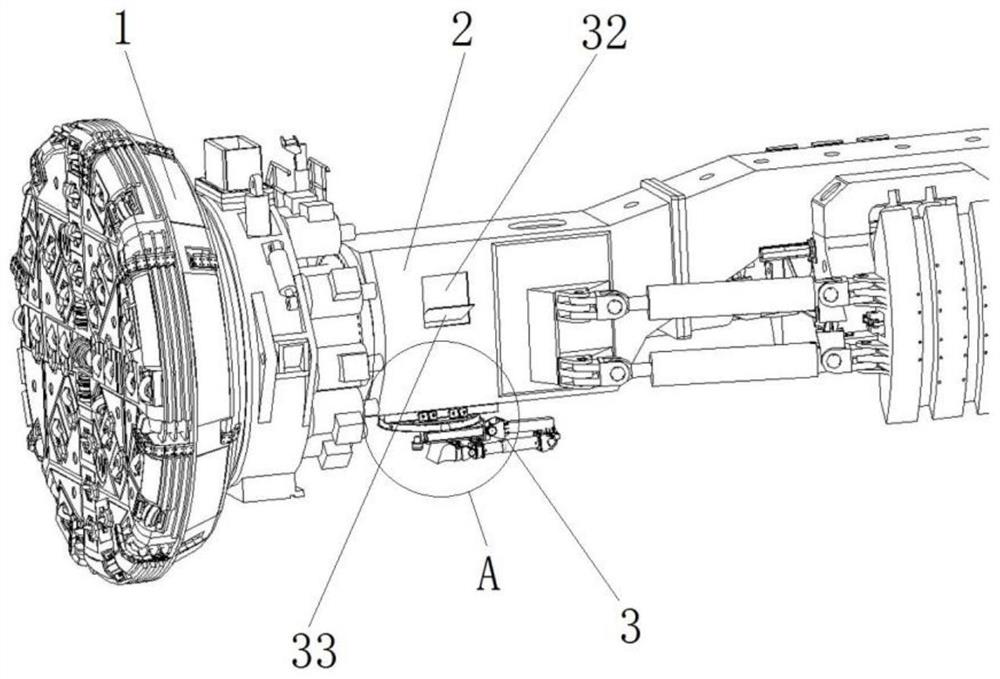

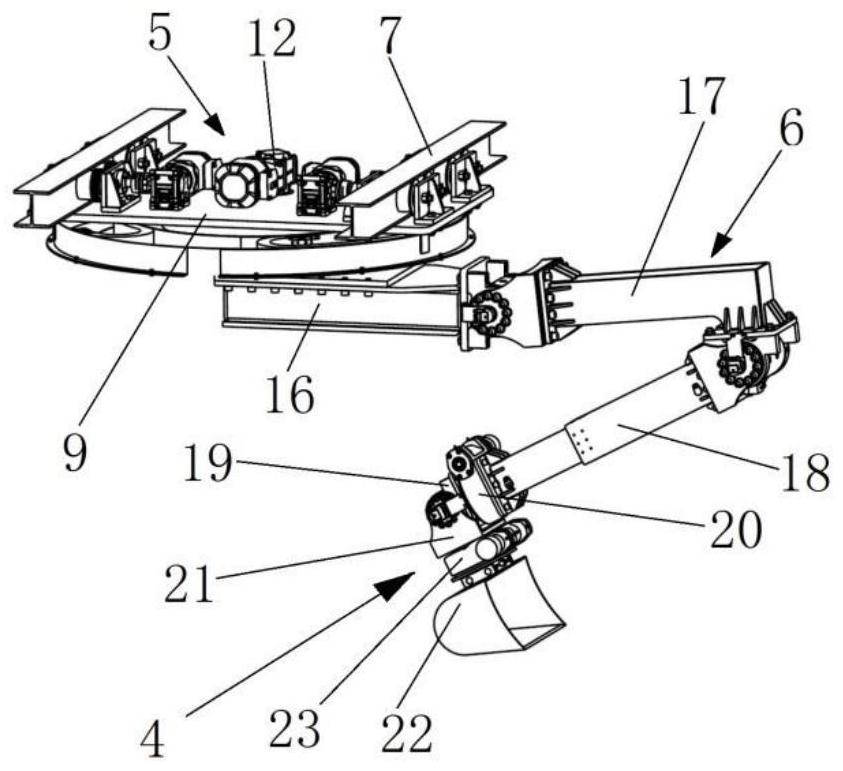

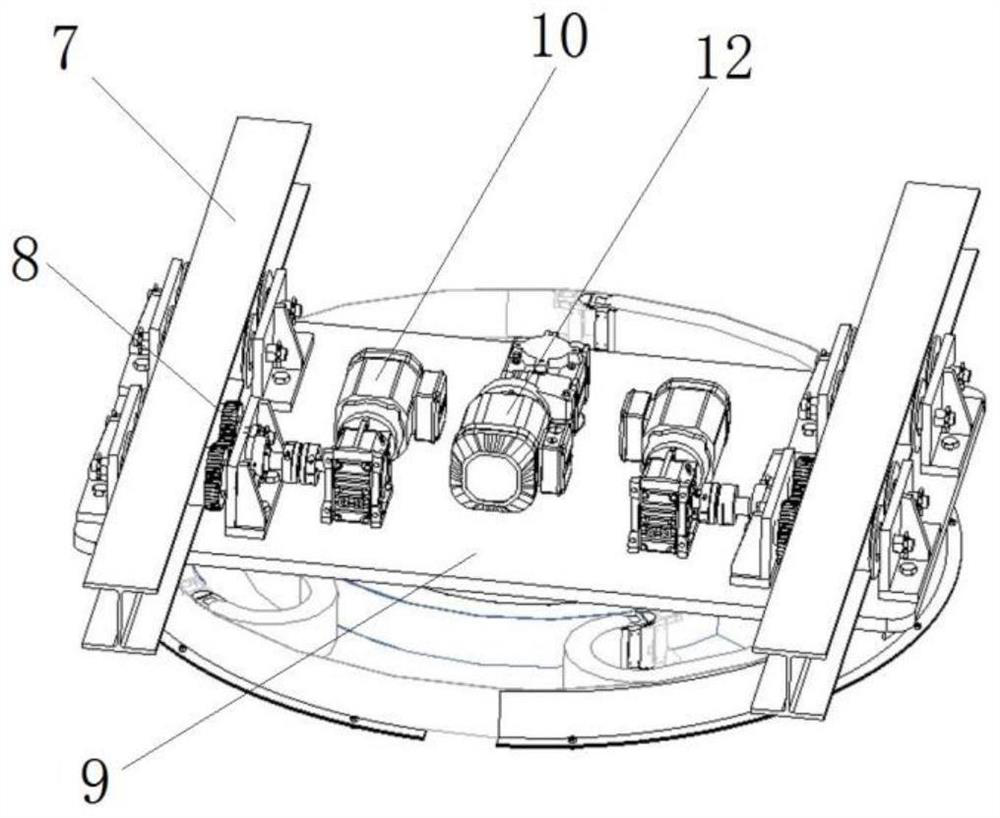

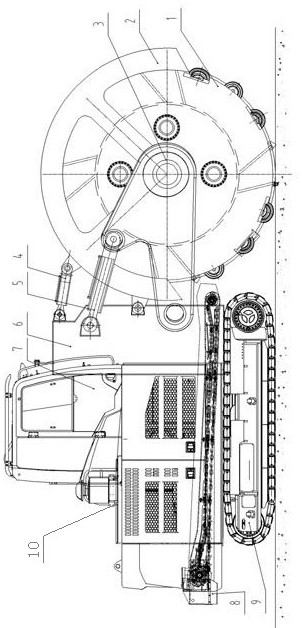

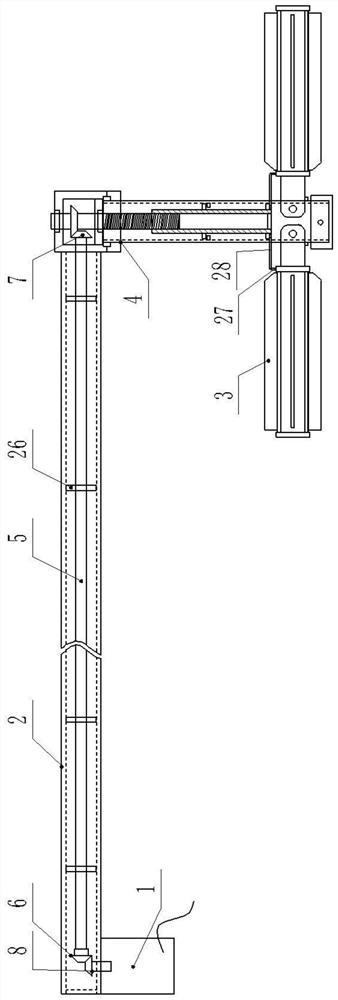

Tunneling machine slag removing device and tunneling machine

The invention belongs to the field of tunnel excavation equipment, and particularly relates to a tunneling machine slag removal device and a tunneling machine. The tunneling machine comprises a cutter head, a main beam connected to the cutter head, an equipment bridge located on the rear side of the main beam and a slag conveyor, and further comprises a slag removal device with a slag removal mechanical arm and a slag removal hopper; the slag removal mechanical arm comprises a connecting base connected with the main beam and / or the equipment bridge and a movable arm hinged to the connecting base, the movable arm comprises at least two arm sections, driving devices for driving the corresponding arm sections to be unfolded and folded are arranged between the arm sections and the connecting base and between the arm sections, and the slag removal hopper is connected to the last-stage arm section. The active slag removal hopper can be driven by a slag removal mechanical arm to actively take slag, the slag removal hopper is provided with a slag discharging position for feeding the taken slag into a slag conveyor on a main beam of the heading machine, and the slag removal hopper is provided with a discharging door and a discharging driving device. Or a material pouring driving device for driving the slag removal hopper to pour out the slag is arranged between the slag removal hopper and the slag removal mechanical arm, so that automatic slag removal is realized.

Owner:CHINA RAILWAY ENGINEERING EQUIPMENT GROUP CO LTD

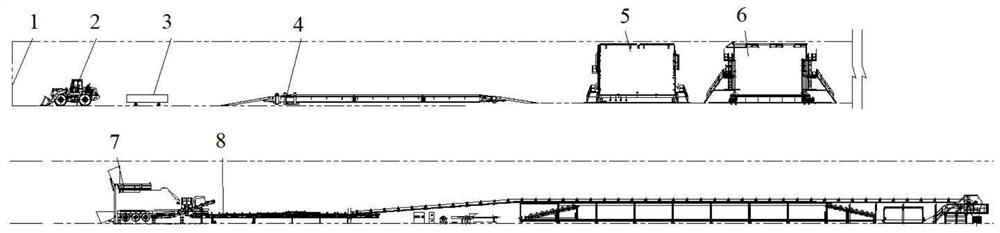

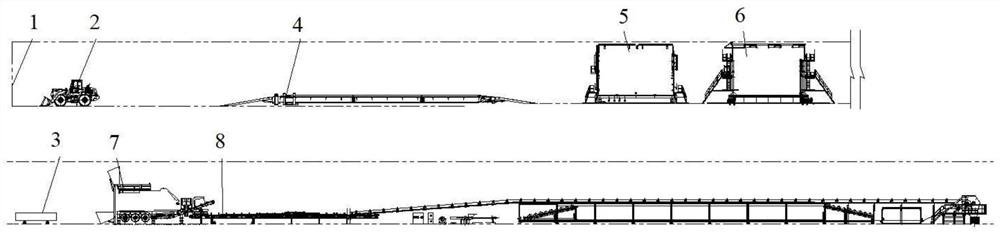

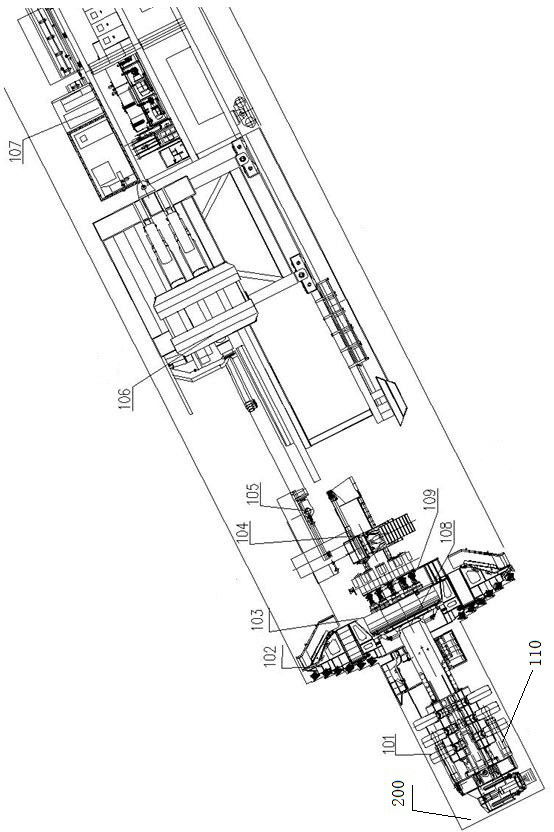

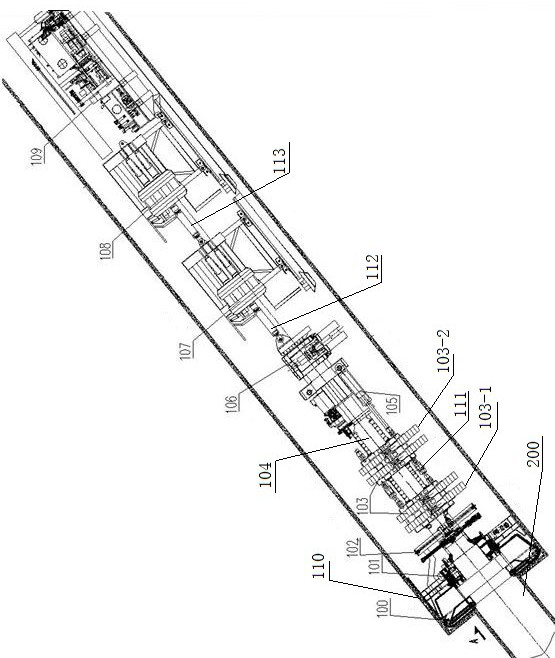

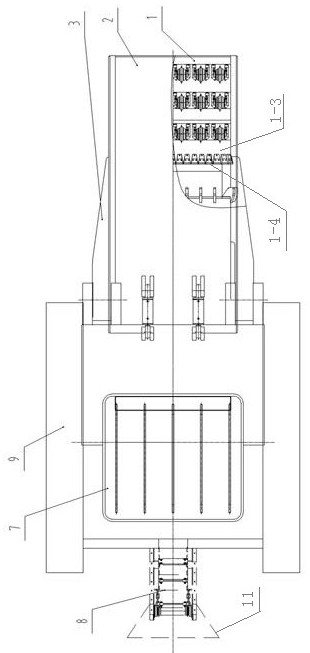

Drilling and blasting method construction muck discharging system

InactiveCN111894622AGuaranteed short distance luckReduce dependencyTunnelsMuckMechanical engineering

The invention discloses a drilling and blasting method construction muck discharging system. The system comprises a muck soil transferring device and a conveyor which are arranged from front to back in the preset linear direction, the conveying direction of the conveyor is the front-back direction, and the conveyor is a conveyor capable of stretching out and drawing back front and back. Accordingto the system, drilling and blasting method equipment and the telescopic conveyor are arranged in a combined mode, in the normal conveying process, full-process tunnel deslagging is completed throughrelay of the muck soil transferring device and the conveyor, the material receiving end of the conveyor can move forwards continuously along with the muck soil transferring device, short-distance transferring of the muck soil transferring device is guaranteed all the time, and therefore guarantee is provided for efficient deslagging, the conveyor is arranged at the position of a safety area, complex procedures such as evacuation during blasting are not needed, the ballast discharging efficiency can be effectively improved, the dependence on a ballast soil transferring device is reduced, and the ballast discharging safety is improved.

Owner:CHINA RAILWAY CONSTR HEAVY IND

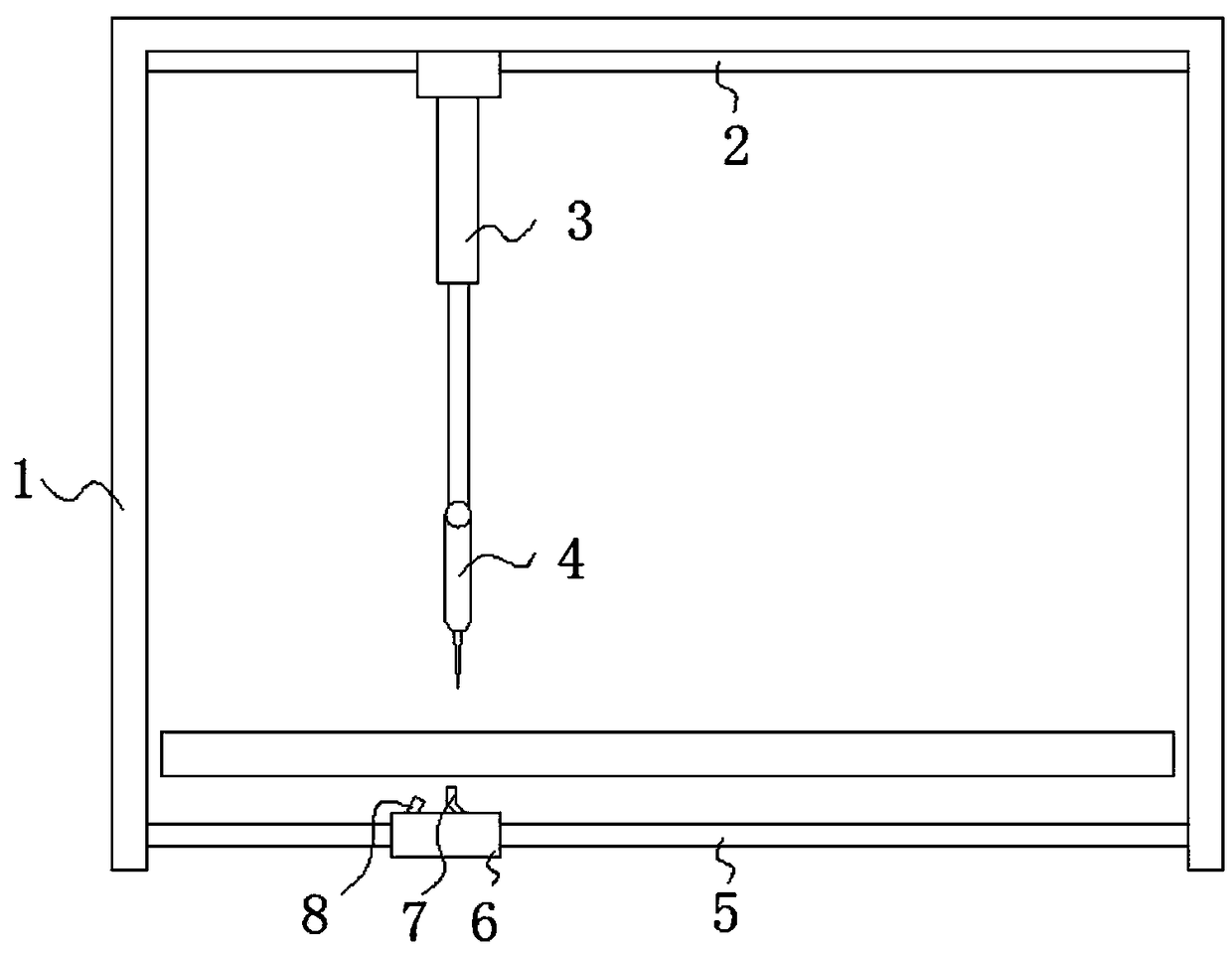

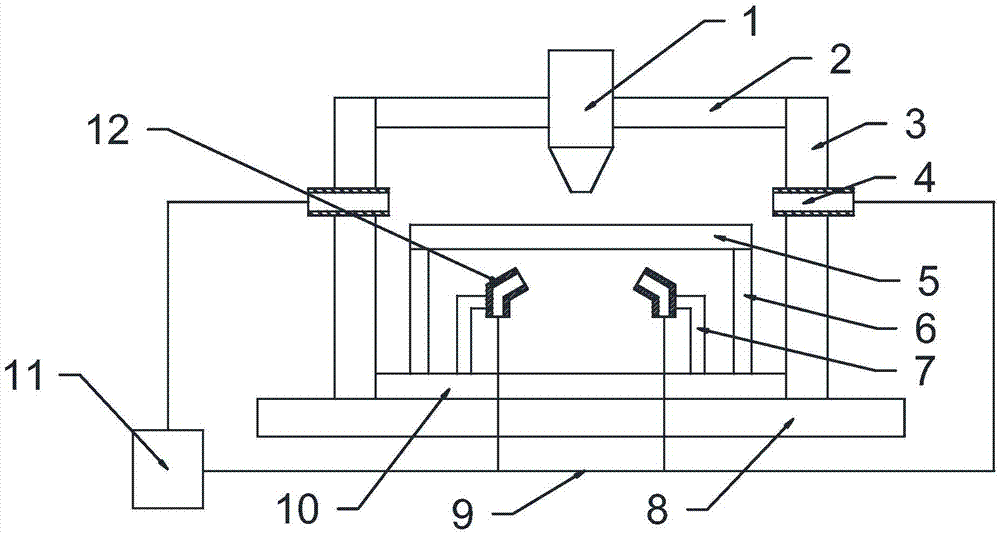

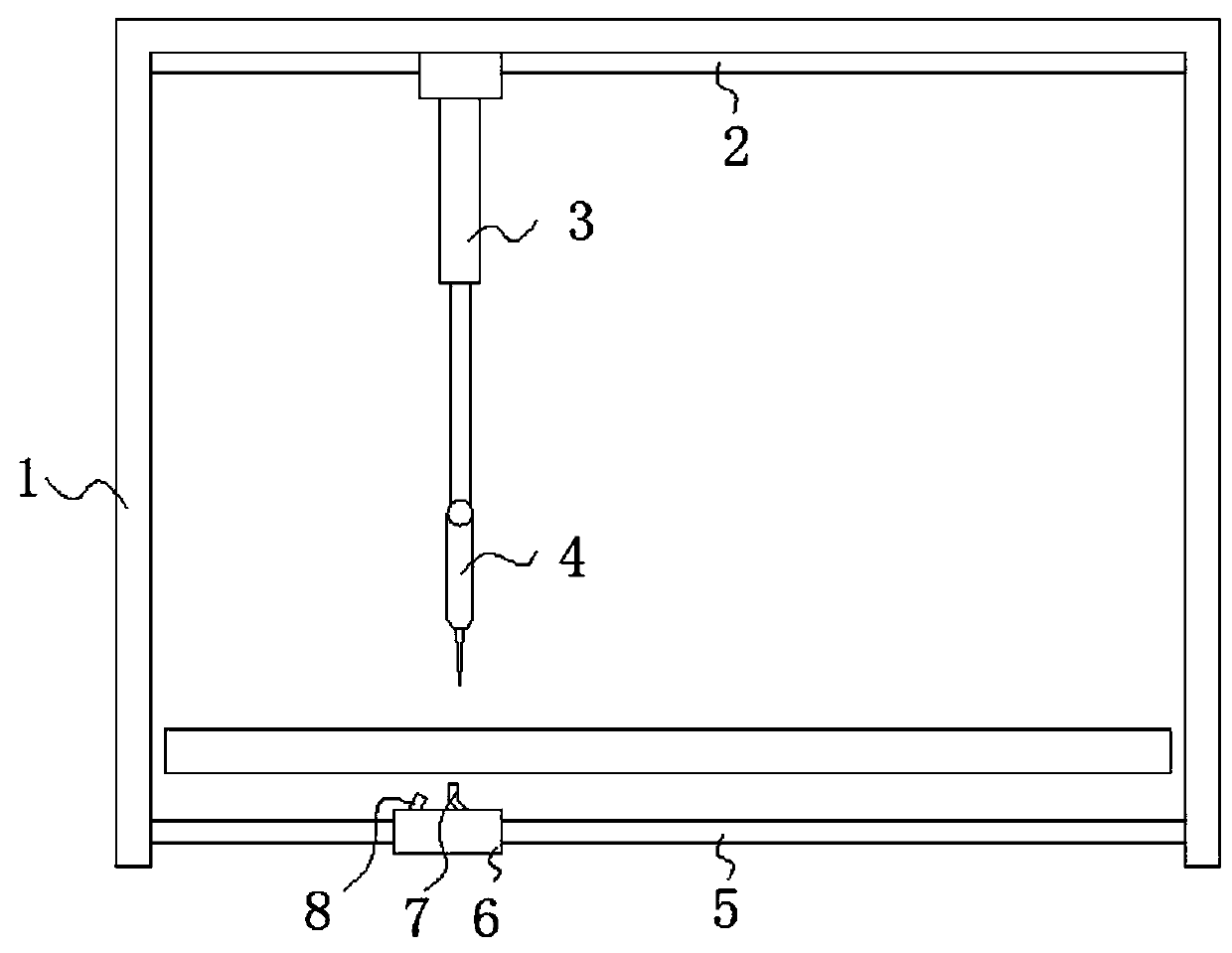

Auxiliary residue removing device for laser cutting machining

InactiveCN105436705AGuaranteed smoothnessImprove processing efficiencyLaser beam welding apparatusNumerical controlEngineering

An auxiliary residue removing device for laser cutting machining comprises a first numerical control moving platform, a second numerical control moving platform, a laser head, a workbench and a base. The laser head is located over the workbench and hung on the first numerical control moving platform. The first numerical control moving platform is fixed to the base through a rack. The second numerical control moving platform is located on the base. The auxiliary residue removing device further comprises two first nozzles symmetrically arranged under the workbench, and the directions of the first nozzles are opposite. The first nozzles are connected with the second numerical control moving platform through nozzle supports. Hinge structures are arranged between the first nozzles and the nozzle supports. The first nozzles are connected with a gas pressurizing device through an auxiliary gas pipe. The auxiliary residue removing device further comprises two second nozzles symmetrically arranged at the two ends of the rack, and hinge structures are arranged between the second nozzles and the rack. The auxiliary residue removing device is reasonable in structural design, and an efficient residue removing effect can be achieved.

Owner:江苏德佳机电科技有限公司

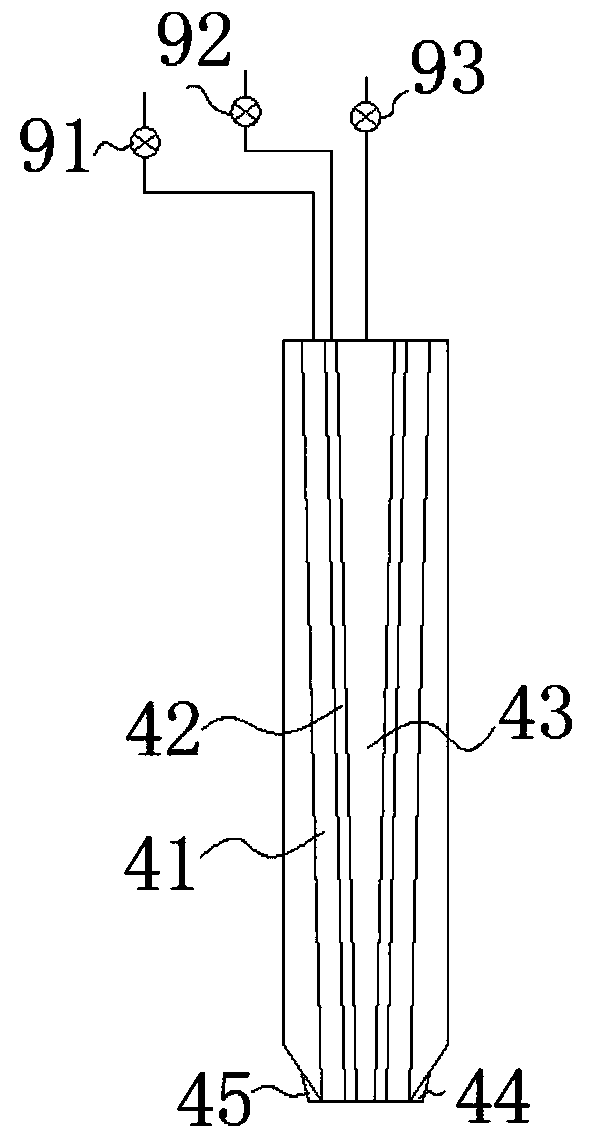

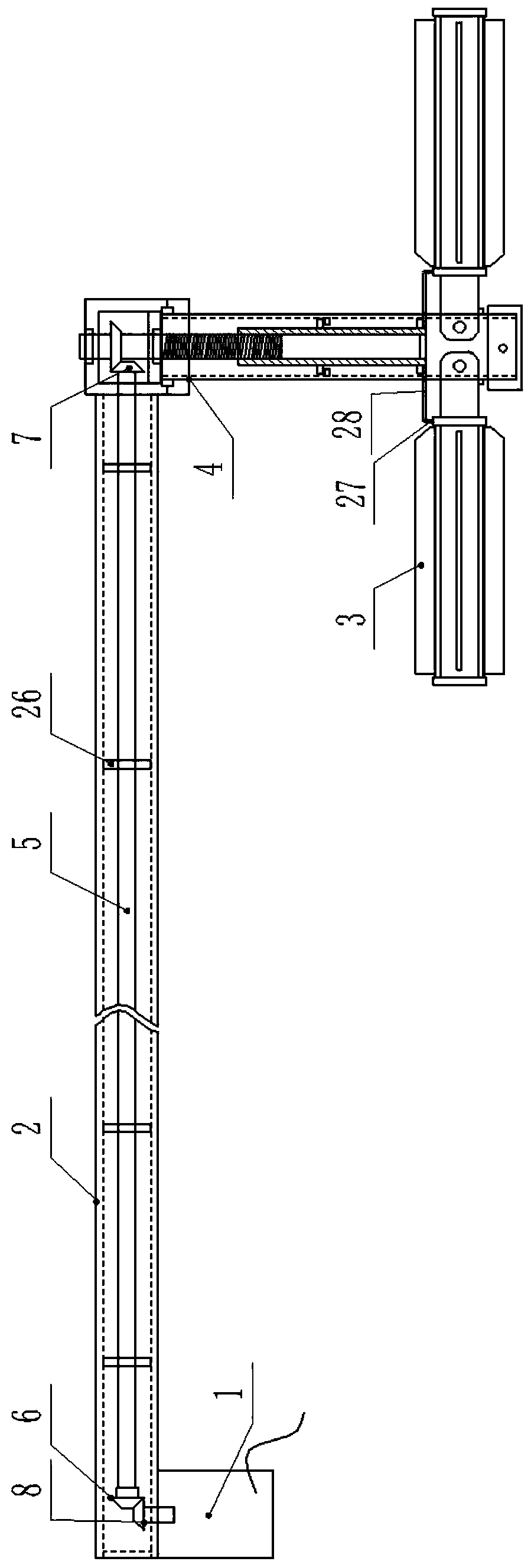

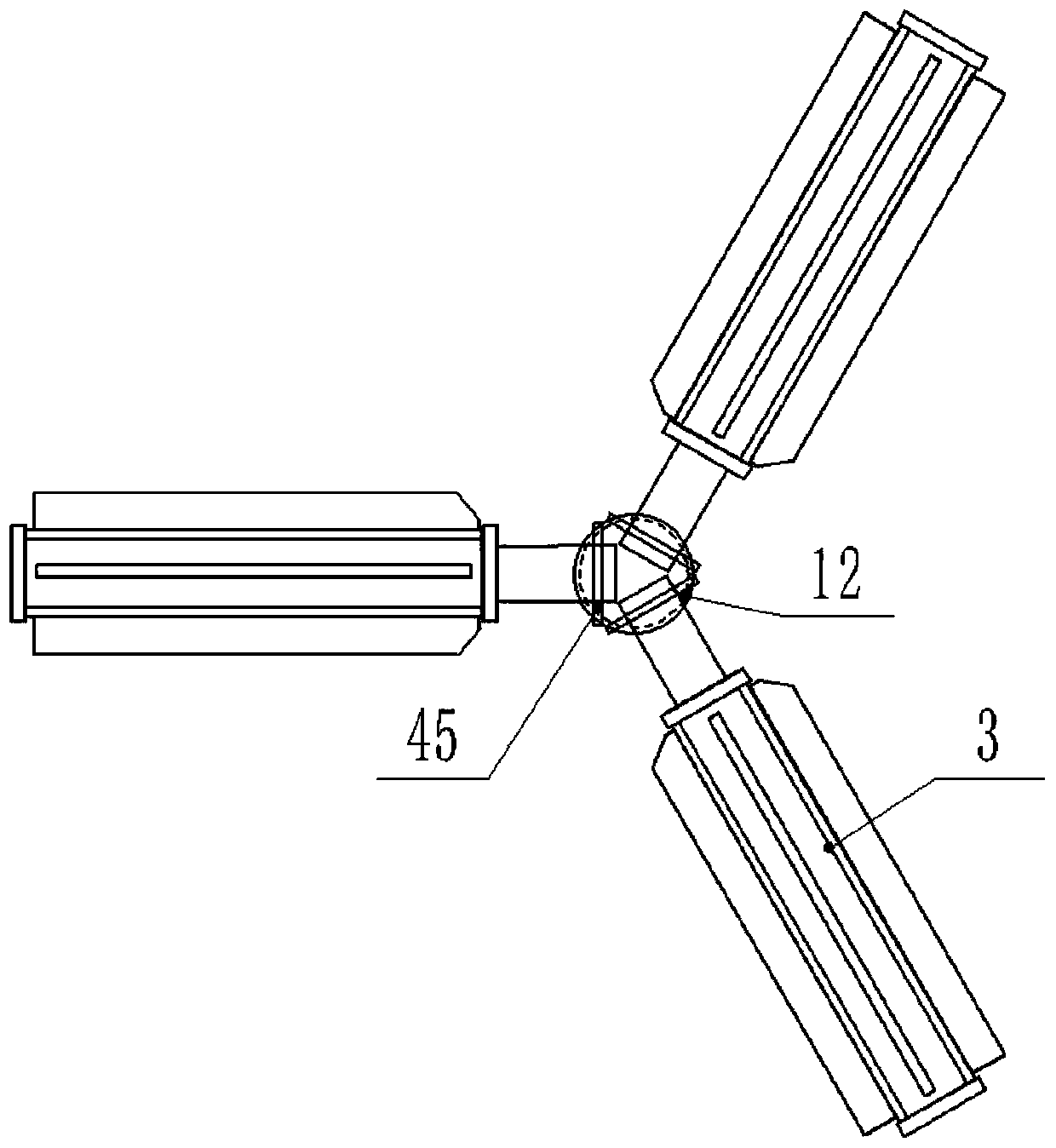

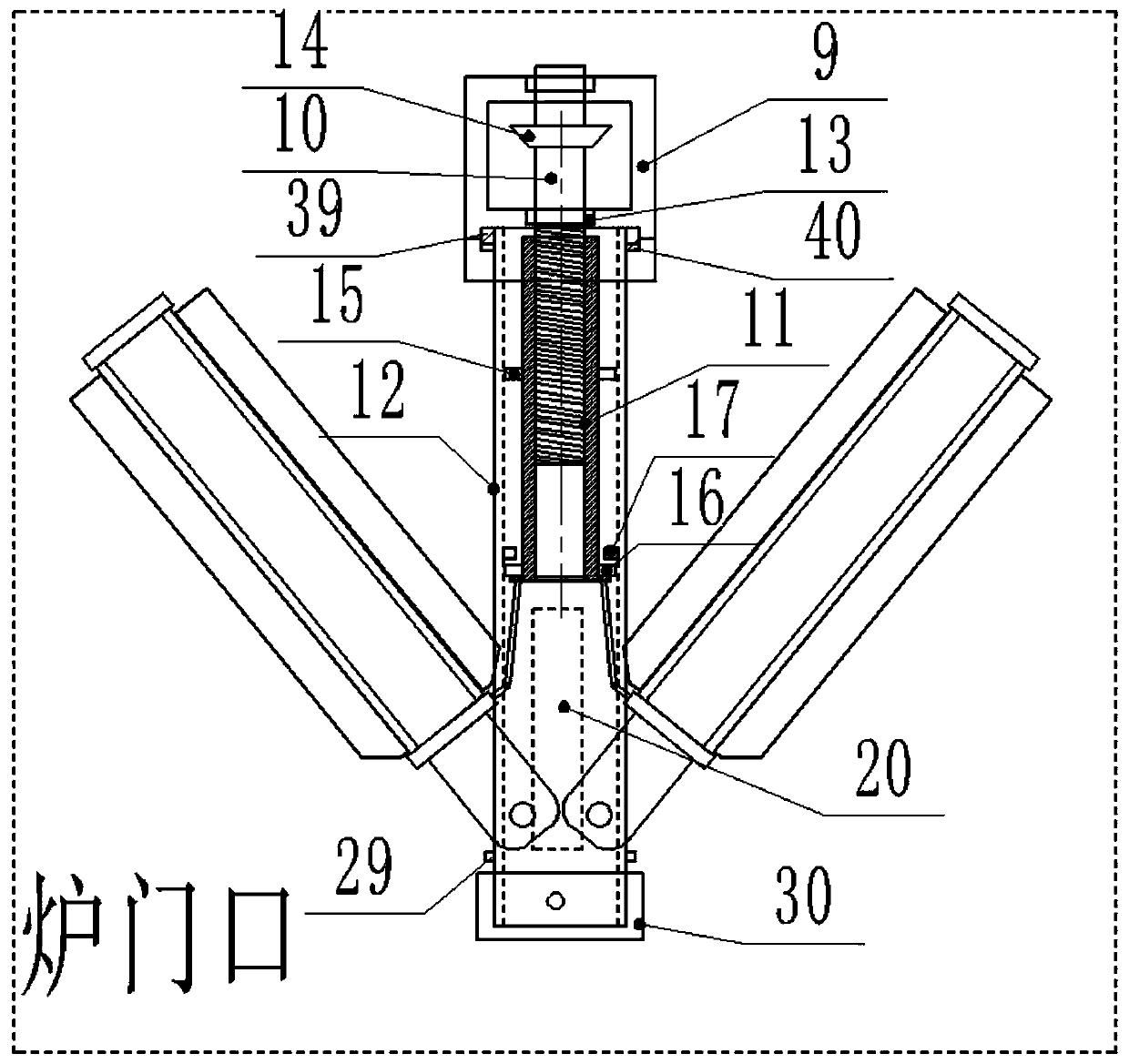

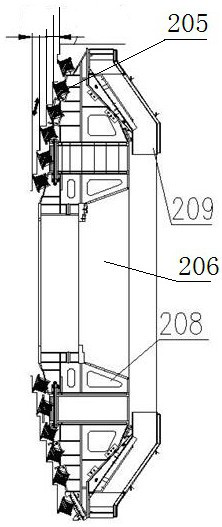

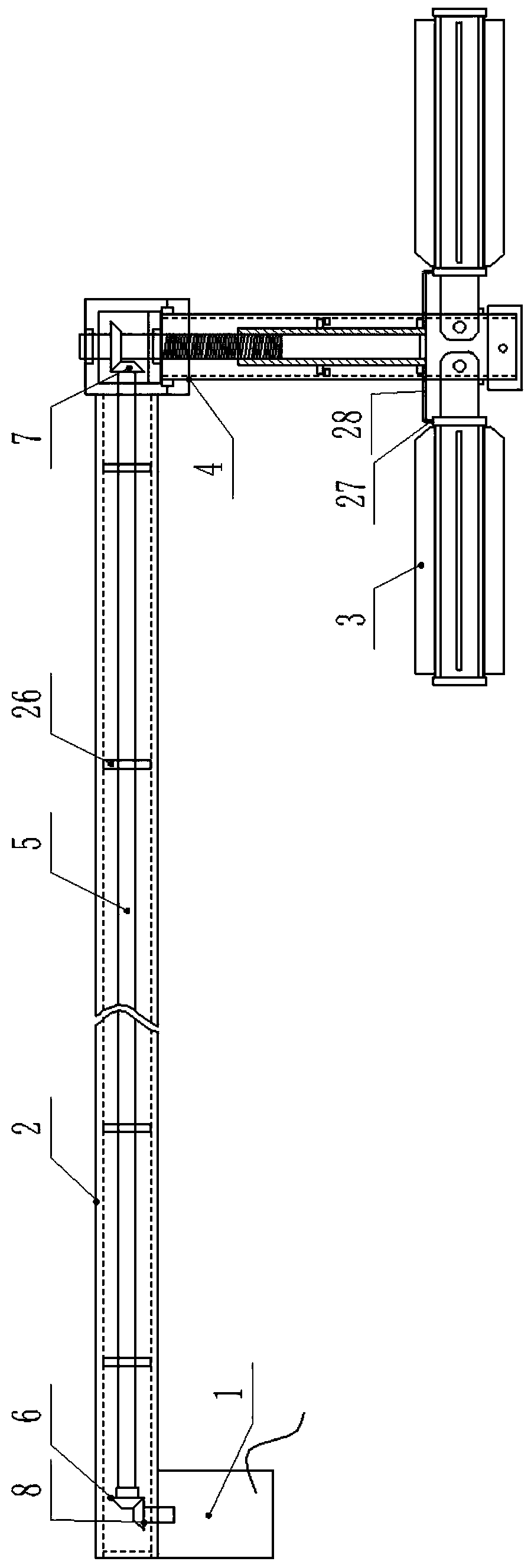

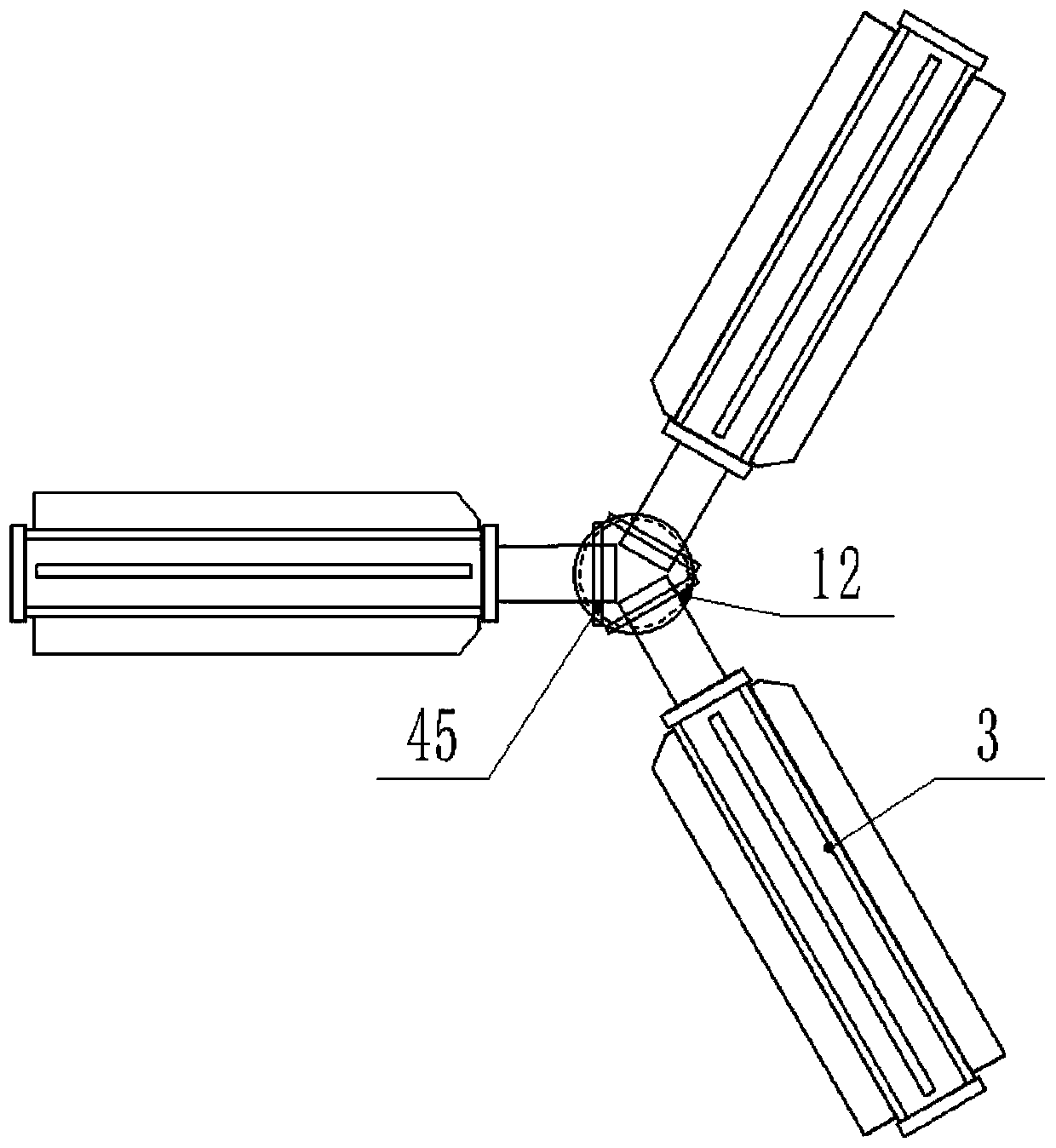

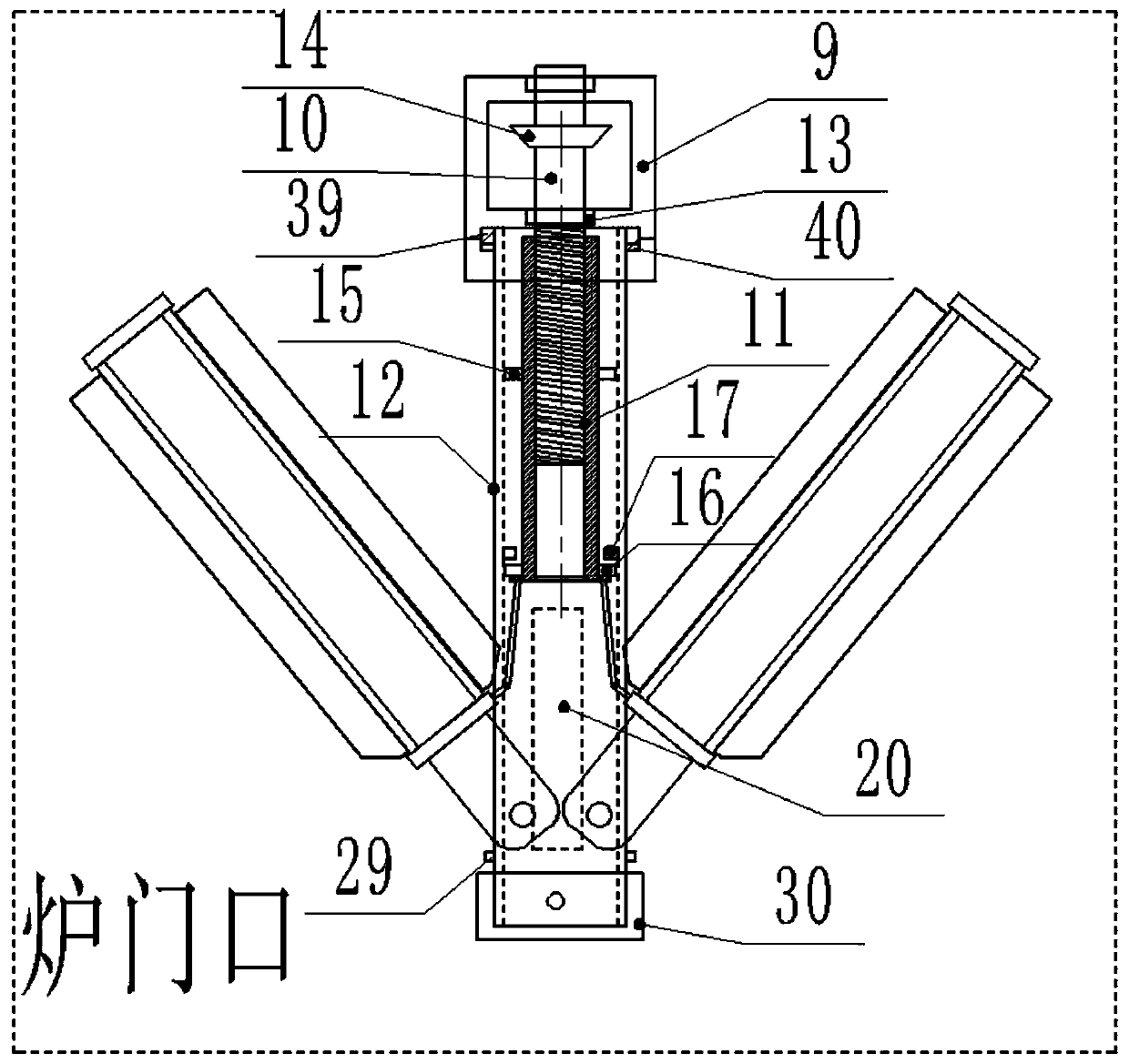

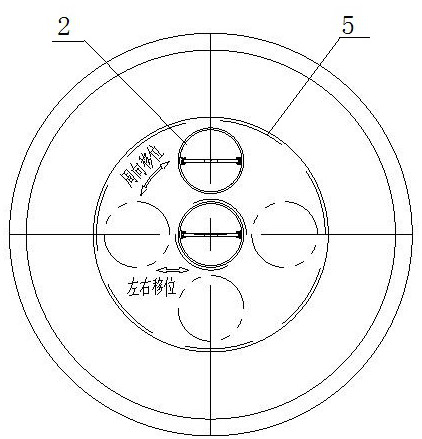

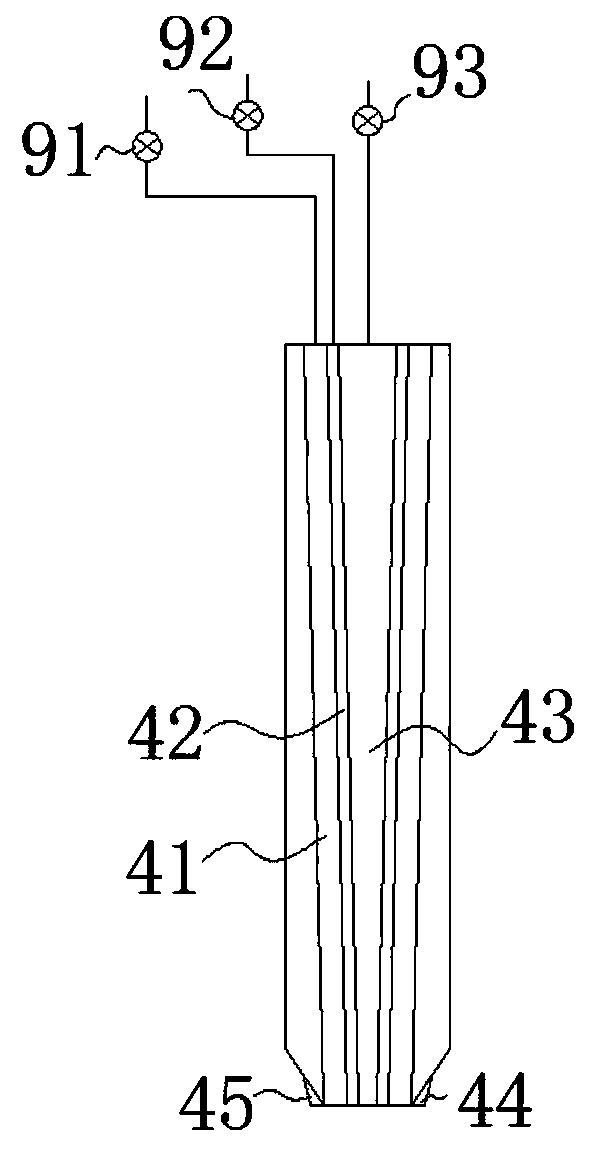

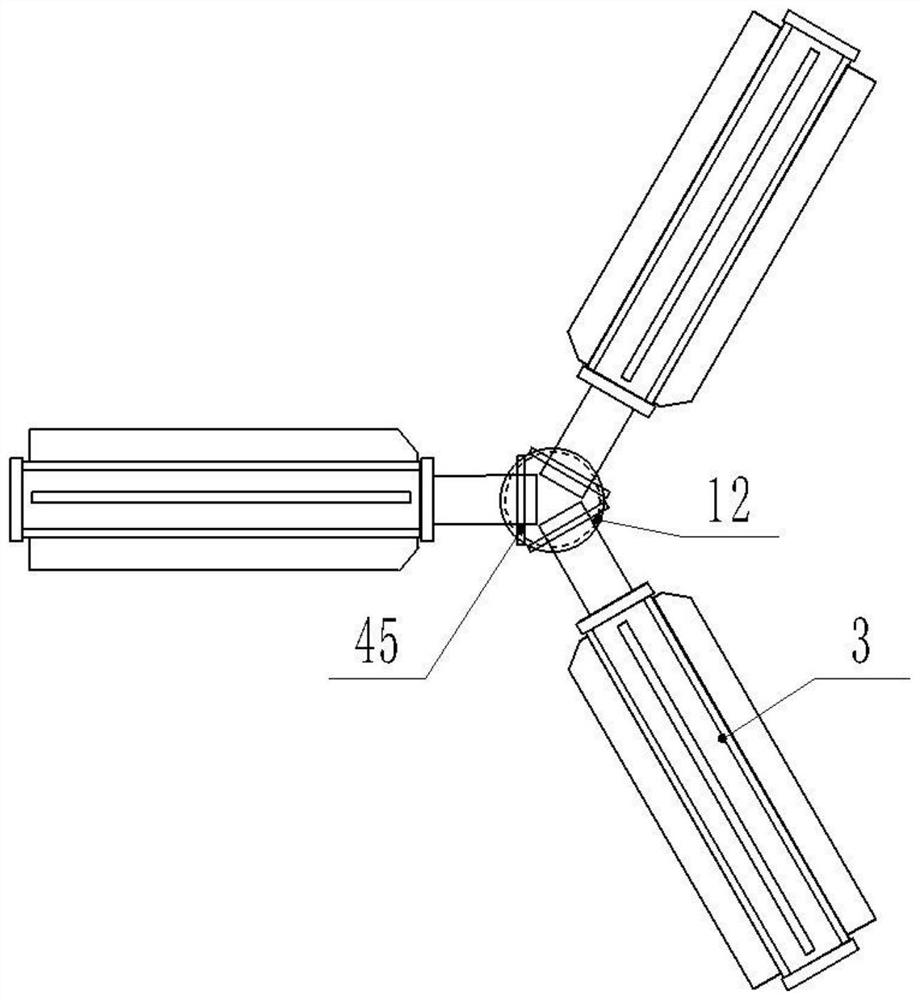

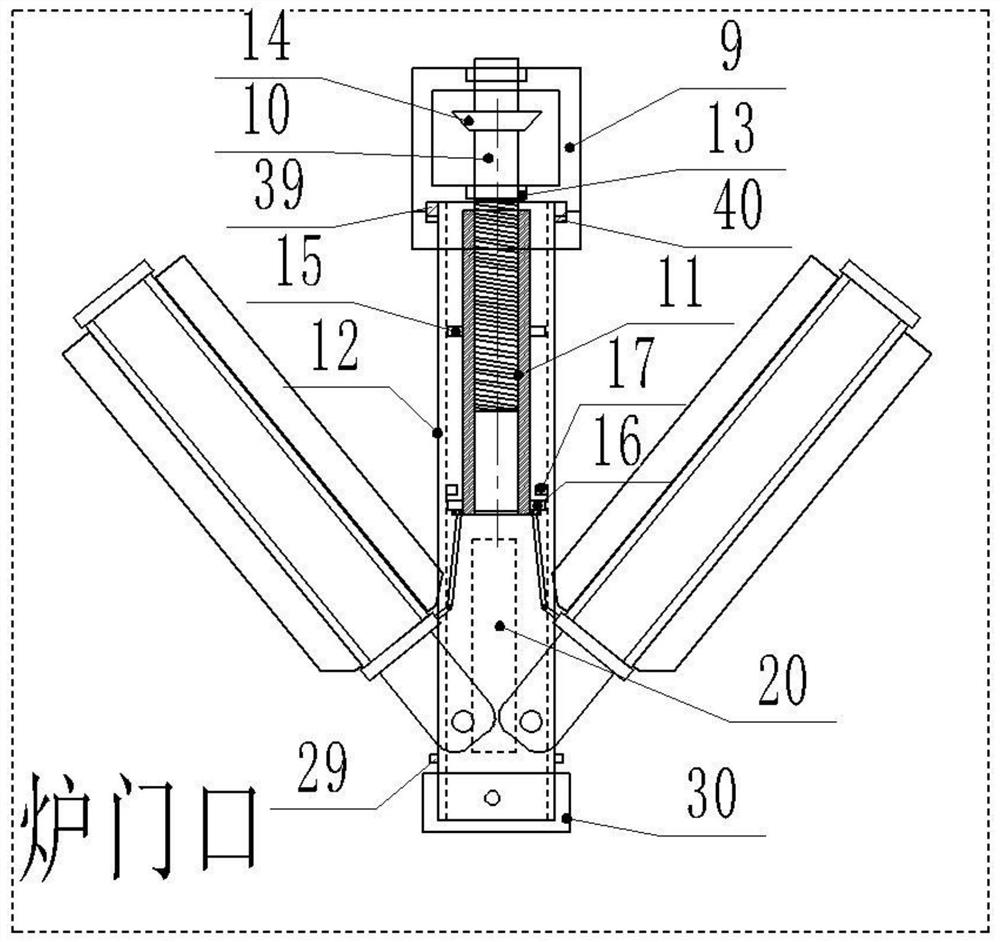

Slagging-off device for molten aluminum refining

ActiveCN110468288ARealize the slag removal operationEfficient slag removalCasting cleaning apparatusProcess efficiency improvementSlagHearth

The invention discloses a slagging-off device for molten aluminum refining. A slag collecting basket is movably arranged at the lower end of a rotary barrel body in a sleeving mode; through observingthe molten aluminum level, slagging-off equipment can be taken out from a hearth without dross; rotary slagging-off head devices need to be folded at the moment firstly; in the process of the foldingof the rotary slagging-off head devices, each rotary slagging-off head device rotates around a connecting rotating shaft, and an outlet of the inner end of a rotary slagging-off connecting barrel canbe inclined downwards to guide a slag body into the rotary barrel body; the slag body is collected in the slag collecting basket through the rotary barrel body, and the slag collecting basket only needs to be washed after slagging-off every time to be used next time; and thereof, the rotary slagging-off head devices are folded not only for folding, but also for collecting the slag body, and the centralized treatment of the dross removed out is facilitated, so that the automation and the convenience of slagging-off treatment is really realized, and the labor intensity of workers is greatly reduced.

Owner:浙江玮宏金属制品有限公司

Refining flux used for purifying and processing aluminum or aluminum alloy melt, and preparation method thereof

The invention discloses a refining flux used for purifying and processing aluminum or aluminum alloy melt, and its preparation method. The invention is characterized in that the raw material formula of the refining flux is a powder mixture composed of the following components by mass: 25 to 35% of NaCl, 25 to 35% of KCl, 15 to 25% of Na3AlF6 and / or K3AlF6, 4 to 10% of Na2SO4 and / or K2SO4, 3 to 10% of CaCO3 and / or Na2CO3, 3 to 6% of REF3 and / or RECl3; wherein, a mass ratio of NaCl to KCl is 1:1; RE is Ce or La. The refining flux can be fully diffused after entering the melt without adsorption agglomeration and pore plugging; and has high efficient capability for producing dry slag without viscous aluminum melt; even the refining flux has a slight reaction with aluminum melt, the reaction products can be removed with slag; the refining flux provided in the invention has high efficiency of gas and slag removing.

Owner:SOUTH CHINA UNIV OF TECH +1

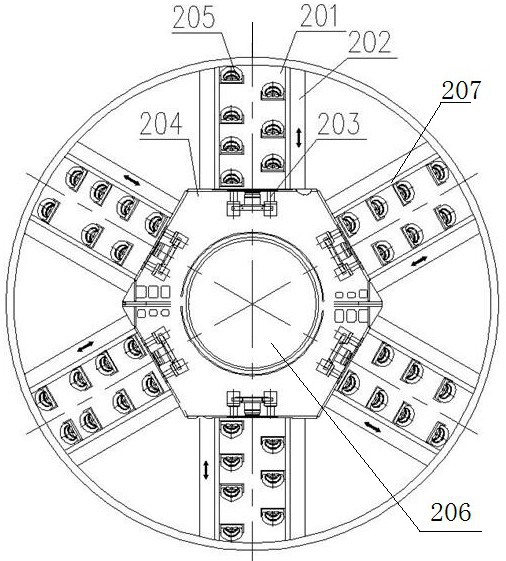

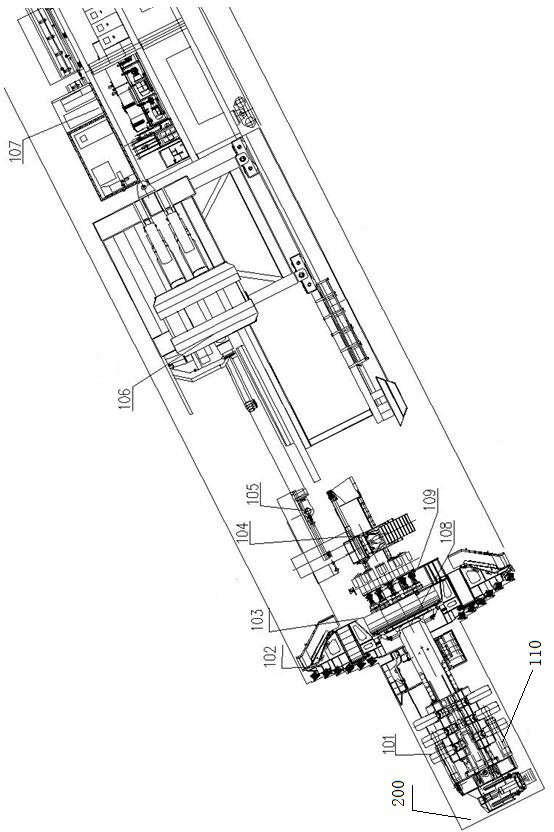

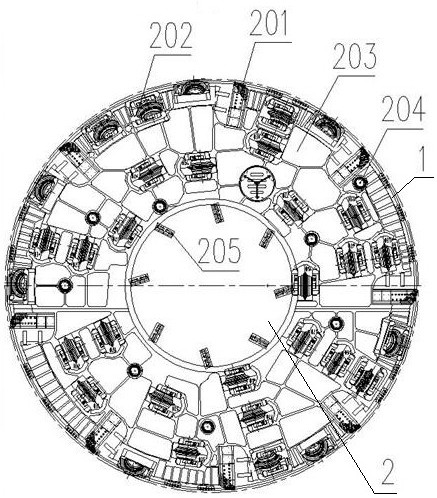

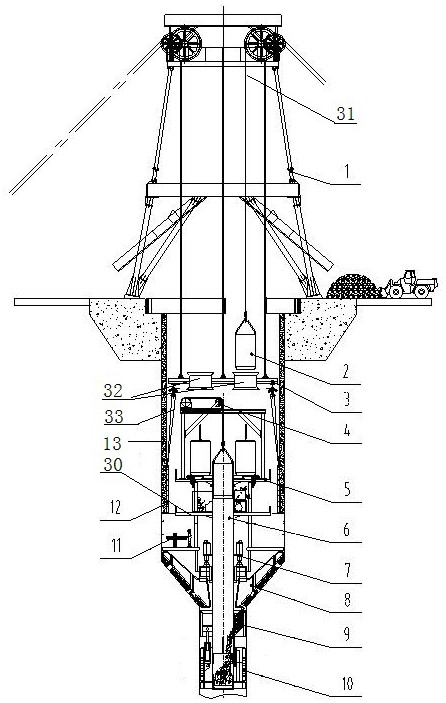

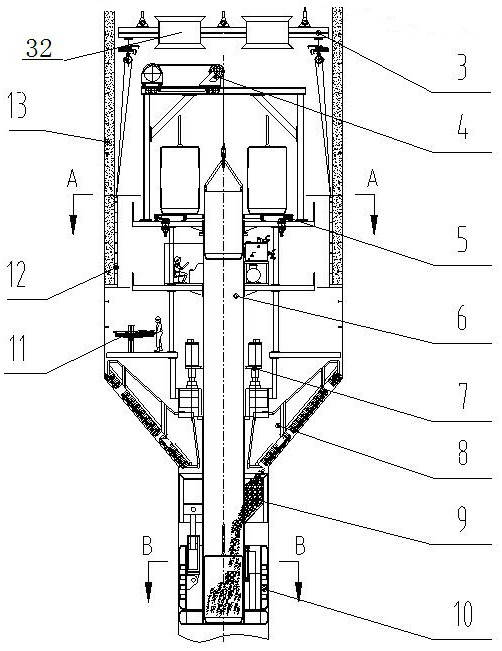

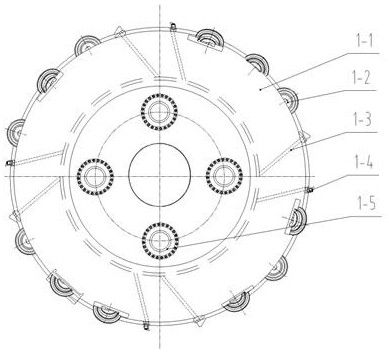

Pilot tunnel chambering suspension cutting TBM for inclined shaft and construction method

ActiveCN112343610AEfficient slag removalReduce disturbanceTunnelsStructural engineeringCompressive strength

The invention discloses a pilot tunnel chambering suspension cutting TBM for an inclined shaft and a construction method. The problem that in the prior art, the inclined shaft pilot tunnel chamberingsuspension cutting efficiency is low is solved. The pilot tunnel chambering suspension cutting TBM for the inclined shaft comprises a central main beam and a suspended-cutting and expanded-excavatingcutter head, the front end of the central main beam penetrates through the center of the suspended-cutting and expanded-excavating cutter head and is provided with a pilot tunnel supporting shoe, thepart, located behind the suspended-cutting and expanded-excavating cutter head, of the central main beam is connected with a propelling system, a driving supporting shoe device and a safety supportingshoe device, and the tail part of the safety supporting shoe device is connected with a rear matching sleeve. According to the pilot tunnel chambering suspension cutting TBM for the inclined shaft and the construction method, aiming at pilot tunnel expanding excavation from top to bottom, the suspended-cutting and expanded-excavating cutter head is adopted for conducting suspended cutting excavation layer by layer on a rock stratum around a pilot tunnel, the cutting and expanding excavation efficiency is improved, the suspended-cutting and expanded-excavating cutter head changes the traditional TBM hob rolling rock breaking principle, the characteristic that the rock shearing strength is far smaller than the uniaxial compressive strength and free face rock breaking is utilized, a suspended cutting hob is adopted for rock breaking, and the rock breaking efficiency and the rock breaking specific energy are improved.

Owner:CHINA RAILWAY ENGINEERING EQUIPMENT GROUP CO LTD

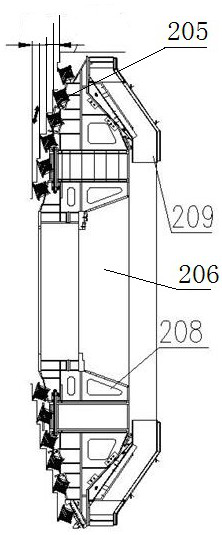

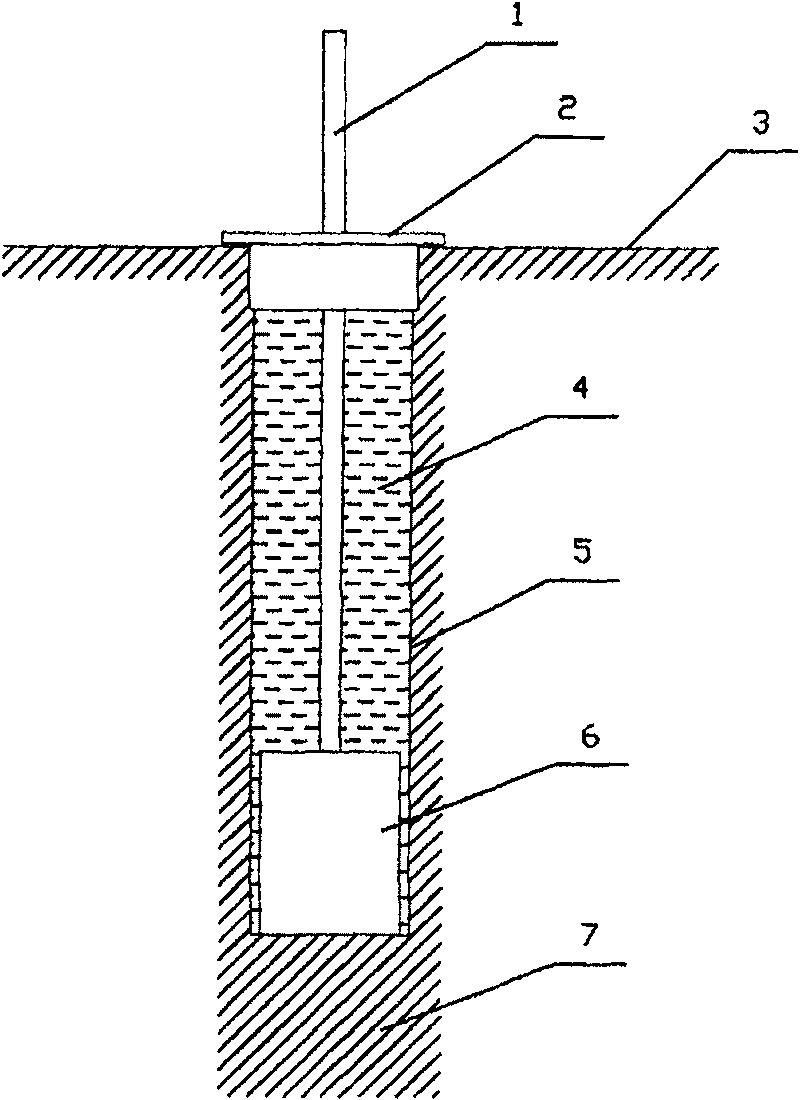

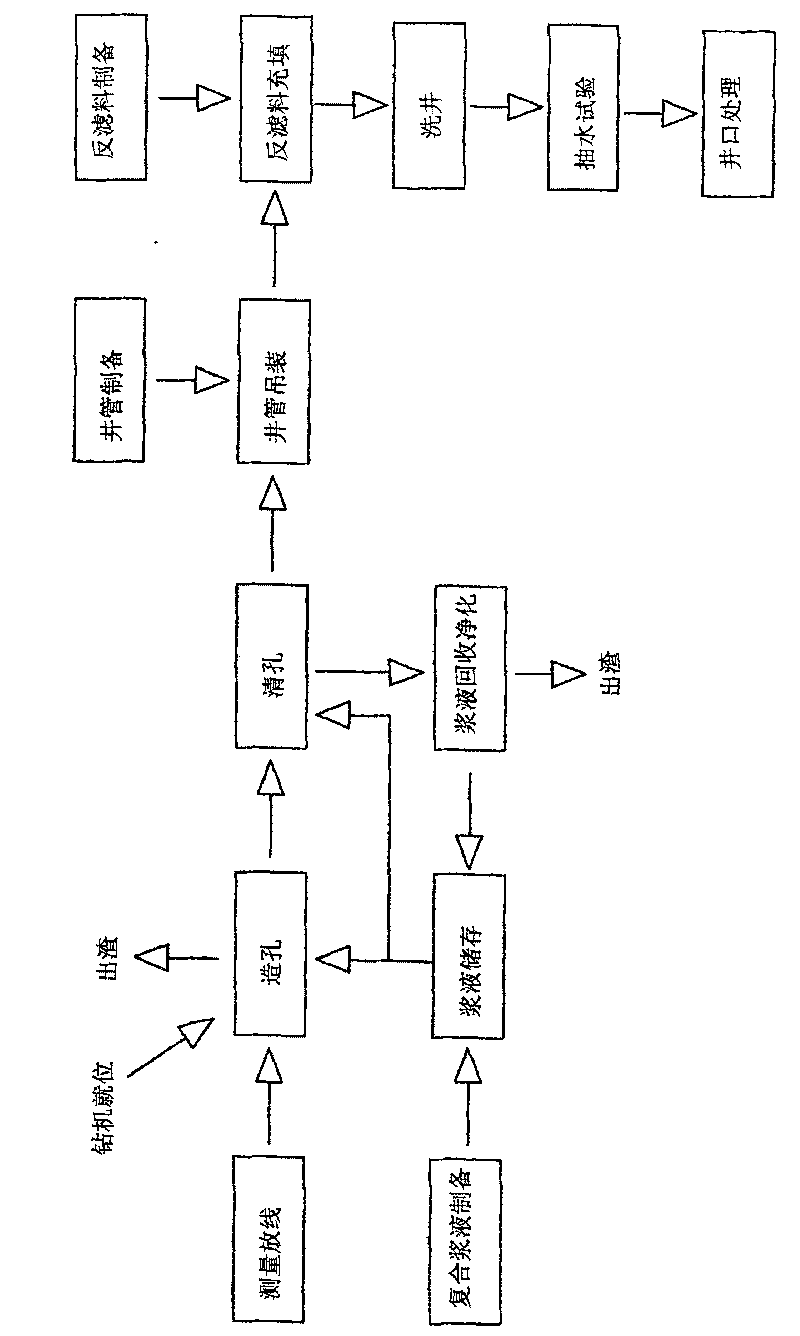

Construction method of relief well

ActiveCN101285303BReduce churnReduce infiltrationCoastlines protectionFoundation engineeringCelluloseCyclic process

The invention relates to the engineering technique for protecting a river dyke, in particular to a method for constructing a relief well, comprising the steps of: hole creating, hole cleaning, borepipe making and hoisting, filter material making and filling, hole flushing, pumping test and well top processing, etc. The method is characterized in that: in the hole creating step, a direct soil-borrowing type drilling machine is used to create holes, and created holes are protected by high polymer composite slurry; in the hole clean step, the high polymer composite slurry is directly used to clean holes, and the hole clean step includes a cyclic process of the recovery, the purification, the storage and the reutilization. The high polymer composite slurry is prepared by following components in portion by weight: 1000 portions of water, 70 to 130 portions of bentonite, 5 to 25 portions of polyacrylamide, 2 to 15 portions of cellulose ether, 0 to 9 portions of weight additive, 0 to 5 portions of industrial alkali and 0 to 3 portions of fluid loss additive, and the mixture is stirred into slurry by a swirling flow type pulping machine. The method has the advantages of easy and quick operation, high production efficiency, good product quality and long service life; moreover, in the process of construction, the method has the advantages of energy and water conservation, low cost, low noise and no pollution.

Owner:GUANGDONG CONSTR ENG GRP +1

A magnetic rod self-rotating permanent magnet filter device

ActiveCN109201326BNot easy to wear and deformPrevent decontamination from being incompleteCleaning using toolsMagnetic separationMotor driveReciprocating motion

The invention discloses a magnetic bar rotation type permanent magnet filtering device. Driven by a motor transmission mechanism, the magnetic link periodically reciprocates and enters below the liquid level of a box used to store cold rolling coolant, thereby filtering the liquid in the coolant. Metal dust is adsorbed; above the magnetic link mechanism, a decontamination mechanism is also provided. The decontamination mechanism is arranged perpendicularly or at an angle to the plane of the upper surface of the magnetic link to decontaminate the reciprocating magnetic link above the liquid level. During this process, each magnetic rod moves perpendicular to the length of the magnetic rod and rotates to scrape off the metal dust on the magnetic rod. It can effectively avoid the deformation or damage of the magnetic rod caused by the rigid contact with the decontamination device during the movement of the magnetic rod, and prevent the decontamination mechanism from getting stuck, causing equipment shutdown failure caused by the magnetic rod transmission chain; in addition, it can greatly reduce the overall size of the equipment. At the same time, it significantly improves the running speed and following performance of the magnetic link mechanism, and has wider applicability.

Owner:WUHAN UNIV OF SCI & TECH

Device for automatically skimming sewage to generate methane for increasing value

InactiveCN102911857AWith controllable conditionsWith in and outGas production bioreactorsWaste based fuelWater sourceSlag

The invention discloses a device for automatically skimming sewage to generate methane for increasing value. In order to overcome the defects of single sewage treatment function, poor effective utilization and value increase, large pollution to water sources, disadvantage to environmental friendliness, and the like of the traditional sanitary sewage, digestion tanks and the like, the device comprises a cavity for accommodating sewage, wherein the cavity is provided with a slag discharging mechanism, a sewage inputting mechanism, an air inlet slag flushing mechanism and a sewage level control emission mechanism; an opening of the sewage level control emission mechanism, which is arranged in the cavity, is lower than an opening outside the cavity and is positioned in sewage in the cavity; an opening of the sewage level control emission mechanism, which is arranged outside the cavity, accords with the height of the required sewage level in the cavity. The device disclosed by the invention is mainly used for treating the sanitary sewage to generate methane, is capable of reducing water source pollution to ensure that the sewage is subjected to harmless treatment and is value-added, and is low in treatment cost and high in degree of automation.

Owner:WEIMING BIOLOGY ENVIRONMENT TECH GRP

A kind of pilot hole reaming suspension cutting TBM for inclined shaft and its construction method

ActiveCN112343610BEfficient slag removalReduce disturbanceTunnelsClassical mechanicsStructural engineering

The invention discloses a guide hole reaming suspension cutting TBM for inclined shafts and a construction method, which solves the problem of low expansion and excavation efficiency of inclined shaft guide holes in the prior art. The guide hole reaming suspension cutting TBM for inclined shafts of the present invention includes a central main beam and a suspension cutting expansion cutterhead. The part of the beam located at the rear of the hanging cutting and expanding cutter head is connected with a propulsion system, an active boot device and a safety shoe device, and the rear part of the safety shoe device is connected with a rear supporting device. The present invention aims at expanding and excavating the pilot tunnel from top to bottom, adopts the hanging cutting and expanding excavation cutter head to carry out the layer-by-layer hanging cutting and excavation of the rock formation around the pilot tunnel, improves the efficiency of cutting and expanding excavation, and the hanging cutting and expanding excavation cutter head changes the traditional The principle of rock breaking by TBM hob rolling utilizes the characteristics that the shear strength of rock is much smaller than the uniaxial compressive strength and rock breaking on the air surface, and adopts the suspension cutting hob to break rock to improve the rock breaking efficiency and rock breaking specific energy.

Owner:CHINA RAILWAY ENGINEERING EQUIPMENT GROUP CO LTD

Flat plate solar aluminum alloy clad layer and preparing method thereof

InactiveCN107828997AImprove thermal conductivityAccelerated corrosionWear resistanceUltimate tensile strength

The invention discloses a flat plate solar aluminum alloy clad layer and a preparing method thereof. A clad layer material is prepared by following raw materials including, by mass proportion, 0.2%-0.3% of Ti, 0.3%-0.5% of Si, 1%-2% of Ag, 0.1%-1% of Mn, 2%-5% of Fe, 1.5%-2.5% of Ni, 0.2%-0.3% of Zr, 0.1%-0.3% of Ce, 0.1%-0.3% of La and the balance aluminum and inevitable impurities. The clad layer material preparing method is simple, the clad layer material and a base body are well combined, and falling off is not likely to happen; and the prepared aluminum alloy clad layer is attractive, good in corrosion resistance and abrasion resistance, high in strength and ductility and high in heat absorbing and transmitting capability.

Owner:GUANGXI CHAOXING SOLAR ENERGY TECH

Method for removing ladle dross

ActiveCN100340363CFast slag removalEfficient slag removalCasting cleaning apparatusLiquid slagMolten steel

The invention provides the method of removing liquid steel scum, comprising the following steps: dragging the scum from liquid steel liquid level with harrow rotary dragging method, at the same time, adding the anti-oxidization agent on the clean liquid steel surface. Because of adopting the harrow rotary dragging method, the invention solves the problems of big loss of scarfing cinder, hard operation and heavy labor strength. Adding the anti-oxidization agent avoids the secondary oxidization of liquid steel. The method uses the freezing slag agent to solidify the liquid slag. It strengthens the effect of removing slag.

Owner:YANTAI SHENGLIDA ENG TECH

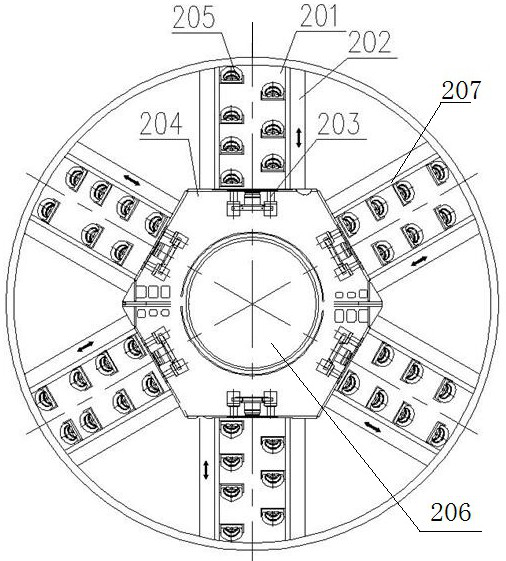

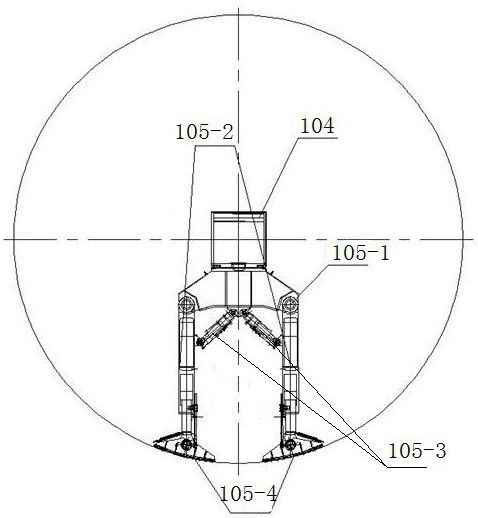

A kind of hollow TBM cutterhead, TBM and construction method for pilot hole expansion and excavation for inclined shafts

ActiveCN112343609BImprove the efficiency of excavationEfficient slag removalTunnelsPilot holeArchitectural engineering

The invention discloses a hollow TBM cutter head, a TBM for expanding and digging a pilot hole for an inclined shaft, and a construction method. The TBM for expanding and digging a pilot hole for an inclined shaft includes the hollow TBM cutter head and a main beam connected to a shield body And the main drive, the main drive is connected with the hollow TBM cutter head, and the main beam is provided with a front support device, a double support shoe mechanism and a bottom support in sequence from front to back. It also includes a rear supporting device, a first safety device and a second safety device are connected between the rear supporting device and the main girder, and the first safety device and the second safety device are arranged in series. The invention adopts the TBM method to expand and excavate the pilot tunnel, gets rid of the drilling and blasting excavation method, improves the quality of the tunnel, reduces the disturbance to the surrounding rock, reduces potential safety hazards, and improves the efficiency of expanding and excavating the pilot tunnel.

Owner:CHINA RAILWAY ENGINEERING EQUIPMENT GROUP CO LTD

A kind of liquid aluminum slag removal method

ActiveCN110508798BRealize the slag removal operationEfficient slag removalCasting cleaning apparatusElectric machineSlag

The invention discloses a molten aluminum slagging-off method. Rotating slagging-off head devices are placed on the molten aluminum level, slagging-off work begins to be operated, a worker operates aslagging-off operation rod to enable a slagging-off work face formed by the three rotating slagging-off head devices to move back and forth on the molten aluminum face, in the rotating process of a rotating slagging-off head, an arc slag filter plate continuously collects dross floating on the molten aluminum level and suspension slag below the molten aluminum level on the inner side face of the arc slag filter plate, when the arc slag filter plate is in the vertical state or tends to be in the vertical state, slag slides towards the direction of a rotating cylinder from the inner side face ofthe arc slag filter plate to enter a rotating cylinder slag inlet, when the rotating cylinder slag inlet is aligned with a slag inlet formed in the upper portion of a rotating slagging-off connectingcylinder, slag can enter the rotating slagging-off connecting cylinder to be collected, when no dross exists, a slagging-off motor is shut down, the rotating slagging-off heat devices leave the molten aluminum level, the slagging-off motor is started for reverse rotation, a lifting transmission shaft drives a lifting cylinder to rise, and when it is observed that the rotating slagging-off head devices reversely rotate, folding of the rotating slagging-off head devices is finished.

Owner:贵州莹月帆铝制品有限公司

A shaft expansion excavator and its construction method

ActiveCN111119898BOvercome rock breaking resistanceEfficient excavationDerricks/mastsShaft sinkingSupporting systemSlag

The invention discloses a shaft expansion excavator and a construction method thereof. The shaft expansion excavation machine includes a derrick and a main engine, the derrick is connected with the main engine through a winch mechanism, and the main engine includes a central column that can be used as a slag discharge channel. The lower part of the main engine is equipped with a cutter head system and propulsion device, the upper part of the main machine is equipped with a slag discharge system and a support system, the lower part of the central column is connected with the cutter head system, and the upper part corresponds to the slag discharge system. The invention has ingenious design, high driving efficiency and greatly shortens the excavation expansion period, is a great innovation in the expansion and excavation of shafts, and has high popularization value.

Owner:CHINA RAILWAY ENGINEERING EQUIPMENT GROUP CO LTD

A free-section hard rock excavation equipment

The invention discloses a free section hard rock excavation equipment, which solves the problem of low excavation efficiency of a super large section shaft in the prior art. The invention includes a mobile car body, the front end of the mobile car body is hinged with a connecting frame, the connecting frame is provided with a drum-type cutter head, the connecting frame is connected with the mobile car body through a telescopic drive mechanism, and the drum-type cutter head is connected to the mobile car body. The slag conveying mechanism on the car body is corresponding. Preferably, the mobile vehicle body is provided with a cab and a base, the base is located at the front of the cab, the connecting frame is hinged on the base, and the bottom of the mobile vehicle body is provided with a crawler walking mechanism. The invention realizes the flexible and high-efficiency excavation of the hard rock section through the excavation of the drum type cutterhead and the movement of the crawler, is suitable for the excavation of shafts with super large sections and free sections, and reduces equipment investment. A certain number of slag outlets are set along the circumference of the drum-type cutter head, through which the rock slag is transported to the rock slag conveying mechanism and discharged to the rear of the equipment to achieve efficient slag discharge.

Owner:CHINA RAILWAY ENGINEERING EQUIPMENT GROUP CO LTD

A high vanadium steel continuous casting flame cutting process

ActiveCN109277543BGuaranteed cutting qualityAvoid high temperature oxidationFlame cuttingMolten slag

Owner:SICHUAN DESHENG GRP VANADIUM & TITANIUM CO LTD

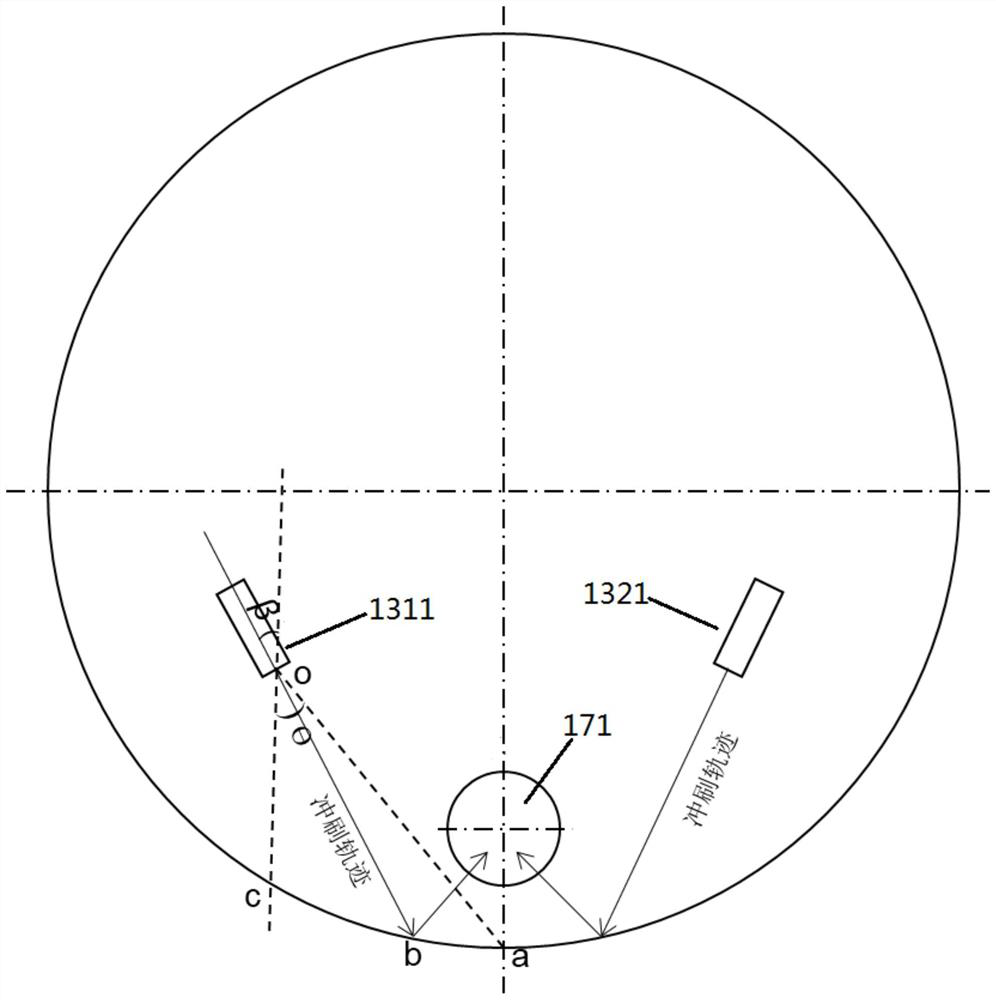

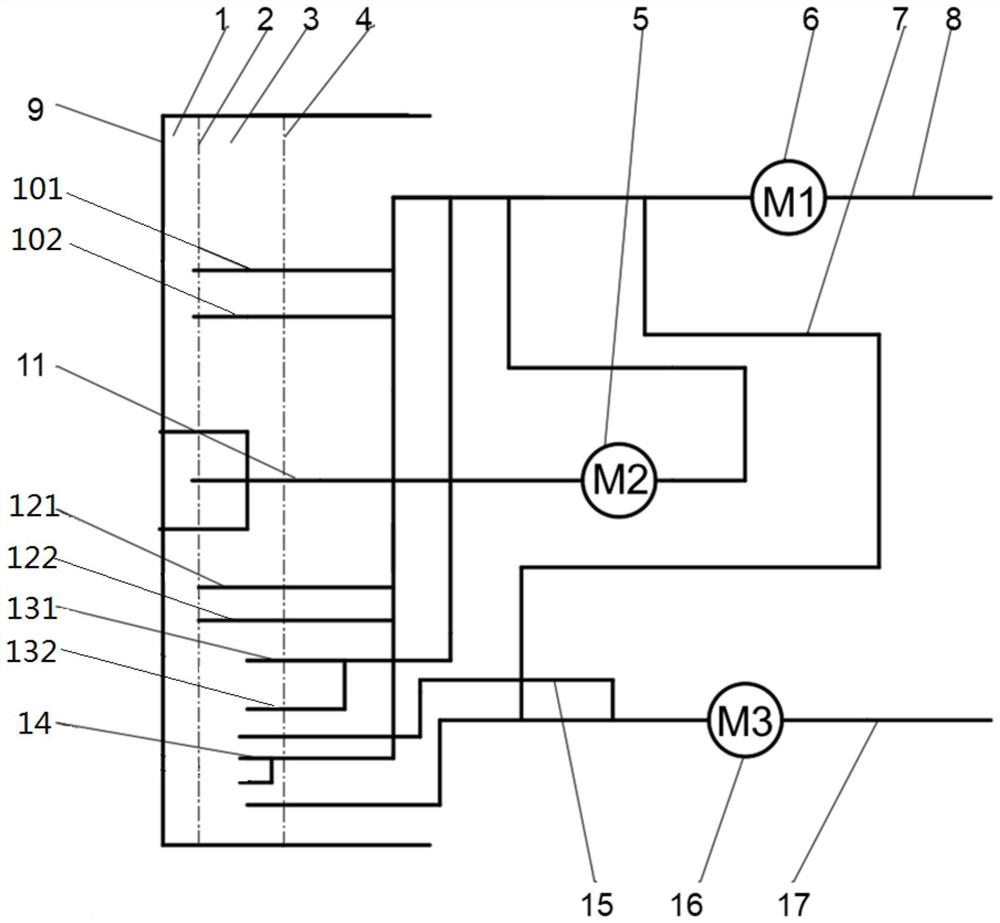

Shield tunneling machine, scouring device and slurry circulation system

The invention discloses a shield tunneling machine, a scouring device and a slurry circulation system.The slurry circulation system comprises a slurry inlet pipeline and a slurry inlet pump, the slurry inlet pipeline is connected with a left bentonite nozzle pipeline and a right bentonite nozzle pipeline, and the left bentonite nozzle pipeline and the right bentonite nozzle pipeline are connected with a left bentonite nozzle and a right bentonite nozzle respectively; the air cushion is connected into the air cushion bin; the included angle between the normal of the left bentonite nozzle and the vertical direction is smaller than the included angle between the connecting line of the center point of the outlet of the left bentonite nozzle and the center point of the bottom of the shield body and the vertical direction. The included angle between the normal of the right bentonite nozzle and the vertical direction is smaller than the included angle between the connecting line of the center point of the outlet of the right bentonite nozzle and the center point of the bottom of the shield body and the vertical direction. According to the slurry circulation system, the left bentonite nozzle and the right bentonite nozzle are used for washing the soil at the bottom of the bin at the angles deviating from the center of the bottom of the shield body, so that the slag carrying capacity and the washing effect of the system can be greatly improved, rapid slag discharging can be achieved, and blockage of a slurry discharging opening is reduced.

Owner:CHINA RAILWAY CONSTR HEAVY IND

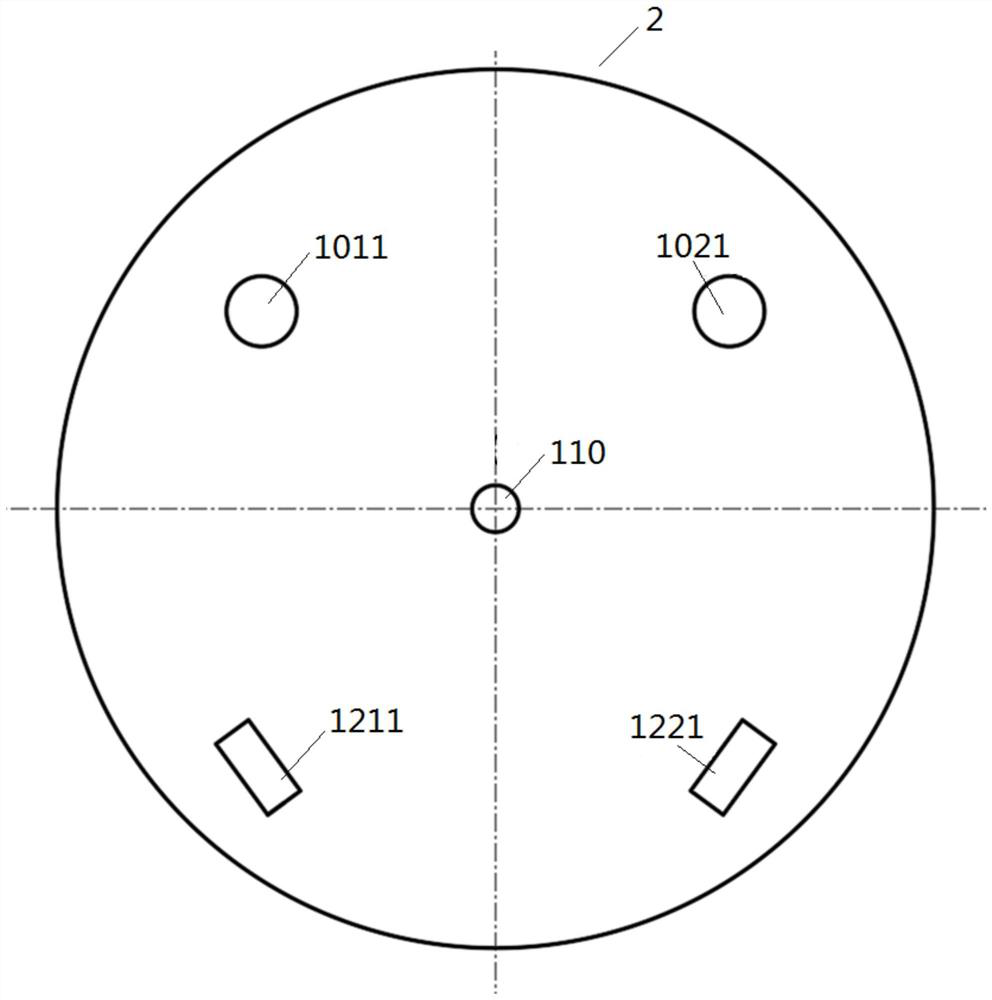

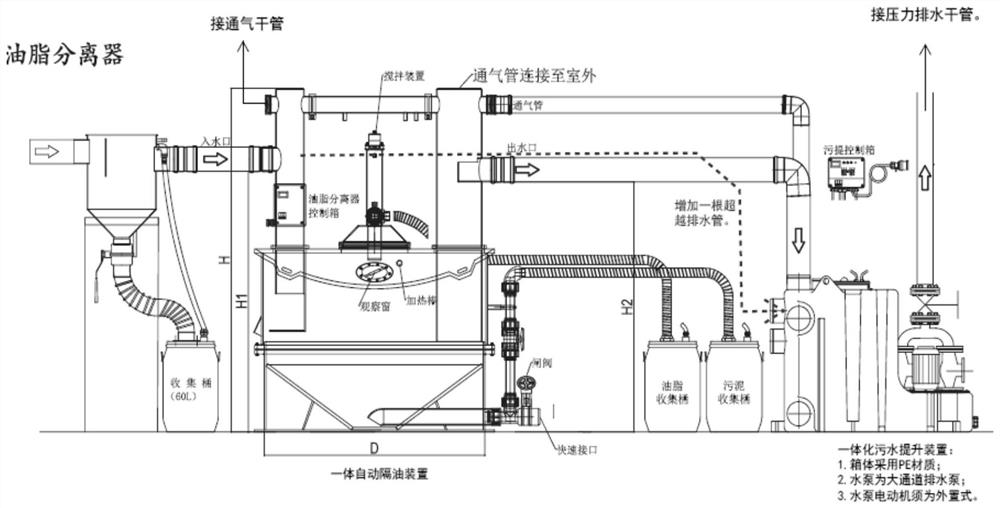

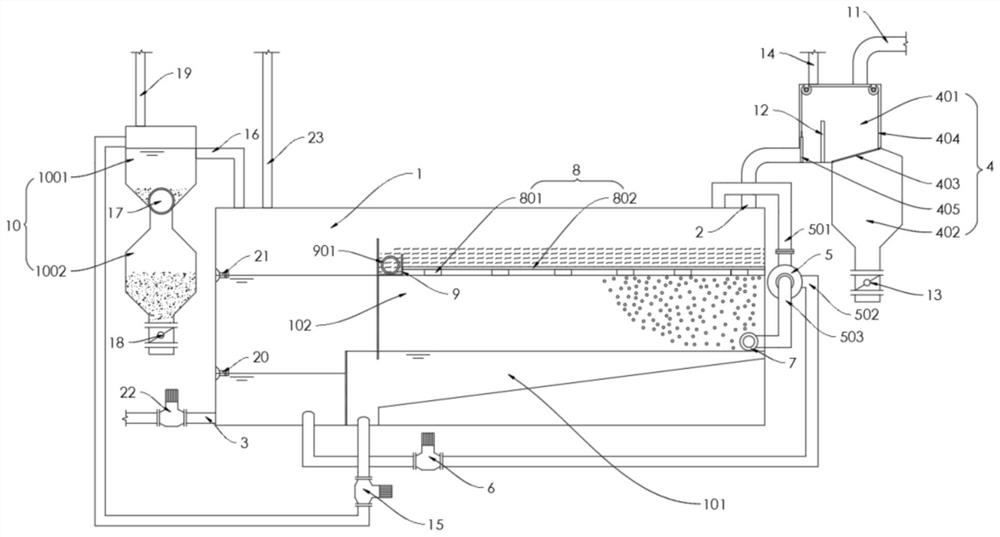

Multifunctional efficient oil separator

PendingCN112661236AGuaranteed separation effectLow costFatty/oily/floating substances removal devicesLiquid separationThermodynamicsVegetable oil

The invention relates to a multifunctional efficient oil separator which comprises an oil separation container; a deslagging mechanism which is arranged at an oil separation water inlet of the oil separation container and is used for feeding water and deslagging; a jet device, wherein the air inlet end of the jet device is connected to the top of the oil separation container in a communicating mode, the water inlet end of the jet device is connected to the bottom end of the oil separation container through a circulating pipeline pump, and a perforated aeration pipe is fixedly arranged in the oil separation container and connected to the water outlet end of the jet device in a communicating mode; a latticed electric heating mechanism which is used for heating to prevent animal and vegetable oil from being condensed, wherein the specific gravity of the latticed electric heating mechanism is lighter than that of water and heavier than that of oil; an oil collecting tank which is fixedly arranged at the upper part of the oil separation area and is used for collecting oil stains and discharging the collected oil stains; a mud-water separator which is connected to the bottom of the settling zone and is used for removing mud. According to the oil separator, the deslagging, oil separation and mud removal effects can be effectively improved on the basis of an existing oil separator, and therefore treatment of kitchen oily wastewater is effectively promoted under the condition that the cost is low.

Owner:上海市建工设计研究总院有限公司

A kind of slag removal device for aluminum liquid refining

ActiveCN110468288BRealize the slag removal operationEfficient slag removalCasting cleaning apparatusProcess efficiency improvementSlagEngineering

The invention discloses a slag removal device for refining aluminum liquid. A slag body collection basket is movably sleeved on the lower end of a rotating cylinder, and the slag removal device can be taken out from the furnace by observing the aluminum liquid level without scum. At this time, it is first necessary to close the rotary slag removal head device. During the retraction process of the rotary slag removal head device, each piece of the rotary slag removal head device rotates around the connecting shaft, and the inner end of the rotary slag removal connection cylinder of each piece of rotary slag removal head device The outlet will tilt downward to introduce the slag into the rotating cylinder, and collect it into the slag collection basket through the rotating cylinder. After each slag removal, you only need to clean the slag collection basket and then use it next time. The folding of the device is not only to realize the folding, but also to collect the scum, so as to facilitate the centralized treatment of the scum, which truly realizes the automation and convenience of scum removal, and greatly reduces the labor intensity of workers.

Owner:浙江玮宏金属制品有限公司

Laser cutting machine and deslagging method thereof

ActiveCN113385830AImprove processing qualityEfficient slag removalLaser beam welding apparatusSlagEngineering

The invention discloses a laser cutting machine. The laser cutting machine comprises a fixed chuck, a laser cutting head located on the right side of the fixed chuck, a movable chuck located on the left side of the fixed chuck, a slag remover located on the right side of the laser cutting head and a gas extractor, wherein the slag remover is provided with an inner cavity, a gas suction inlet and a gas suction pipe, the gas suction inlet is located in the left side face of the slag remover and communicates with the inner cavity, one end of the gas suction pipe communicates with the inner cavity, and the other end is connected to the gas suction device, in addition, the invention further provides a slag removal method which comprises the following steps of starting the gas extractor to extract gas from the inner cavity of the slag remover, and the slag remover is driven to move relative to a metal pipe, so that the gas exhaust inlet of the slag remover communicates with one end of the metal pipe, and gas exhaust is conducted on a pipe cavity of the metal pipe. Compared with a mode that a scrap removing pipe is inserted into the metal pipe to remove scraps, the metal pipe in the cut state serves as a part of the slag remover, the inner diameter of the metal pipe is larger than that of the scrap removing pipe, when the metal pipe is vacuumized, the pipe cavity of the metal pipe can achieve the ideal vacuum degree more easily, and the scrap removing effect can be improved.

Owner:FOSHAN LONGXIN LASER TECH CO LTD

Reinforcing process of removing slag at the bottom of cast-in-place pile

ActiveCN106120783BImprove structural strengthEfficient slag removalBulkheads/pilesEngineeringHigh pressure water

The invention discloses a reinforcement process method for pile bottom sediment removal of a pouring pile. The reinforcement process method comprises the following steps: forming at least one sediment removal hole in the top of a pile body, and ensuring that the sediment removal hole extends to a pile bottom sediment layer; installing sediment removal equipment in place, stretching a water tube and a gas tube from the sediment removal hole and enabling tube orifices to approach to a hole bottom position; starting water supply equipment, and carrying out high-pressure water jetting on the pile bottom sediment layer through the water tube to complete primary sediment removal treatment; starting gas supply equipment, charging a high-pressure gas in the pile bottom sediment layer and carrying out the high-pressure water jetting on the pile bottom sediment layer through the water tube and the gas tube, and completing secondary sediment removal treatment through the double processes of high-pressure water jetting and gas lift circulation; pulling away the water tube and installing a grouting tube in situ, starting grouting equipment and the gas supply equipment simultaneously, and carrying out reinforcement treatment on the pile body through a gas-injecting and grouting method; and stopping the equipment when a grout overflows from the orifice of the sediment removal hole. The reinforcement process method disclosed by the invention is capable of realizing efficient and thorough elimination for pile bottom sediments, good in sediment removal effect, and capable of increasing the structural strength of the pile body, meeting safety indexes, and meeting the requirements of construction technical indexes.

Owner:GUANGZHOU CITY LUBAN CONSTR

Laser cutting machine and its slag removal method

ActiveCN113385830BImprove processing qualityEfficient slag removalLaser beam welding apparatusEngineeringLaser cutting

Owner:FOSHAN LONGXIN LASER TECH CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com