Slagging-off device for molten aluminum refining

A technology for removing slag and aluminum liquid, which is applied in the field of slag removing devices for refining aluminum liquid, which can solve the problems of long use time and poor effect of slag removal, and achieve high-efficiency slag removal and high-efficiency slag removal

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

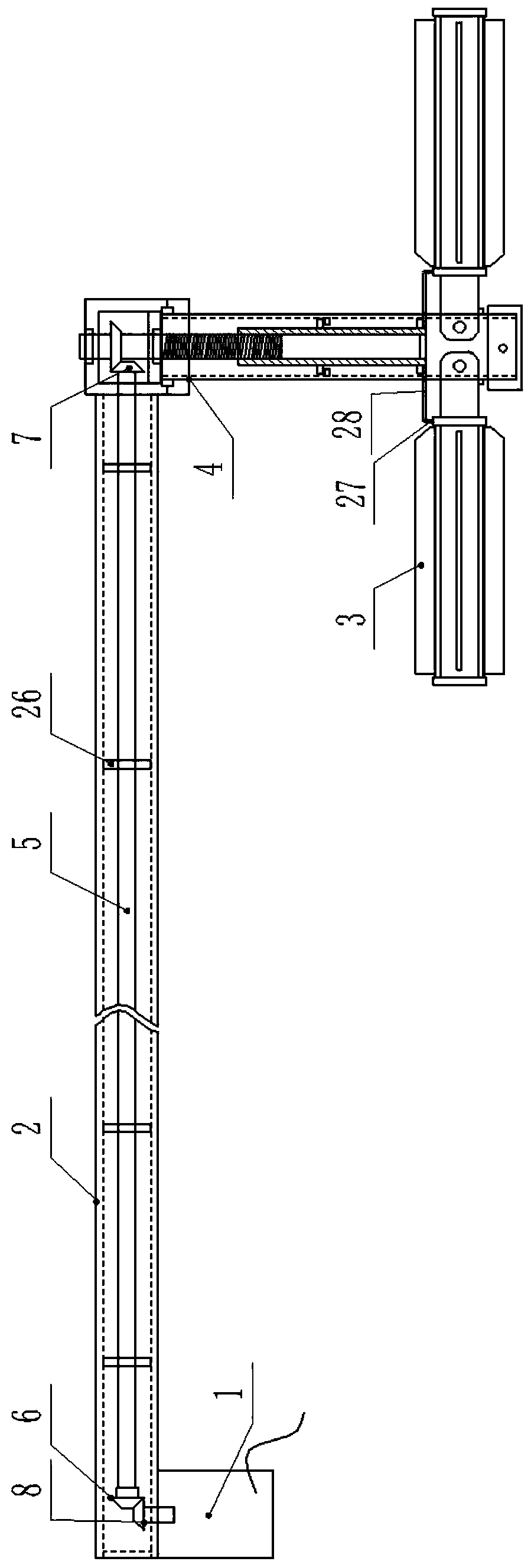

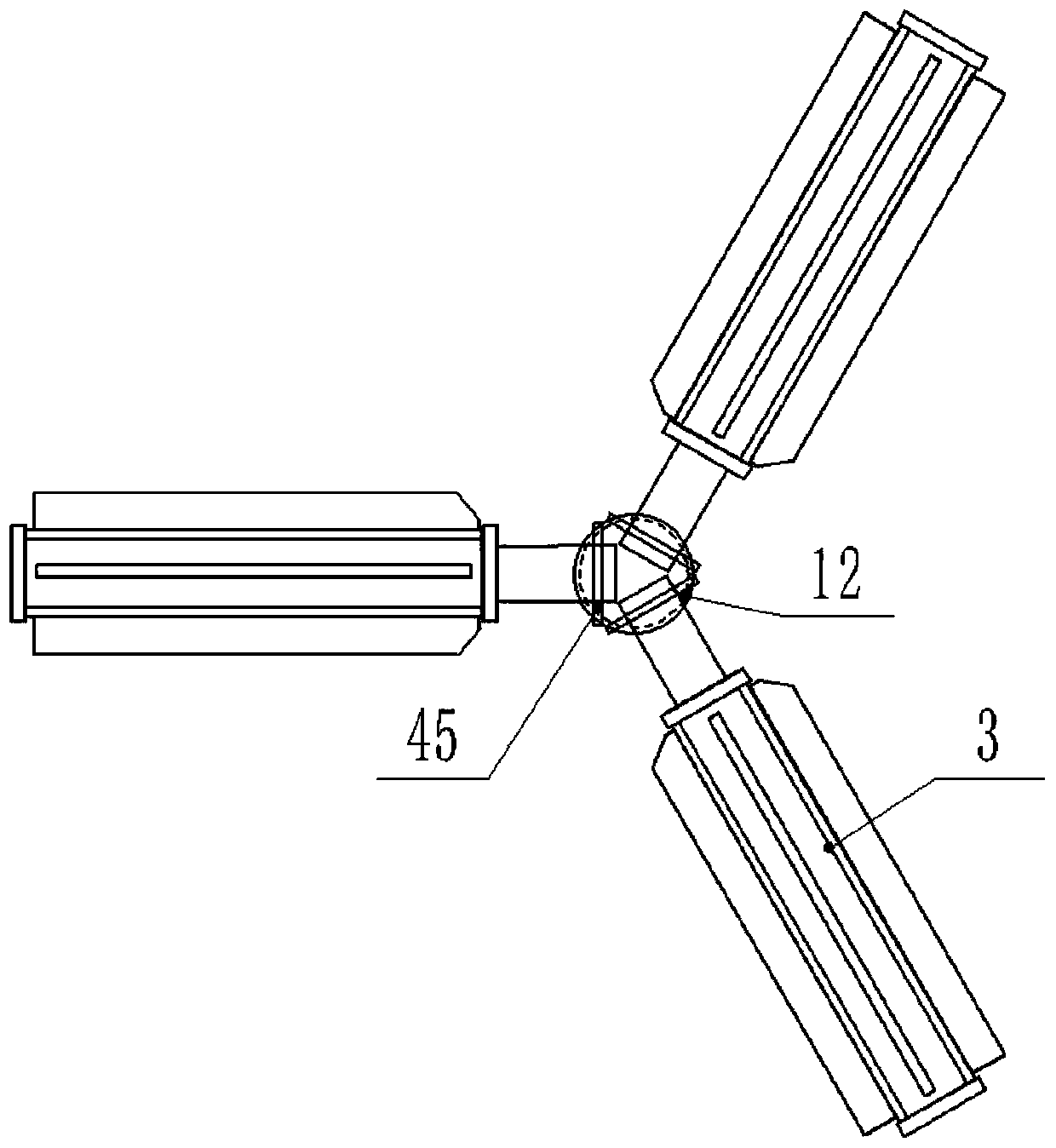

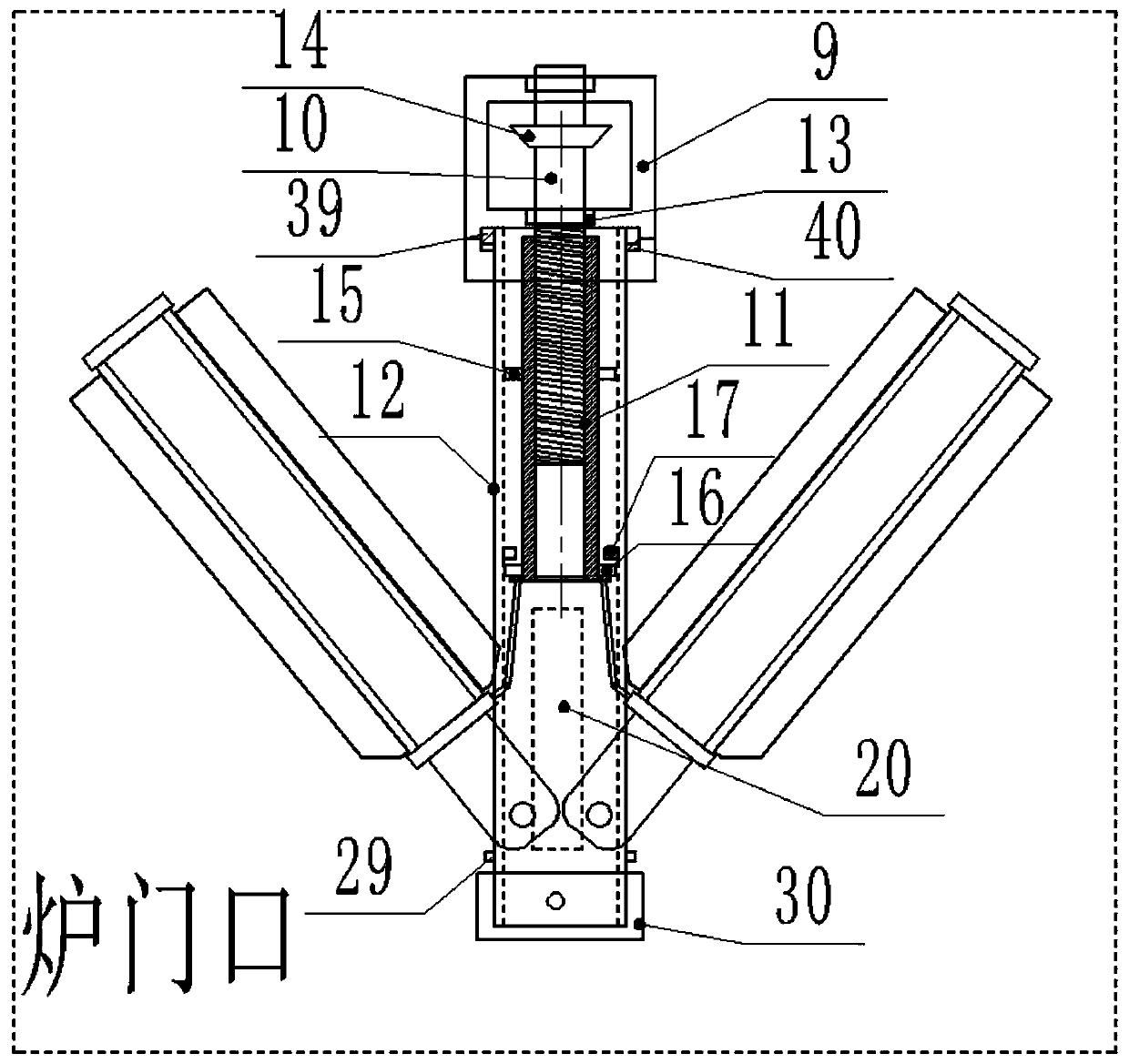

[0038] Such as Figure 1-10 As shown, the present invention is a slag removal device for aluminum liquid refining, including a slag removal motor 1, a slag removal operating rod 2, a rotating slag removal head device 3 and a slag removal head transmission device 4, since the structural components of the present invention are in It works under high temperature environment, so the material should try to choose stainless steel or high temperature resistant material. figure 1 The slag removal operation rod 2 described in the above is a tubular structure, made of stainless steel pipe, a transmission shaft 5 is arranged inside the slag removal operation rod 2, the outer end of the transmission shaft 5 is provided with a bevel tooth 6 at the outer end of the transmission shaft, and the inner end of the transmission shaft 5 is Bevel teeth 7 at the inner end of the transmission shaft are provided, and the slag removal motor 1 is vertically arranged at the outer end of the slag removal ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com