Method for measuring molecular ratio of electrolyte in aluminum electrolysis process

A measurement method and electrolyte technology, applied in the field of aluminum electrolysis, can solve the problems of lack of great guiding significance in the production process, error in measurement results, and high labor intensity of electrolyte molecules.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] Since the molecular ratio of the electrolyte is calculated from the concentration of aluminum fluoride and sodium fluoride in the electrolyte, the chemical properties of sodium fluoride are relatively stable, and the concentration in the electrolyte does not change much with time, so it can be taken as a constant in a sampling period. Aluminum fluoride is volatile and is constantly added during the electrolysis process to keep the electrolysis process running efficiently. The molecular ratio can be calculated by estimating the concentration of aluminum fluoride, and this calculated molecular ratio is called the equivalent molecular ratio in this paper.

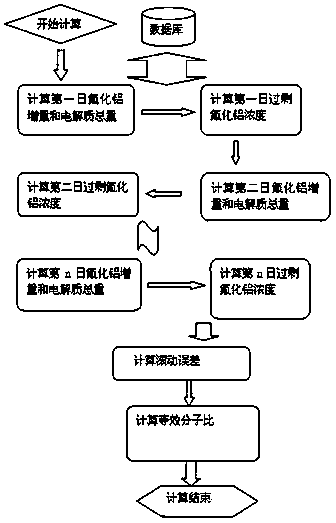

[0016] see figure 1 , the soft sensor method of the present invention is divided into several steps:

[0017] (1) Off-line parameter identification to determine the coefficients of the aluminum fluoride increment calculation equation in the electrolyte.

[0018] The core of this method is the calculation of the alumin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com