Three-coordinate measuring method for circumferential uniformly-distributed hole true position error

A technology of three-coordinate measurement and hole position degree, applied in the field of measurement, can solve problems such as loss of manufacturers, measurement and calculation errors, and achieve the effect of improving production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The present invention will be further described below in conjunction with accompanying drawing:

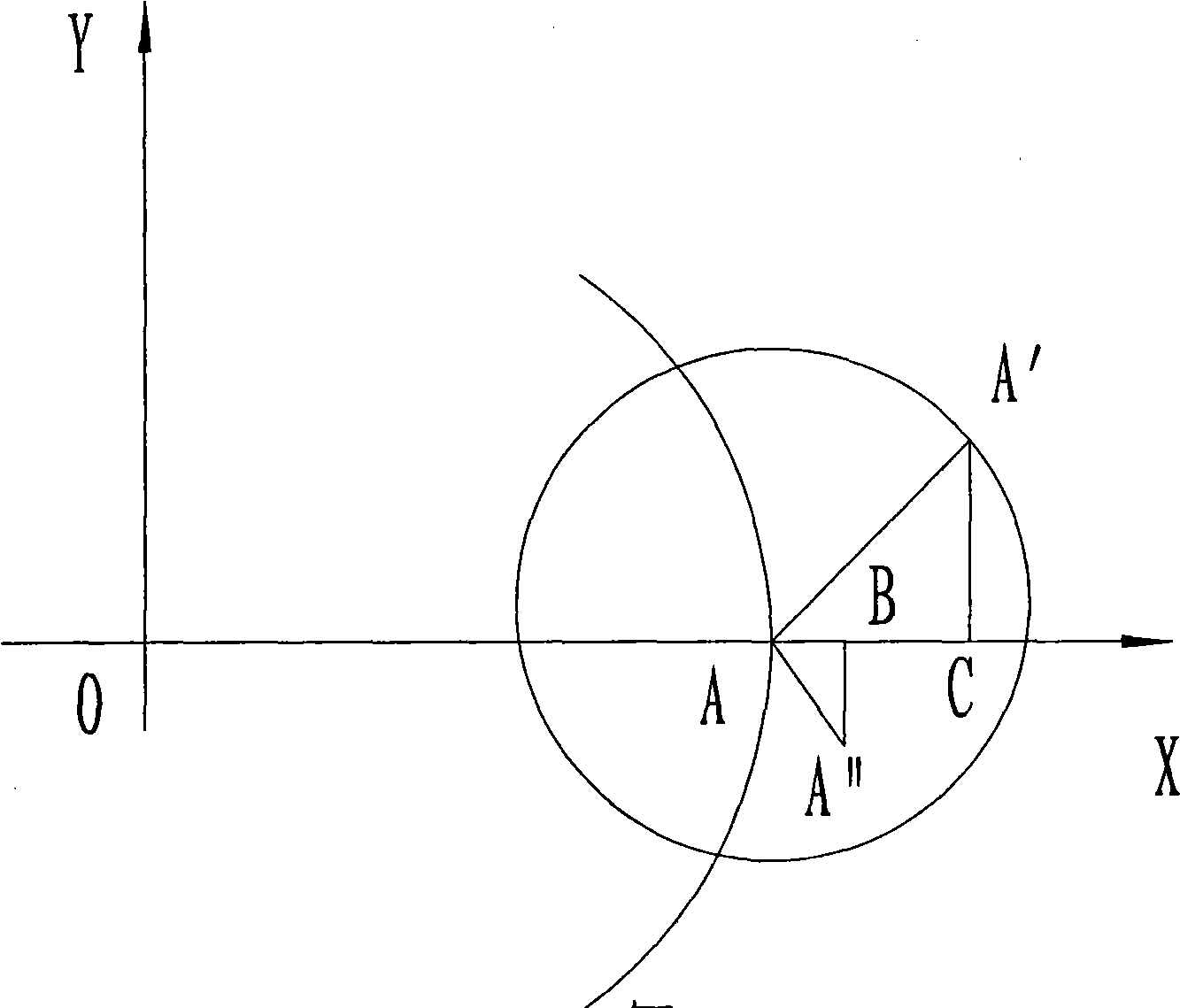

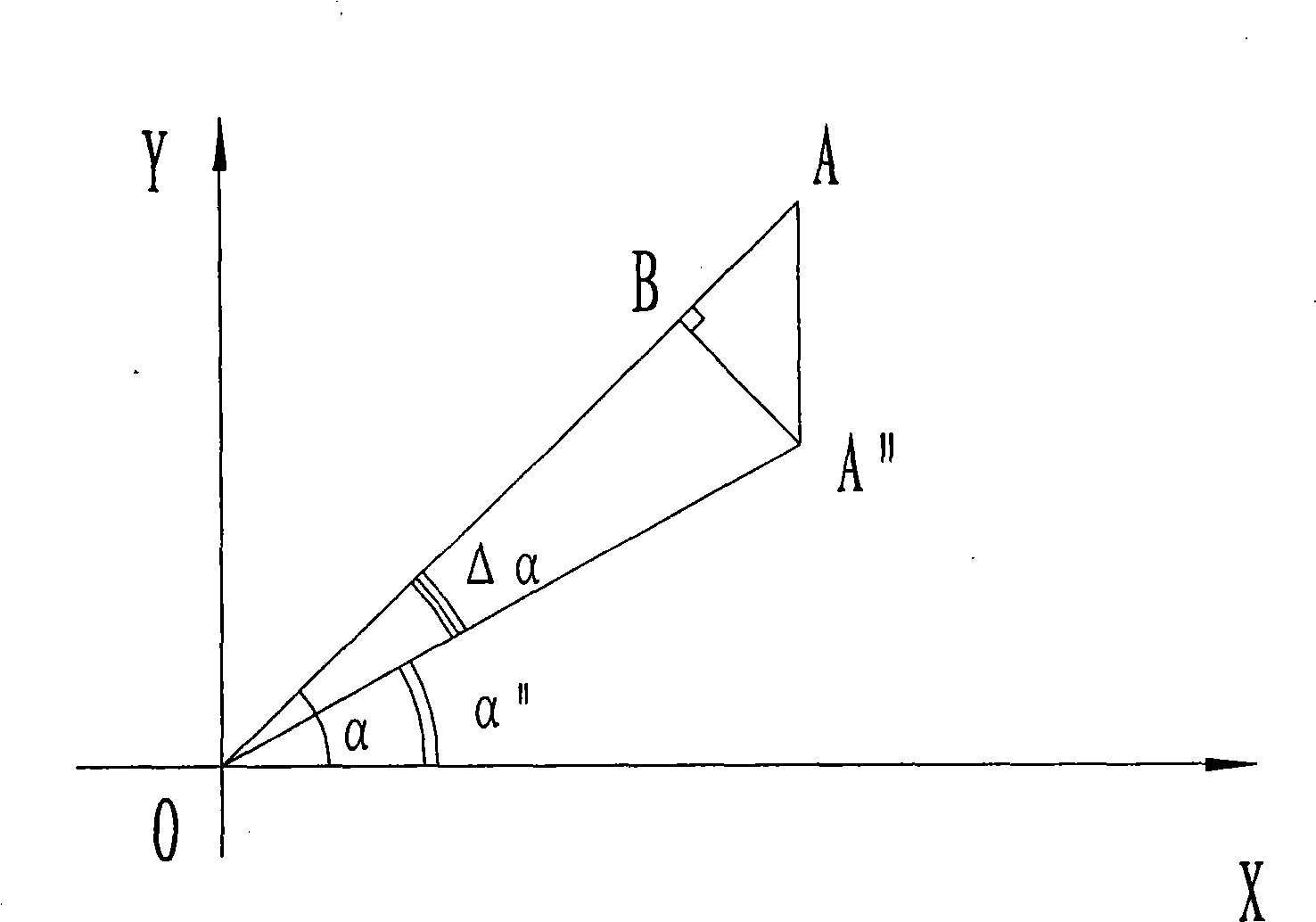

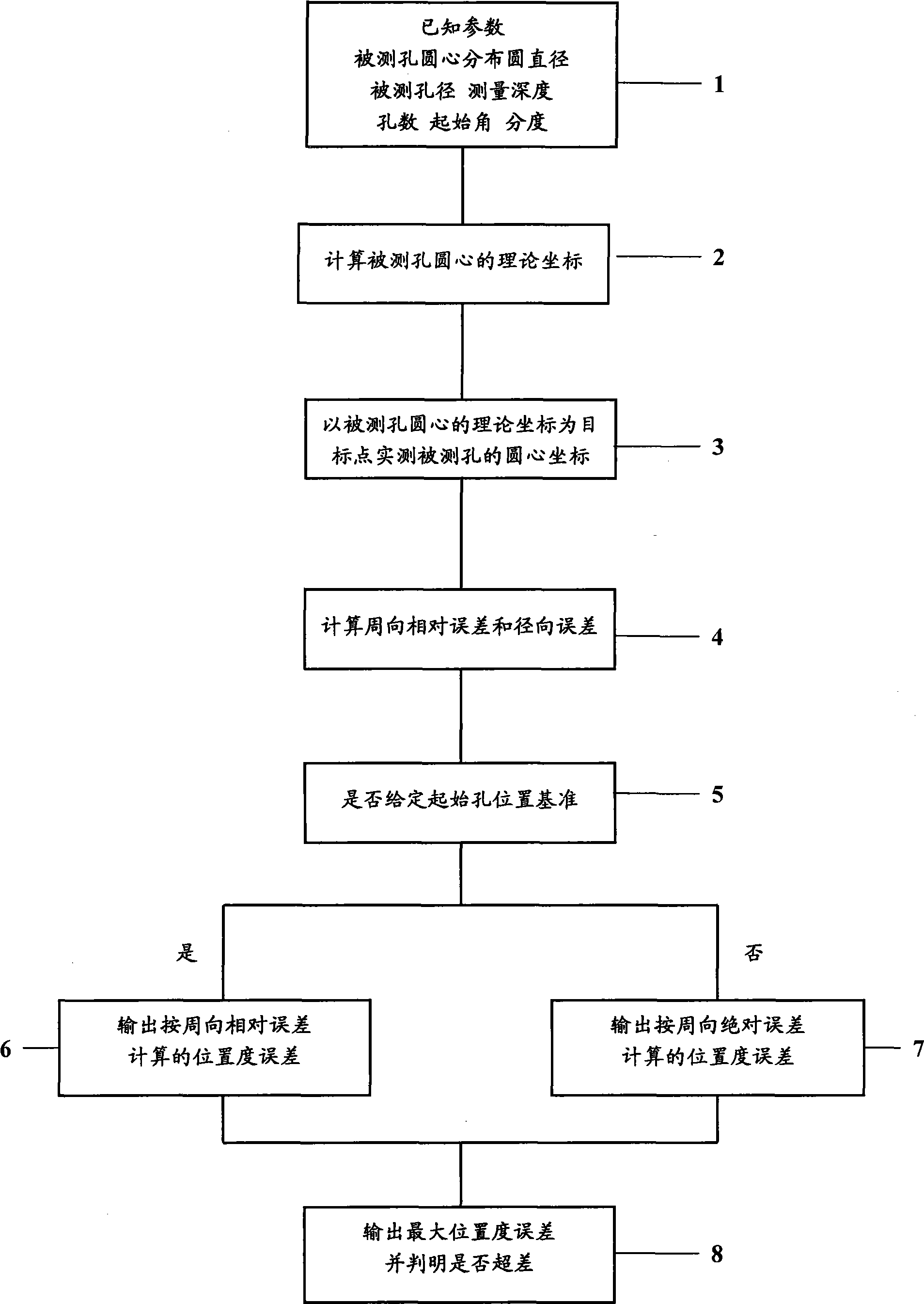

[0026] Such as figure 1 , figure 2 and image 3 As shown, the three-coordinate measuring method of the uniformly distributed hole position error of the same circumference of the present invention is realized by programming, and the program is stored in the central computer of the three-coordinate measuring machine, and the operation process of the three-coordinate measuring machine Carry out according to the step of the inventive method:

[0027] (1) Determine the theoretical coordinates of the center of the measured hole by calculation

[0028] Input the known parameters given in the drawing, the theoretical center of the measured hole A, the diameter of the distribution circle D, the measured hole diameter d, the measured depth Z, the number of measured holes N, the starting angle β and the division δ into the three-coordinate measuring machine central computer, such...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com