Patents

Literature

447results about How to "Solve measurement problems" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

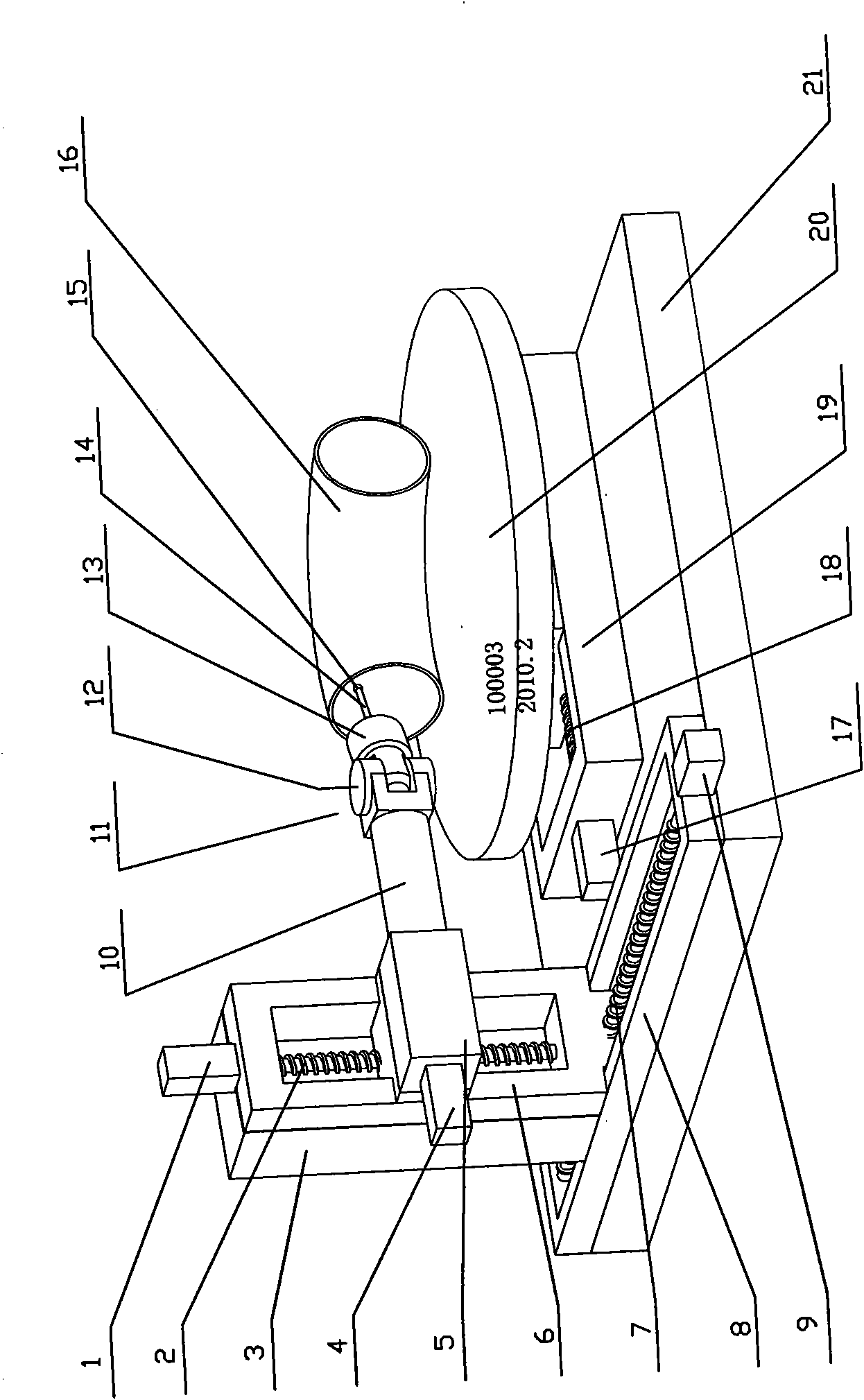

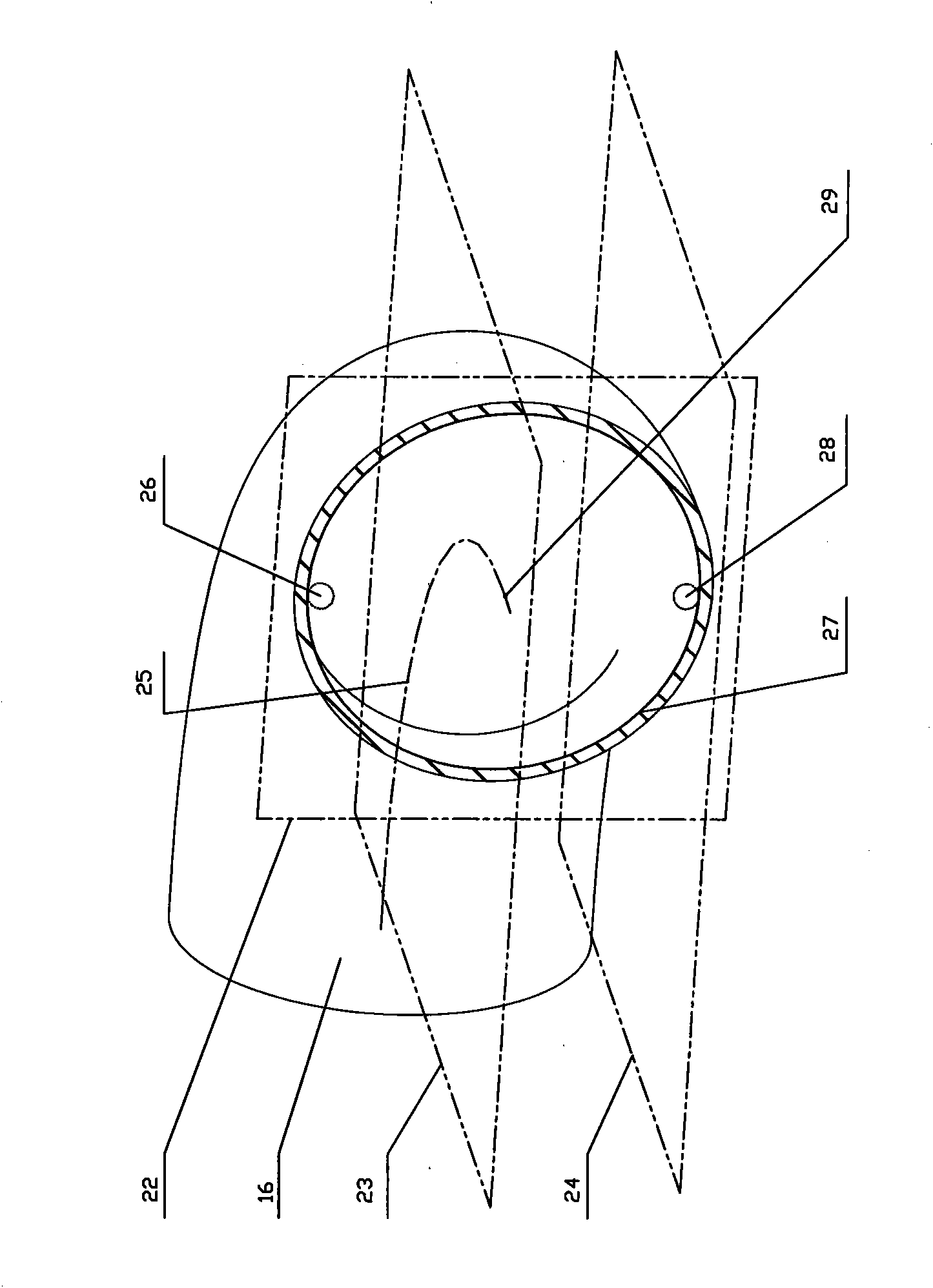

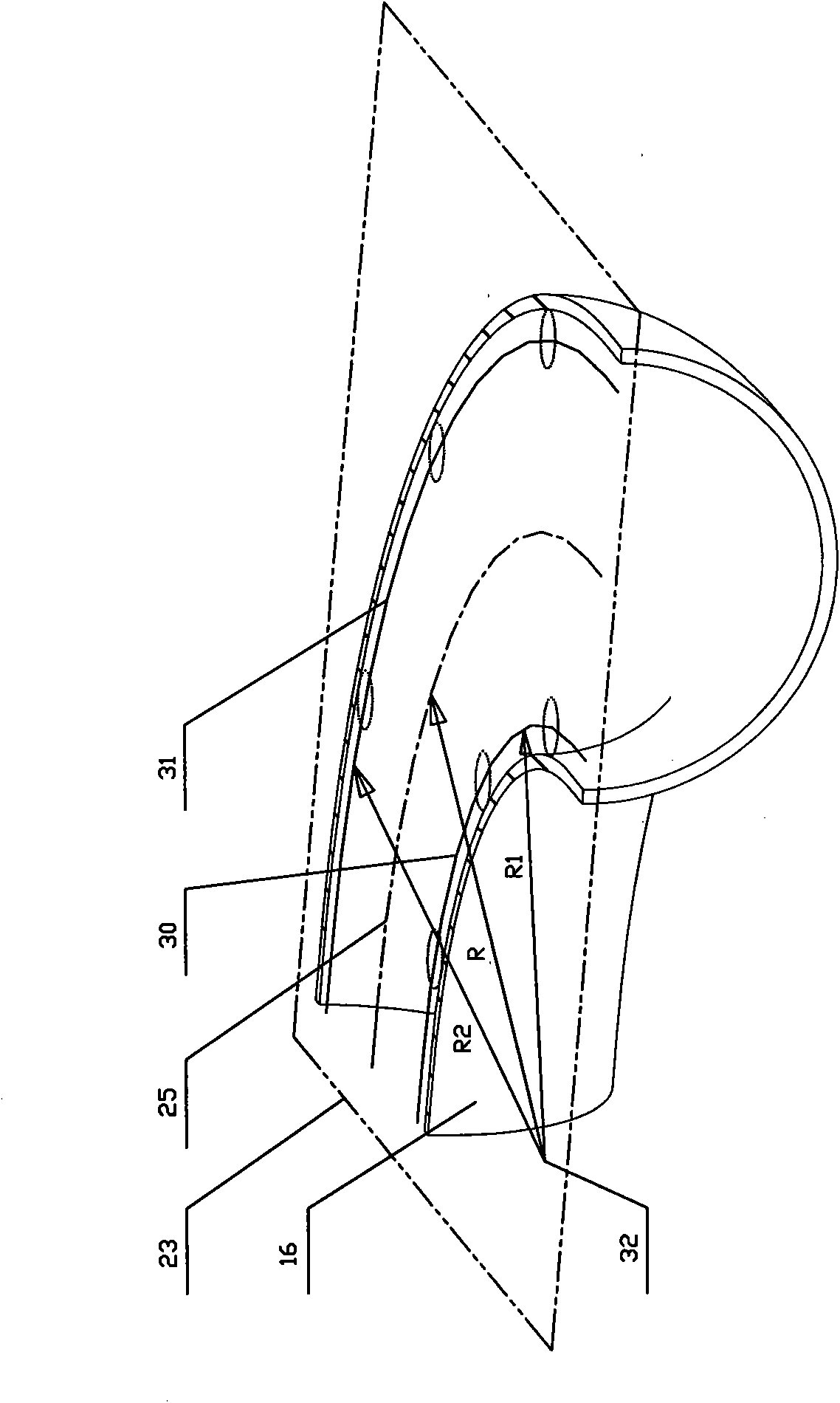

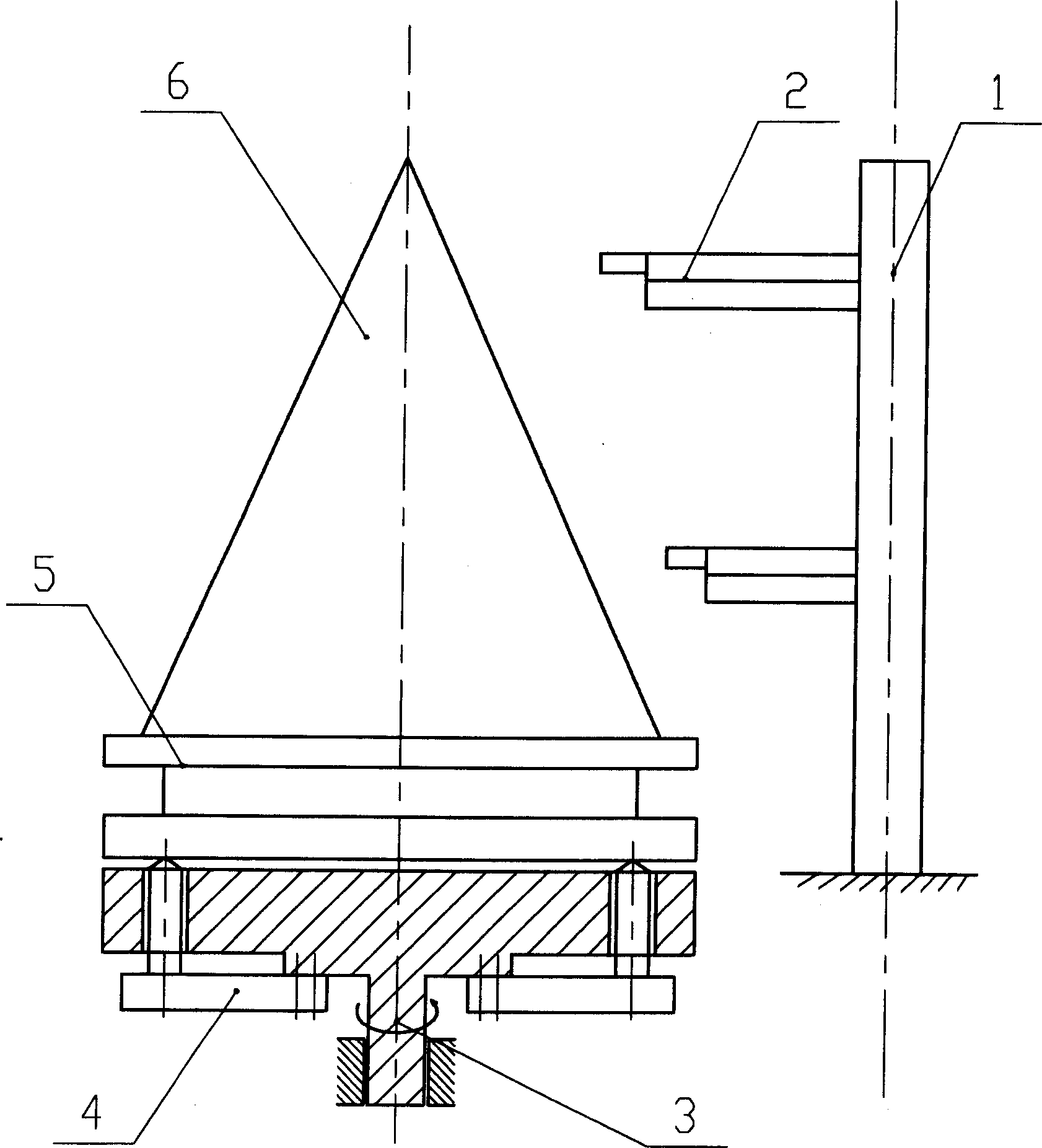

Measuring device and measuring method for geometric parameters of inner wall of elbow

InactiveCN101852582AStructural scienceHigh measurement accuracyMechanical diameter measurementsMeasurement deviceMeasurement problem

The invention relates to a measuring device and a measuring method for geometric parameters of an inner wall of an elbow, belonging to the testing instrument and meter field. The measuring device is provided with three motional freedom degrees and one rotational freedom degree, a measuring pin is installed at the tail end of a measuring arm for measuring overhanging and can rotate around the axle center of the measuring arm, and the pivot angle of the measuring pin can be manually regulated. In the measuring method for the geometric parameters of the elbow, the inner diameter and the bending radius of the elbow are measured by the measuring device, and the measuring process sequentially comprises the following steps: determining the center line plane of the elbow, measuring the bending radius and measuring the inner diameter of the elbow. The measuring method solves the problem on the measurement of the geometric parameters of the inner cavity of the elbow, and no locating surface needs to be additionally arranged in the measuring process, thus the invention achieves a large caliber application scope, and is especially applicable to occasions having higher requirements for the measurement accuracy of the geometric parameters of the elbow.

Owner:NORTH CHINA UNIVERSITY OF SCIENCE AND TECHNOLOGY

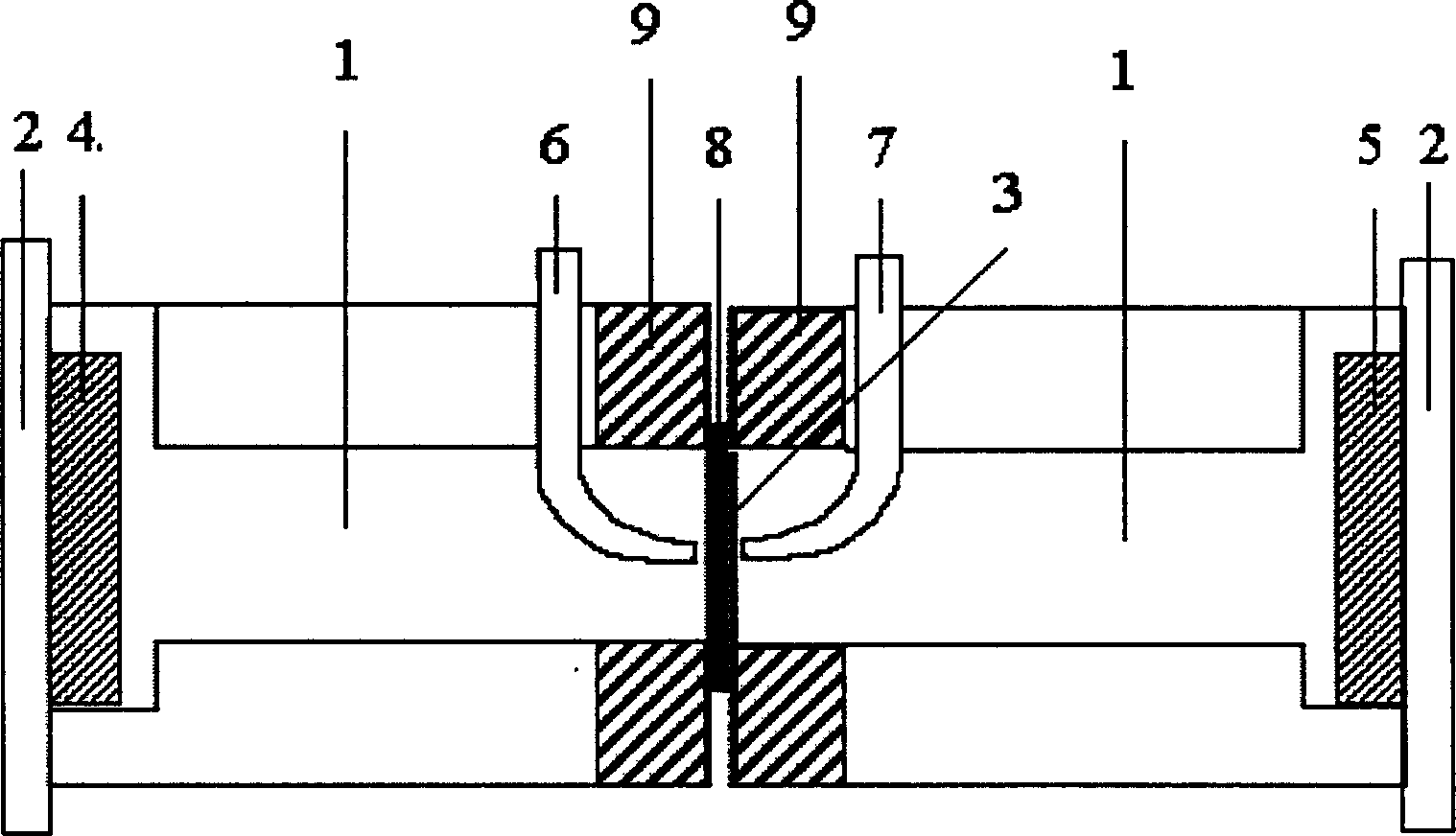

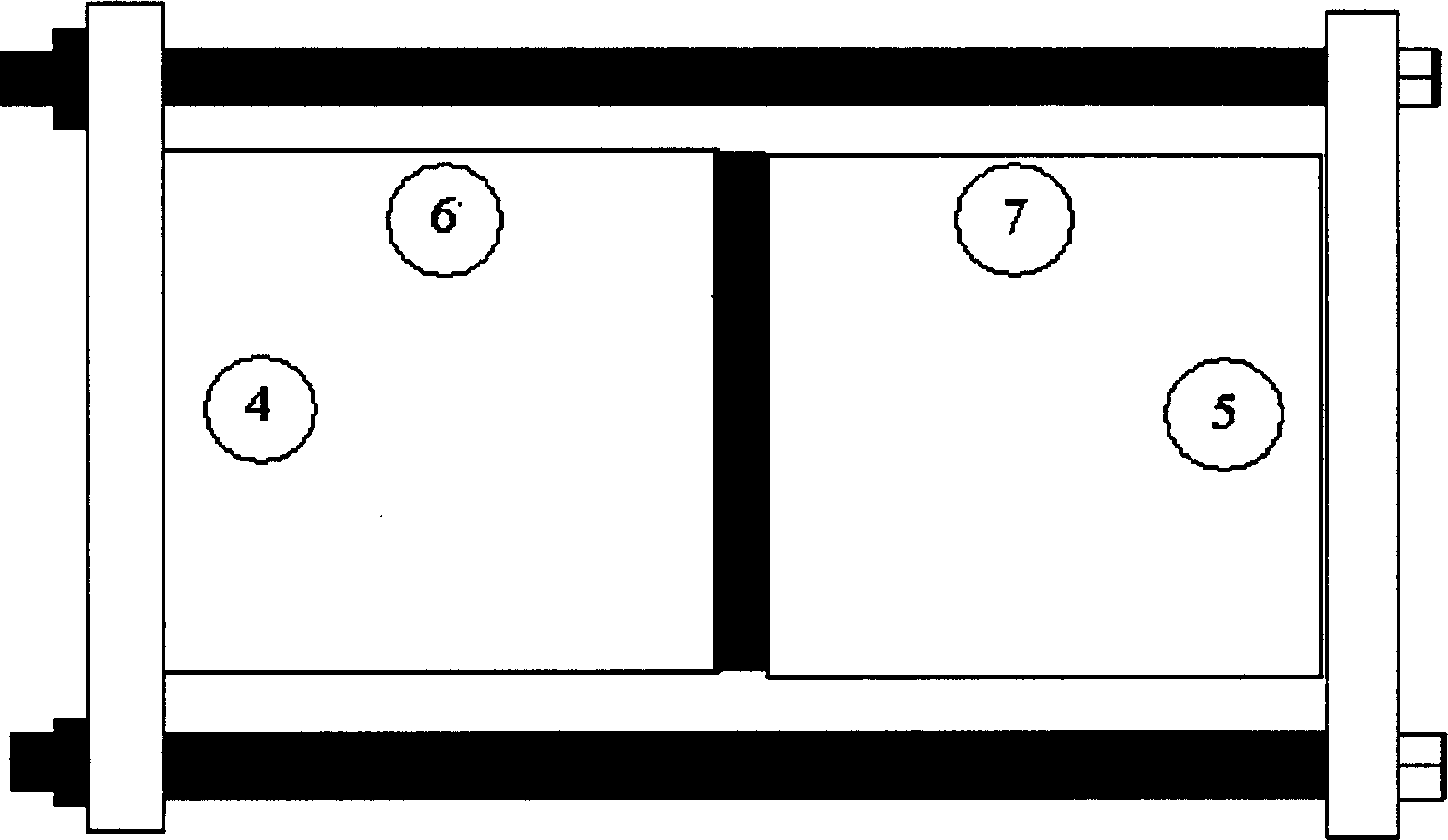

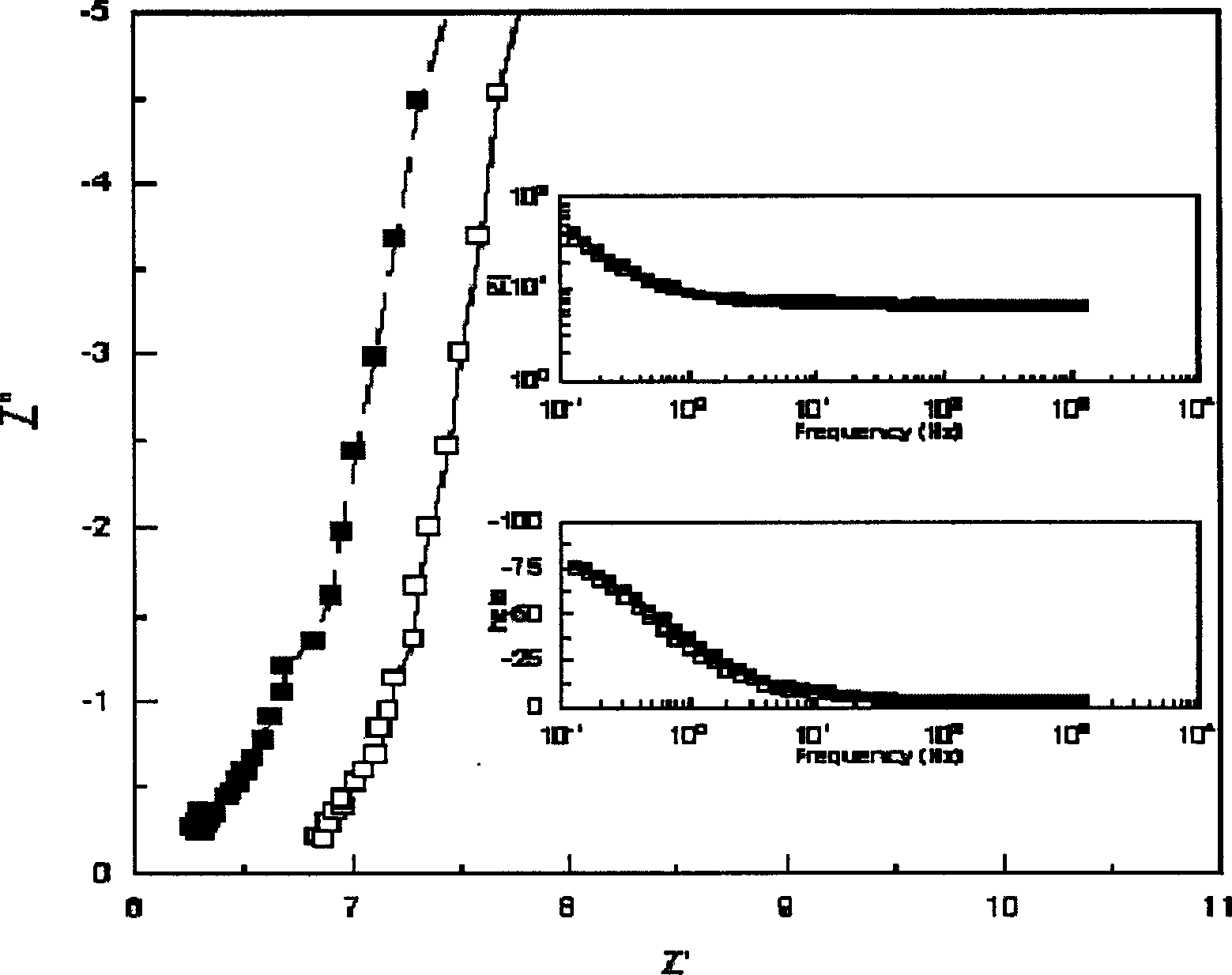

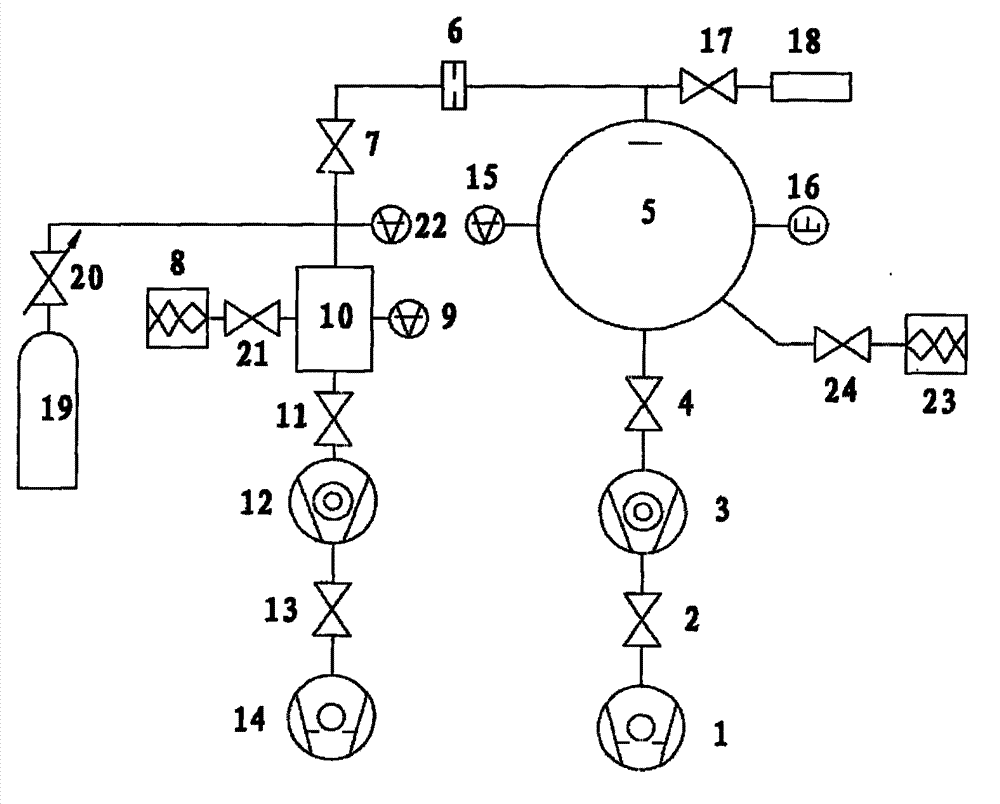

Testing method and appliance for horizontal conductivity of fuel cell proton exchange membrane

InactiveCN1564014AAvoid polarizationSolve measurement problemsElectrical testingAuxiliary electrodeEngineering

Four electrodes or three electrodes system are adopted in the invention. Carbon electrode is in sue for working electrode and auxiliary electrode for loading test current, and saturated calomel electrode is in use for reference electrode for testing response voltage. In testing, exchange membrane is placed in middle of connection hole corresponding to two electrolytic cells. Transverse resistance is measured by using AC impedence method. Conductivity of membrane is calculated out from thickness of membrane and area of the connection hole. The invented method prevents polarization issue occurred in DC test method is applicable to testing transverse conductivity of diaphragms used in other fuel cells and lithium ion cells.

Owner:UNIV OF SCI & TECH BEIJING

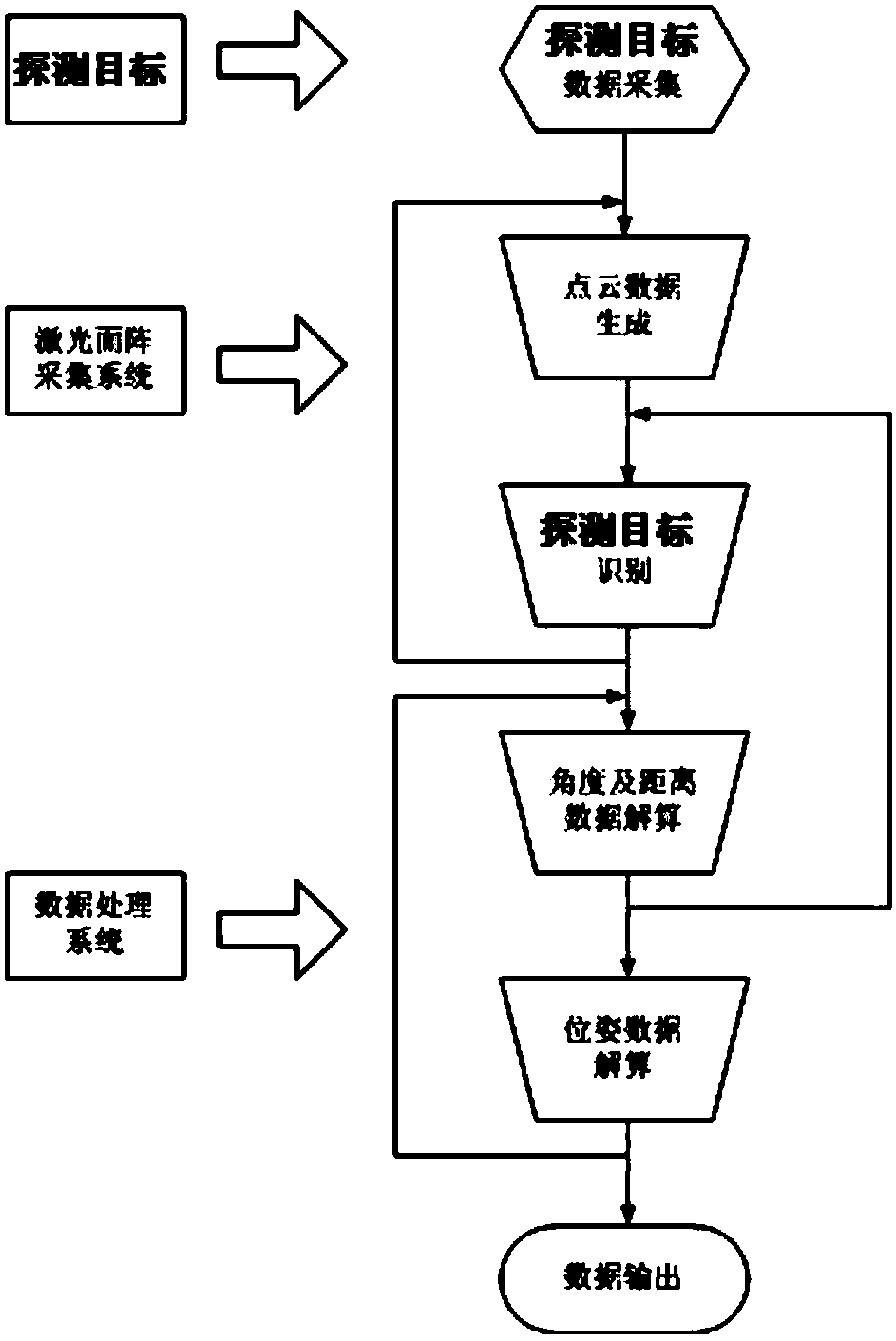

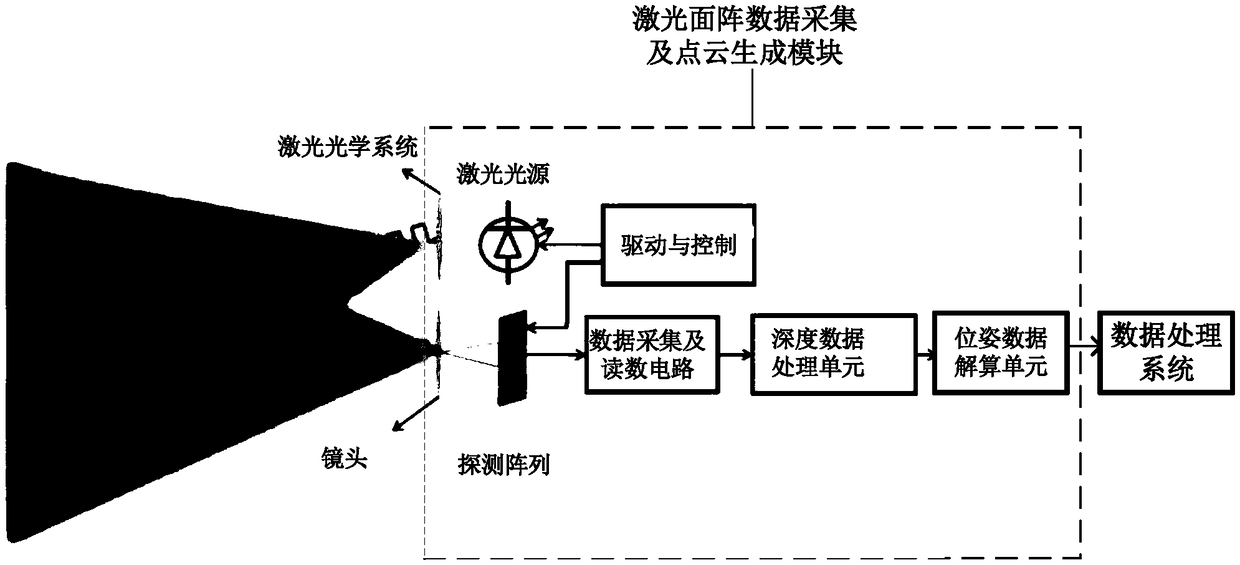

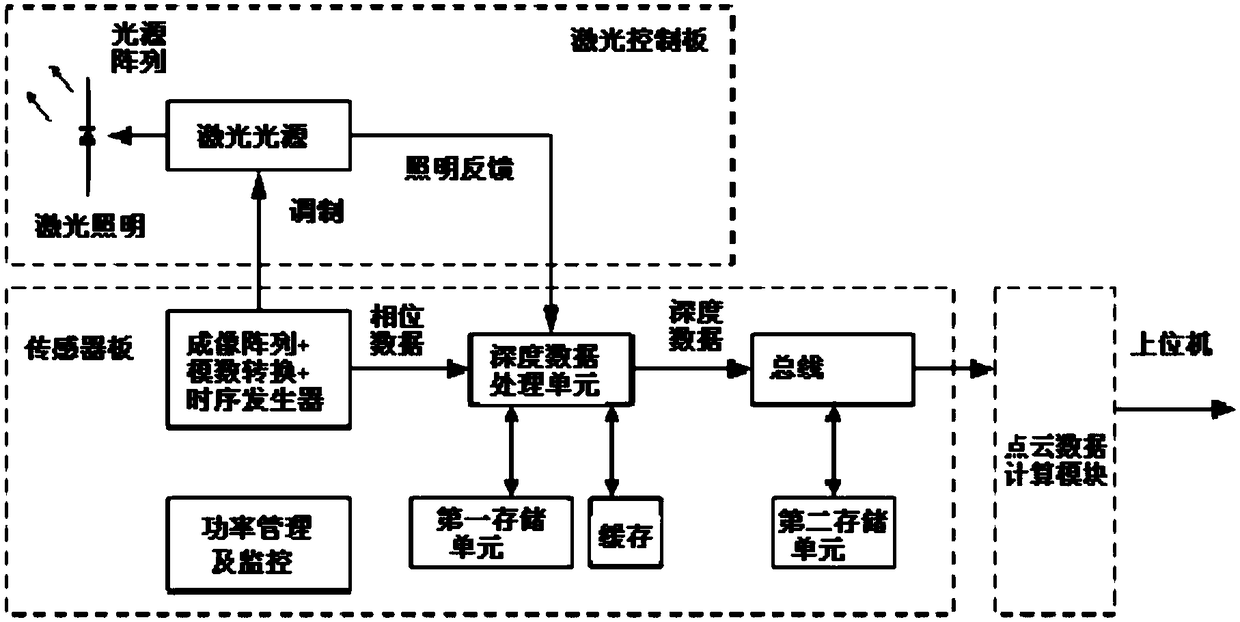

All-solid-state planar array three-dimensional imaging laser radar system

ActiveCN109375237ASolve measurement problemsSolving Imaging ProblemsElectromagnetic wave reradiationRadar systemsData acquisition

The invention provides an all-solid-state planar array three-dimensional imaging laser radar system, which comprises a detection target, a laser planar array data acquisition and point cloud generating module, and a data processing system, wherein the detection target is installed on a butting surface of a all-solid-state planar array three-dimensional imaging laser radar, so that a pulse laser signal transmitted by means of the laser radar for tracking the detection target returns in the original path, a reception and detection system of the laser radar completes the searching and capture ofthe detection target, acquires relative distance and position measurement parameters of the detection target in real time and acquires a plurality of feature points of the detection target in a laserirradiation range of the detection target and the laser radar, and the feature points are set in an optical field of view region with a fixed divergence angle; the laser planar array data acquisitionand point cloud generating module completes the measurement of the detection target and the depth data generation of the feature points, and transmits the depth data to the data processing system; andthe data processing system calculates azimuth information according to the depth data of each feature point and pixel positions in the field of view region, calculates angle and distance data and calculates attitude data of the detection target.

Owner:BEIJING HUA KEBO BOCHUANG TECH

Method and system for measuring bottleneck bandwidth and remanent bandwidth

InactiveCN1770711ATroubleshoot bandwidth measurement issuesSolve measurement problemsData switching networksWide bandBottle

This invention relates to measure method and system for bottle wide and remain wide band in the label barrel speed limit network path, wherein, the method comprises the following steps: establishing send end and receive end for data interacting; firstly detecting and judging whether the linkage is label speed limit network path; if yes, then computing linkage each label parameters, bottle and remain wide band; if not adopting traditional method to measure and compute the bottle wide band and remain wide band. The invention is free of label speed limited.

Owner:史文勇

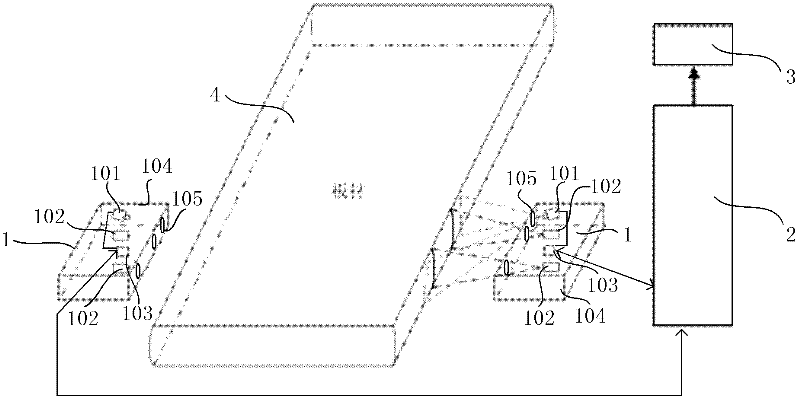

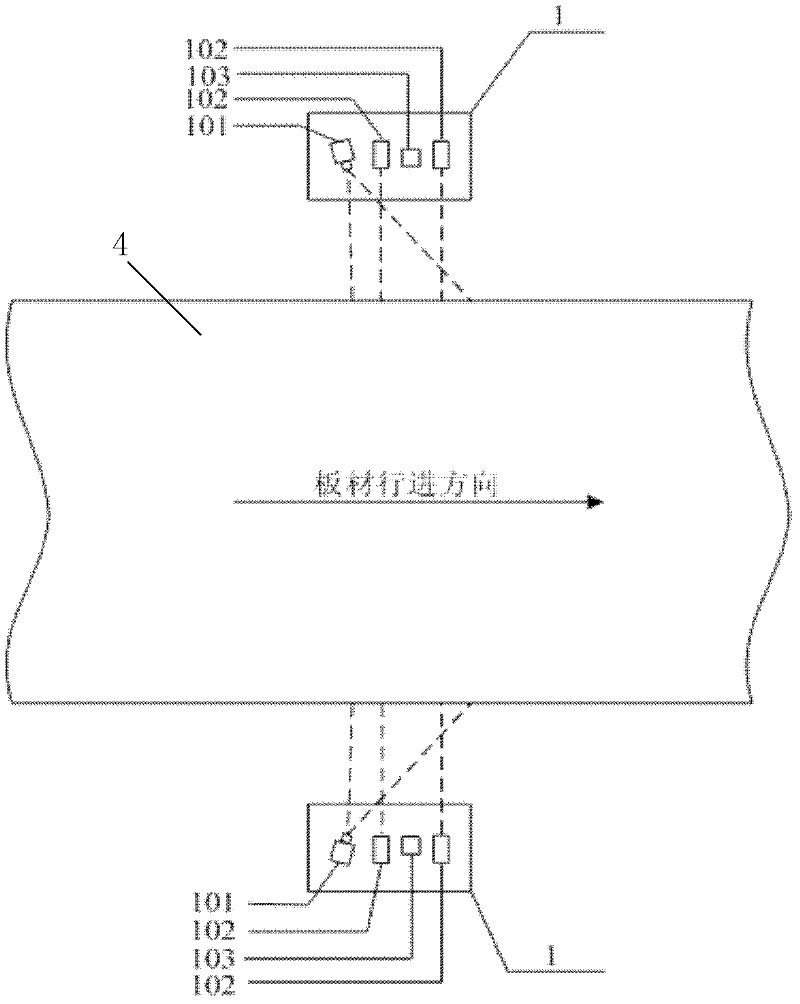

Plate width, side shape and side defect measuring instrument and measuring method thereof

InactiveCN102500627AResolve Edge ShapesSolve edge defectsMeasuring devicesMetal rolling arrangementsMeasuring instrumentDisplay device

The invention discloses a plate width, side shape and side defect measuring instrument and a measuring method thereof; the instrument comprises two sets of side measuring devices, a measurement control cabinet and a displayer; the method comprises the steps that: first, a user calibrates the measurement datum planes of the side measuring devices; second, a linear laser radiates the surface of the thickness direction of a measured plate, and a vertical laser radiation line is formed; third, a high-definition surface scanning camera quickly shoots the changes of the position of the laser radiation line of the side surface of the measured plate which is moving, and an image which is shot by the high-definition surface scanning camera is sent to a data acquisition board card; fourth, the data acquisition board card acquires the position of each point on the laser radiation line of the side surface of the measured plate and transmits the positions to the measurement control cabinet; and fifth, the measurement control cabinet measures the distance between the side of the measured plate and a base position through an optical triangular method, and the plate width, side shape and side defects of the plate are obtained.

Owner:BEIJING ARITIME INTELLIGENT CONTROL

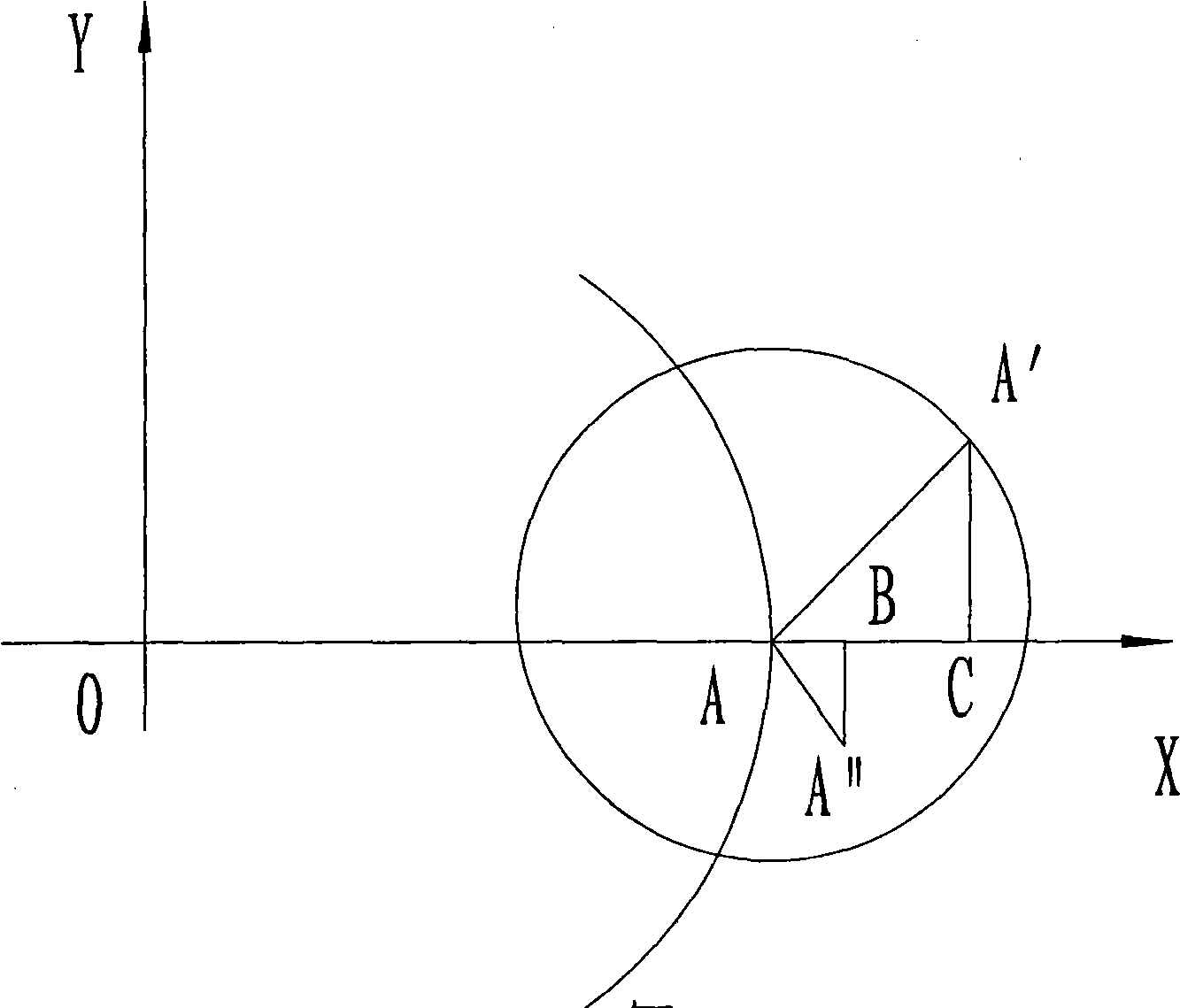

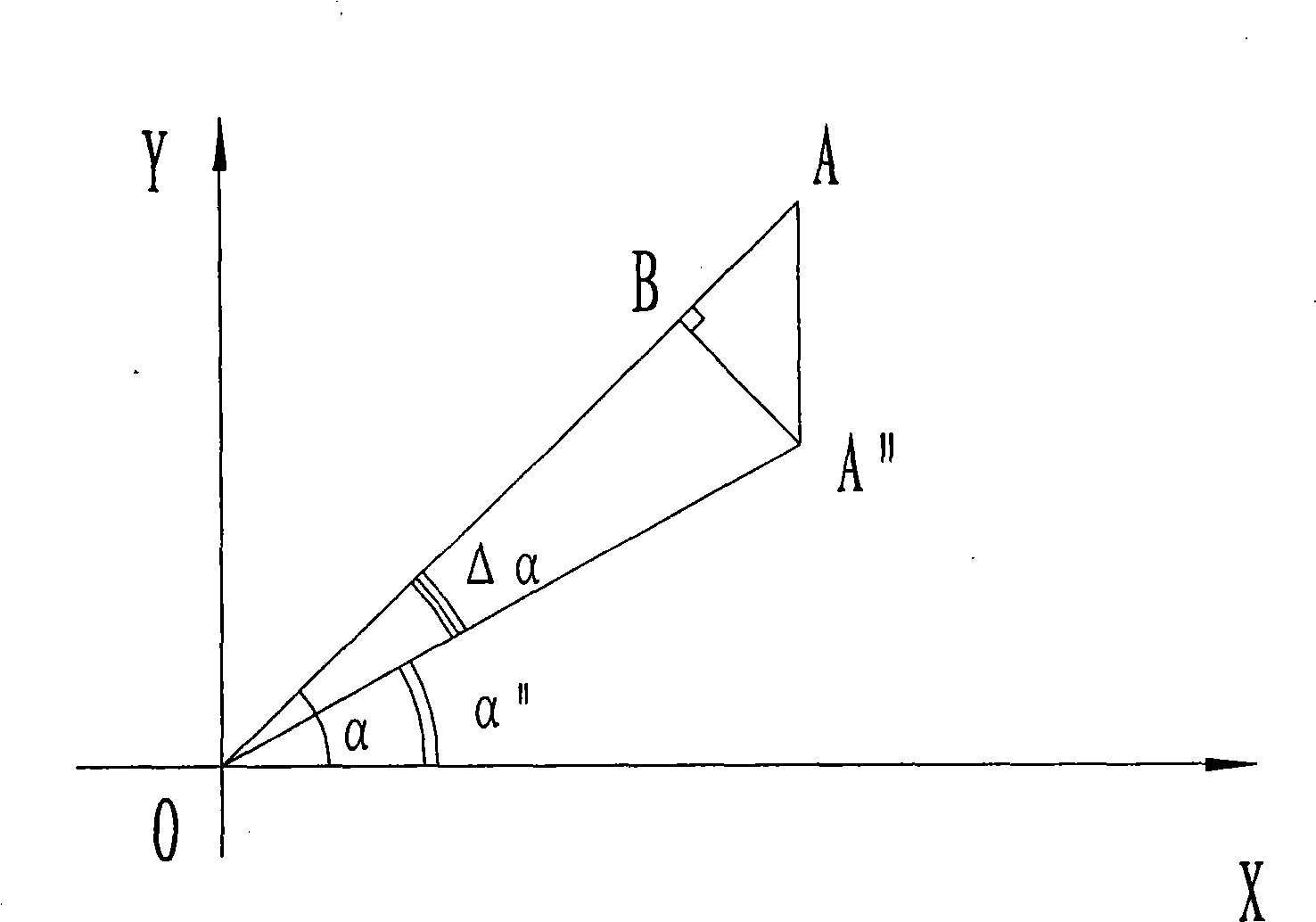

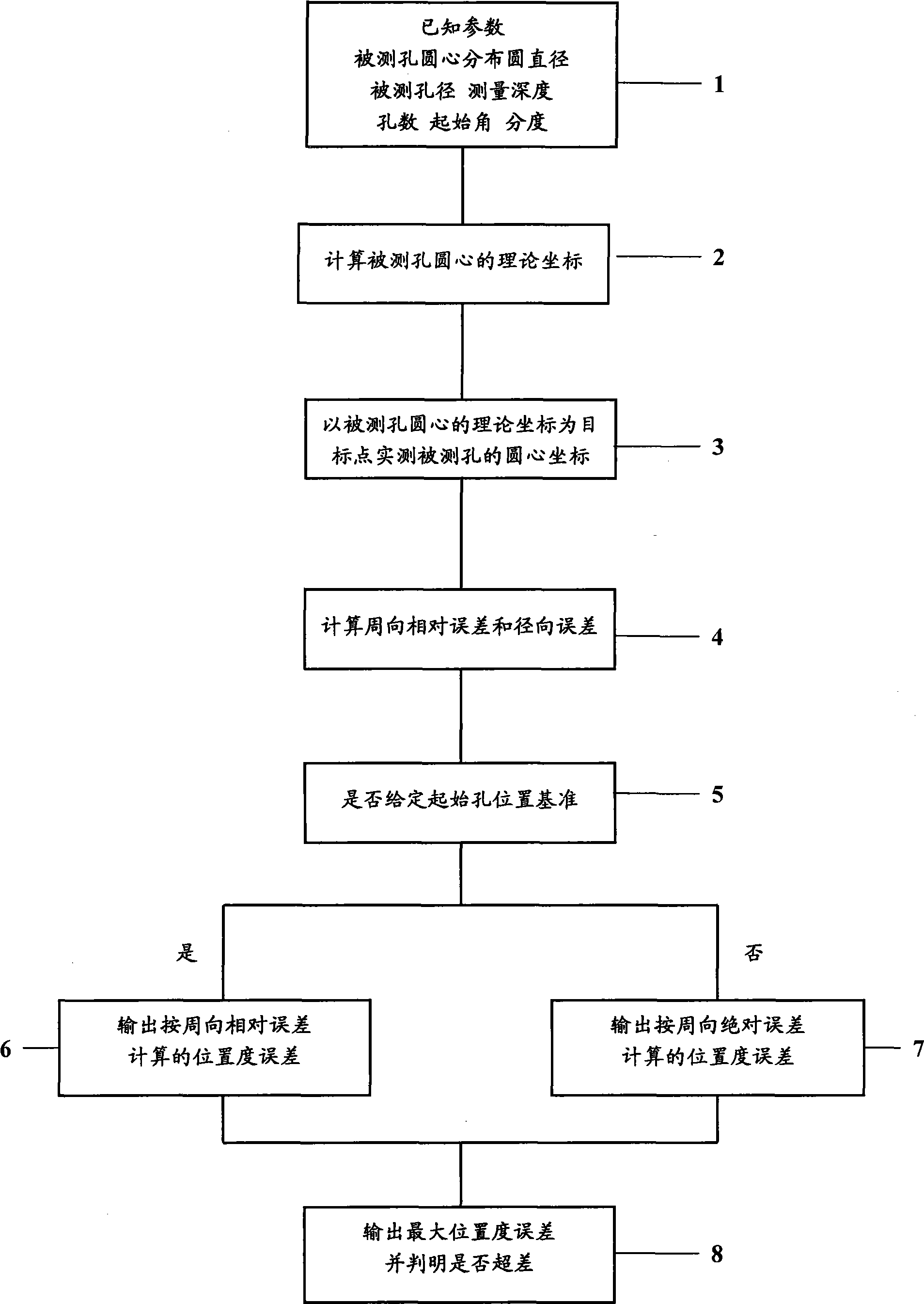

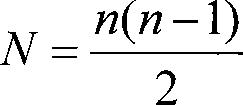

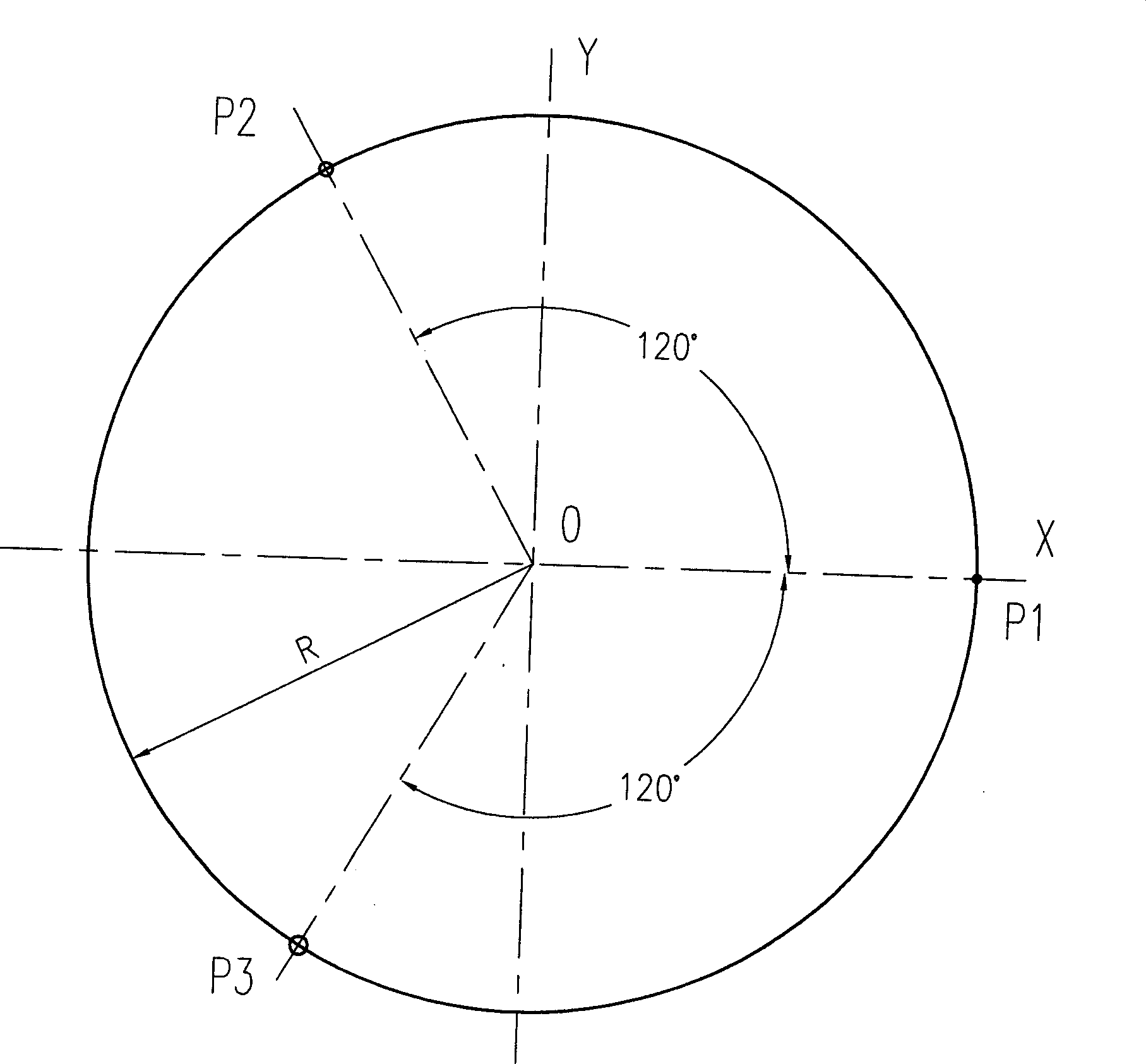

Three-coordinate measuring method for circumferential uniformly-distributed hole true position error

InactiveCN101520296ASolve measurement problemsIncrease productivityMechanical measuring arrangementsRadial errorCoordinate-measuring machine

The invention discloses a three-coordinate measuring method for circumferential uniformly-distributed hole true position error, which comprises the following steps: (1) determining a theoretical coordinate in the center of a circle of a measured hole by calculation; (2) taking the theoretical coordinate in the center of the circle of the measured hole as a target point, and measuring the actual coordinate of the center of the circle of the measured hole; (3) calculating the circumferential relative error and the radial error of the center of the circle of the measured hole; and (4) calculating the true position error according to the circumferential relative error and the radial error or the circumferential absolute error and the radial error, finding out the maximum true position error, and judging whether the maximum true position error exceeds the set error. The three-coordinate measuring method can ensure that a three-coordinate measuring machine realizes automatic measurement and automatic calculation, can accurately measure the benchmark of a given initial datum hole and the benchmark of a non-given initial datum hole, has high universality and simple calculation, and avoids the occurrence that the error caused by the measurement and the calculation makes qualified products in the actual assembly detected as unqualified products so as to bring huge loss to manufactures.

Owner:AVIC HUIYANG AVIATION PROPELLER

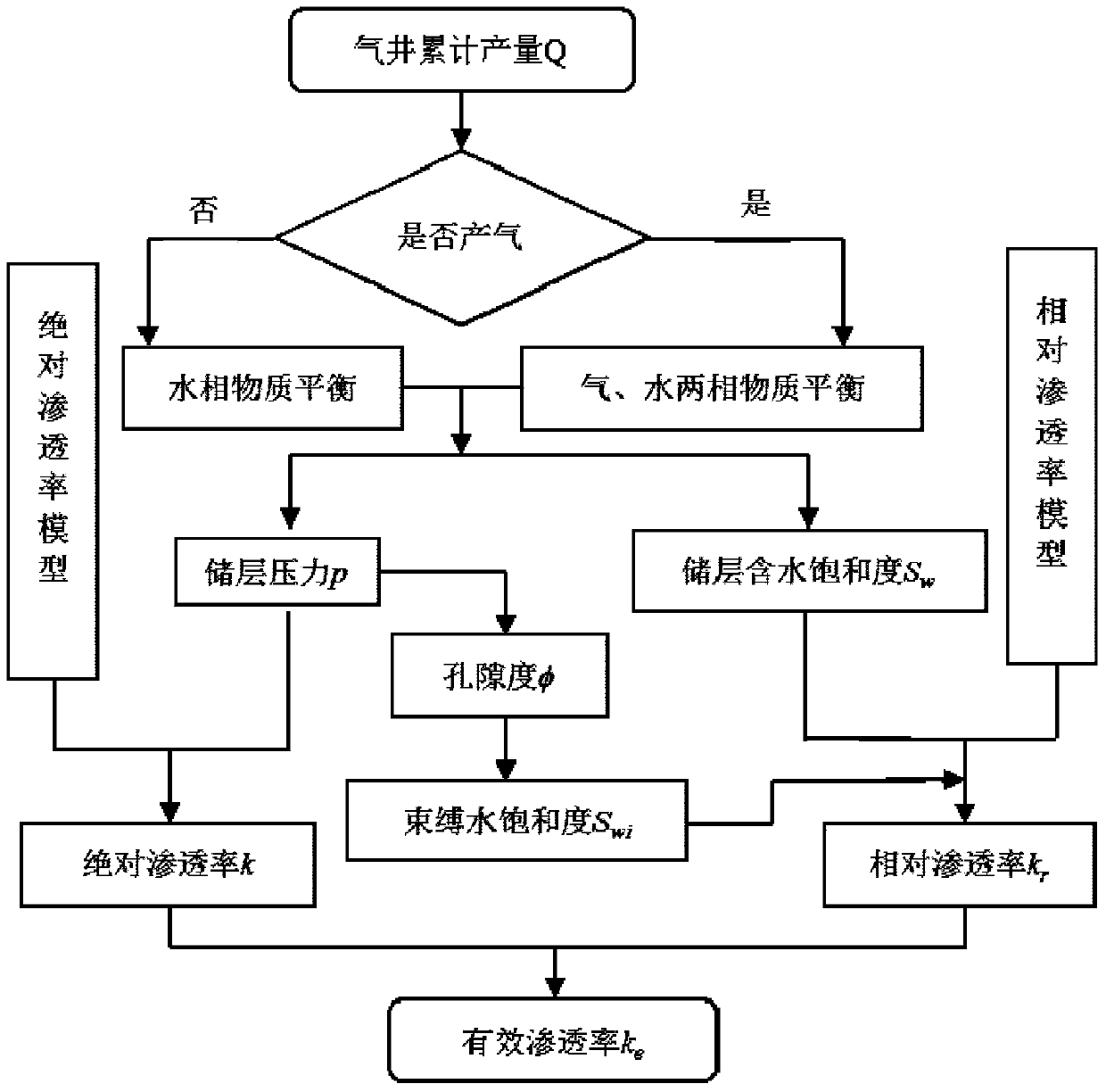

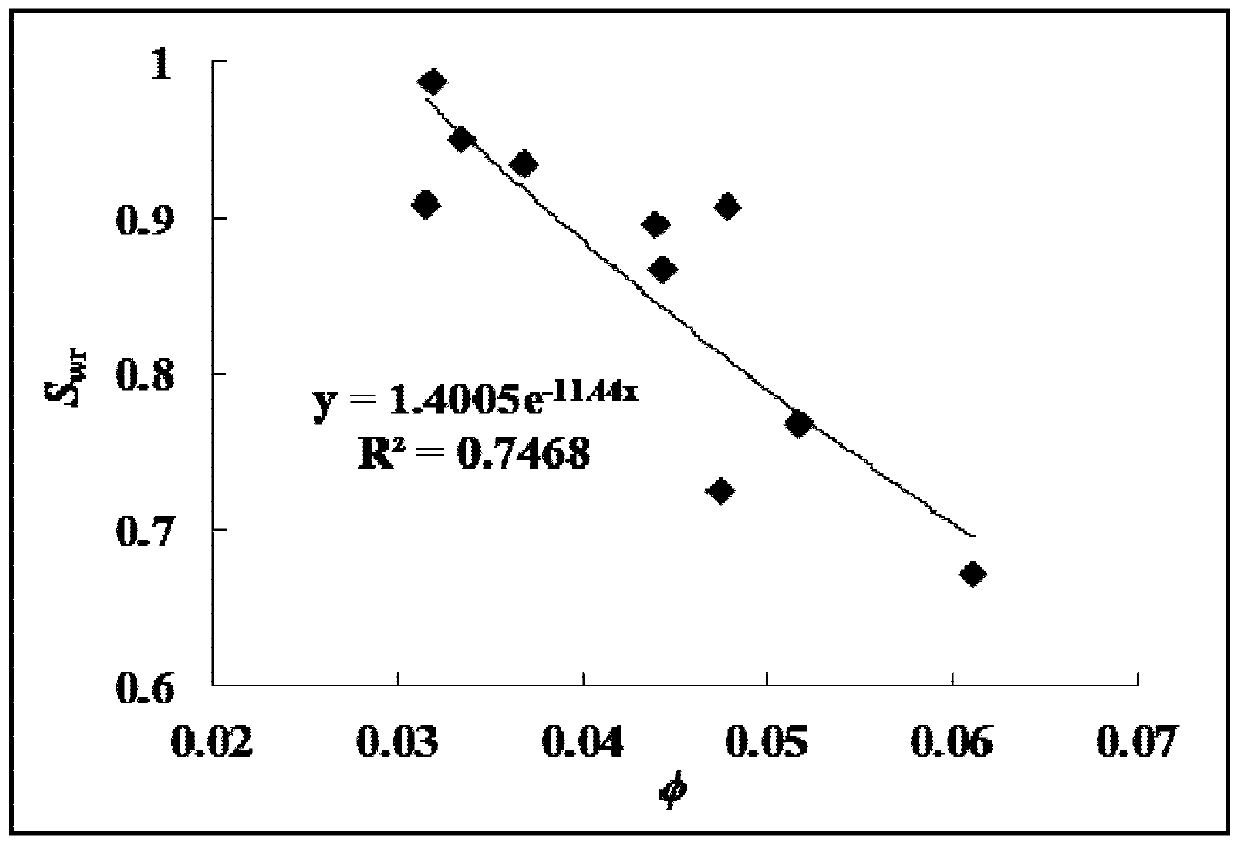

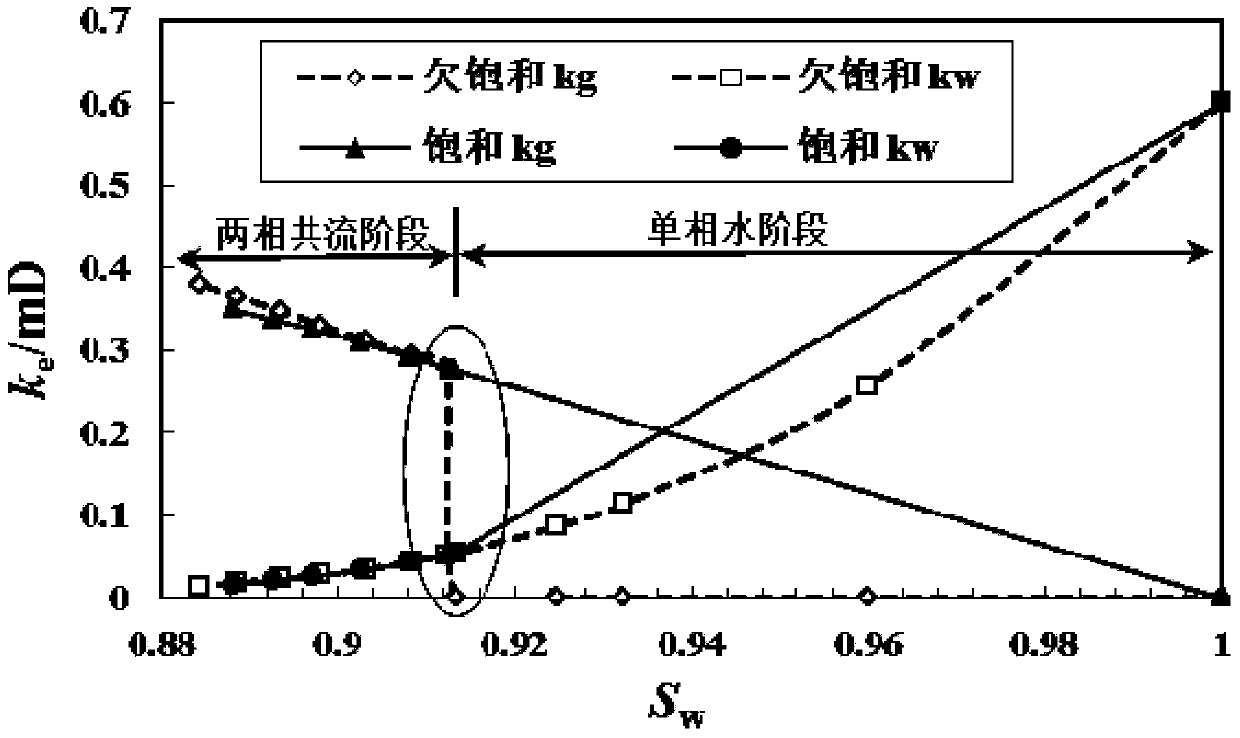

Method for measuring gas and water production dynamic relative permeability curve in undersaturation coal reservoir development

InactiveCN104196524ASolve measurement problemsHigh precisionBorehole/well accessoriesNMR - Nuclear magnetic resonanceWater production

The invention discloses a method for measuring a gas and water production dynamic relative permeability curve in undersaturation coal reservoir development. The method comprises the steps that gas well accumulation production Q is obtained; a production phase of a production well is judged; reservoir pressure p and reservoir water saturation Sw are obtained; the reservoir pressure p is introduced into an improved absolute permeability model, and the absolute permeability K is obtained; irreducible water saturation Swr is predicted by measuring the porosity phi; the reservoir water saturation Sw and the irreducible water saturation Swr are introduced into a relative permeability model, and the relative permeability kr is obtained; the relative permeability and the absolute permeability are coupled on the condition of the identical the reservoir pressure p and the identical reservoir water saturation Sw, and the effective permeability ke at the moment is obtained. The method solves the problem of measuring the undersaturation coal reservoir gas and water relative permeability curve, the positive and negative effects and the slippage effect in the developing process are taken into consideration, the changes of a two-phase common flow area relative permeability curve can be represented, the changes of a single-phase water stage relative permeability curve can be better represented, the influence of water invasion is taken into consideration, and the actual production of undersaturation coal gas reservoirs are better met; a nuclear magnetic resonance method is used, convenience, fastness and non-destruction are achieved, precision is higher, and practicability is higher.

Owner:CHINA UNIV OF GEOSCIENCES (BEIJING)

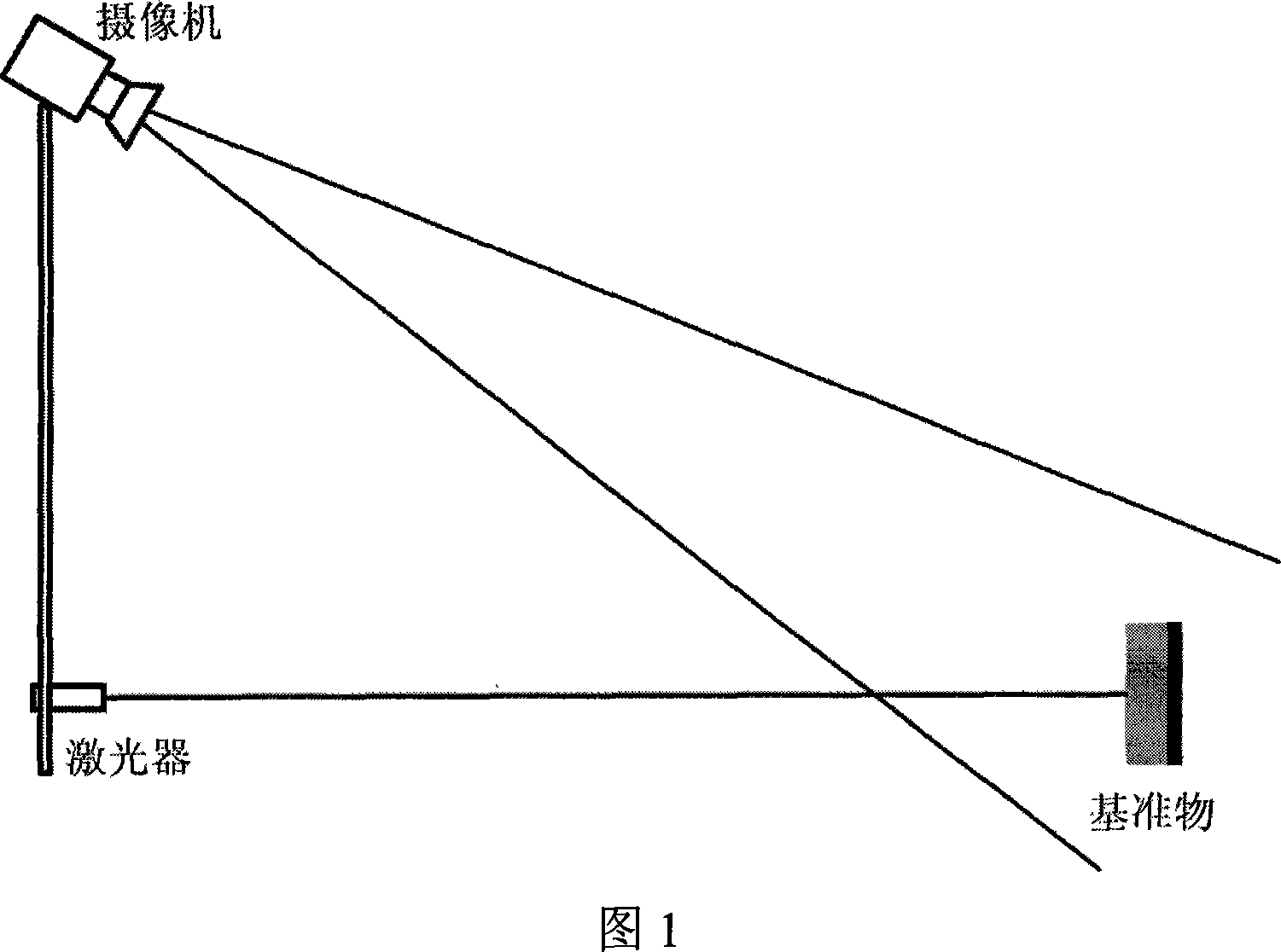

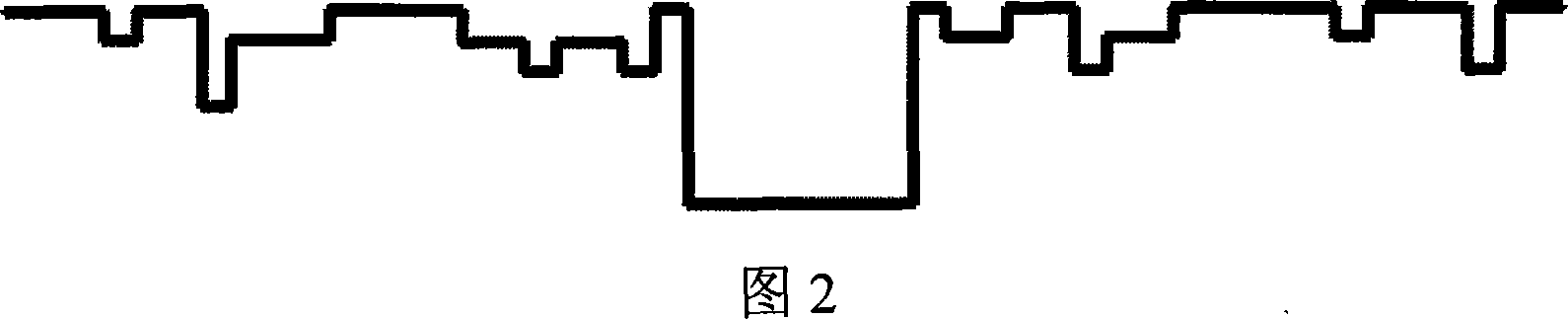

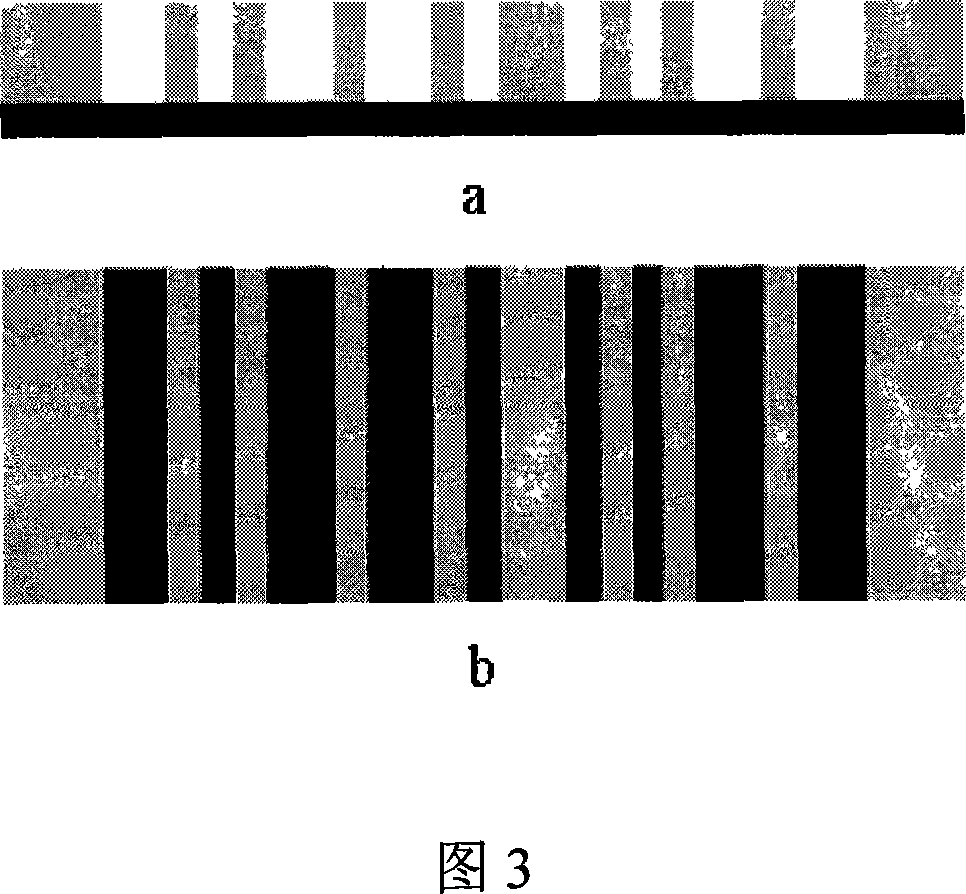

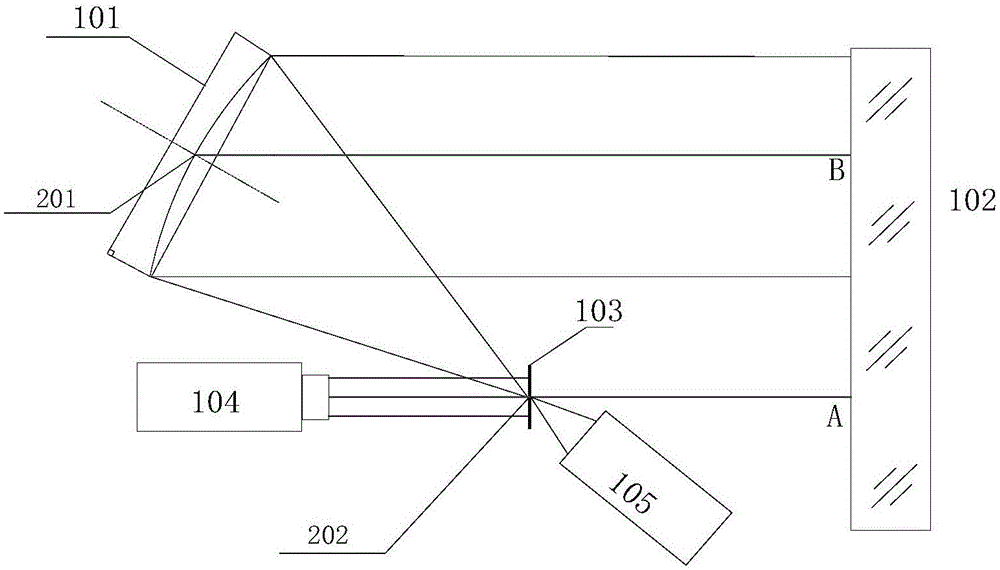

Laser image measurement based coal coke oven carbonization chamber position detection method

InactiveCN101059338AImprove adaptabilityImprove reliabilityPicture interpretationLaser transmitterLocation detection

The invention relates to a coal coke oven charring room position measuring method based on laser image measurement, wherein an oven opposite to the door of coal coke oven charring room is arranged with a reference body, an engine is arranged with a straight laser emitter and a camera to pick the laser image information of reference body, to recognize the reference body via the relationship between the orthogonal coordinate of laser line in the image and the surface concave-convex size of the oven, to calculate the position error between the engine and the target door of the charring room, via the horizontal pixel of reference body in the image. Or else, the invention uses a solid bar code to replace the reference body, to read inside code information via picked solid bar code laser image, to recognize the serial number of the charring room door via the code, and calculate out the position error between the horizontal pixel and the charring room door via the bar code. The inventive measuring method belongs to non-contact absolute position measuring technique, with strong adaptability on the coke oven producing condition, to realize oven number recognition and accurate measurement of door position error.

Owner:赵跃

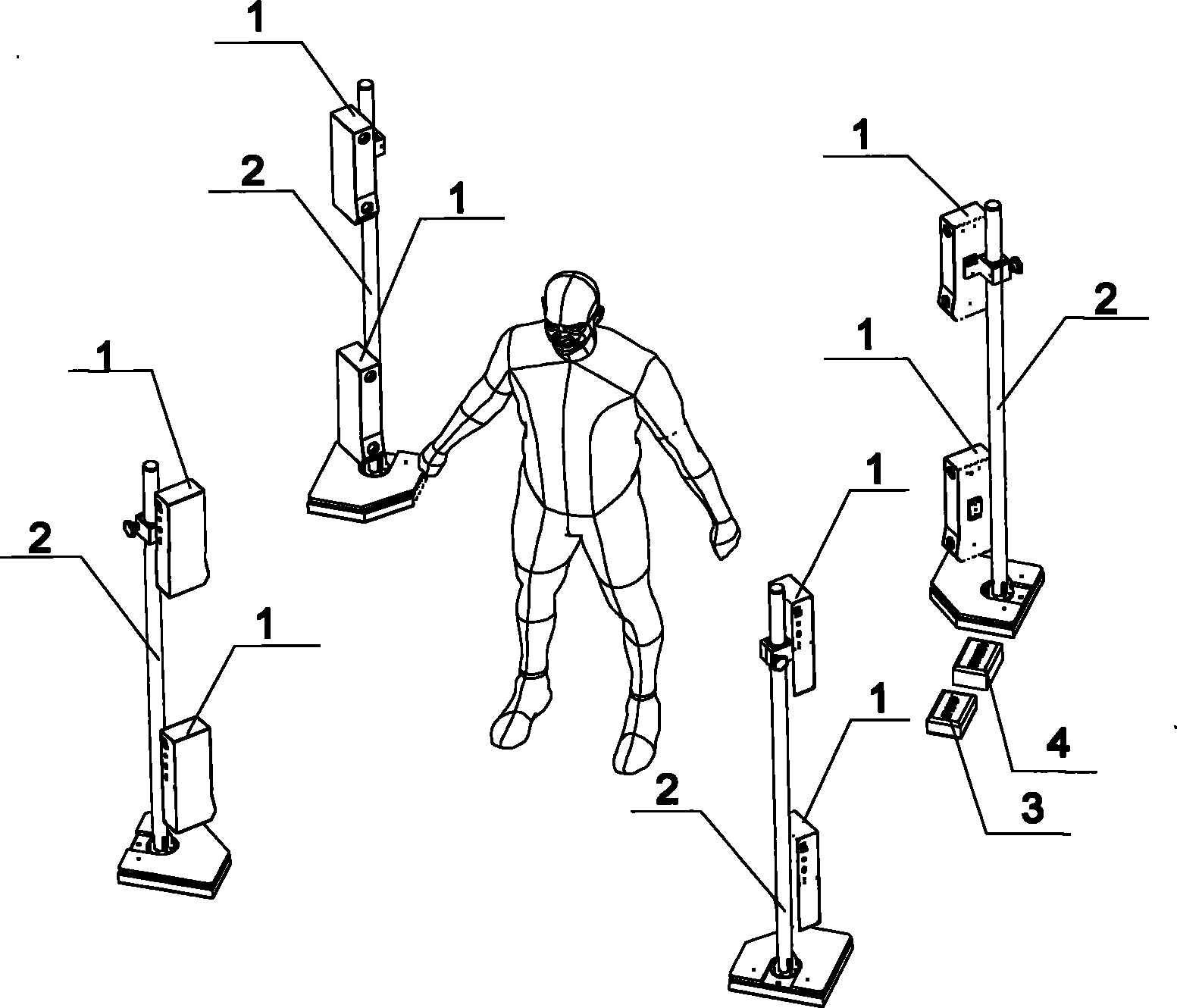

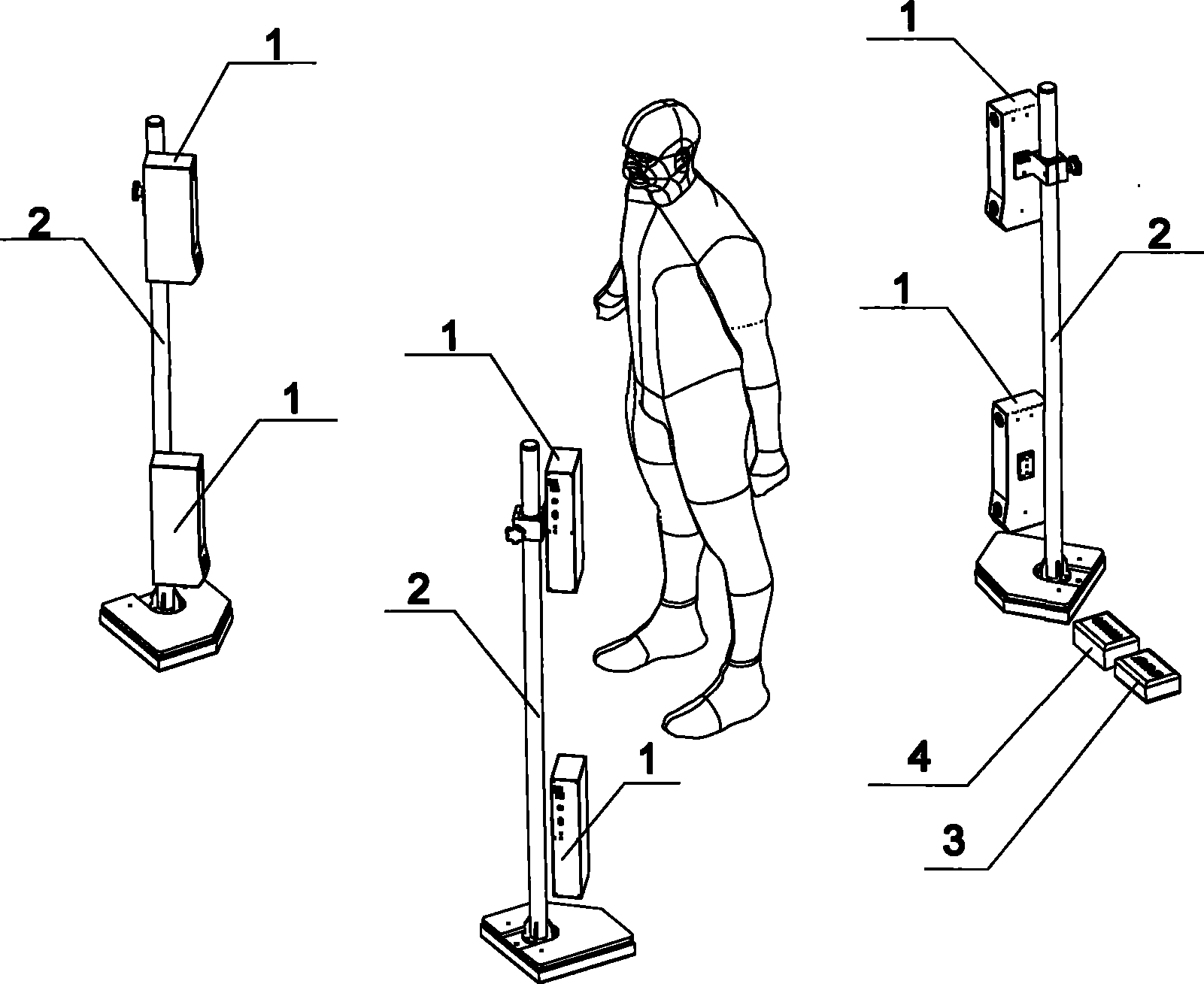

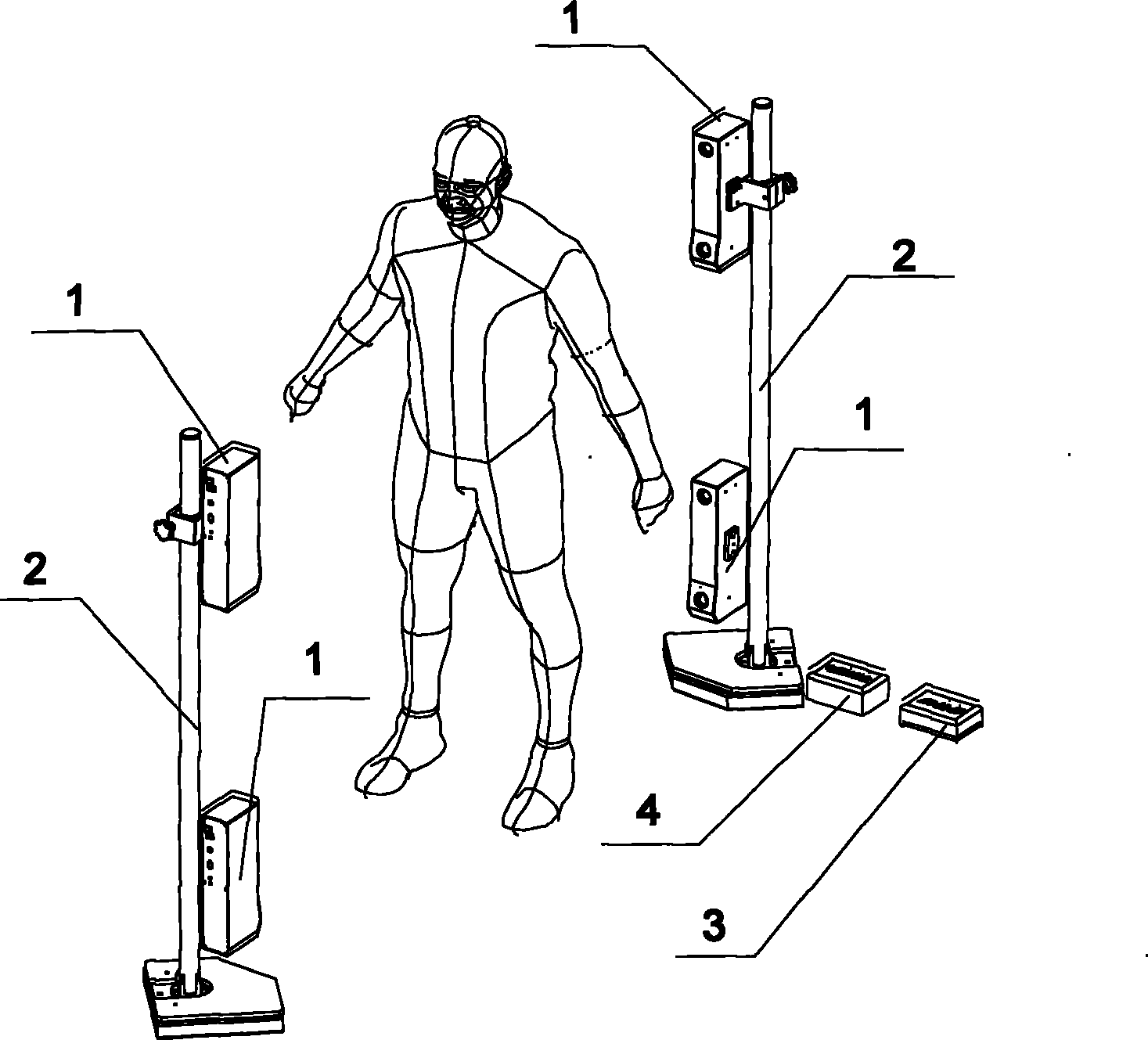

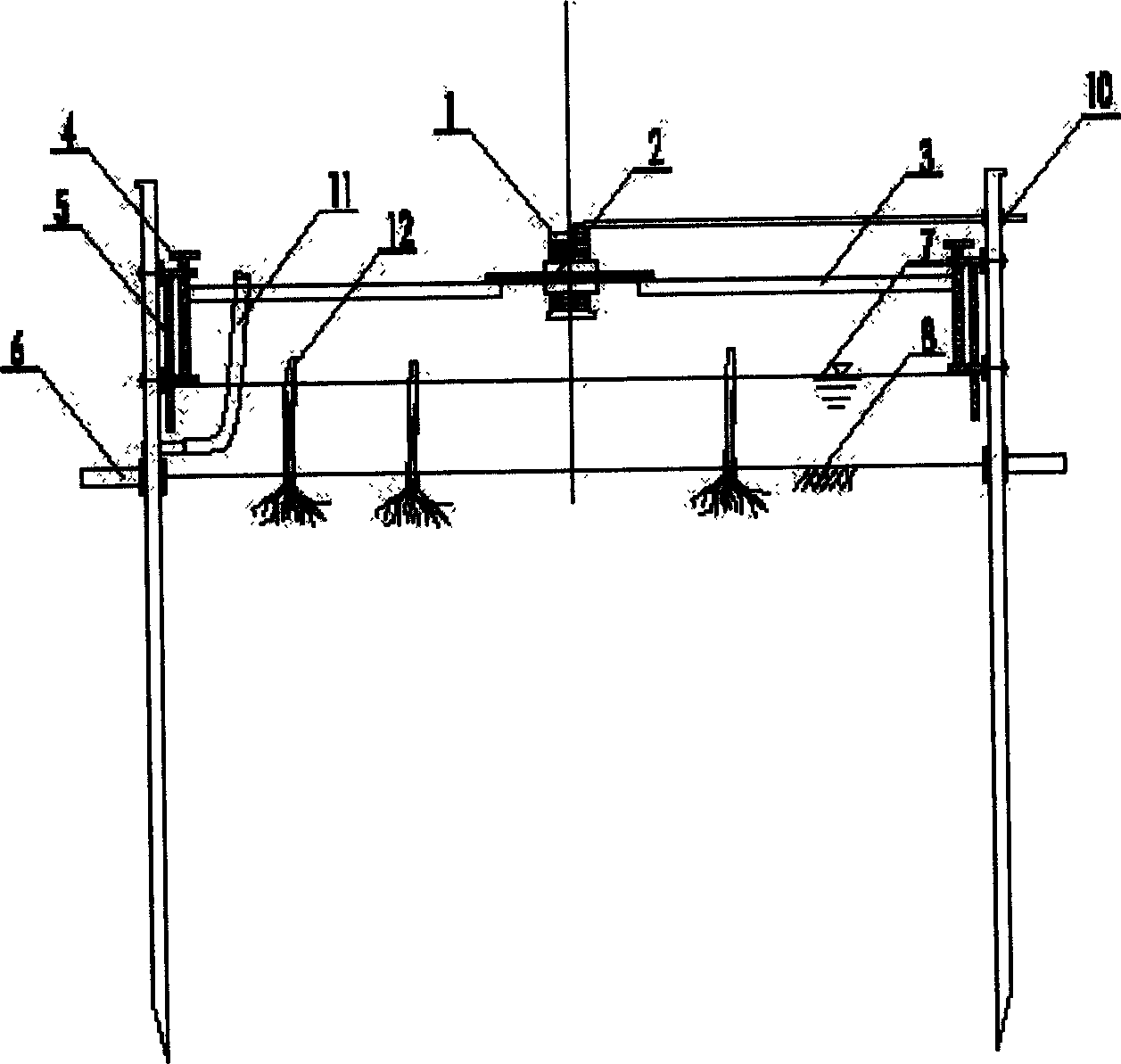

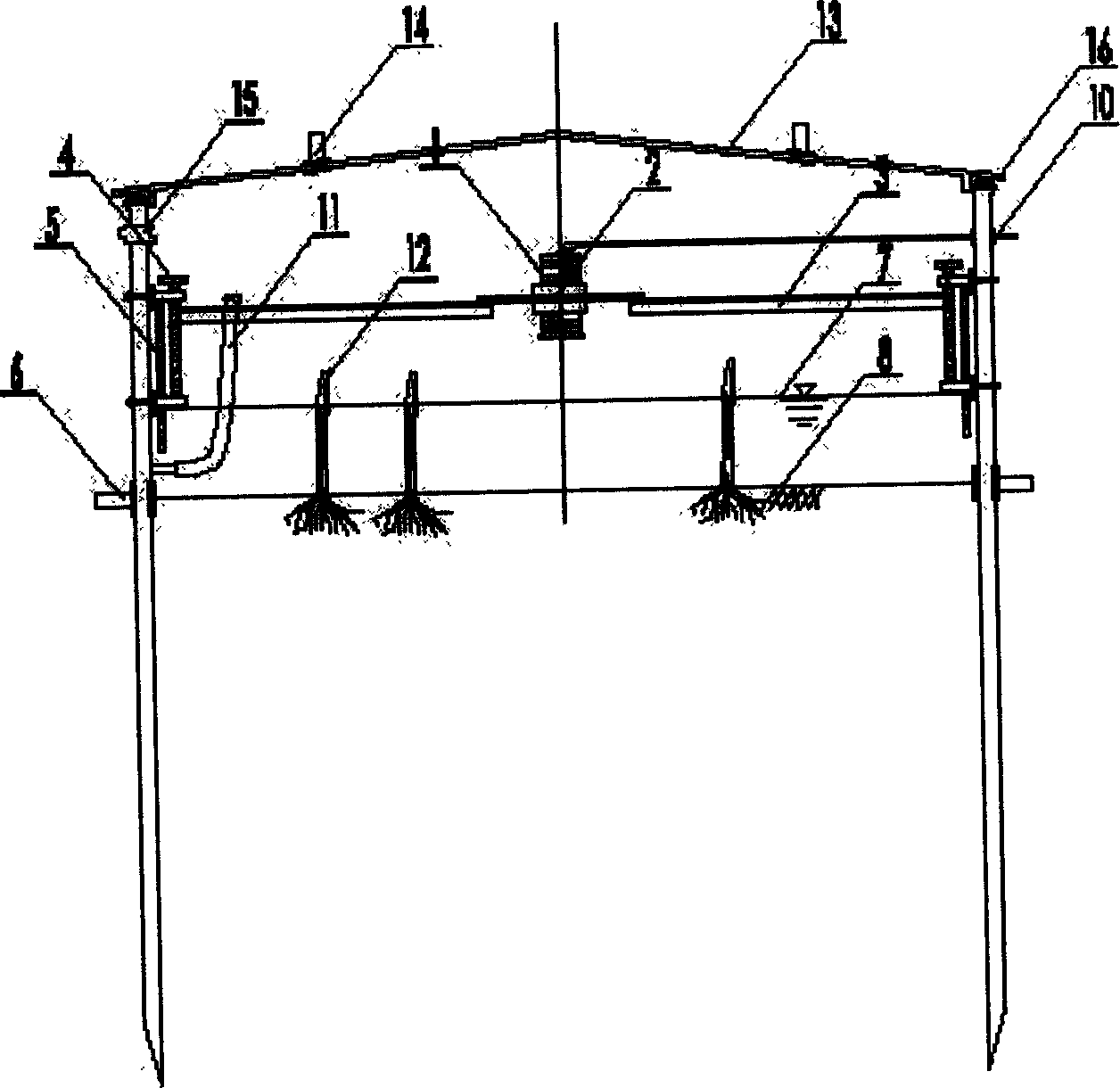

Multi-scanner fast human body three-dimensional scanning system

InactiveCN103263249ASolve measurement problemsDiagnostic recording/measuringSensorsContinuous scanningHuman body

The invention discloses a multi-scanner combined fast human body three-dimensional scanning system which is professional and capable of acquiring human body three-dimensional data rapidly. The system comprises a plurality of monocular vision optical scanners which are in coordination with a continuous scanning switch control technique, and the scanning system can acquire human body three-dimensional data in 6 seconds. The scanning height of the scanning system is 2100mm. The scanning system can be combined flexibly according to actual needs, including a eight-scanner whole-body combination, a six-scanner whole-body combination, a four-scanner whole-body combination, a four-scanner half-body combination, a three-scanner half-body combination and a two-scanner half-body combination. The multi-scanner combined fast human body three-dimensional scanning system is simple in structure, free of motion mechanisms, and convenient to maintain. The used LED cold light sources are harmless to human bodies. Size of various parts of human bodies can be acquired fast by the scanning system in coordination with parameter extraction software, so that the scanning system is quite applicable to clothing industries.

Owner:3D CAMEGA

Method for detecting coaxiality and verticality of large container by optical instrument

ActiveCN101929852AEasy and fast measurementRealize autonomous measurementUsing optical meansOptical axisEngineering

The invention relates to a method for detecting coaxiality and verticality of a large container by an optical instrument. The large petrochemical containers have common characteristics such as complicated structure, large geometric dimension and high manufacturing precision requirement. The method for detecting coaxiality and verticality of the large container by the optical instrument comprises the two steps of: (1) establishing a datum axis line by using a micro-alignment telescope, mounting a triangular centre bracket at a measured seal head, and reading an offset value of the bracket centre relative to the datum axis line by a micro-drumwheel; and (2) arranging a verticality measuring scale at the end face of the measured seal head, enabling an auto-collimation image to be completely superposed with a local image with an auto-collimation method when a reflector or a large reflection object in front of the telescope is vertical to the principal optical axis of the telescope, if the auto-collimation image is not superposed with the local image, adjusting the included angle between the large reflection object and the principal optical axis of the telescope to enable the auto-collimation image to be completely superposed with the local image, and computing the value of the verticality by using the scale value of a displacement graticule on the telescope and the read value of the micro-drumwheel. The invention is used for detecting the coaxiality and the verticality of the large container.

Owner:HARBIN BOILER

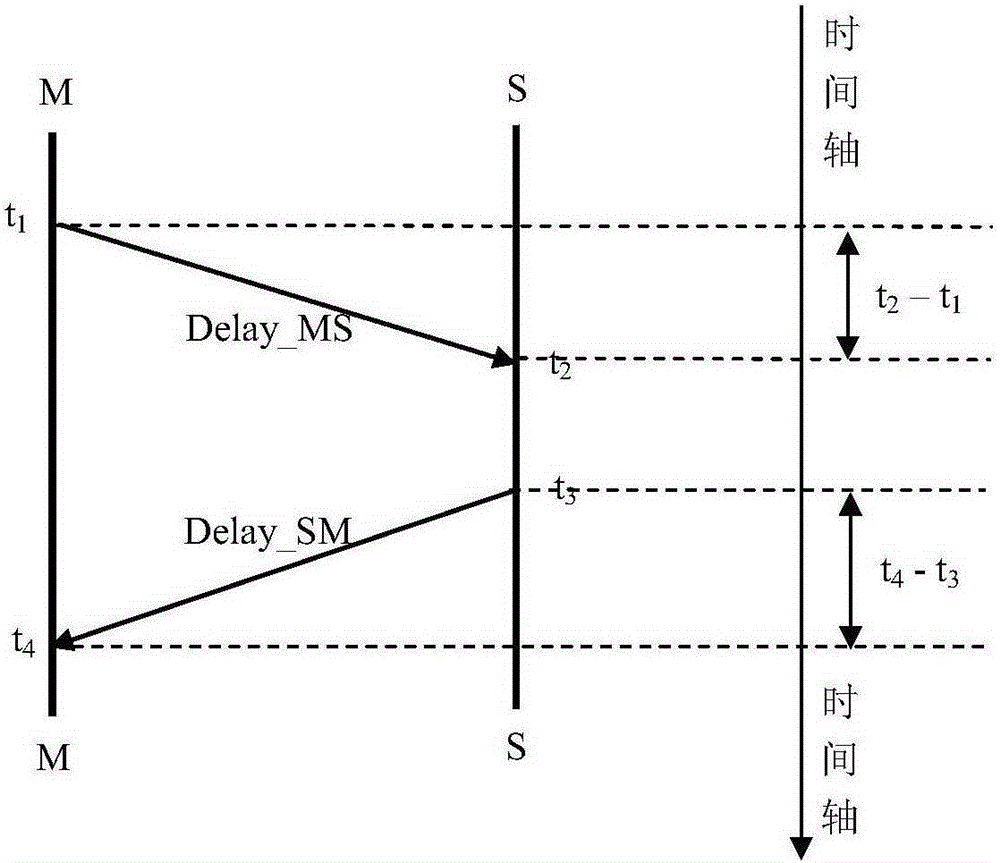

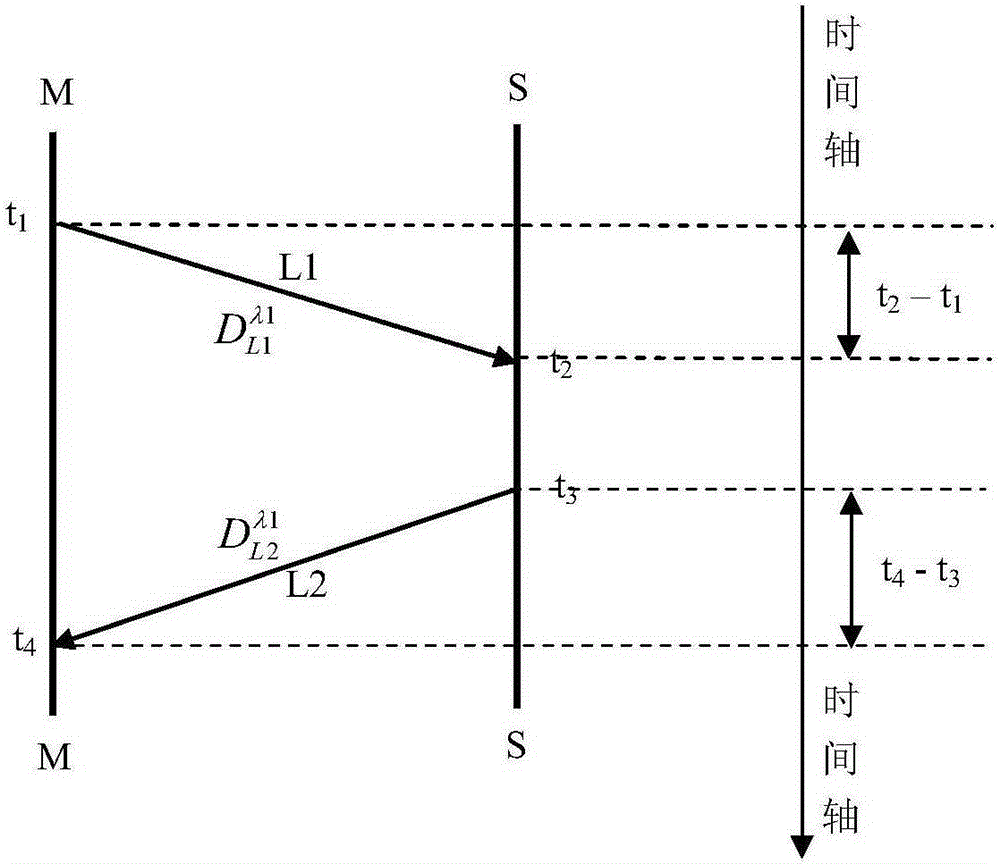

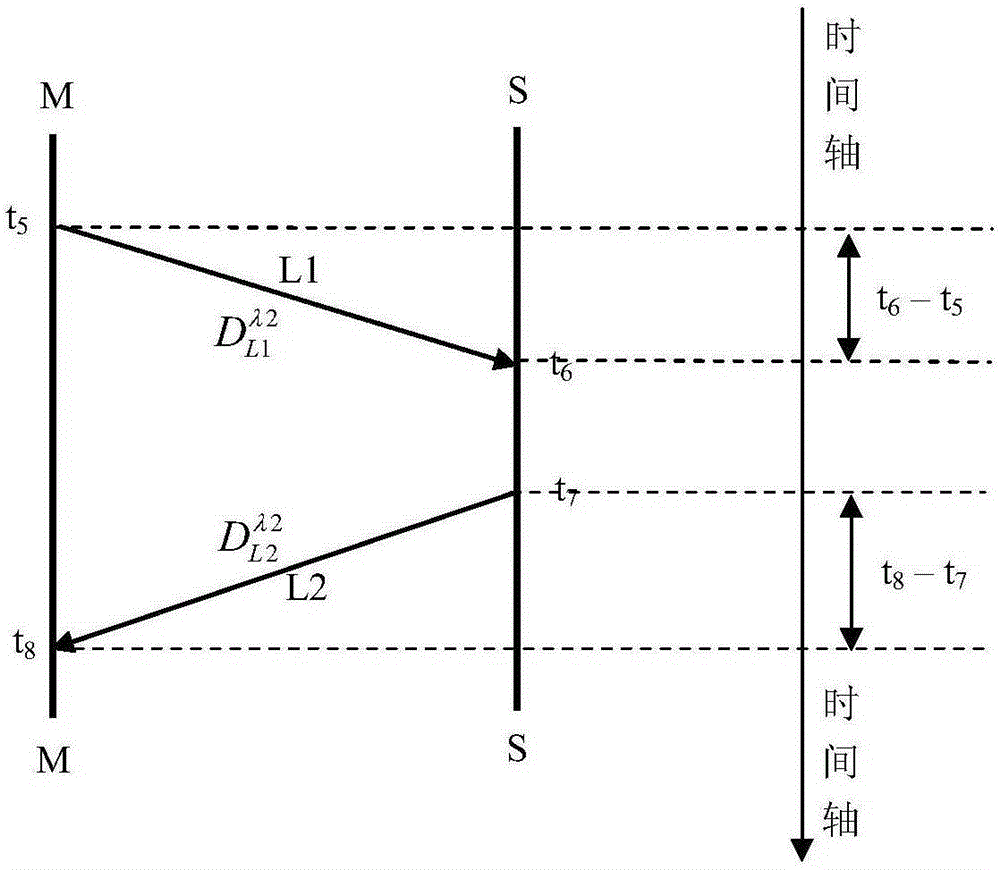

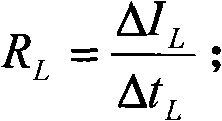

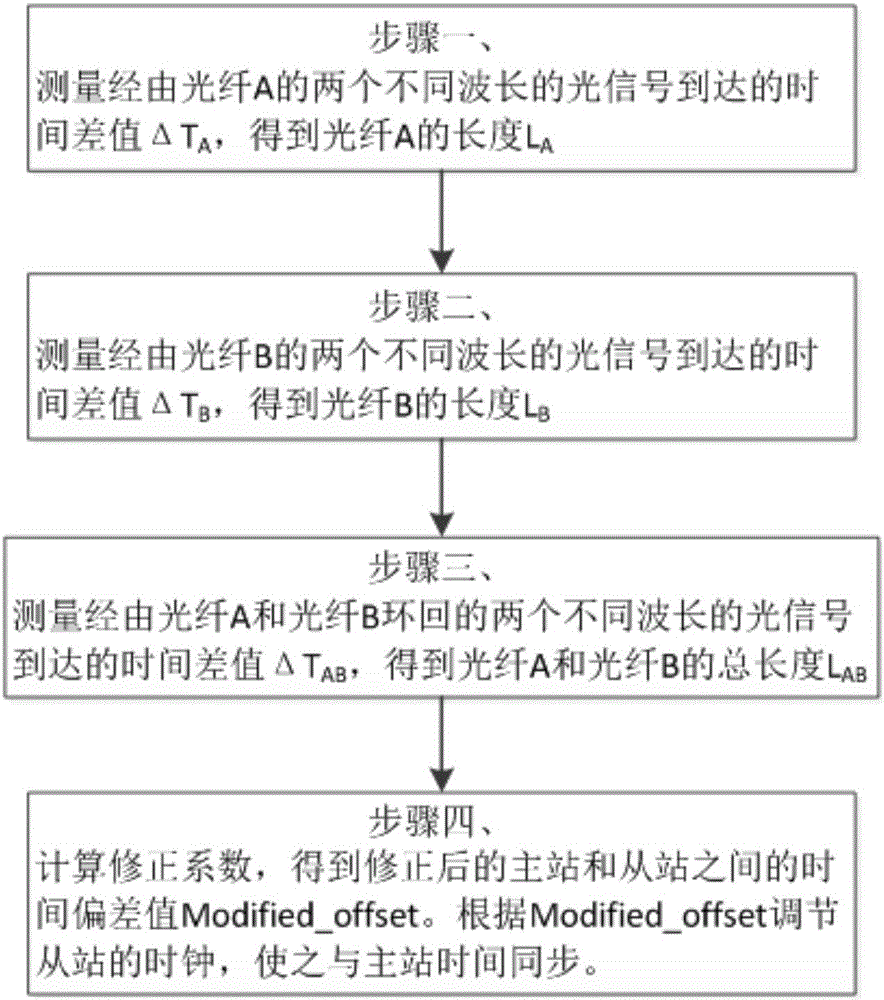

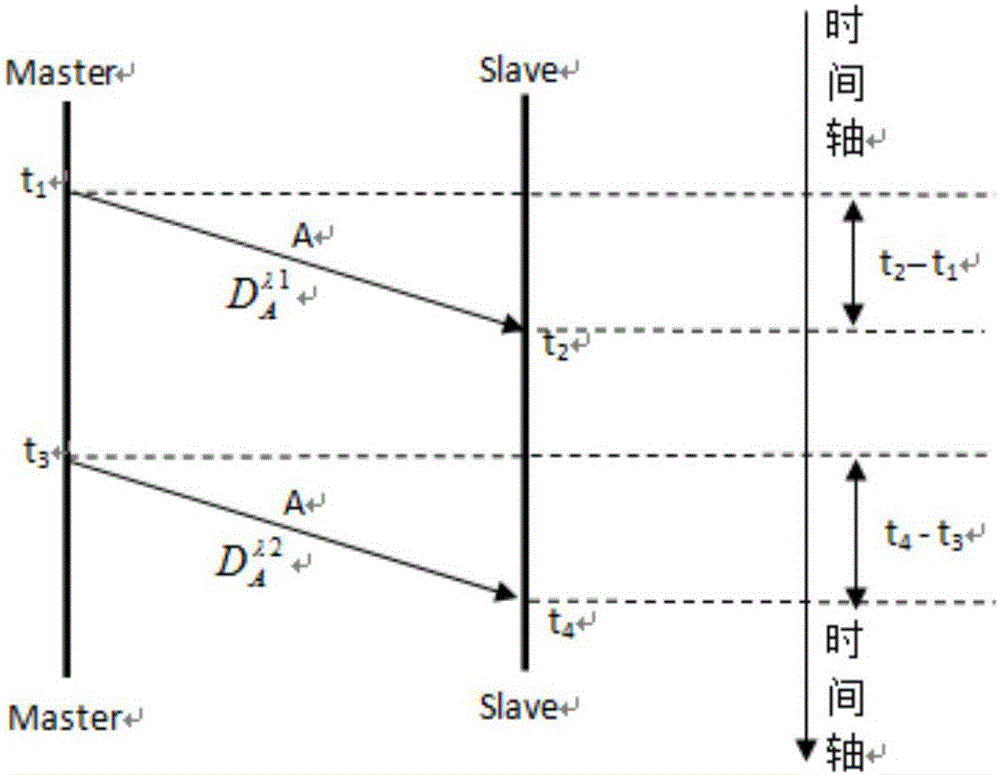

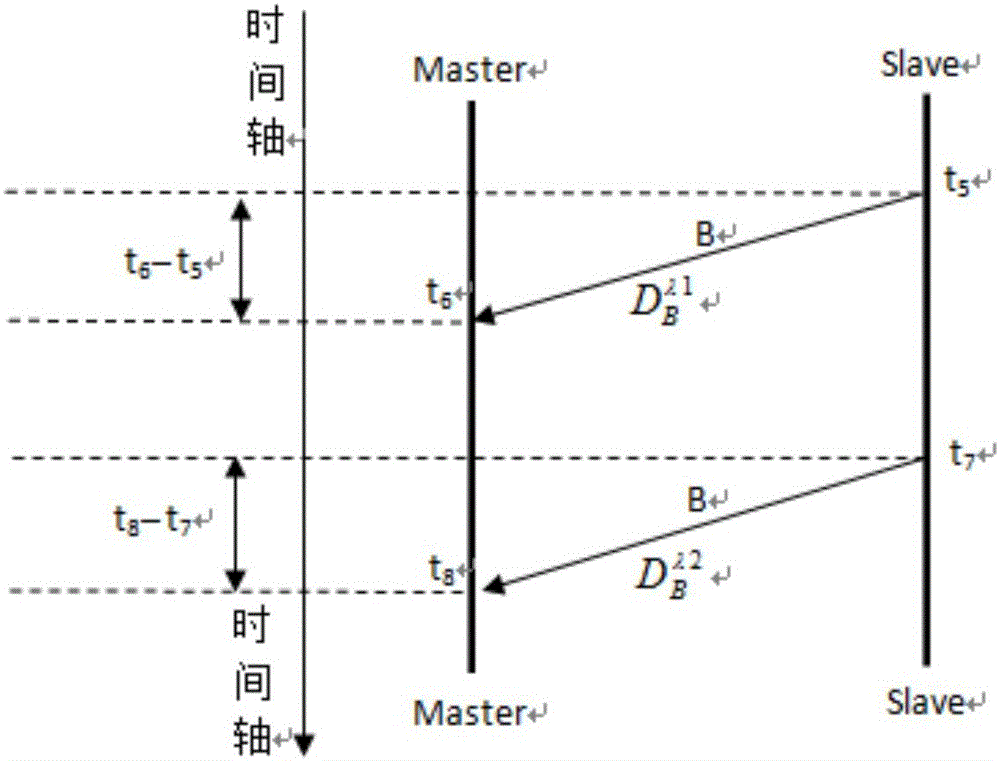

Method and device for measuring optical fiber transmission link asymmetric time delay

ActiveCN105187275ASolve asymmetric delaySolve the measurement problem of asymmetric delayElectromagnetic transmissionData switching networksTime delaysOptical communication

The invention discloses a method and a device for measuring optical fiber transmission link asymmetric time delay, relating to the optical communication technology field and high precision time frequency synchronization technology field. The method disclosed by the invention comprises steps of transmitting optical signals having wavelengths of ^1 and optical signals having wavelength of ^2 between a main station device and a slave station, obtaining moment values of the main station and the slave station which mutually transmit and receive messages, and calculating the optical fiber link asymmetric time delay value between the main device and the slave device according to the moment value and performing synchronization correction.

Owner:四川泰富地面北斗科技股份有限公司

System and method capable of extending lower limit of gas micro-flow calibration to 10<-14> Pam<3>/s

InactiveCN102928172AGood high vacuumHigh sensitivityDetection of fluid at leakage pointTesting/calibration apparatusGas cylinderSolenoid valve

The invention relates to a system and a method capable of extending the lower limit of gas micro-flow calibration to 10<-14> Pam<3> / s, which are used for the calibration and the test on vacuum holes, a leak detector and a gas micro-flowmeter. The system comprises a mechanical pump, two solenoid valves, six vacuum valves, two molecular pumps, a mass spectrum analysis chamber, a small hole, two degasifier pumps, a pressure stabilizing chamber, three vacuum gauges, a gas bomb, a micrometering valve and a quadrupole mass spectrometer, wherein the degasifier pumps are adopted to pump the pressure stabilizing chamber so as to eliminate the influence on the pressure measurement caused by non-inert gas released by the wall of the pressure stabilizing chamber, a magnetic floating rotor gauge is adopted to accurately measure the gas pressure P in the pressure stabilizing chamber, the gas in the pressure stabilizing chamber is input into the mass spectrum analysis chamber through the continuous expansion of the existing flow guiding hole, the calibration is realized by adopting an accumulation method, and the measurement and calibration technologies of the micro-flow of minimum gas within the scope being 10<-11>-10<-14> Pam<3> / s can be realized.

Owner:北京宏宇永达科技发展有限公司

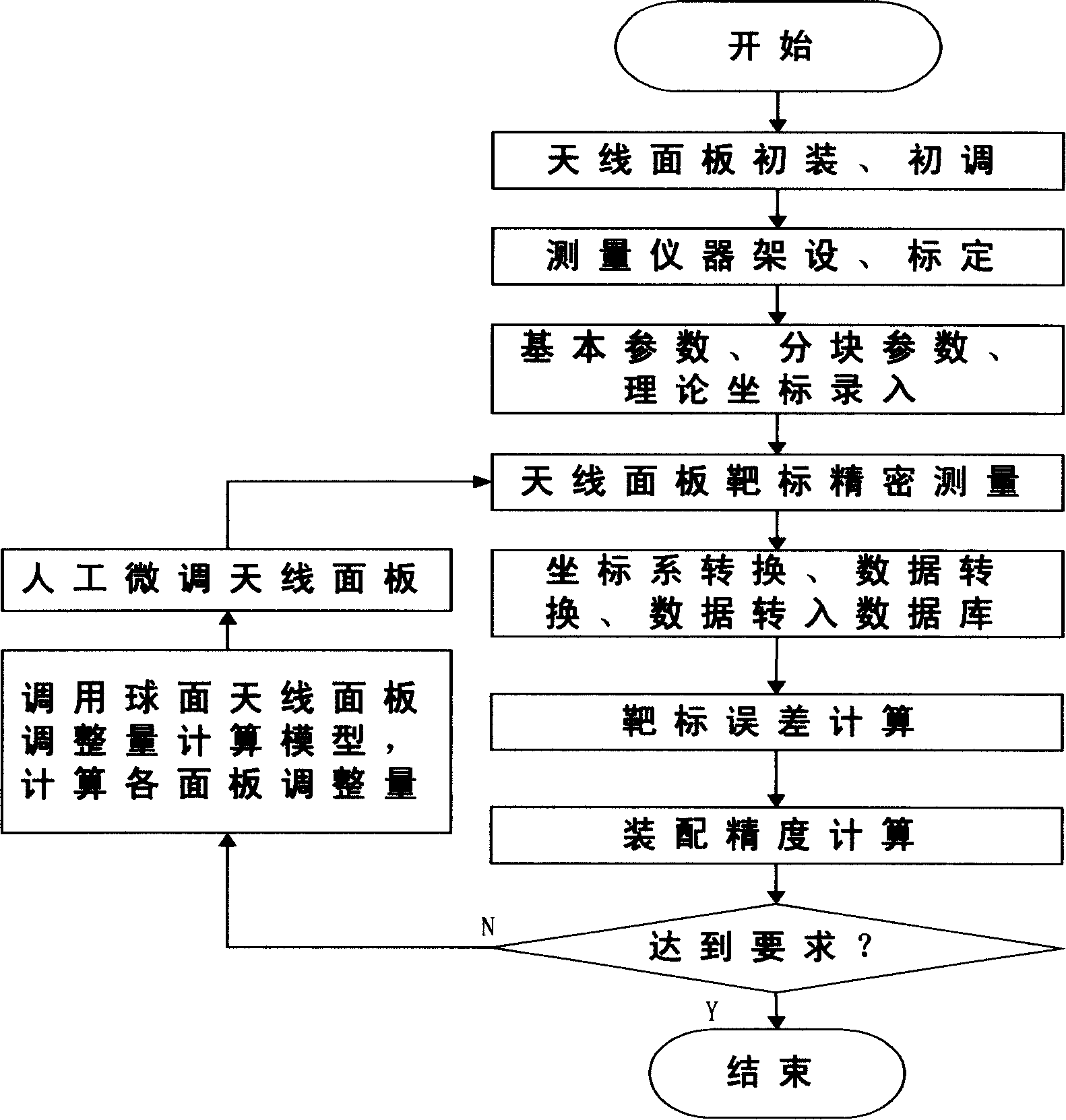

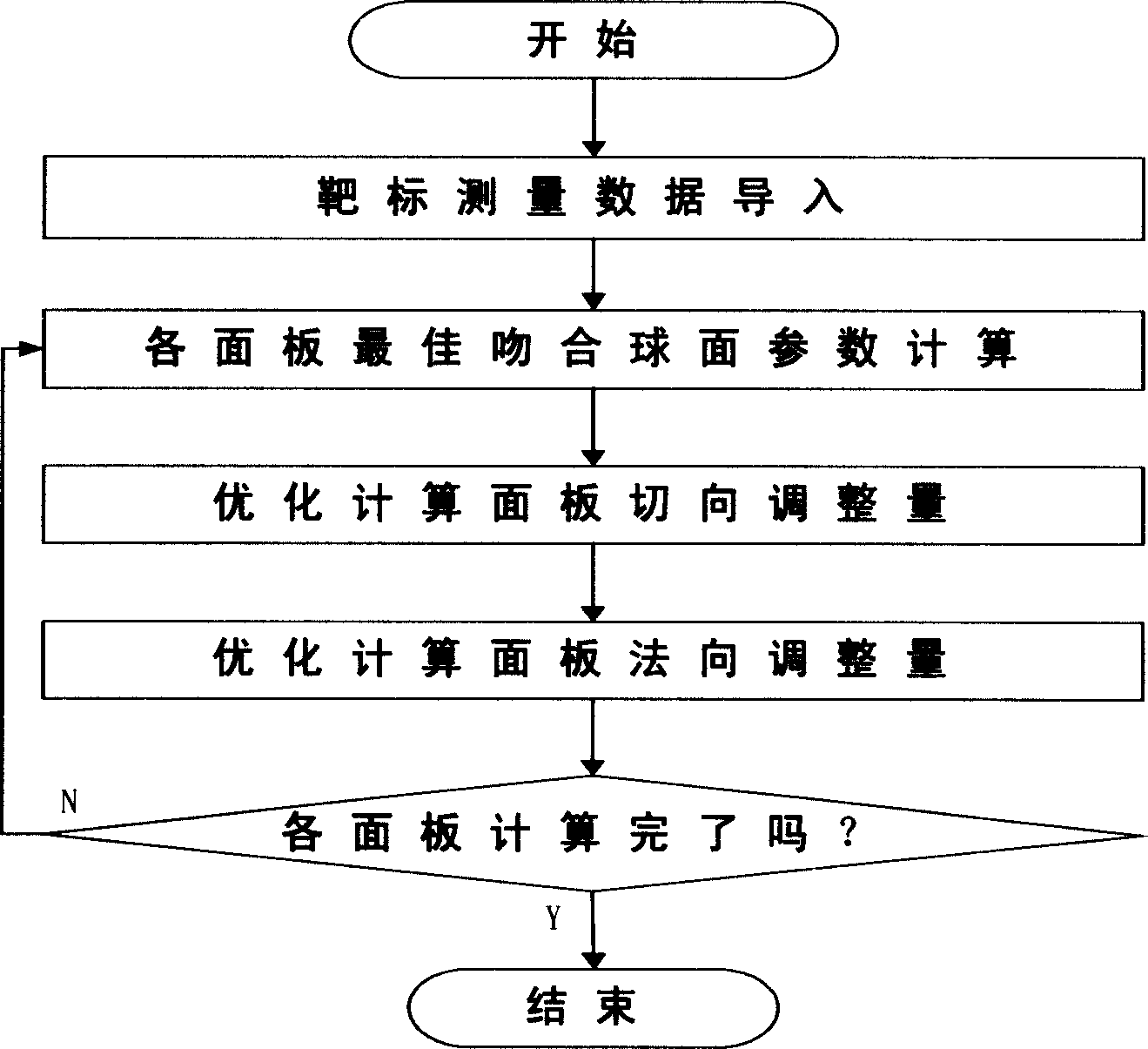

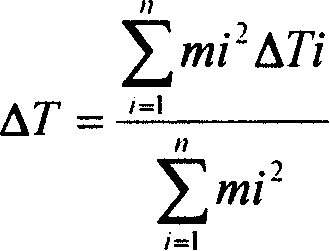

Large-scale high precision spherical antenna panel measuring and assemblage adjusting method

InactiveCN1764013AHigh measurement accuracyImprove measurement efficiencyElectrically short antennasTheodoliteComputer science

The invention discloses a measurement and installation regulation method for large-scale high-accuracy spherical antenna panel, which comprises: completing nun-contact real-time three-dimension coordinate measurement of antenna panel target ento-ectad from circle to circle with high-accuracy electronic theodolite controlled by computer; building relation between coordinate systems according to measured data to translate target coordinate from measurement coordinate system to antenna coordinate system, translating the data and inputting into software database, and optimizing the tangential and normal regulation values of every panel regulation point; according to calculated result, making space reflection plane coincidence to designed target reflection surface; repeating the said process till satisfying accuracy require. This invention has high regulation accuracy and wide application.

Owner:XIDIAN UNIV

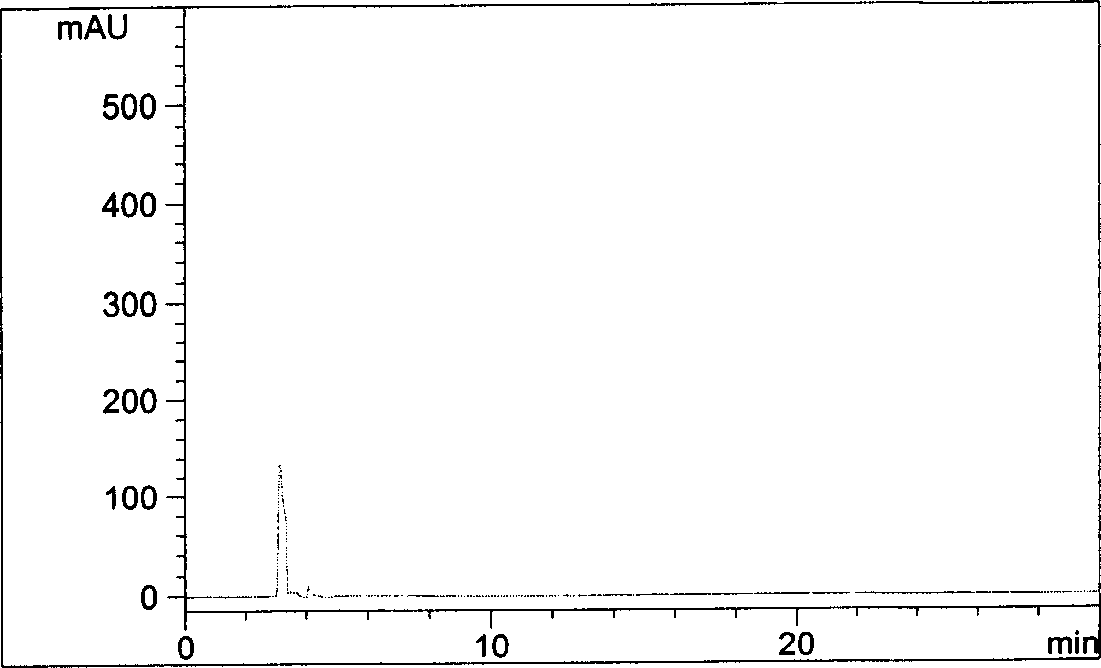

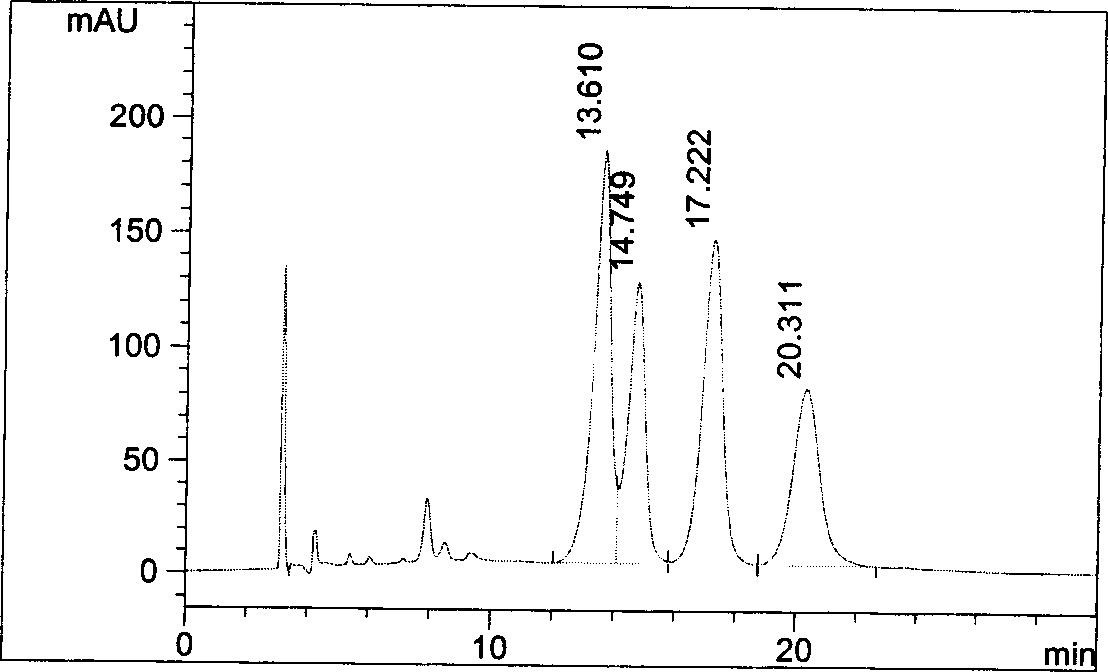

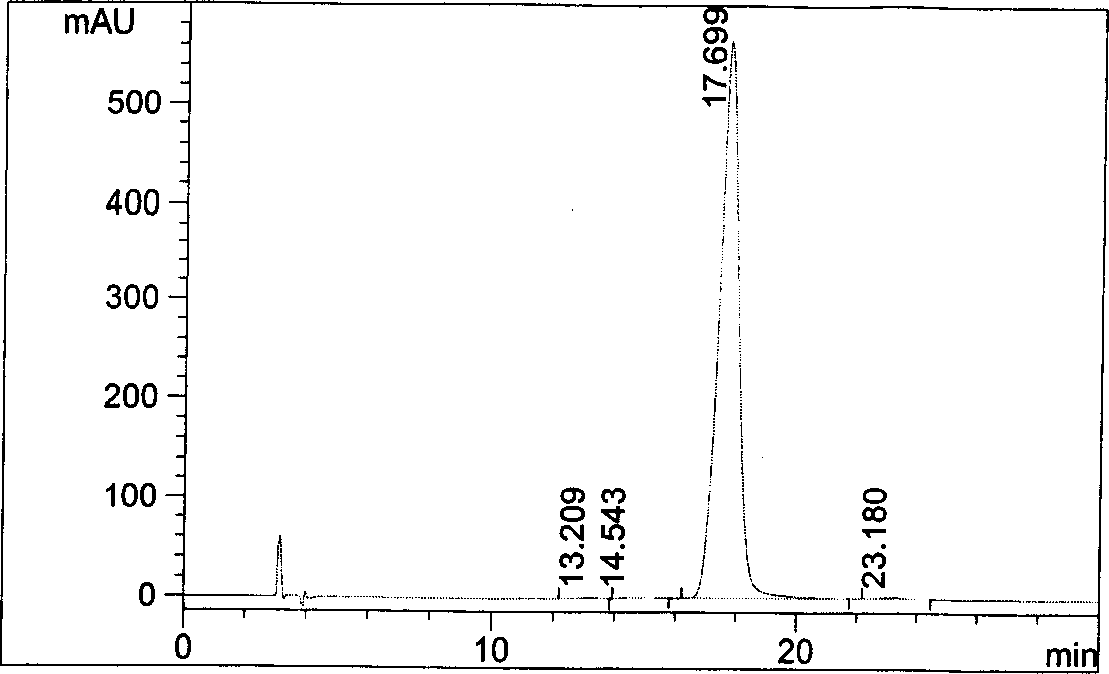

Method for separating and determining pitavastatin and its optical isomer by means of liquid chromatography

InactiveCN1790012AEffective separation assayGuaranteed stabilityOther chemical processesComponent separationPitavastatin calciumMass spectrography

The invention discloses a segregation detection method of drapery tartan calcium and optical isomer (impurity), which is characterized by the following: adapting high effective gas-chromatography or high effective gas-chromatography mass spectrography to detect the optical isomer of drapery tartan calcium; segregating the drapery tartan calcium and optical isomer of drapery tartan calcium.

Owner:CHONGQING PHARMA RES INST +1

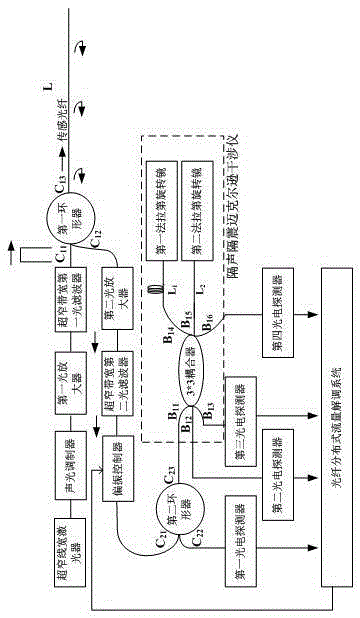

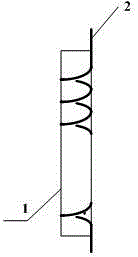

Downhole optical fiber distributed flow monitoring system

ActiveCN105258745ADemodulation of environmental influencesSolve measurement problemsConstructionsVolume/mass flow measurementRayleigh scatteringLine width

The invention relates to a downhole optical fiber distributed flow monitoring system. The downhole optical fiber distributed flow monitoring system comprises an ultra-narrow line width laser, wherein laser light passes through an acousto-optic modulator, a first light amplifier and an ultra-narrow bandwidth first light filter, then enters a first circulator and then is filled into sensing optical fibers, and Rayleigh back-scattering light in the sensing optical fibers returns back to the first circulator, passes through a second light amplifier, enters an ultra-narrow bandwidth second light filter, passes through a polarization controller, enters a second circulator, then enters a 3x3 coupler, is split into a first faraday rotator mirror, a second faraday rotator mirror and a fourth photoelectric detector; the fourth photoelectric detector feeds electric signals into an optical fiber distributed flow demodulation system; the Rayleigh back-scattering light passes through the 3x3 coupler and enters a second photoelectric detector, a third photoelectric detector and the second circulator, and the second circulator outputs light signals to a first photoelectric detector; the first photoelectric detector, the electric signals of the second photoelectric detector and the third photoelectric detector simultaneously arrive at the optical fiber distributed flow demodulation system.

Owner:LASER RES INST OF SHANDONG ACAD OF SCI

Asymmetric fiber link transmission delay measuring method

InactiveCN105933085AHigh measurement accuracySolve measurement problemsTime-division multiplexElectromagnetic transmissionNon symmetricEngineering

Owner:SOUTHWEST UNIVERSITY FOR NATIONALITIES

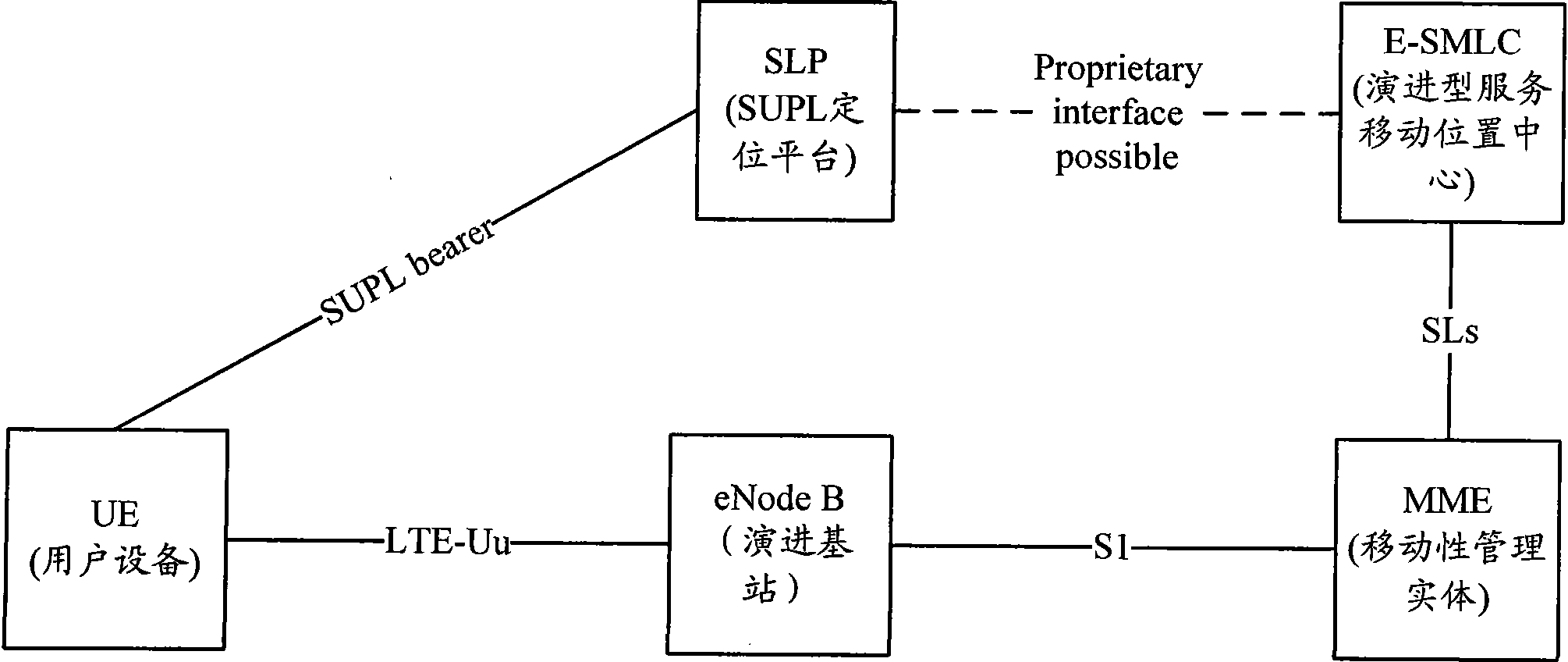

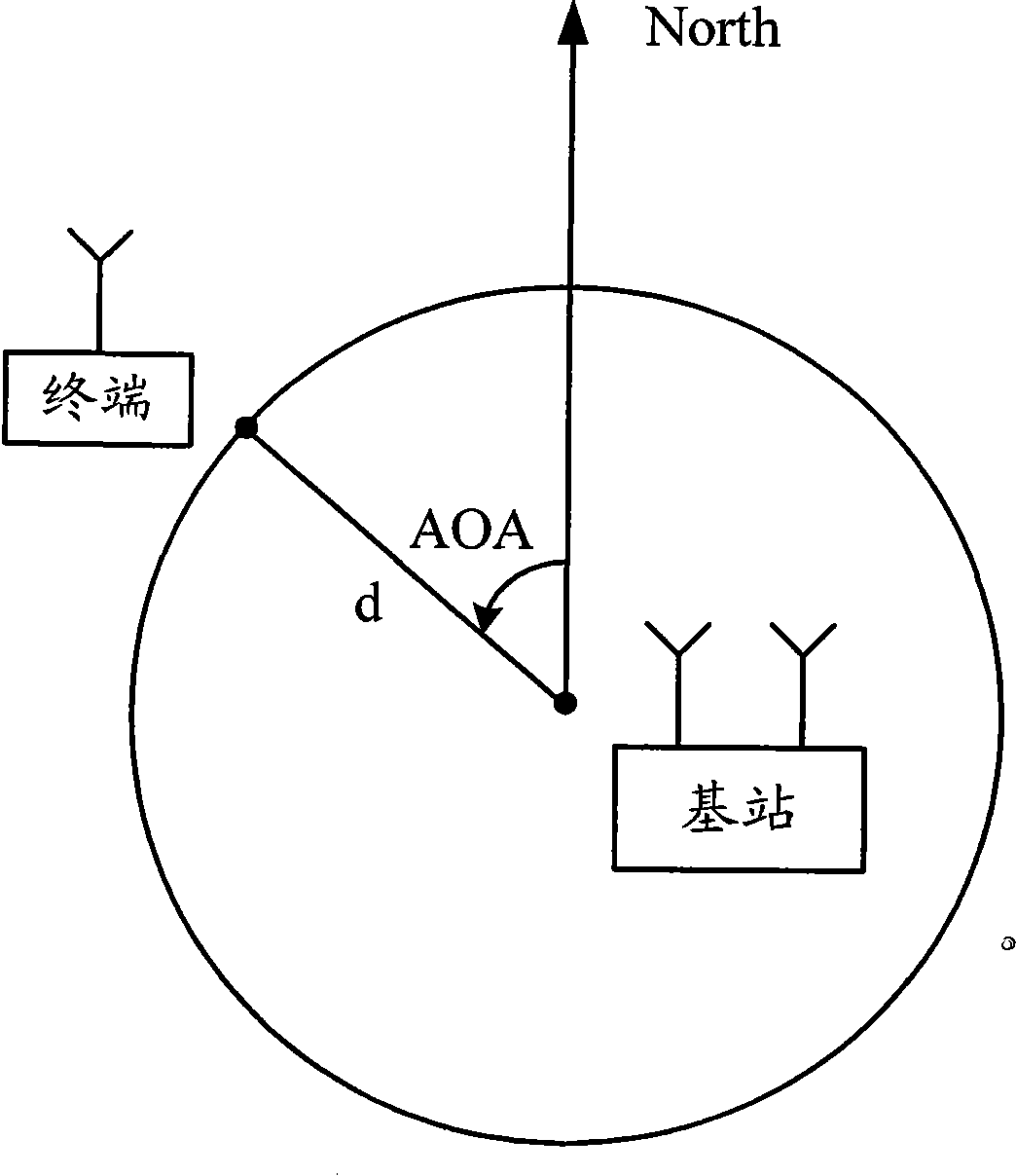

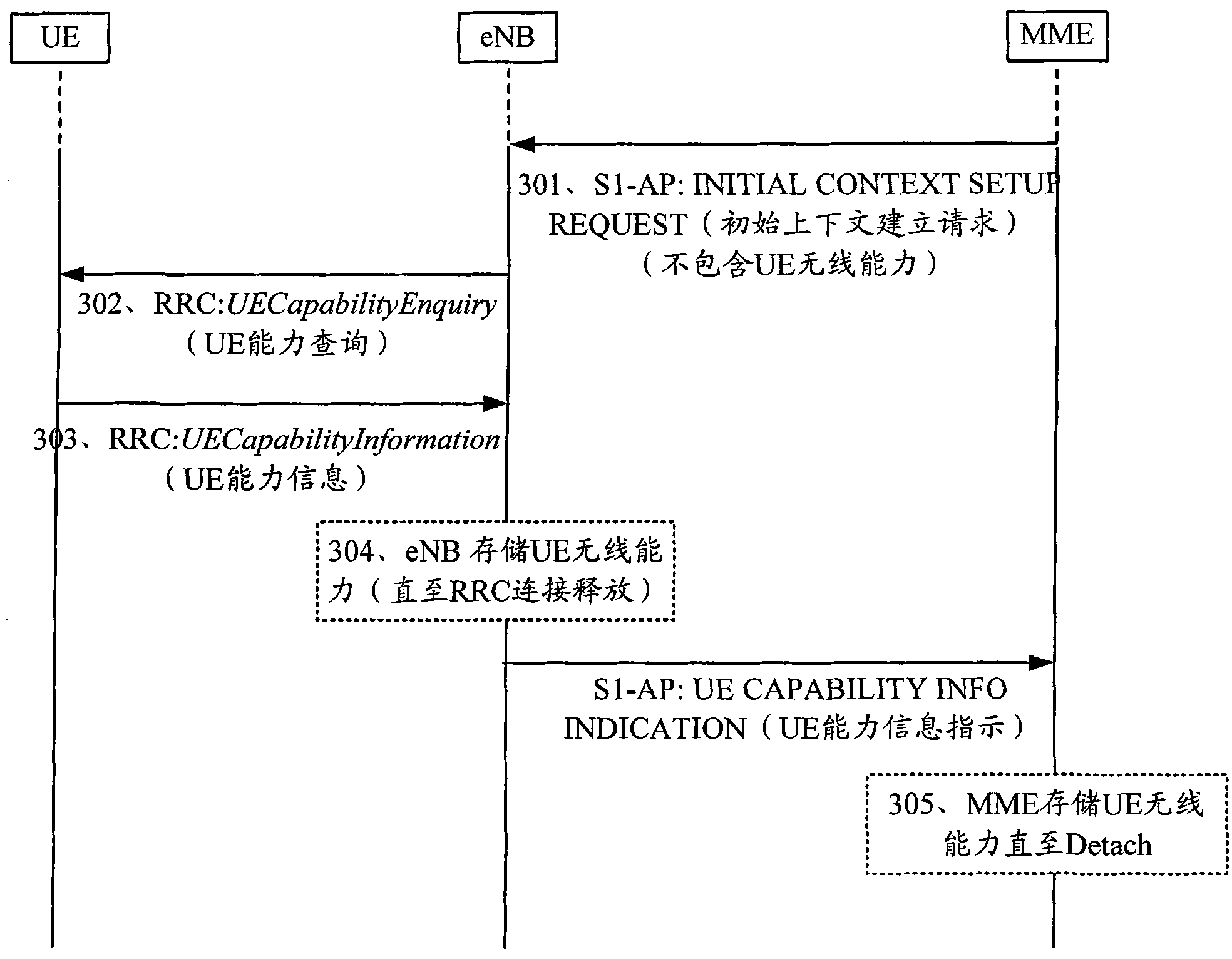

Positioning processing method and equipment

ActiveCN102056221ASolve measurement problemsSolve the reportWireless communicationTime differenceReal-time computing

The invention discloses a positioning processing method and positioning processing equipment. The method comprises the following steps that: user equipment (UE) determines supporting capacity of measuring and reporting transceiving time difference of UE; and UE reports UE wireless capacity information, wherein the UE wireless capacity information carries the information of supporting capacity of measuring and reporting transceiving time difference of UE. Through the method and the equipment, the problems of how to notify whether network UE supports to measure and report the transceiving time difference of UE and how to select time advance (TADV) measurement types in the conventional enhanced cell identification (E-CID) positioning scheme are solved; therefore, an evolved node B (eNB) can determine the supported TADV measurement type in the positioning process by combining the positioning capacity of the eNB.

Owner:DATANG MOBILE COMM EQUIP CO LTD

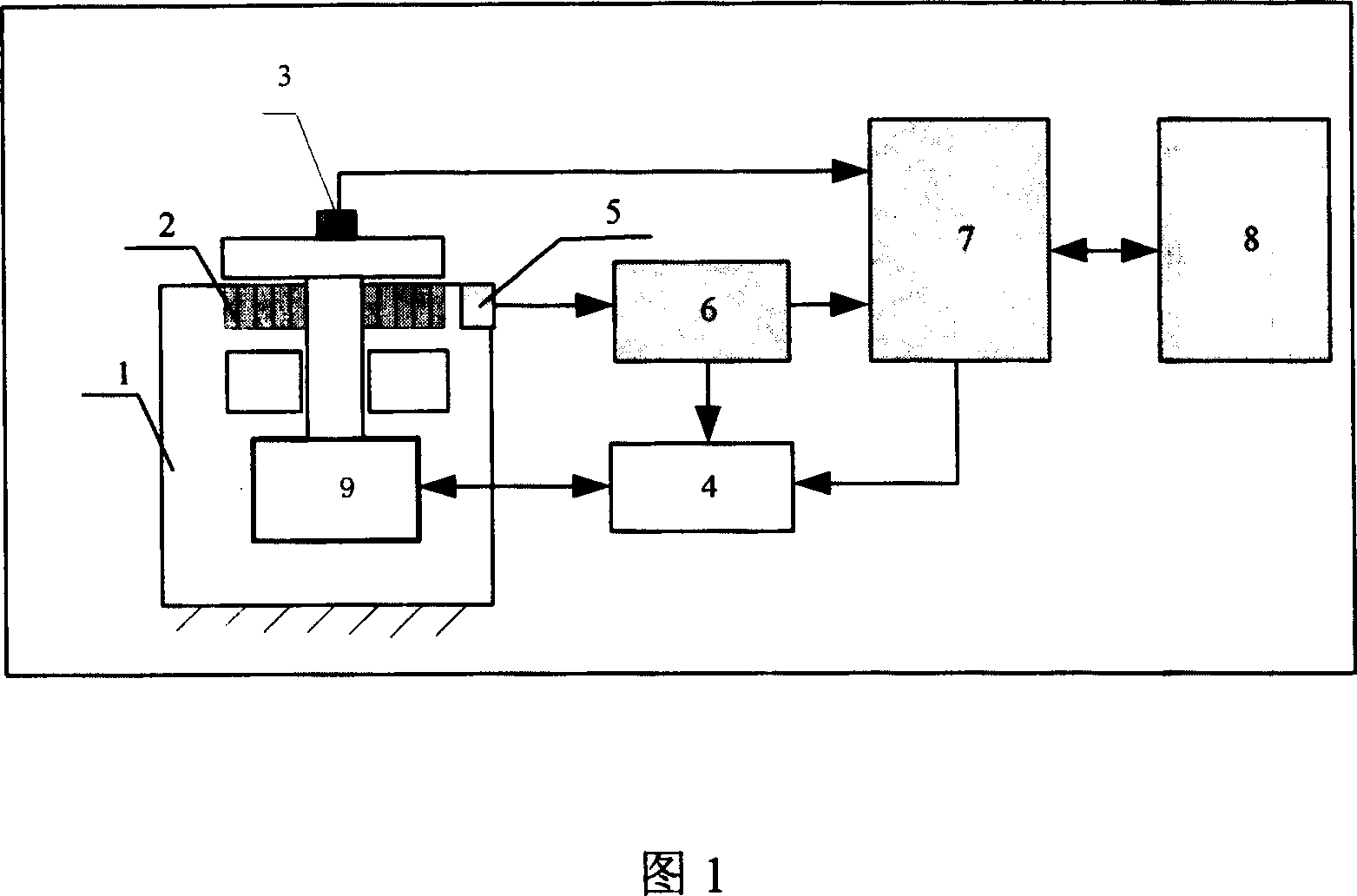

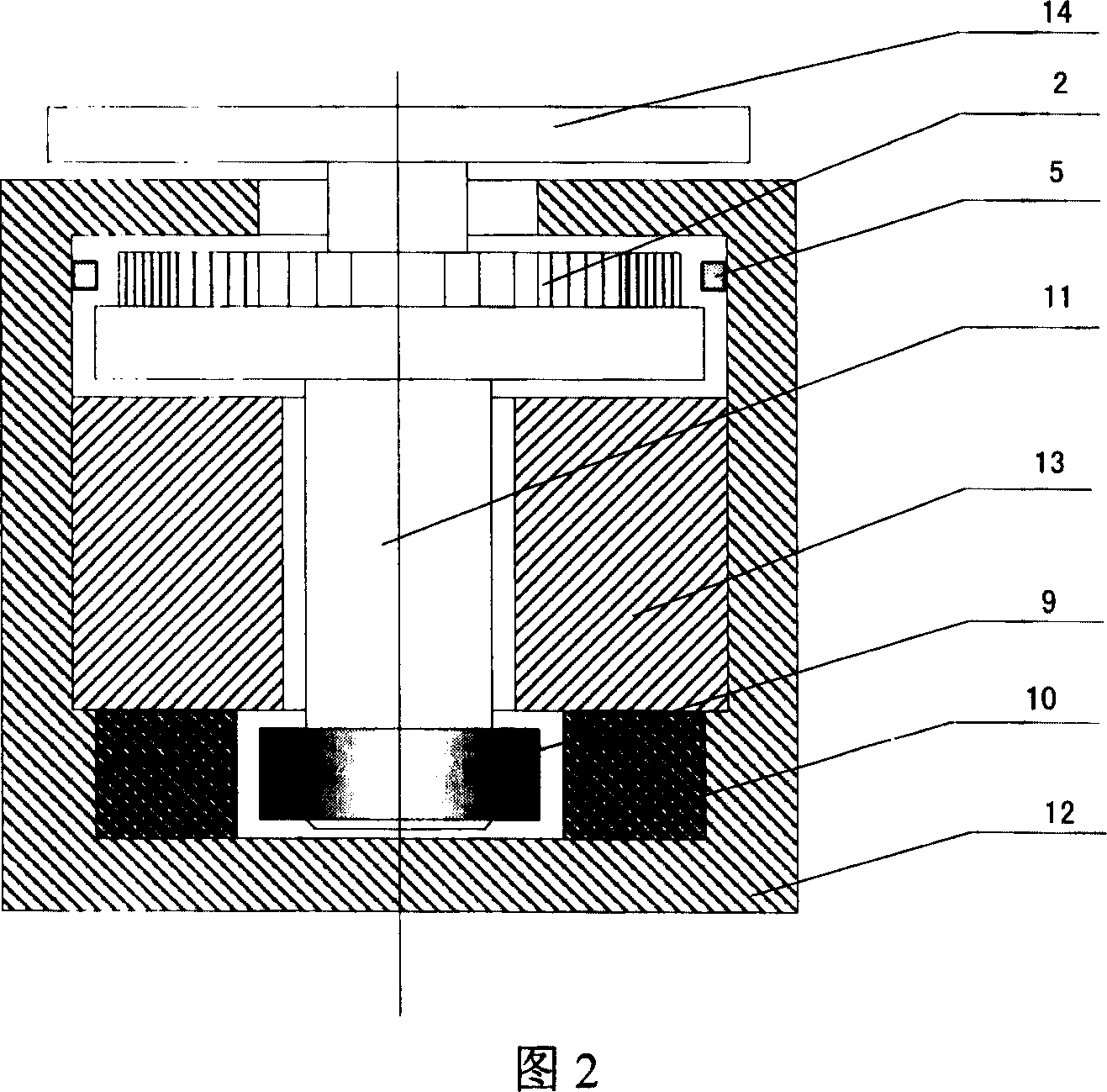

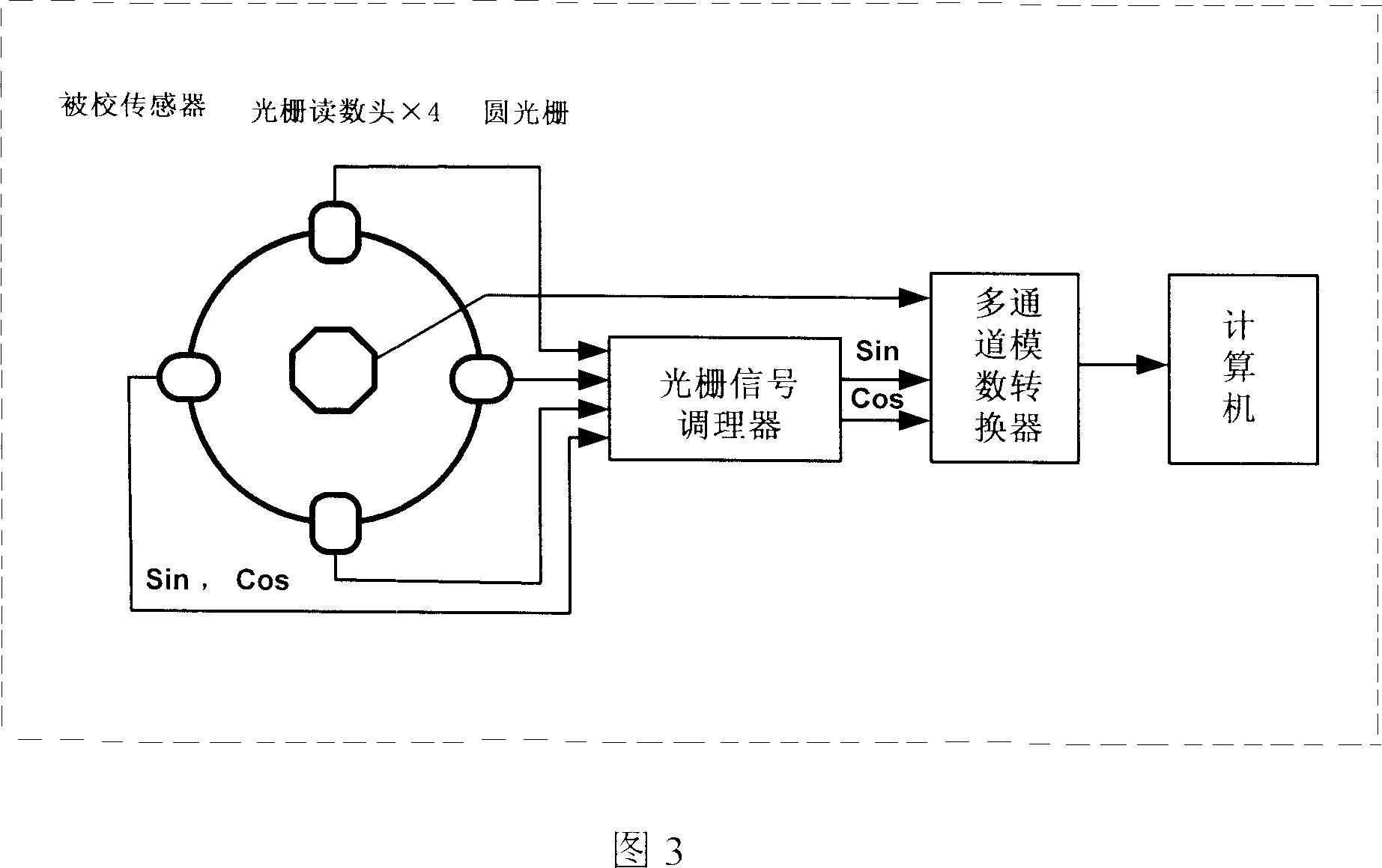

Low frequency angle vibration table

InactiveCN1955644AHigh rotation accuracyImprove athletic abilityTesting/calibration of speed/acceleration/shock measurement devicesSignal qualityGrating

An angular vibration table of low frequency is prepared as using control system to control mechanical vibration table to generate sine vibration according to property of calibrated transducer, sending one path of grating output signal to control system for carrying out closed loop control and another path to data collection system being used to simultaneously collect output signals of grating and calibrated transducer, obtaining relation curve of time and movement amount after said signals are processed by data processing unit then calculating out phase-shift and magnitude sensitivity of calibrated transducer.

Owner:BEIJING CHANGCHENG METERING TEST TECH INST NO 1 GRP CO CHINA AVIATION IND

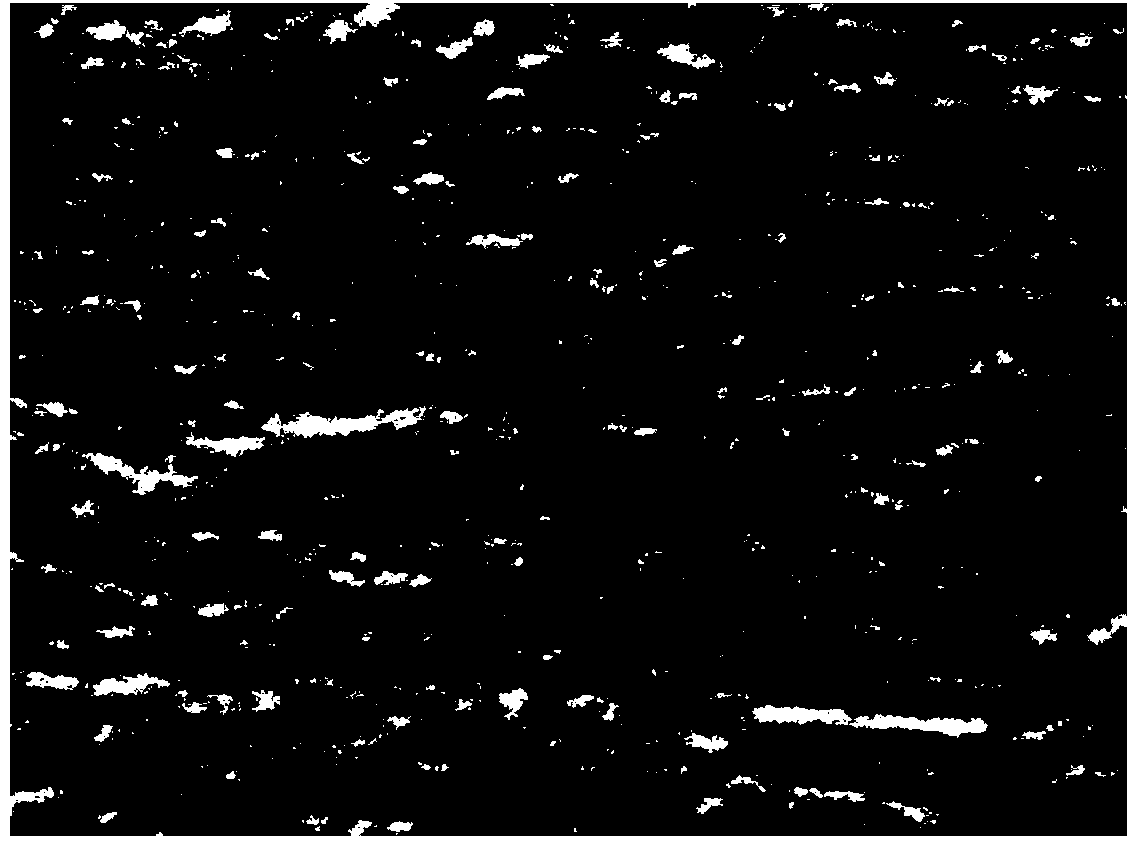

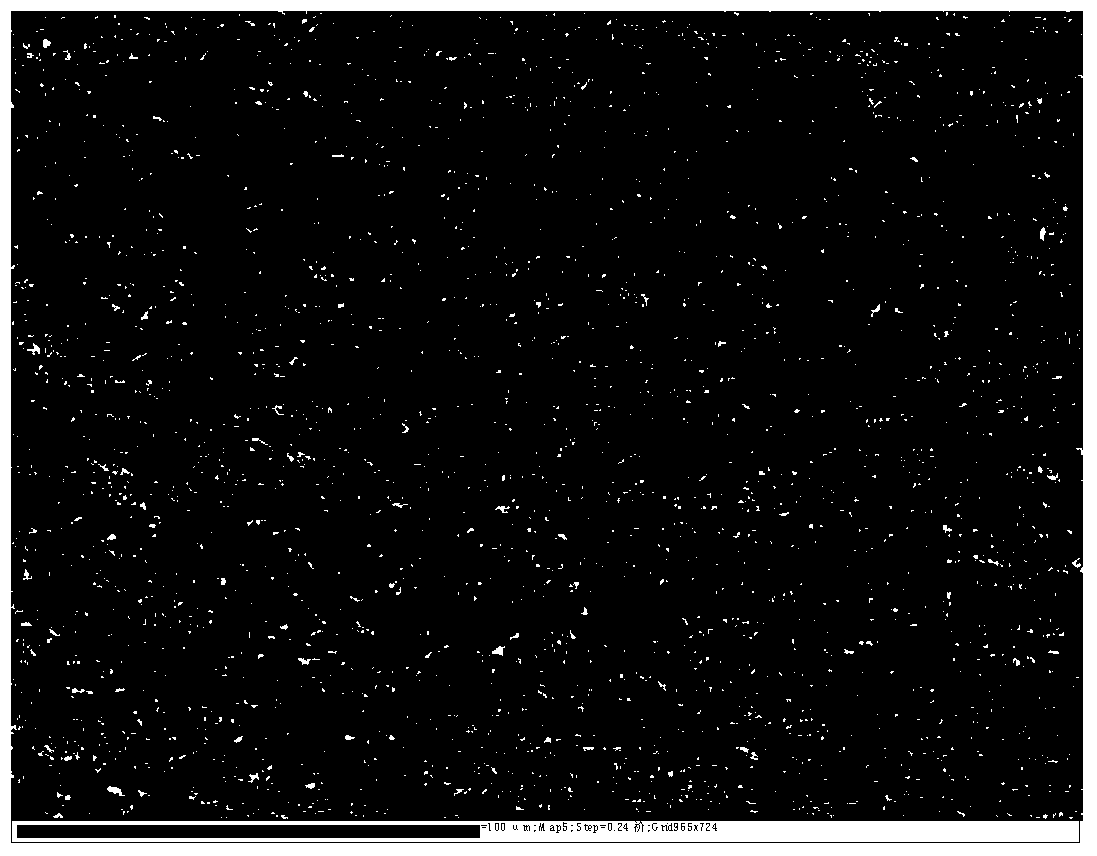

Measurement method for effective grain size of structural steel with complex microstructure

ActiveCN103529065ASolve measurement problemsEfficient measurementMaterial analysis using radiation diffractionMisorientationMicrostructure

The invention relates to a measurement method for the effective grain size of structural steel with a complex microstructure. The method comprises the following steps: acquiring a crystal diffraction pattern by using EBSD; measuring misorientation of crystal boundaries through the diffraction pattern and drafting a misorientation distribution curve chart; calculating threshold values of an effective grain size based on the misorientation distribution curve chart; and measuring transversal or longitudinal space between misorientation of the threshold values of the effective grain size and subjecting space data to statistical treatment so as to obtain average space between misorientation of average threshold values, wherein the average space is the effective grain size of a measured material. According to the invention, misorientation between crystal grains is used as a standard for measurement of the effective grain size, a prediction method for the threshold values of the effective grain size is brought forward, and it is convenient to formulate the threshold values of the effective grain size according to specific conditions of the material.

Owner:BC P INC CHINA NAT PETROLEUM CORP +1

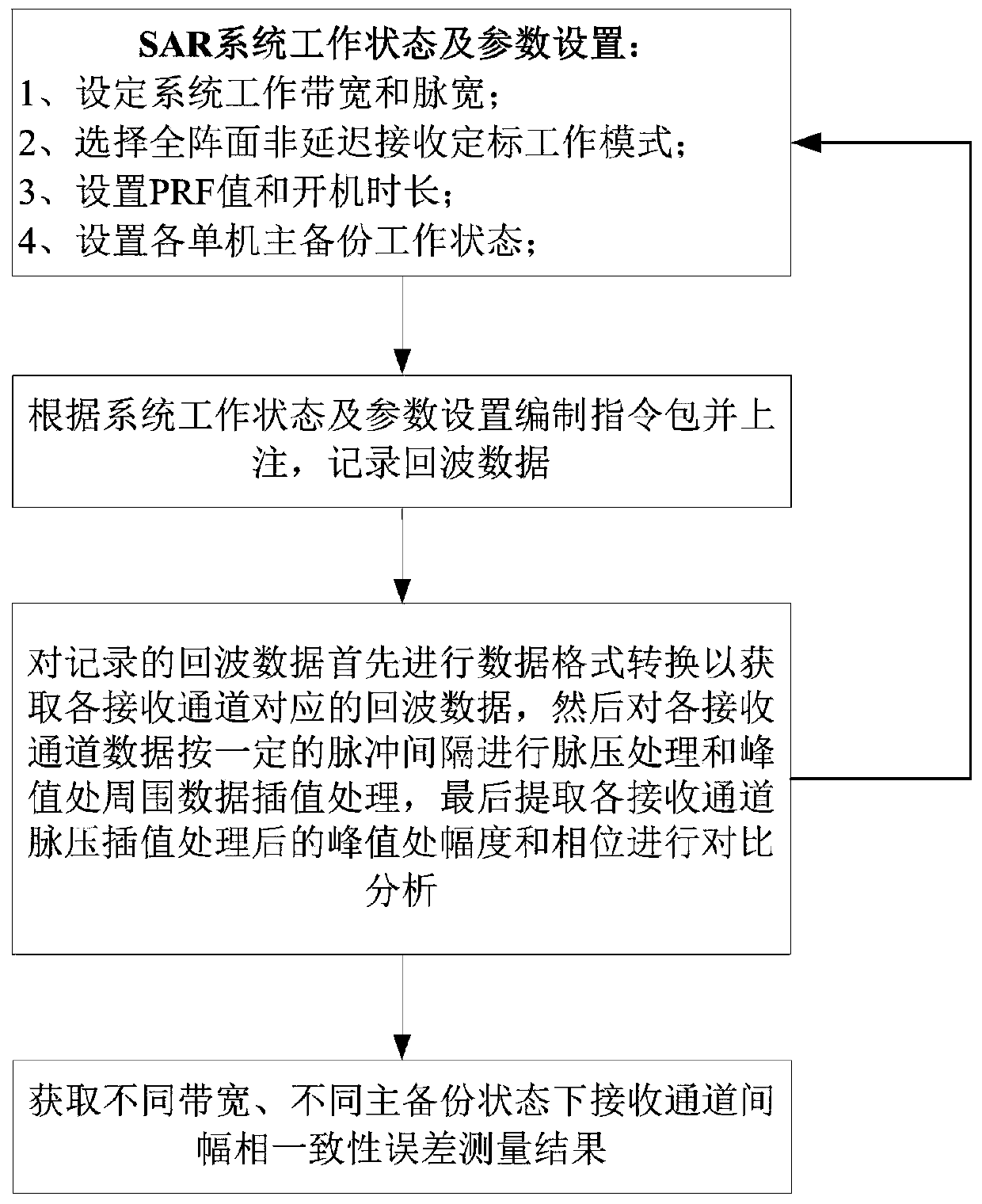

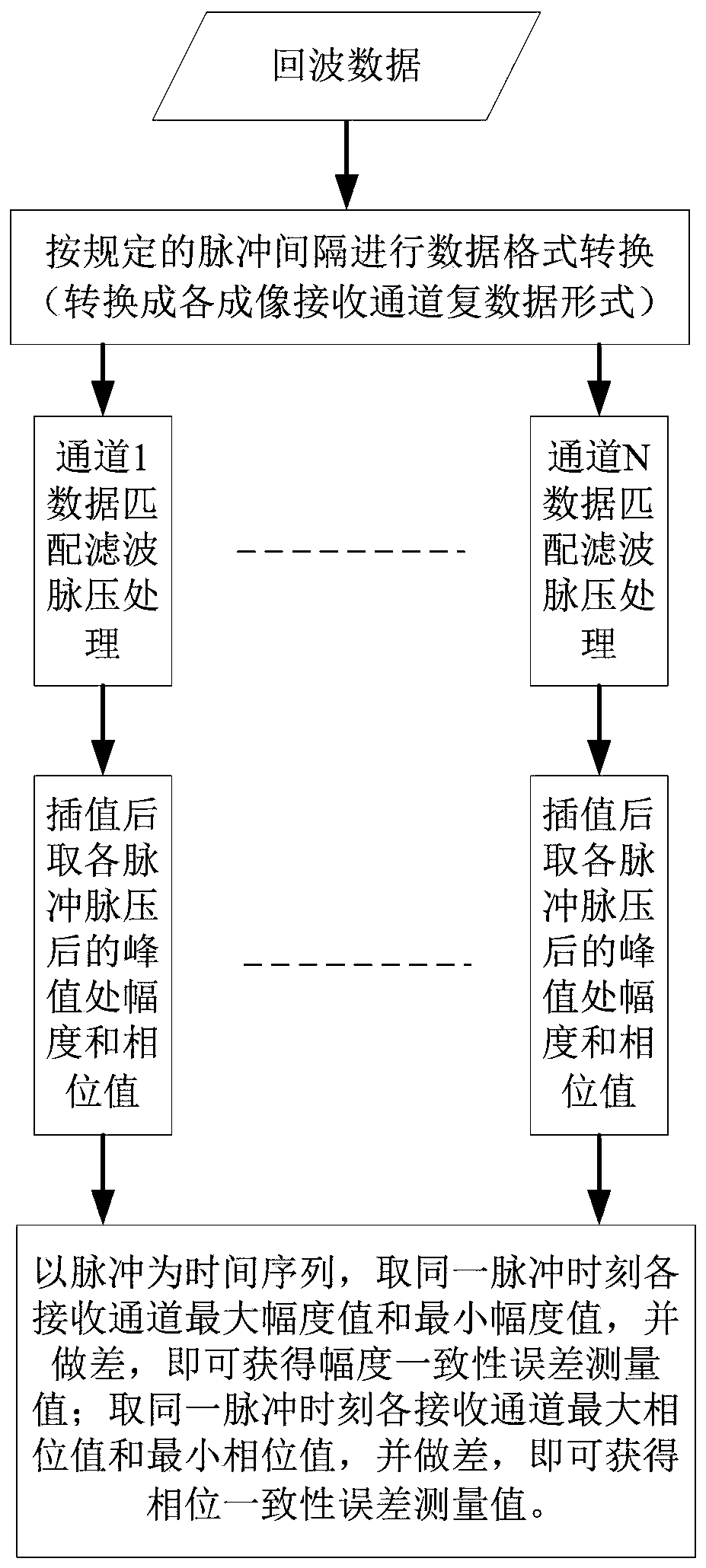

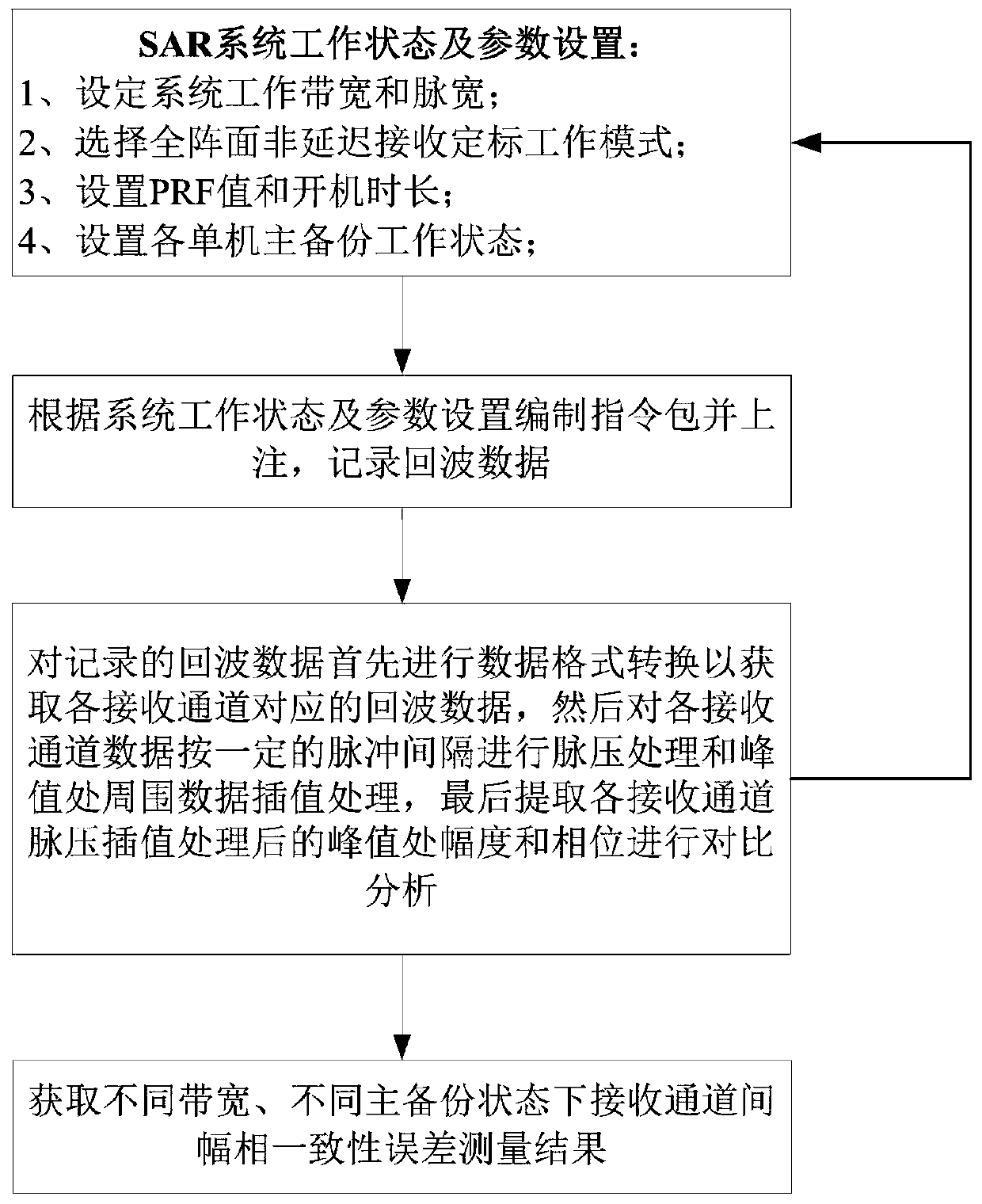

Calibration and measurement method for amplitude and phase consistency errors among satellite-borne SAR imaging receiving channels

ActiveCN110018455ASolve measurement problemsEasy to monitorWave based measurement systemsMicrowavePulse pressure

The invention relates to a calibration and measurement method for amplitude and phase consistency errors among satellite-borne SAR imaging receiving channels in the technical field of satellite-borneSAR imaging. The method comprises the steps of: (1) setting the working state and parameters of an SAR system, wherein the working state and parameters comprise signal working bandwidth and pulse width, a working mode, a single machine master backup state, a PRF value and the boot duration; (2) according to the working state and the parameter setting values of the system, compiling and noting an instruction packet to achieve start-up of the SAR system, and recording echo data; (3) performing format conversion and the pulse pressure processing for the recorded echo data to extract an amplitudeand a phase at a peak value after the pulse voltage for comparison and analysis; and (4) repeating the step 1 and the step 3 to finish the measurement of the amplitude and phase consistency errors ofthe imaging receiving channels under different bandwidths and different master backup states.

Owner:SHANGHAI SATELLITE ENG INST

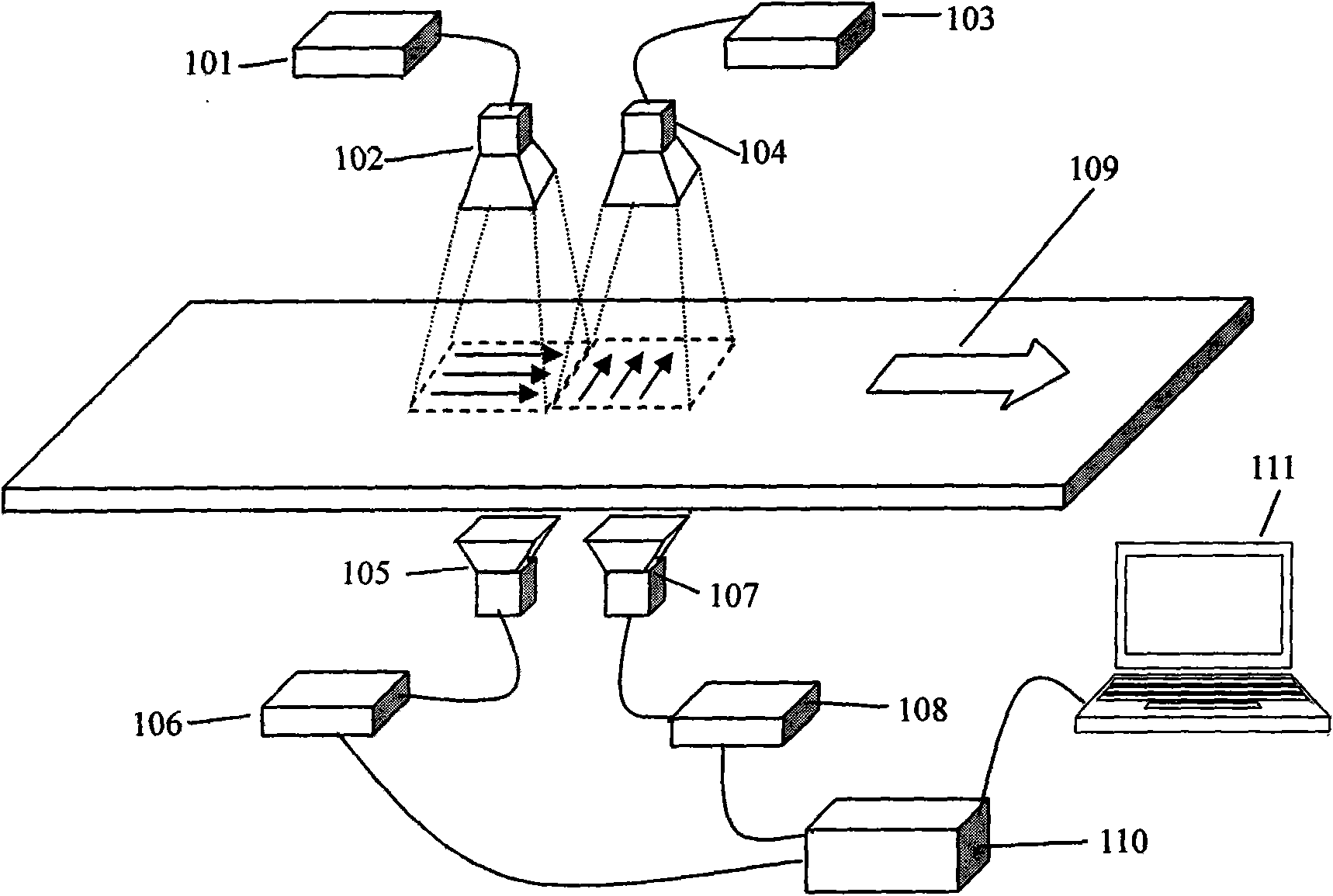

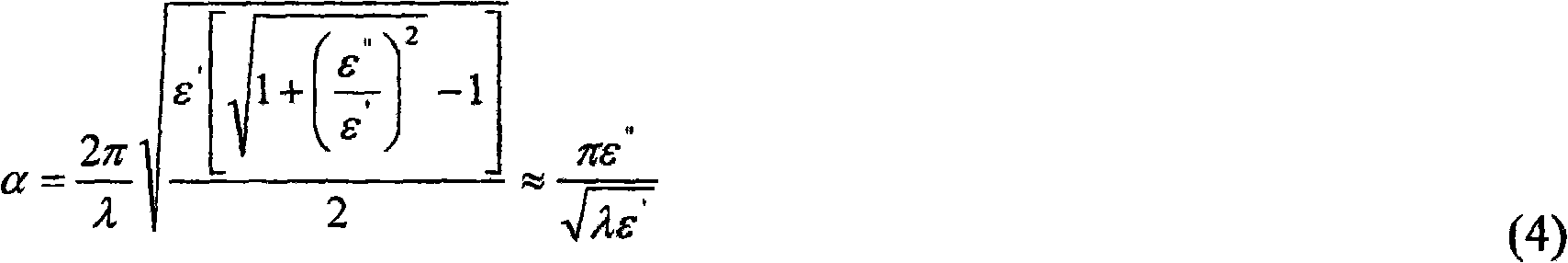

Dual-source dual-probe orthogonal device for measuring water content by microwave and measurement method

InactiveCN101566587AAvoid crosstalkSolve measurement problemsMoisture content investigation using microwavesData acquisitionMicrowave power

The invention discloses a dual-source dual-probe orthogonal device for measuring water content by microwave and a measurement method, belonging to the technical field of microwave measurement; the device is used for measuring the water content of coals on a coal conveyor belt by a microwave transmission way. The device comprises emitting antennas of 9.4GHz and 2.4GHz; the emitting antennas are arranged above the coal conveyor belt in parallel along the conveying direction of the coal and are connected with a microwave signal source with the same frequency respectively; the device also comprises two receiving antennas of 9.4GHz and 2.4GHz; the two receiving antennas are arranged below the coal conveyor belt and are connected with a radiodetector with the same frequency respectively; the device also comprises the radiodetectors of 9.4GHz and 2.4GHz; the two radiodetectors are connected with a data collecting card; and the data collecting card uploads the collected microwave power signals to a computer in which a suitable processing program is installed, thus obtaining the real-time water content of the coals on the conveyor belt. The device and the method can improve the measurement range, improve the measurement precision simultaneously, overcome the contradiction between the measurement range and the measurement precision of the traditional method, effectively eliminate mutual interference and meet the requirement of dynamic measurement.

Owner:TSINGHUA UNIV

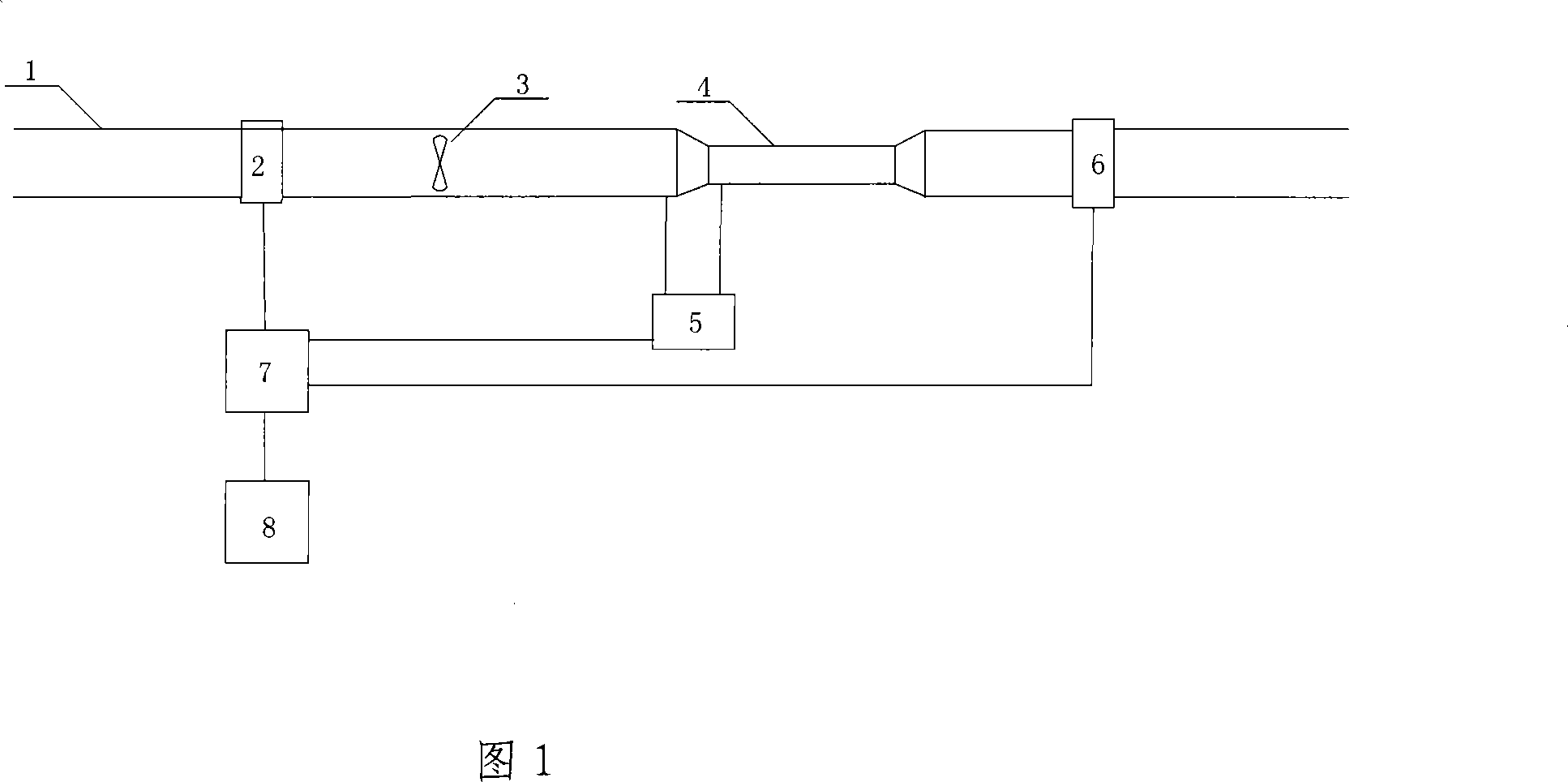

Low gas content gas-liquid two-phase flow measuring apparatus based on capacitance sensor and standard venturi tube

InactiveCN101162165AHigh precisionImprove real-time performanceVolume meteringVolume flow measuring devicesDifferential pressureEngineering

The present invention discloses a low air rate gas-liquid two-phase flow measuring device based on a capacity transducer and a standard venturi tube. The device consists of a metering conduit, a capacity transducer arranged in the front end of the metering conduit, a mixed flow device arranged in the middle of the metering conduit, a standard venturi tube and a temperature sensor arranged on the rear of the metering conduit, a differential pressure pickup connected with the standard venturi tube, an A / D transition card and a computer. The capacity transducer is connected with the computer through the A / D transition card. The invention is characterized by small volume, simple structure, convenient installation, relatively low loss of pressure, a plurality of acquirable measuring parameters, high flow measuring precision and good real-time. The invention is suitable for measurement of low air rate gas-liquid two-phase flow of oil, gas, etc.

Owner:王微微

Measuring mechanism used for measuring substance mass center, shape center and mass center deviation

InactiveCN1904573ASolve measurement problemsAccurate calculationStatic/dynamic balance measurementEngineeringLoad cell

Owner:ZHENGZHOU RES INST OF MECHANICAL ENG CO LTD

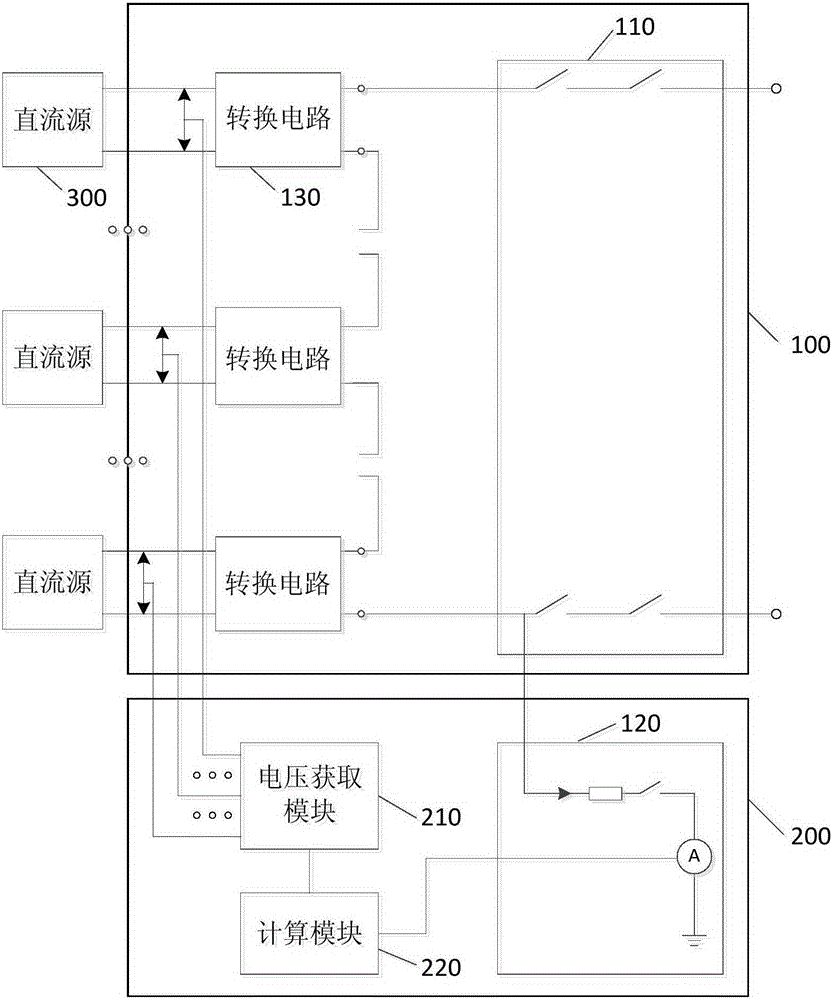

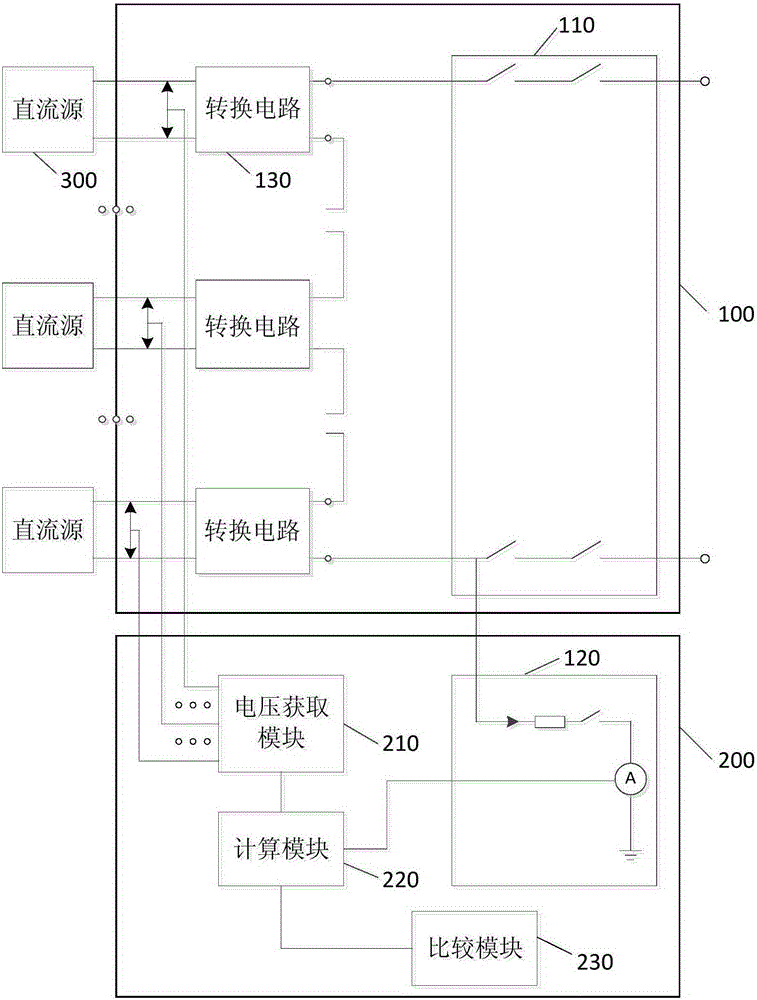

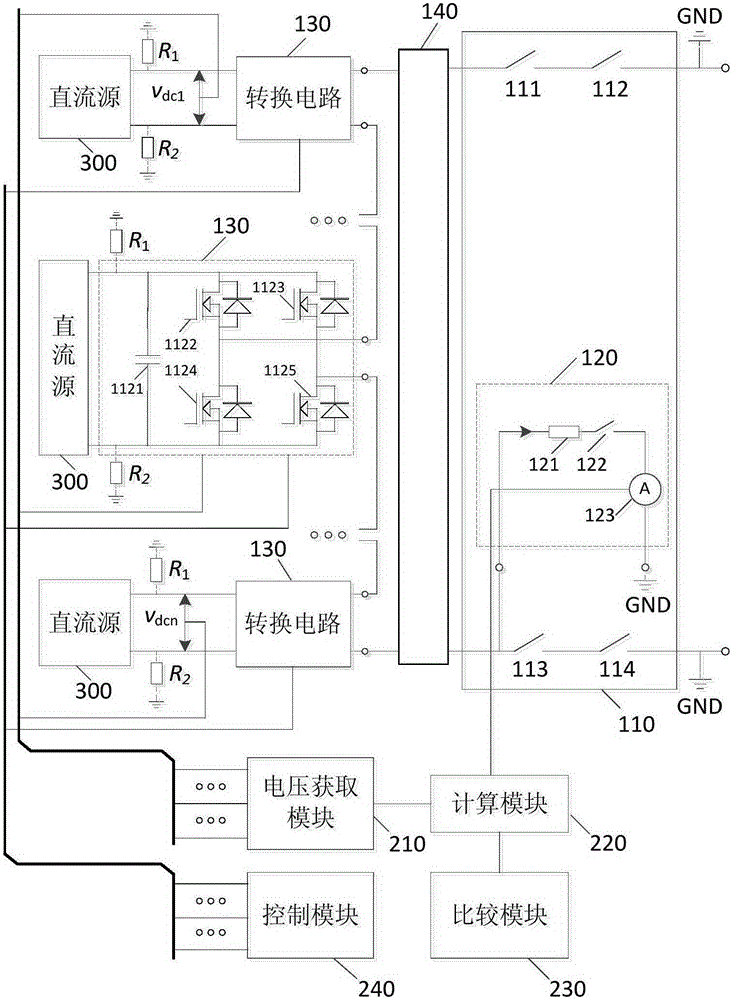

Self-checking system and self-checking method for cascaded multilevel converter

ActiveCN105337519ASolve measurement problemsSolve computing problemsDc-dc conversionImpedence measurementsComputer moduleEngineering

The invention discloses a self-checking system and a self-checking method for a cascaded multilevel converter. The self-checking system for the cascaded multilevel converter comprises a cascaded multilevel converter and a self-checking device, wherein the cascaded multilevel converter comprises at least two converting circuits which are cascaded, the self-checking device comprises at least one current detecting circuit, a voltage acquisition module and a computation module; the current detecting circuit is used for detecting a first detection circuit and a second detection circuit, the voltage acquisition module is used for acquiring a first busbar voltage and a second busbar voltage, and the computation module is used for acquiring insulation resistance of the cascaded multilevel converter according to the first detection current, the second detection current, the first busbar voltage and the second busbar voltage. The self-checking system provided by the invention can detect the insulation resistance of the cascaded multilevel converter, so that too heavy leakage current due to too low integral insulation resistance is avoided, and potential safety hazard can not be caused.

Owner:SUNGROW POWER SUPPLY CO LTD

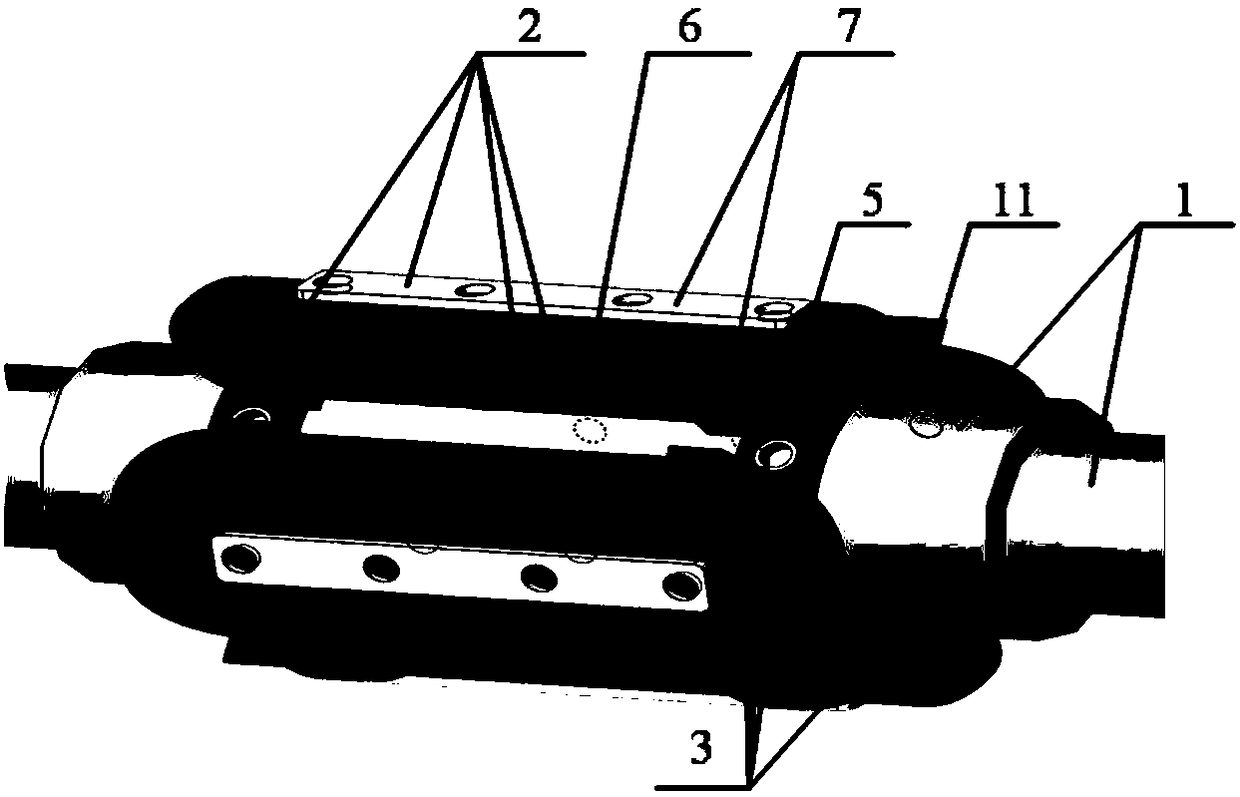

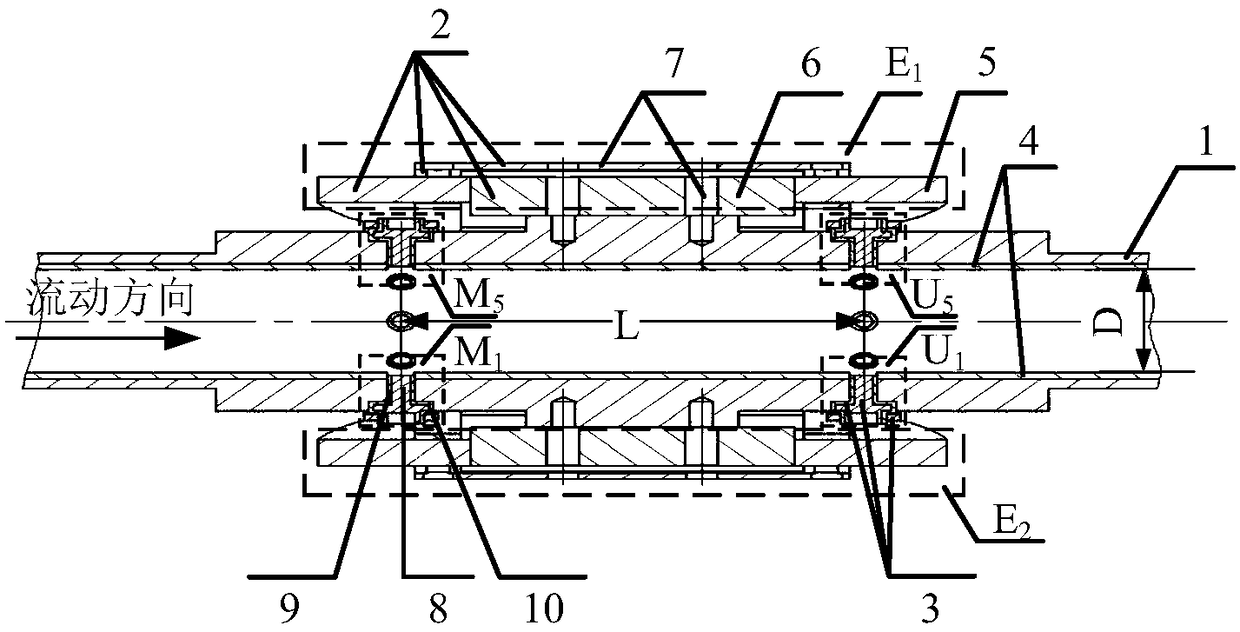

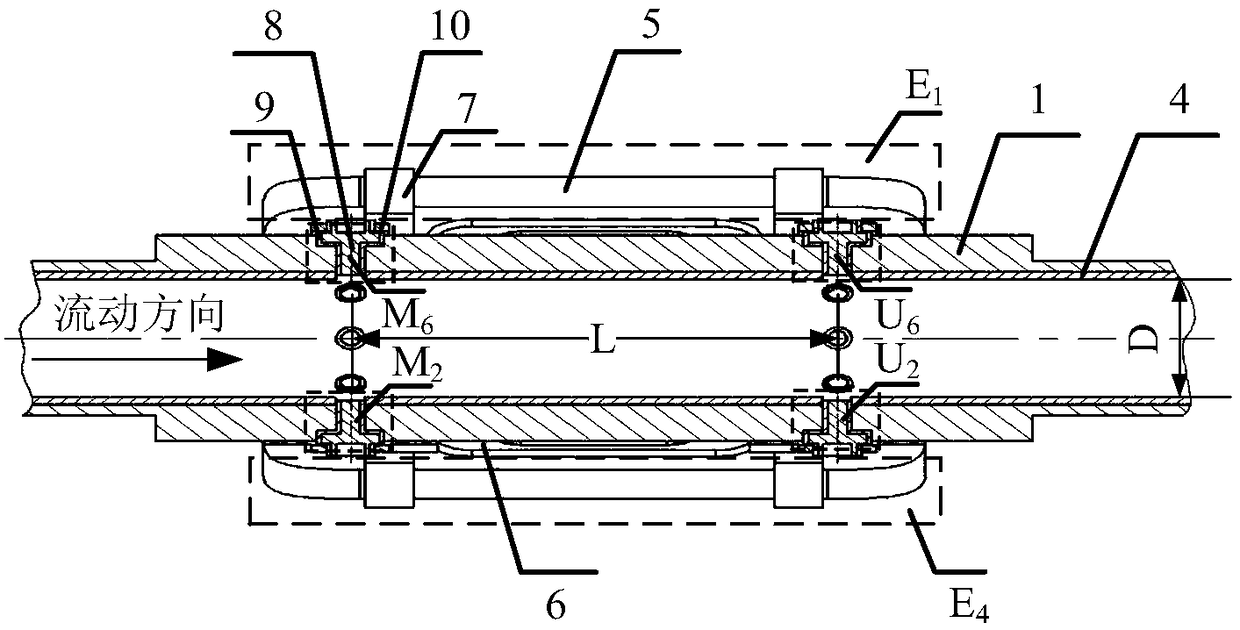

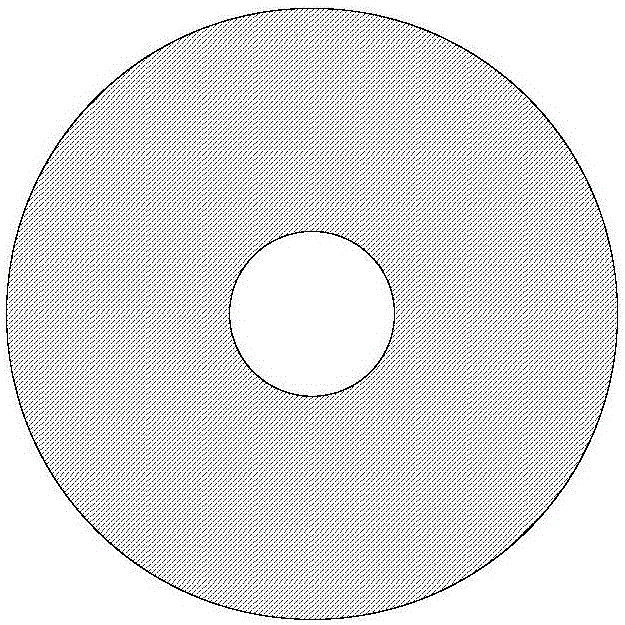

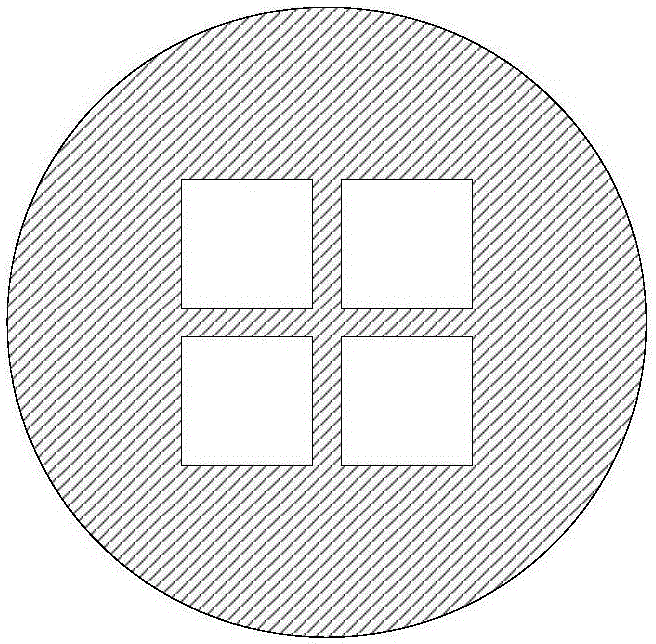

Two-group excitation coil multi-electrode electromagnetic correlation flow meter sensor

ActiveCN109115286ARealize measurementSolve measurement problemsVolume/mass flow by electromagnetic flowmetersTwo-vectorConductive materials

The invention provides a two-set excitation coil multi-electrode electromagnetic correlation flow meter sensor, which can specifically comprise: a measuring tube, two sets of excitation structure components, two sets of array detecting electrode components, and an insulating lining, wherein the two sets of excitation structure components are vertically distributed with each other and are arrangedon the same circumference parallel to the outer wall of the measuring tube; furthermore, the two mutually perpendicular sets of excitation structure components cooperate to produce two vector magneticfields which are uniform and mutually perpendicular; the two sets of array detecting electrode components are located in the two mutually perpendicular vector magnetic fields generated by the two sets of excitation structure components, and are arranged, in the measuring tube, on two sections of the upstream and downstream in the flow direction thereof; the mutual spacing of the two sections in the axial direction of the measuring tube is L; and the insulating lining is arranged on the inner tube wall of the measuring tube. The two-set excitation coil multi-electrode electromagnetic correlation flow meter sensor can effectively realize horizontal well production profile fluid flow measurement containing non-conductive materials which are especially in non-axisymmetric flow field distribution.

Owner:YANSHAN UNIV

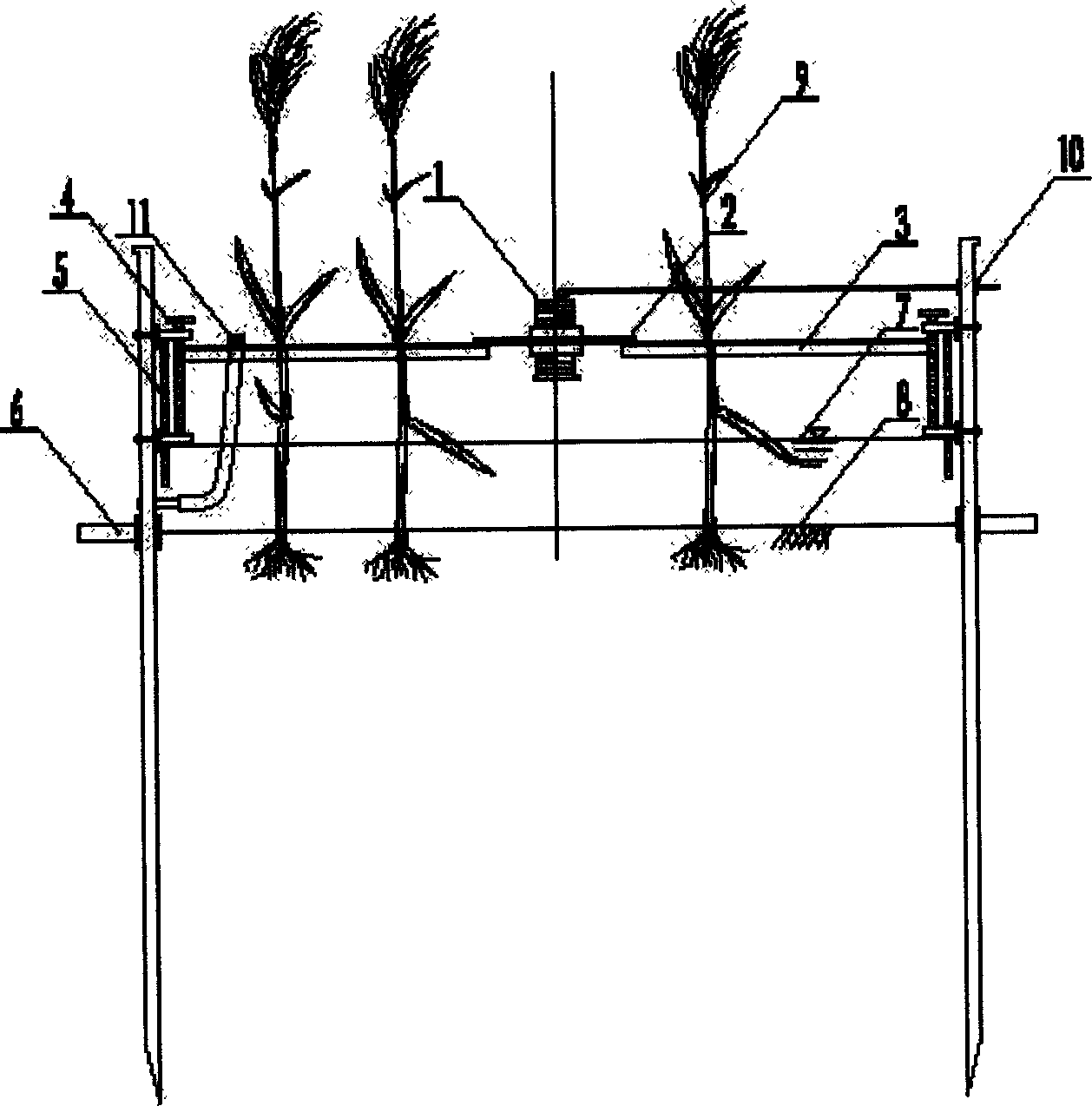

Three barrel compensating type evaporation and penetration measuring device

InactiveCN1514227AUndisturbed growth stateSolve the problem of evapotranspiration measurementMachines/enginesLevel indicatorsMeasurement deviceEvaporation

A device has characteristics as the follows: three cylinders are made of stainless steel as bottom is ground sharp, two handles are symmetrically welded at outside of cylinder wall, transducer is fixed at inner wall by triangle supports as three support points are equipped separately with height adjusting device for scale, stainless steel guide tube is welded on three cylinders wall with tube outer end being flated on outer wall of cylinder, screen casing is set tube opening, one of cylinders has its opening covered by head, sealed with gasket at edge; air hole is set on cylinder wall with windproof casing on it, 24 VDC is for three transducers and data can be automatically collected and processed in the device.

Owner:DALIAN UNIV OF TECH

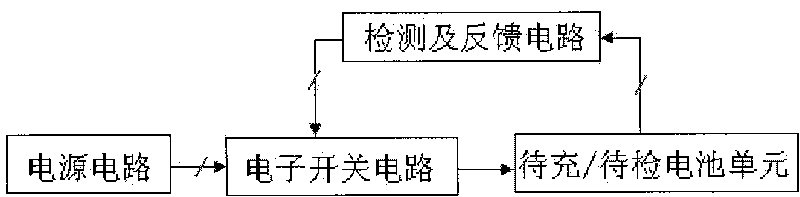

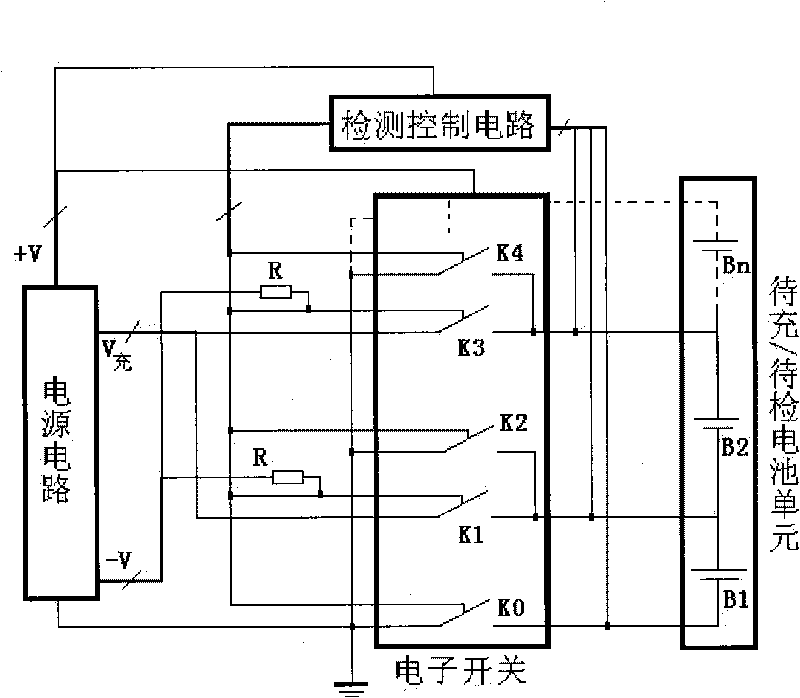

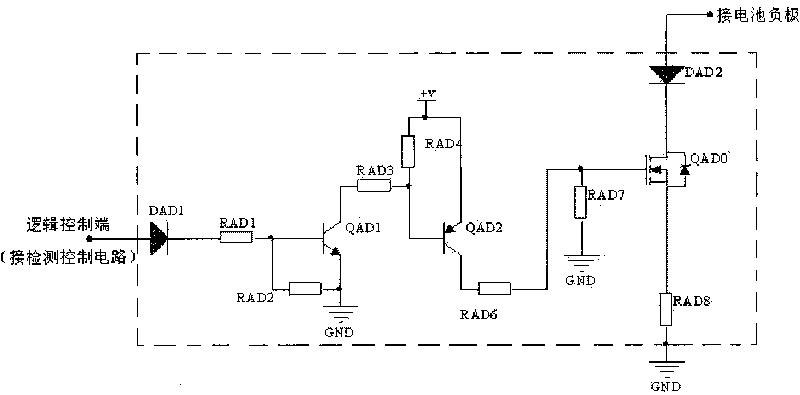

Battery equilibrium charging and detecting and repairing device

InactiveCN101728852AImprove driving abilityEnsure continuityBatteries circuit arrangementsElectric powerElectrical batteryElectronic switch

The invention discloses a battery equilibrium charging and inspecting and repairing device comprising a power circuit, an electronic switching circuit, a detecting control circuit and a charging pending / detecting pending battery unit, wherein both ends of each battery in the battery unit are respectively connected to at least one electronic switch in the electronic switching circuit; each electronic switch is an NMOS logic circuit working in the switch status, and the logic control end of the NMOS logic circuit is connected to the grid electrode of a corresponding N-type field effect tube; and the logic control end of each electronic switch connected to the anode of each battery is also provided with a subcircuit connected to a negative power supply by a resistor. The battery equilibrium charging and inspecting and repairing device can realize charging autoadaptation and carries out any combination of equilibrium charging on each battery in the battery unit; the full N-type field effect tube is adopted, enabling the circuit to be simpler and more reliable; and linear isolation measurement and multiple safety isolation are adopted, thereby solving the problems of danger, low precision and virtual ground of measurement and control. The invention can also be used as a battery load on-line tester.

Owner:秦永振

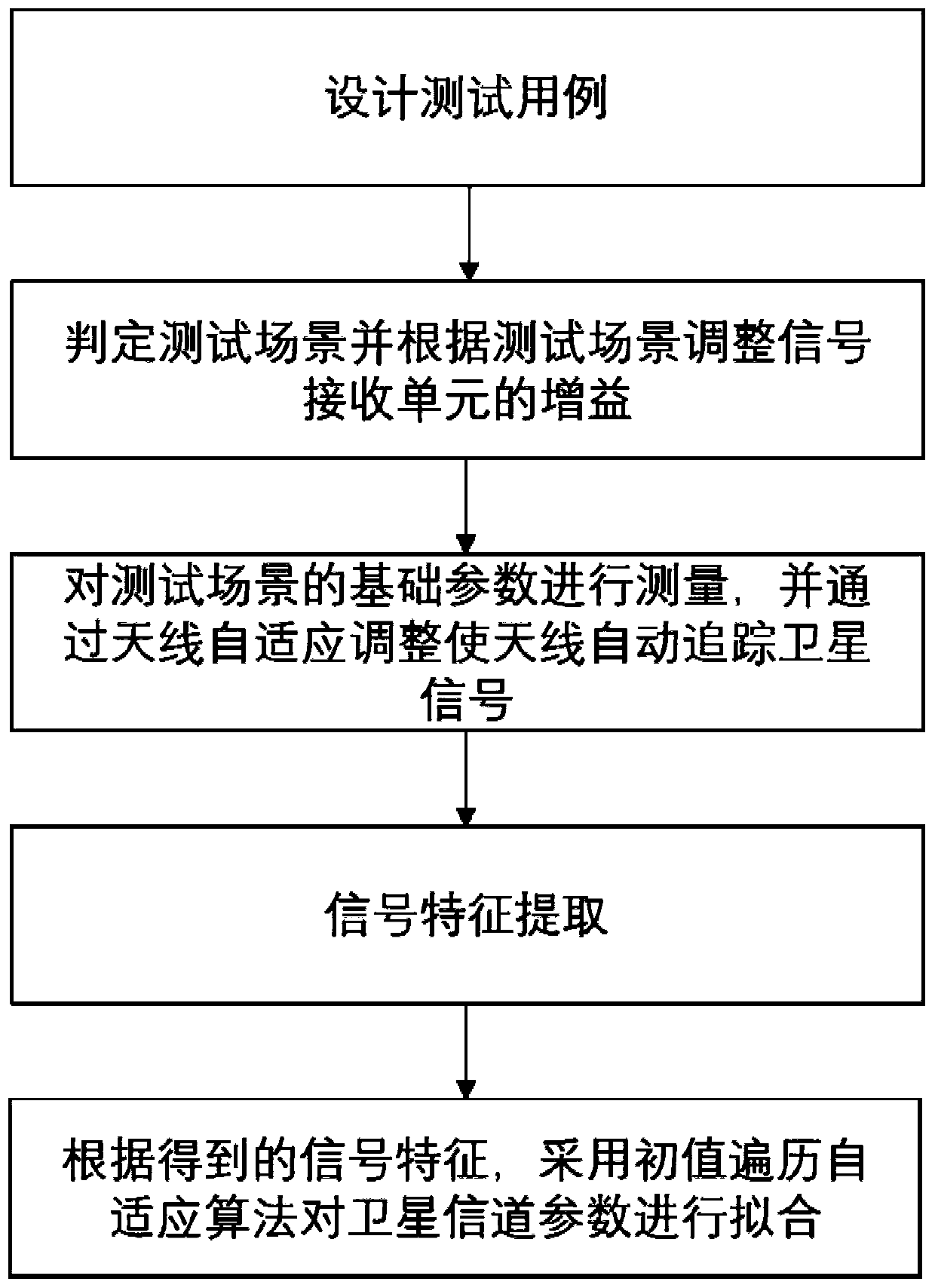

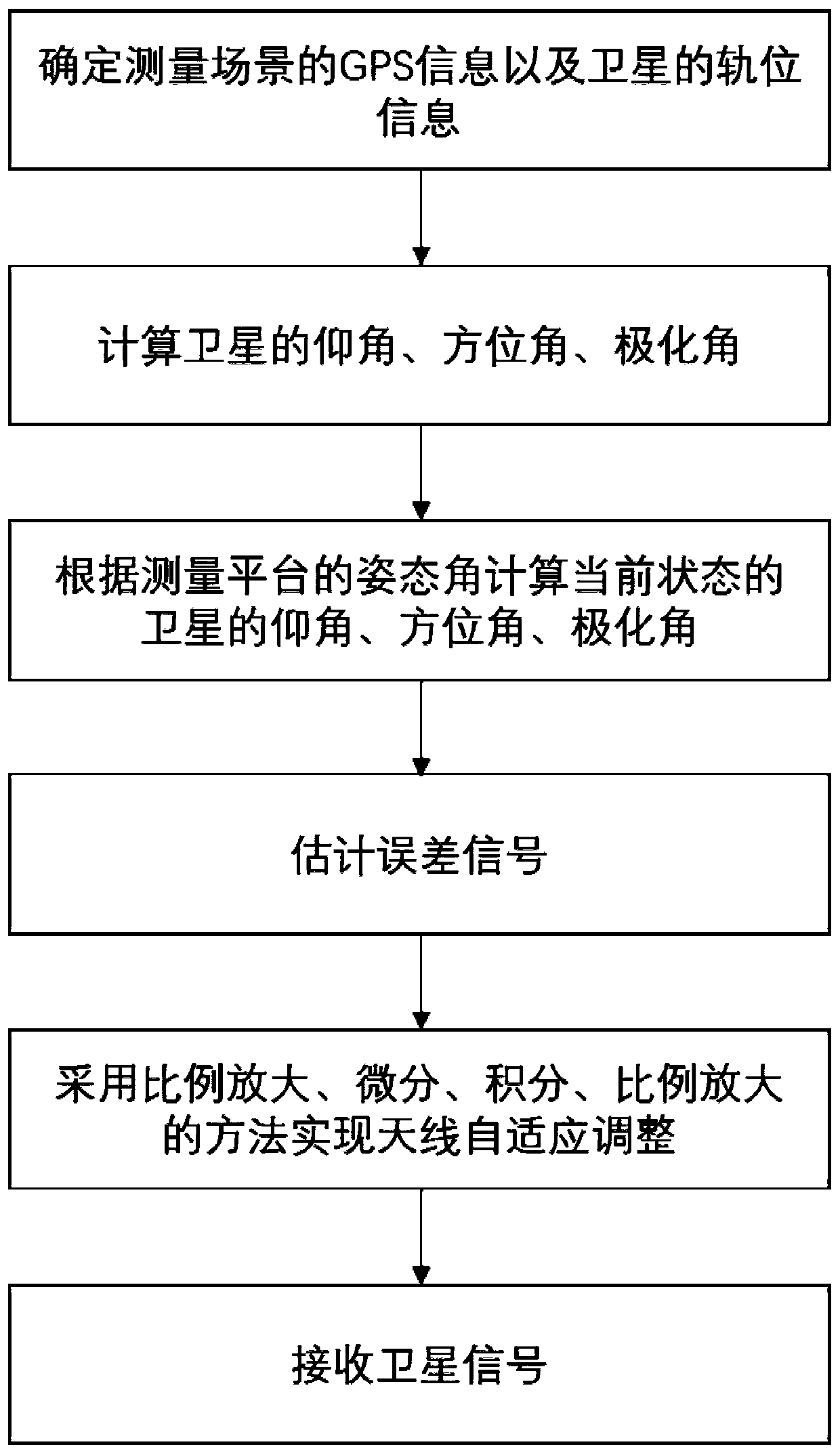

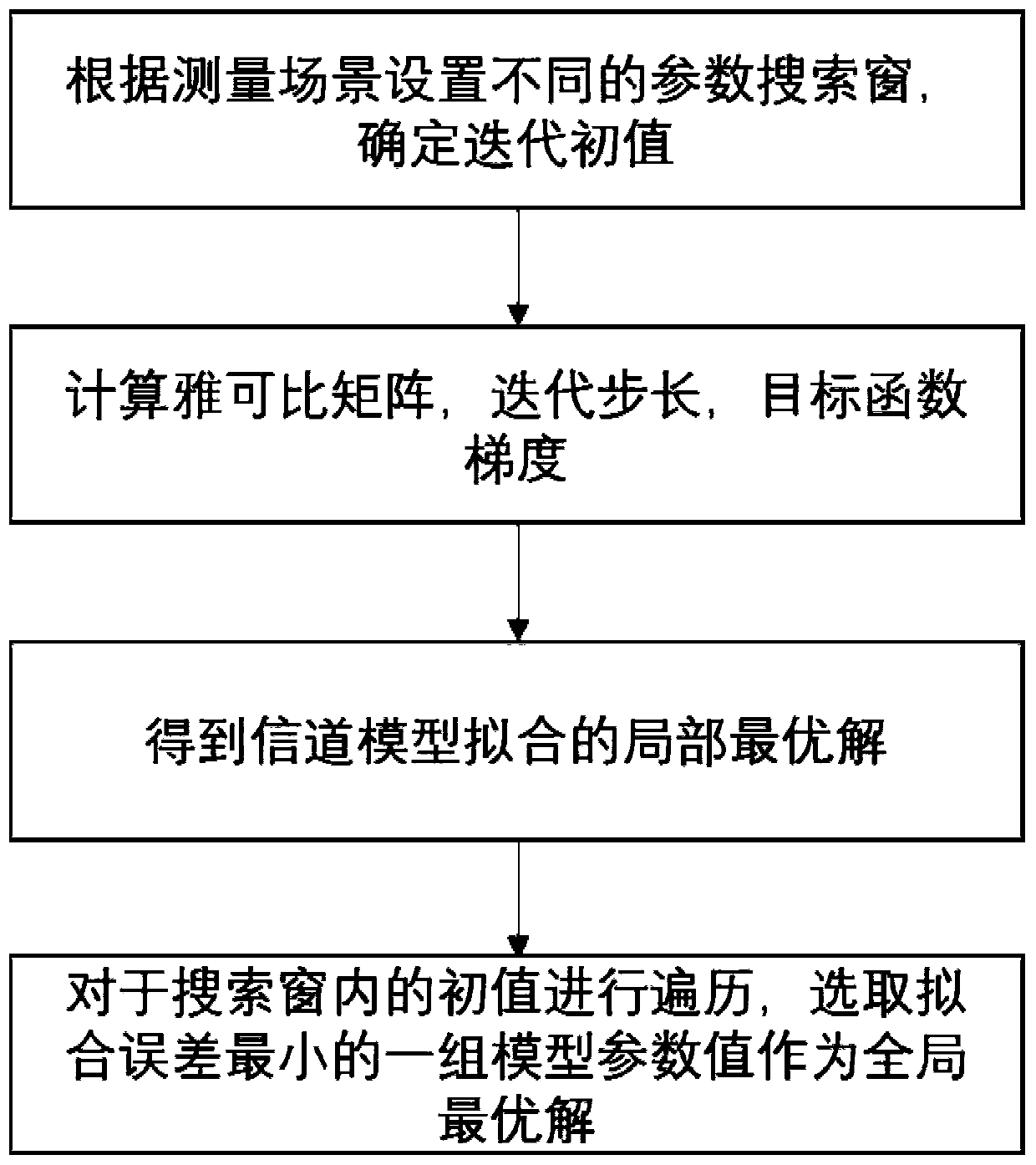

Method for receiving and processing scene adaptive satellite signals

ActiveCN109725333ASolve measurement problemsImplement Adaptive ProcessingSatellite radio beaconingLongitudeTransmission channel

Disclosed is a method for receiving and processing scene adaptive satellite signals. The method comprises generating a test case; judging measurement environment; adaptively adjusting gain; measuringbasic parameters; completing the adaptive adjustment of an antenna; obtaining collineation component and the satellite signal of a target measurement scene; and finally extracting satellite signal characteristics to complete channel model fitting. According to the method for receiving and processing the scene adaptive satellite signals, compared with the prior art, the present invention is for theS-band satellites and is used for measuring satellite signal transmission channel parameters from satellite orbits to the surface under different latitude and longitude conditions, and different surface and geomorphology conditions; the problem of the satellite channel parameter measurement under rapid scene change is solved; and the method has a good use value.

Owner:CHINA ACADEMY OF SPACE TECHNOLOGY

Off-axis paraboloid off-axis amount measurement device and method

ActiveCN105157570ASolve measurement problemsThe principle is simpleUsing optical meansMeasurement devicePlane mirror

The invention discloses an off-axis paraboloid off-axis amount measurement device and a method. The device comprises a converging light interferometer, a parallel light interferometer, an auto-collimating plane mirror, a flange plate and a marker for visible band high absorption. The principle of light linear propagation is used, the clear aperture geometrical center and the focal point of the off-axis paraboloid mirror are projected to the auto-collimating plane mirror and are marked respectively, and through measuring the marker distance, the off-axis amount of the off-axis paraboloid mirror is measured. The device and the method of the invention have the advantages that the principle is simple, operation is easy, and the off-axis paraboloid off-axis amount measurement problem can be solved.

Owner:SHANGHAI INST OF TECHNICAL PHYSICS - CHINESE ACAD OF SCI

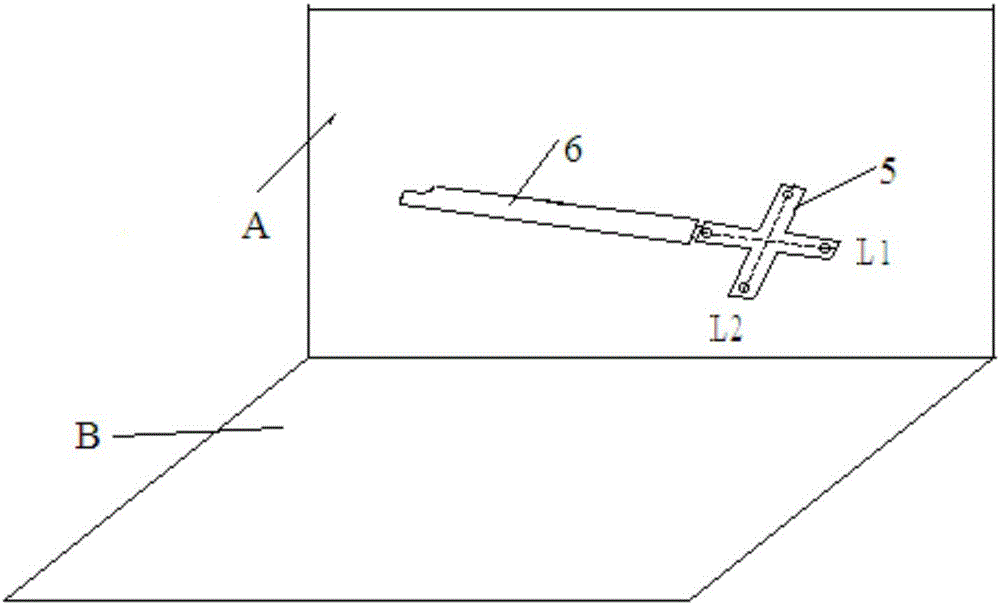

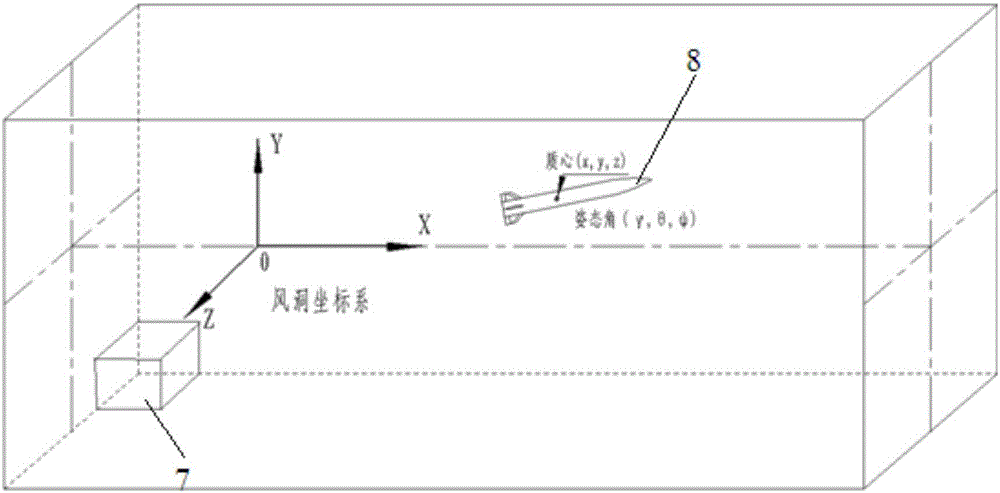

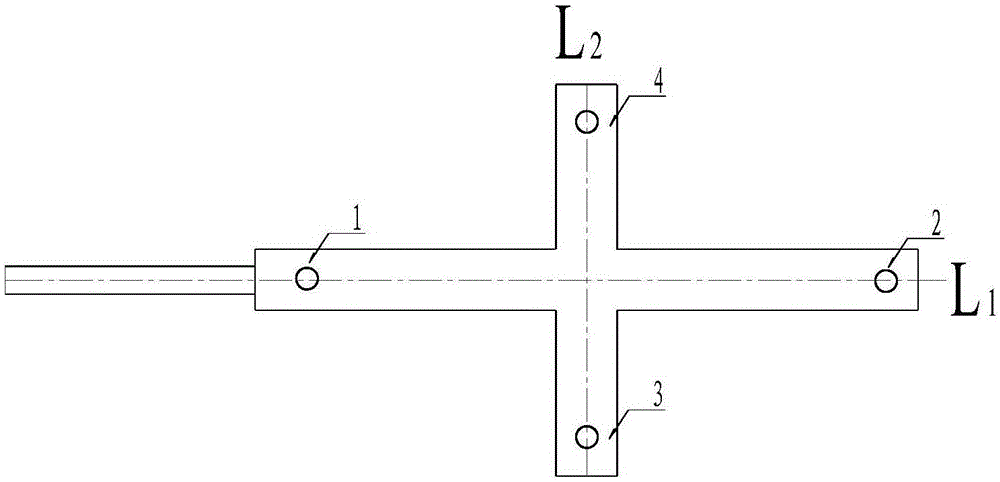

Method for measuring six-freedom-degree displacement and attitude of model

ActiveCN106226026ASolve measurement problemsHigh measurement accuracyAerodynamic testingAbsolute measurementMeasurement precision

The invention discloses a method for measuring the six-freedom-degree displacement and attitude of a model. A cross calibration rack is used for simulating a model and a wind tunnel coordinate system is established by using an absolute measuring arm; on the basis of measurement of coordinate values of a first circular hole, a second circular hole, a third circular hole and a fourth circular hole in the cross calibration rack under the wind tunnel coordinate system, a vector L1 of an axis of a first rod piece and a vector L2 of an axis of a second rod piece are calculated and an included angel between the vector L1 and a horizontal plane, an included angle between vector L1 and a vertical surface, and an included angle between the vector L2 and the horizontal plane are calculated; a pitching angle, a yaw angle and a rolling angle of the cross calibration rack are calculated and thus a pitching angle, a yaw angle, and a rolling angle of the model are calculated; and a mass center coordinate of the model under the wind tunnel coordinate system is calculated by using a coordinate value of a calibration hole in the wind tunnel coordinate system. Therefore, the integrated measuring problem of the displacement and attitude of the wind tunnel testing model can be solved; and measurement on the six-freedom-degree displacement and attitude of the model is realized. The measuring precision is high and the calculation speed is fast.

Owner:CHINA ACAD OF AEROSPACE AERODYNAMICS

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com