Aluminum electrolysis cell production process control method

A technology of production process and control method, applied in the field of aluminum electrolysis production, can solve the problems of shortening the service life of steel claws, violating the operation rules of electrolytic cells, increasing labor intensity of workers, etc., and achieving the effect of ensuring the electrolysis temperature

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The invention has been in operation for one year in the 500KA series electrolytic cell of an aluminum plant, the cell condition is very stable, the bottom of the furnace is clean, the side steel window of the electrolytic cell, the cathode steel rod, and the temperature of the bottom of the furnace all meet the design requirements, and the economic and technical indicators are stable and improving .

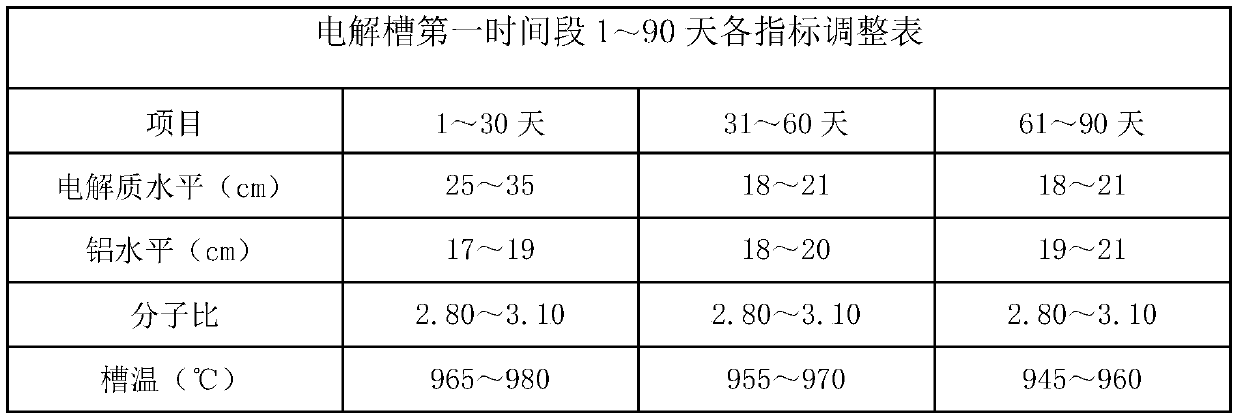

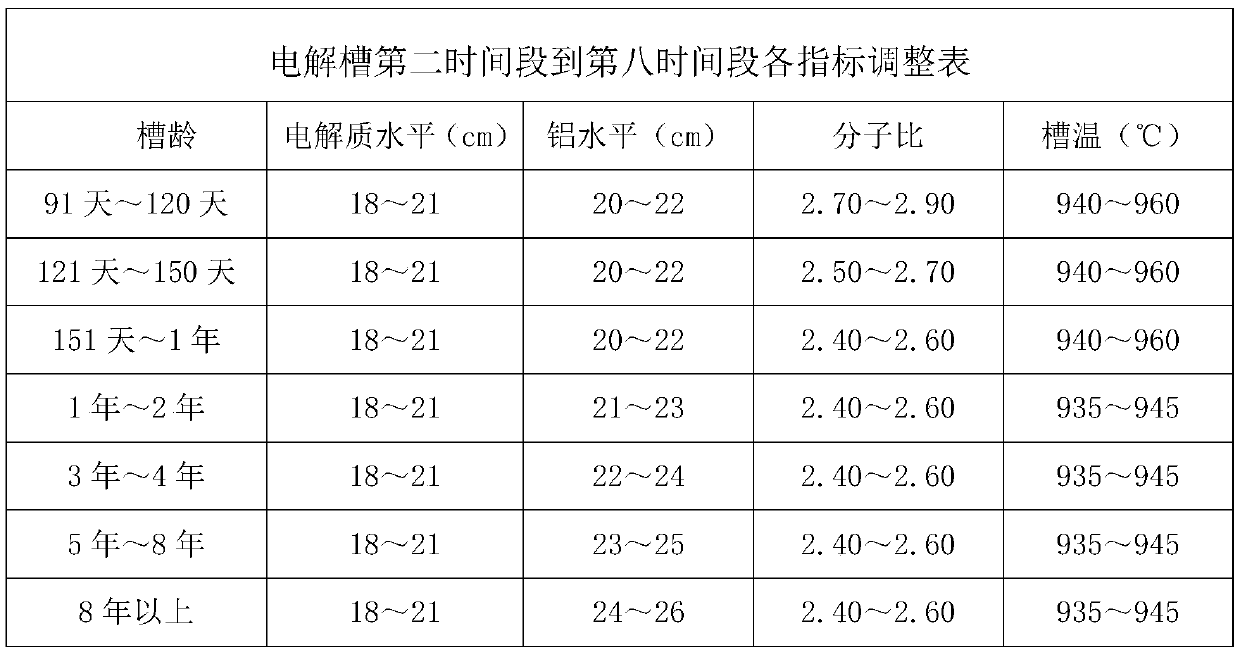

[0023] The normal production period of the electrolyzer is divided into eight time periods according to the age of the tank, and the eight time periods are: the first time period is 1 to 90 days; the second time period is 91 days to 120 days; the third time period is 121 days to 150 days days; the fourth time period is 151 days to 1 year; the fifth time period is 1 year to 2 years; the sixth time period is 3 years to 4 years; the seventh time period is 5 years to 8 years; the eighth time period is more than 8 years;

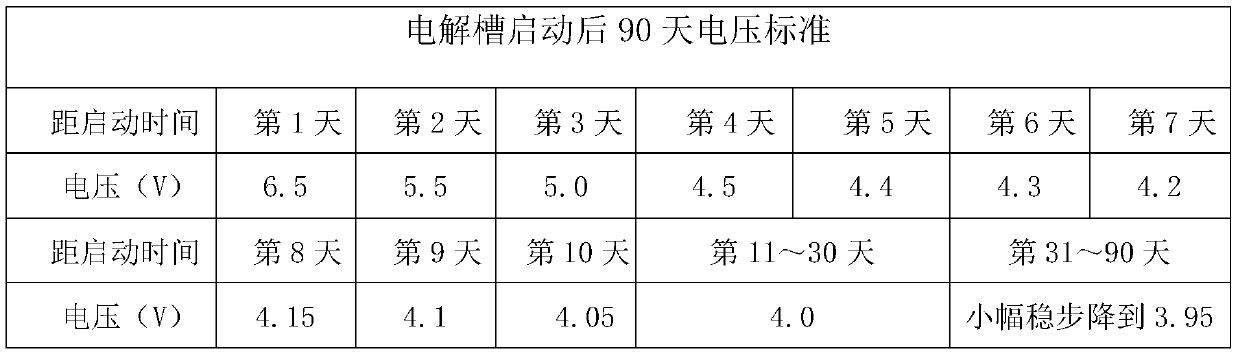

[0024] Adjust and control the voltage level, electrolyt...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com