System and method capable of extending lower limit of gas micro-flow calibration to 10<-14> Pam<3>/s

A micro-flow, gas technology, applied in the field of measurement to achieve the effect of improving sensitivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

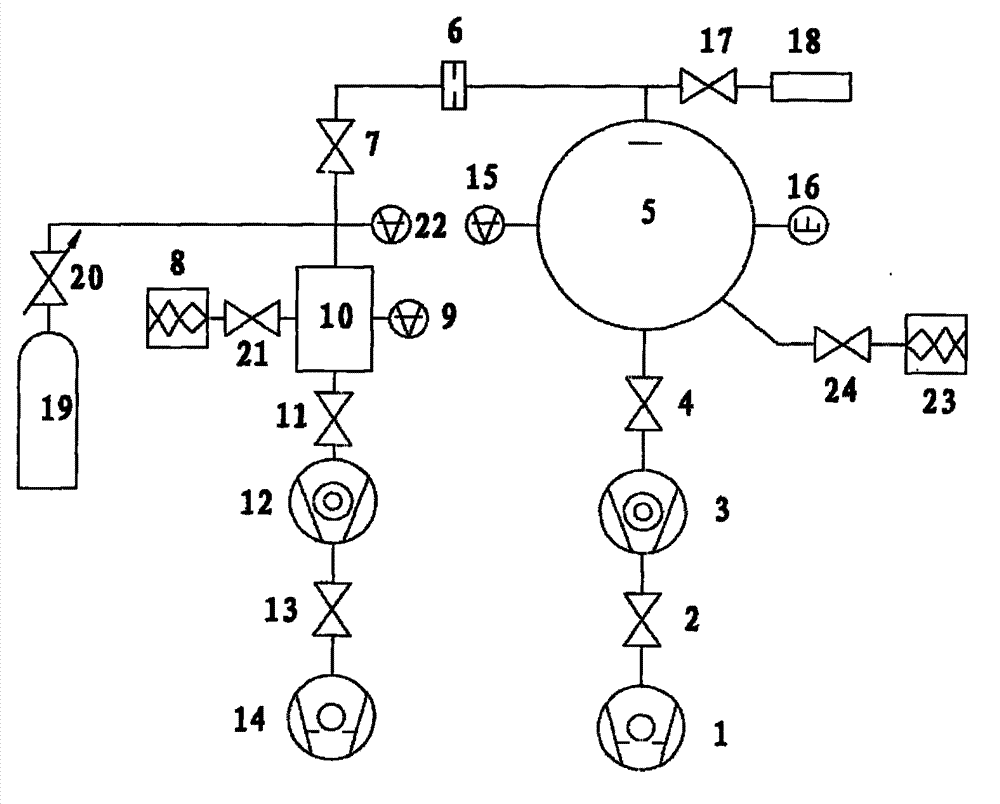

[0049] (1) Connect the measured gas micro-flow rate (vacuum leak) to the fourth vacuum valve 17, and check the tightness, then close the fourth vacuum valve 17;

[0050] (2) Turn on the first mechanical pump 1 and the second mechanical pump 14 of the machine, and then open the first electrovalve valve 2, the first vacuum valve 4, the second vacuum valve 7, the third vacuum valve 11, and the second electromagnetic valve 13 pairs The mass spectrometry chamber 5 and the valve pipeline are evacuated, and the second vacuum gauge 15 is opened. When the measured value of the second vacuum gauge 15 is less than 10 Pa (1.2Pa), the first molecular pump 3 and the second molecular pump 12 are turned on to evacuate to maintain the environment. The temperature is 23±3°C (23±0.5°C);

[0051] (3) Open the first vacuum gauge 9 when the gas pressure in the plenum 10 is less than 1Pa (0.1Pa), and the vacuum degree in the plenum 10 is less than 1×10 -4 Pa(6.2×10 -5 Pa) when opening the fifth va...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com