Cathode copper electrolytic method for changing electrolyte level and electrolytic cell

An electrolysis method and electrolyte technology, which are applied in the field of electrolytic cells, can solve the problems of cathode copper falling off, the residual electrode is easily broken, etc., and achieve the effects of convenient liquid level and simple structure.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] A kind of cathode copper electrolysis method of the present invention changes electrolyte level, comprises the following steps:

[0021] (1) When the electrolyzer is energized after the tank is installed, the liquid level is controlled at a high level and electrolyzed;

[0022] (2) Four days after electrification, reduce the electrolyte level to a low level and continue electrolysis;

[0023] (3) One day before the copper is released, the electrolyte level is controlled at a high level and then energized and electrolyzed for one day;

[0024] (4), out of copper.

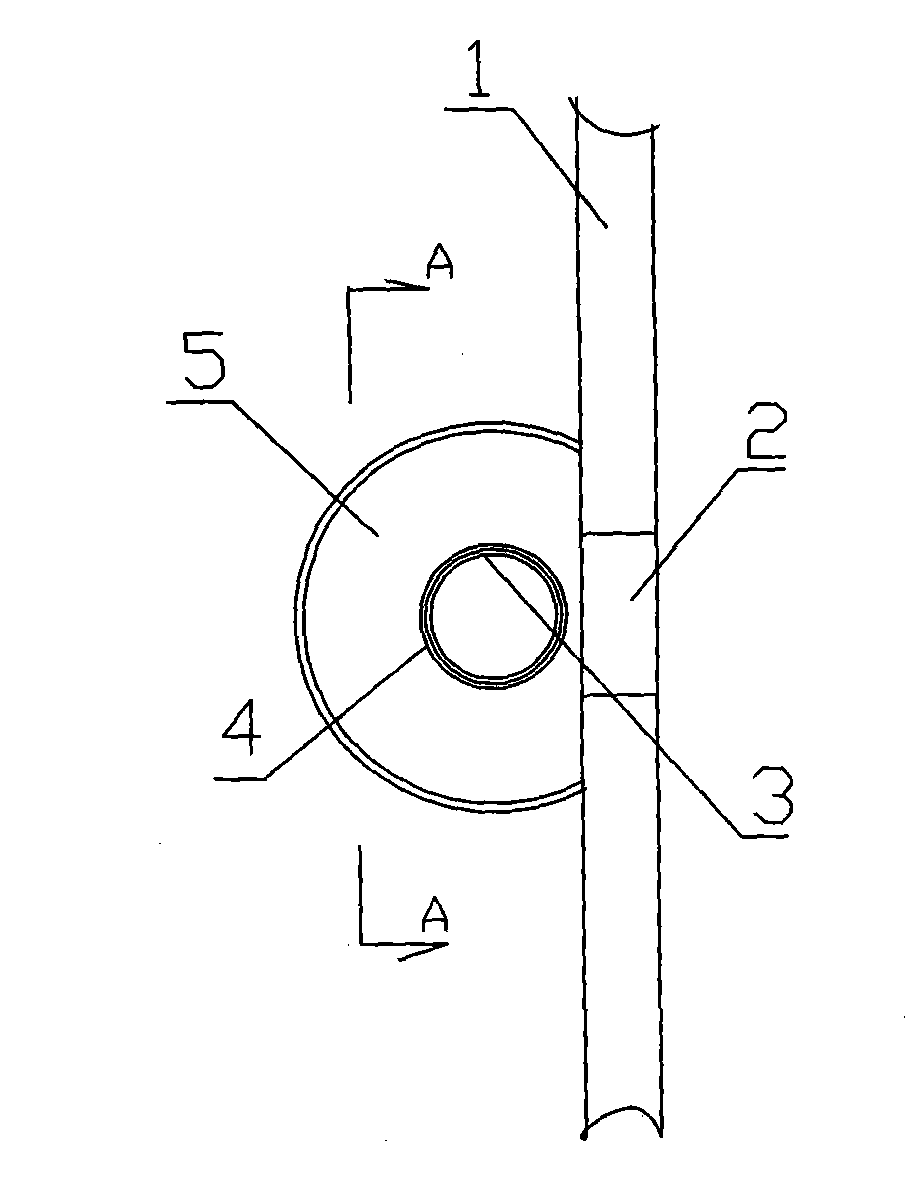

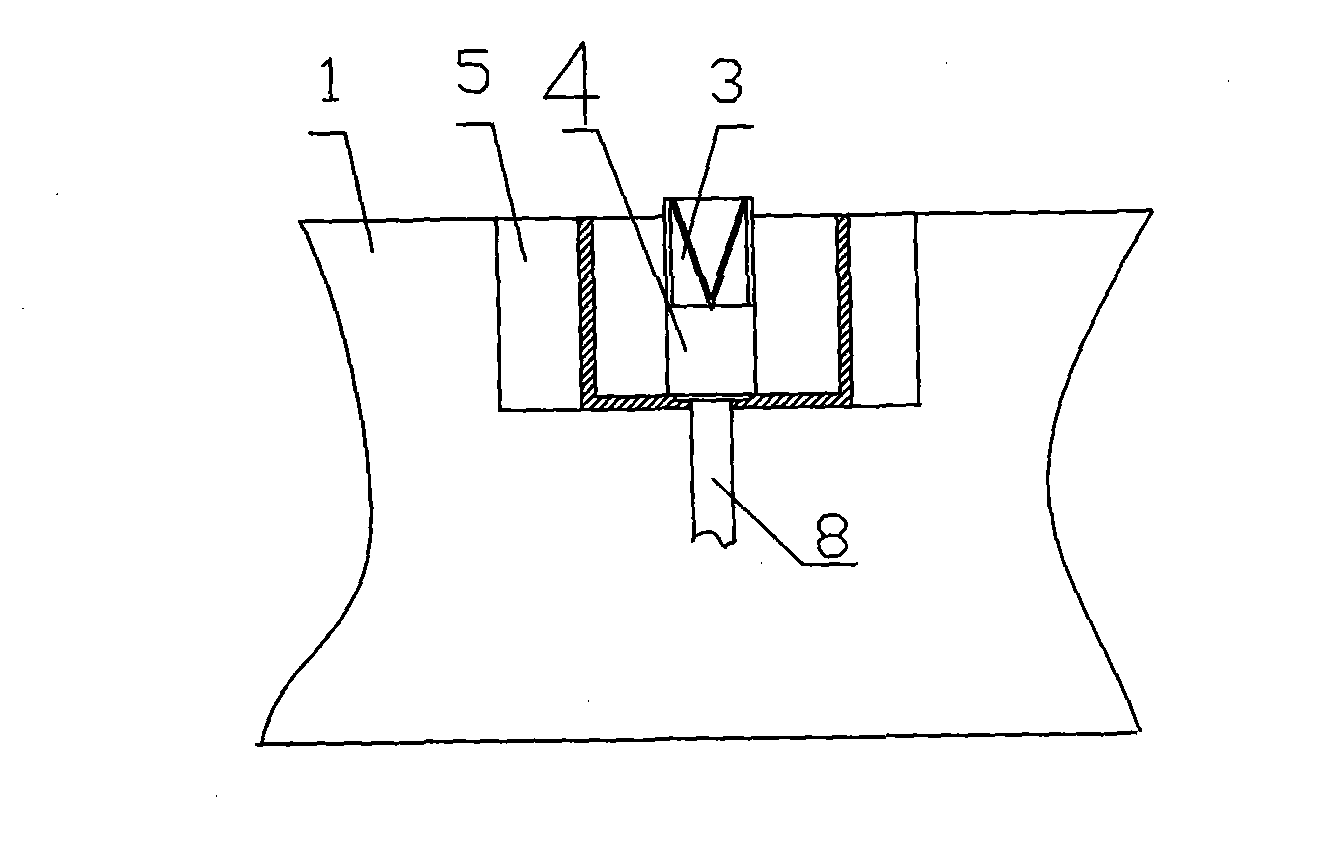

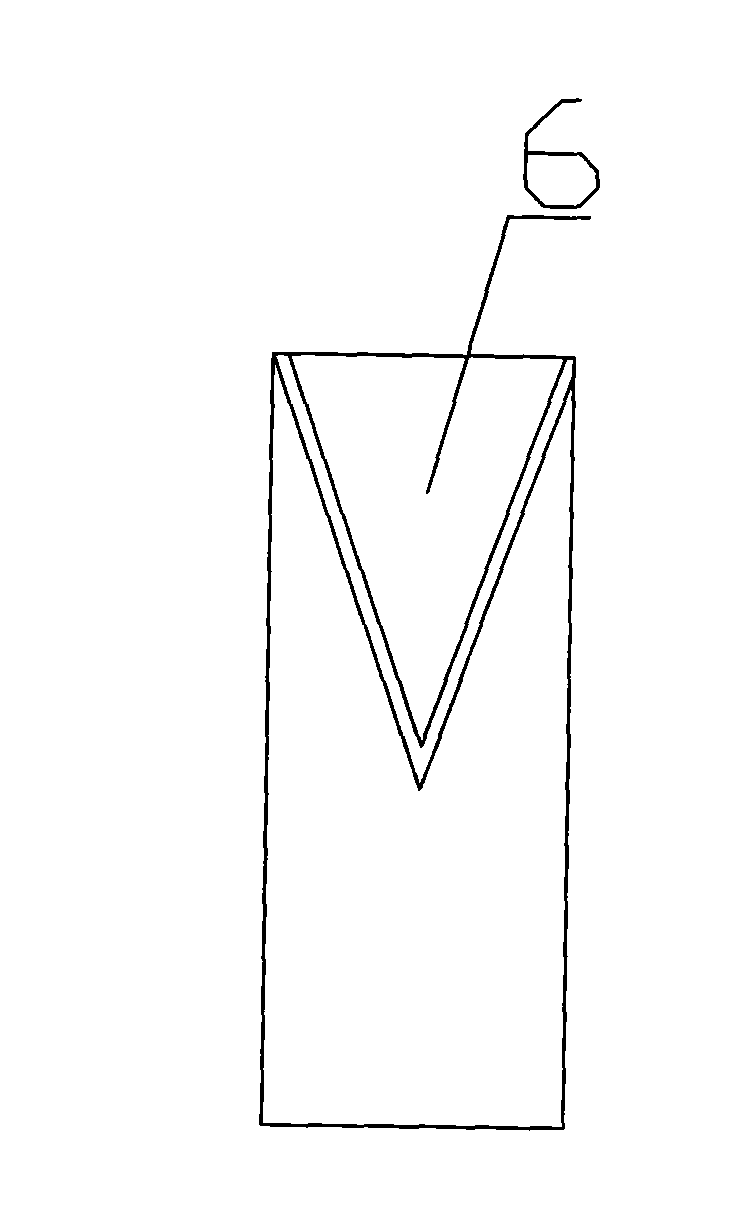

[0025] Electrolyzer of the present invention such as figure 1 As shown, it includes a tank body, one end of the tank body 1 is provided with an overflow port 2, the outlet of the overflow port 2 is provided with an overflow tank 5, and the bottom surface of the overflow tank 5 is provided with a through hole, and the electrolyte passes through the through hole and the return pipe 8 Connected to each other, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com