Patents

Literature

51 results about "Aluminum levels" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Preparation method of lead electrobath for transitting to electrolysis in low termperature

This invention relates to a low-temperature electrolysis method electrolyzing aluminum in an aluminum electrolytic tank. The method comprises: (1) adjusting the electrolyte composition to lower the initial crystallization temperature; (2) controlling the voltage of the electrolytic tank; (3) controlling overheat of the electrolysis; (4) controlling the aluminum level; (5) controlling the intelligent fuzzy parameters; (6) finely operating. The method can improve the electrolytic conditions of the electrolytic tank, lower the initial crystallization temperature of 905-915 deg.C and the electrolysis temperature to 915-930 deg.C, raise the current efficiency, and reduce the electricity consumption.

Owner:GUIZHOU BRANCH CHINA ALUMINUM IND

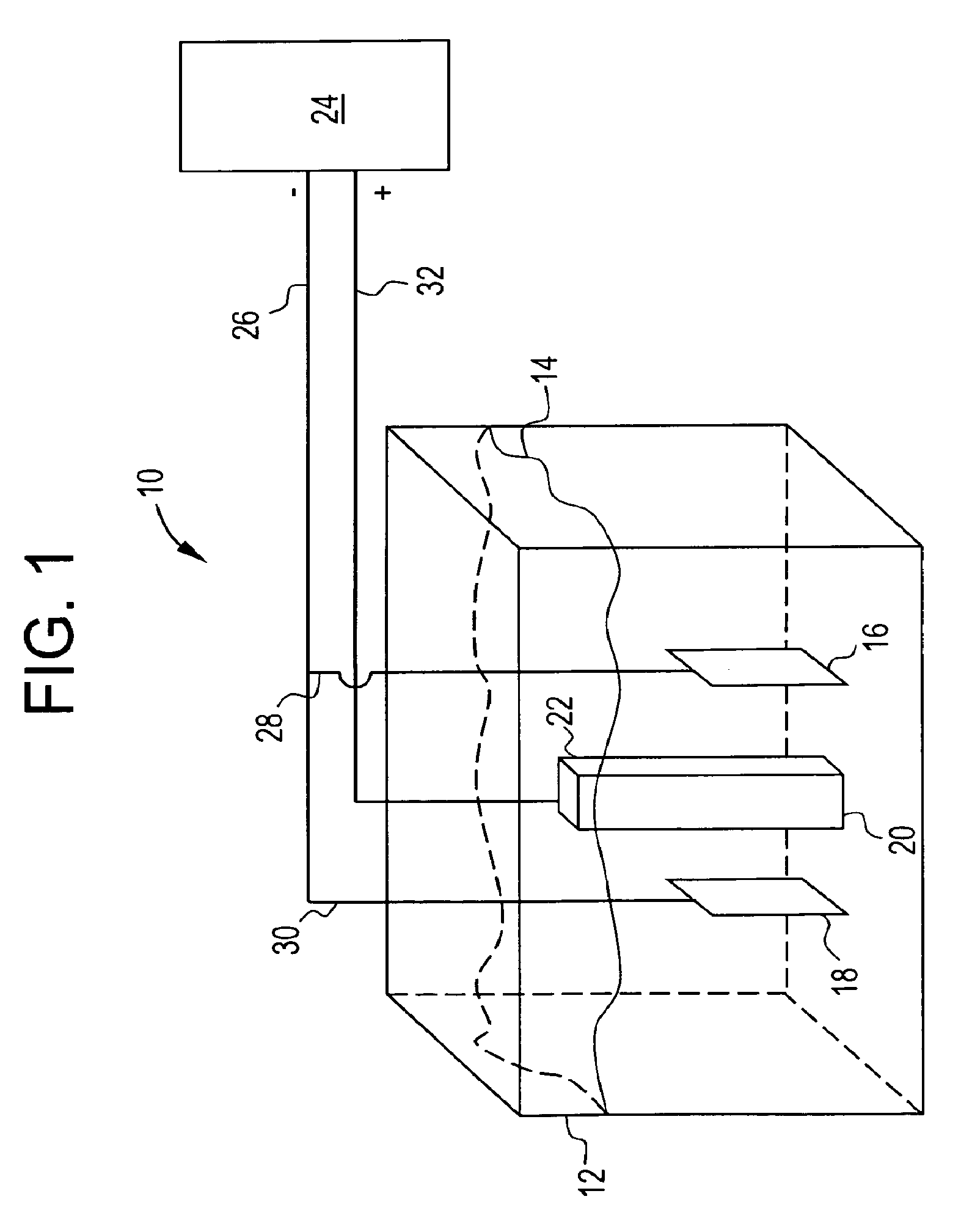

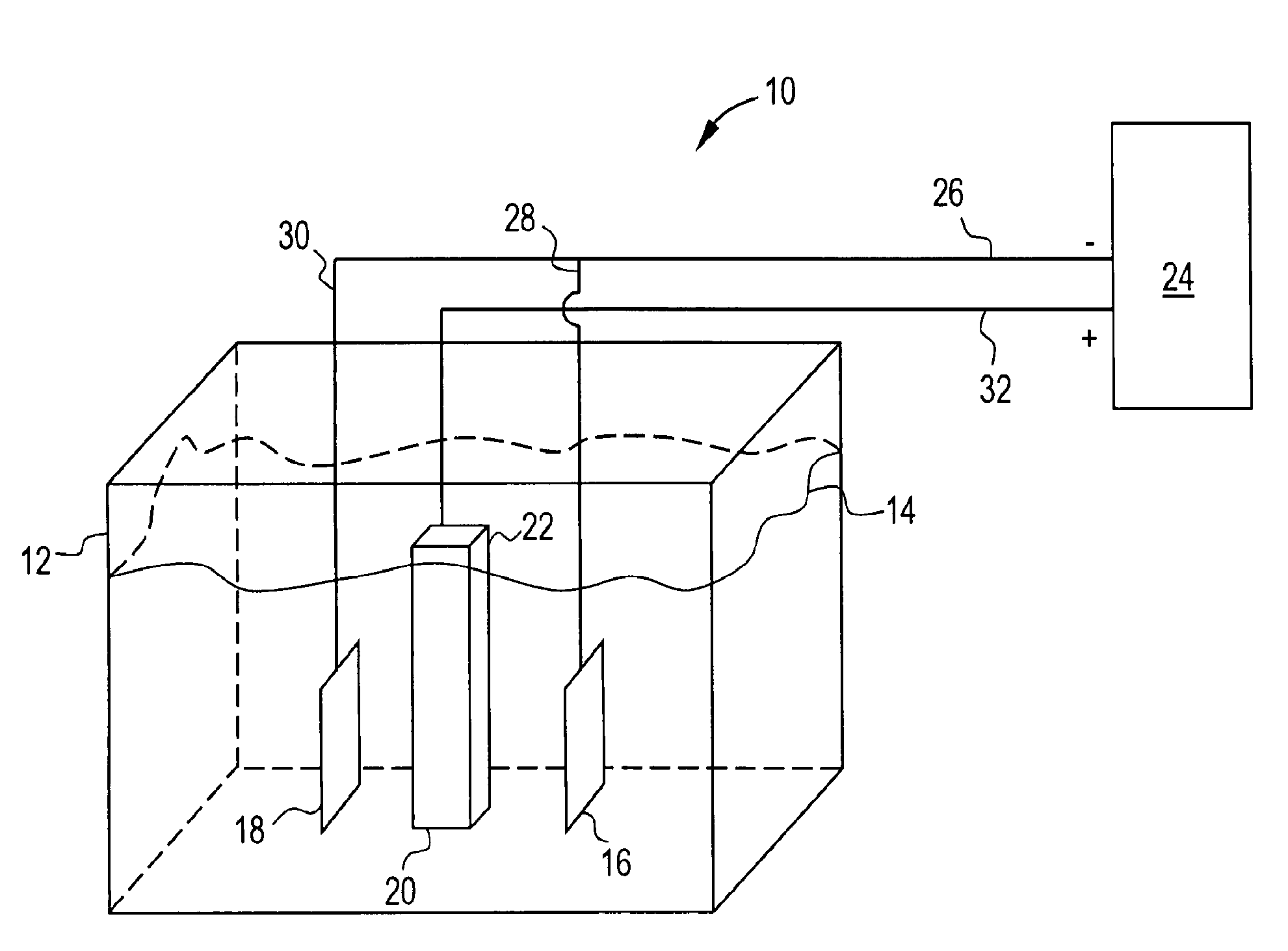

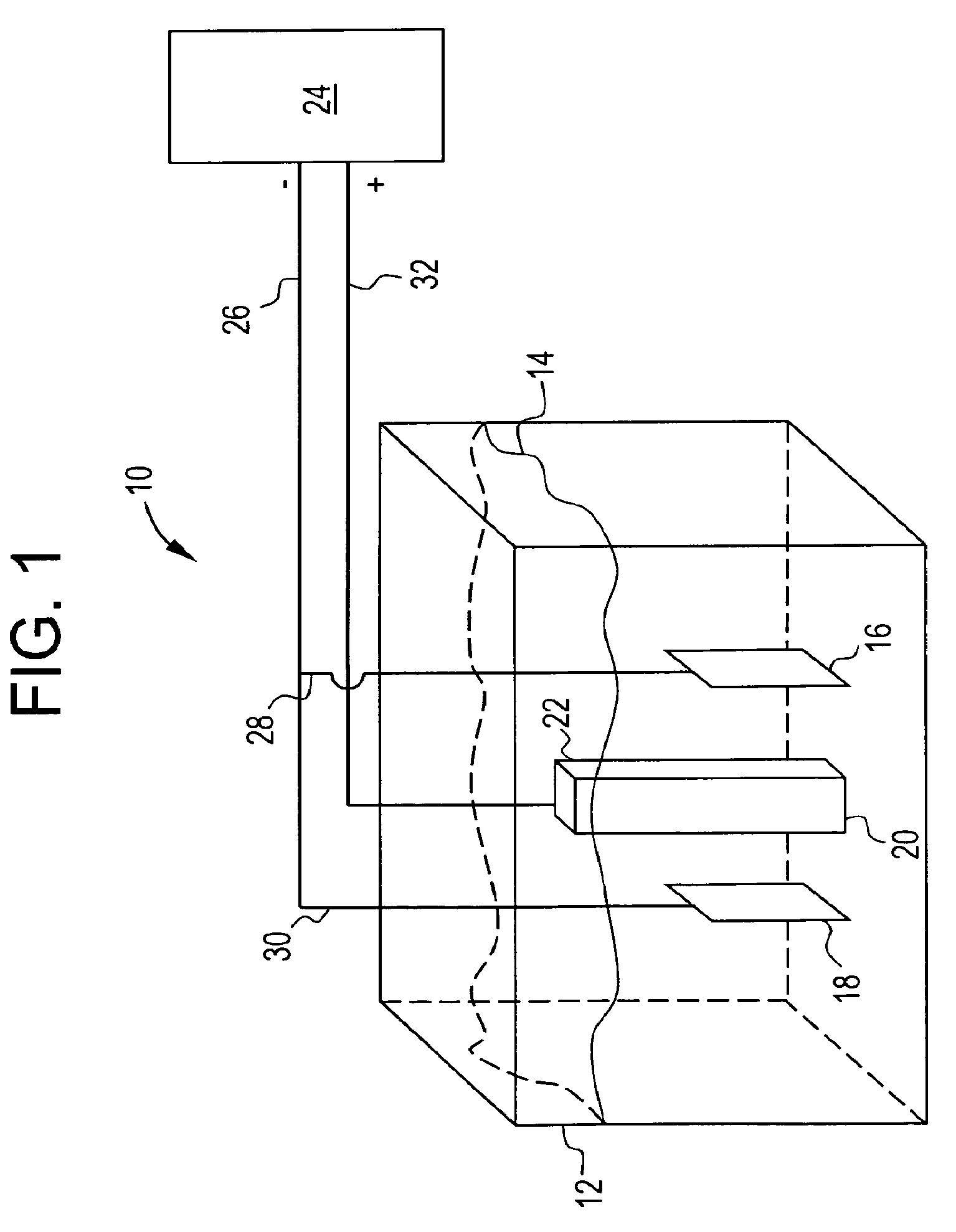

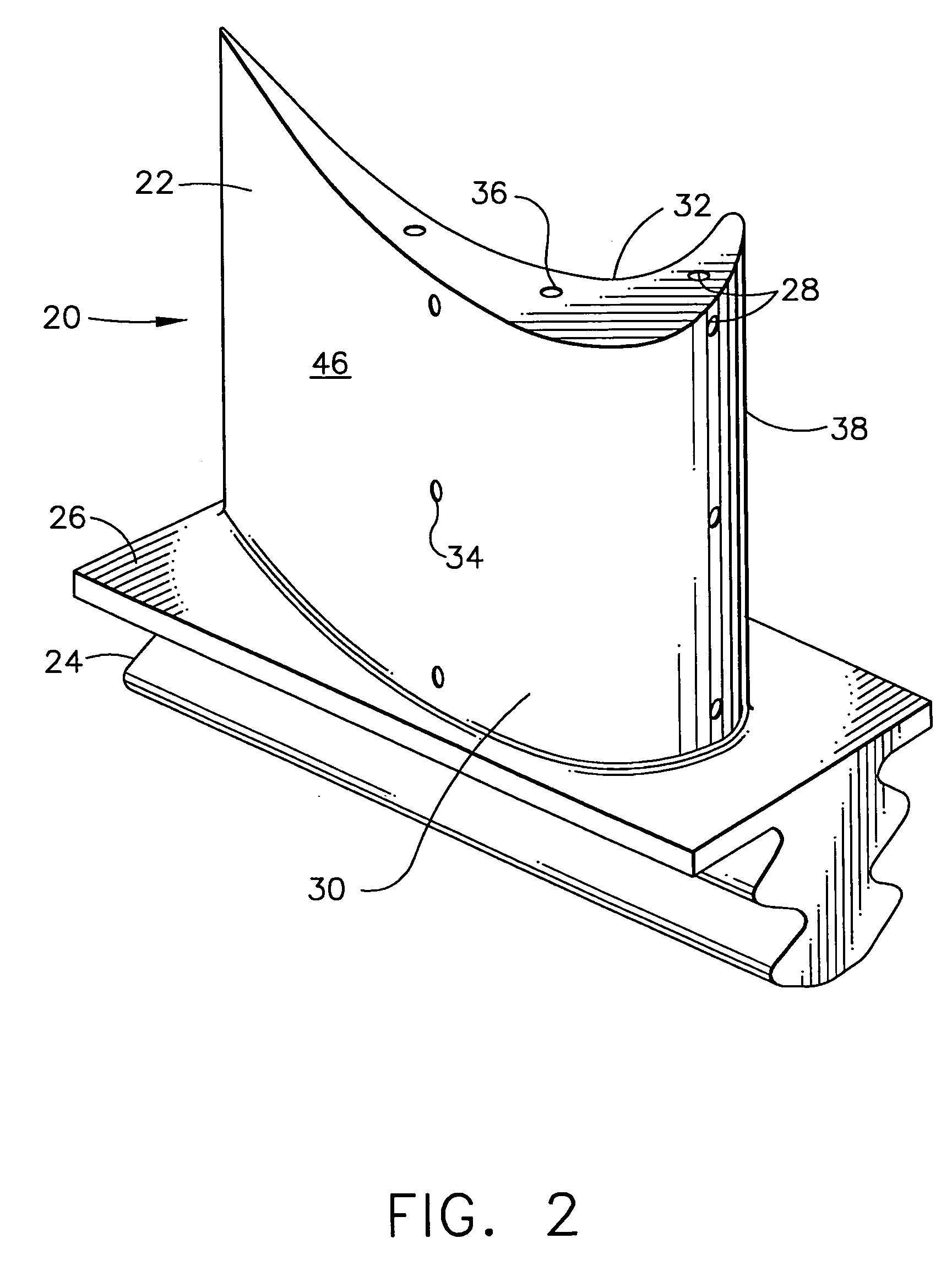

Method for selectively removing coatings from metal substrates

ActiveUS20090261068A1Low aluminum contentIncrease resistanceDecorative surface effectsBlade accessoriesAluminum levelsMetallic substrate

A method for selectively removing an aluminum-poor overlay coating from a substrate of a component, which as a result of its low aluminum content is highly resistant to a selective stripping solution. The method entails diffusing aluminum into the overlay coating to form an aluminum-infused overlay coating having an increased aluminum level in at least an outer surface thereof. The diffusion step is carried out so that the increased aluminum level is sufficient to render the aluminum-infused overlay coating removable by selective stripping. The outer surface of the aluminum-infused overlay coating is then contacted with an aqueous composition to remove the aluminum-infused overlay coating from the substrate. The aqueous composition includes at least one acid having the formula HxAF6, and / or precursors thereof, wherein A is Si, Ge, Ti, Zr, Al, and / or Ga, and x is from 1 to 6.

Owner:GENERAL ELECTRIC CO

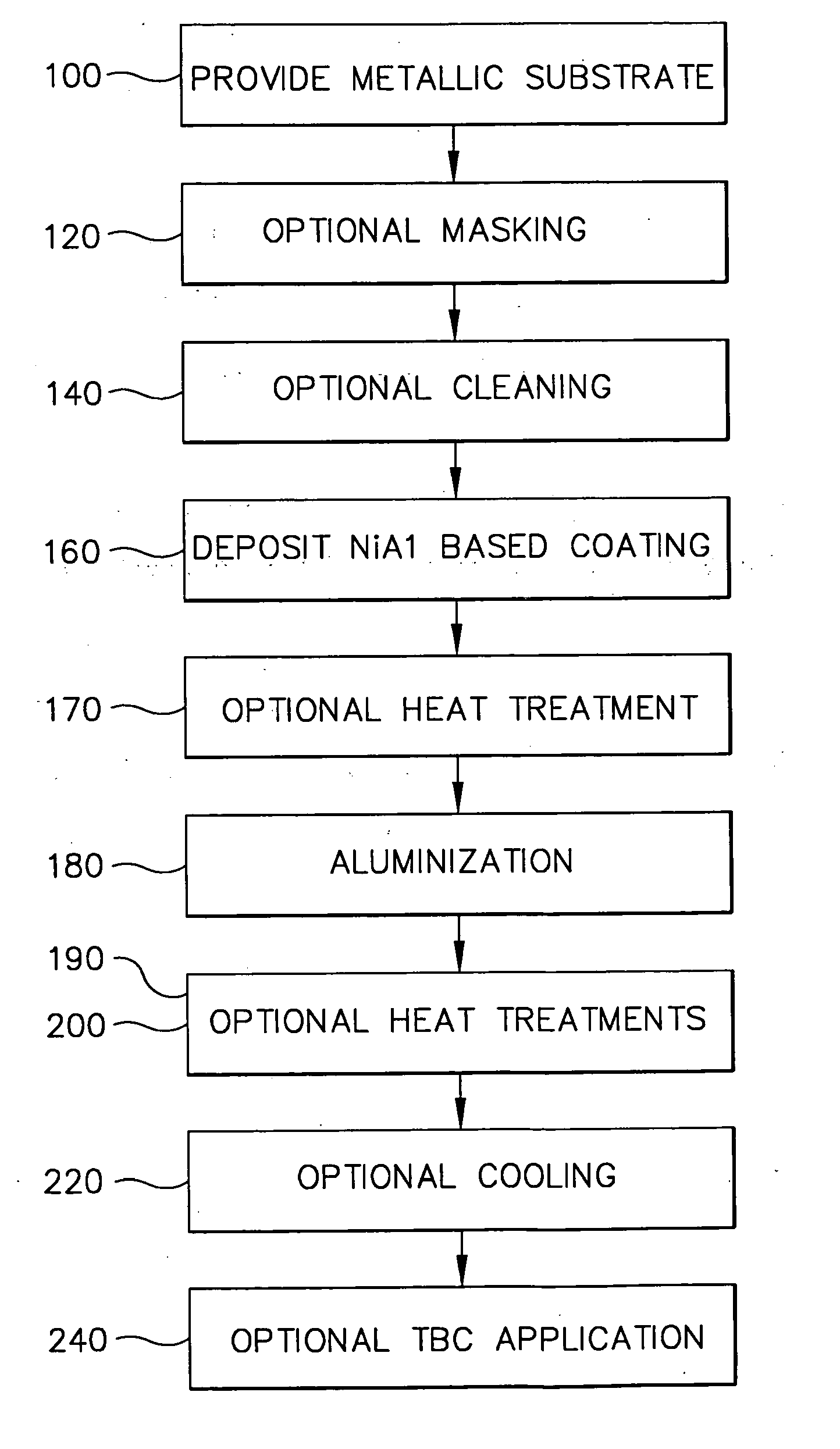

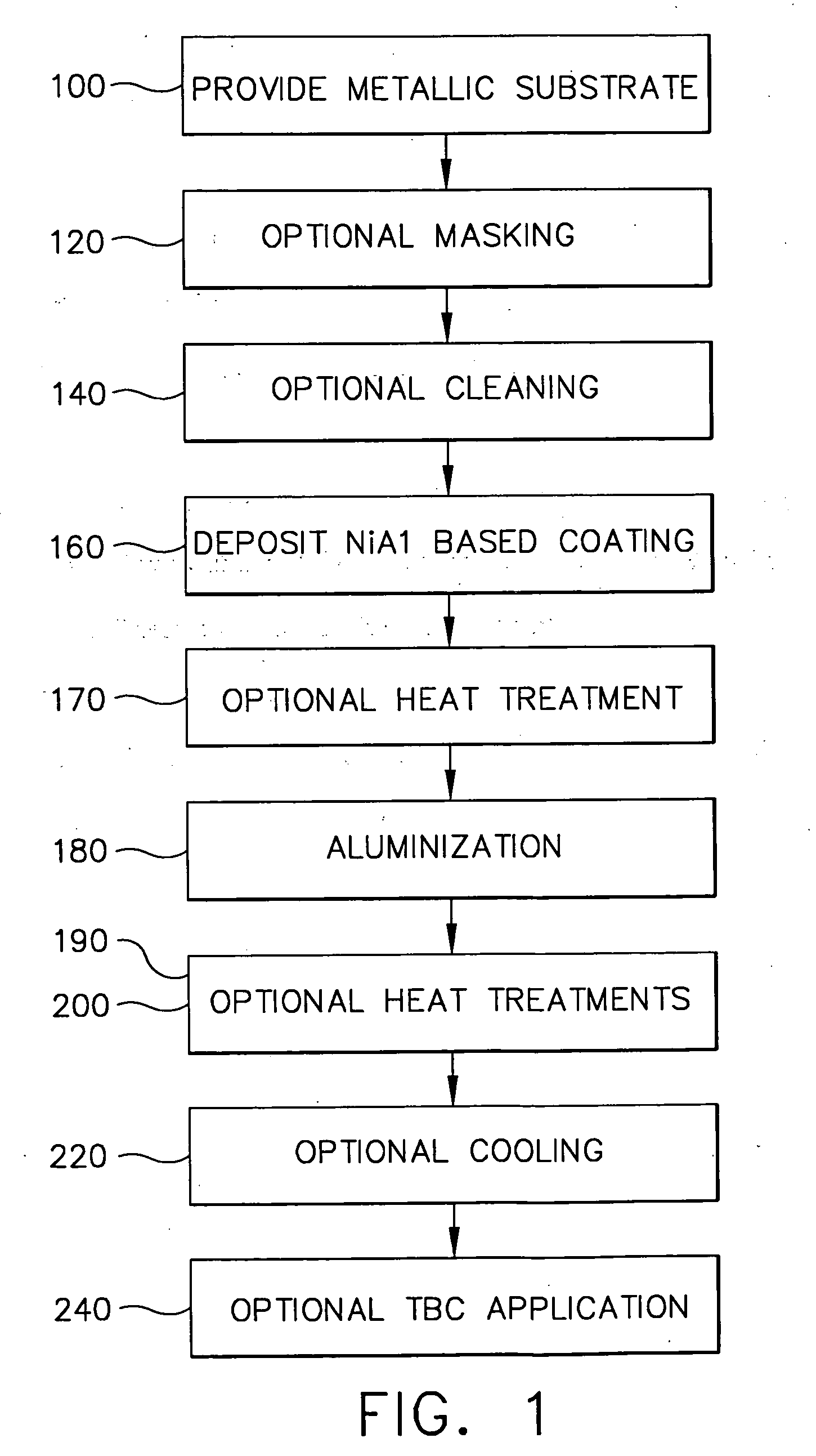

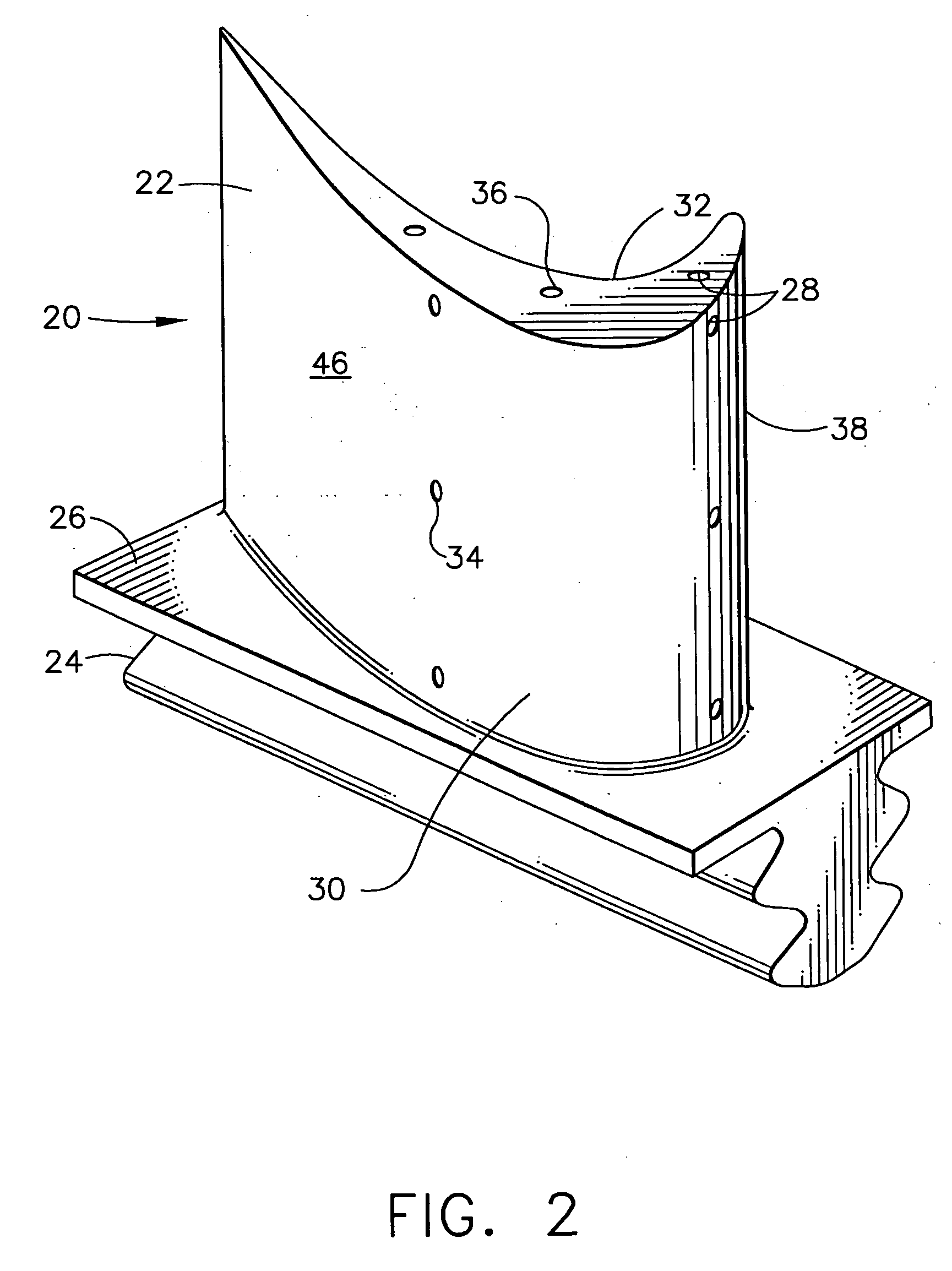

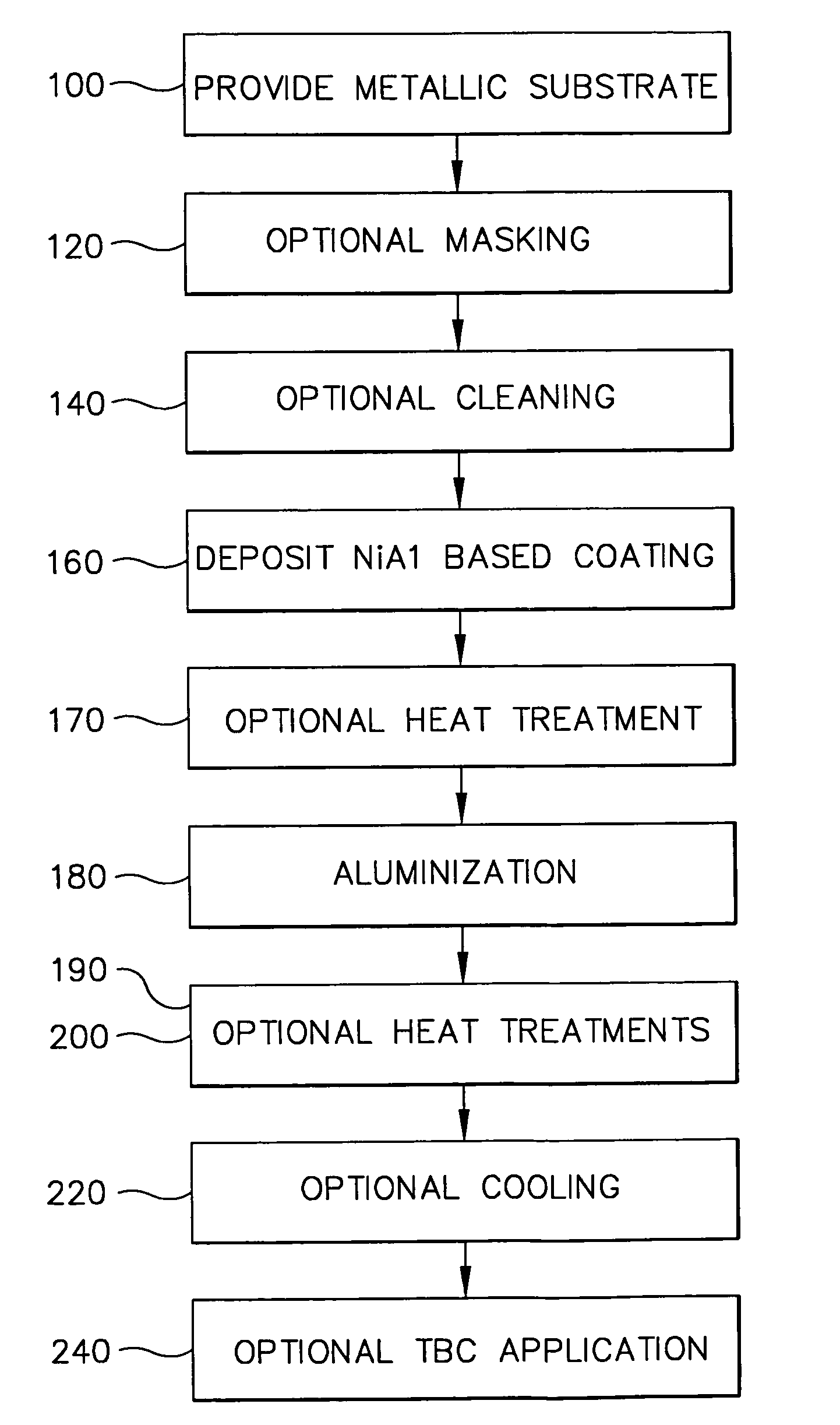

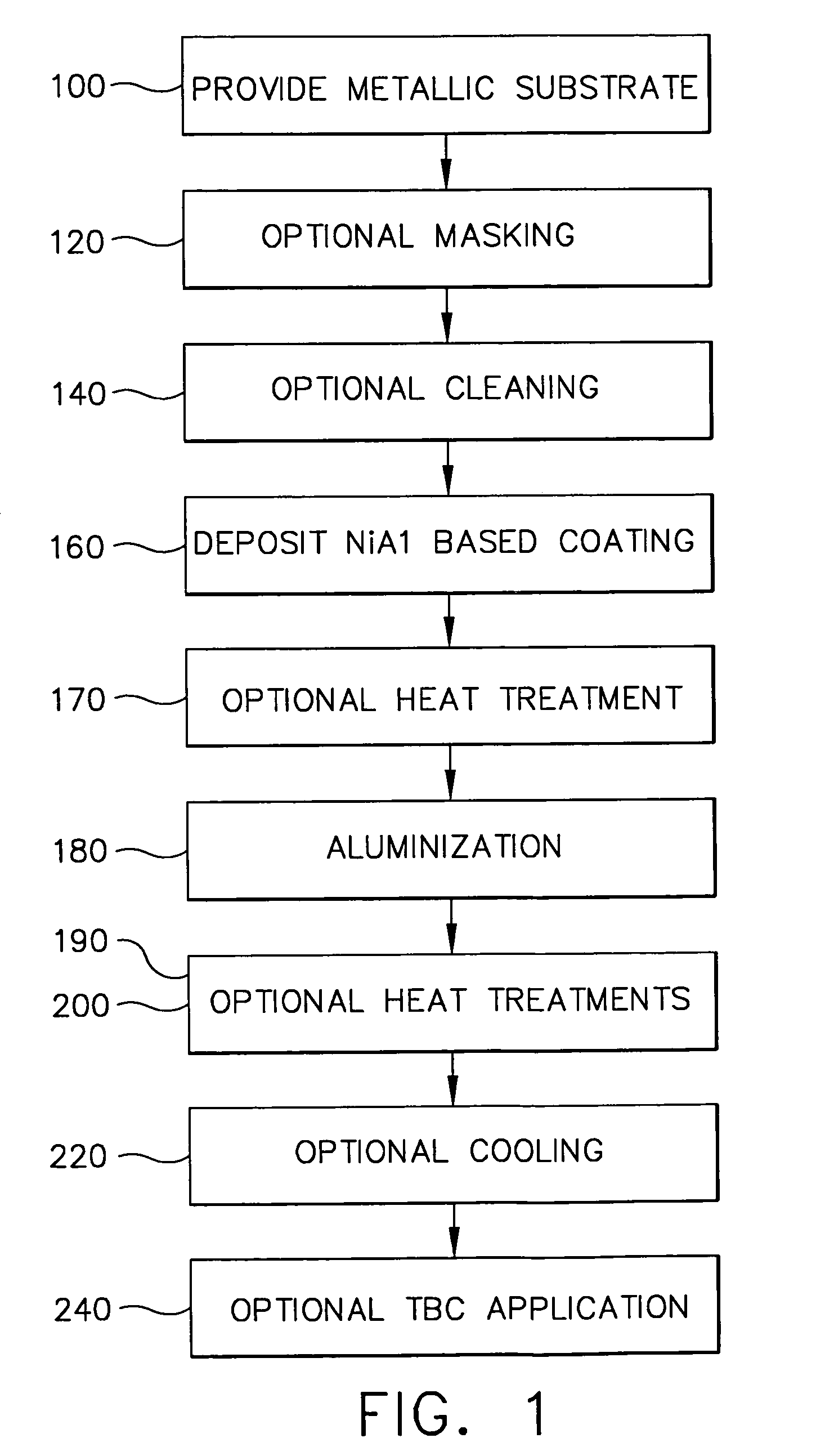

Bond coat with low deposited aluminum level and method therefore

A method for applying a NiAl based bond coat and a diffusion aluminide coating to a metal substrate comprises, in part, coating a portion of the external surface of the superalloy substrate, by physical vapor deposition with a layer of a NiAl based metal alloy, wherein the deposited NiAl based metal alloy includes a controlled amount of about 6 to 25 weight percent aluminum, wherein the deposited aluminum level of the NiAl based metal alloy is controlled to be about 50-100% of its final level after aluminizing to form a coated external portion; and subsequently, simultaneously aluminizing the coated external portion and a different surface of the superalloy substrate.

Owner:GENERAL ELECTRIC CO

Low polar distance energy-saving production method for aluminum electrolysis bath

The invention discloses a low polar distance energy-saving manufacturing method for an aluminum cell, which meets the requirement of energy balance by adjustment of technical parameters on the basis of the prior art, comprising the steps that: firstly, voltage adjustment, namely the set voltage of the electrolytic cells is adjusted to be 4.1 volts in the first two weeks, adjusted from 4.1 volts to 4.05 volts in the third week, adjusted from 4.05 volts to 4.0 volts in the fourth week and adjusted from 4.0 volts to 3.99 volts in the fifth week; secondly, adjustment of the aluminum level and the electrolyte level, namely cryolites or electrolyte blocks are added for improving 1 to 2 centimeters of the electrolyte height and the aluminum level is improved 1 to 2 centimeters or so by use of three to five weeks; thirdly, improvement of the molecule ratio and reduction of the superheat degree, namely the molecule ratio is improved from the prior 2.2 to 2.3 to 2.35 to 2.45 within three to five weeks by adoption of the method for reducing the addition amount of aluminum fluorides. The improvement of the primary crystal temperature and the reduction of the superheat degree play an important role in stabilizing electrolyte production, play a certain role in formation of a hearthside and a furnace cavity, and enable the hearthside and the furnace cavity to enter the state of normal production in advance.

Owner:HENAN ZHONGFU IND

High-performance double zero aluminum foil and manufacturing method

InactiveCN108060334AImprove yieldHigh strengthMetal rolling arrangementsEconomic benefitsAluminum foil

The invention discloses a high-performance double zero aluminum foil and a manufacturing method. The method comprises the steps of smelting, casting rolling, cold rolling, high temperature annealing,secondary cold rolling, intermediate annealing, finished product forming through foil rolling and the like and is used for producing the high-performance double zero aluminum foil, and an obtained aluminum foil blank is low in strip breakage number, high in yield, smooth and clean in surface and free of color difference; the obtained high-performance double zero aluminum foil is good in performance and high in strength and exceeds zero aluminum foil produced through common cast-rolled blanks, the difference of anisotropism of the internal structure of the cast-rolled blank is reduced, hot-rolled rough materials can be replaced, the double high advantages of economic benefits and production efficiency are achieved, meanwhile, a liquid level monitoring device is arranged, constancy of the molten aluminum level in a certain precision range is ensured, the production quality of the aluminum foil is ensured, and the performance of the high-performance double zero aluminum foil is improved indirectly.

Owner:JIANGSU DINGSHENG NEW MATERIAL JOINT STOCK CO LTD

Method for selectively removing coatings from metal substrates

ActiveUS8021491B2Reduce contentIncrease resistanceDecorative surface effectsBlade accessoriesAluminum levelsMetallic substrate

A method for selectively removing an aluminum-poor overlay coating from a substrate of a component, which as a result of its low aluminum content is highly resistant to a selective stripping solution. The method entails diffusing aluminum into the overlay coating to form an aluminum-infused overlay coating having an increased aluminum level in at least an outer surface thereof. The diffusion step is carried out so that the increased aluminum level is sufficient to render the aluminum-infused overlay coating removable by selective stripping. The outer surface of the aluminum-infused overlay coating is then contacted with an aqueous composition to remove the aluminum-infused overlay coating from the substrate. The aqueous composition includes at least one acid having the formula HxAF6, and / or precursors thereof, wherein A is Si, Ge, Ti, Zr, Al, and / or Ga, and x is from 1 to 6.

Owner:GENERAL ELECTRIC CO

Fast voltage-reducing energy-saving starting method for aluminum electrolysis bath

The invention discloses a method for quick starting, voltage reduction and energy conservation of an aluminum cell, comprising the following steps that: the molecule ratio is quickly reduced by maintenance of the electrolysis temperature in the aluminum cell on the basis of the prior art; the intermediate electrolysis temperature is maintained; the low-effect coefficient is matched so as to maintain the aluminum level and the electrolyte level at adequate height; operation of low alumina concentration in the cell is maintained; the operating voltage is quickly reduced; a hearthside of the electrolytic cell is quickly formed; and the new energy balance is established, which lays a foundation for quick reduction of the voltage. By adoption of the invention, compared with normal starting and final-period management, a single electrolytic cell directly reduces 12 volt voltage or so and directly saves 92200 degree electricity; moreover, when the electrical energy is saved, the influence of intermediate production management on equipment is declined; the service life of the electrolytic cell is indirectly improved and exhaust of dusty gases is reduced; the production operating cost is indirectly reduced and the aim of environmental control is achieved.

Owner:HENAN ZHONGFU IND

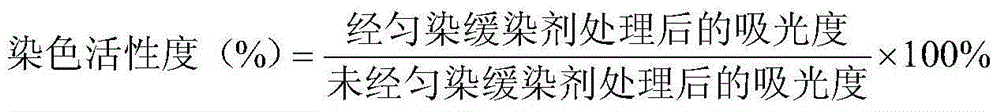

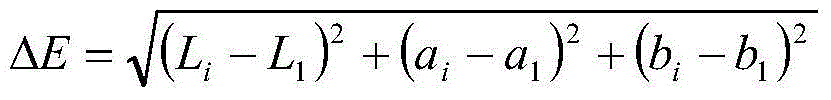

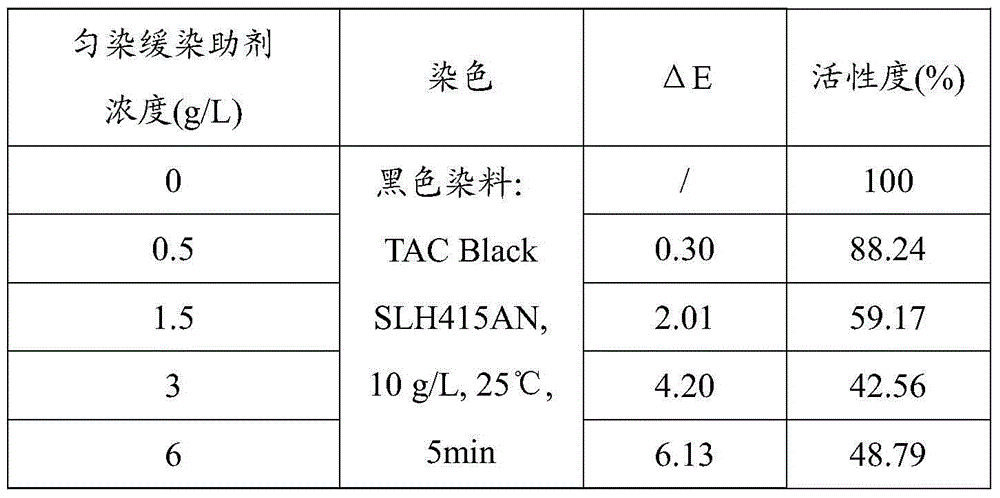

Anodic aluminum level dyeing retarding aid and operating liquid thereof as well as anodic aluminum level dyeing retarding treatment process

ActiveCN104651905ANo need to reduce film thicknessReduce film thicknessSurface reaction electrolytic coatingCarboxylic saltCarboxylic acid

The invention provides an anodic aluminum level dyeing retarding aid. The anodic aluminum level dyeing retarding aid comprises a first active ingredient, a second active ingredient and an auxiliary additive; the first active ingredient comprises one or more of compounds containing a carboxylic acid group, carboxylates, substituted carboxylates, carboxylic acid anhydride, amino acid salts and amino acid anhydride; the second active ingredient comprises a compound containing a sulfonic acid group and / or a sulfonate; and the auxiliary additive comprises one or more of a pH stabilizer, an anti-caking agent and an anti-scaling agent. The aid has an excellent level dyeing retarding effect, and is capable of solving the problem of easy local chromatic aberration or surface floating in the dyeing step of anodized aluminum in the prior art and smoothly realizing chromatic aberration-free undertint dyeing and finishing under the circumstance of keeping excellent mechanical and chemical properties of an anodized film. The invention also provides an anodic aluminum level dyeing retarding aid operating liquid based on the aid, and an anodic aluminum level dyeing retarding treatment process.

Owner:RAMBO NANOTECH SHENZHEN

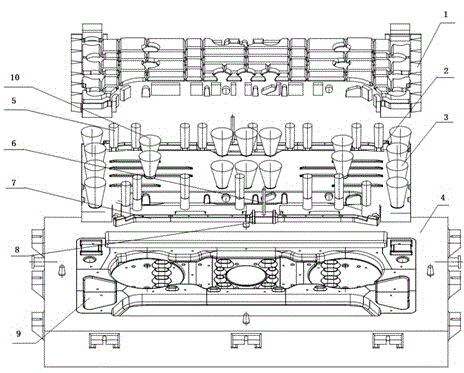

Casting system and casting method for aluminum alloy sleeper beam of standard motor train unit steering frame

The invention discloses a casting system and a casting method for an aluminum alloy sleeper beam of a standard motor train unit steering frame. The system is characterized by being composed of random chilling blocks on the upper portion, a middle cavity and a lower metal bottom mold. Cross gates, gate sprues and gap gates are formed in the cavity, and a ceramic filter pipe is arranged at the connecting positions of the cross gates and the gate sprues. The casting method is characterized by comprising the steps that (1) molten aluminum is injected into a casting groove, and enters the gate sprues, and through slag removing of the ceramic filter piece, the molten aluminum enters the double-bridge cross gates, and then enters the cavity; (2) when the middle heat preservation risers, heat preservation risers at the two ends and heat preservation side risers are filled with the molten aluminum by one half, pouring is stopped, the molten aluminum level in the risers descends, and at the moment, a certain amount of the molten aluminum is directly casted into the risers. The system and method have the advantages that a casting manner of gravity two-end opposite casting is adopted, smooth filling is ensured, generation of splashing and casting defects is avoided, the risers and multi-chilling-block chilling feeding are adopted in local heat joints, and the internal quality and body performance of a casting are obviously improved.

Owner:辽宁北方精密设备有限公司

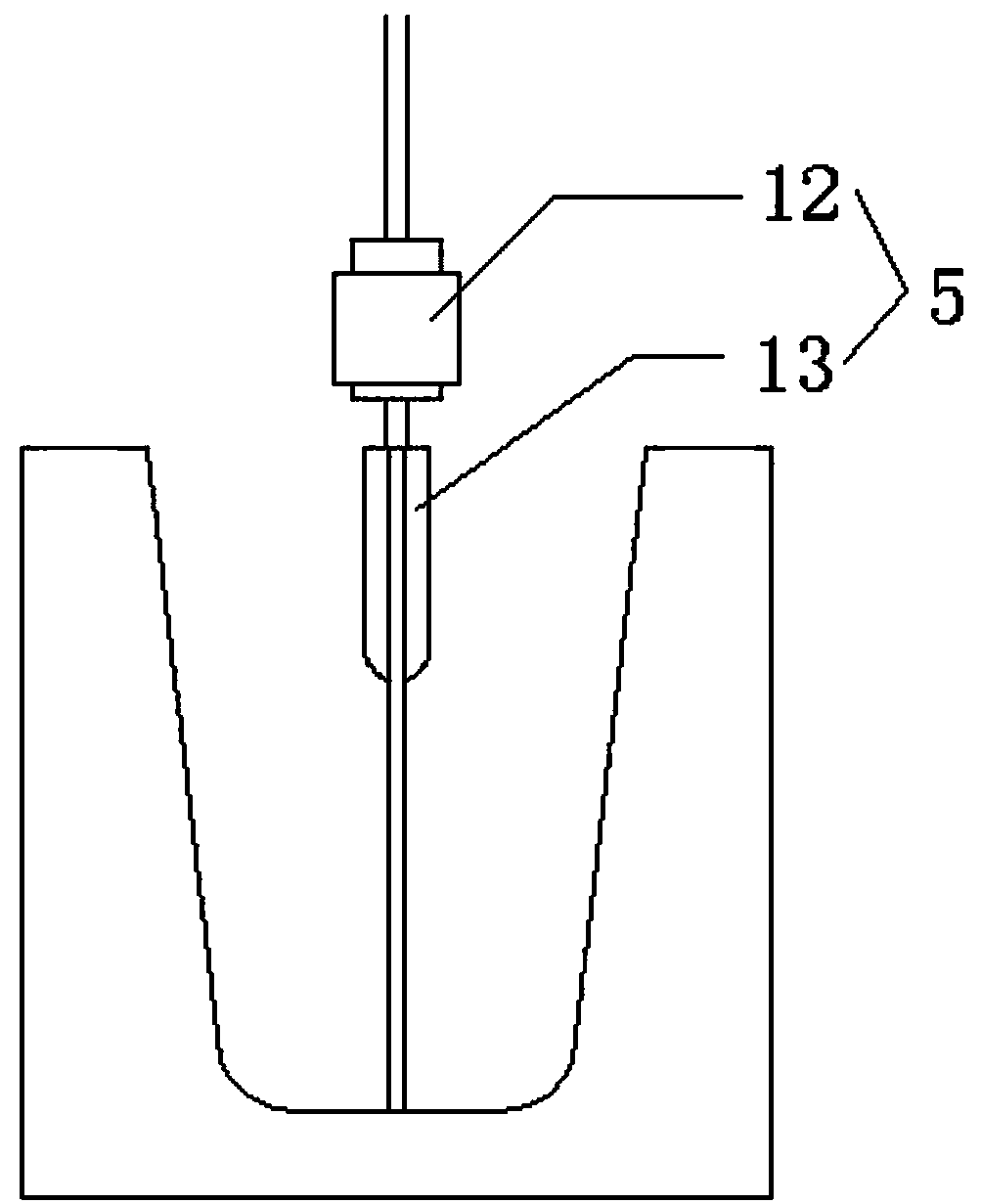

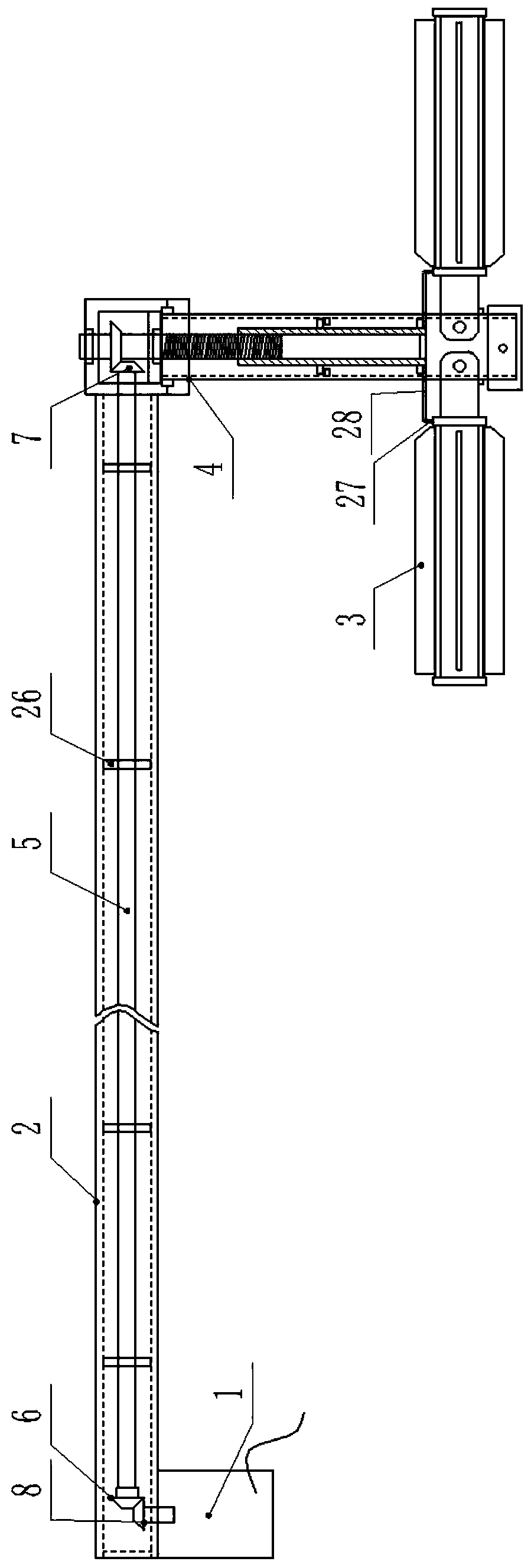

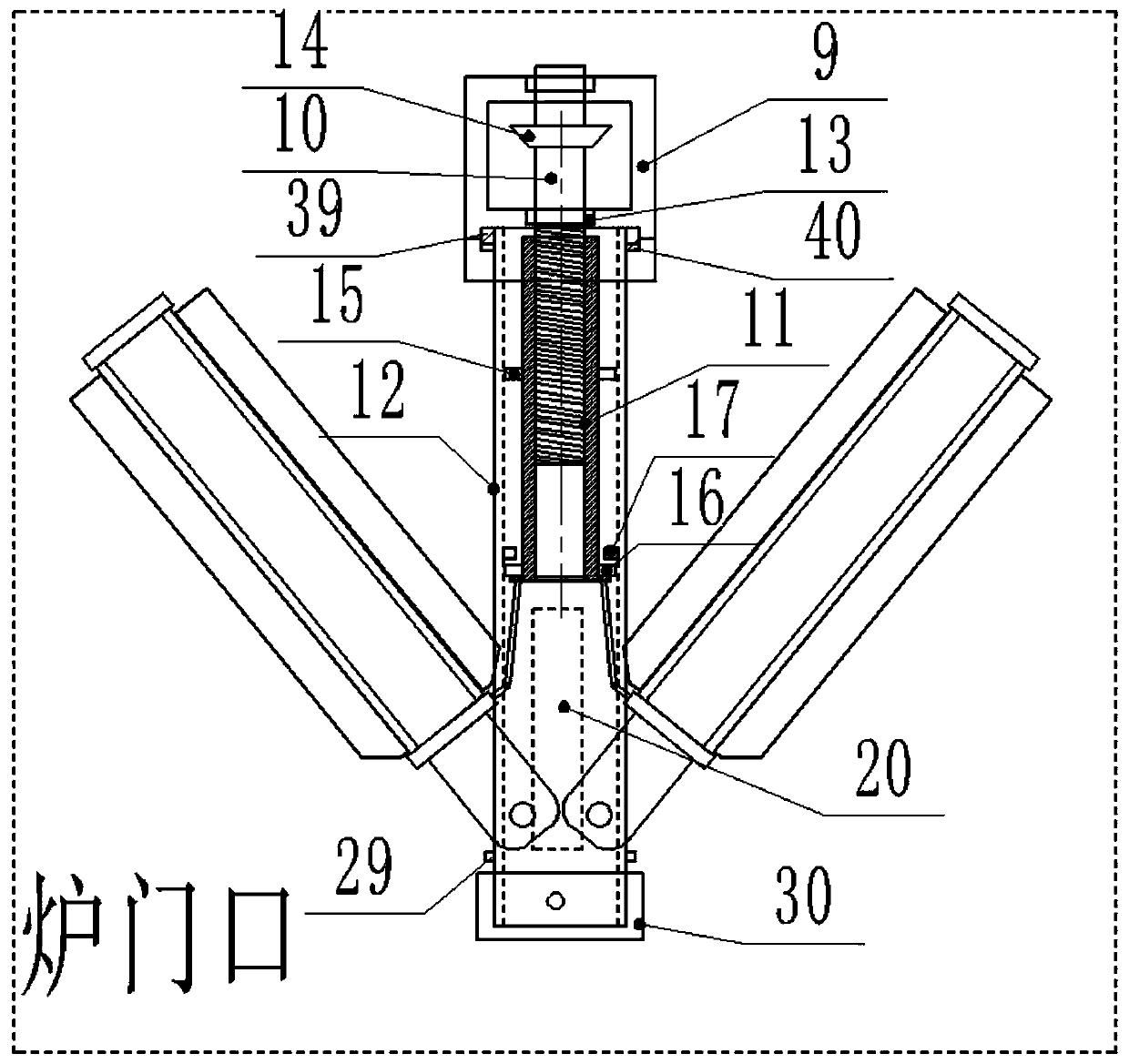

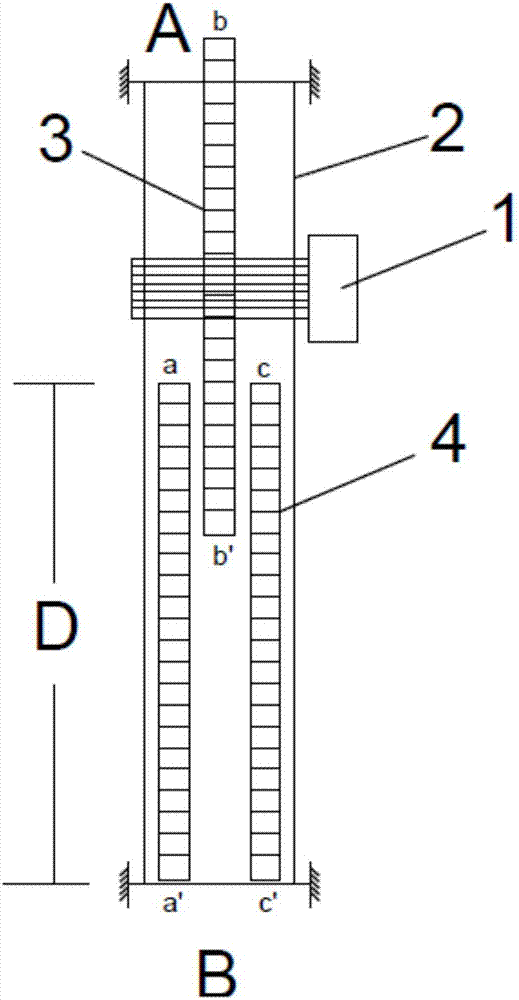

Aluminum level and electrolyte level measurement tool and method of aluminum electrolysis cell

InactiveCN103791978AGuaranteed uptimeAvoid the effects of surface conditionsMachines/enginesLevel indicatorsElectrolytes levelsAluminum levels

The invention discloses an aluminum level and electrolyte level measurement tool and method of an aluminum electrolysis cell. The aluminum level and electrolyte level measurement method of the aluminum electrolysis cell comprises steps that a probe is inserted into the aluminum electrolysis cell vertically, and first preset distance is reversed between the lower end of the probe and a cathode carbon block at the bottom of the aluminum electrolysis cell. According to the aluminum level and electrolyte level measurement method of the aluminum electrolysis cell, the first preset distance is reversed between the lower end of the probe and the cathode carbon block at the bottom of the aluminum electrolysis cell, therefore, the probe does not contact with the cathode carbon block, influence of the surface situation of the cathode carbon block on the measured aluminum level and electrolyte level is avoided, accuracy and comparable performance of the measured aluminum level and electrolyte level are improved, and normal and stable operation of the aluminum electrolysis cell is ensured.

Owner:YUNNAN YONGXIN ALUMINUM +1

Bond coat with low deposited aluminum level and method therefore

A method for applying a NiAl based bond coat and a diffusion aluminide coating to a metal substrate comprises, in part, coating a portion of the external surface of the superalloy substrate, by physical vapor deposition with a layer of a NiAl based metal alloy, wherein the deposited NiAl based metal alloy includes a controlled amount of about 6 to 25 weight percent aluminum, wherein the deposited aluminum level of the NiAl based metal alloy is controlled to be about 50-100% of its final level after aluminizing to form a coated external portion; and subsequently, simultaneously aluminizing the coated external portion and a different surface of the superalloy substrate.

Owner:GENERAL ELECTRIC CO

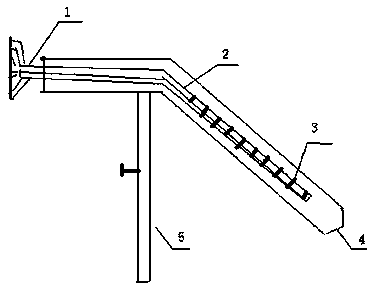

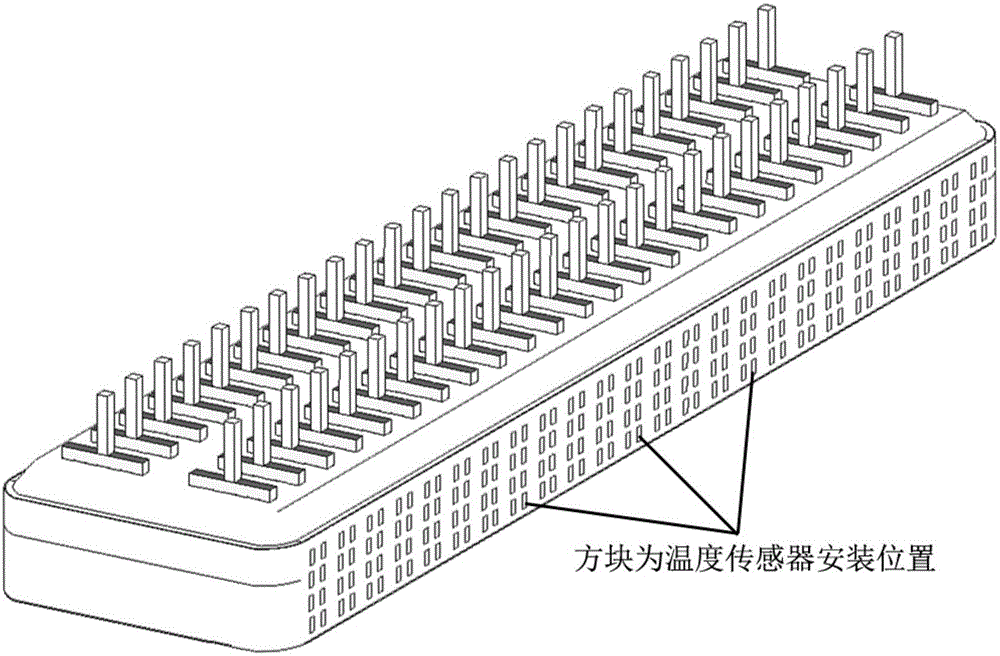

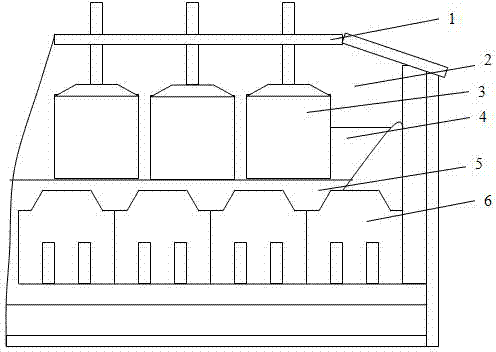

Device and method for comprehensively measuring temperature and aluminum level in aluminum electrolytic process

InactiveCN103954320AReduced measurement timeLow costMeasurement devicesMeasurement deviceAluminum levels

The invention discloses a device for measuring temperature and aluminum level in the aluminum electrolytic process. The device comprises 8-12 temperature sensing nodes which are linearly arranged, and the distances between adjacent temperature sensing nodes are 0.8-1.2 cm. In measurement, nodes of a sensor are inserted into molten aluminum and electrolyte, and the aluminum level is calculated according to temperature measured by the temperature sensing nodes. The device can be used for measuring electrolyte temperature, molten aluminum temperature and aluminum level at the same time, and measuring time is greatly shortened. In addition, temperature measuring and aluminum level measuring sensors and instruments are integrated, and cost is not increased.

Owner:NORTH CHINA UNIVERSITY OF TECHNOLOGY

Control method for clearing up furnace hearth of aluminum cell

The invention discloses a control method for clearing up a furnace hearth of an aluminum cell. The steps are as follows: reducing the opening degree of a smoke valve of the electrolytic cell, regulating the opening degree of the smoke valve of the aluminum cell to be 10-70 degrees, regulating the additive amount of aluminum fluoride in electrolyte, controlling the molecular ratio to be 2.4-2.6, controlling the temperature of the electrolytic cell to be 958-968 DEG C and the degree of overheat to be 10-15 DEG C, and keeping the regulating time for 15-60 days; after regulating for 20-30 days, increasing the opening degree of the smoke valve, regulating the opening degree of the smoke valve to be 30-80 degrees, and regulating the voltage and aluminum level of the aluminum cell; controlling the voltage of the aluminum cell to be between 3.76V and 3.95V and regulating the aluminum level to be 23-28 cm; and regulating the molecular ratio of the aluminum cell to be 2.3-2.4, and controlling the temperature of the aluminum cell to be 950-960 DEG C and the degree of overheat to be 6-10 DEG C. The control method can improve the distribution uniformity of the current in the electrolytic cell, and improve the current efficiency and the stability of the electrolytic cell.

Owner:LIAOCHENG XINYUAN GRP CO LTD

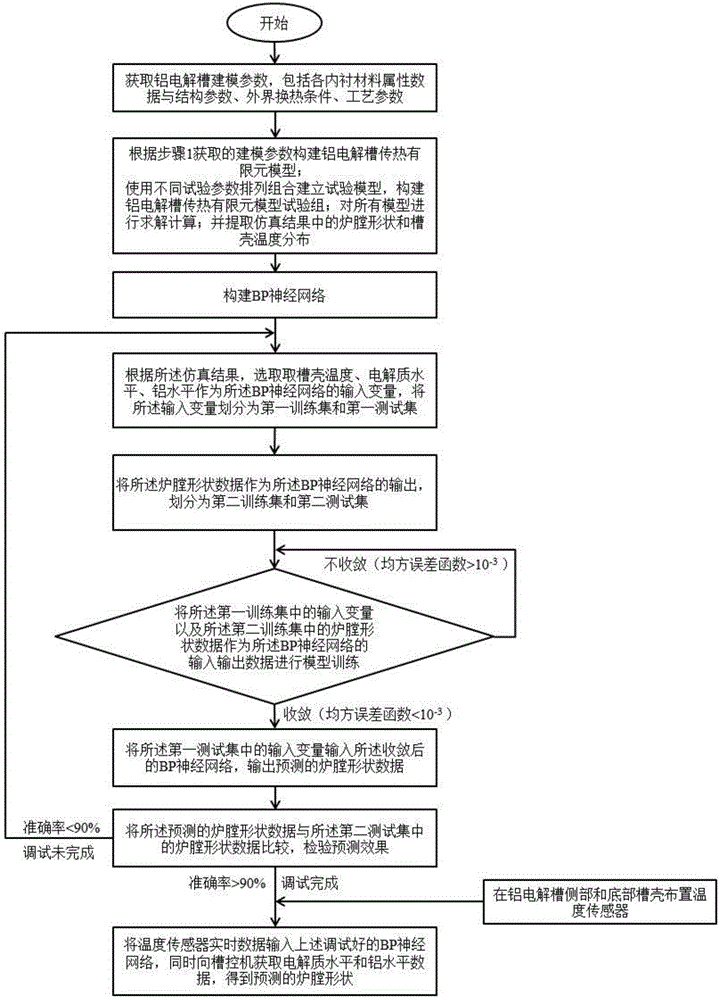

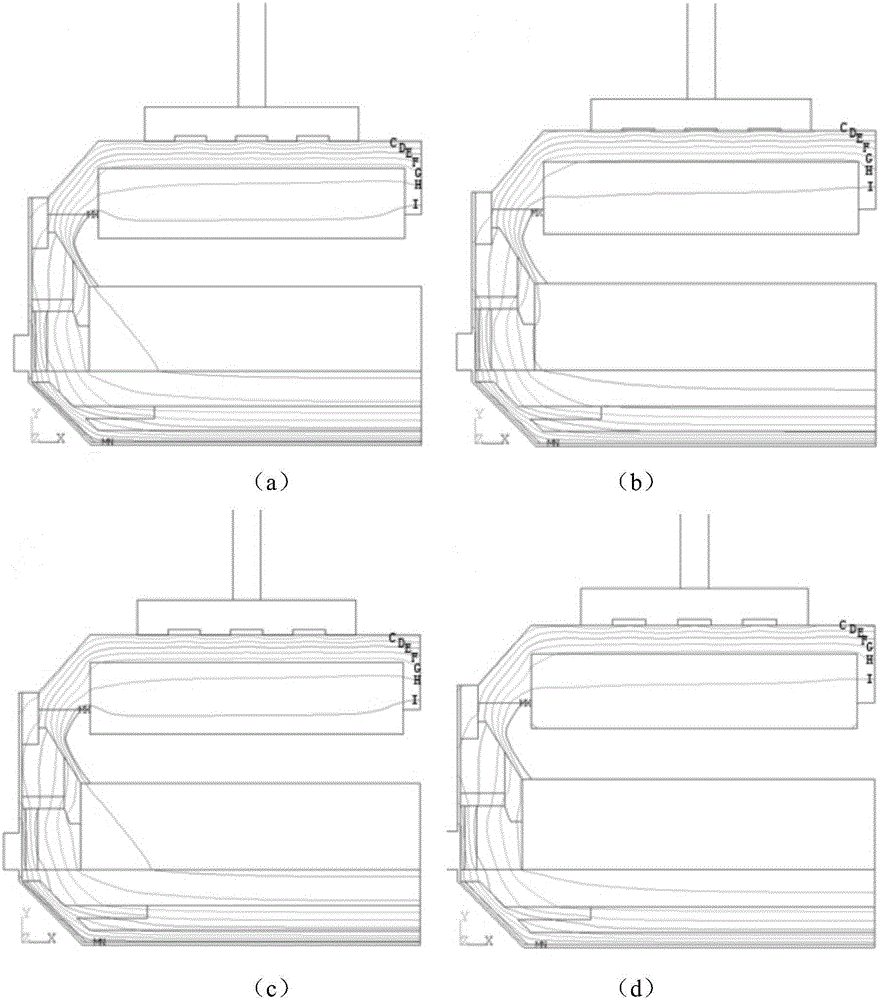

Neural network-based method and system for predicting shapes of three-dimensional hearths of aluminum cells in real time

ActiveCN106709149AEnsure safe productionGuaranteed convergenceDesign optimisation/simulationSpecial data processing applicationsNerve networkElement model

The invention discloses a neural network-based method and system for predicting the shapes of three-dimensional hearths an aluminum cells in real time. The method comprises the following steps of: 1) obtaining aluminum cell modeling parameters; 2) constructing an aluminum cell heat transfer finite element model according to the aluminum cell modeling parameters, carrying out permutation and combination on different experimental parameters to form experimental groups, and respectively inputting each group of experimental parameters in the experimental groups into the aluminum cell heat transfer finite element model to carry out simulation calculation, so as to obtain a hearth shape and a cell shell temperature corresponding to each group experimental parameters; 3) constructing a BP neural network by taking the cell shell temperature, an electrolyte level and an aluminum level as input variables and taking the hearth shape as an output variable; 4) training the BP neural network on the basis of a simulation result in the step 2); and 5) measuring and obtaining the cell shell temperature, the electrolyte level and the aluminum level in real time, and inputting the cell shell temperature, the electrolyte level and the aluminum level into the BP neural network trained in the step 4), so as to obtain a finally predicted hearth shape. According to the method and system disclosed by the invention, the shapes of the three-dimensional hearths of the aluminum cells can be correctly and rapidly predicted.

Owner:CENT SOUTH UNIV

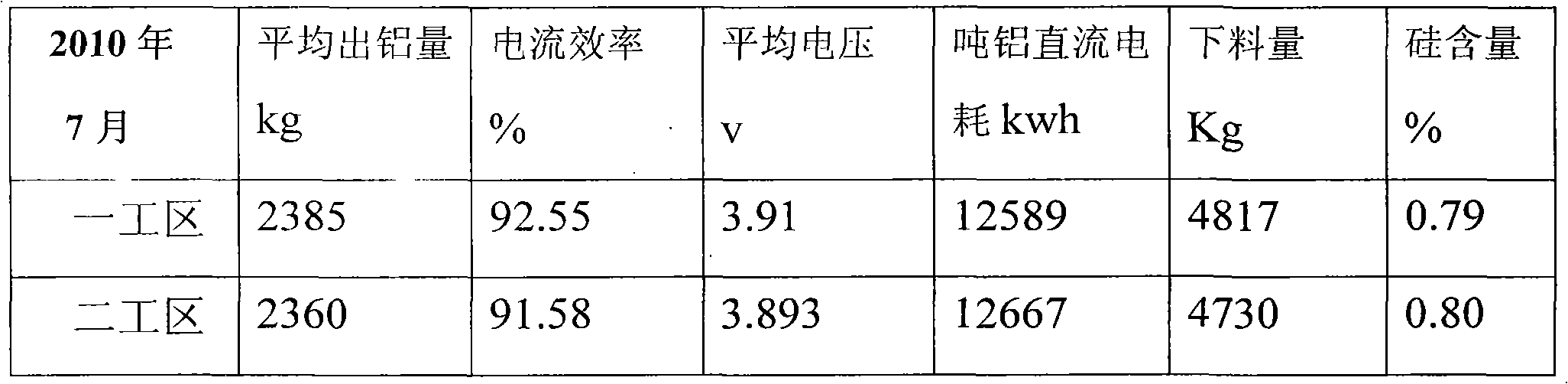

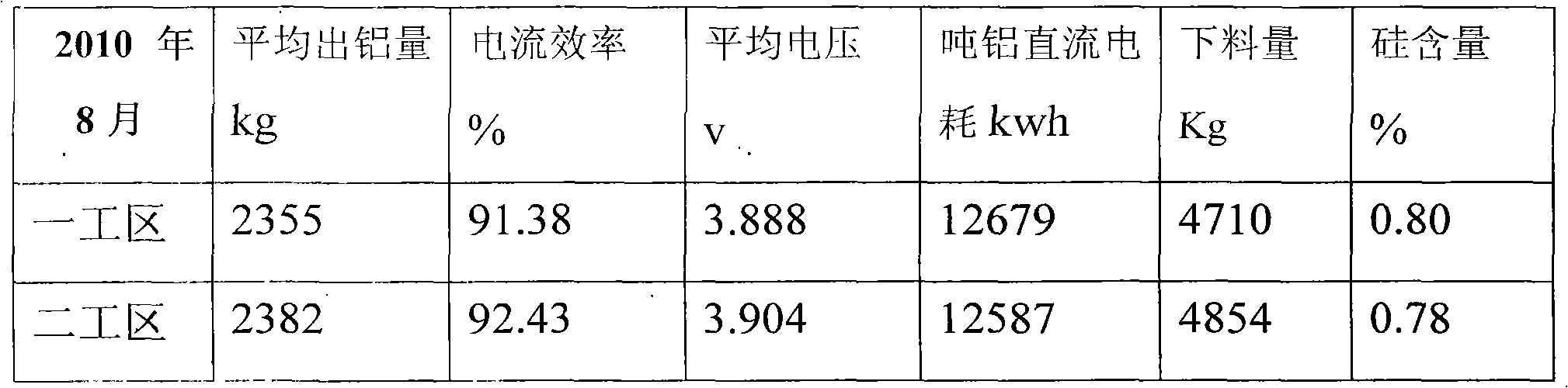

Heat balance control method for aluminum electrolysis cell in low-voltage operation

The invention provides a heat balance control method for an aluminum electrolysis cell in low-voltage operation, which comprises the following steps of: judging the heat and cold trend of the cell condition and determining extruded aluminum yield by controlling cell temperature, electrolyte, aluminum level, feeding amount and a burst effect coefficient and observing the electrolyte viscosity, carbon residue separation condition and burner blocking condition of the electrolysis cell, wherein the extruded aluminum yield is increased or reduced; determining that the aluminum yield of a single cell is 2,200 to 2,500kg; finely adjusting voltage according to the heat and cold trend of the cell condition, namely raising the voltage of an electrolysis cell tending to the cold trend by 10 to 50mv and reducing the voltage of the electrolysis cell tending to the heat trend by 10 to 20mv; and controlling the extrusion period of extruded aluminum to 7 to 10 days, so that the heat and cold amplitude of the cell condition is prevented from being changed due to overlong extrusion period of the extruded aluminum. The method has the advantages of keeping good heat balance of the electrolysis cell, improving current efficiency, reducing the direct current power consumption of each ton of aluminum, and increasing economic benefit.

Owner:HENAN ZHONGFU IND

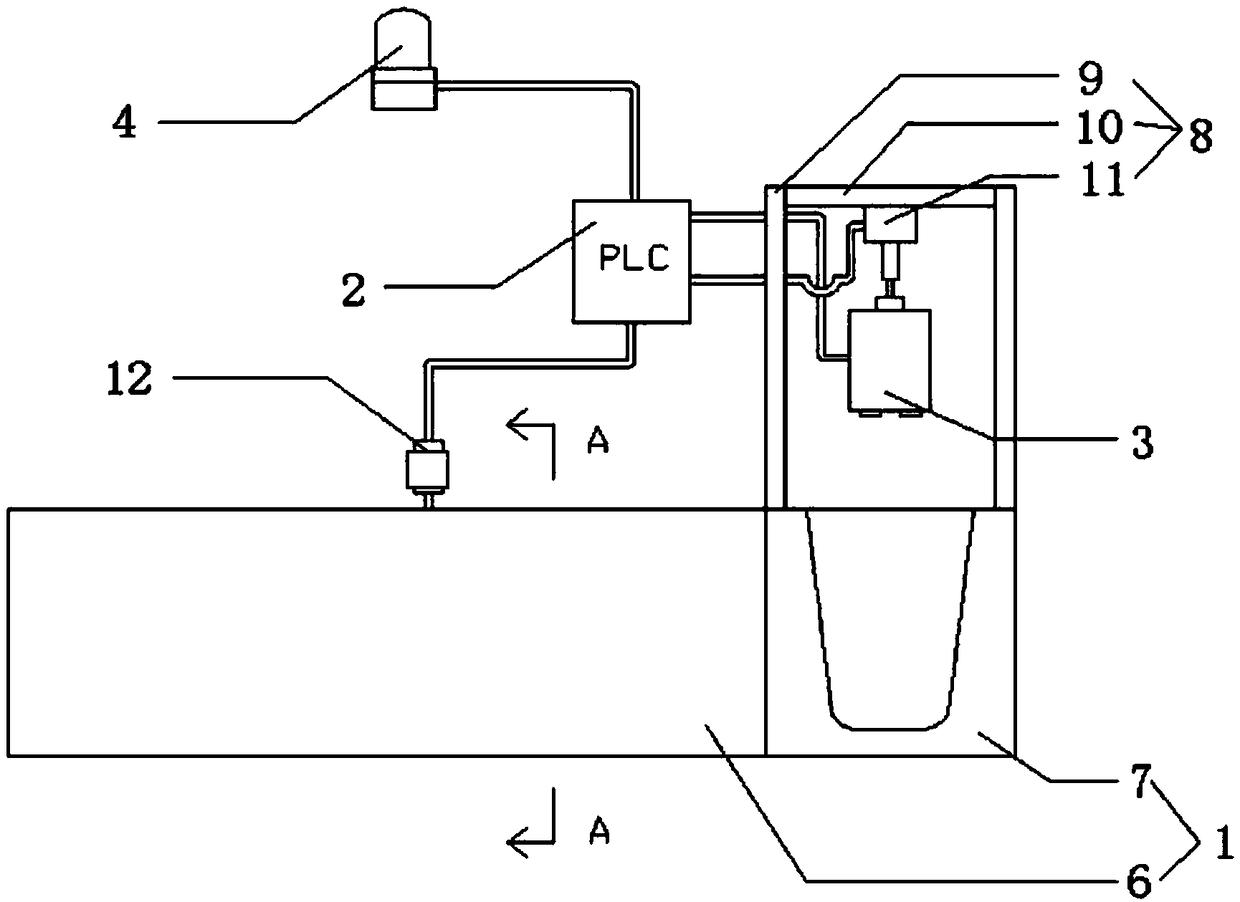

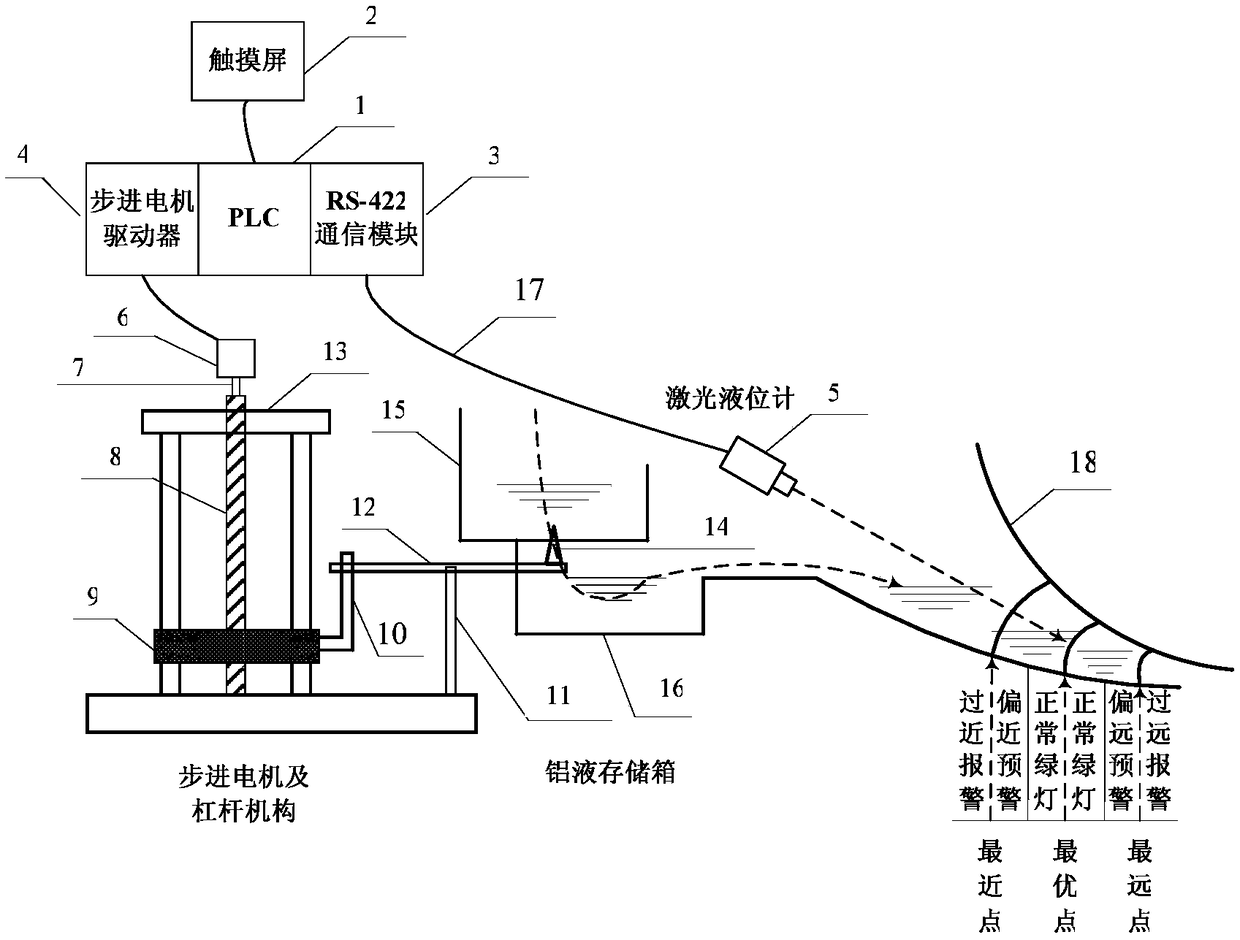

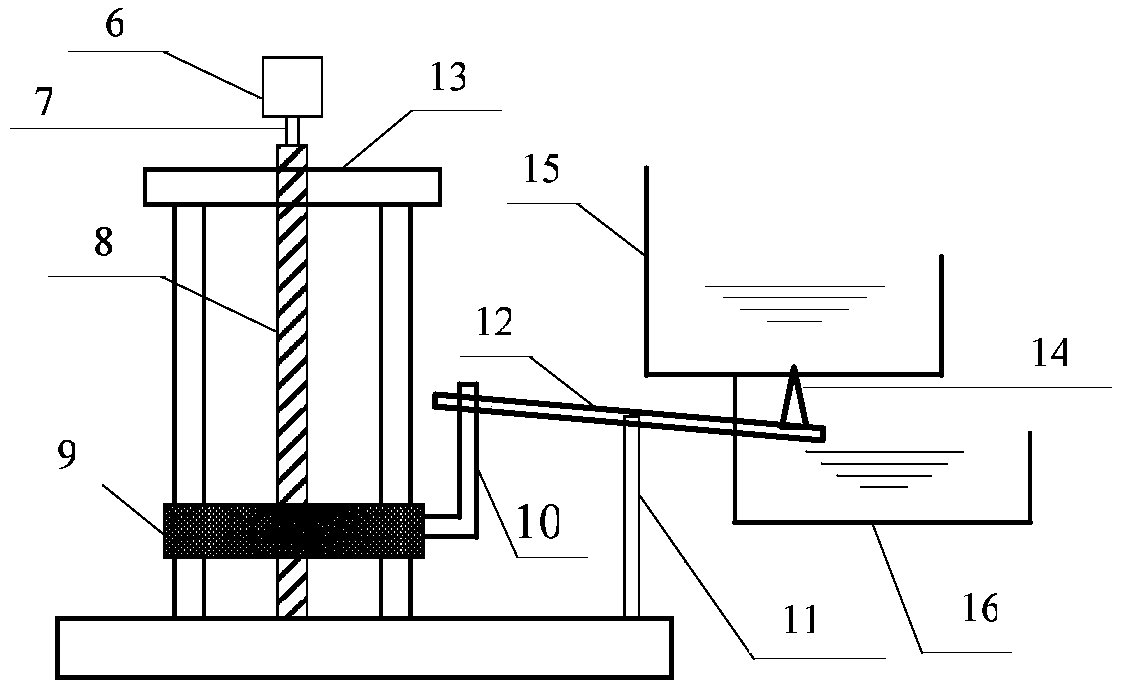

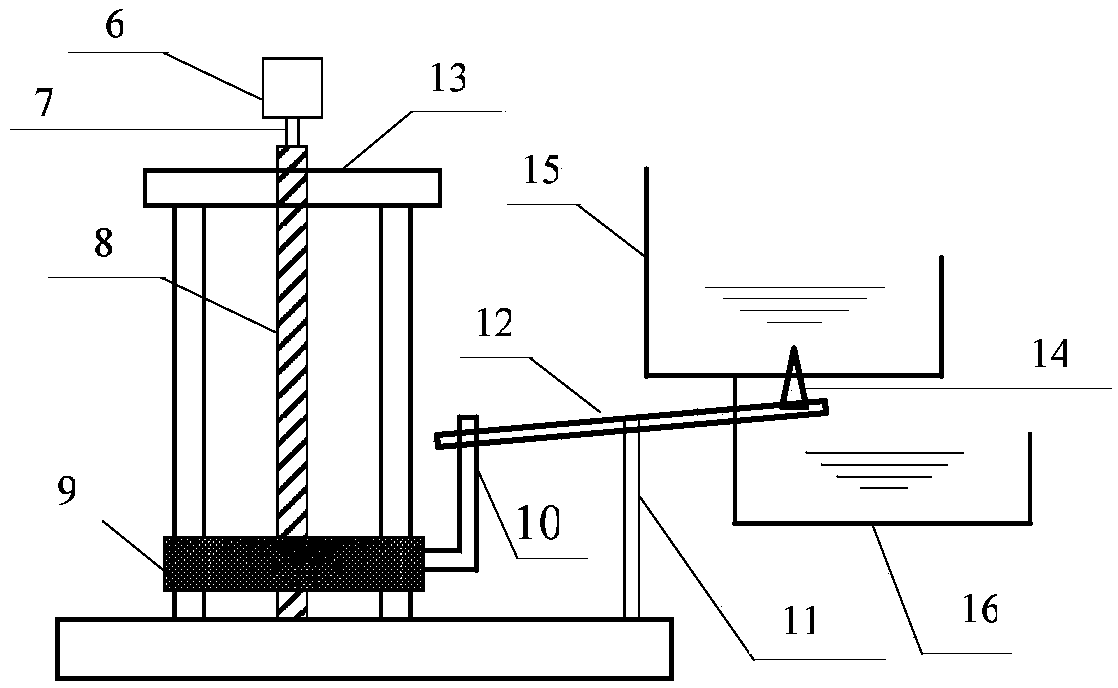

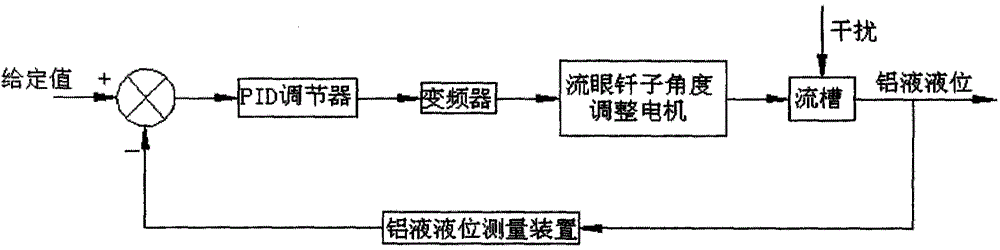

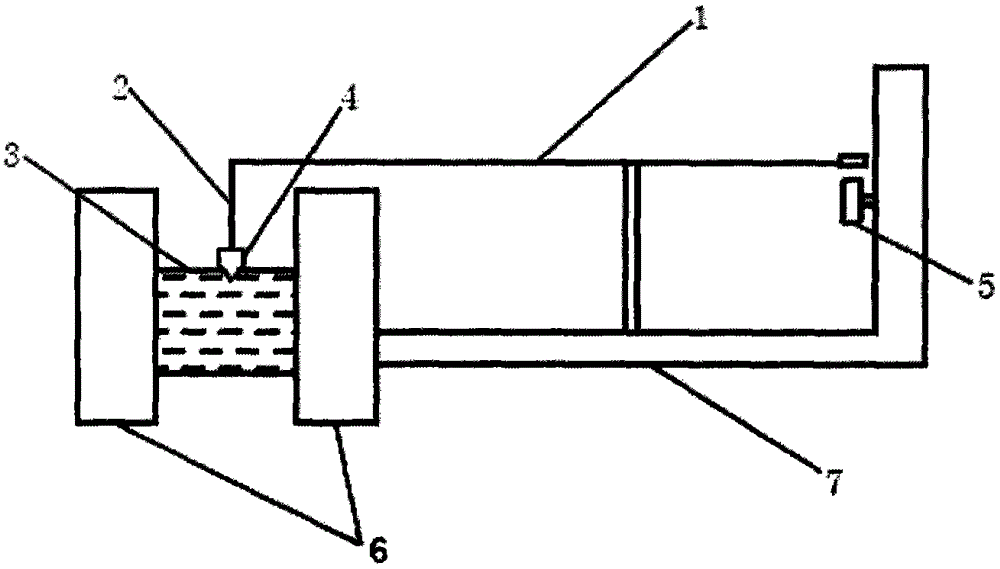

Method of controlling casting molten aluminum level of aluminum wire rolling mill based on variable parameter increment (PI) control algorithm

The invention discloses a method of controlling the casting molten aluminum level of an aluminum wire rolling mill based on a variable parameter increment (PI) control algorithm. The method comprisesthe following steps of: continuously collecting multiple liquid level data through a laser liquid gauge, and transferring the multiple liquid level data to a PLC (Programmable Logic Controller); firstly using the PLC to carry out median filtering on multiple liquid level data collected by the laser liquid gauge, and then carrying out smooth filtering to obtain a liquid level value; and using the PLC to analyze the liquid level value, judging the liquid level limit to which the limit level belongs, forming a deviation value e (k)=gk-yk through the liquid level value yk and the set height valuegk of the molten aluminum level, and controlling the positive rotation or negative rotation of a stepper motor through the parameter increment (PI) control algorithm.

Owner:SHANGHAI ZHONGTIAN ALUMINUM WIRE

A low temperature control method for aluminum electrolysis

InactiveCN102296328AImprove current efficiencyReduced DC power consumptionFiberEnvironmental resistance

The invention relates to a low temperature control method for aluminum electrolysis. 1) The electrolysis temperature during electrolysis is 930-936°C, the lithium carbonate content in the electrolyte is 2.8-3.0% of the mass fraction of the electrolyte, the molecular ratio of sodium fluoride to aluminum fluoride in the electrolyte is 2.3-2.5; the aluminum level is not low 2) Compulsory thermal insulation measures for the electrolytic cell: the bottom of the cell and the small window are sealed with aluminum silicate fiber blanket thermal insulation material. In the case of not changing the equipment and facilities in the production of aluminum electrolysis, by adjusting the electrolysis process, regularizing the furnace, realizing fine operation, improving the stability of the electrolytic cell, strengthening heat preservation, reducing heat loss, lowering the electrolysis temperature, and improving the current efficiency, the electrolytic cell The service life has been extended, and the effect of energy saving and emission reduction is remarkable, which provides a guarantee for the realization of safety, high efficiency, energy saving and environmental protection in electrolytic production.

Owner:YUNNAN YONGXIN ALUMINUM +1

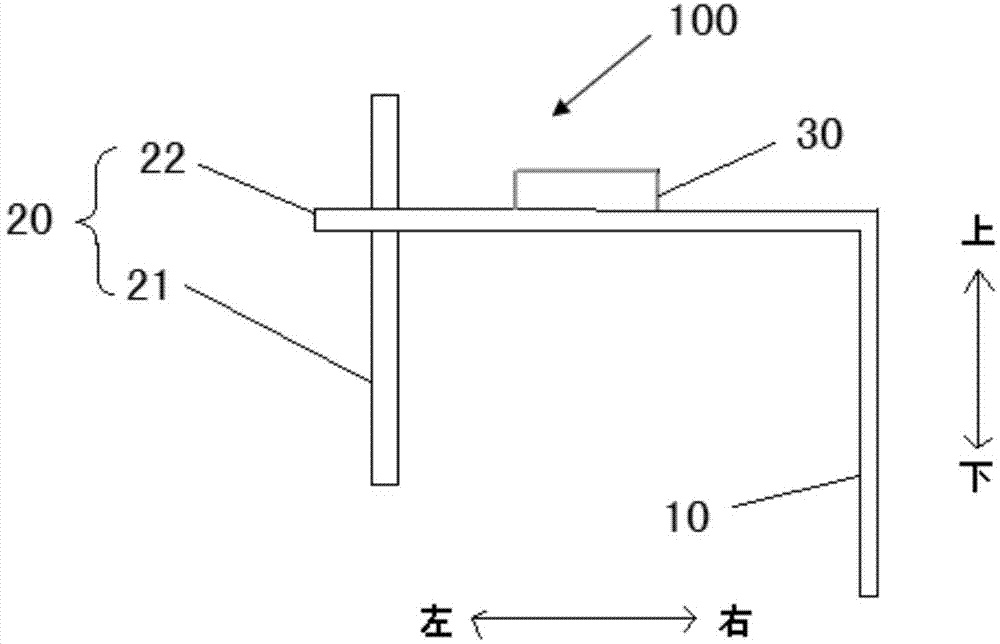

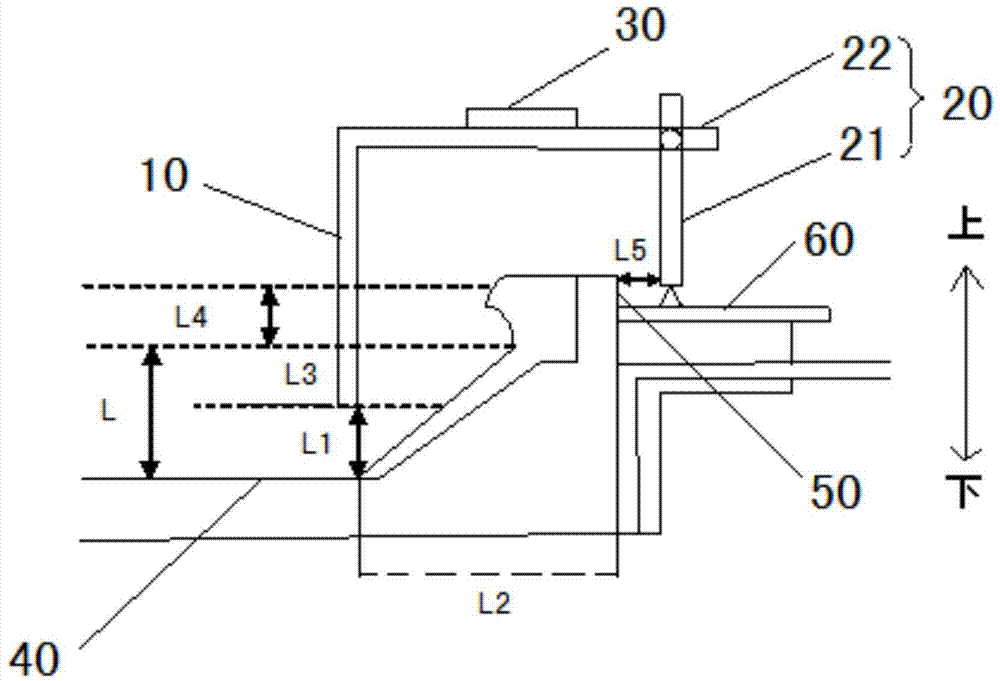

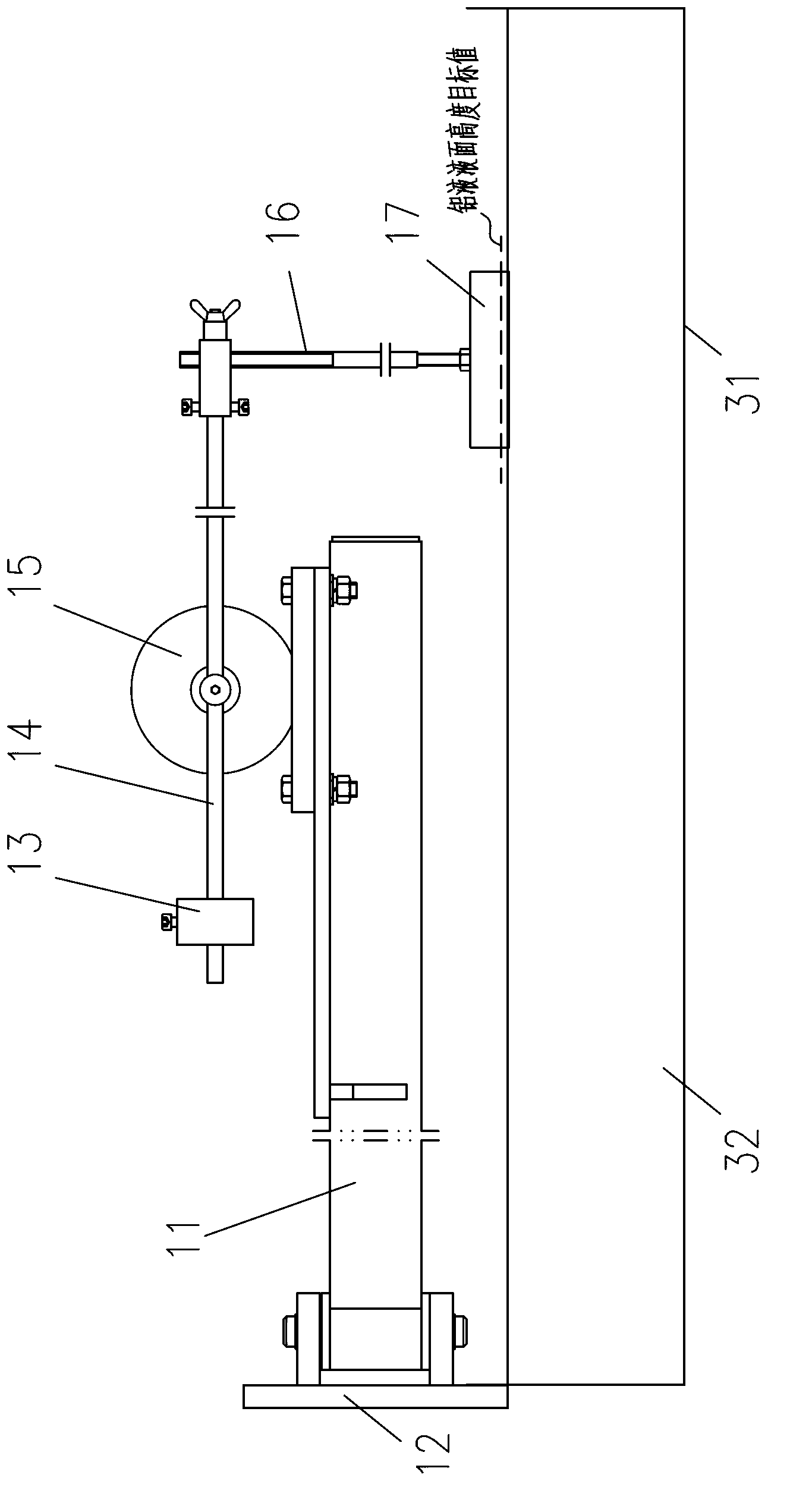

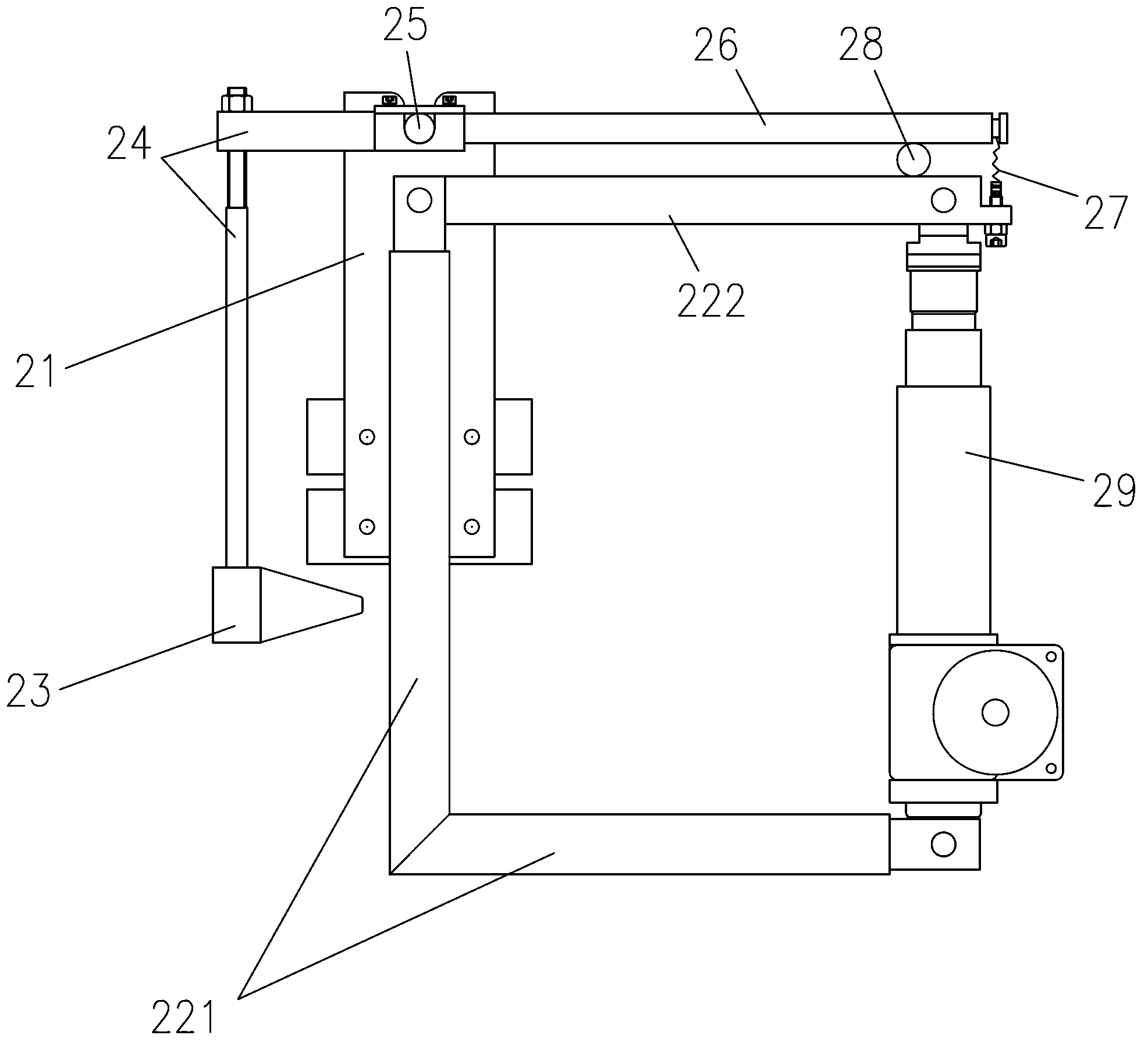

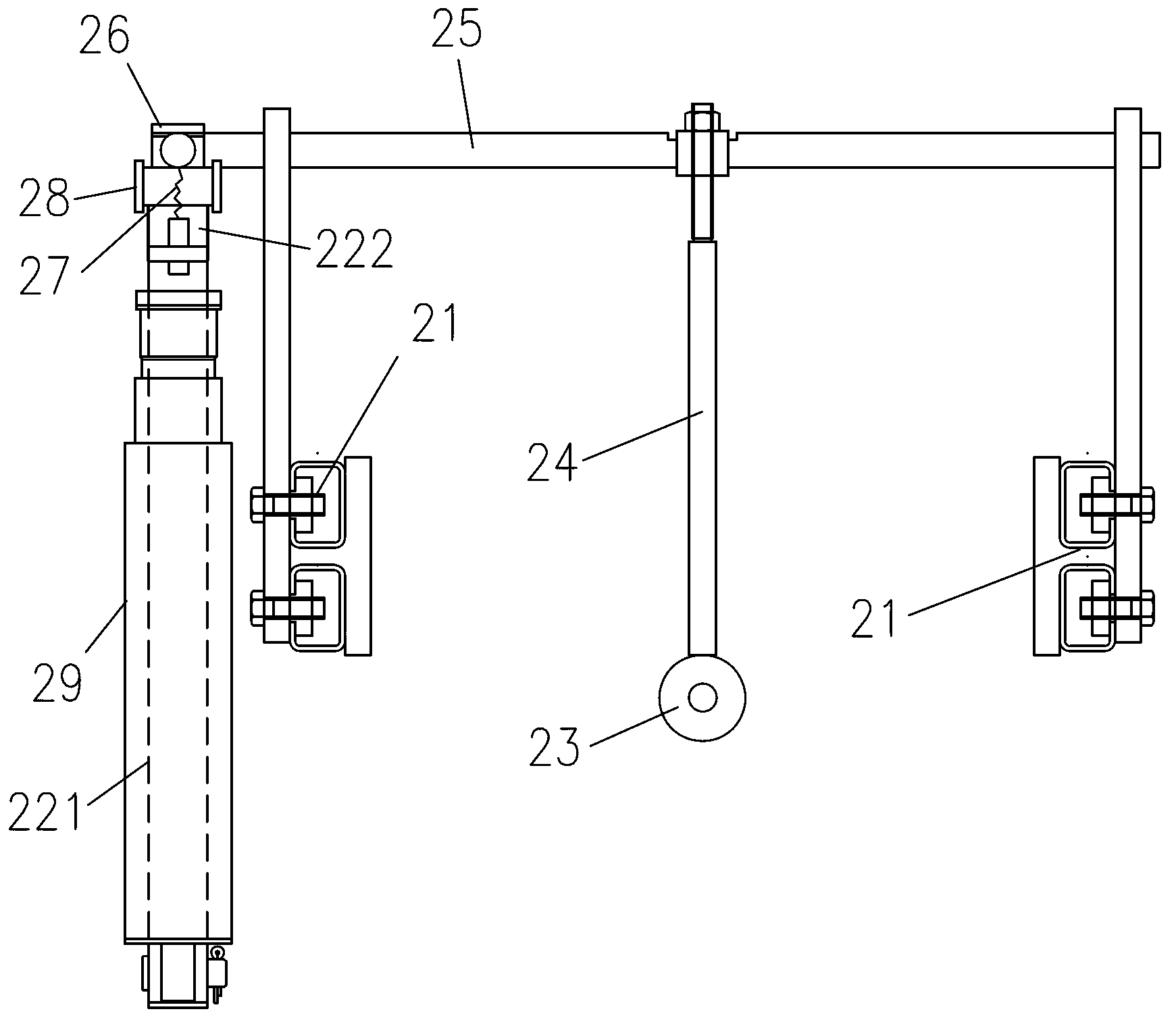

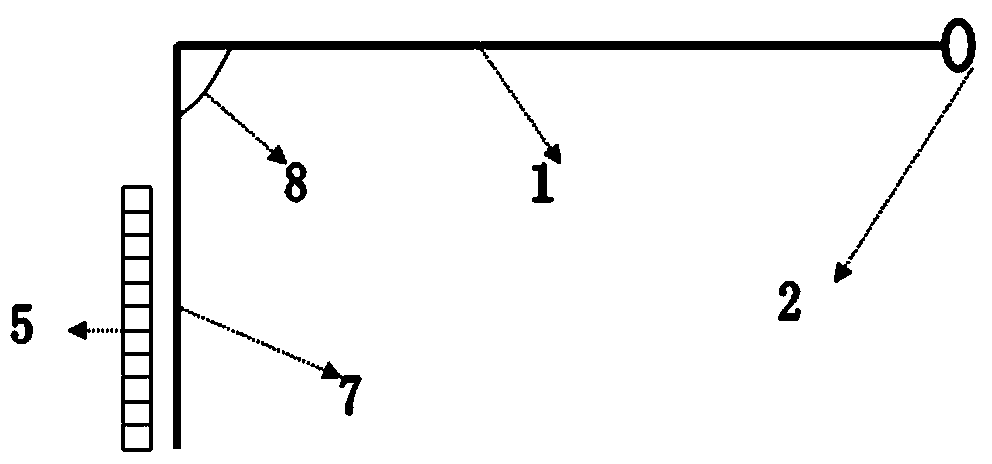

System and method for controlling level of molten aluminum in front box of aluminum strip billet cast-rolling machine

ActiveCN103264051AAvoid Board DefectsAvoid leaking aluminumMeasuring devicesProfile control deviceAutomatic controlMetallurgy

The invention discloses a system and method for controlling the level of molten aluminum in a front box of an aluminum strip billet cast-rolling machine. The system for controlling the level of the molten aluminum in the front box of the aluminum strip billet cast-rolling machine comprises a molten aluminum level detecting device and an automatic molten aluminum level control device, wherein the molten aluminum level detecting device comprises a swinging support, the swinging support is installed on a fixed support in a rotating mode, an angular displacement sensor is installed on the swinging support, the input end of the annular displacement sensor is connected with the middle portion of a horizontal guiding rod, the output end of the annular displacement sensor is connected with the corresponding signal end of a controller, a balancing weight is installed at one end of the horizontal guiding rod, the other end of the horizontal guiding rod is connected with the upper end of a vertical guiding rod, a buoy is connected with the lower end of the vertical guiding rod, the automatic molten aluminum level control device comprises a flow control plug corresponding to a molten aluminum flow control outlet in the front box, and the flow control plug is connected with a plug opening-and-closing control mechanism. The method for controlling the level of the molten aluminum in the front box of the aluminum strip billet cast-rolling machine is realized based on the system for controlling the level of the molten aluminum in the front box of the aluminum strip billet cast-rolling machine. The system and method for controlling the level of the molten aluminum in the front box of the aluminum strip billet cast-rolling machine has the advantages that the level of the molten aluminum in the front box of the aluminum strip billet cast-rolling machine can be automatically controlled in real time, and the control accuracy is high.

Owner:涿州北方重工设备设计有限公司

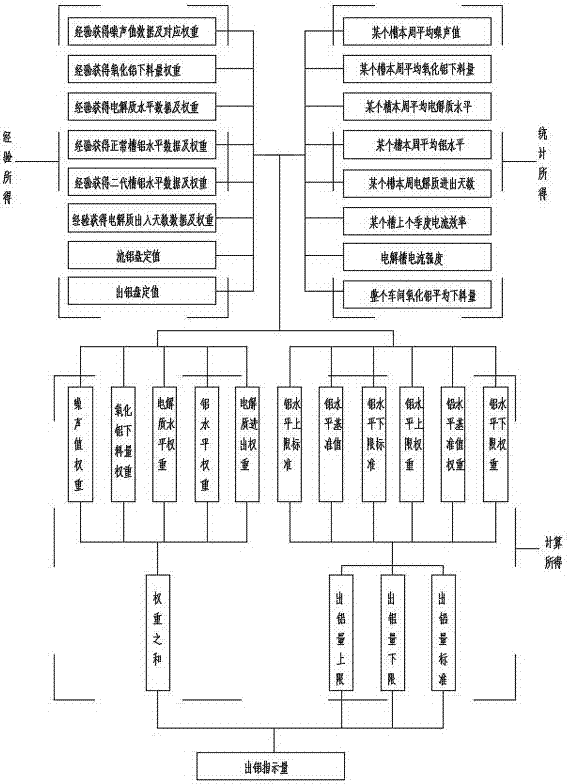

Aluminum discharging task calculation method

The invention relates to the field of aluminum electrolysis, in particular to an aluminum discharging task calculation method. The aluminum discharging task calculation method includes the steps that the in-groove average noise value G5 in this week is counted, the in-groove noise value weight H5 is calculated, the in-groove aluminum oxide blanking quantity weight H8 is calculated, the electrolyte level weight H11 is calculated, the aluminum level weight H17 is calculated, and the weight sum H23 is calculated so that the aluminum discharging amount lower limit B23, the aluminum discharging amount standard value C34 and the aluminum discharging amount upper limit D34 can be finally calculated. The method can be led into EXCEL to automatically calculate the aluminum discharging indicating quantity; process control is more stable, and because the aluminum discharging indicating quantity issuing method of the standard value and the modified value is adopted, the parameter selecting dimensions are more, and reliability is higher; the parameter weight is smoother, and the situation that the value of a certain dimension is too large, and final judgment is affected is avoided; and the finally acquired aluminum discharging indicating quantity value is accurate and reliable.

Owner:CHONGQING QINENG ELECTRICITY & ALUMINUM

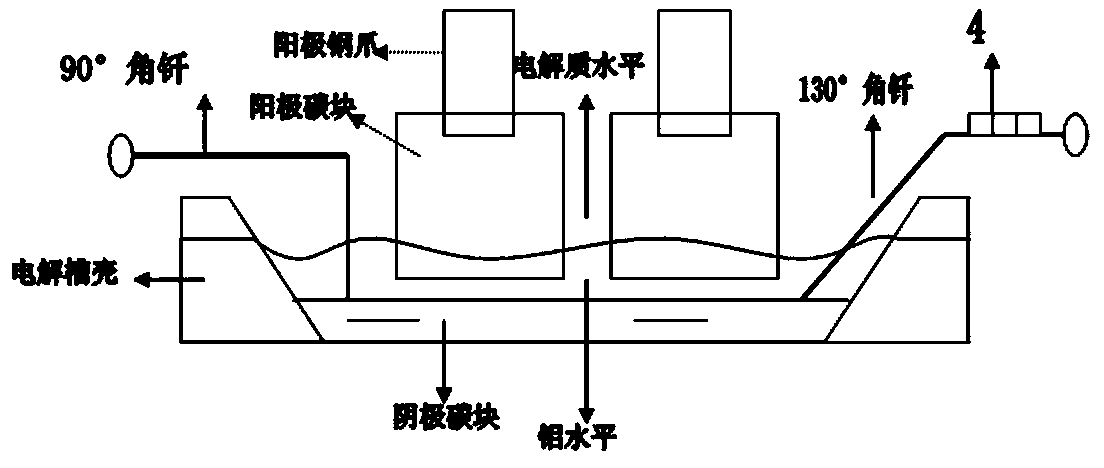

Tool for measuring electrolyte level and aluminum liquid level in aluminum electrolysis cell

InactiveCN104075772AOvercome the defect of inaccurate level measurementAccurate measurementLevel indicators by dip membersElectrolysisElectrolytes levels

The invention belongs to the technical field of aluminum electrolysis, and particularly relates to a tool for measuring an electrolyte level and an aluminum liquid level in an aluminum electrolysis cell. The tool for measuring the electrolyte level and the aluminum liquid level in the aluminum electrolysis cell comprises a measure ruler horizontal rod, a measure ruler vertical rod, an operating handle and an H-shaped support, wherein a right angle of 90 degrees is formed between the measure ruler horizontal rod and the measure ruler vertical rod, the H-shaped support is composed of two support rods and a cross rod, the H-shaped support is erected on the measure ruler horizontal rod, and the tool for measuring the electrolyte level and the aluminum level in the aluminum electrolysis cell is made of round solid steels 18mm in diameter. The tool for measuring the electrolyte level and the aluminum liquid level in the aluminum electrolysis cell can overcome the defect that the aluminum liquid level is inaccurately measured caused by the reasons that aluminum oxide on the surface of a cathode carbon block crusts and deposits, or the cathode carbon block is deepened and the like well, can accurately measure the aluminum liquid level, and thereby can guarantee stable proceeding of normal electrolysis production work.

Owner:ZHENGZHOU FAXIANG ALUMINUM IND

High-efficiency and energy-saving starting method for heat flow coke calcination in aluminum electrolysis

The invention discloses a high-efficiency and energy-saving starting method for heat flow coke calcination in aluminum electrolysis. The method comprises the following steps of: 1), when filing an electrolytic bath, filling a half of a cabin with electrolyte powder; 2), after the electrolytic bath is electrified for calcinating for 72 hours, executing the operation of lifting a positive pole for 8 hours; 8 hours later, starting the aluminum electrolytic bath; 3), rapid adjustment of the control technology: (1) adjustment of electrolyte constituent, (2) voltage adjustment and (3) aluminum level adjustment. By the rapid adjustment to the control technology, within 30 days, the bath voltage drops to the normal production standard, the aluminum level reaches more than 30cm, and the normal production condition is realized. The method not only guarantees enough molten electrolyte for filing the negative pole gap, but also protects the negative pole from oversize expansion and deformation caused by overlarge heat shock, avoids waste of electric energy and improves the energy utilization rate.

Owner:YUNNAN ALUMINUM

Aluminum liquid level simulation control system for casting and rolling mill

ActiveCN103713658BImprove continuityHigh working reliabilityLevel controlLiquid level measurementControl system

Owner:华北铝业新材料科技有限公司

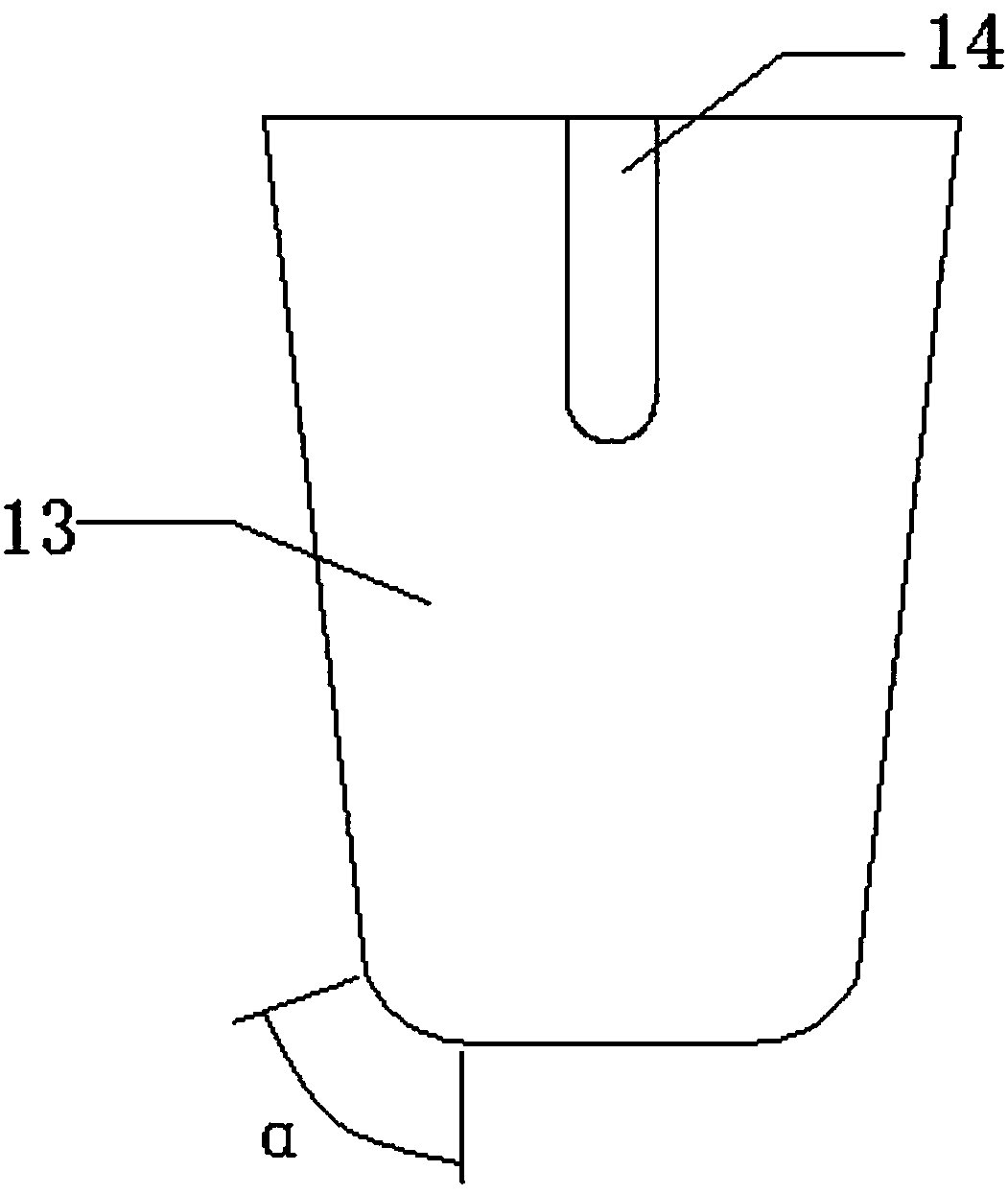

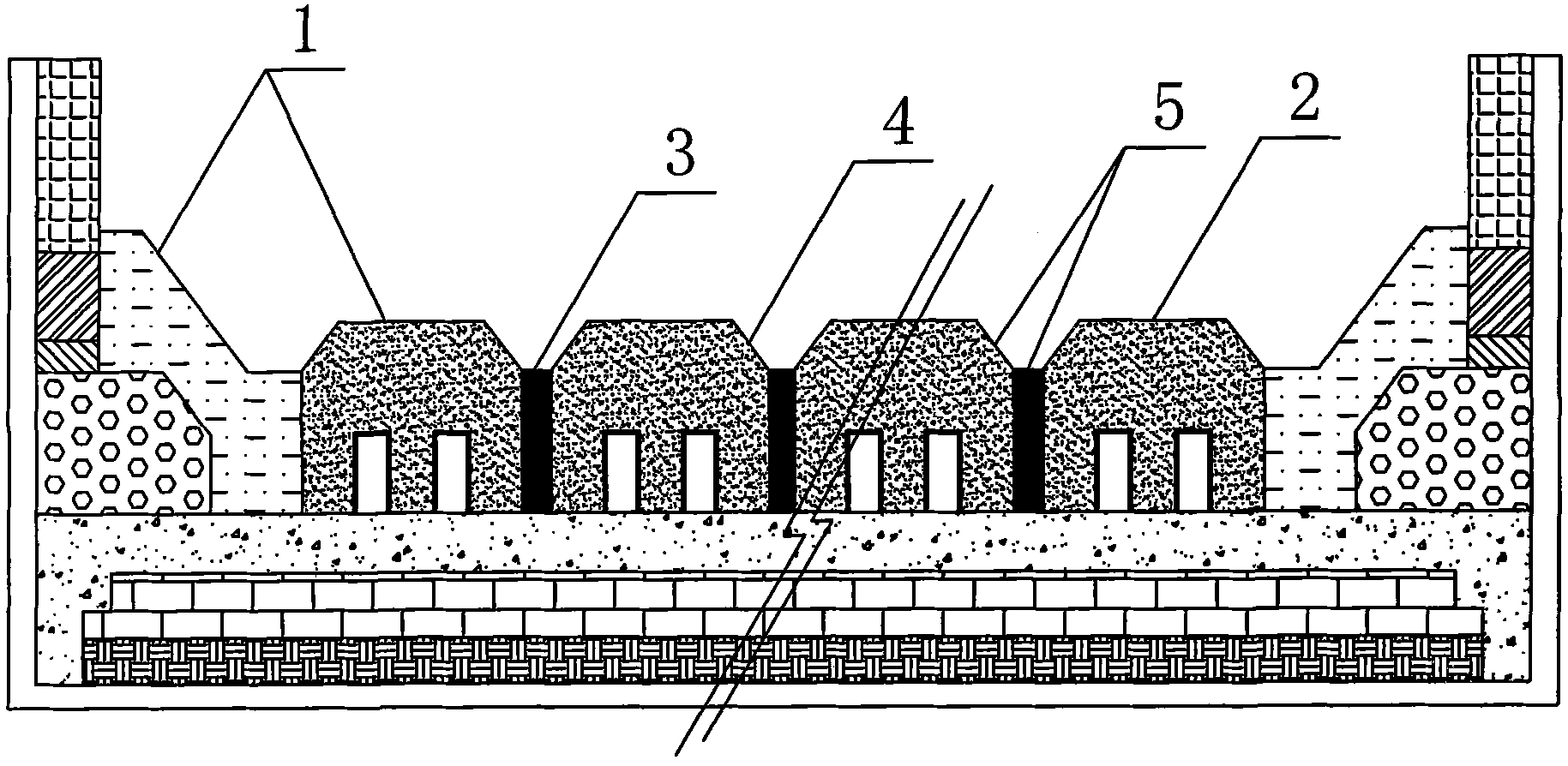

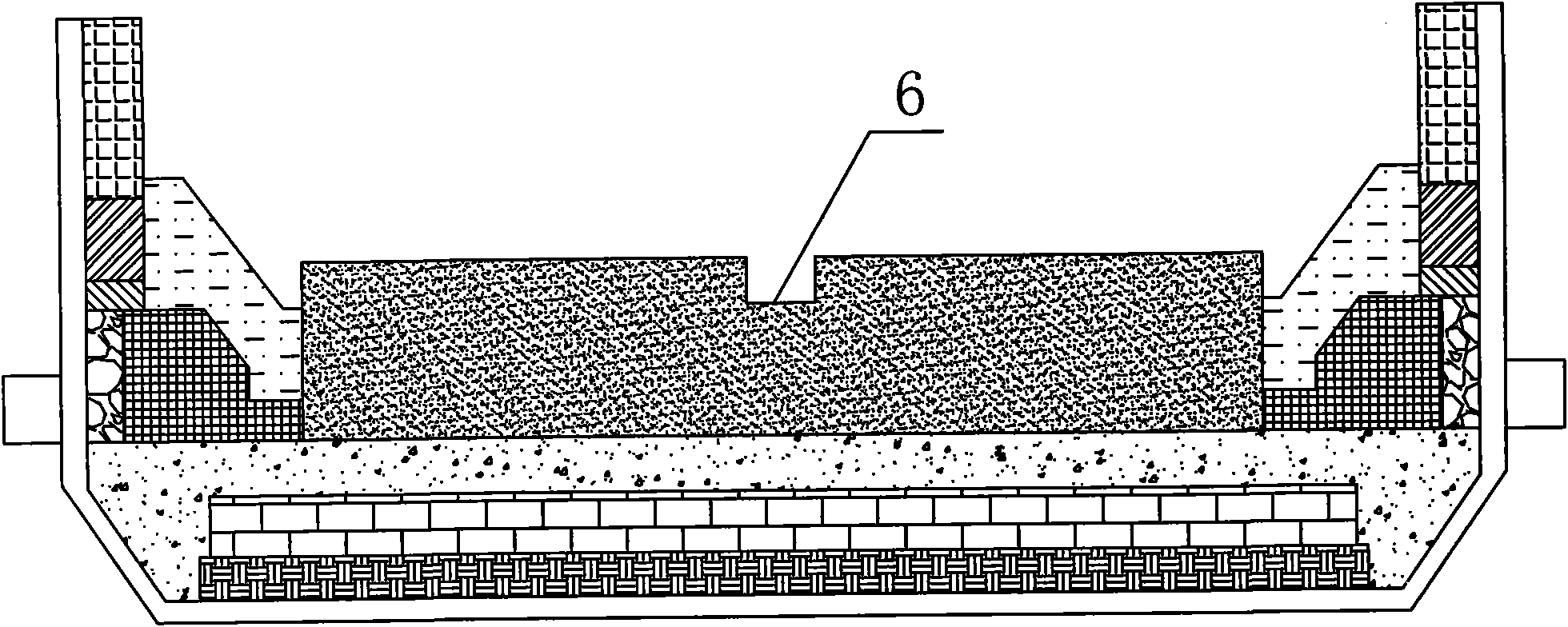

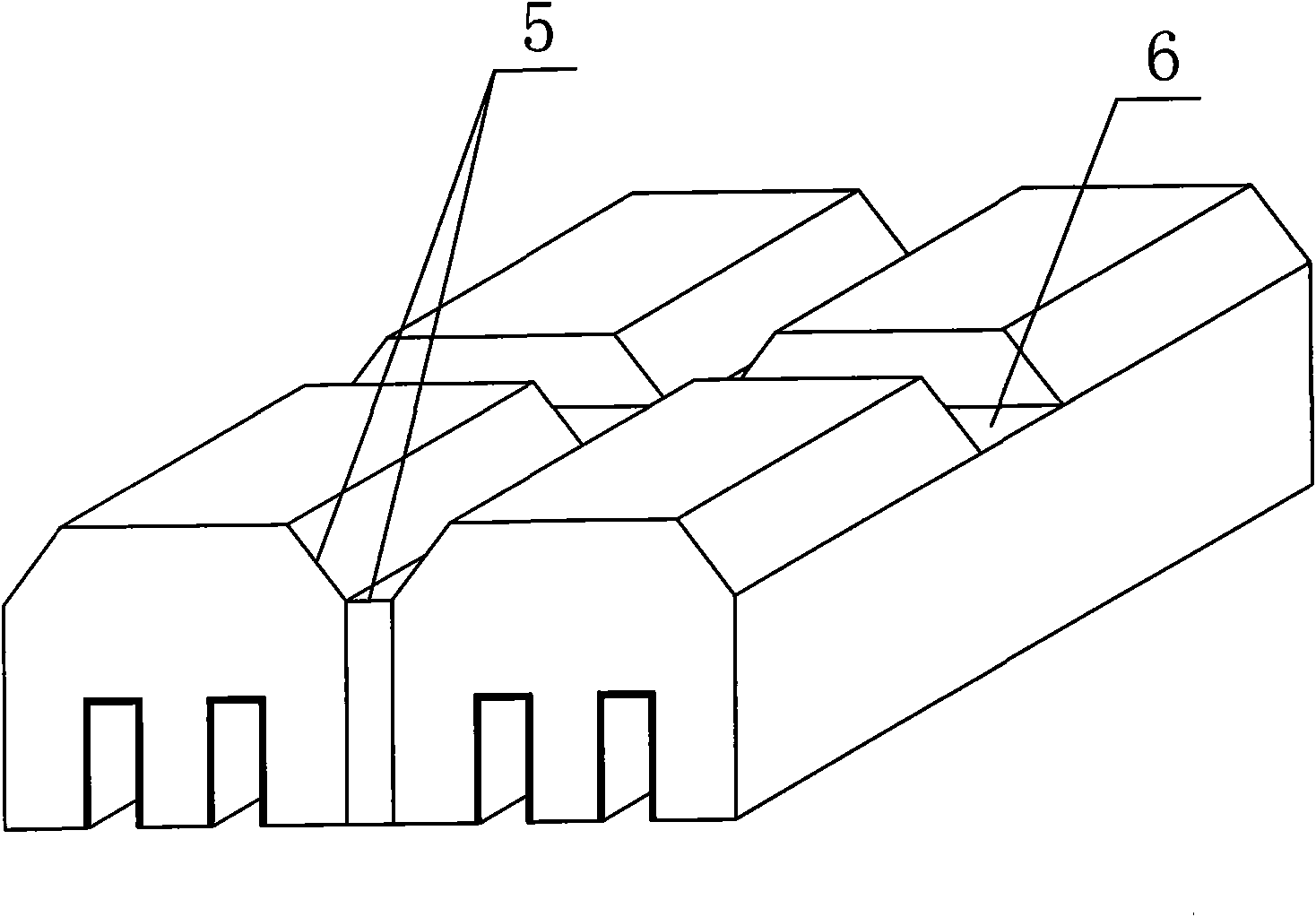

Using method for aluminum electrolytic cell

The invention relates to a using method for an aluminum electrolytic cell, which comprises the following steps of: (1) adopting the aluminum electrolytic cell in which a longitudinal trapezoidal groove and a horizontal groove are crossed on the surface of a bottom cathode block, chamfering an upper end part of the cathode block longitudinally, and forming the horizontal groove on the top of the cathode block; (2) adopting wet-process calcining to start the electrolytic cell, filling the longitudinal trapezoidal groove and the horizontal groove with graphite scraps so as to be flush with an upper surface of the cathode block before calcining, filling a layer of medium with the thickness of 0.5 to 5cm and different resistivity in different subregions on the upper surface of the cathode of the whole electrolytic cell, and starting the electrolytic cell; and (3) setting the following electrolytic conditions of the electrolytic cell: the average voltage of the electrolytic cell is 3.50 to 3.90V, the electrolytic temperature is between 900 and 970 DEG C, the electrolyte molecular ratio is 2.0 to 3.0, the electrolyte level is 14 to 30cm, the aluminum level is 16 to 28cm, the electrode distance is 3.2 to 4.2cm and the alumina concentration is 1.0 to 3.0 percent.

Owner:SNTO TECH GRP

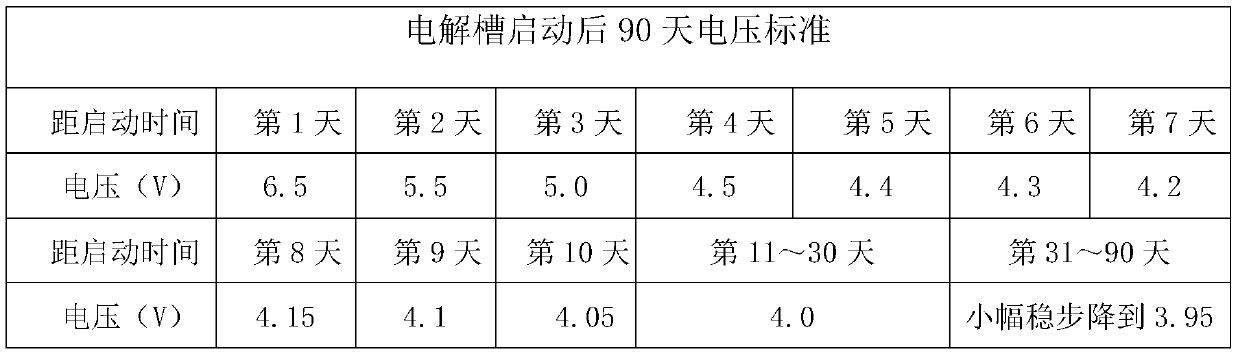

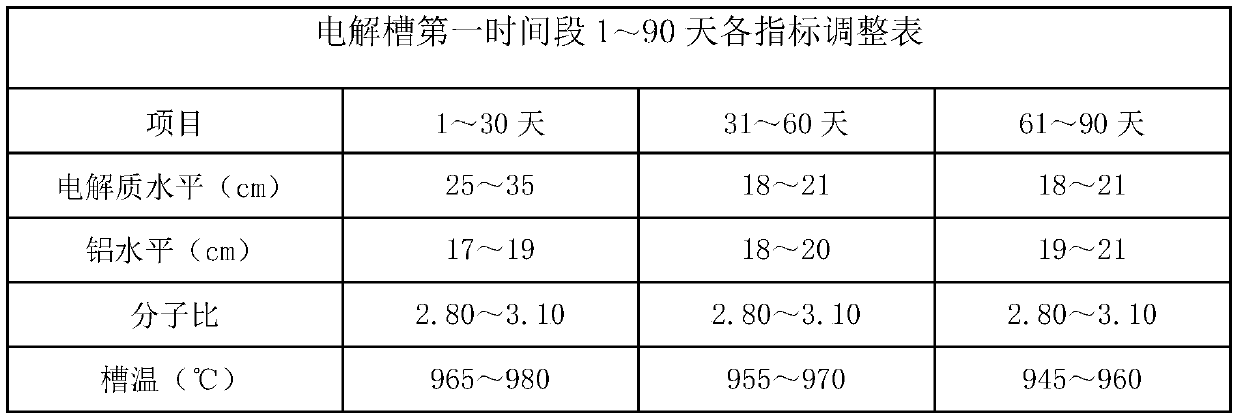

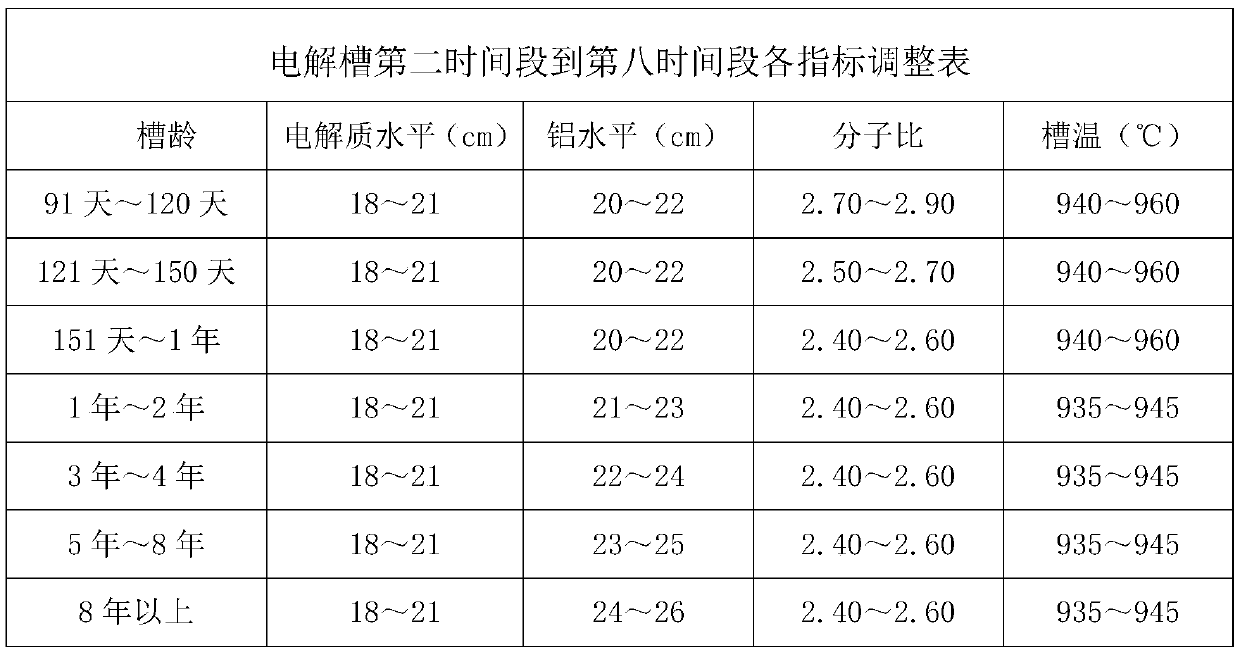

Aluminum electrolysis cell production process control method

InactiveCN110541176AGuaranteed electrolysis temperatureStrengthen control of anode insulationElectrolysisElectrolytes levels

The invention belongs to the technical field of aluminum electrolysis production, and particularly relates to an aluminum electrolysis cell production process control method. The invention mainly solves such problems as different thoughts on the electrolysis cell process control aspect in domestic aluminum electrolysis industry, greater control effect differences of all enterprises, short life ofelectrolysis cells and weak economical index. The control method divides normal production period of the electrolysis cells into eight time periods according to the cell life, adjusts the voltage level, and controls the electrolyte level, the aluminum level, the molecular ratio level and the cell temperature.

Owner:山西中铝华润有限公司

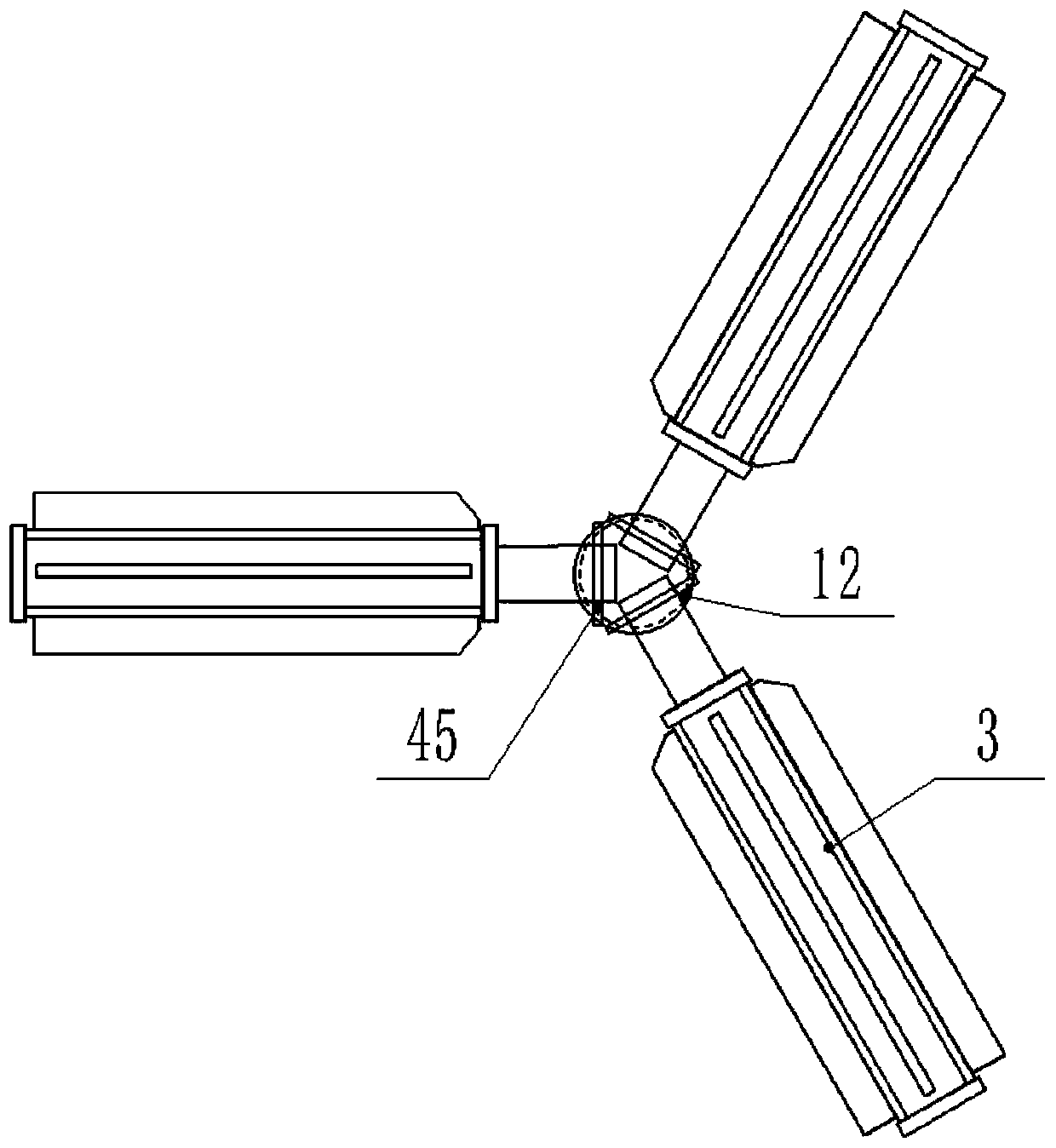

Slagging-off device for molten aluminum refining

ActiveCN110468288ARealize the slag removal operationEfficient slag removalCasting cleaning apparatusProcess efficiency improvementSlagHearth

The invention discloses a slagging-off device for molten aluminum refining. A slag collecting basket is movably arranged at the lower end of a rotary barrel body in a sleeving mode; through observingthe molten aluminum level, slagging-off equipment can be taken out from a hearth without dross; rotary slagging-off head devices need to be folded at the moment firstly; in the process of the foldingof the rotary slagging-off head devices, each rotary slagging-off head device rotates around a connecting rotating shaft, and an outlet of the inner end of a rotary slagging-off connecting barrel canbe inclined downwards to guide a slag body into the rotary barrel body; the slag body is collected in the slag collecting basket through the rotary barrel body, and the slag collecting basket only needs to be washed after slagging-off every time to be used next time; and thereof, the rotary slagging-off head devices are folded not only for folding, but also for collecting the slag body, and the centralized treatment of the dross removed out is facilitated, so that the automation and the convenience of slagging-off treatment is really realized, and the labor intensity of workers is greatly reduced.

Owner:浙江玮宏金属制品有限公司

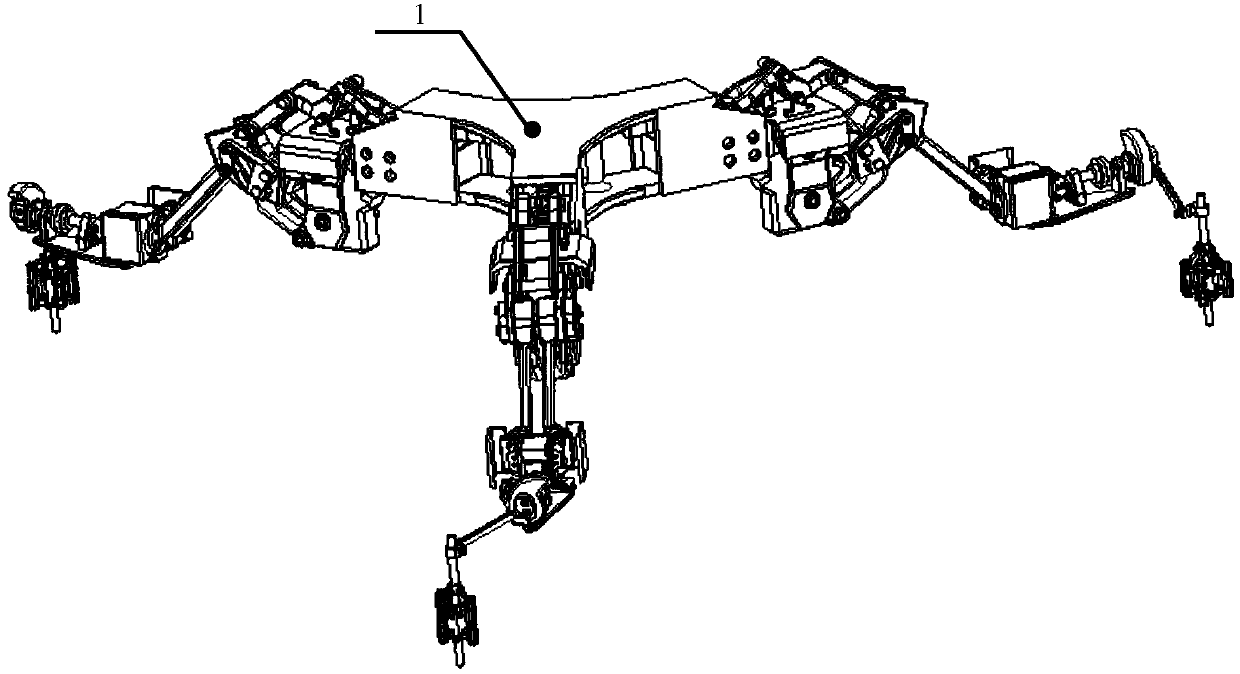

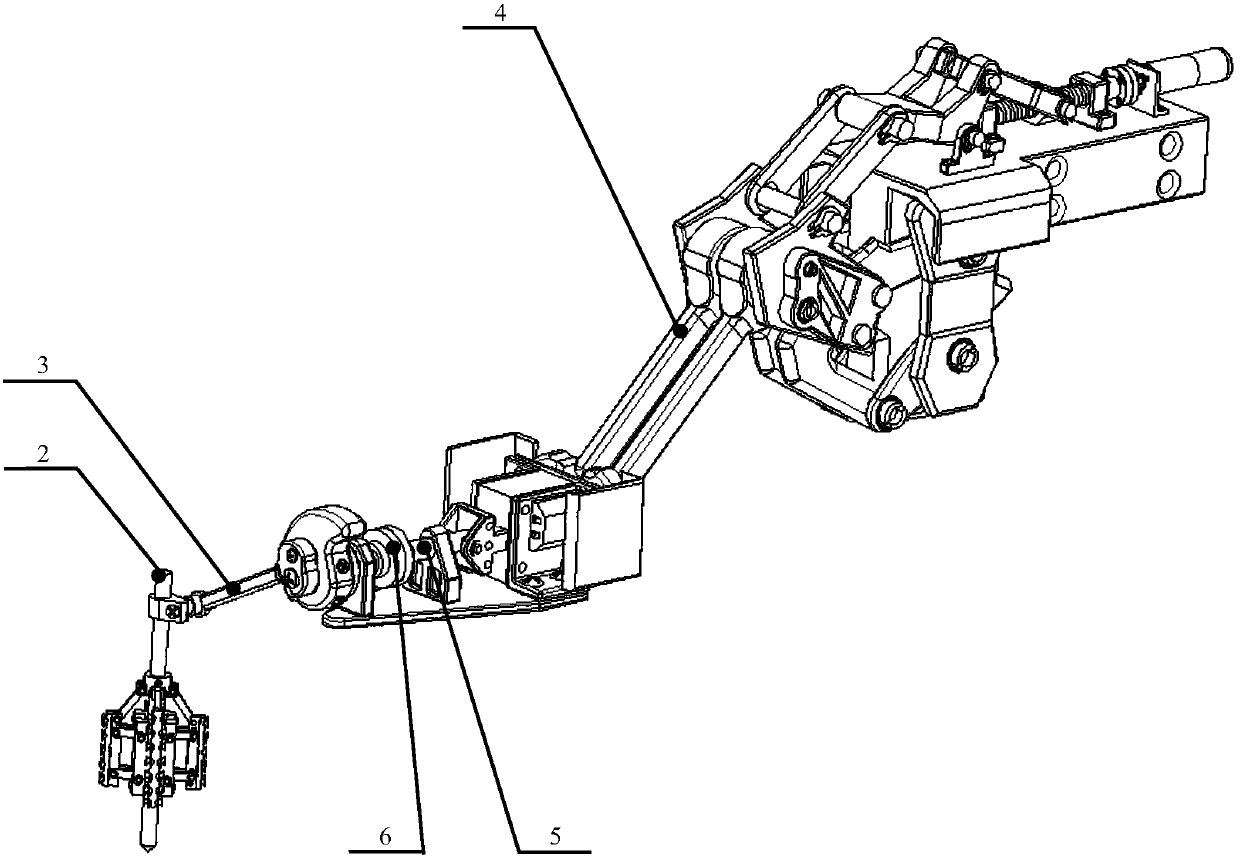

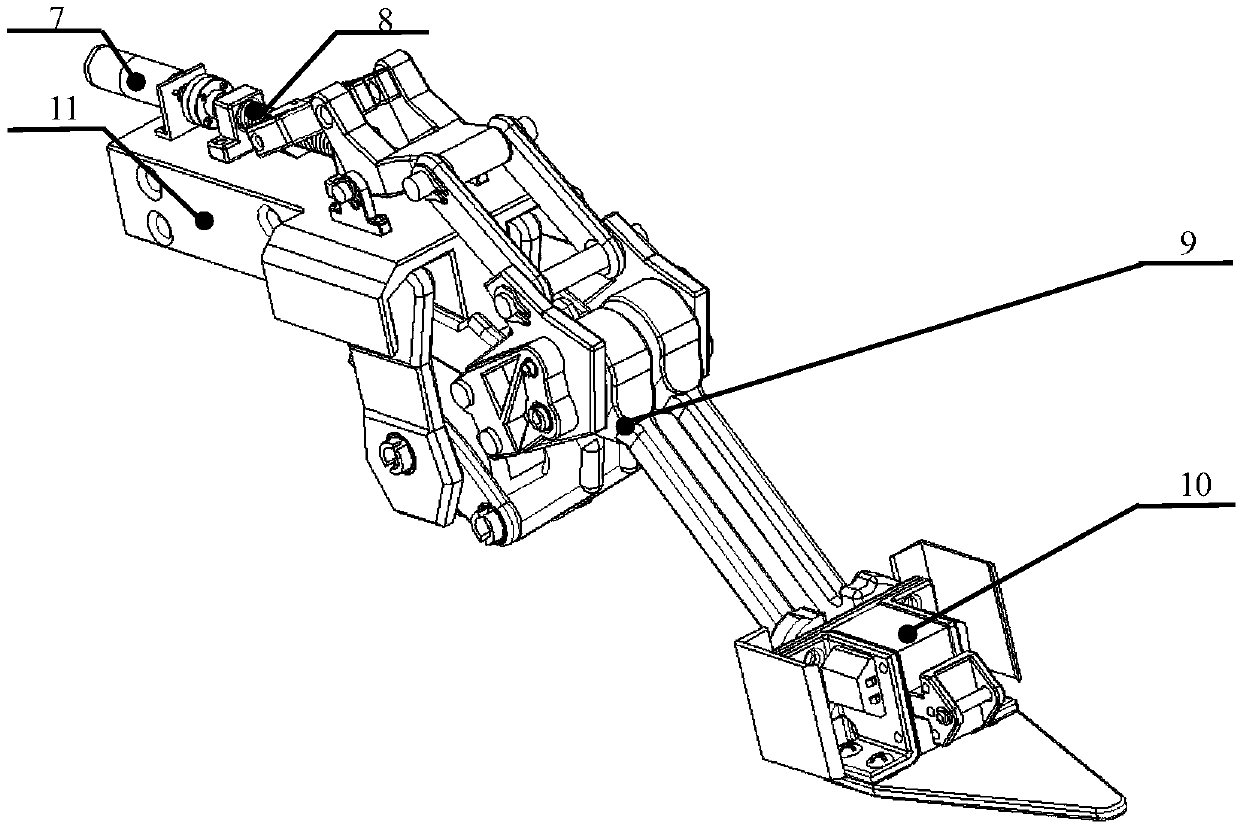

Mechanical weeding mechanism with function of changing track to avoid seedlings

InactiveCN107926166AImprove weeding efficiencyLow injury rateSoil-working equipmentsMachine visionEngineering

The present invention aims to provide a mechanical weeding mechanism with the function of changing the track and avoiding the seedlings. The equipment includes a supported aluminum horizontal turntable, a module with the function of changing the track and avoiding the seedlings, and a loose cutting ruler mechanism. Power is provided by the motor to drive the aluminum horizontal turntable. On this basis, machine vision is used to collect and analyze the poses of field seedlings and grass, and the function of changing tracks and avoiding seedlings is realized through the multi-degree-of-freedom movement of the claw arm. This mechanism is helpful Improve the weeding effect, increase the rate of weeding between plants, reduce the rate of injury to seedlings, and ensure soil compactness.

Owner:NORTHEAST AGRICULTURAL UNIVERSITY

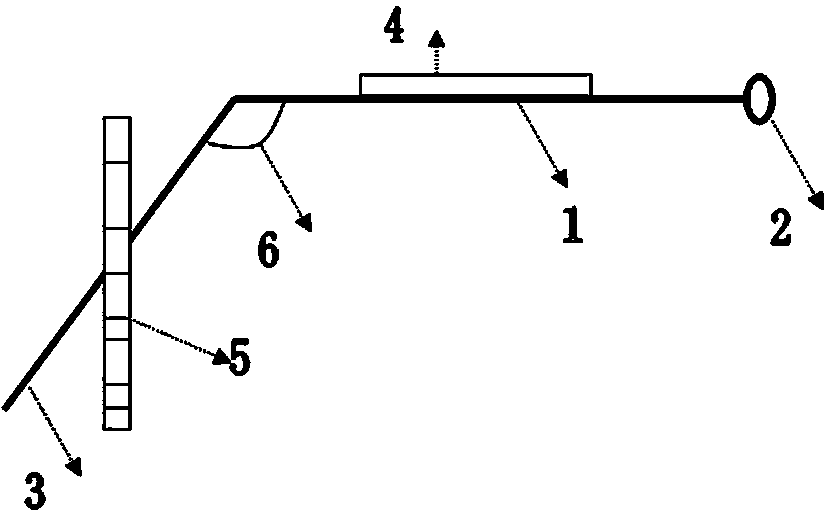

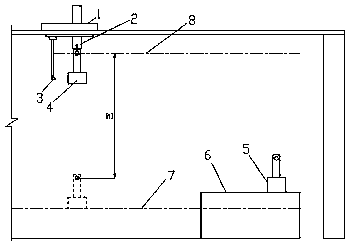

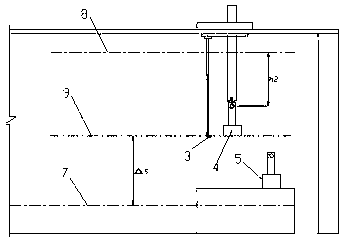

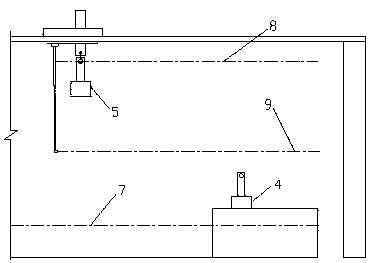

Quantitative control method for carbon anode replacement in aluminum electrolysis process

ActiveCN111118549AAccurate placementGuarantee the actual settlement depthIncreasing energy efficiencyMetallurgyPhysical chemistry

The invention discloses a quantitative control method for carbon anode replacement in the aluminum electrolysis process. The quantitative control method for carbon anode replacement in the aluminum electrolysis process comprises the following steps that a, zero position point (8) and a reference point (9) are sequentially arranged from top to bottom above a molten aluminum level (7); b, the heighth1 of upward movement of a used carbon anode A (4) to the zero position point (8) is recorded; c, the height h2 of descent of the bottom face of the carbon anode A (4) to the position flush with thereference point (9) is recorded; d, the height difference delta s between the reference point (9) and the molten aluminum level (7) is calculated, and delta s=h1-h2; e, a replacing new carbon anode B(5) is lifted to the zero position point (8); f, the descent height h3 of the bottom face of the carbon anode B (5) to the position flush with the reference point (9) is recorded; g, the total descent height H of the carbon anode B (5) is calculated, and the total descent height H=h3+delta s+ delta h, wherein delta h is the design height, existing when the carbon anode sinks below the molten aluminum level (7), of the carbon anode. The quantitative control method for carbon anode replacement in the aluminum electrolysis process has the features that the accuracy is high, the structure is simple, operation is easy, the carbon anode replacement convenience is high, the replacement efficiency is high, and the safety is good.

Owner:浙江捷创智能技术有限公司

Preparation method of aluminum electrobath for transitting to electrolysis in low temperature

ActiveCN100532652CImprove production conditionsImprove current efficiencyEngineeringParameter control

The invention relates to an aluminum electrolysis production technology, in particular to an aluminum electrolysis cell and a low-temperature electrolysis transition production method. The production method of the present invention comprises the following steps: a) adjusting the electrolyte composition to reduce the primary crystal temperature step; b) electrolytic cell setting voltage control step; c) electrolytic overheat control step; d) aluminum level control step; e) intelligent fuzzy parameter control step ; f) Fine operation steps. The present invention has the following beneficial effects: the method of the present invention improves the production conditions of the electrolytic cell, keeps the primary crystal temperature of the electrolytic cell in a lower range (905°C-915°C) all the time, and enables electrolytic production to be carried out at an electrolytic temperature of 915°C-930°C work, the current efficiency of the electrolytic cell is improved, and the power consumption is reduced; the invention is suitable for the transition from aluminum electrolytic cells to low-temperature electrolytic production, and can also be applied to the transformation of electrolytic cells in other industries to low-temperature production.

Owner:GUIZHOU BRANCH CHINA ALUMINUM IND

Low polar distance energy-saving production method for aluminum electrolysis bath

The invention discloses a low polar distance energy-saving manufacturing method for an aluminum cell, which meets the requirement of energy balance by adjustment of technical parameters on the basis of the prior art, comprising the steps that: firstly, voltage adjustment, namely the set voltage of the electrolytic cells is adjusted to be 4.1 volts in the first two weeks, adjusted from 4.1 volts to4.05 volts in the third week, adjusted from 4.05 volts to 4.0 volts in the fourth week and adjusted from 4.0 volts to 3.99 volts in the fifth week; secondly, adjustment of the aluminum level and theelectrolyte level, namely cryolites or electrolyte blocks are added for improving 1 to 2 centimeters of the electrolyte height and the aluminum level is improved 1 to 2 centimeters or so by use of three to five weeks; thirdly, improvement of the molecule ratio and reduction of the superheat degree, namely the molecule ratio is improved from the prior 2.2 to 2.3 to 2.35 to 2.45 within three to fiveweeks by adoption of the method for reducing the addition amount of aluminum fluorides. The improvement of the primary crystal temperature and the reduction of the superheat degree play an importantrole in stabilizing electrolyte production, play a certain role in formation of a hearthside and a furnace cavity, and enable the hearthside and the furnace cavity to enter the state of normal production in advance.

Owner:HENAN ZHONGFU IND

Electrolytic cell aluminum level and electrolyte level height and cell temperature online measuring method

InactiveCN107576409ARealize online measurementSimple methodThermometers using electric/magnetic elementsUsing electrical meansEngineeringElectrolytes levels

The invention discloses an electrolytic cell aluminum level and electrolyte level height and cell temperature online measuring method. According to the method, two equal-height guide rods are insertedinto two levels and aluminum water, voltage is applied at the tail ends of the two guide rods, one guide rod is moved upwards, voltage change of the tail ends of the guide rods is different when thetail ends of the guide rods move in the two levels as the electrical conductivities of the two levels are different, movement time of the movement guide rods in the two levels can be calculated, so that movement tracks of the guide rods are calculated, namely, the heights of two levels are calculated, the height of the aluminum level needs to add the distance between the tail end of the guide rodwithout moving and a cell bottom, and a thermoelectric couple is inserted into electrolyte solution, so that cell temperature is measured. By the method, the heights of the two levels can be accurately measured, the cell temperature can be measured, and the method is quite simple and convenient to maintain.

Owner:张安全

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com