Method for preparing nanometer particles through electrochemistry discharging

A nanoparticle and electrochemical technology, applied in the direction of electrochemical processing equipment, manufacturing tools, metal processing equipment, etc., can solve the problems of high cost and low yield of nanoparticle preparation, and achieve strong operability, high yield, The effect of easy operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

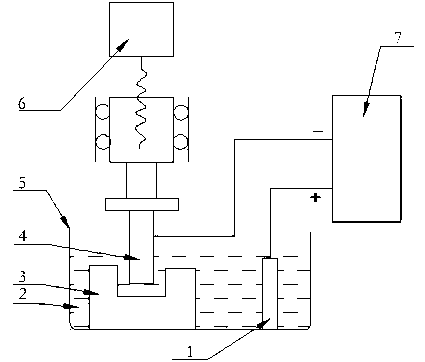

[0027] Silicon nanoparticles can be prepared by electrochemical discharge method.

[0028] Choose to use as figure 2 The shown electrochemical discharge method can prepare silicon nanoparticles. 2 CO 3 solution, the workpiece material 3 used is intrinsic silicon, the tool electrode 4 used is a molybdenum rod, and the feed block selected is a graphite electrode.

[0029] Add a pulse voltage with an amplitude of 100V, a frequency of 100Hz, and a duty cycle of 50% between the tool electrode 3 and the power supply block 1, so that hydrogen bubbles are continuously generated between the workpiece 3 and the tool electrode 4, and as the processing continues , the hydrogen bubbles completely wrap the tool electrode, completely isolate the tool electrode from the electrolyte, and form a potential difference. When the voltage reaches the voltage value required for the discharge, the hydrogen bubble layer is broken down, and the discharge is generated. The energy of the discharge is u...

Embodiment 2

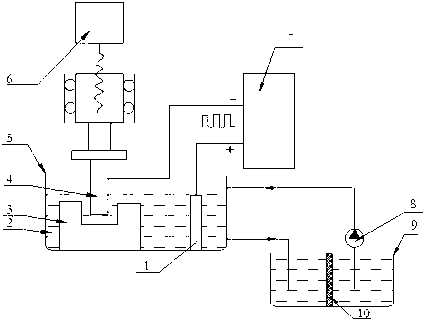

[0033] PZT ceramic particles can be prepared by electrochemical discharge method.

[0034] Choose to use as figure 2 The electrochemical discharge method shown is a device for preparing PZT ceramic particles. First, add an electrolyte solution 2 with a concentration of 10% NaOH solution in the working solution tank 5. The workpiece material 3 used is PZT ceramics, and the tool electrode 4 used is molybdenum Rod, the selected power supply block is stainless steel.

[0035] A pulse voltage with an amplitude of 150V, a frequency of 100Hz, and a duty cycle of 50% is applied between the tool electrode 3 and the power supply block 1, so that hydrogen bubbles are continuously generated between the workpiece 3 and the tool electrode 4. , as the processing continues, the hydrogen bubbles completely wrap the tool electrode, completely isolate the tool electrode from the electrolyte, and form a potential difference. When the voltage reaches the voltage value required for the discharge,...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com