Patents

Literature

113 results about "Electrolytes levels" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

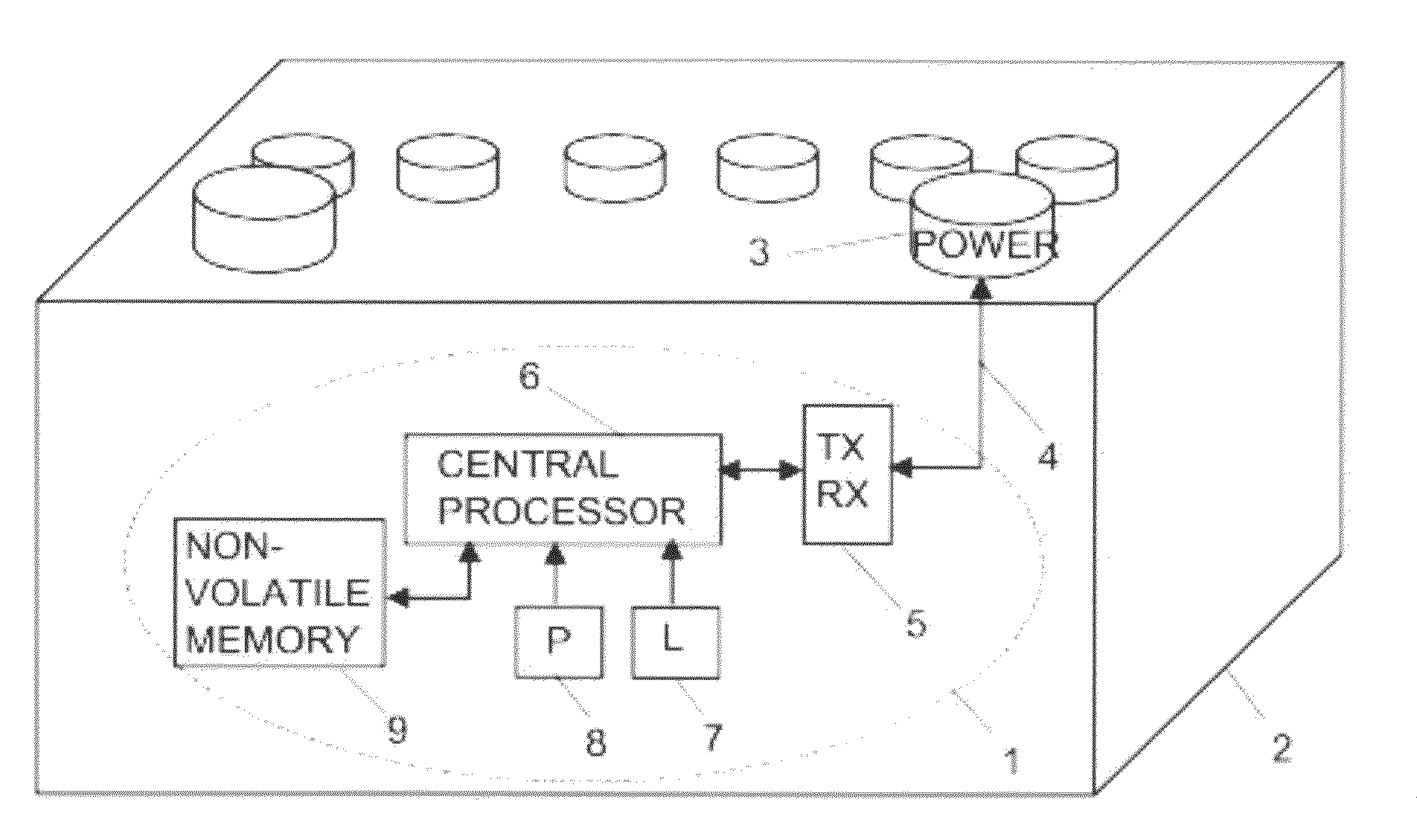

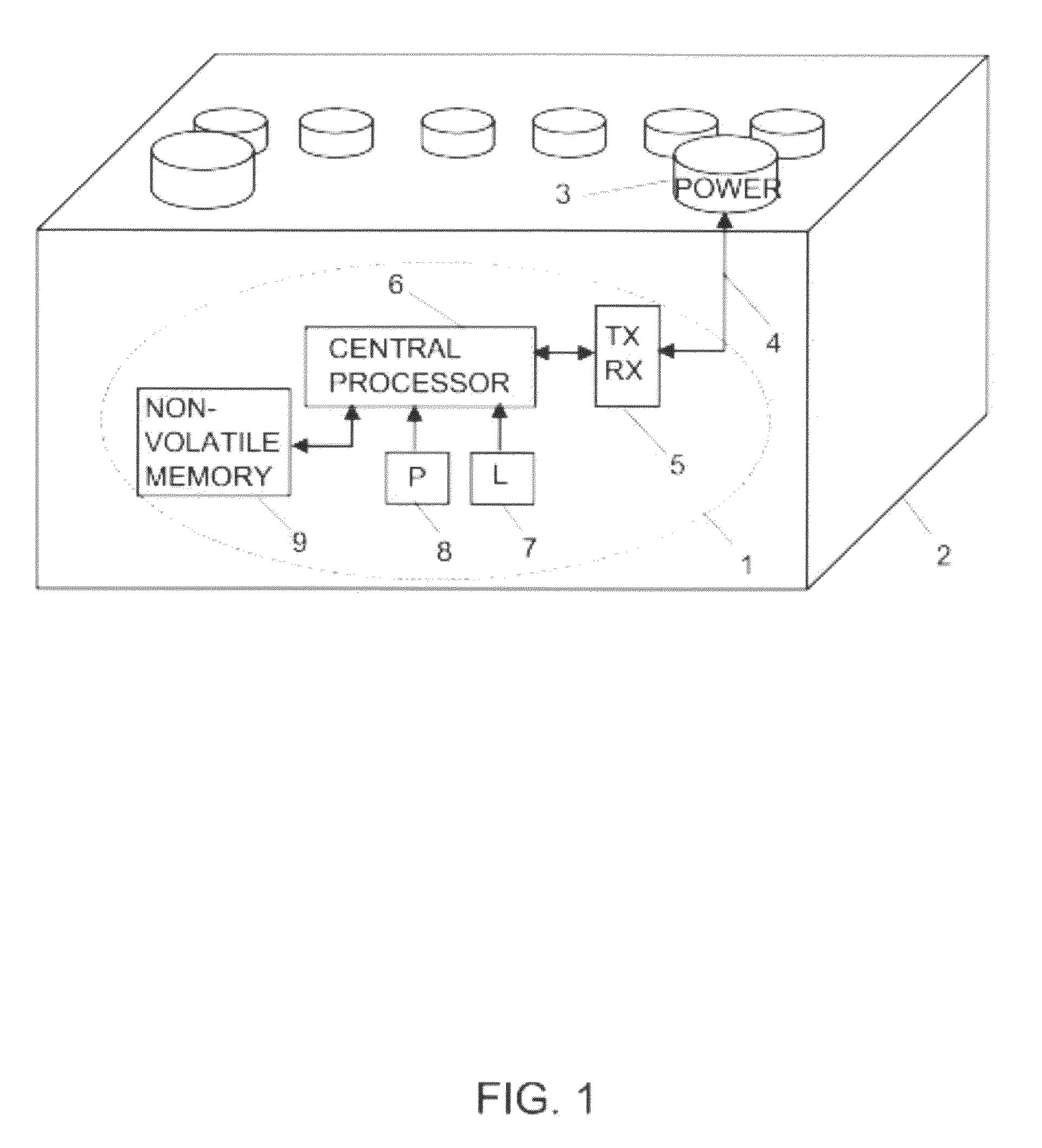

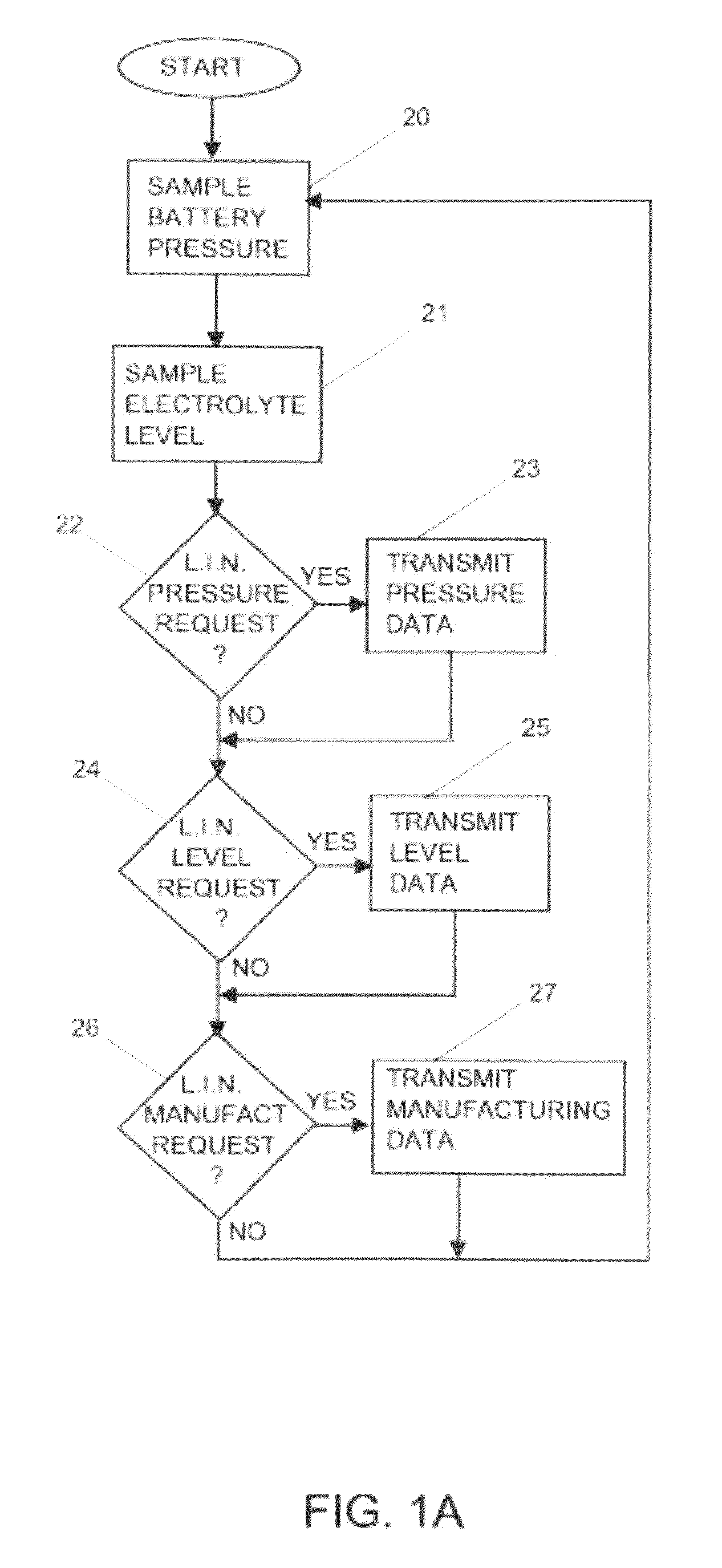

Embedded microprocessor system for vehicular batteries

InactiveUS20100217551A1Batteries circuit arrangementsError detection/correctionElectrical batteryComputerized system

A computer system embedded inside a starter or deep cycle battery that includes manufacturing data, the means to monitor battery pressure, the means to monitor electrolyte level and the means to transfer information to an external device.

Owner:4 PEAKS TECH

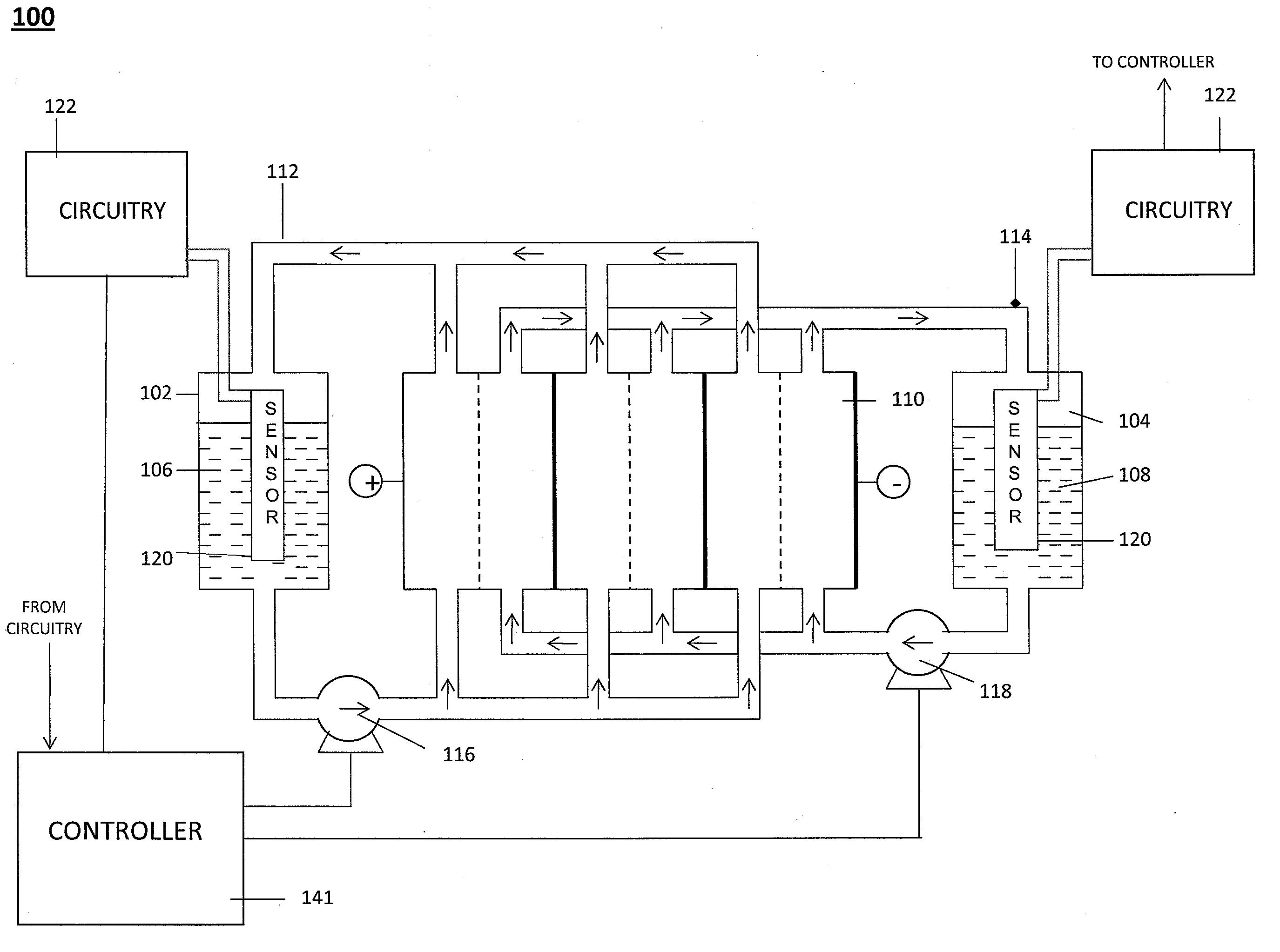

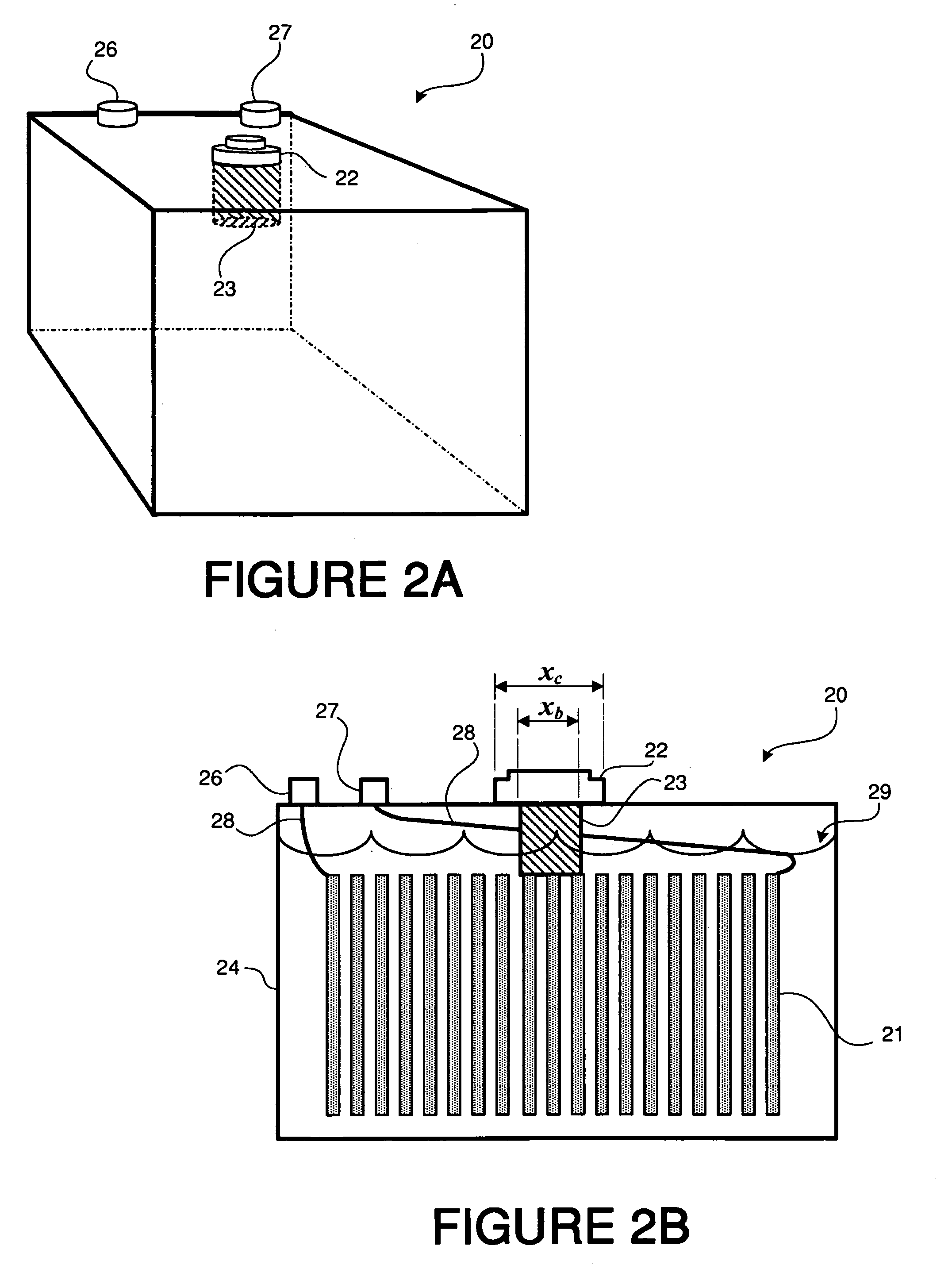

Level Sensor for Conductive Liquids

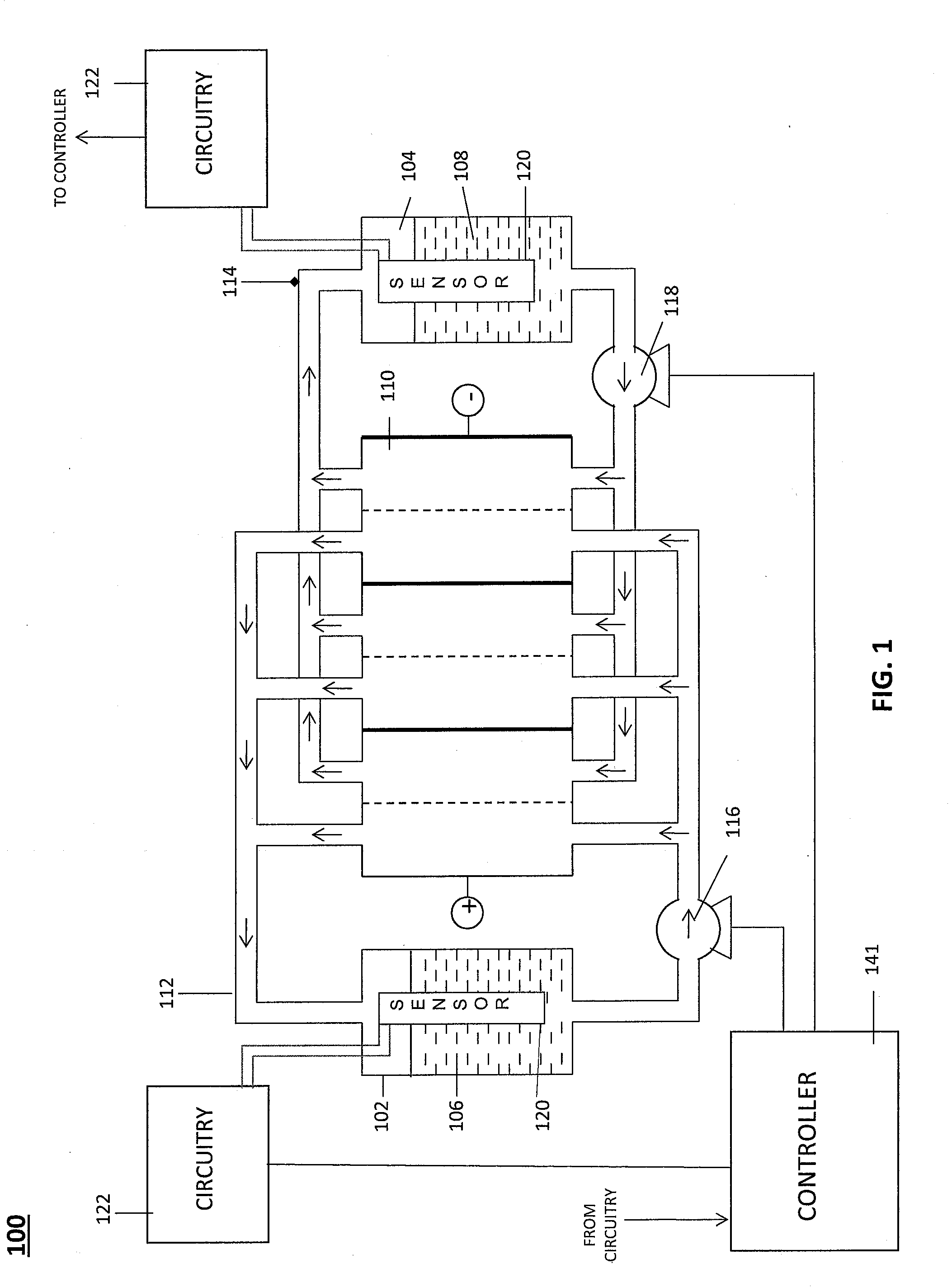

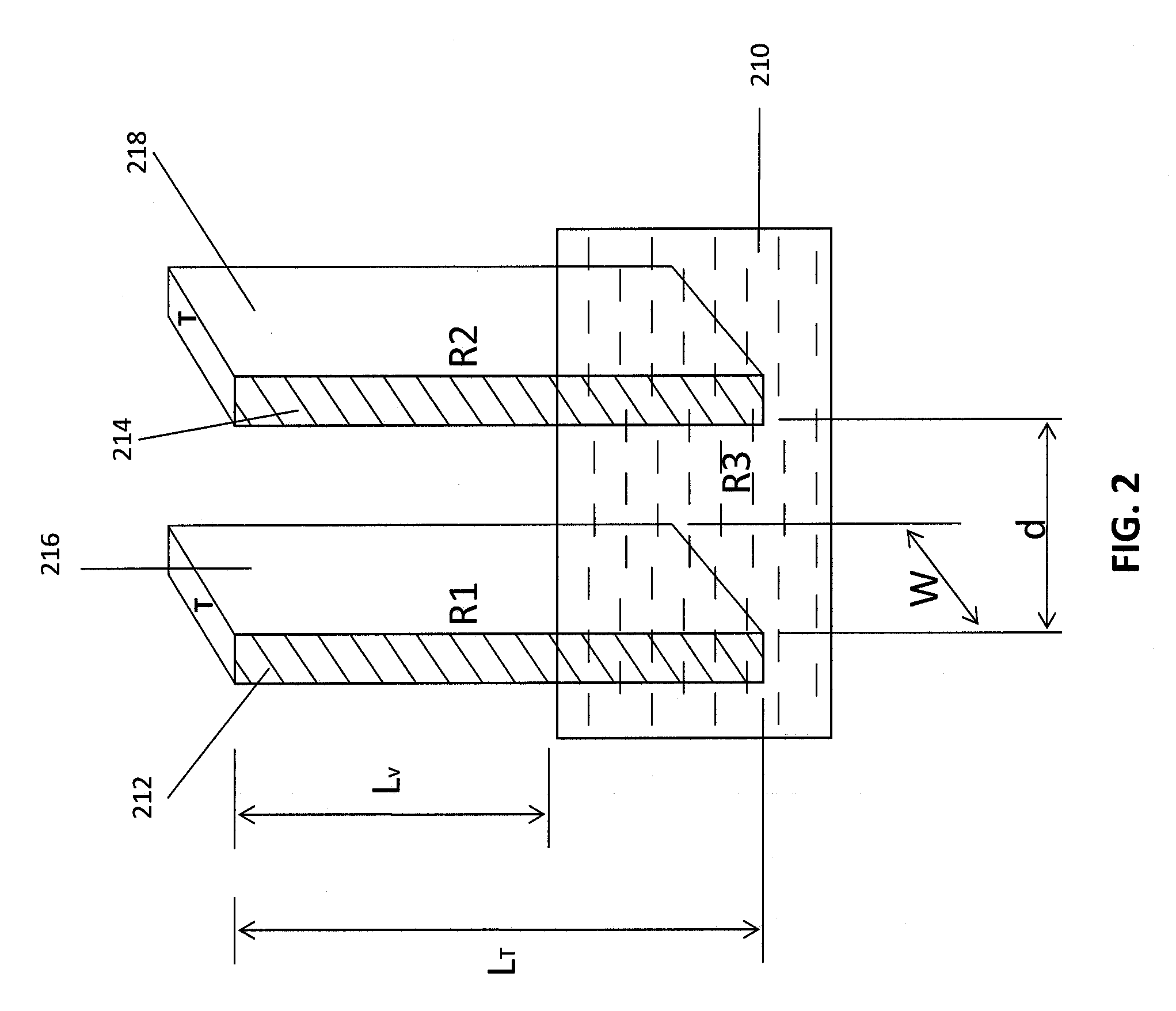

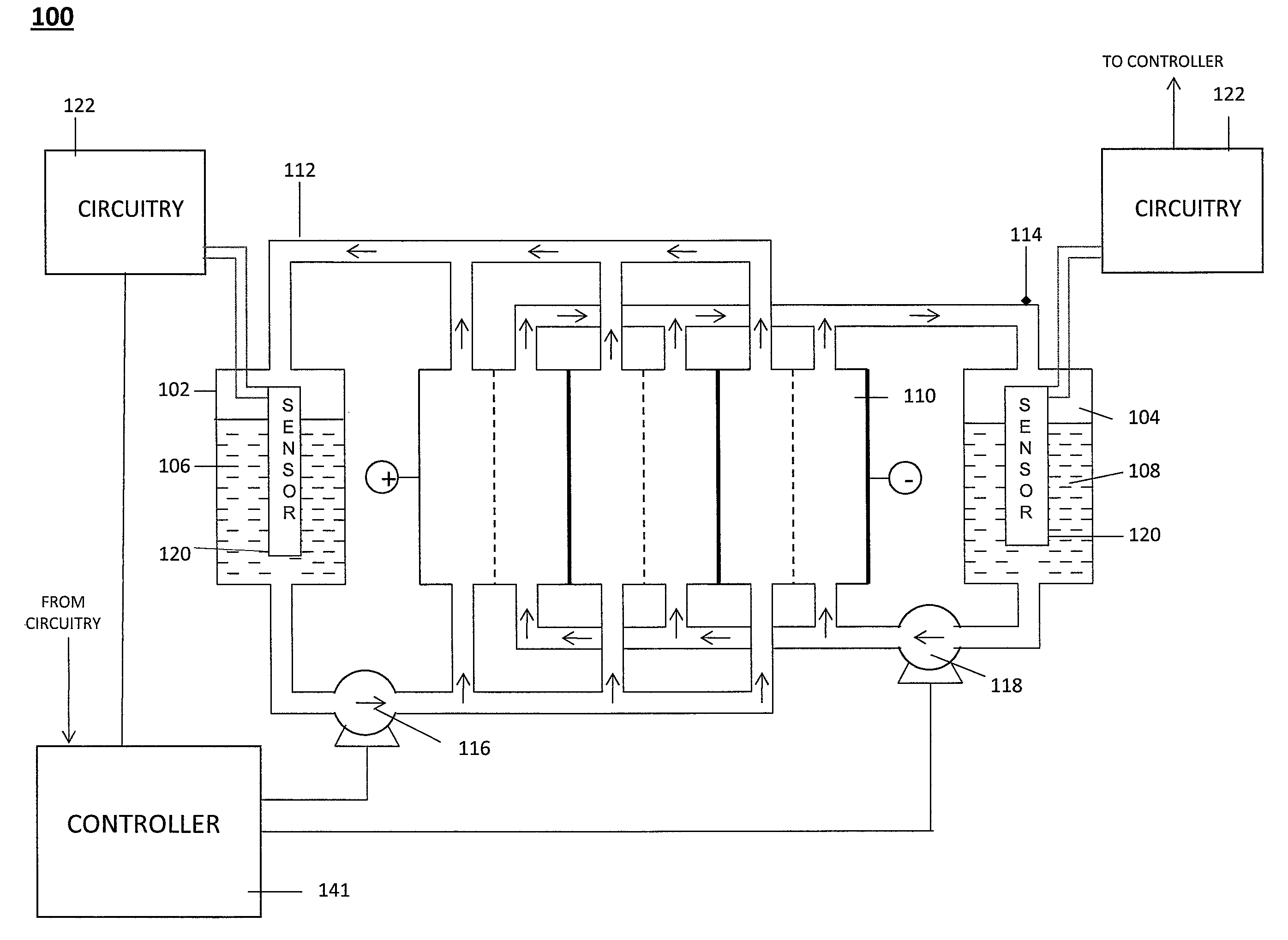

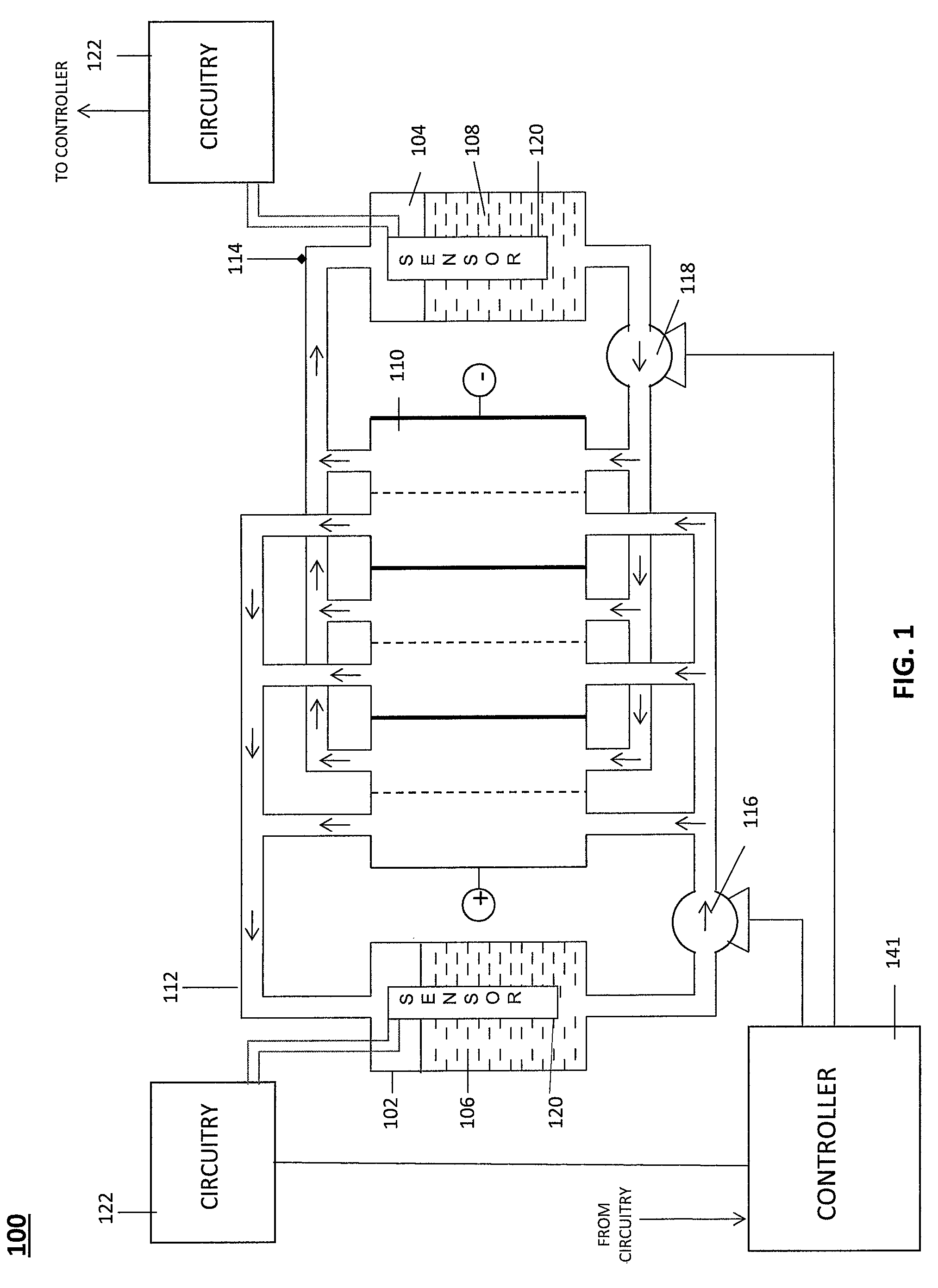

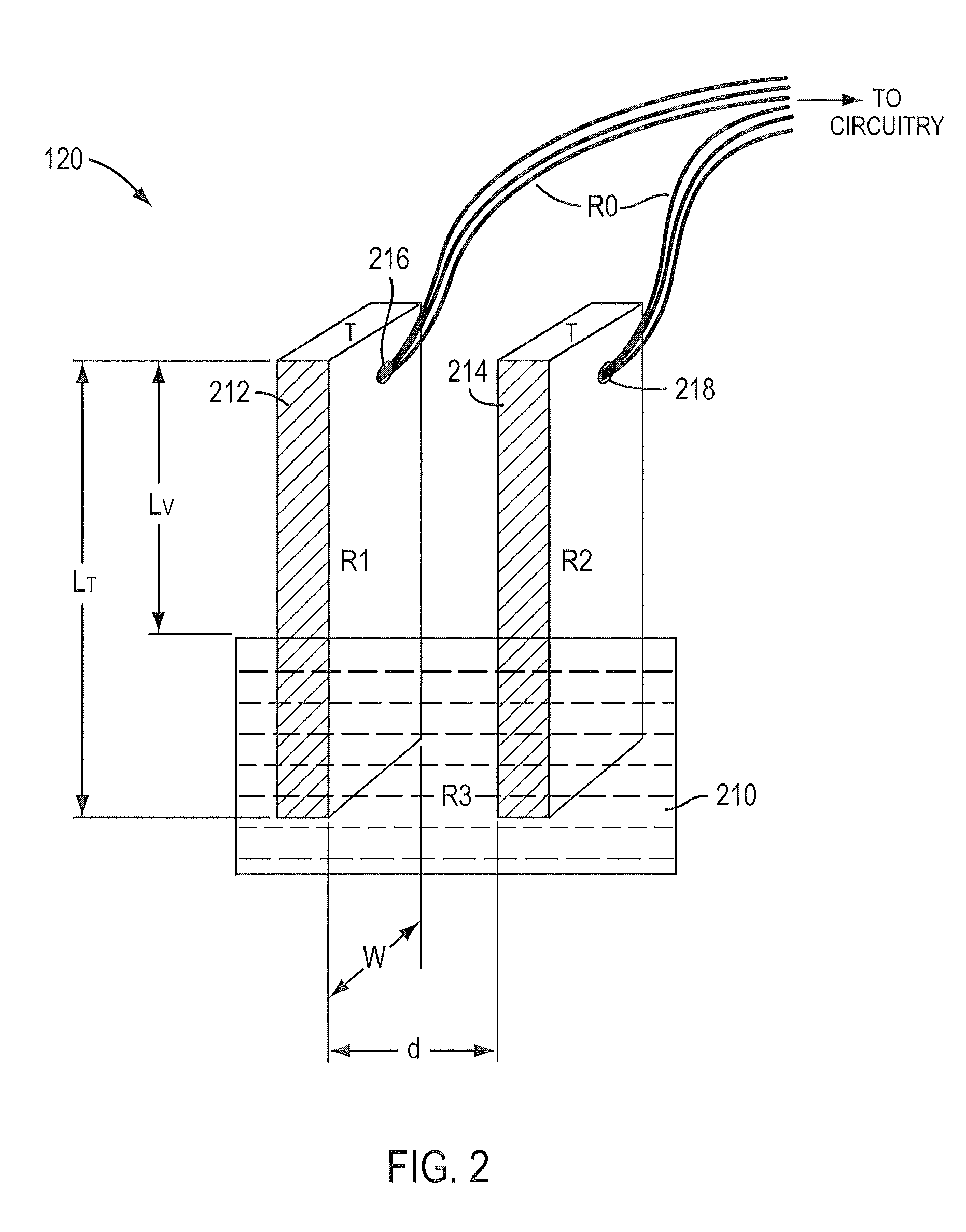

A sensor for measuring a level of a conductive liquid, is provided. The sensor includes at least two electrodes that can be positioned in a holding tank so as to be partially submerged in the conductive liquid, sensor leads coupled to the at least two electrodes, and circuitry and a controller for determining the properties of the electrolyte, the circuitry being coupled to the at least two electrodes via the sensor leads, and the controller being coupled to the circuitry. The sensor may be used as an electrolyte level sensor in a flow battery system.

Owner:IMERGY POWER SYST

Battery monitoring device

InactiveUS20100019773A1Lead-acid accumulatorsMaterial analysis by electric/magnetic meansElectricityDisplay device

A battery monitoring device includes a probe for insertion into a valve of a lead acid battery. The probe includes an electrolyte monitoring probe connected to an electrolyte level sensor, and a temperature probe connected to a temperature sensor. The battery monitoring device also includes a display for communicating the temperature and electrolyte level of the lead acid battery, and an LED for indicating that the electrolyte level is low. At appropriate intervals, the battery monitoring device can deliver pulses of electricity to the lead acid battery and counteract sulfation, in order to enhance battery performance and extend the useful lifetime of the battery.

Owner:SON HONG K

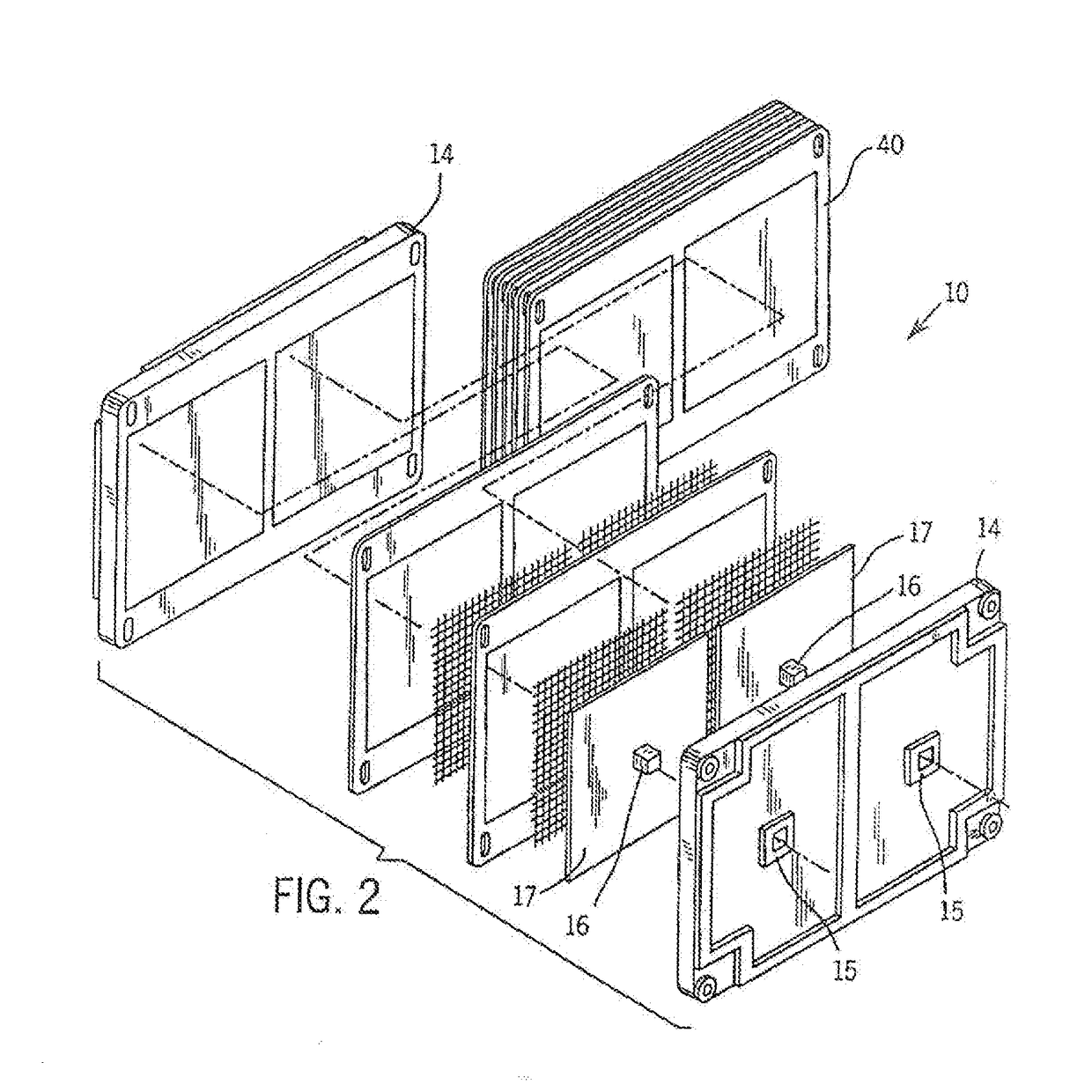

Hydrogen and oxygen generator having semi-isolated series cell construction

InactiveUS20100065419A1Improve sealingFirmly connectedCellsPhotography auxillary processesThermoplasticHysteresis

Owner:RICHARDSON DAVID THOMAS

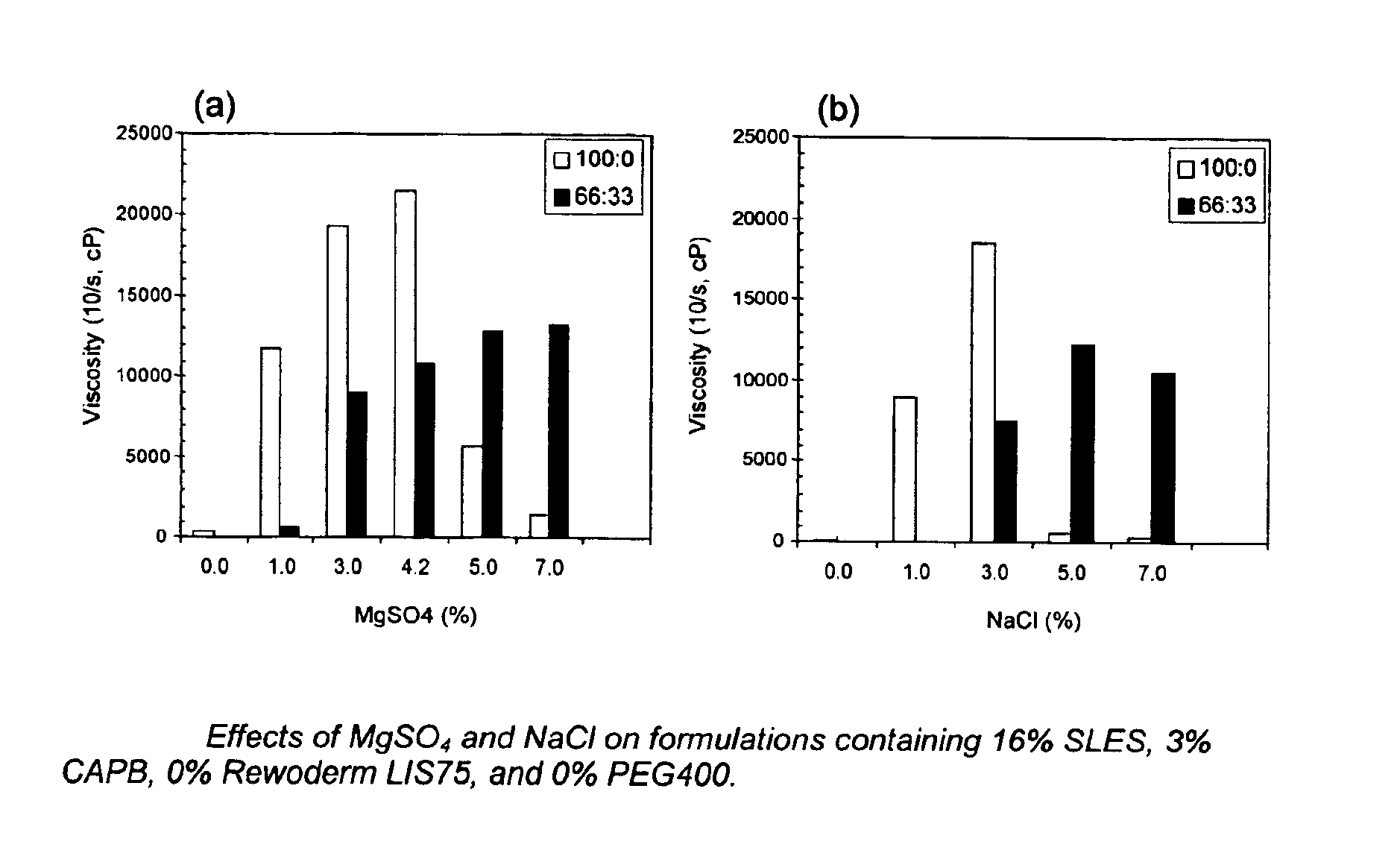

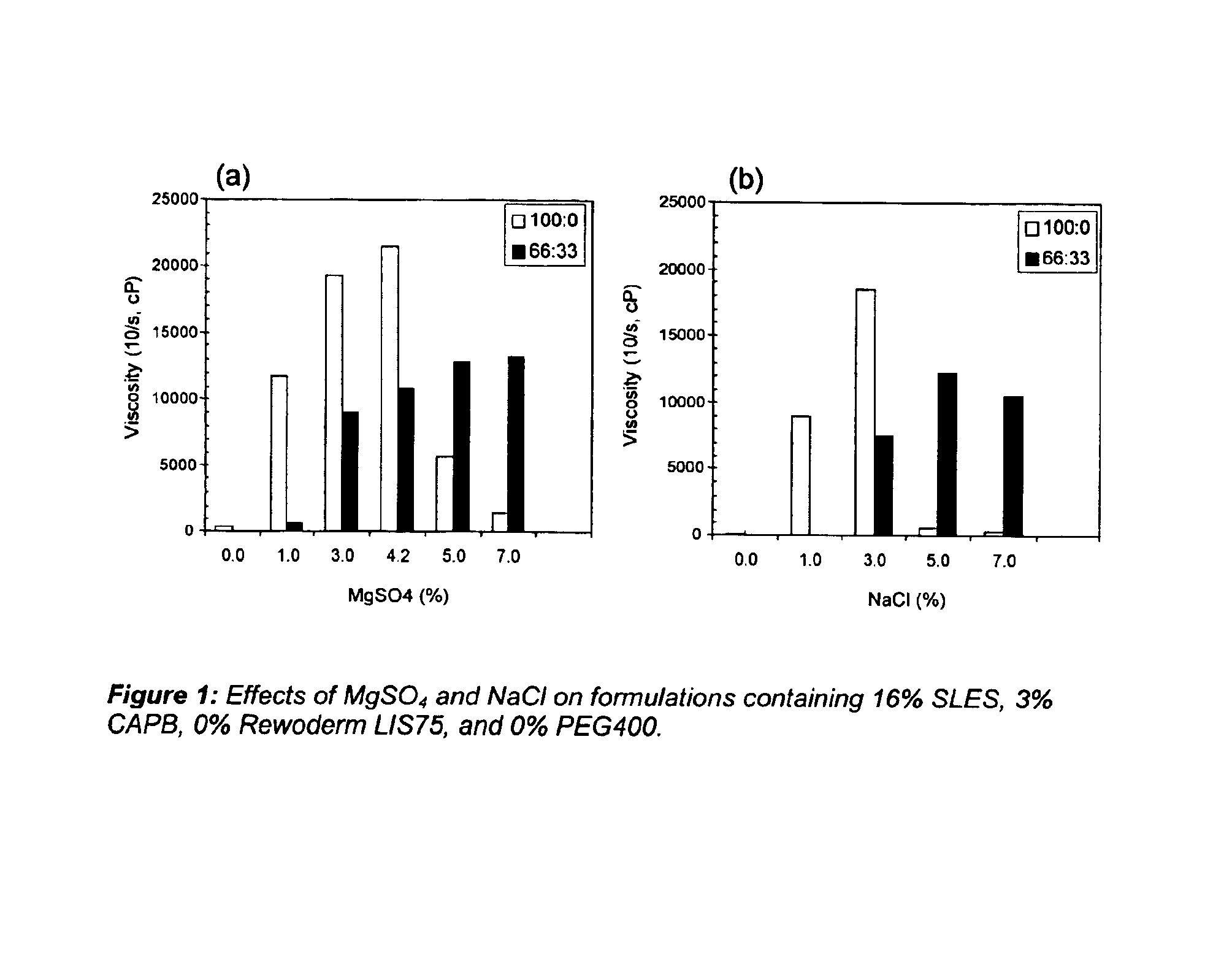

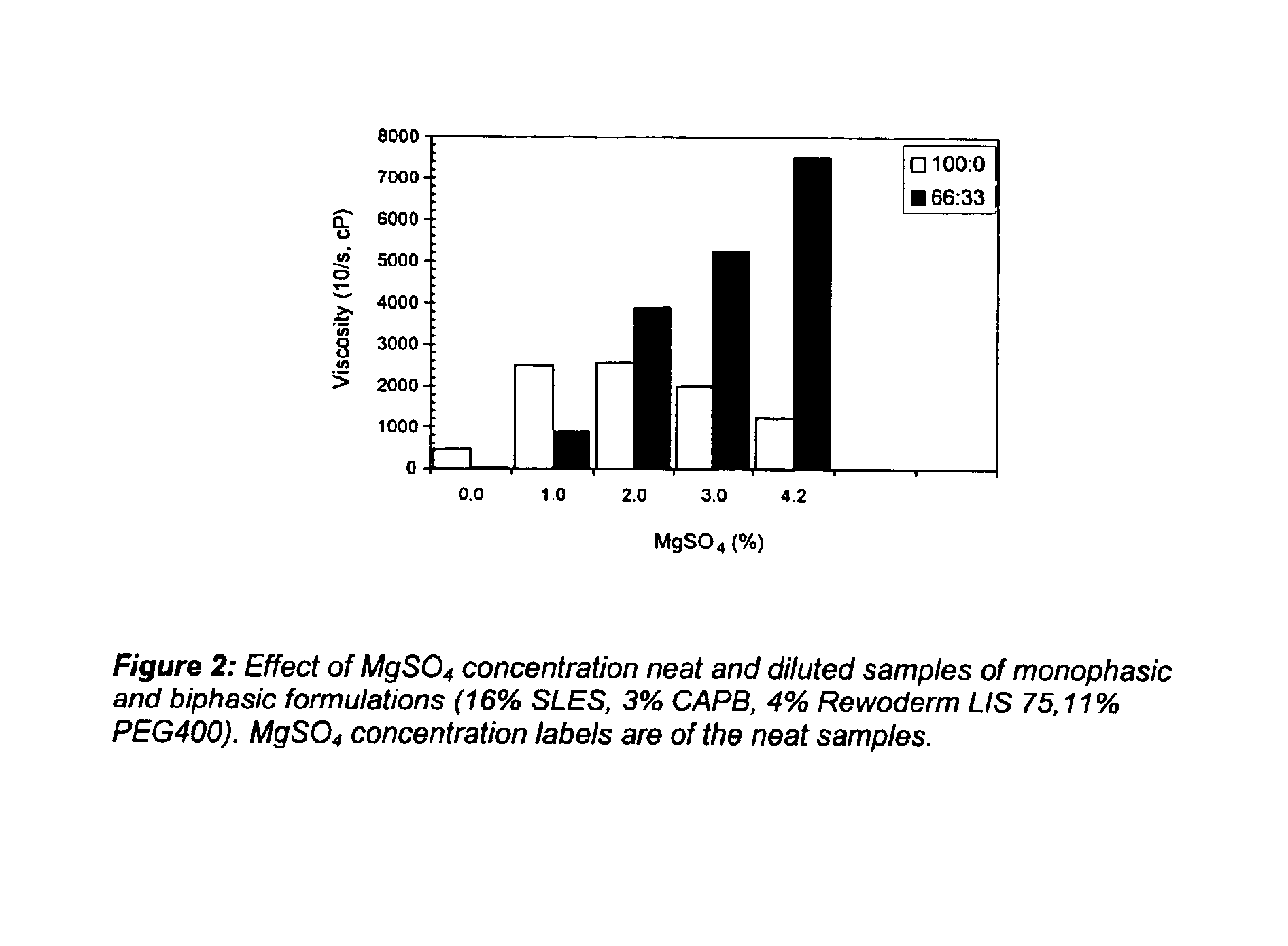

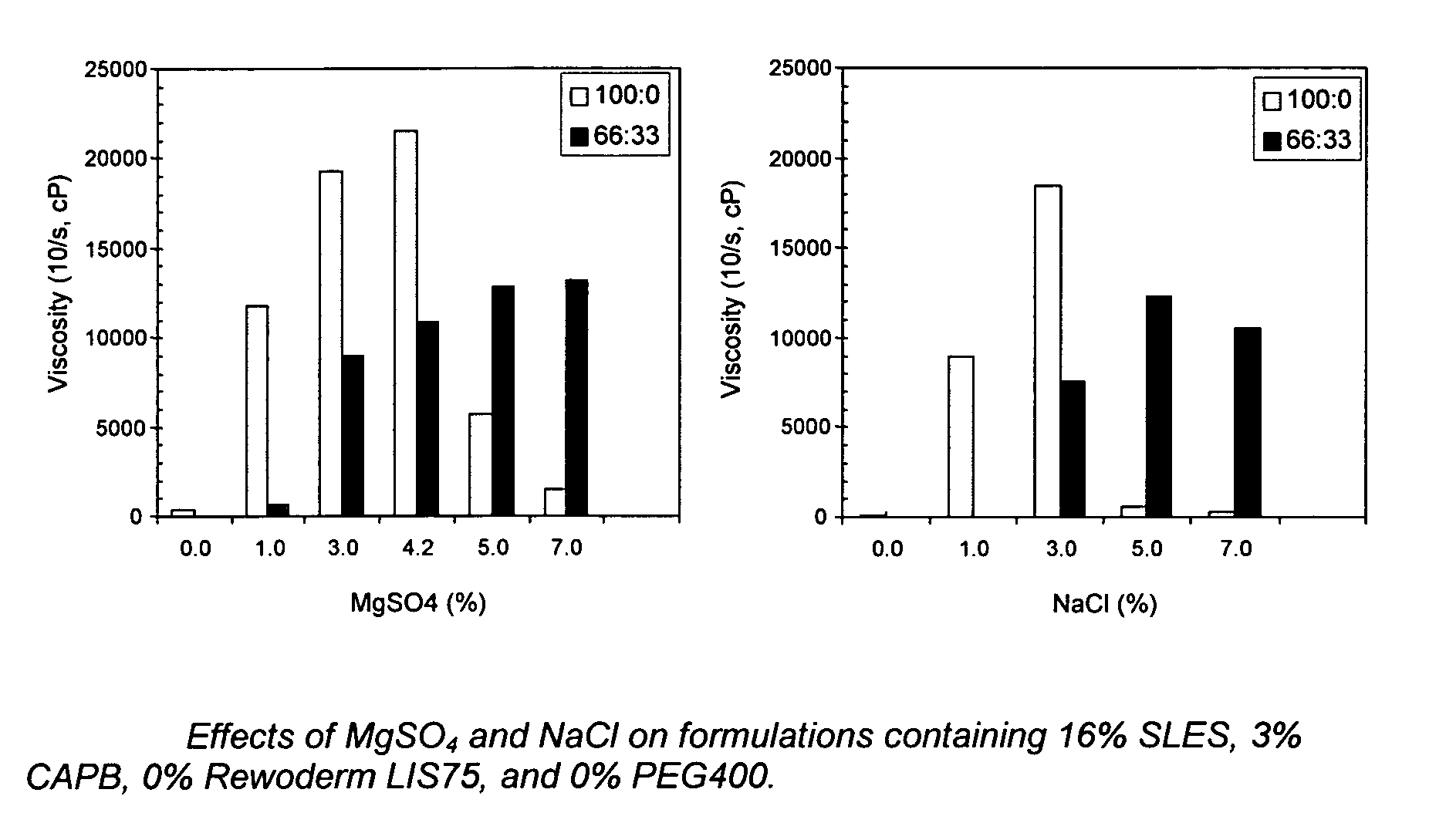

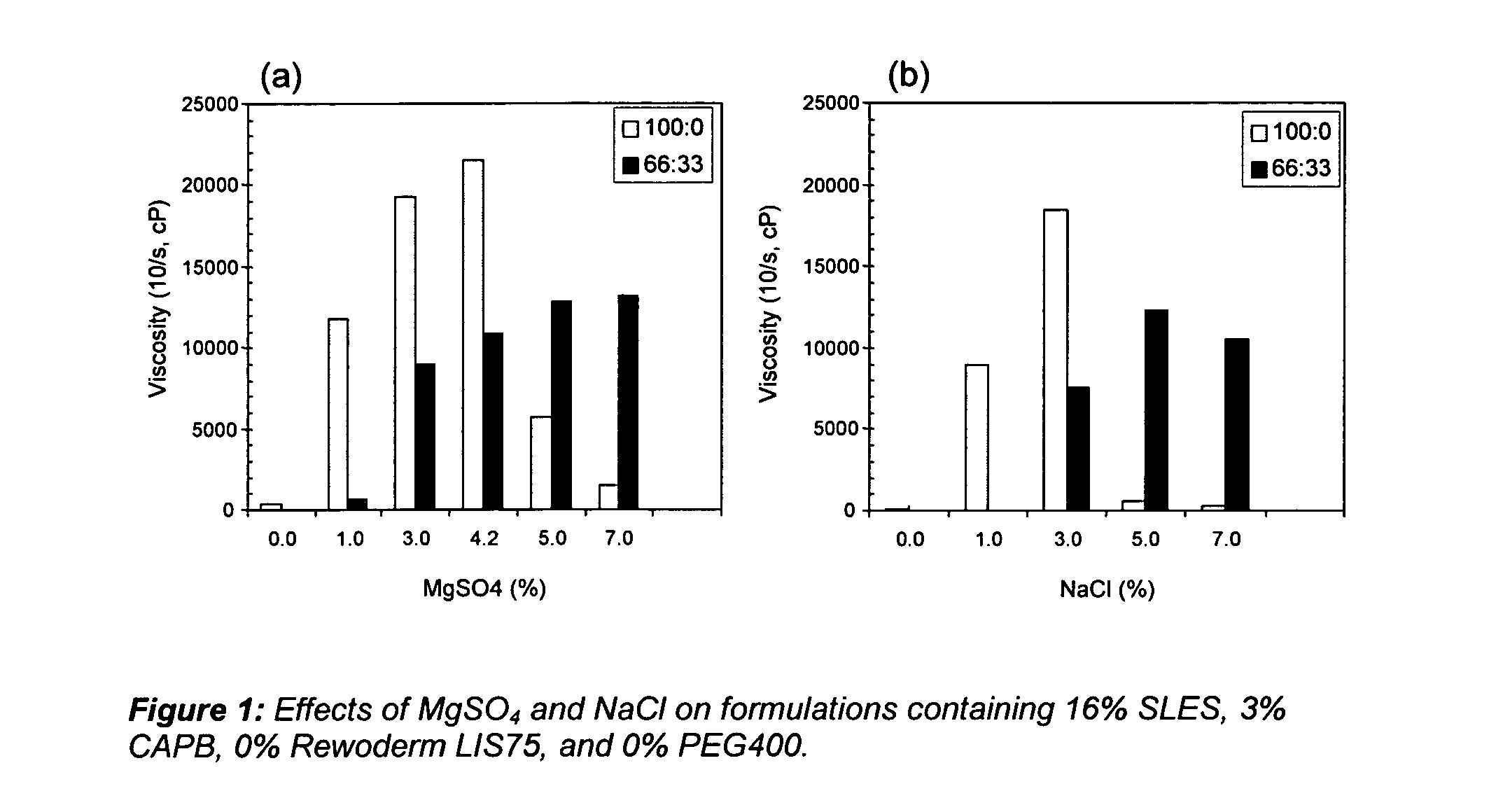

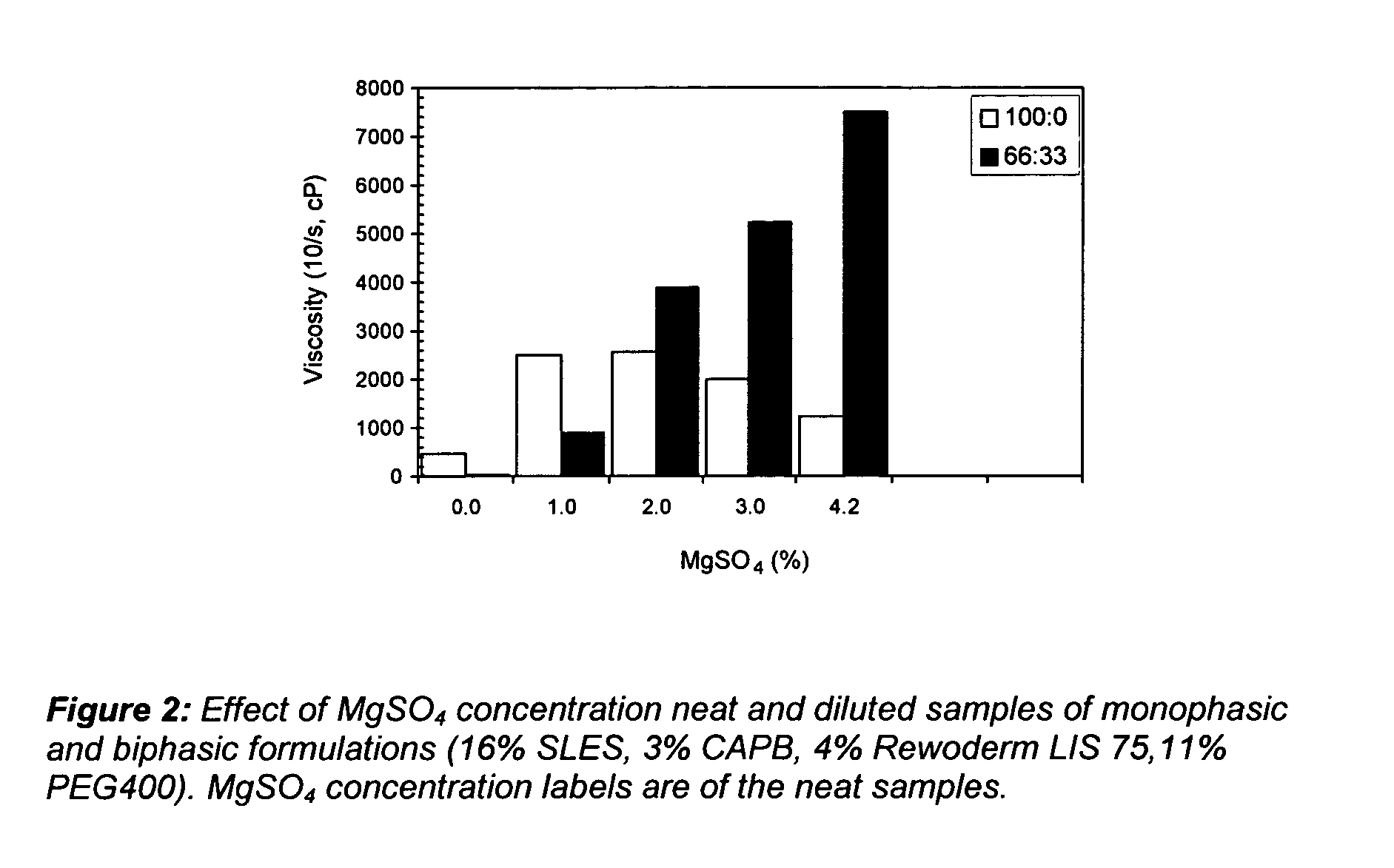

Process for lowering level of salt required for dilution thickening

InactiveUS6919303B2Not hard on skinInorganic/elemental detergent compounding agentsCosmetic preparationsElectrolytes levelsElectrolyte

The invention relates to a process for making single phase dilution thickening compositions comprising electrolyte. By adding defined associative thickener to said compositions applicants have found one can lower level of salt / electrolyte required to obtain dilution thickening effect.

Owner:UNILEVER HOME & PERSONAL CARE USA DIV OF CONOPCO IN C

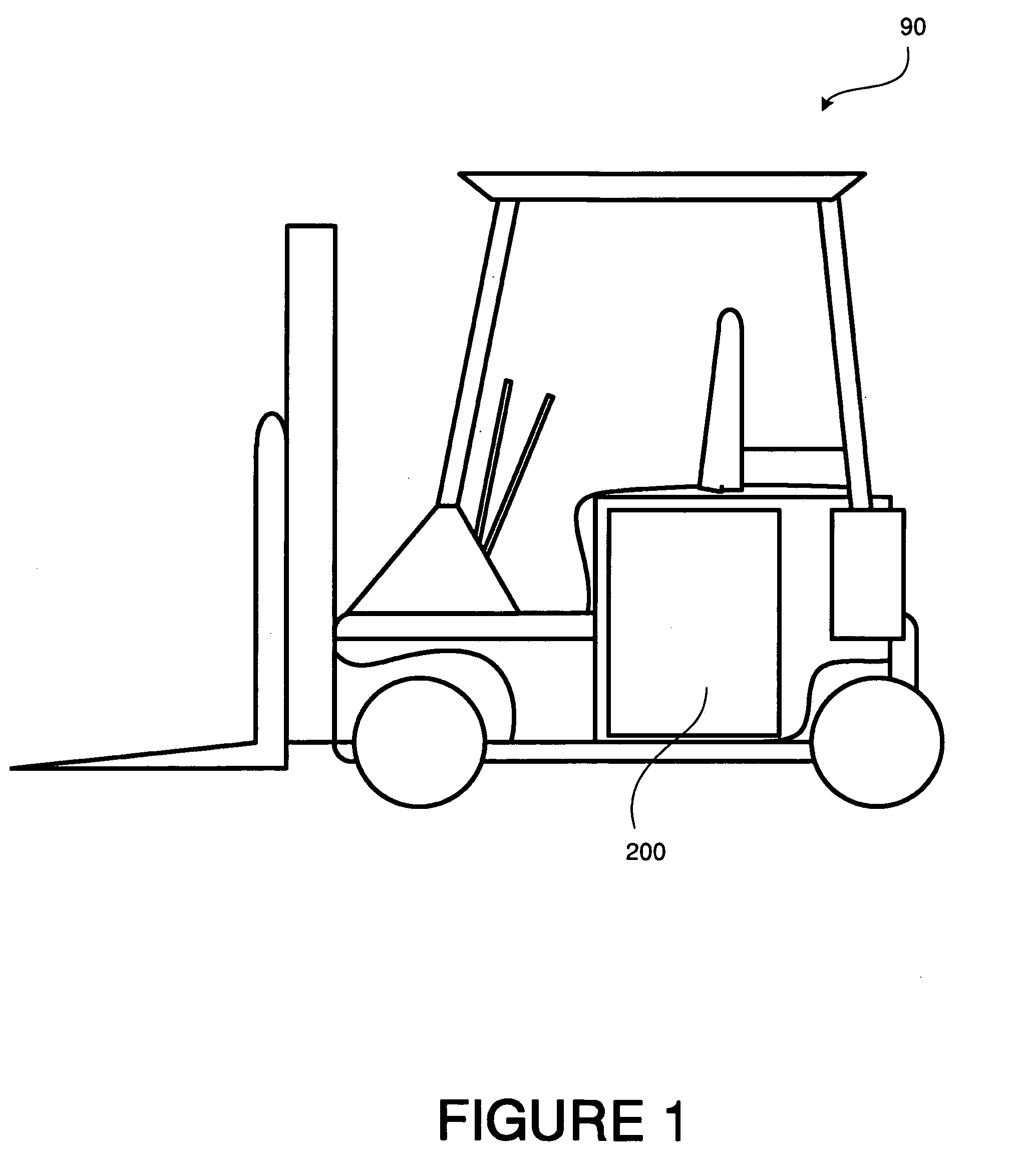

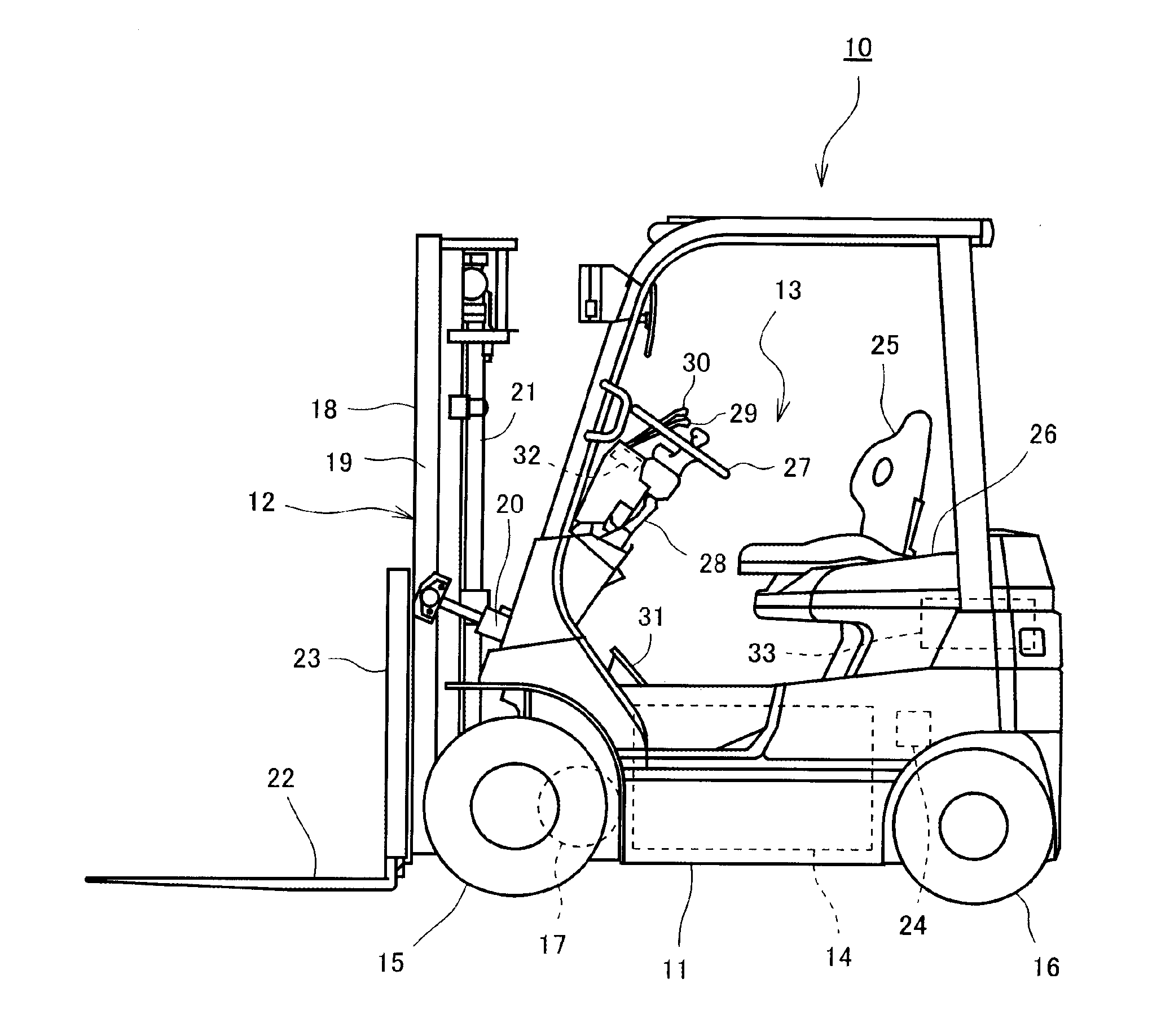

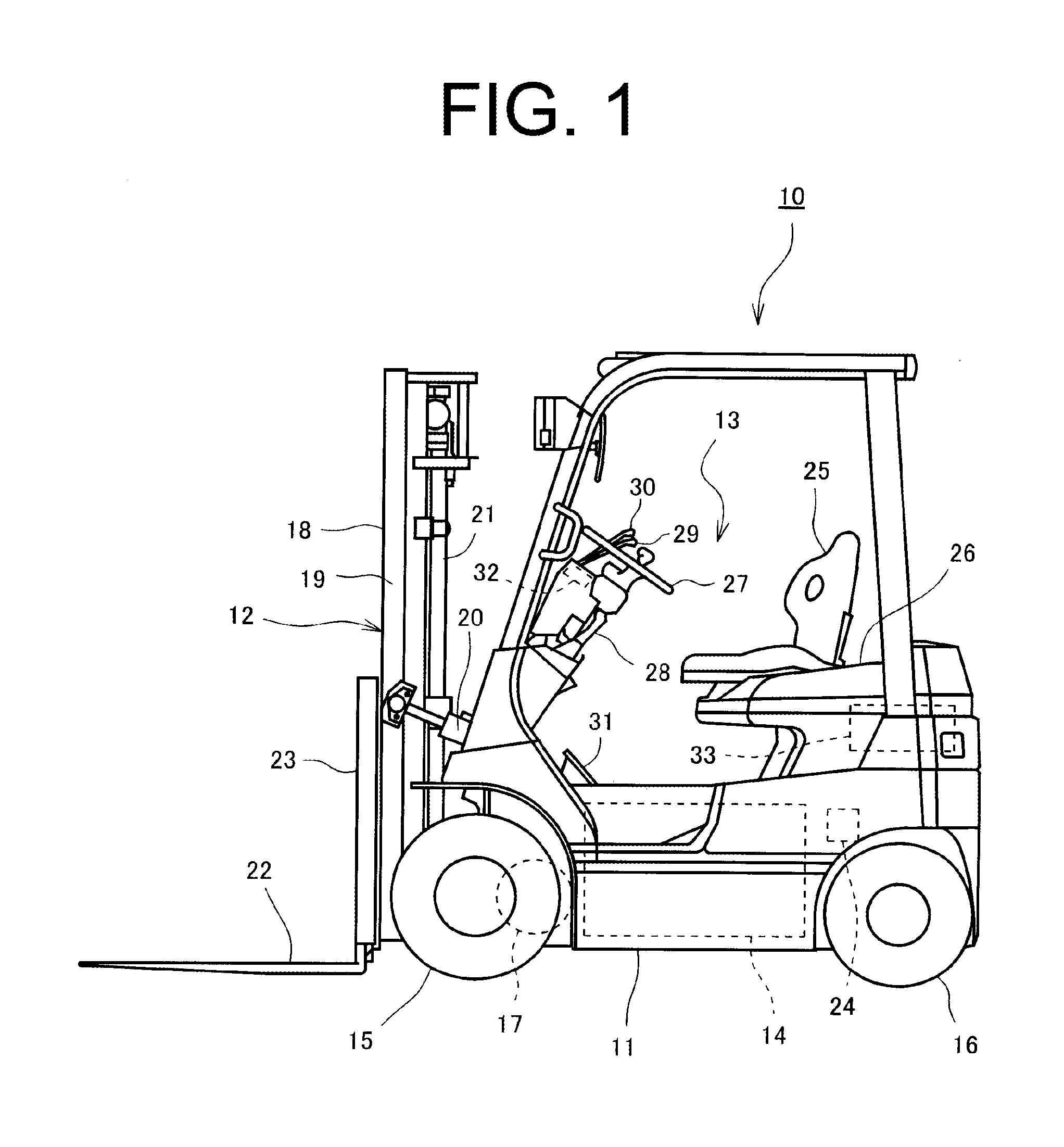

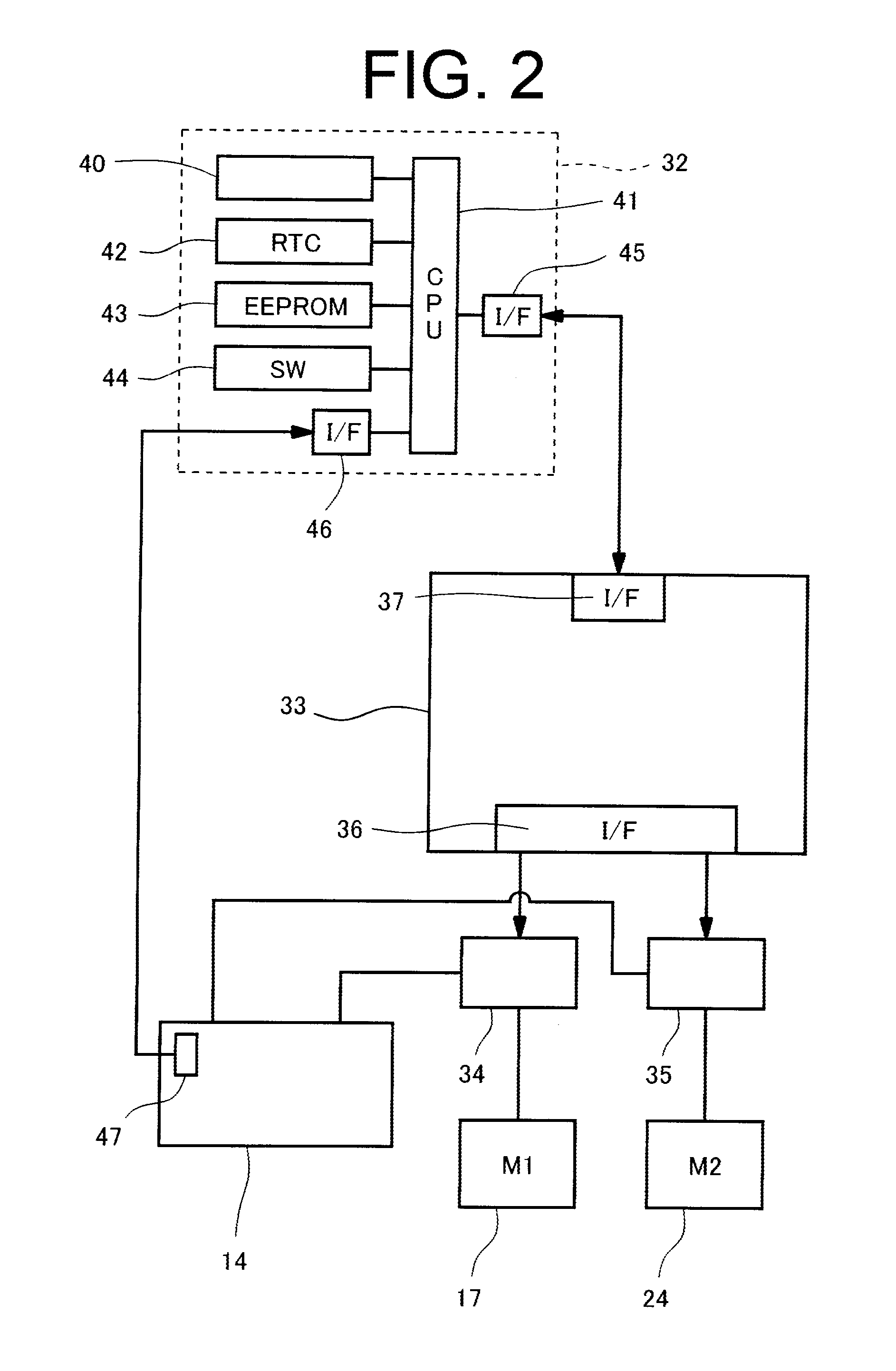

Industrial vehicle

An industrial vehicle having a vehicle body includes a battery, an electric motor, an electrolyte level sensor, a vehicle operating with lowered electrolyte level, a vehicle operating time calculator, a data-storing device storing data of the vehicle operating time, an electric motor limiting condition and a motor controller. The electric motor is driven to generate torque. The electrolyte level sensor detects whether or not electrolyte level of the battery is lower than a predetermined level. The vehicle operating time is a time elapsing while the electrolyte level is lower than the predetermined level. The vehicle operating time calculator counts the vehicle operating time in accordance with the detection of the electrolyte level. The electric motor limiting condition limits operation of the electric motor gradually in accordance with the vehicle operating time. The motor controller controls operation of the electric motor based on the electric motor limiting condition.

Owner:TOYOTA IND CORP

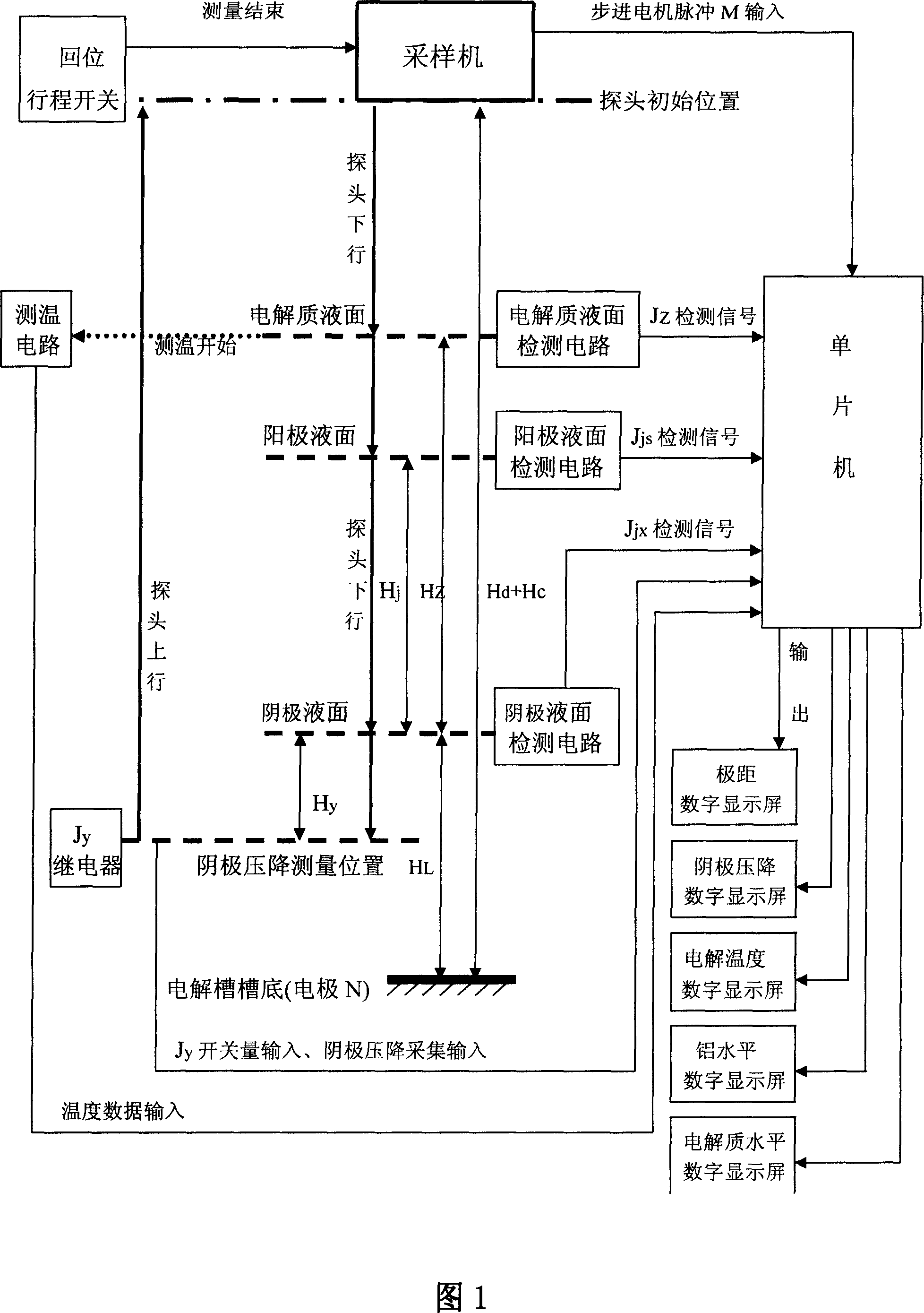

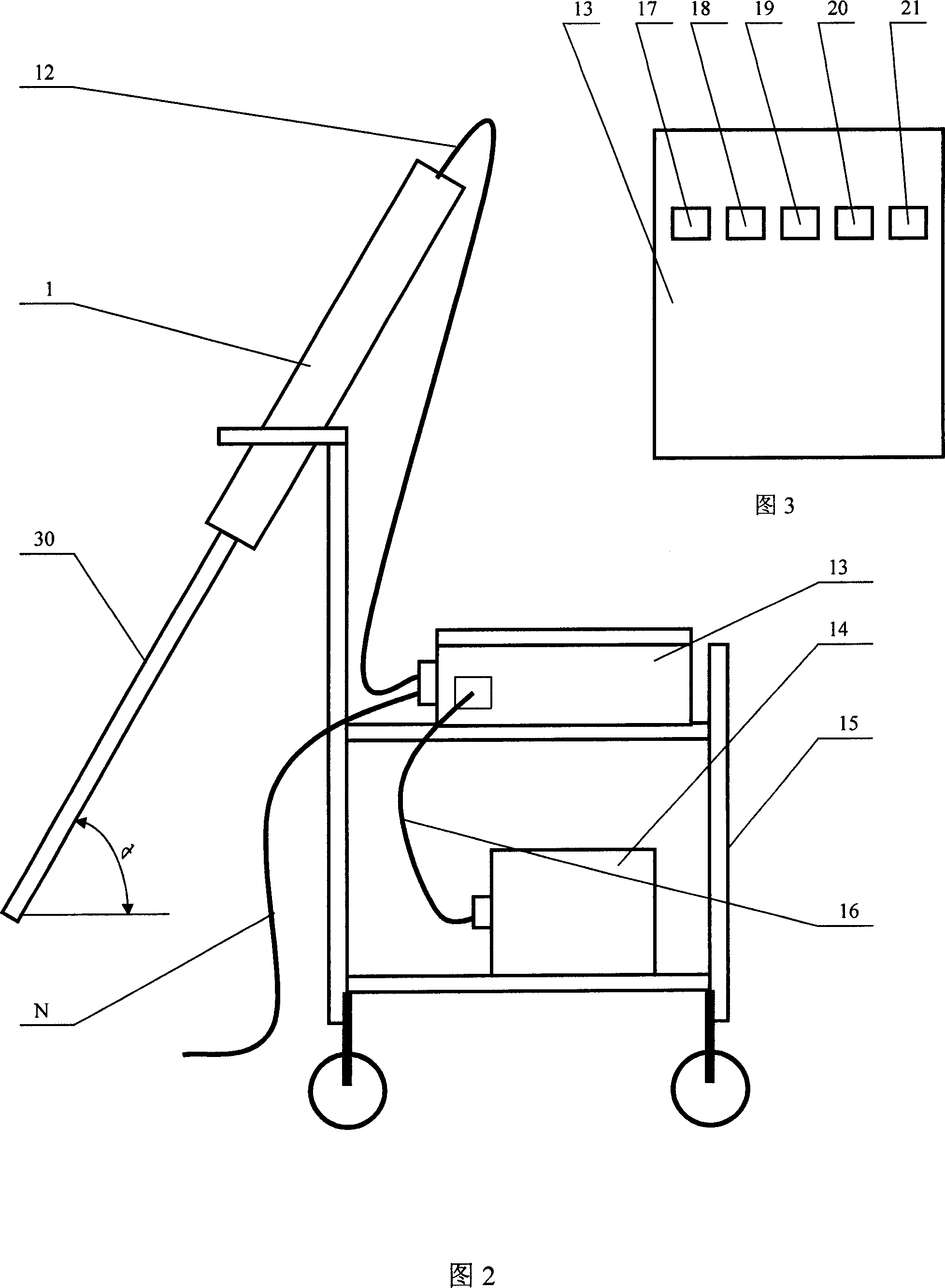

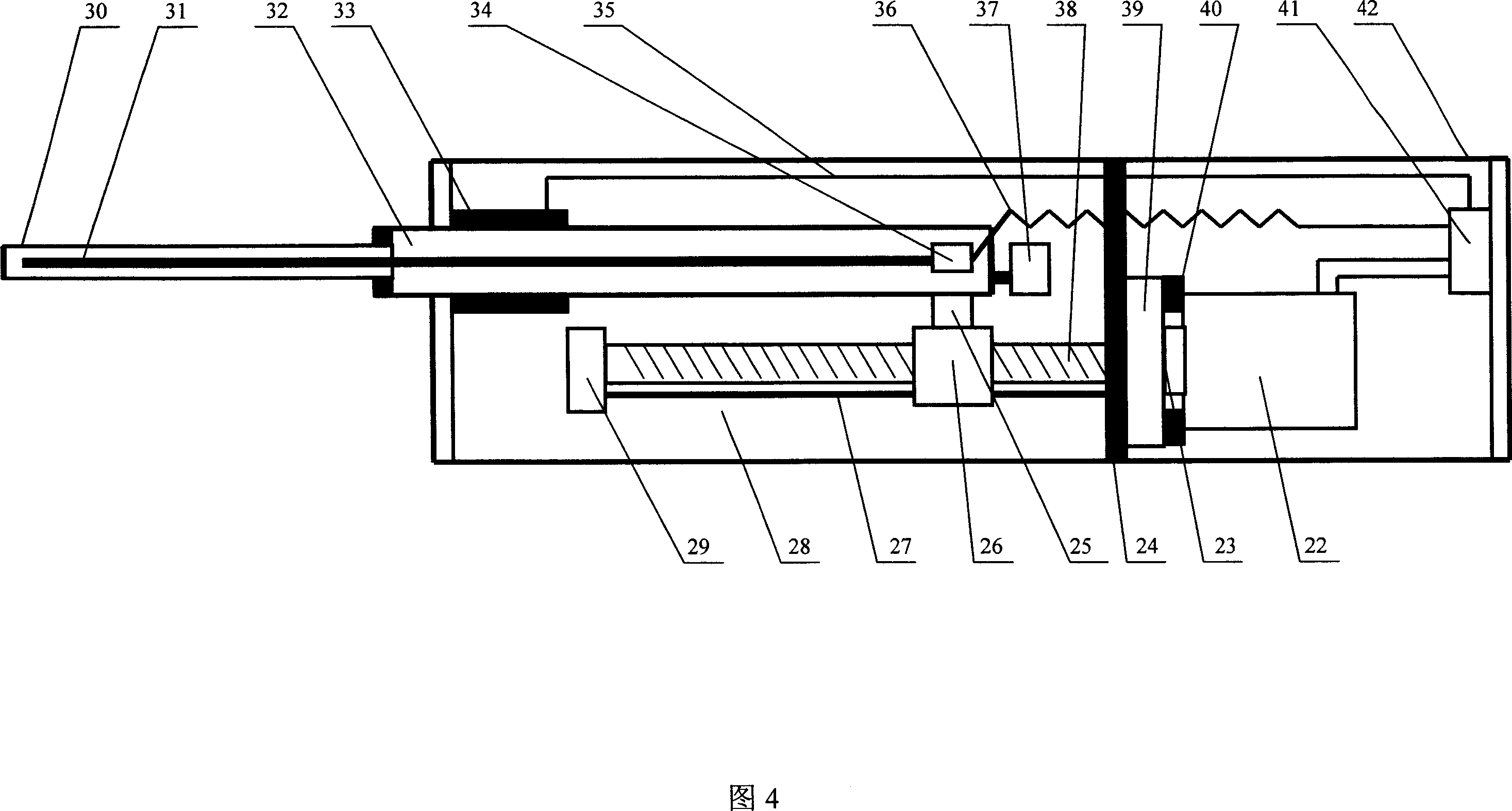

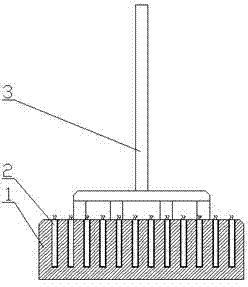

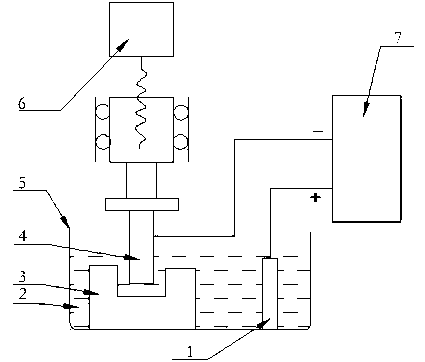

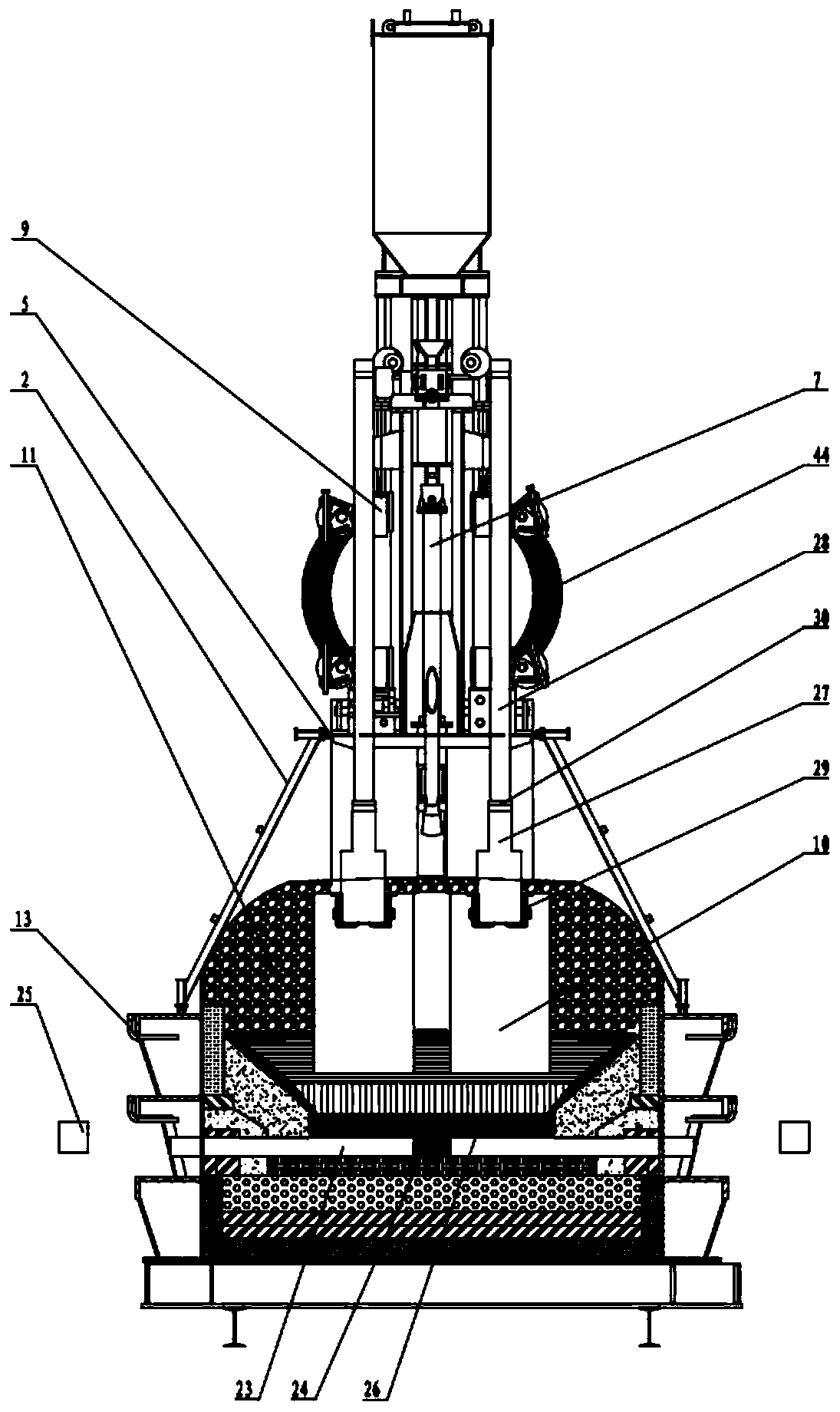

Prebaked aluminum electrolytic tank parameter measuring method and its device

The invention discloses a method for measuring technological parameter for prebaked cell for aluminum-reduction, comprising following steps: inserting measuring probe driven by stepper motor into electrolyser, the impulse frequency of rotation rate for stepper motor continuously input into monolithic machine for counting and storing; checking electrolyte liquid surface, anode liquid surface and cathode liquid surface by relative checking circuit according to voltage change feature of different layer in aluminum cell solution, inputting relative measuring signal into monolithic machine; monolithic machine counting out polar distance, aluminum concentration and electrolyte concentration according to set mathematical model; the measured voltage is cathode voltage when the down vertical distance of measuring probe in aluminium liquid is 60- 100 mm; the polar distance, aluminum concentration, electrolyte concentration and electrolytic temperature are input into display screen by monolithic machine for real time display; the over travel-limit switch resetting measuring probe. The measuring device mainly comprises sampling machine and controlling tank; controlling tank is equipped with polarization layer measuring circuit and spacing measuring cathode pressure differential circuit; and sampling machine comprises data collecting device and operation power device.

Owner:GUIZHOU BRANCH CHINA ALUMINUM IND +1

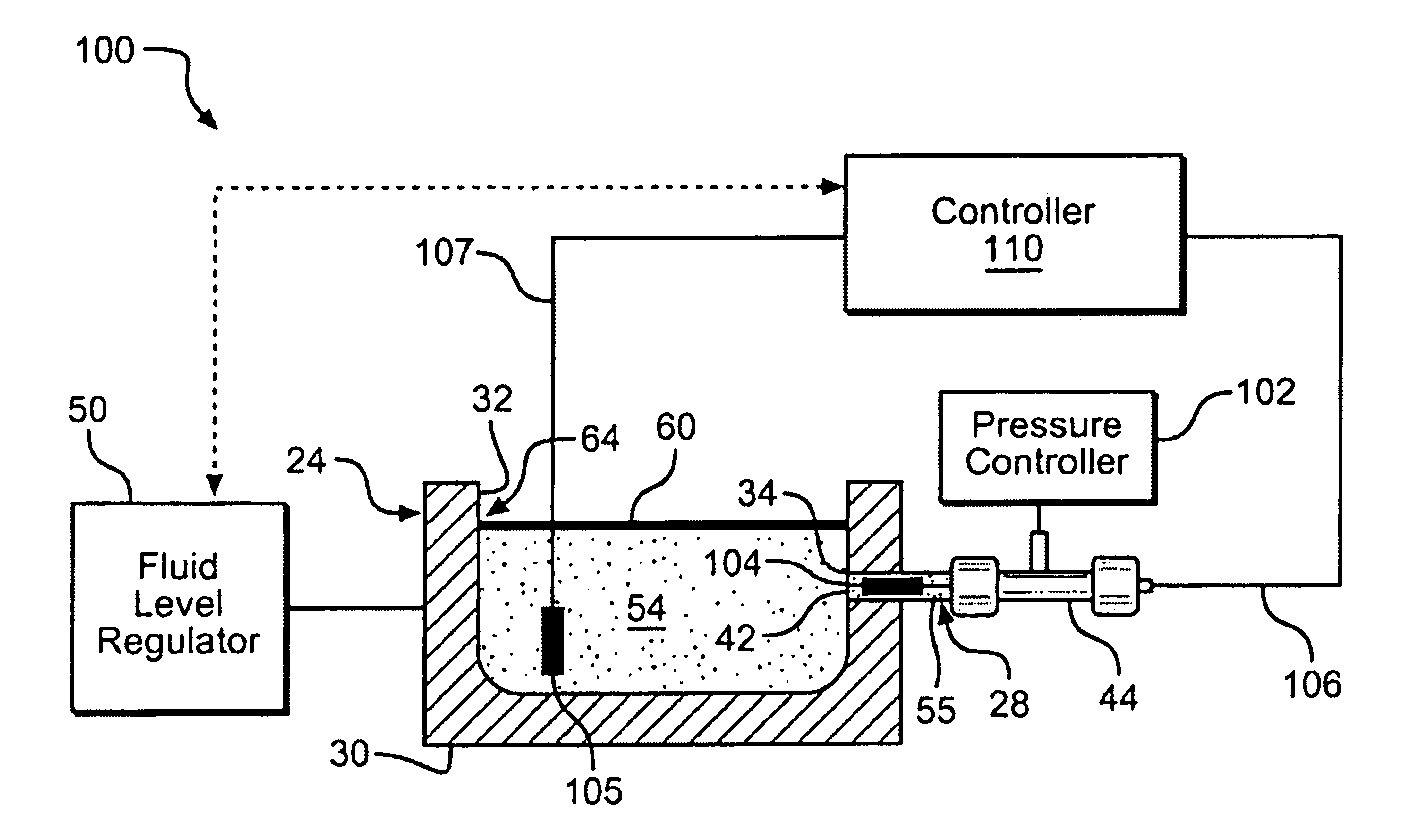

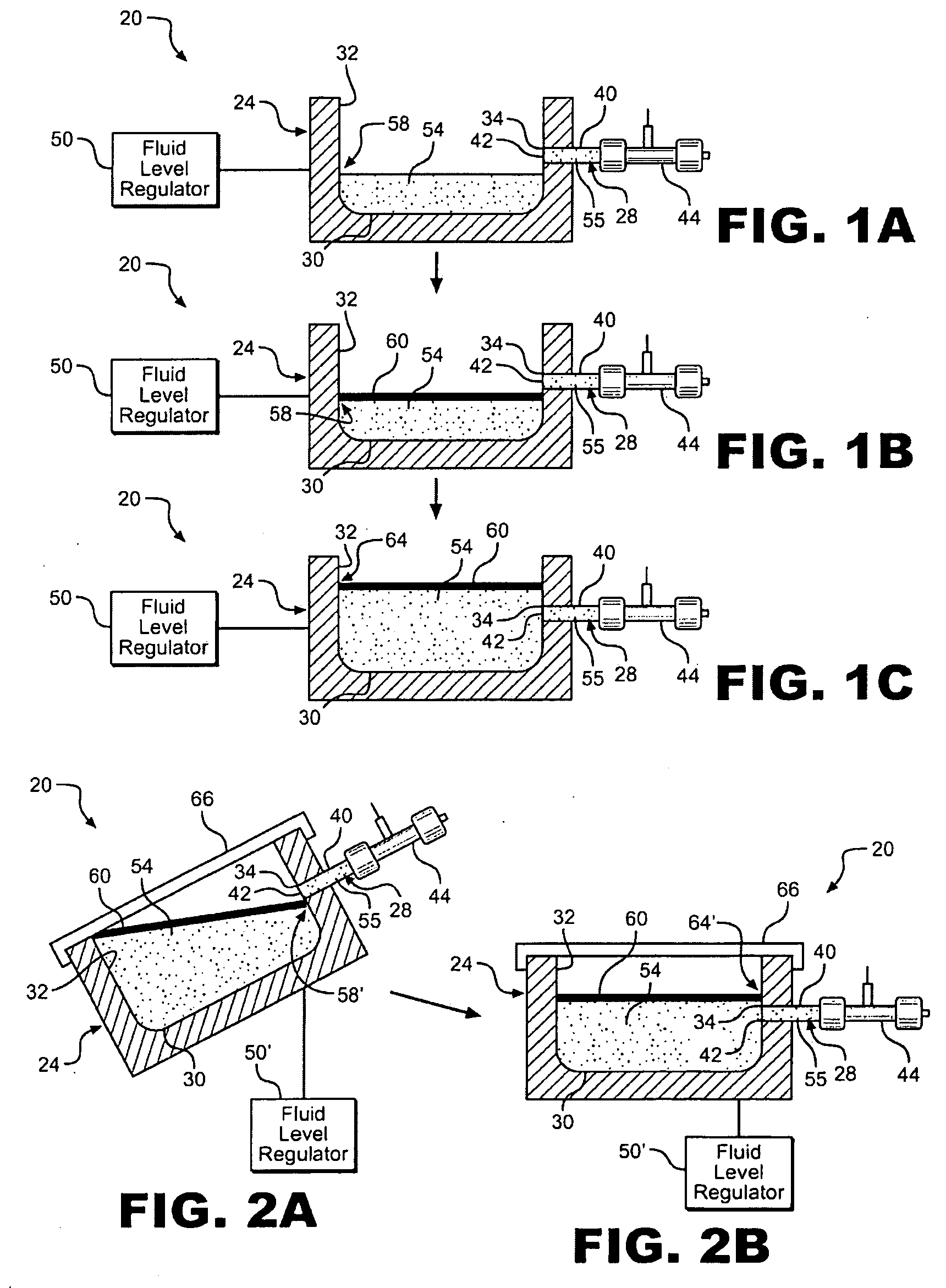

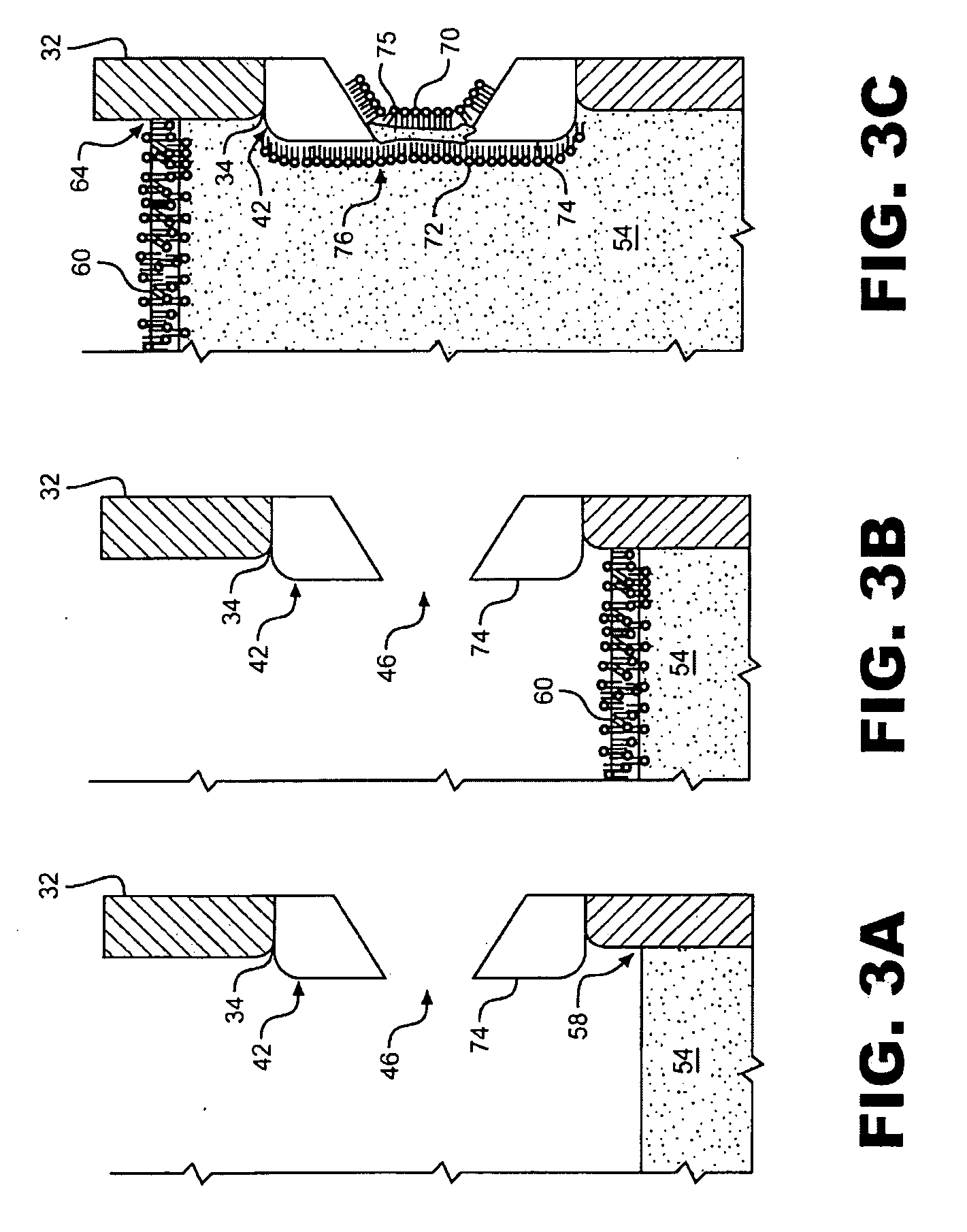

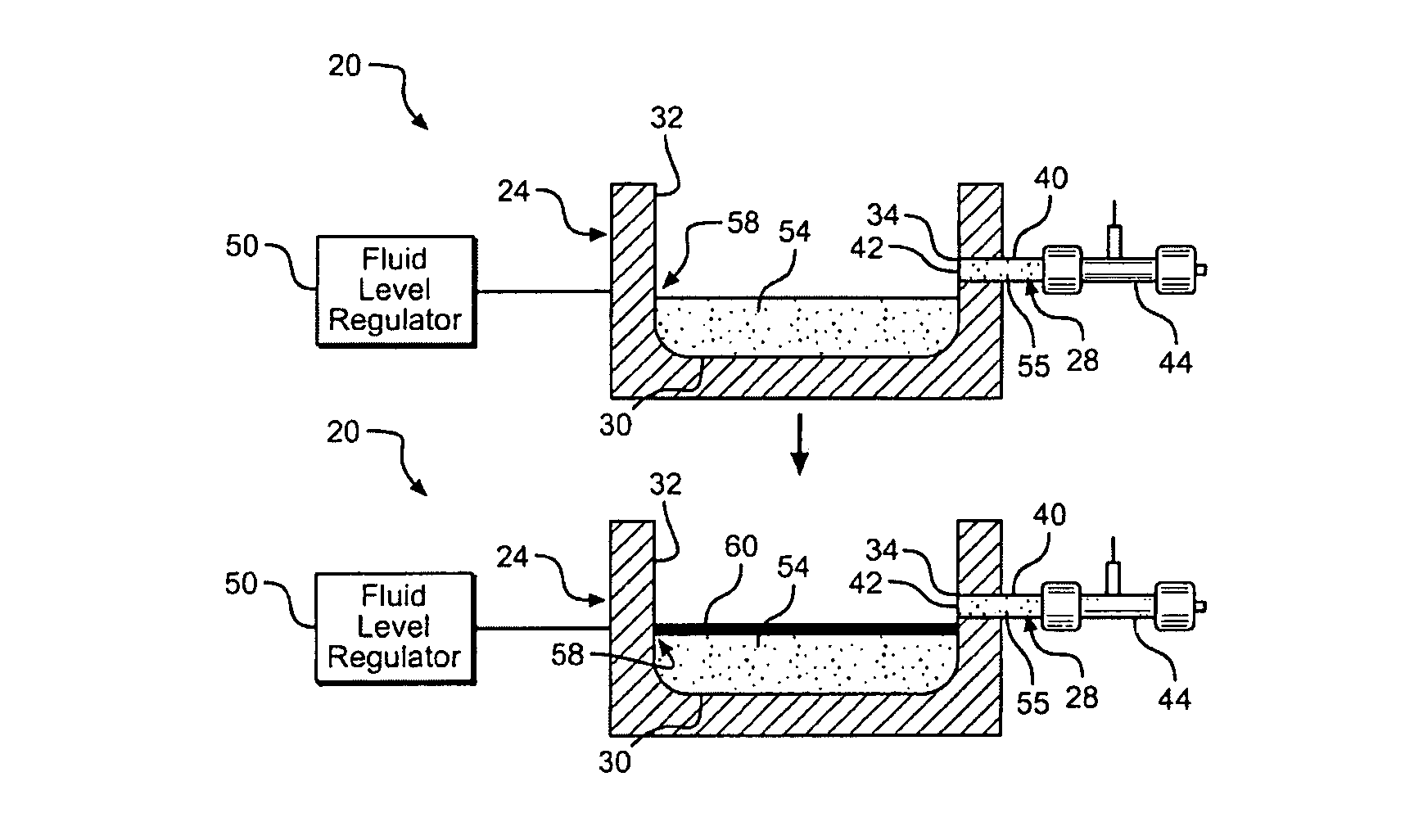

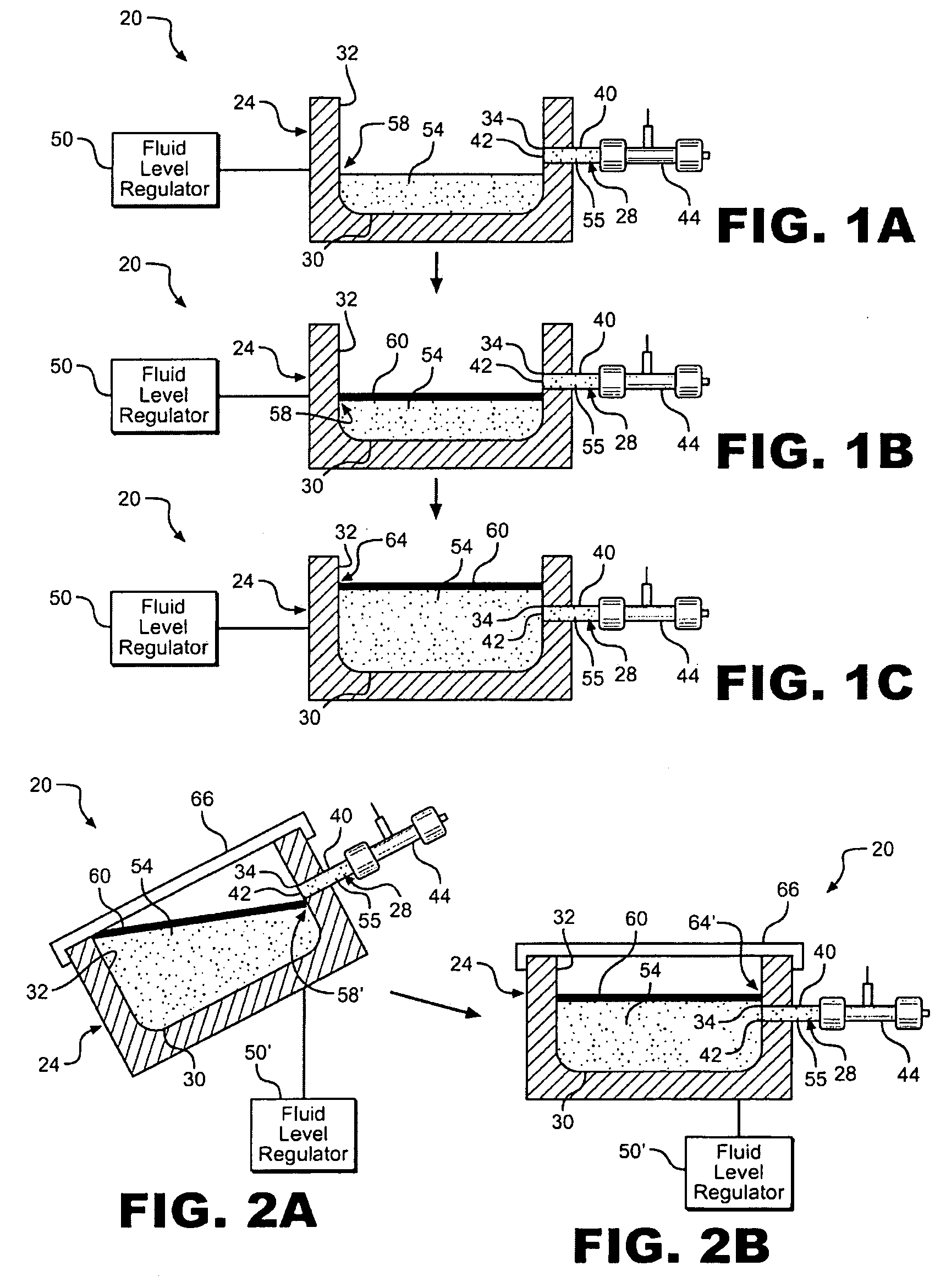

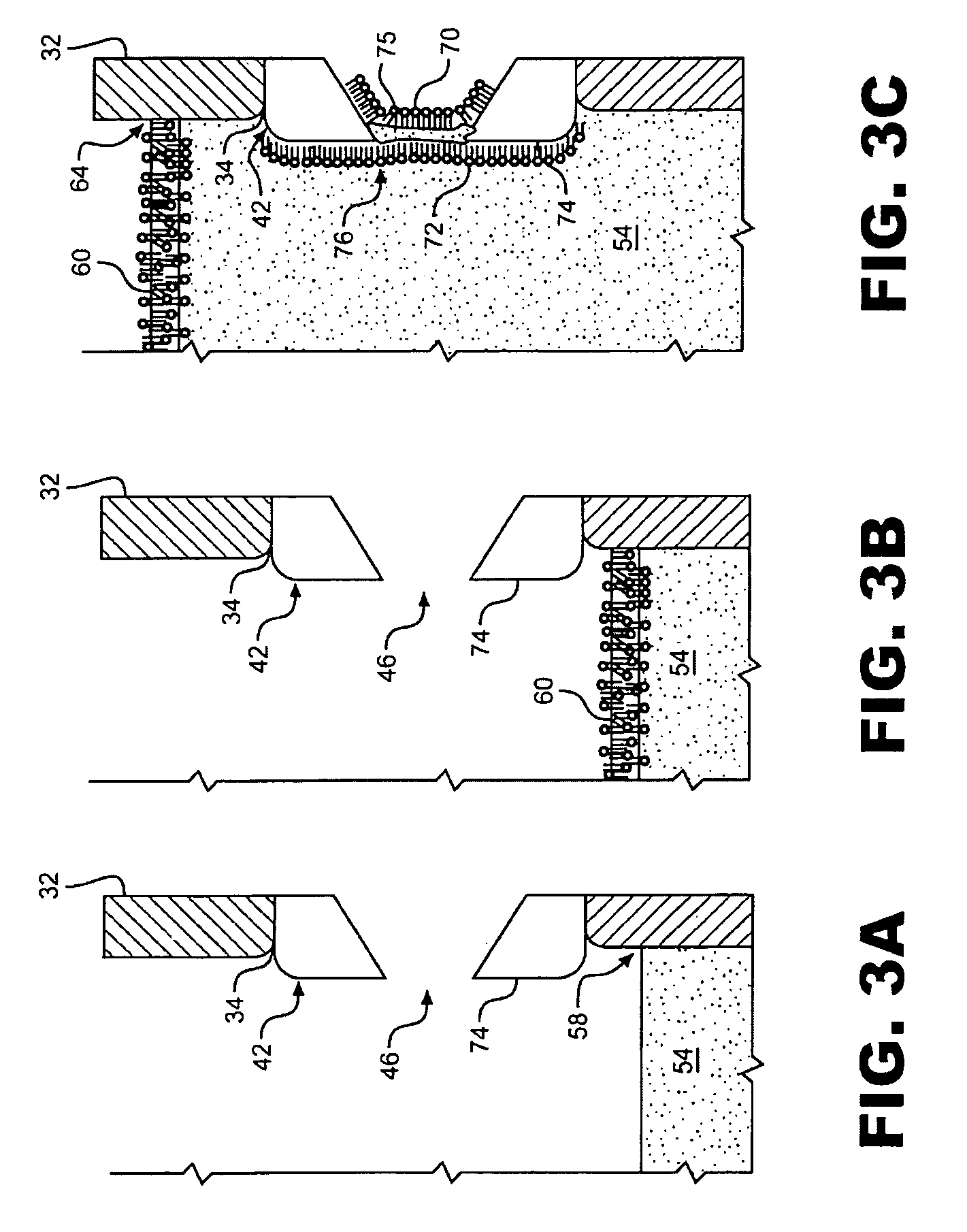

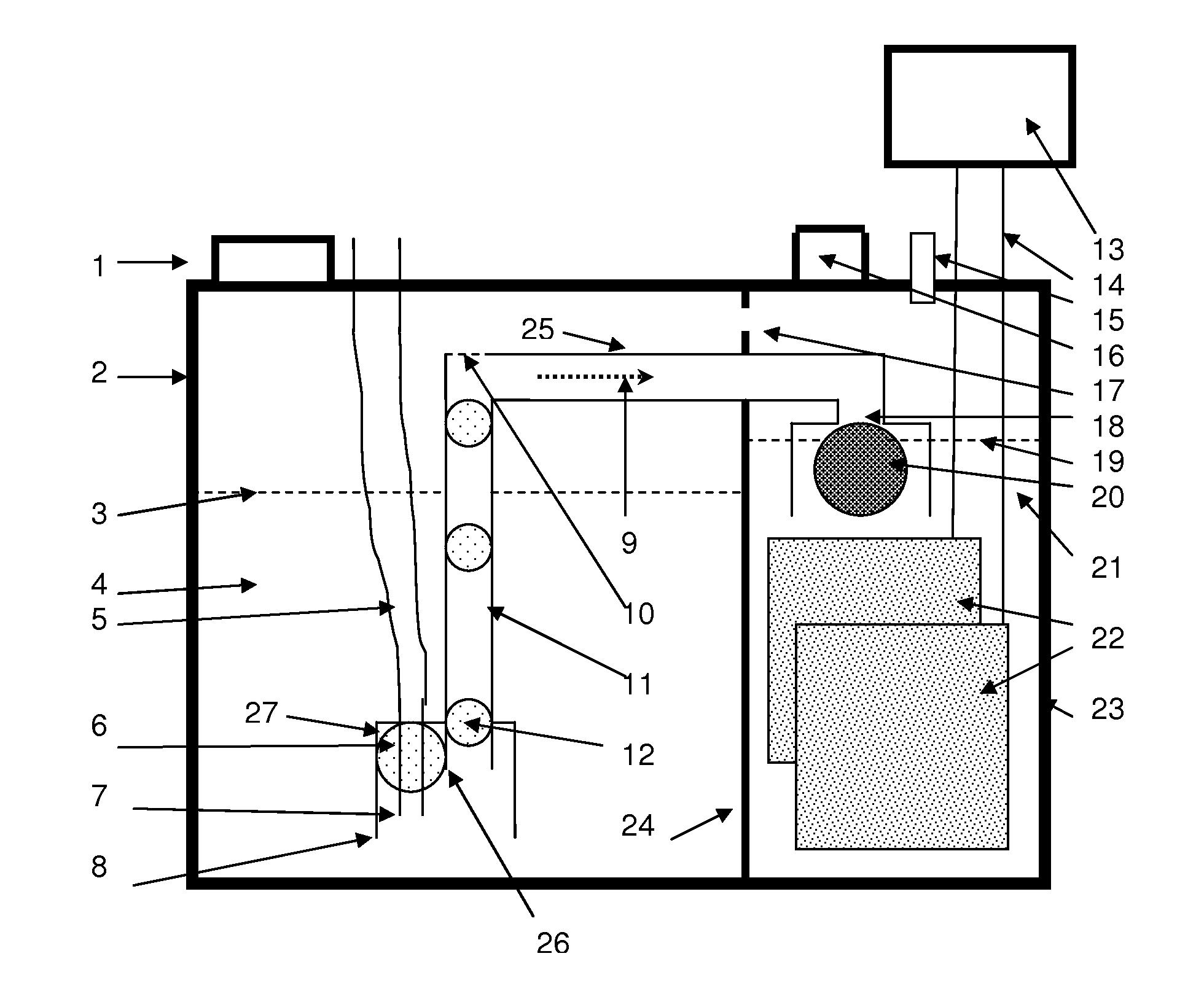

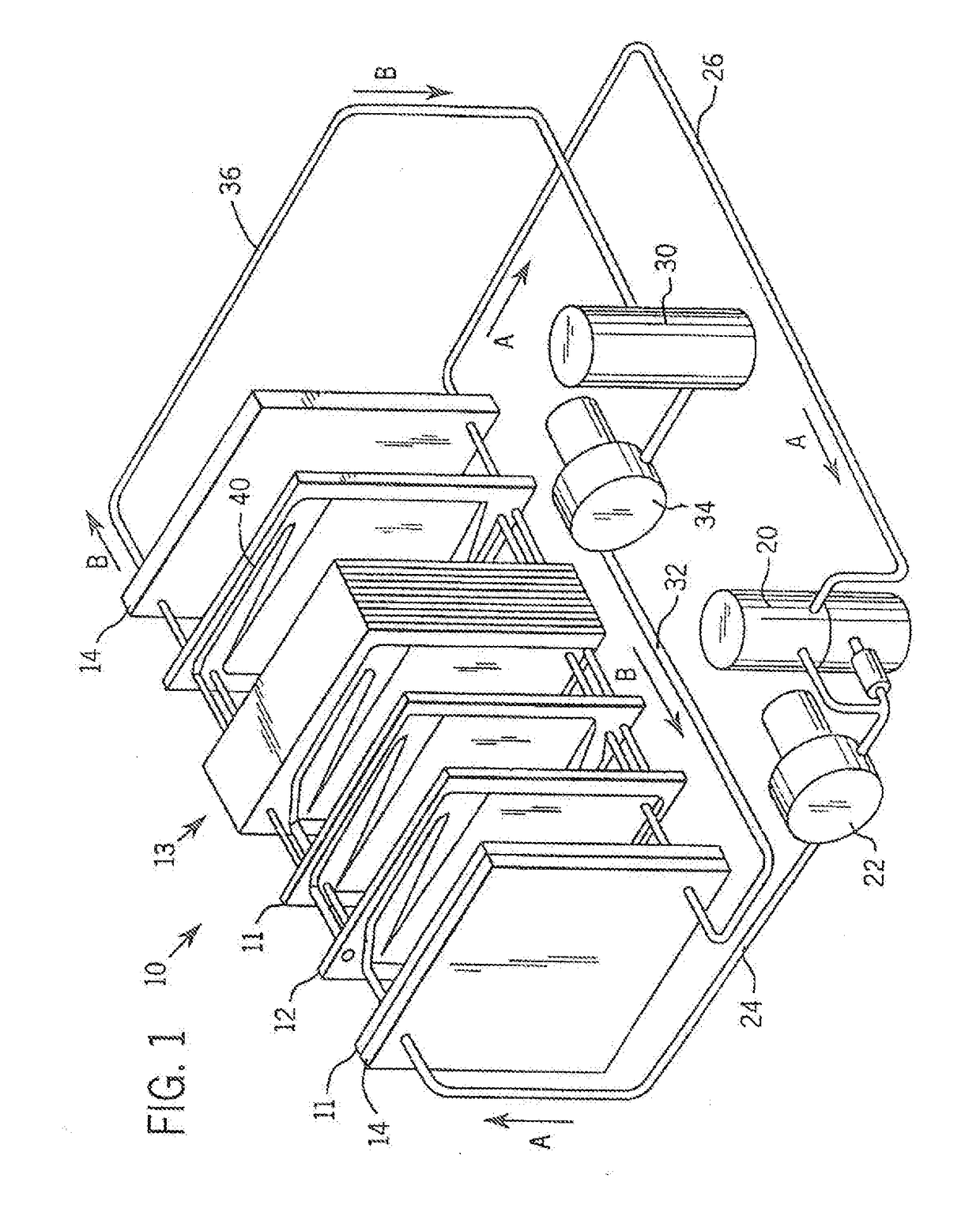

Method and Apparatus for Single Side Bilayer Formation

ActiveUS20090142504A1Avoids significant learning curveResistance/reactance/impedenceConductive materialLipid formationFeedback control

An apparatus for single-sided bilayer formation includes a first fluid chamber including a sidewall and a second fluid chamber extending through the sidewall. A barrier wall separates the first and second fluid chambers and includes a nanopore therein across which a planar lipid bilayer (PLB) is formed. In use, an electrolyte is added to the first and second fluid chambers and a lipid / organic solvent mixture is added to the first fluid chamber to form a lipid / organic solvent layer. The electrolyte level within the first fluid chamber is adjusted such that the lipid layer is raised above the barrier wall and a PLB is formed. Electrolyte levels may be adjusted manually or utilizing a fluid level regulator with or without feedback control. Optionally, the apparatus may be in the form of a nanopore array. The apparatus may be incorporated into an ion channel sensing system wherein an electrical current through each PLB is separately recorded.

Owner:ELECTRONICS BIOSCI

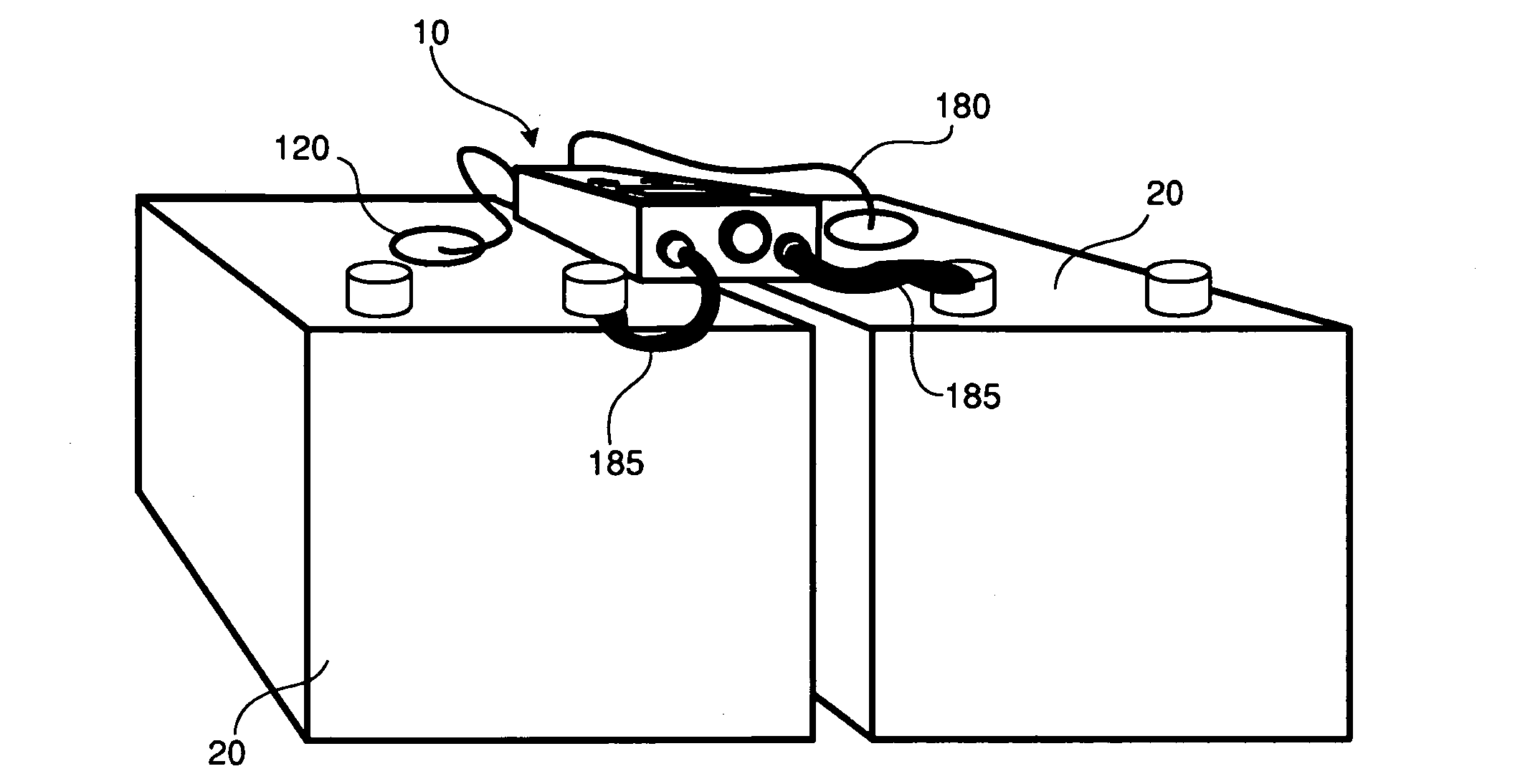

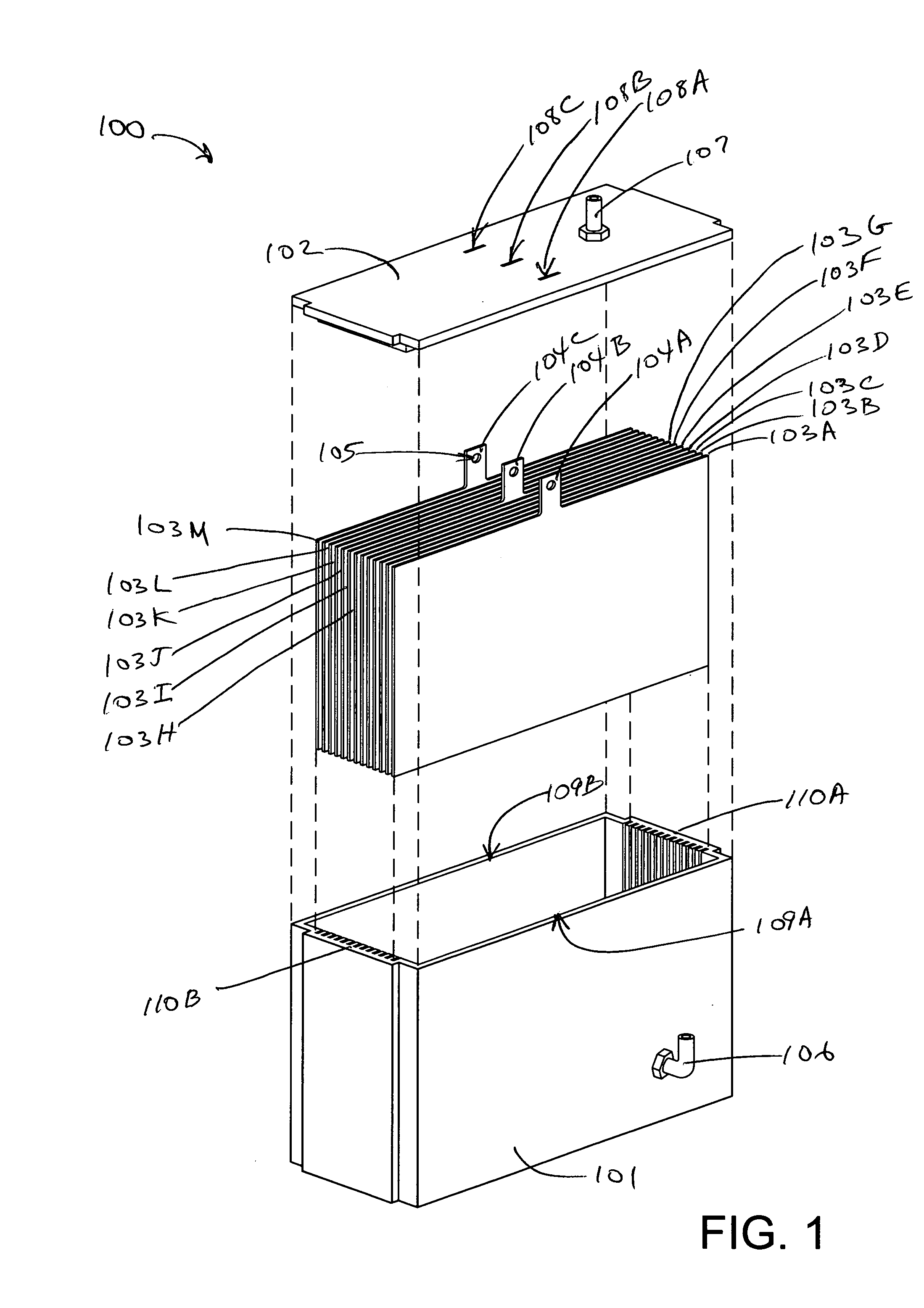

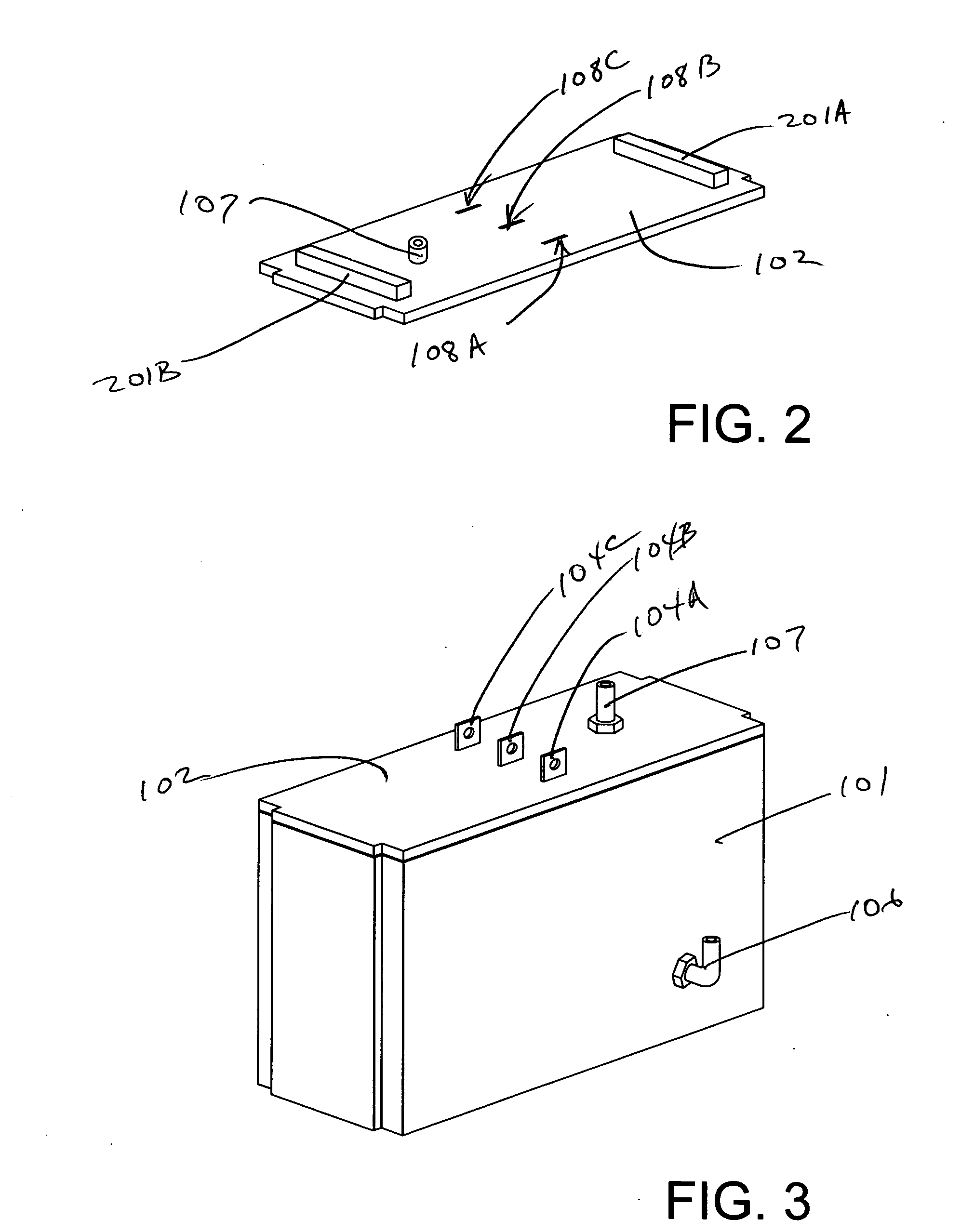

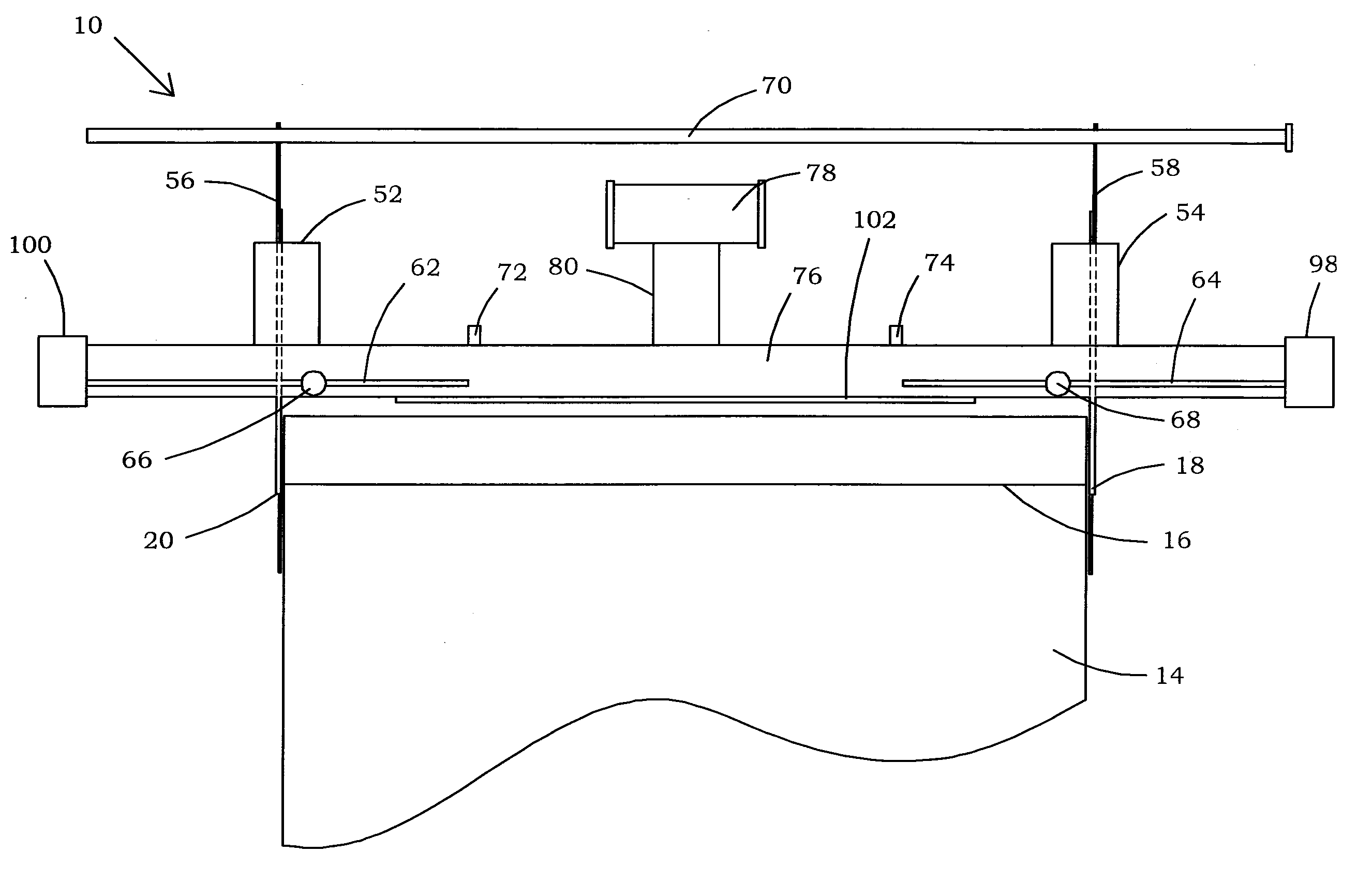

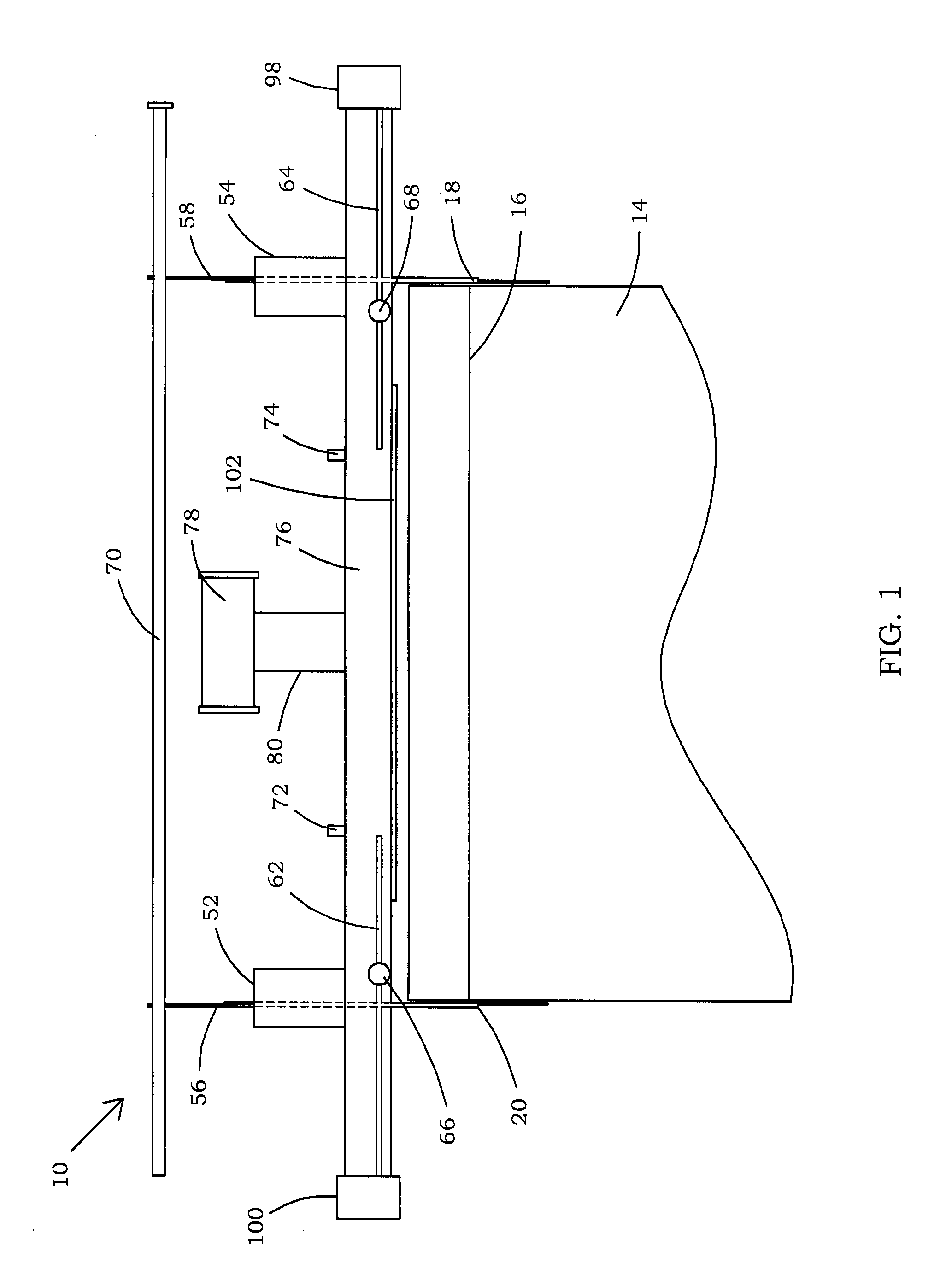

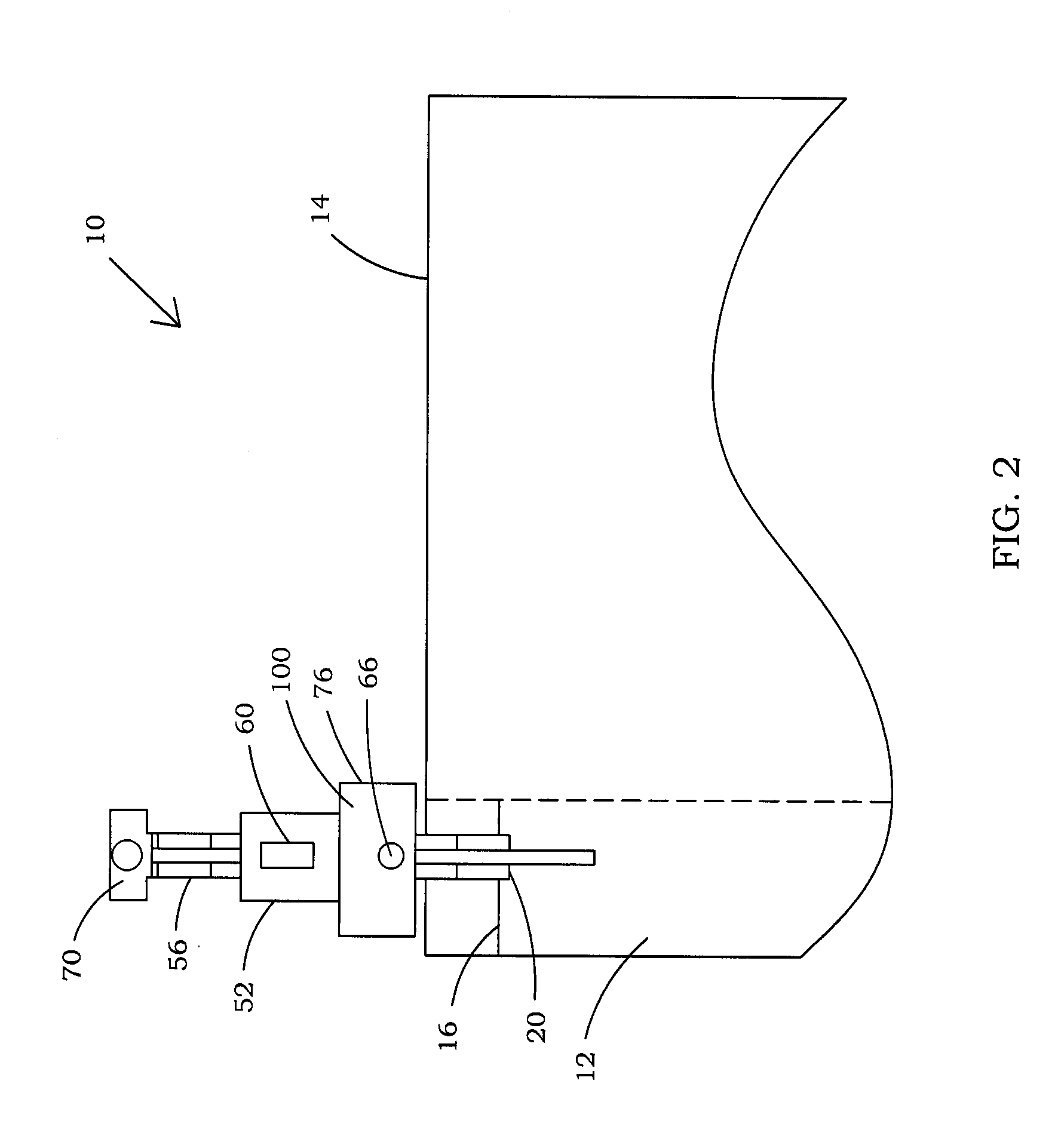

Battery Electrolyte Level Detector Apparatus

InactiveUS20110183168A1Improve efficiencyImprove accuracySecondary cellsLevel indicatorsMicrometerAcoustic energy

An electrolyte detector is provided that includes two micrometers which slide relative to each other along a frame to adjust the electrolyte detector to a size of the battery. A transmitter rod and a receiver rod support an acoustic transmitter and an acoustic receiver, respectively, and are slidably mounted with respect to the micrometers. The micrometers measure the position of the transmitter and receiver for placement on the side of the battery at a desired level of electrolyte. A transmitter director and receiver director concentrates the transmission and receipt of acoustic energy to locate the electrolyte level. An electronic circuit analyzes the received signal to determine whether the signal is transmitted through air or through an electrolyte.

Owner:THE UNITED STATES OF AMERICA AS REPRESENTED BY THE SECRETARY OF THE NAVY

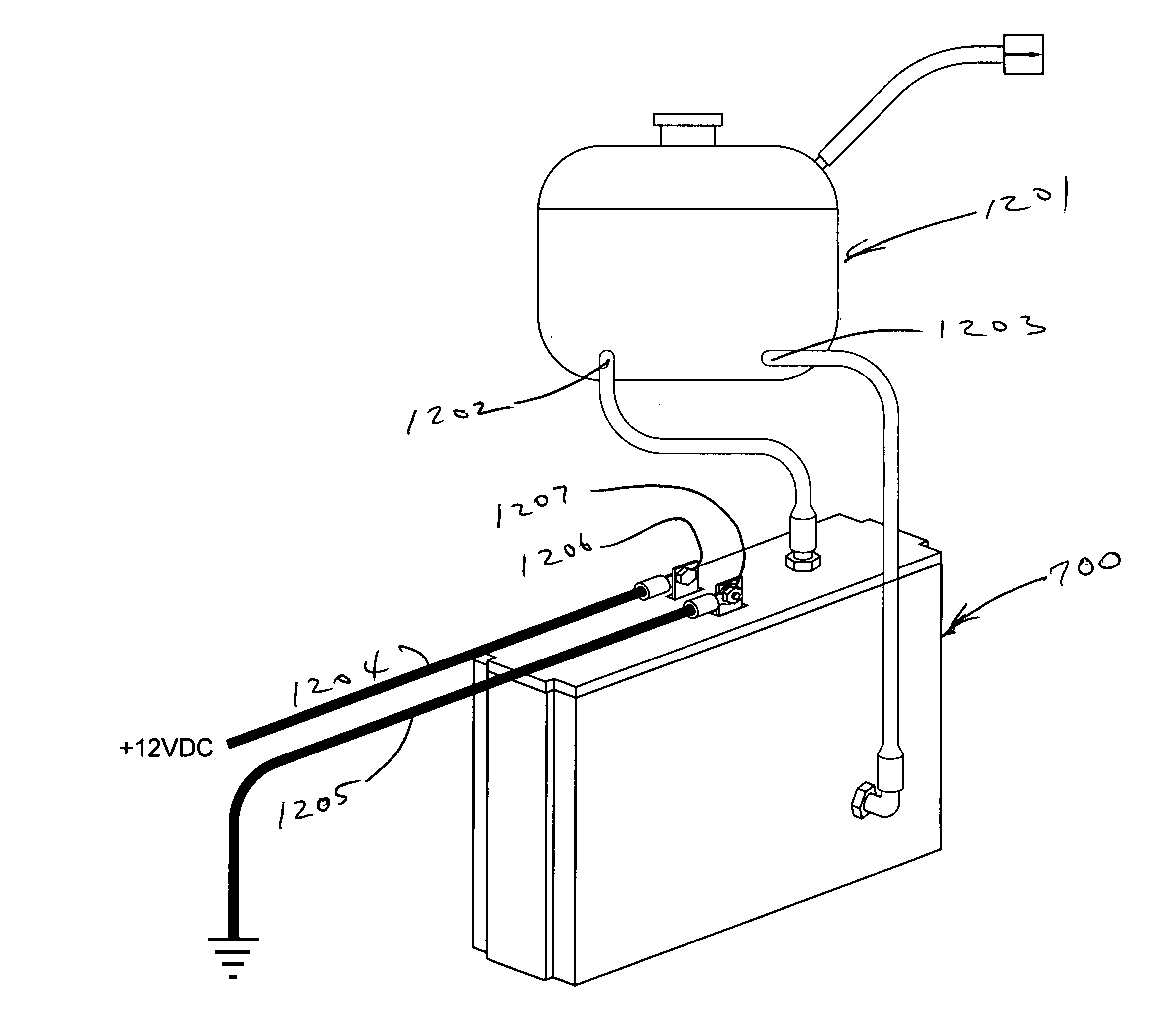

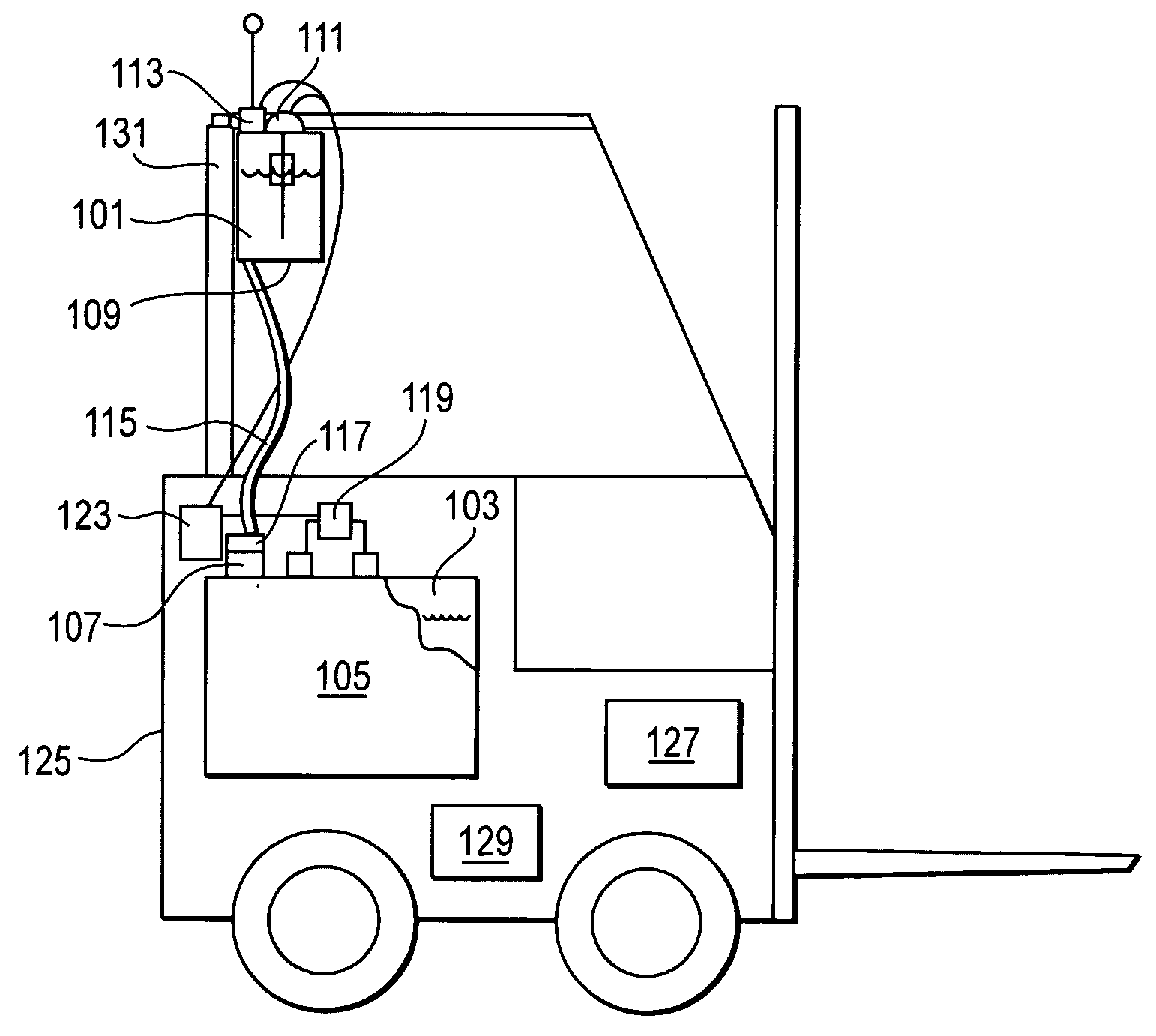

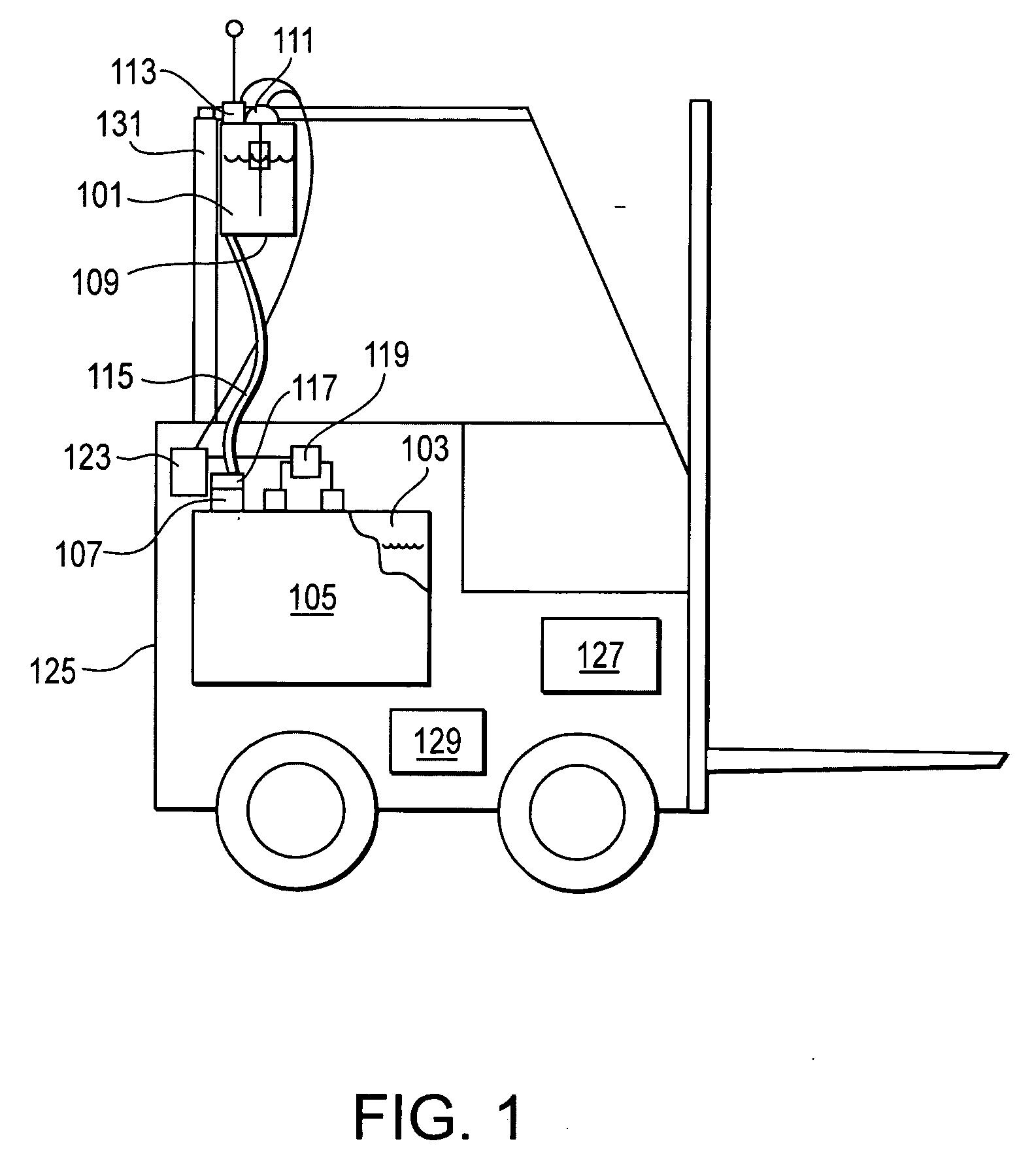

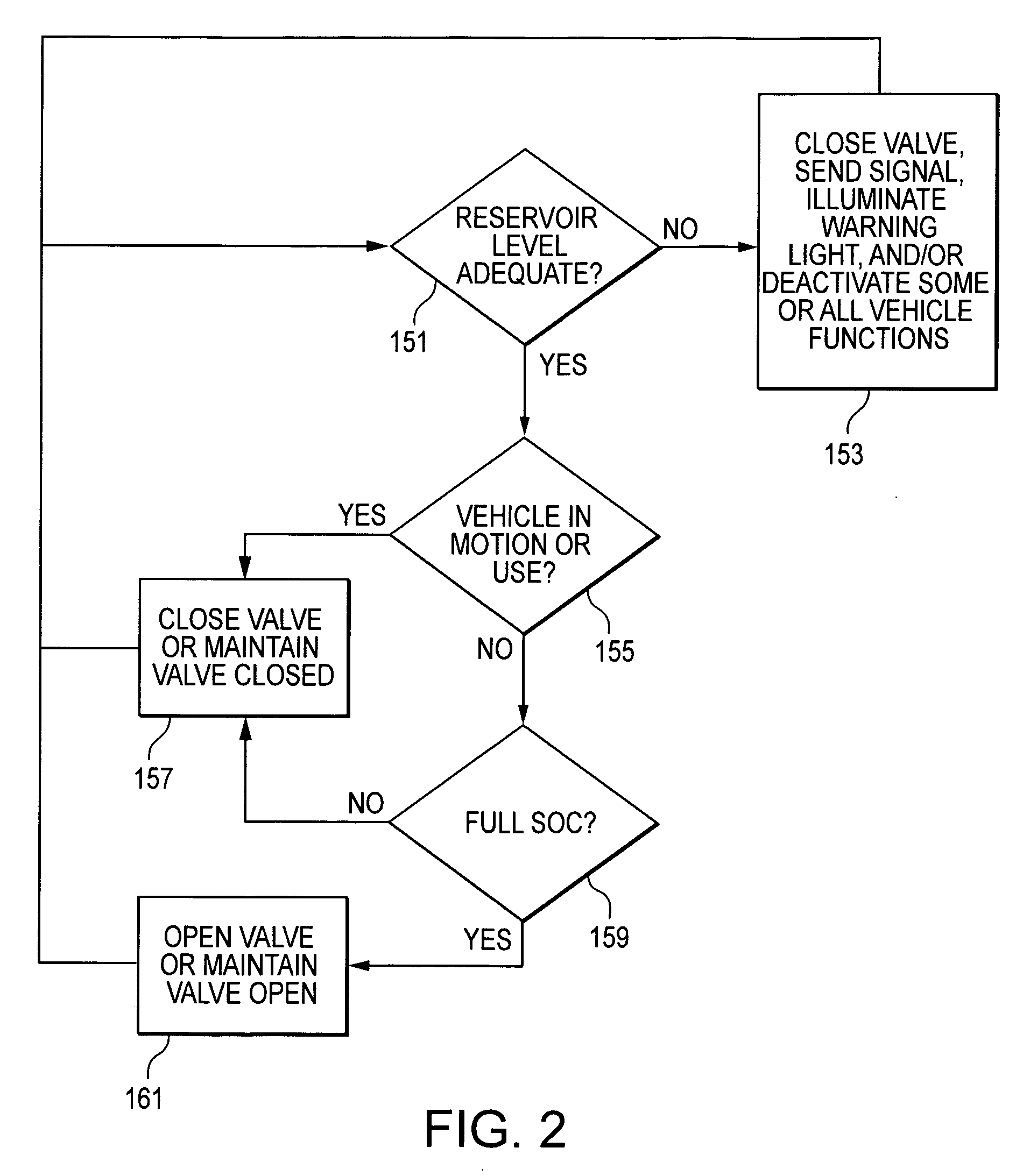

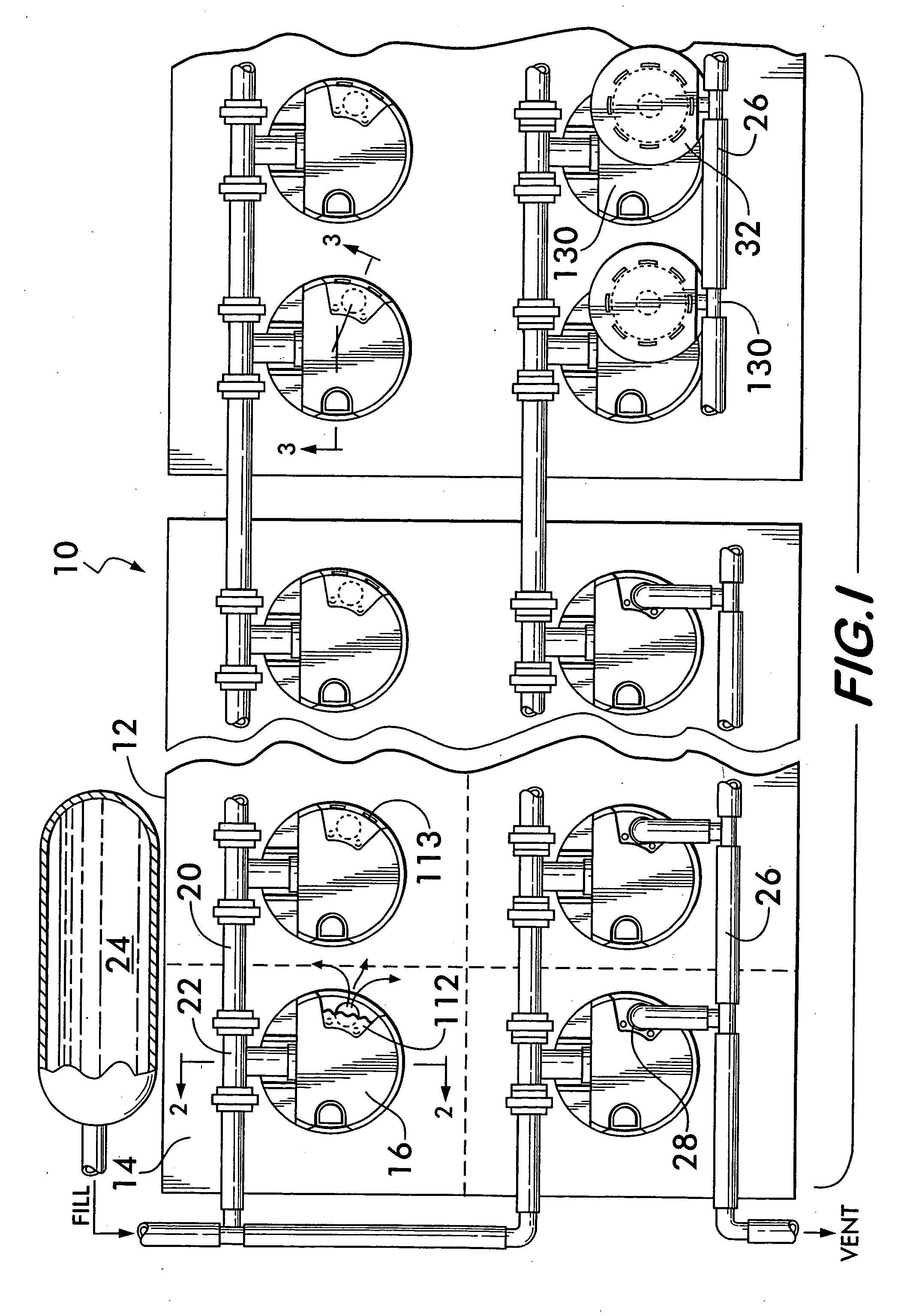

Battery electrolyte level control system

InactiveUS20060281000A1Maintain battery lifeSimple and safe operationLevel controlLifting devicesBattery state of chargeBattery charge

An electrolyte level control system for adding a quantity of water to raise the electrolyte level in a forklift battery having a hydro-mechanical cutoff valve. The system includes a reservoir, a reservoir-level sensor, a transmitter, a distribution system, a battery-charge sensor, a solenoid valve, a battery electrolyte level sensor, and a battery-electrolyte control system that controls the position of the solenoid valve in light of the detection of a battery state of charge from the battery charge sensor, and the detection of the battery electrolyte level from the battery electrolyte level sensor. The system provides for watering the battery when the state of charge is full and the electrolyte level is not full.

Owner:AEROVIRONMENT INC

Battery electrolyte level indicator

InactiveUS6040079AGuaranteed uptimePromotes rapid oxidationCells with cell condition indicationsSecondary cells servicing/maintenanceElectrolytes levelsLight-emitting diode

A battery electrolyte level indicator constructed for substitution of a battery cap on a multi-cell battery. The electrolyte level indicator has an outer housing construction in the shape of a cap to be screw mounted into the open upper end of the port leading into the battery cell. A probe extends from the housing or cap, into the battery electrolyte. A light indicator, such as a light emitting diode, is mounted on the exterior of the cap housing and will become automatically energized in a fail-safe condition if the electrolyte is at a sufficient level within the cell. However, if the level of the electrolytes should drop below the depth of the probe, then the indicator light will be deenergized, thereby immediately providing an advisory signal to the operator of an unsafe battery condition. The probe is constructed so as to operate as an anode in combination with a cathode of the battery. Moreover, the probe is formed of a material which, when connected in this arrangement, is highly resistant to corrosion.

Owner:HYDRA EYE

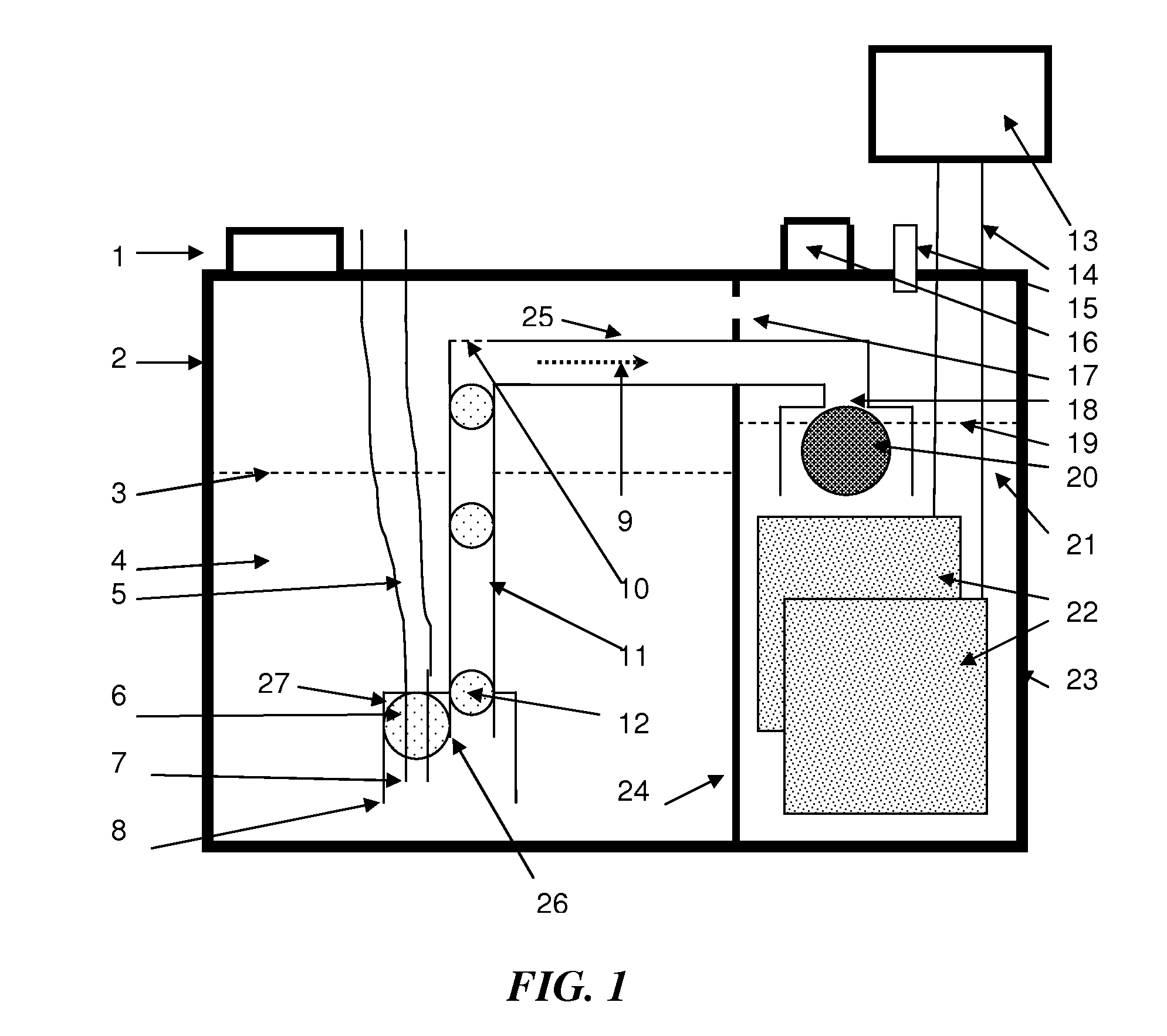

Method and apparatus for single side bilayer formation

ActiveUS8124191B2Avoids significant learning curveConductive materialPretreated surfacesFeedback controlElectrolyte

An apparatus for single-sided bilayer formation includes a first fluid chamber including a sidewall and a second fluid chamber extending through the sidewall. A barrier wall separates the first and second fluid chambers and includes a nanopore therein across which a planar lipid bilayer (PLB) is formed. In use, an electrolyte is added to the first and second fluid chambers and a lipid / organic solvent mixture is added to the first fluid chamber to form a lipid / organic solvent layer. The electrolyte level within the first fluid chamber is adjusted such that the lipid layer is raised above the barrier wall and a PLB is formed. Electrolyte levels may be adjusted manually or utilizing a fluid level regulator with or without feedback control. Optionally, the apparatus may be in the form of a nanopore array. The apparatus may be incorporated into an ion channel sensing system wherein an electrical current through each PLB is separately recorded.

Owner:ELECTRONICS BIOSCI

Preheating starting method for inertia anode aluminum electrolyzer

ActiveCN101709484AImprove operating conditionsEasy to useElectrical resistance and conductanceEnergy balanced

The invention relates to a preheating starting method for an inertia anode aluminum electrolyzer, which is characterized in that the preheating starting process orderly comprises the steps of: (1) laying a set of electrical heaters which has same number of electrodes on a hearth, (2) filling up solid electrolyte in the hearth, electrically heating till the solid electrolyte fused, and continuously adding solid electrolyte till the electrolyte level meets the production requirement, (3) lowering the power of the electrical heater after the electrolyte level meets the production requirement, and simulating the heat value of normal running electrolyzer, and (4) supplying fluorine salt, adjusting the component of electrolyte, establishing energy balance and thickness of furnace stack, exchanging a set of inertia anode and cathode when switching off a set of inner heating resistance after reaching energy balance, electrifying on full load after finishing exchange. The method of the invention can preheat inertia anode electrolyzer, provide a nice running condition to the inertia anode in order to promote the use effect and prolong the service life of the inertia anode.

Owner:GUIZHOU BRANCH CHINA ALUMINUM IND

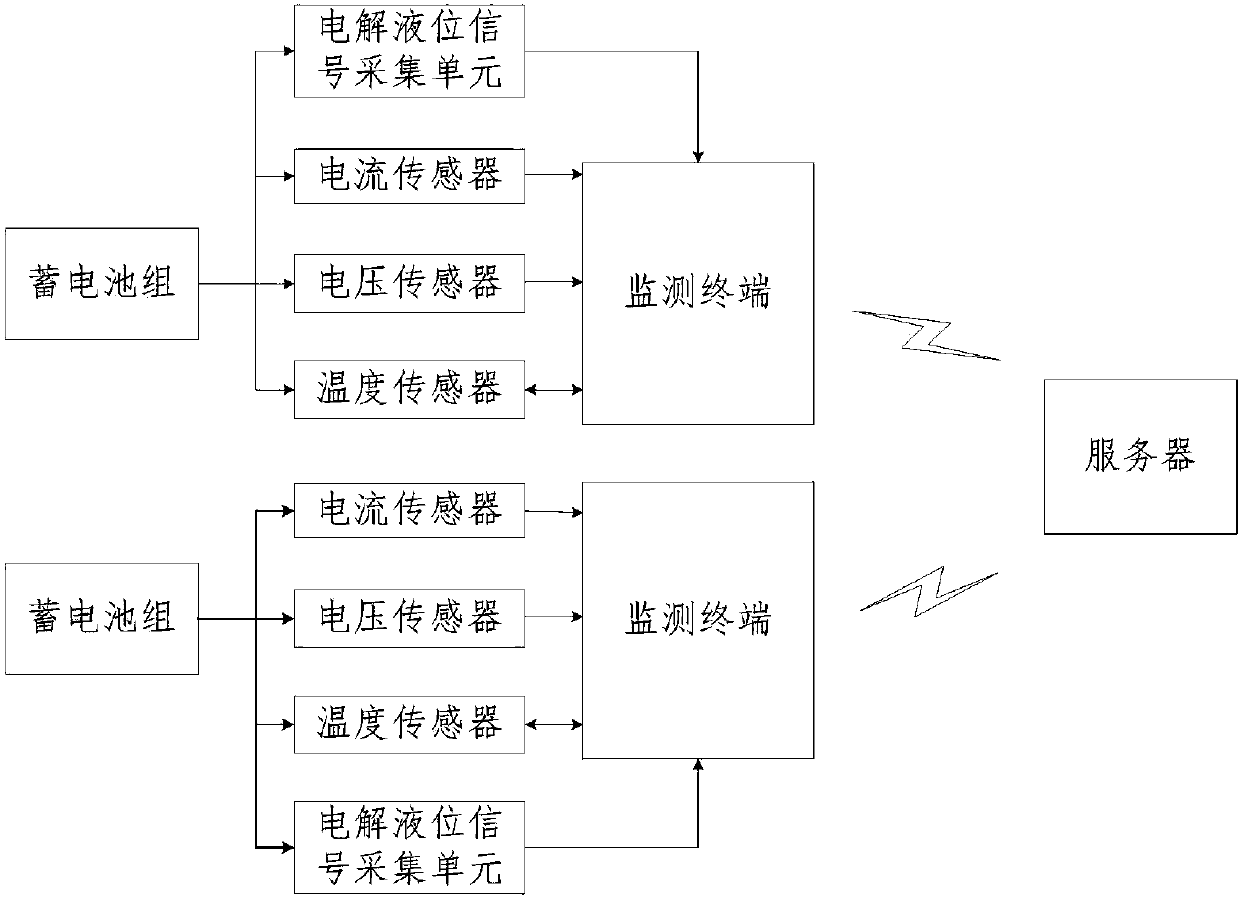

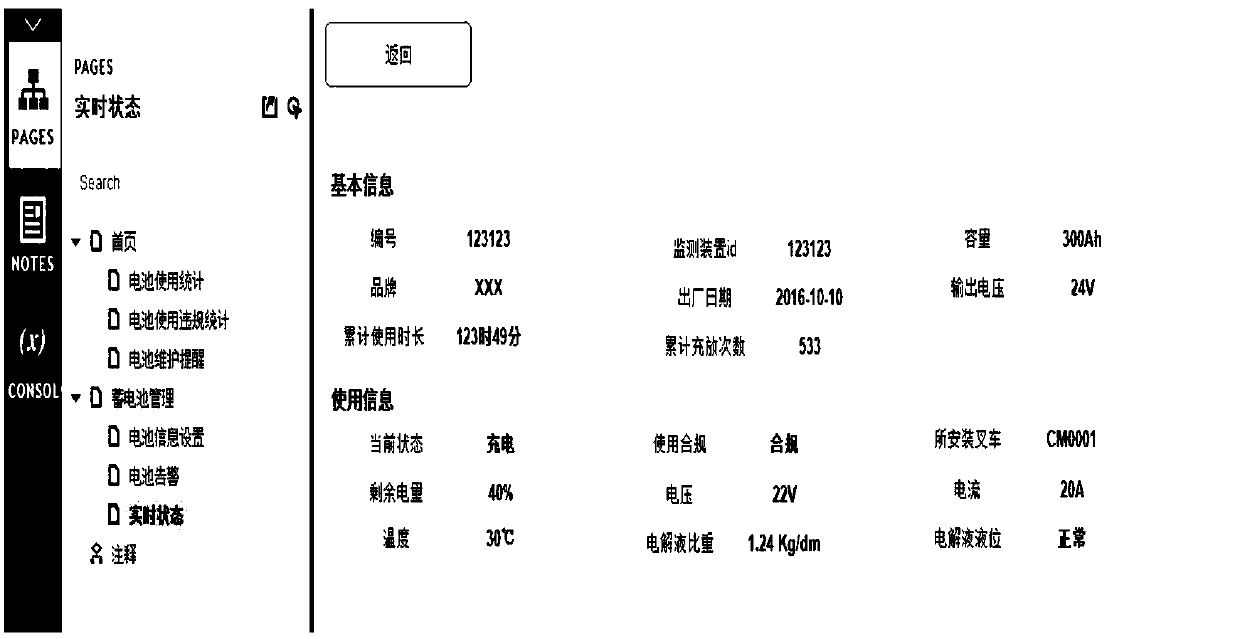

Battery pack monitoring system

The invention provides a battery pack monitoring system which mainly includes a server, multiple monitoring terminals, multiple sensor units, and a mobile phone APP. Each battery pack corresponds to one monitoring terminal and one external sensor unit. Each sensor unit includes a current sensor for collecting the current on the bus of the corresponding battery pack, a voltage sensor for collectingthe voltage on the bus of the corresponding battery pack, a temperature sensor for collecting the charging temperature on the surface of the corresponding battery pack, and an electrolyte level sensing unit for collecting the electrolyte level of the corresponding battery pack. Each monitoring terminal is used for collecting the signal of the corresponding external sensor unit and sending the current, voltage, charging temperature and electrolyte level of the corresponding battery pack to the server. The battery pack monitoring system can monitor each battery pack in a vehicle team. Thus, each battery pack can be effectively monitored, maintenance and management of battery packs are facilitated, the service life of battery packs is prolonged, the use safety of battery packs is improved, the use cost is reduced, and greater economic benefit is achieved.

Owner:WUHAN AVIATION SENSING TECH

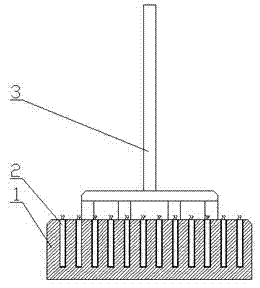

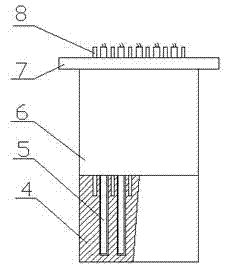

Device and method for preparing metal needle point

ActiveCN102901846AProcess stabilityGood repeatabilityScanning probe microscopyElectrochemical responseEngineering

Owner:SUZHOU INST OF NANO TECH & NANO BIONICS CHINESE ACEDEMY OF SCI

Preheating starting method for aluminium electrolysis cell

The invention relates to a preheating starting method for an aluminium electrolysis cell, and the preheating starting method comprises the following preheating starting processes: (1) drilling on the upper surface of a carbon or graphite electrode, and pre-embedding a heating element in the electrode; (2) heating a hearth by using a heating assembly according to a roasting curve; (3) after reaching a target temperature, adding a solid or liquid electrolyte until reaching a required electrolyte level, regulating the power of the heating assembly, and primarily building heat balance and inner hearth mold required by the electrolysis cell; (4) introducing direct current for electrolyzing a preheating electrode; and (5) gradually utilizing an electrode which normally operates to replace the preheating electrode carrying the heating element. The method disclosed by the invention can evenly heat; in the preheating process, an anode and the bus do not need flexible connection; a traditional cell of which the cathode is in an abnormal-shape structure can be effectively preheated, and an inert electrode aluminium electrolysis cell can be effectively preheated and started; and a stable electrolysis environment is built, current efficiency is improved, and the service life of the electrode is prolonged. The preheating electrode can be reused to lower electrolysis cell starting cost.

Owner:GUIZHOU BRANCH CHINA ALUMINUM IND

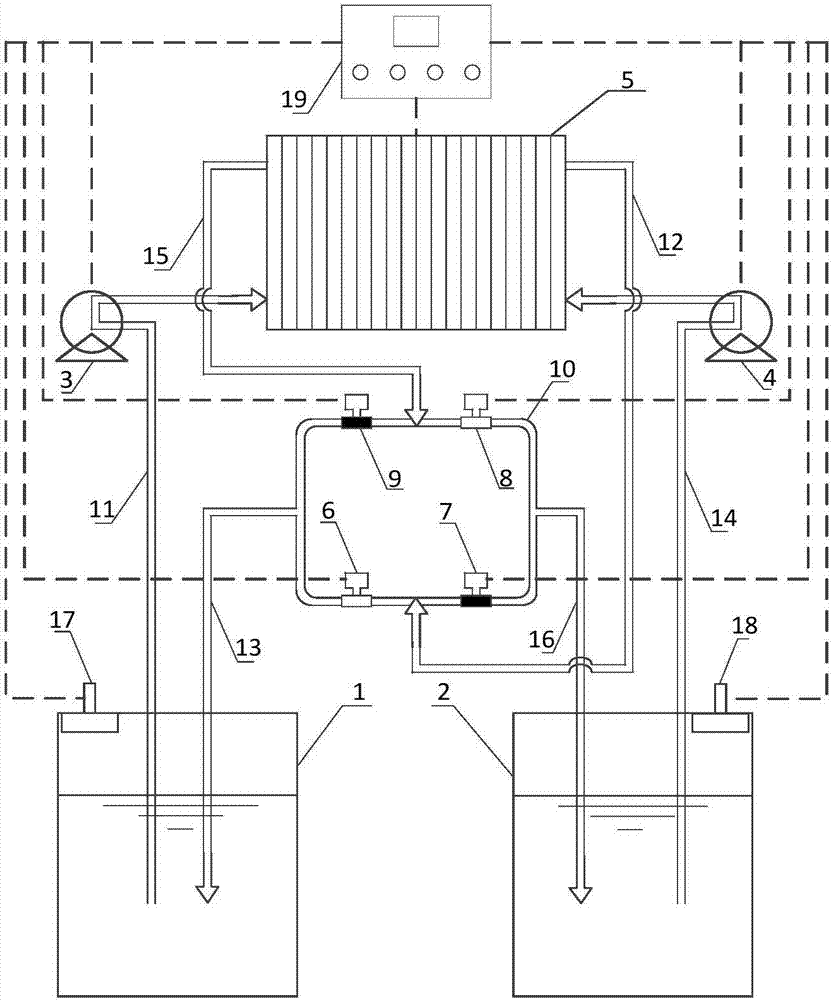

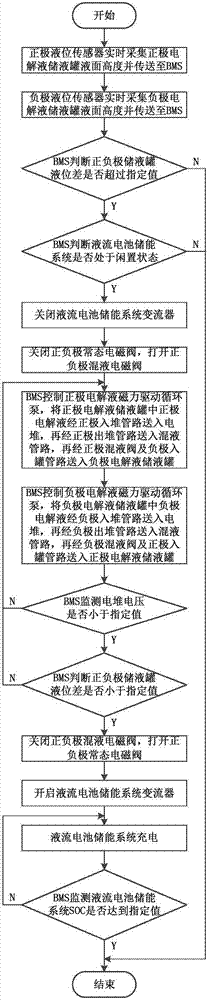

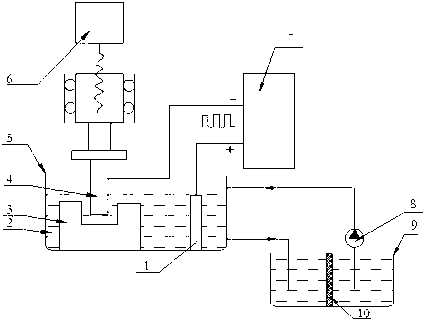

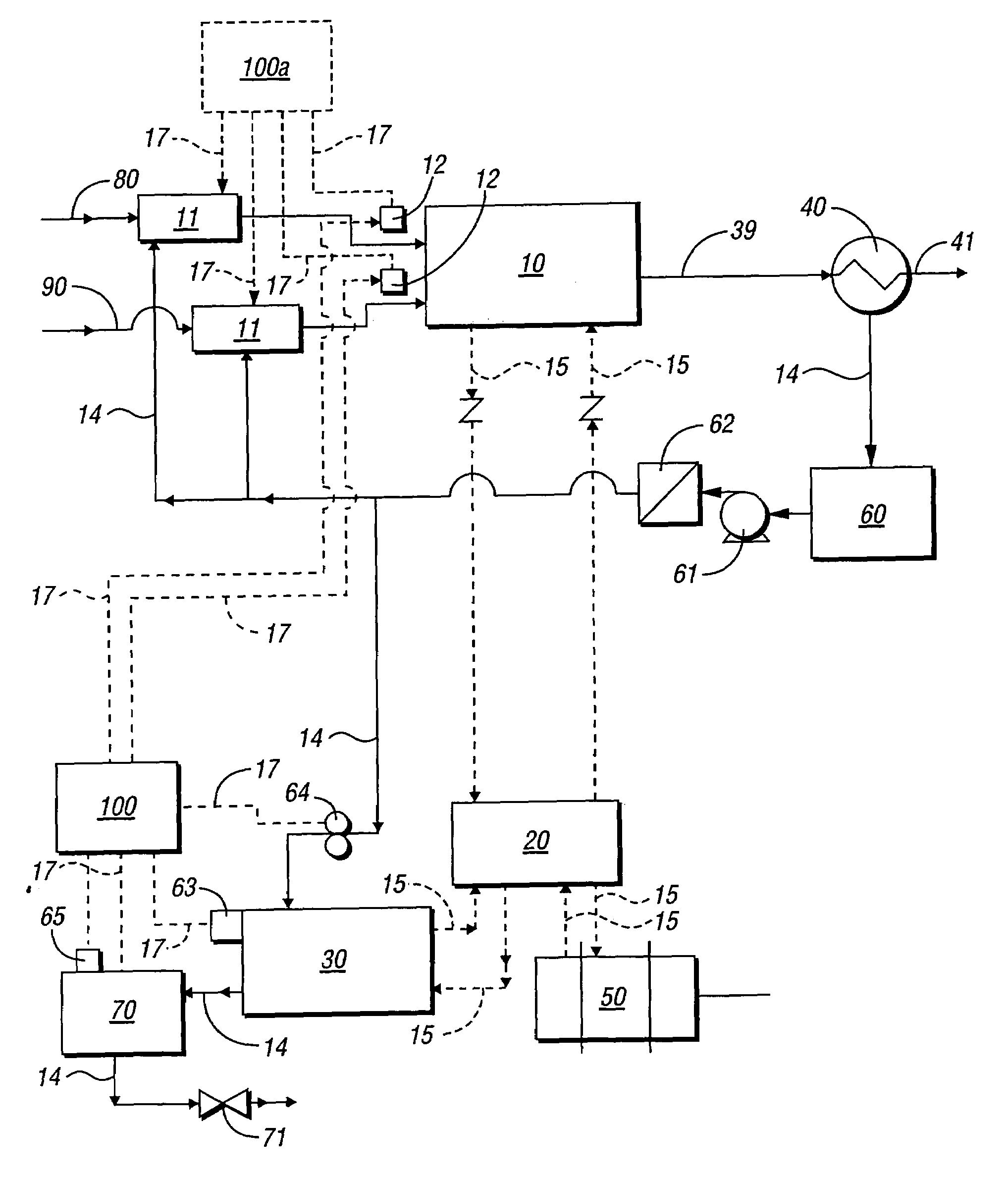

Energy storage and electrolyte mixing system for flow battery, and control method thereof

The invention specifically relates to an energy storage and electrolyte mixing system for a flow battery, and a control method thereof, belonging to the field of energy storage of flow batteries. The energy storage and electrolyte mixing system for the flow battery comprises a positive electrolyte storage tank, a negative electrolyte storage tank, a magnetic force-driven circulating pump for a positive electrolyte, a magnetic force-driven circulating pump for a negative electrolyte, a battery management system (BMS), a positive in-pile pipeline, a positive out-of-pile pipeline, a positive in-tank pipeline, a negative in-pile pipeline, a negative out-of-pile pipeline, a negative in-tank pipeline, a positive electrolyte level sensor, a negative electrolyte level sensor and an electrolyte mixing pipeline. According to the invention, through introduction of the electrolyte mixing pipeline, the electrolyte mixing system can be easily and ingeniously switched between two working modes, i.e., a normal working mode and an electrolyte mixing mode; so the problem of decrease in system capacity is overcome, or even, potential safety hazards of the system are avoided.

Owner:湖南德沃普电气股份有限公司

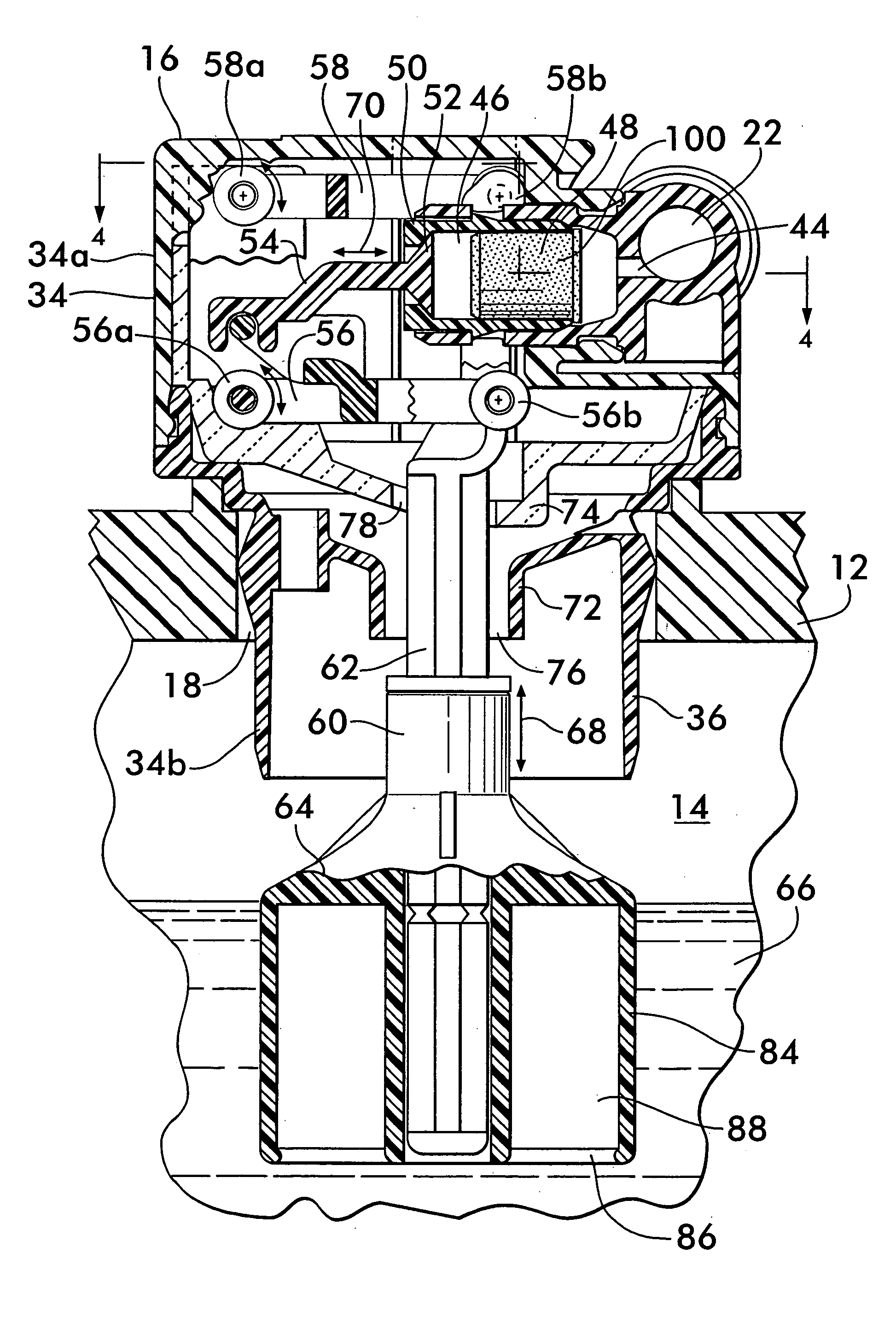

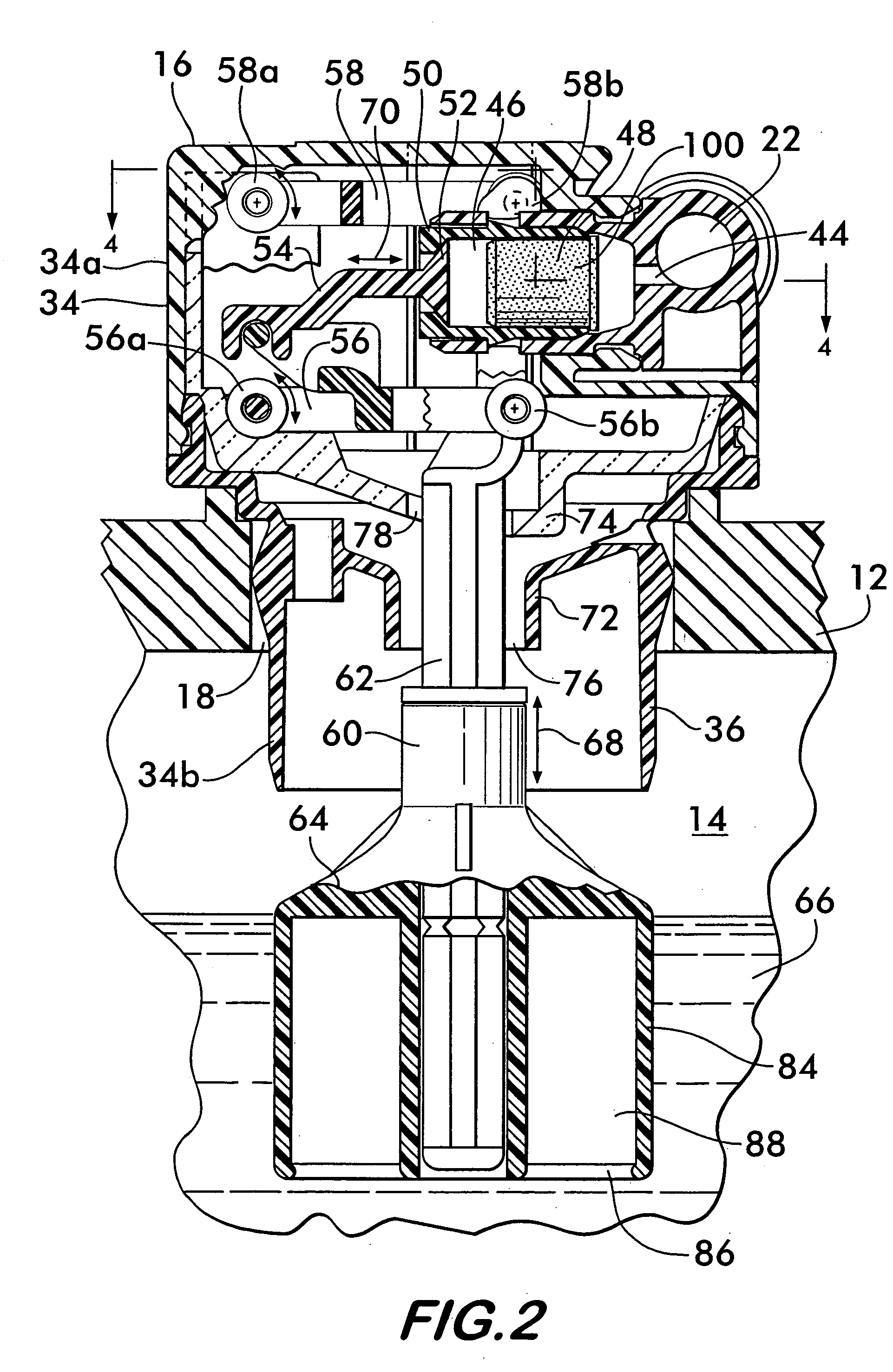

Float valve assembly for battery

ActiveUS20050221166A1Operating means/releasing devices for valvesEqualizing valvesHydrogenWater source

A float actuated valve assembly for battery electrolyte replenishment is disclosed. A housing engages an opening in a battery cell. An inlet in the housing is connetable to a water source. A valve in the housing controls the water flow to the cell. The valve is connected by a link to a four bar mechanism that is attached to a float. The float is buoyantly supported and rises and falls in response to the electrolyte level within the cell opening and closing the valve to admit or halt the flow of water to the cell. A baffle prevent fouling of the mechanism by splashing electrolyte. A flash arrester is positioned between the valve and the inlet to quench hydrogen-oxygen explosions between cells. The float is adjustable for different sized cells. A side viewable electrolyte level indicator is provided in the housing. Flash arresters for venting gas are also mounted.

Owner:PHILADELPHIA SCI +1

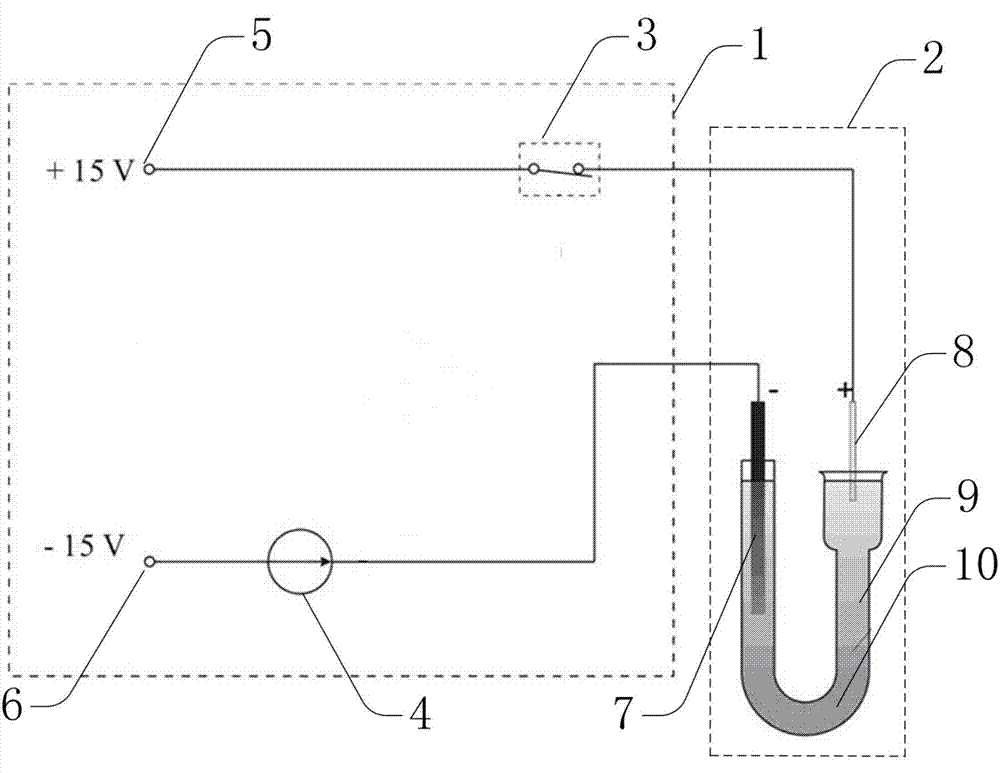

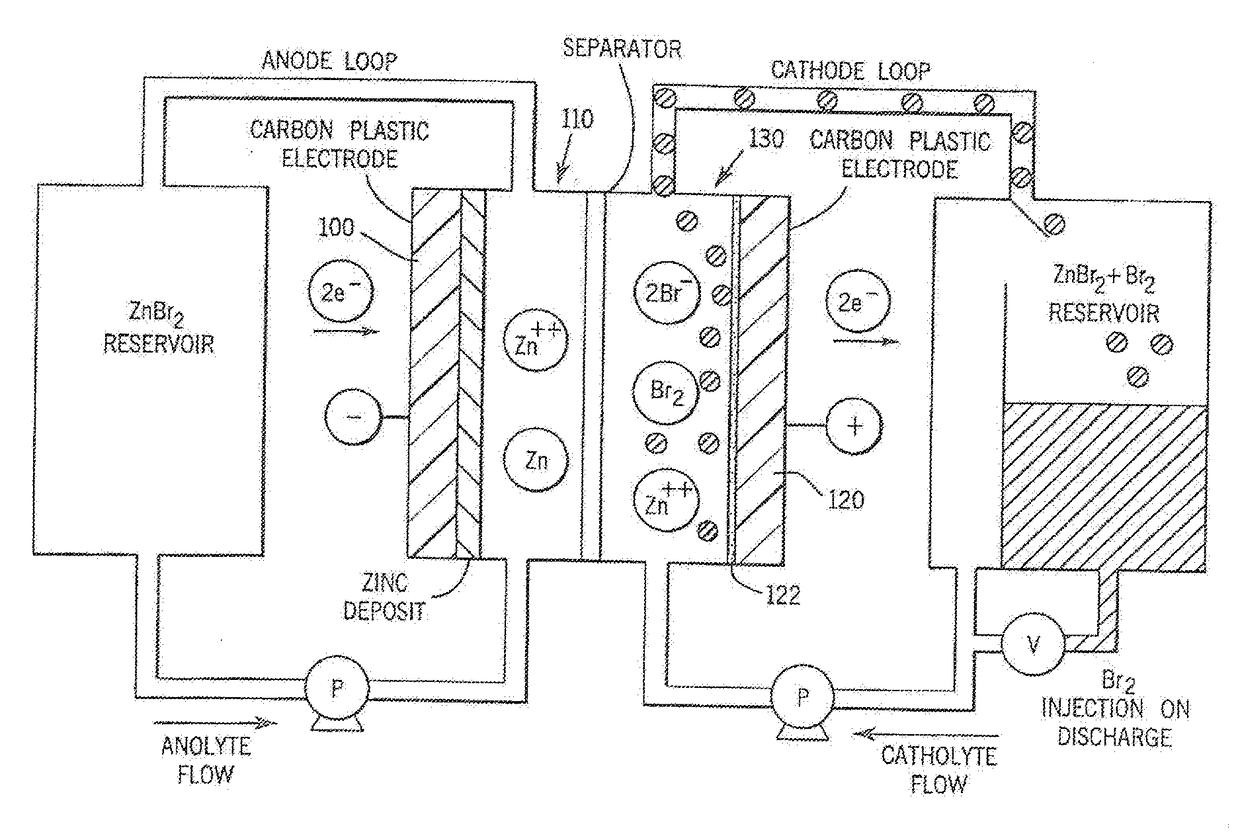

System and Method for Refilling an Electrolyzer Tank from a Water Reservoir

A system for controlling electrolyte level and concentration within a water electrolyzer includes an electrolysis chamber containing electrolyte for production of hydrogen and oxygen, a water reservoir containing make-up water and separated from the electrolysis chamber through a check valve that opens only when electrolyte level drops to a predetermined level, and a gas lift pump within the water reservoir connected to the electrolysis chamber through the check valve and having electrodes immersed in the make-up water. Energization of the electrodes creates bubbles that transport the make-up water to the electrolysis chamber to maintain a desired concentration of the electrolyte during the production of hydrogen and oxygen.

Owner:SMEDLEY STUART I

Level sensor for conductive liquids

A sensor for measuring a level of a conductive liquid, is provided. The sensor includes at least two electrodes that can be positioned in a holding tank so as to be partially submerged in the conductive liquid, sensor leads coupled to the at least two electrodes, and circuitry and a controller for determining the properties of the electrolyte, the circuitry being coupled to the at least two electrodes via the sensor leads, and the controller being coupled to the circuitry. The sensor may be used as an electrolyte level sensor in a flow battery system.

Owner:IMERGY POWER SYST

Low polar distance energy-saving production method for aluminum electrolysis bath

The invention discloses a low polar distance energy-saving manufacturing method for an aluminum cell, which meets the requirement of energy balance by adjustment of technical parameters on the basis of the prior art, comprising the steps that: firstly, voltage adjustment, namely the set voltage of the electrolytic cells is adjusted to be 4.1 volts in the first two weeks, adjusted from 4.1 volts to 4.05 volts in the third week, adjusted from 4.05 volts to 4.0 volts in the fourth week and adjusted from 4.0 volts to 3.99 volts in the fifth week; secondly, adjustment of the aluminum level and the electrolyte level, namely cryolites or electrolyte blocks are added for improving 1 to 2 centimeters of the electrolyte height and the aluminum level is improved 1 to 2 centimeters or so by use of three to five weeks; thirdly, improvement of the molecule ratio and reduction of the superheat degree, namely the molecule ratio is improved from the prior 2.2 to 2.3 to 2.35 to 2.45 within three to five weeks by adoption of the method for reducing the addition amount of aluminum fluorides. The improvement of the primary crystal temperature and the reduction of the superheat degree play an important role in stabilizing electrolyte production, play a certain role in formation of a hearthside and a furnace cavity, and enable the hearthside and the furnace cavity to enter the state of normal production in advance.

Owner:HENAN ZHONGFU IND

Method for preparing nanometer particles through electrochemistry discharging

ActiveCN103252542ALow costEasy to operateElectrochemical machining apparatusElectrolytic agentNanoparticle

The invention discloses a method for preparing nanometer particles through electrochemistry discharging, and belongs to the field of nanometer material preparation. During the process of preparing the nanometer particles, a tool electrode which is connected with a power source negative electrode and an electricity inlet block which is connected with a power source positive electrode undergo an electrochemistry reaction, bubbles are generated and the bubbles are attached on the surface of the tool electrode. As the preparation goes on, the part, below an electrolyte level, of the tool electrode is completely wrapped by the bubbles which are generated continuously, so that the tool electrode is completely isolated from an electrolyte, and therefore a voltage difference is formed between the tool electrode and the electrolyte. Then, a bubble layer of the tool electrode and a bubble layer of the surface of a workpiece are broken down to form a discharging channel, and discharging is conducted. Instantaneous high temperature and high pressure energy inside the discharging channel gasifies the electrolyte on the surface of the workpiece and then further smelts and gasifies the workpiece, corrosion-removing products are generated and dumped into the electrolyte, and the nanometer particles are formed after the products are cooled and solidified. The preparation method is low in cost and high in productivity.

Owner:江苏载驰科技股份有限公司

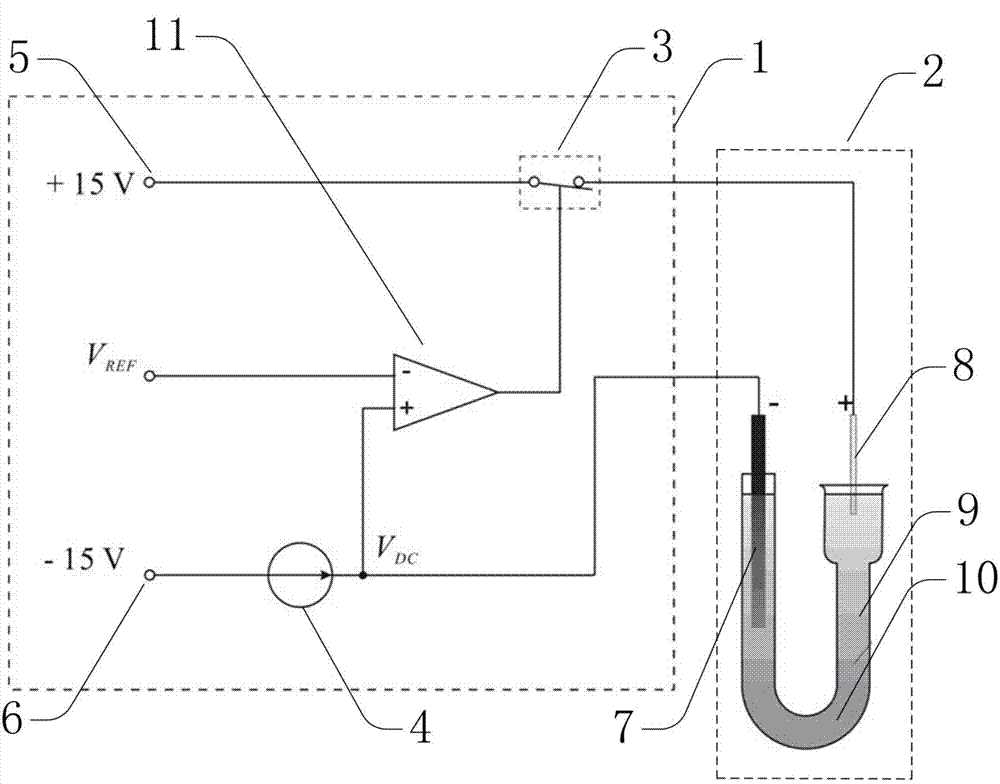

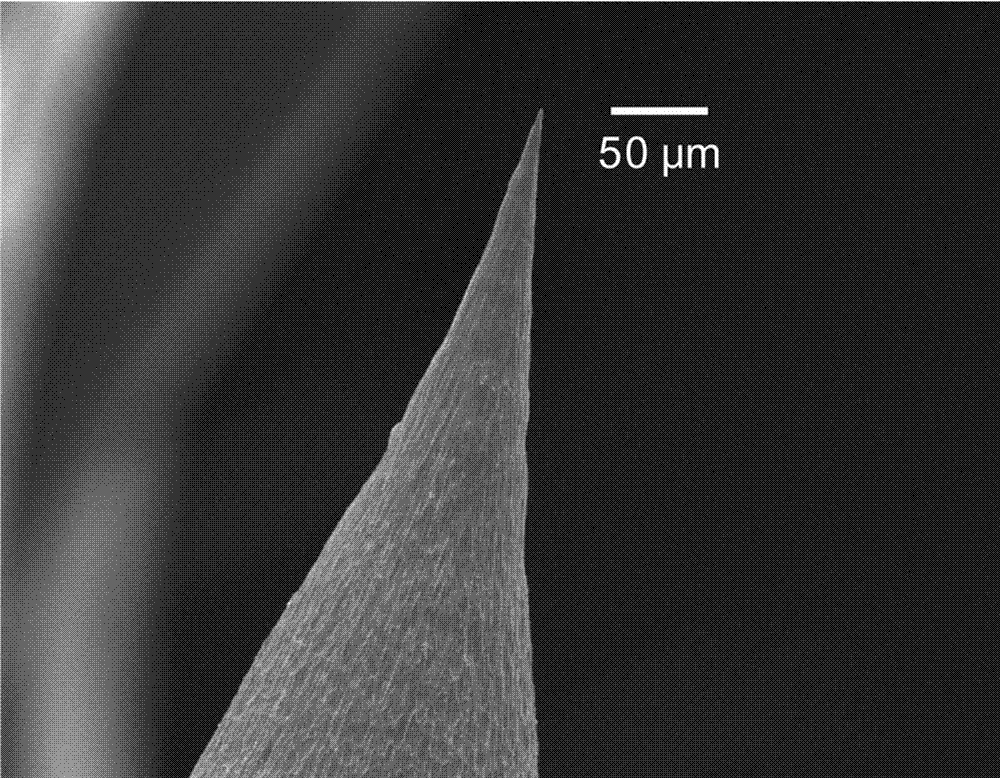

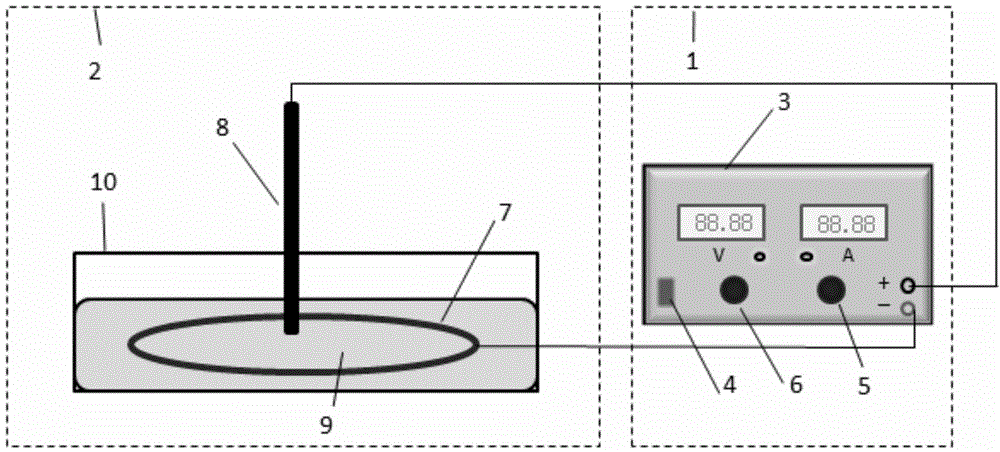

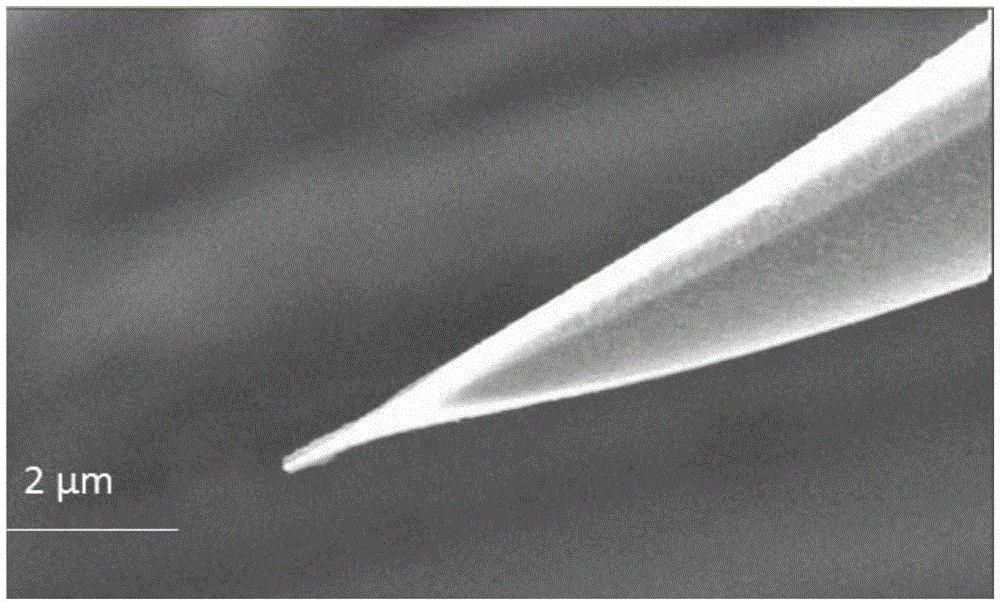

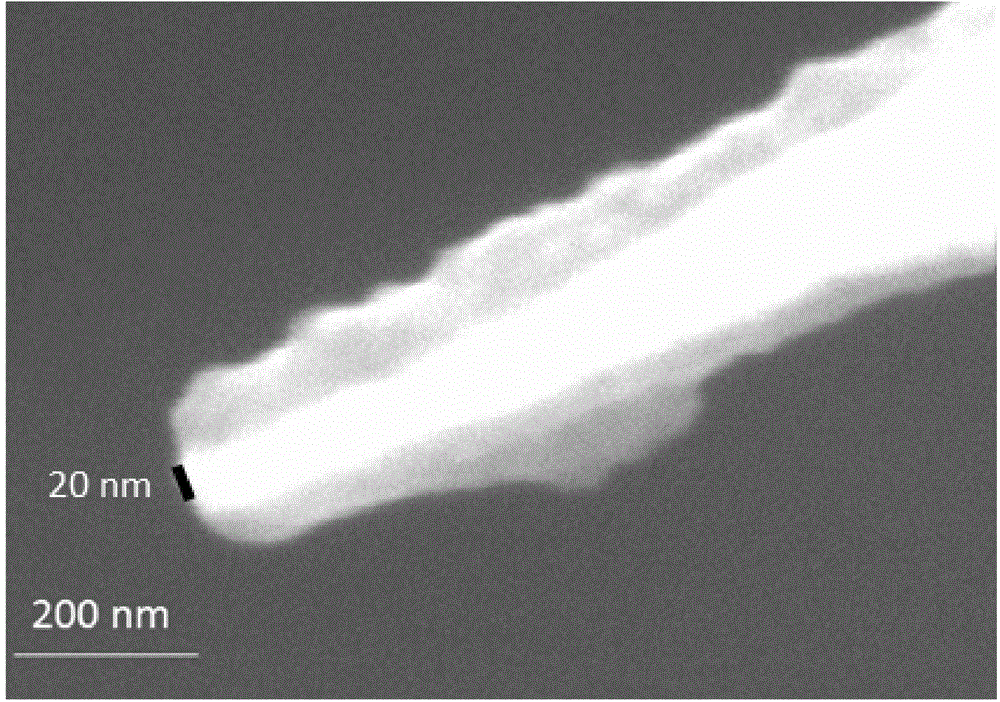

Apparatus and method for preparing metal probe tip

ActiveCN105301288AShort timeShorten the timeScanning probe microscopyConcentration ratioElectrolytes levels

The present invention discloses an apparatus and method for preparing a metal probe tip and controlling the curvature radius of the metal probe tip. The method includes the steps as follows: 1) a magnetic metal wire to be prepared is provided; 2) one end of the metal wire to be prepared is immersed under the electrolyte level of an electrochemical cell, and the other end of the metal wire to be prepared is connected with a positive electrode side of a control circuit; 3) a switch is closed, the constant current or constant voltage of the apparatus is maintained by a constant current and constant voltage source of the control circuit, and the electrochemical cell performs reaction until the metal wire to be prepared forms the metal probe tip under the electrolyte level. The method for preparing the magnetic probe tip has fast preparing speed and high efficiency, and can control the probe tip shape. The curvature radius of the probe tip is small, the probe tip surface is smooth, and the probe tip has stable quality. Additionally, the curvature radius of the probe tip can be controlled by the adjustment of the outputted constant current value and the concentration ratio of electrolyte. The prepared magnetic probe tip can realize spinning resolution in magnetic sample measurement.

Owner:INST OF PHYSICS - CHINESE ACAD OF SCI

Fast voltage-reducing energy-saving starting method for aluminum electrolysis bath

The invention discloses a method for quick starting, voltage reduction and energy conservation of an aluminum cell, comprising the following steps that: the molecule ratio is quickly reduced by maintenance of the electrolysis temperature in the aluminum cell on the basis of the prior art; the intermediate electrolysis temperature is maintained; the low-effect coefficient is matched so as to maintain the aluminum level and the electrolyte level at adequate height; operation of low alumina concentration in the cell is maintained; the operating voltage is quickly reduced; a hearthside of the electrolytic cell is quickly formed; and the new energy balance is established, which lays a foundation for quick reduction of the voltage. By adoption of the invention, compared with normal starting and final-period management, a single electrolytic cell directly reduces 12 volt voltage or so and directly saves 92200 degree electricity; moreover, when the electrical energy is saved, the influence of intermediate production management on equipment is declined; the service life of the electrolytic cell is indirectly improved and exhaust of dusty gases is reduced; the production operating cost is indirectly reduced and the aim of environmental control is achieved.

Owner:HENAN ZHONGFU IND

Fuel cell hybrid vehicle with automatically watered aqueous batteries

A fuel cell hybrid vehicle utilizing flooded aqueous battery or batteries operatively coupled to a fuel cell stack, an electric drive motor, and an integrated watering system, the integrated watering system comprising: a heat exchanger configured to extract water from exhaust air from the fuel cell stack; a reservoir, operatively connected to store the water; a sensor, operatively connected to generate a signal based on the flooded aqueous batteries' electrolyte level; a pump, operatively connected to the reservoir and the flooded aqueous batteries; and a system controller, operatively connected to receive and evaluate the signal from the sensor and actuate the pump to move water from the reservoir to the flooded aqueous battery or batteries.

Owner:FCA US

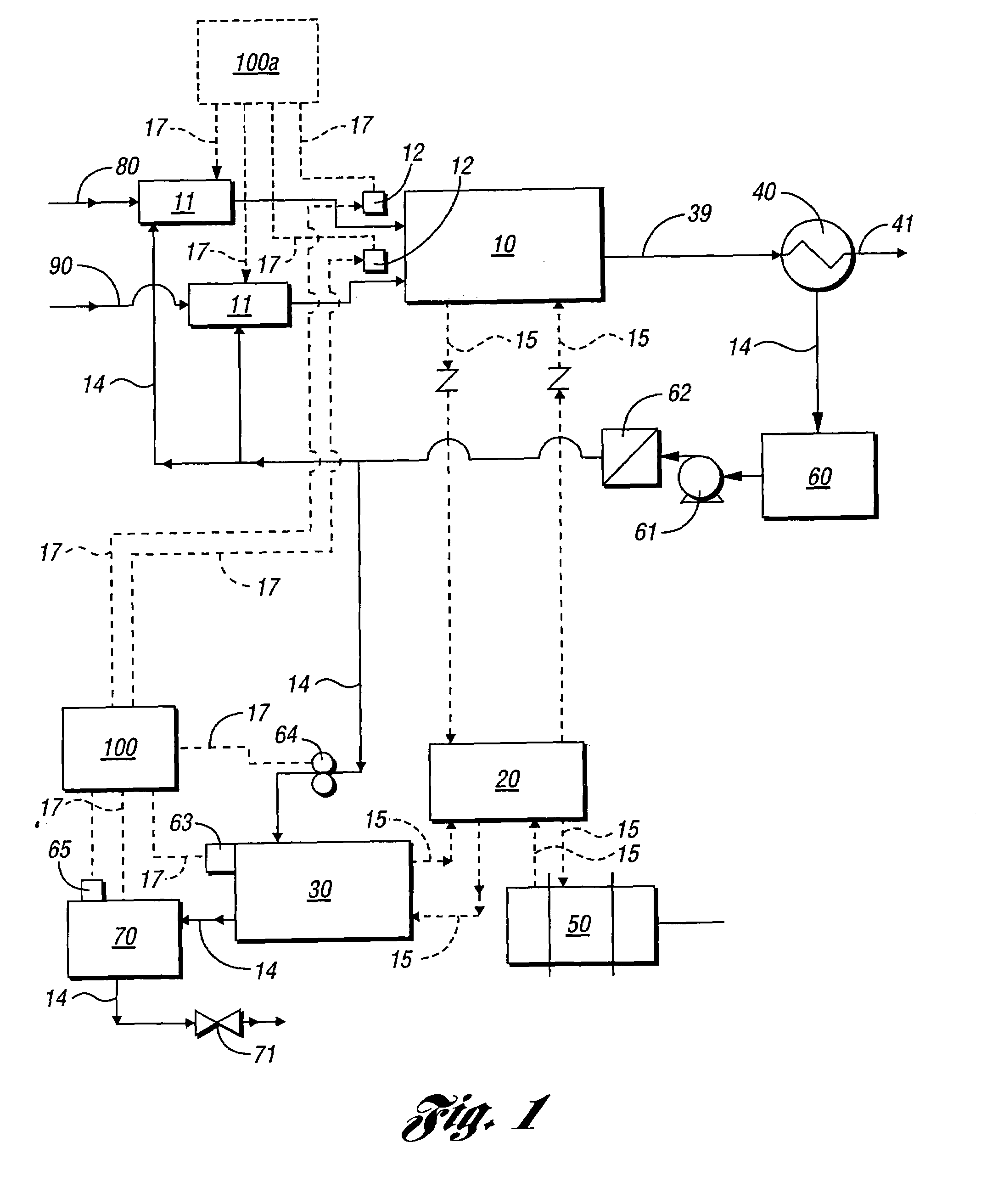

Electrolyte System For Rechargeable Flow Battery

InactiveUS20170214077A1Improve stabilityManufacturing EaseRegenerative fuel cellsAqueous electrolyte fuel cellsHalogenElectrical battery

An electrolyte system is provided for a rechargeable electrode zinc-halogen flow battery that utilizes a highly similar or identical electrolyte positioned on both sides of an ion-conducting membrane. The electrolyte system containing zinc salts, electrolyte conductivity enhancer, and an appropriate amount of bromine complexing agent achieves significant improvements on battery energy efficiency, self-discharge rate, and electrolyte level cycle stability over the prior art electrolyte systems.

Owner:FAITH TECH INC

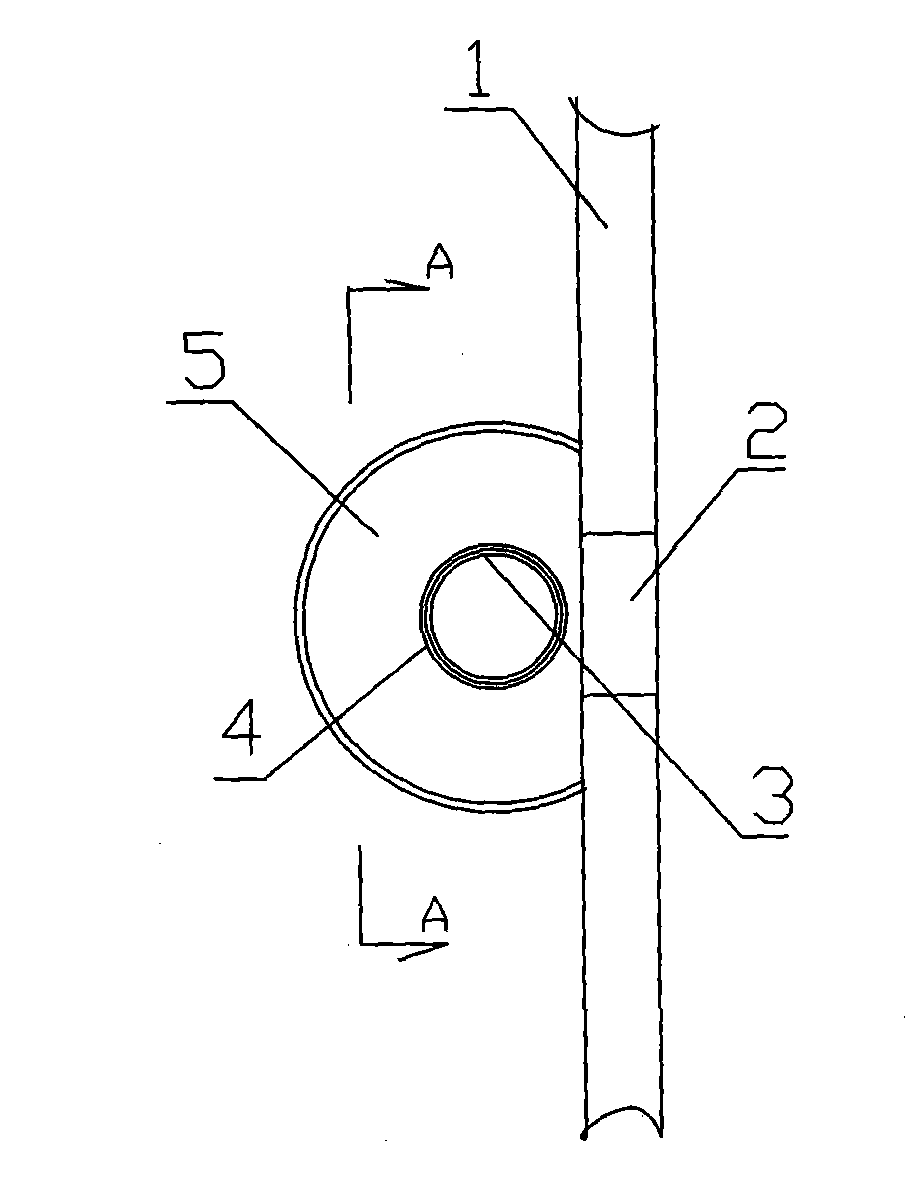

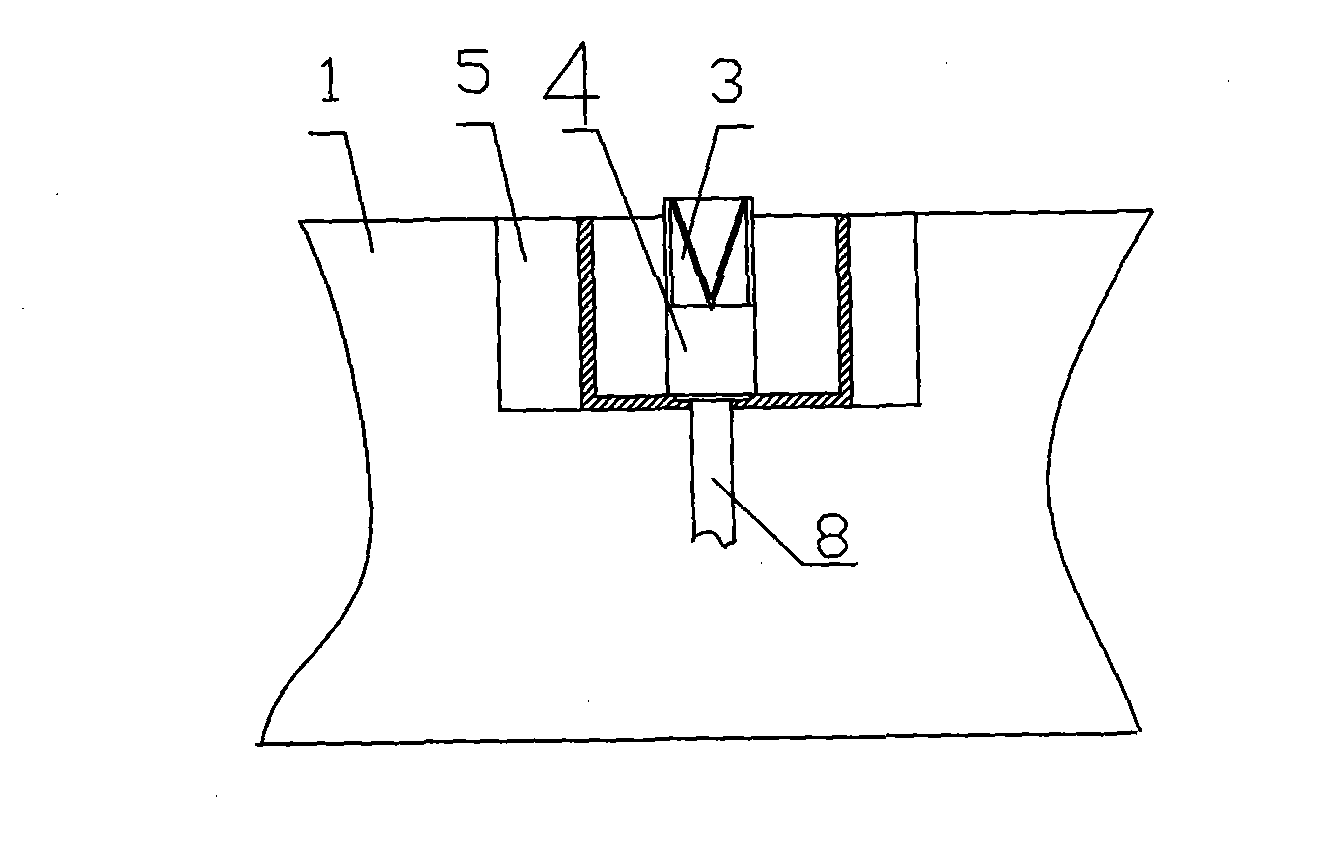

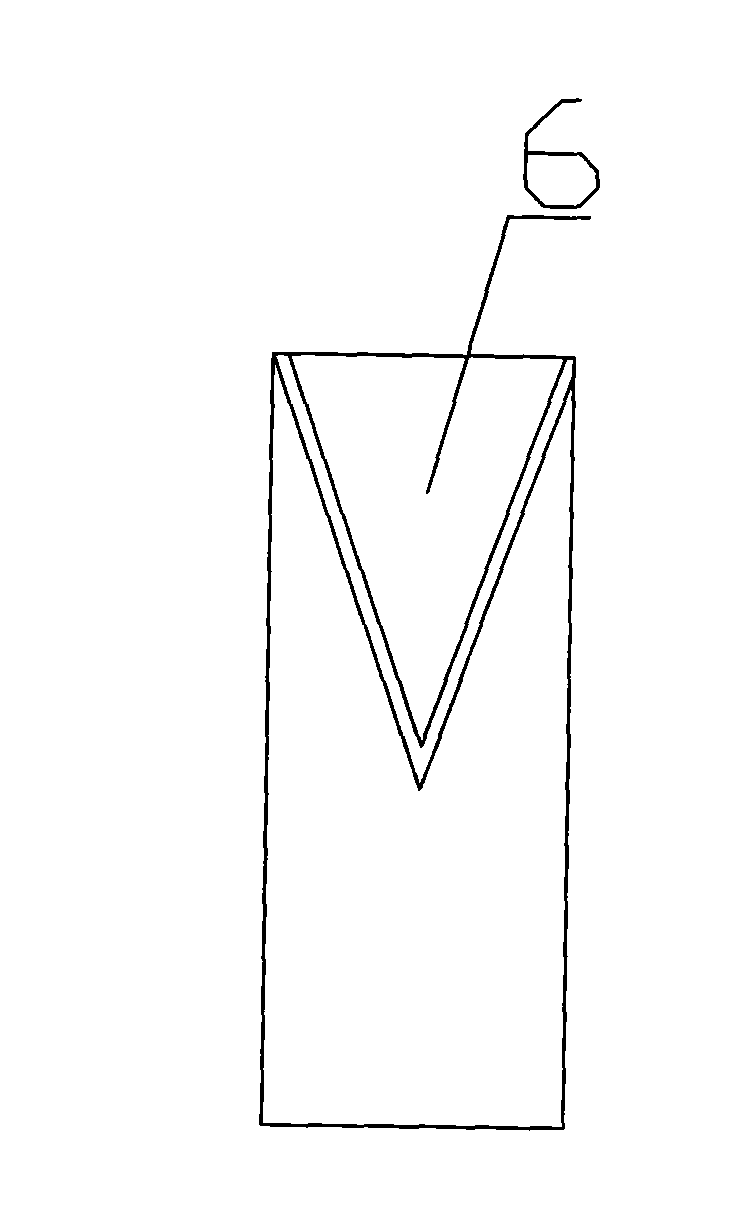

Cathode copper electrolytic method for changing electrolyte level and electrolytic cell

InactiveCN101665954ALiquid level is convenientSimple structurePhotography auxillary processesElectrolysis componentsElectrolytes levelsCopper

The invention relates to a cathode copper electrolytic method for changing electrolyte level and an electrolytic cell. The cathode copper electrolytic method and the electrolytic cell solve problems that the prior electrolyte level is fixed so as to generate the crystal substance on a cathode along particles and on cathode copper along a section, a residual anode is easily broken and the cathode copper drops off at an opening of a washing box. The technical scheme of the invention is to change upper level of the electrolytic level in the electrolytic process so as to effectively solve the problems. An overflow trough of the electrolytic cell realizing the change of the electrolyte level is provided with a level regulation device. The electrolytic cell comprises an external sleeve (4) and an internal sleeve (3) which is sleeved in the external sleeve (4) and forms liquid seal with the external sleeve. A lower end of the internal sleeve (3) is fit with a through hole on a bottom part ofthe overflow trough. A lateral surface on an upper end of the internal sleeve (3) is provided with a V-shaped notch (6). The external sleeve (4) is provided with a rectangle notch (7). Electrolyte level fluctuation is realized through rotating a coincidence area of the external sleeve and the internal sleeve. The cathode copper electrolytic method and the electrolytic cell of the invention can conveniently regulate the electrolyte level.

Owner:JINLONG COPPER

Process for lowering level of salt required for dilution thickening

InactiveUS20050043193A1Enhanced rinse retentionHigh viscosityInorganic/elemental detergent compounding agentsCosmetic preparationsElectrolytes levelsElectrolyte

The invention relates to a process for making single phase dilution thickening compositions comprising electrolyte. By adding defined associative thickener to said compositions applicants have found one can lower level of salt / electrolyte required to obtain dilution thickening effect.

Owner:UNILEVER HOME & PERSONAL CARE USA DIV OF CONOPCO IN C

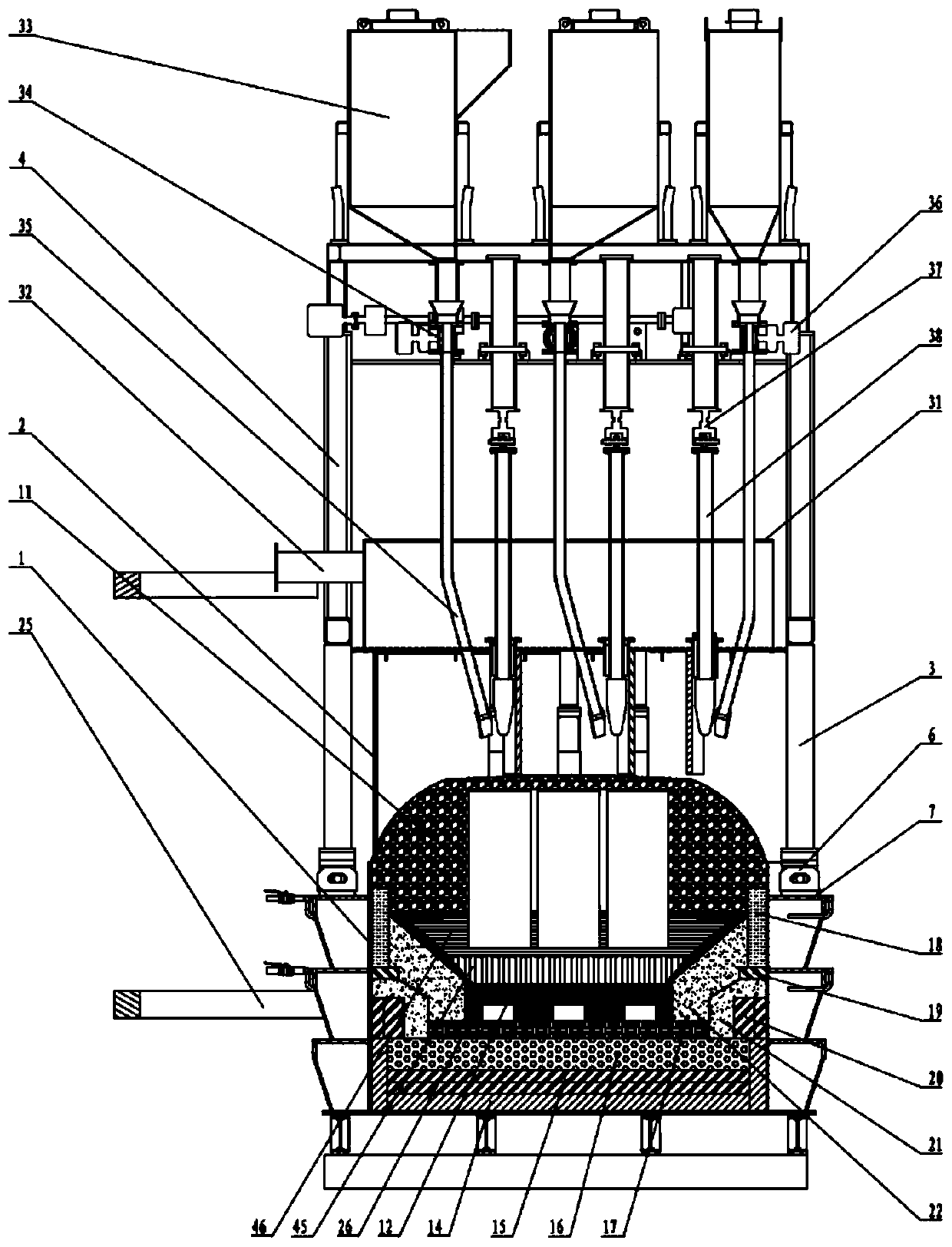

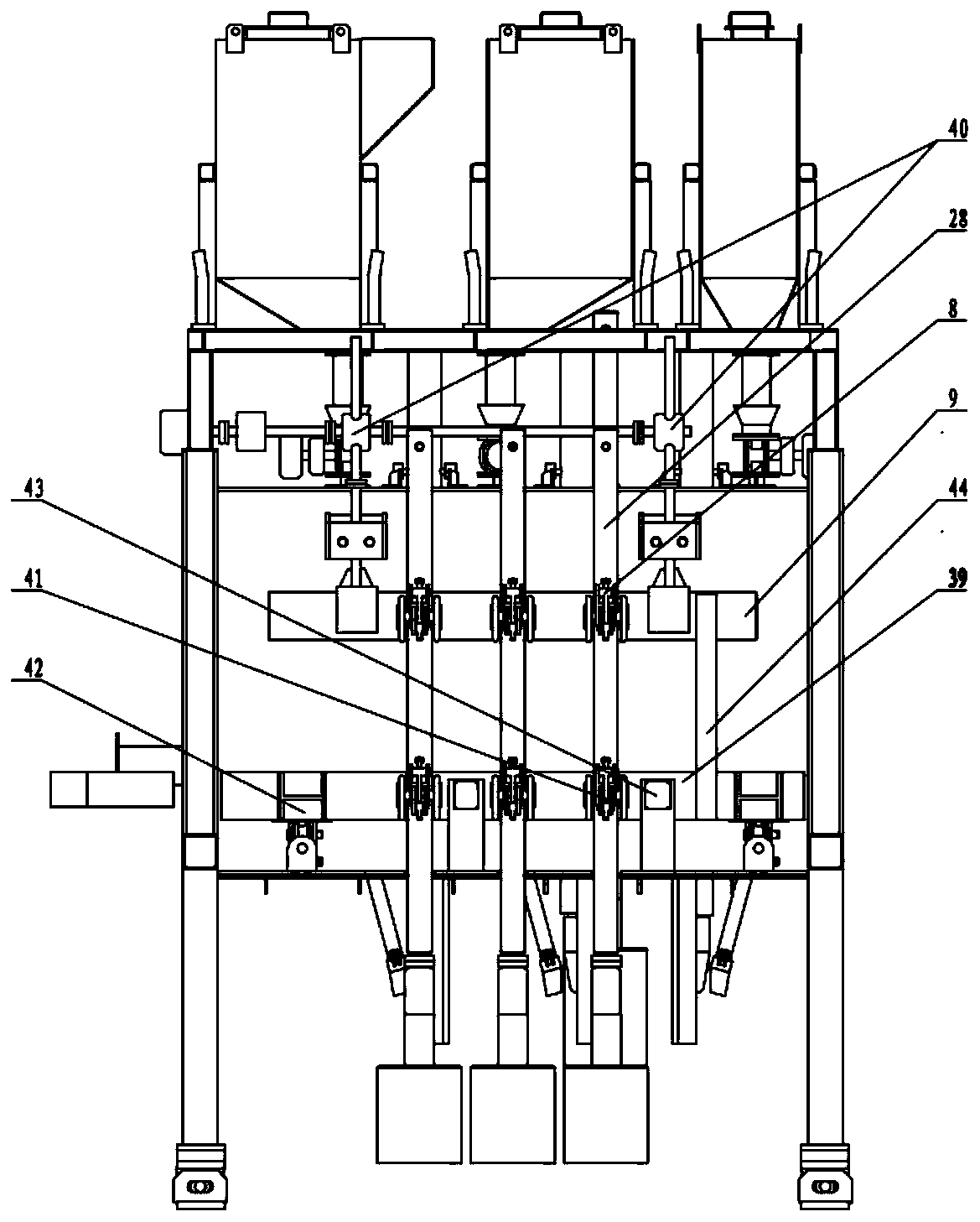

Rare earth electrolytic tank for producing rare earth and alloys thereof

The invention discloses a rare earth electrolytic tank for producing rare earth and alloys thereof. The rare earth electrolytic tank comprises an electrolytic tank body, a cathode group structure, ananode group structure and a tank upper portion structure, wherein the electrolytic tank body comprises a tank shell and a tank lining, the tank upper portion structure comprises a vertical column girder frame, a material feeding system, a shell ramming system, an anode lifting and busbar switching system and a tank hood plate, the upper end of the anode group structure is connected with the anodelifting and busbar switching system, anode blocks at the lower end are vertically inserted in electrolyte inside the tank body, the parts, exposed outside the electrolyte level face, of the anode blocks are covered by an anode covering material, the anode lifting and busbar switching system is used for adjusting the polar distance between the anode blocks and the cathode group structure, the material feeding system, the shell ramming system and the anode lifting and busbar switching system are integrated into an intelligent tank control system, the upper edge of the tank hood plate is connected with the edge of the side portion of a horizontal hood plate, and the lower edge of the tank hood plate is connected with the upper surface of the tank shell to realize closeness of the electrolytictank. By means of the rare earth electrolytic tank for producing the rare earth and the alloys thereof, rare earth electrolytic tank automatic continuous, high-efficiency, low-energy-consumption, low-cost and clean production is realized.

Owner:GUIZHOU BRANCH CHINA ALUMINUM IND

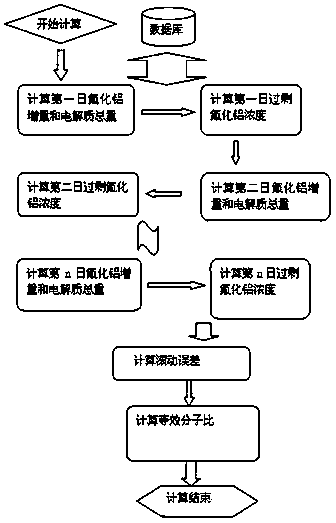

Method for measuring molecular ratio of electrolyte in aluminum electrolysis process

The invention discloses a method for measuring molecular ratio of electrolyte in an aluminum electrolysis process. The method comprises the following steps: (1) determining a coefficient of an incremental calculation formula of aluminum fluoride in electrolyte, wherein the calculation formula is shown as WapAlF=alpha(T-temp0)+betaAlFg+gammaWaAlF+a(T-temp0)2+bAlFg2+c(T-temp0)AlFg+d; (2) calculating the addition frequency and weight each time according to the measured electrolyte level and aluminum fluoride; (3) calculating increment of the aluminum fluoride by utilizing the formula in the step (1); (4) calculating a rolling error; and (5) calculating an equivalent molecular ratio. According to the method, the aim of molecular ratio measurement is achieved, and a basis is provided for control of an electrolytic cell.

Owner:NORTH CHINA UNIVERSITY OF TECHNOLOGY

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com